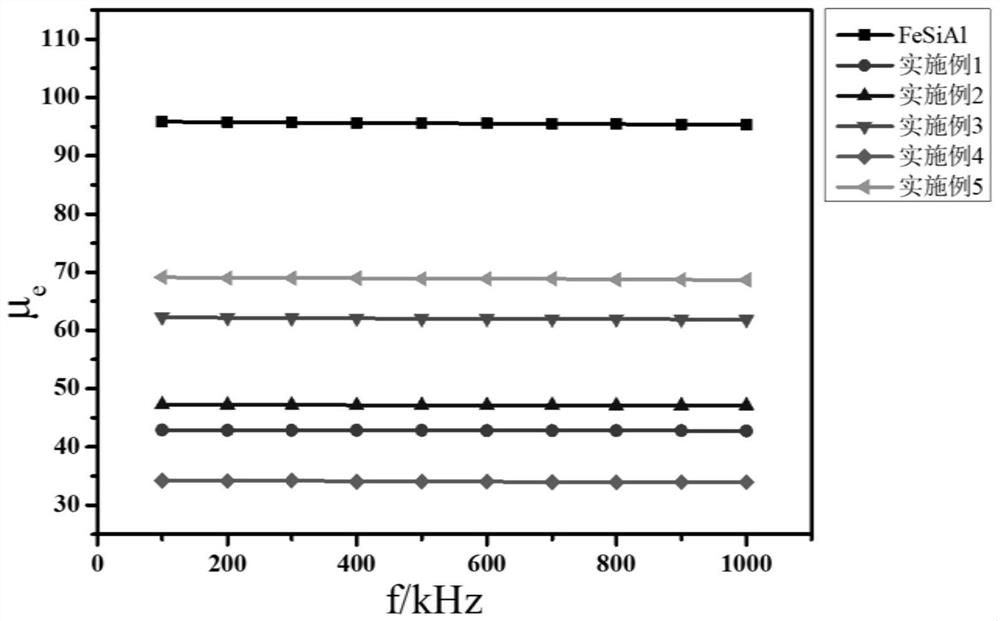

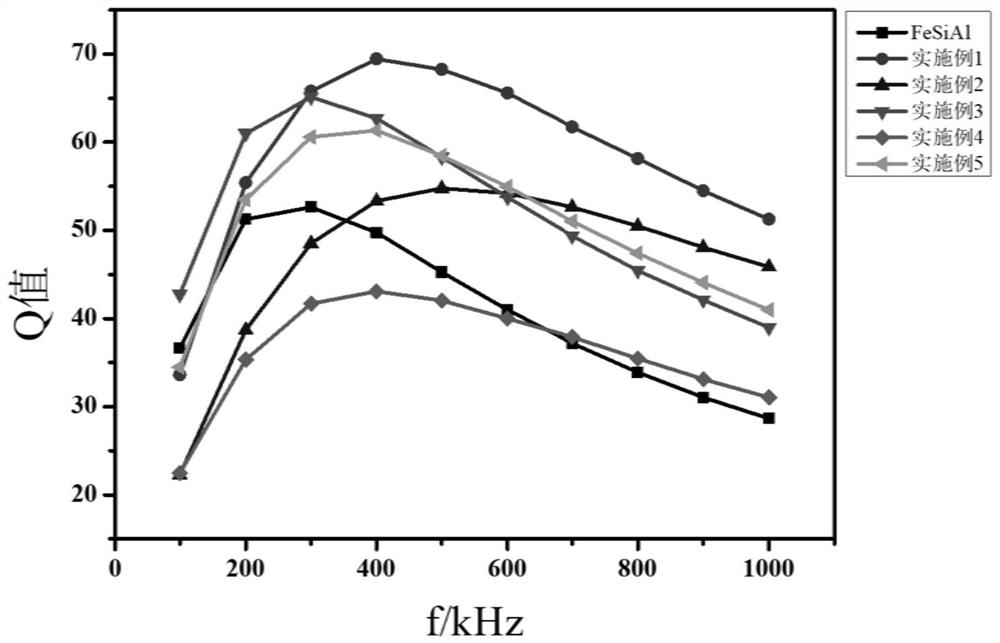

High-frequency high-Q-value FeSiAl@MnZn ferrite soft magnetic composite magnetic powder core and preparation method thereof

