Patents

Literature

169results about How to "Fatigue resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for melting snow and ice based on carbon fiber-glass fiber composite braiding net

InactiveCN101413240AReduce weightGuaranteed equidistantPaving detailsOhmic-resistance heatingCarbon fibersHeat conducting

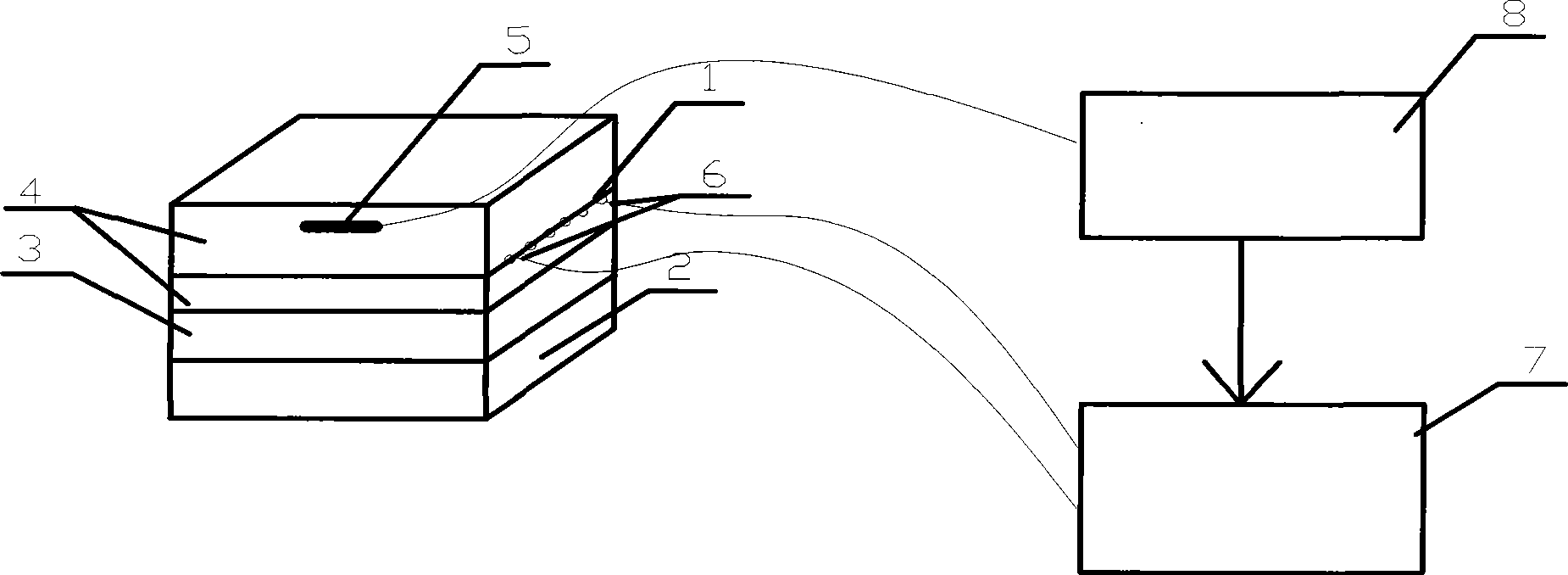

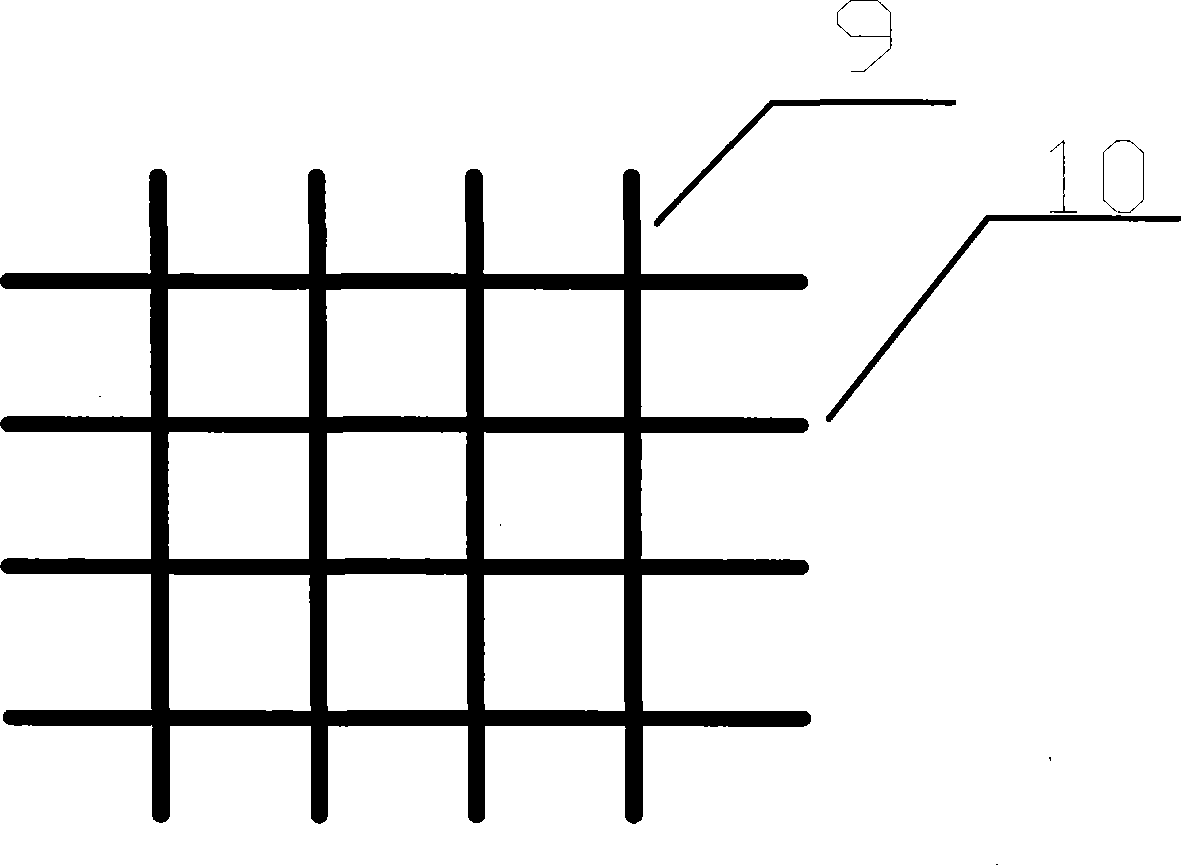

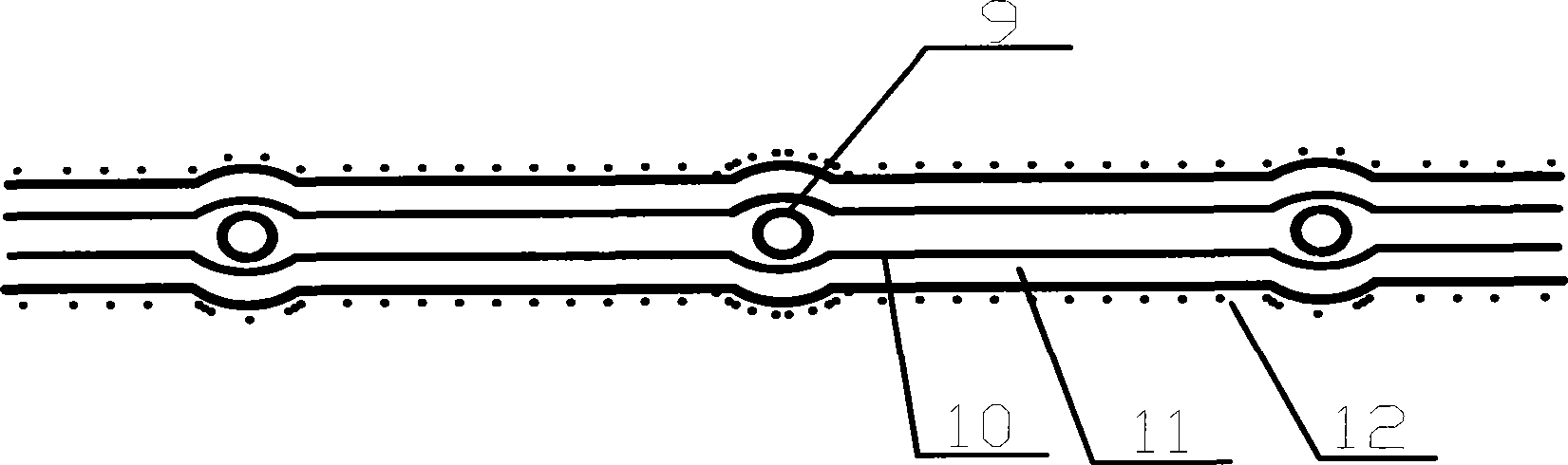

The invention discloses a snow-ice melting method based on carbon-glass fiber composite woven nets, which belongs to the field of transportation and disaster prevention. The method is characterized in that a thermal insulating layer, a heat conducting layer, a carbon-glass fiber composite woven net subjected to electric insulation and sand sticking treatment, and another heat conducting layer are laid in turn on a base layer of a to-be-heated body; a temperature measurement element is buried in a surface layer of the to-be-heated body; a carbon fiber bundle heating element is connected to a controllable power source with protection function in a series parallel connection mode by use of electric conducting silver colloid and a conductor; and according to surface layer temperature of the to-be-heated body, surface wind speed, the thickness of snow cover and ice, air temperature and the expected time for melting snow and ice, a digital PID temperature control system optimizes and adjusts the control parameters of the system and regulates heating power. The method has the advantages of high construction speed, uniform fast heating, stable performance, long life span, low cost and the like, plays a role in preventing cracking and reinforcing, and is an ideal snow-ice melting method for pavement, bridges and other facilities.

