Cover-excavation semi-inverse construction method for assembly type arch top large-span column-free underground structure

An underground structure and construction method technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of traffic congestion on the ground road and poor spatial vision, achieve short road occupation time, and realize industrialization promotion. Application, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Such as Figure 1-Figure 11 As shown, this embodiment provides a cover-excavation and semi-reverse construction method for a large-span column-free underground structure with a prefabricated vault. Taking the underground two-story single-column double-span structure as an example, it includes the following steps:

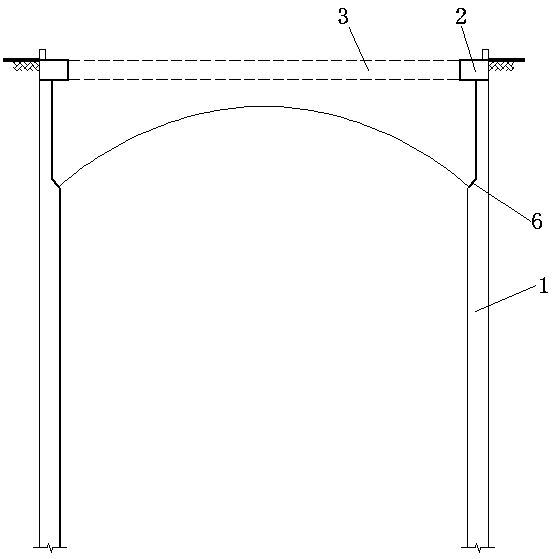

[0057] 1) After completing the construction of the two enclosure structures 1, construct the crown beam 2, erect an inner support 3 between the two enclosure structures, and excavate to the bottom of the foundation pit of the arch roof slab, such as figure 1 shown;

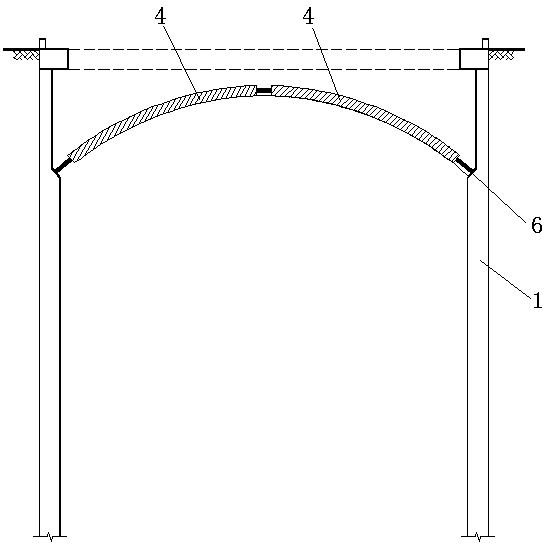

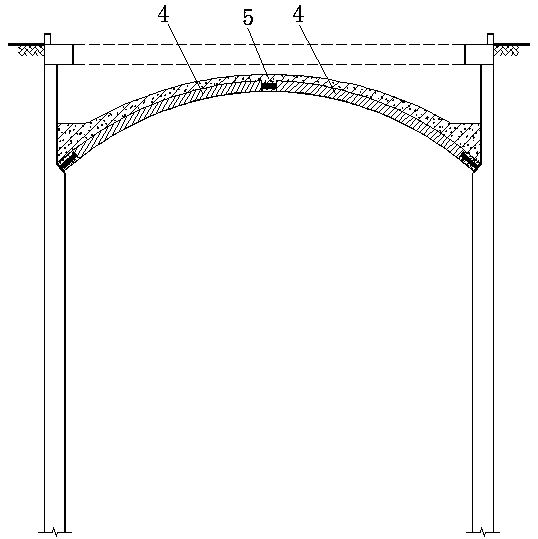

[0058] 2) Hoisting the arc-shaped arch prefabricated part 4, completing the assembly between the two arc-shaped arch prefabricated parts 4 and the fixing between the arc-shaped arch prefabricated part 4 and the enclosure structure 1; using the arc-shaped arch prefabricated part 4 is the bottom formwork, and concrete is poured between the arc-shaped arch slab prefabricated parts 4 and the enclosu...

Embodiment 2

[0075] Such as Figure 12-14 As shown, this embodiment provides a connection method between the prefabricated part and the cast-in-place concrete layer, which can be used when the first side wall adopts a laminated structure and the first layer adopts a fully cast-in-place or laminated structure in Embodiment 1. The connection between the prefabricated part of the first side wall and the cast-in-place layer of the first layer or the first cast-in-place layer can also be used when the second side wall adopts a laminated structure, and the second layer adopts a fully cast-in-place or laminated structure The connection of the second side wall prefabricated part 13 and the second floor slab cast-in-place layer or the reinforced concrete cast-in-place layer 38; the connection method to the second side wall prefabricated part 13 and the reinforced concrete cast-in-place layer 38 is now described as an example, The connection method between the second side wall prefabricated part and...

Embodiment 3

[0086] This embodiment provides a method for connecting prefabricated parts to prefabricated parts, which can be used for the connection between the first ply prefabricated part 18 and the first ply prefabricated part 18 when the first ply board adopts a superimposed structure in the first embodiment. Connection, the connection between the second layer prefabricated part and the second layer prefabricated part when the second layer board adopts the superimposed structure; now the two first layer board prefabricated parts 18 The connection method will be described as an example, and the connection method of the two second layer prefabricated parts is the same, and will not be described in detail here.

[0087] Such as Figure 15-18 As shown, this embodiment provides a connection method between two first layer prefabricated parts 18, specifically as follows:

[0088] First, determine the diameter and spacing of the steel bars of the steel bar frames on the two first layer prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com