Construction method for large-area concrete weighbridge

A construction method and concrete technology, applied in the direction of floors, buildings, building structures, etc., can solve the problem of large use of formwork in the later maintenance costs of the ground, difficult to control the overall flatness of the floor, and easy emptying of the floor when it is poured in layers. problems, to achieve the effect of saving labor, tight schedule requirements, and reducing construction joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

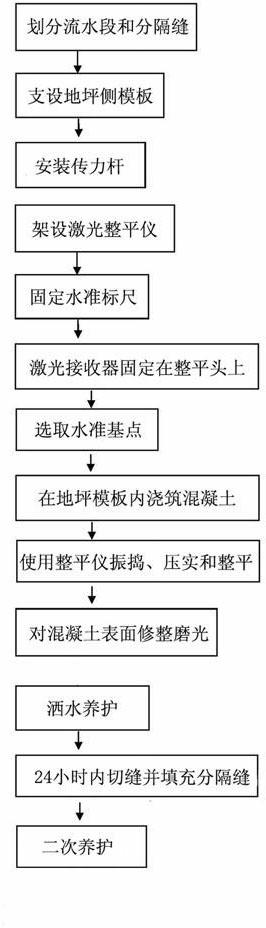

[0043] Examples see figure 1 As shown, a construction method of a large-area concrete floor, the construction steps are as follows:

[0044] Step 1: Divide the construction flow section and the location of the construction separation joint. According to the on-site construction deployment, the foundation floor and the structural roof of the construction area are divided into flow sections respectively. According to the division of flow sections, the pouring area of the foundation floor and foundation roof is calculated.

[0045] The flatness detector for testing the flatness plans the measurement line according to the boundary of the flow section. All the measurement lines are parallel straight lines and perpendicular to the longest flow section boundary. The measurement lines are divided into north-south measurement lines and east-west measurement lines. The measurement lines are at least The length is 3.3528m, the measuring line is 1.2192m shorter than the length and width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com