Owner:DALIAN UNIV OF TECH

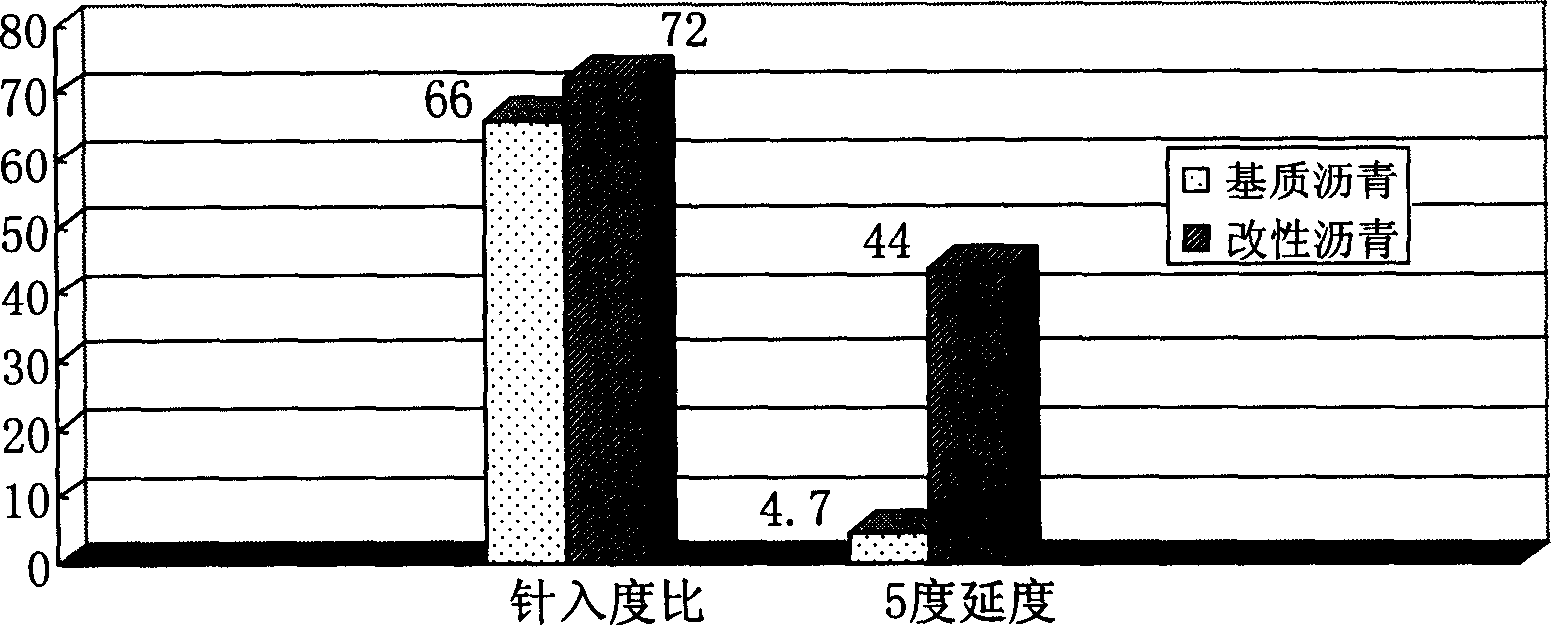

Modified asphalt material for road and its prepn