A soft magnetic composite, ferrite technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc. problems, to achieve the effect of improving quality factor and permeability, stable strength, and improving quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of FeSiAl@MnZn ferrite composite magnetic powder core with high magnetic permeability and high Q value under high frequency of the present invention, the steps include:

[0032] S1. Selection of powder: Take mechanically crushed FeSiAl powder, its composition is Si: 8%-13%, Al: 4%-7%, and the rest is Fe. Pass the crushed FeSiAl powder through a 200-mesh sieve, and take the under-sieved powder.

[0033] S2. Preparation of coating agent solution: according to the three metal elements Fe in MnZn ferrite 2+ : Zn 2+ :Mn 2+ The molar ratio of 2:x:(1-x), where x is 0~1, x≠0 and x≠1, respectively weigh iron salt, zinc salt and manganese salt, dissolve them in deionized water, and stir After dissolving completely, obtain Fe-Mn-Zn mixed salt solution;

[0034]S3. Coating process: Pour the FeSiAl powder obtained in step S1 into deionized water with the same quality as the sendust powder to make a suspension, heat it to 50-80°C, and then add the Fe-SiAl p...

Embodiment 1

[0040] 1. Take mechanically crushed FeSiAl powder, its composition is Si: 9%, Al: 6%, and Fe is the balance according to the weight ratio. Pass the FeSiAl powder through a 200-mesh sieve, and take the undersize.

[0041] 2. Coat the surface of FeSiAl powder with MnZn ferrite insulating layer by chemical co-precipitation method, the co-precipitation temperature is 70°C, and the reaction time is 30 minutes.

[0042] 3. With anhydrous FeCl 2 , ZnCl 2 4H 2 O and anhydrous MnCl 2 As a reactant, according to Fe 2+ : Zn 2+ :Mn 2+ The molar ratio is 2:0.9:0.1, respectively weigh chloride salt, dissolve in deionized water, get FeCl 2 -ZnCl 2 -MnCl 2 Mix the salt solution.

[0043] 4. According to the mass ratio of MnZn ferrite:FeSiAl being 0.5:99.5, weigh the mechanically crushed FeSiAl powder, pour it into deionized water, and heat it to 70°C. Slowly drop the corresponding amount of FeCl into the heated FeSiAl magnetic powder 2 -ZnCl 2 -MnCl 2 Mix the salt solution, stir...

Embodiment 2

[0048] 1. Take mechanically crushed FeSiAl powder, its composition is Si: 9%, Al: 6%, and Fe is the balance according to the weight ratio. Pass the FeSiAl powder through a 200-mesh sieve, and take the undersize.

[0049] 2. Coat the surface of the crushed FeSiAl powder with a MnZn ferrite insulating layer by chemical co-precipitation method, the co-precipitation temperature is 70°C, and the reaction time is 30 minutes.

[0050] 3. With anhydrous FeCl 2 , ZnCl 2 4H 2 O and anhydrous MnCl 2 As a reactant, by Fe 2+ : Zn 2+ :Mn 2+ The molar ratio is 2:0.5:0.5 Weigh chloride salt respectively, dissolve in deionized water, get FeCl 2 -ZnCl 2 -MnCl 2 Mix the salt solution.

[0051] 4. According to the mass ratio of MnZn ferrite:FeSiAl being 3:97, weigh the crushed FeSiAl powder, pour it into deionized water equivalent to the mass of FeSiAl powder, and heat to 70°C. Slowly drop the corresponding amount of FeCl into the heated FeSiAl magnetic powder 2 -ZnCl 2 -MnCl 2 Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com