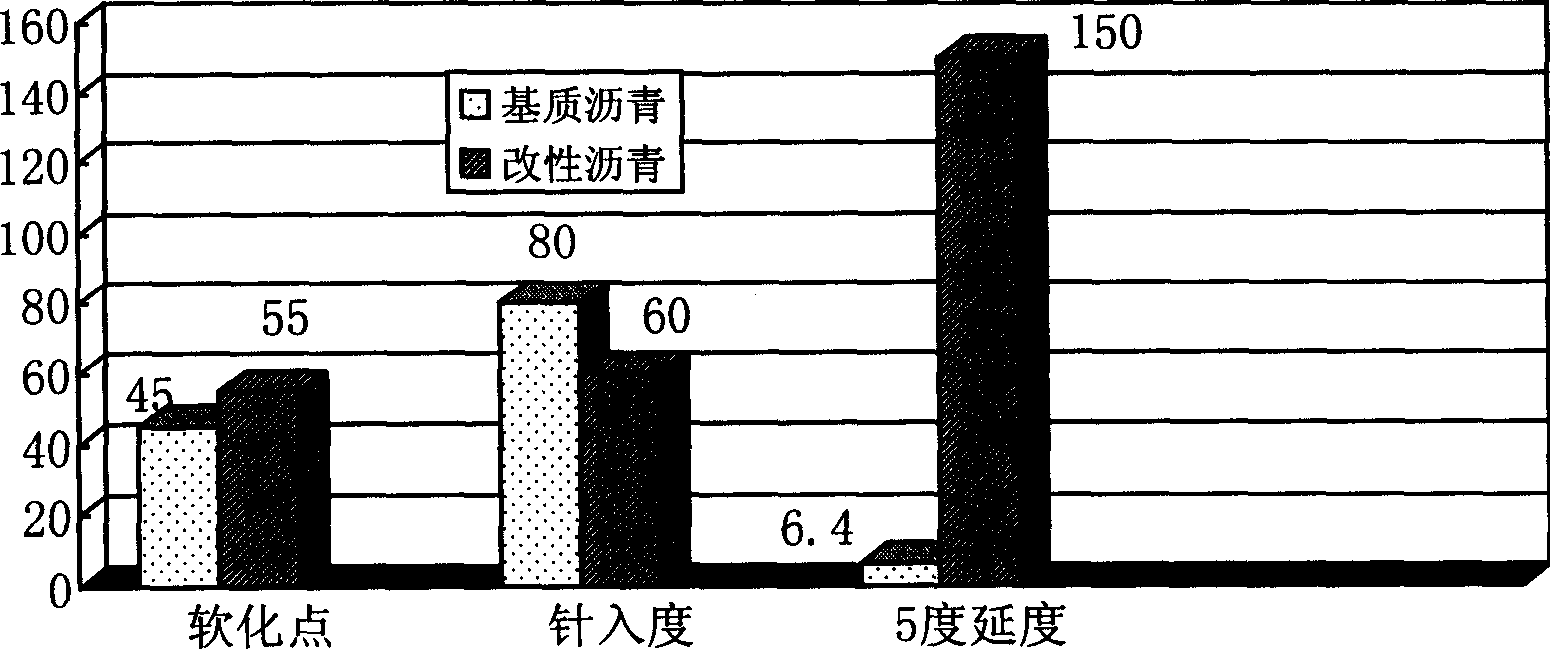

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

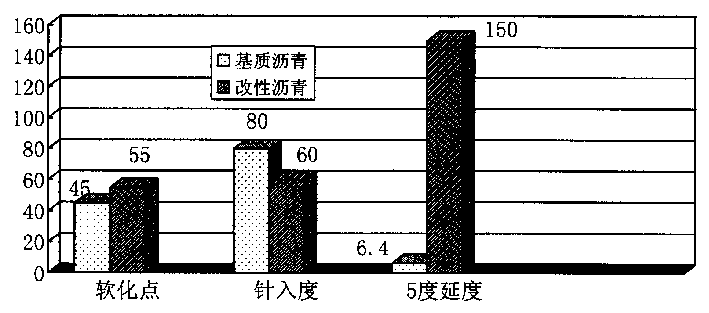

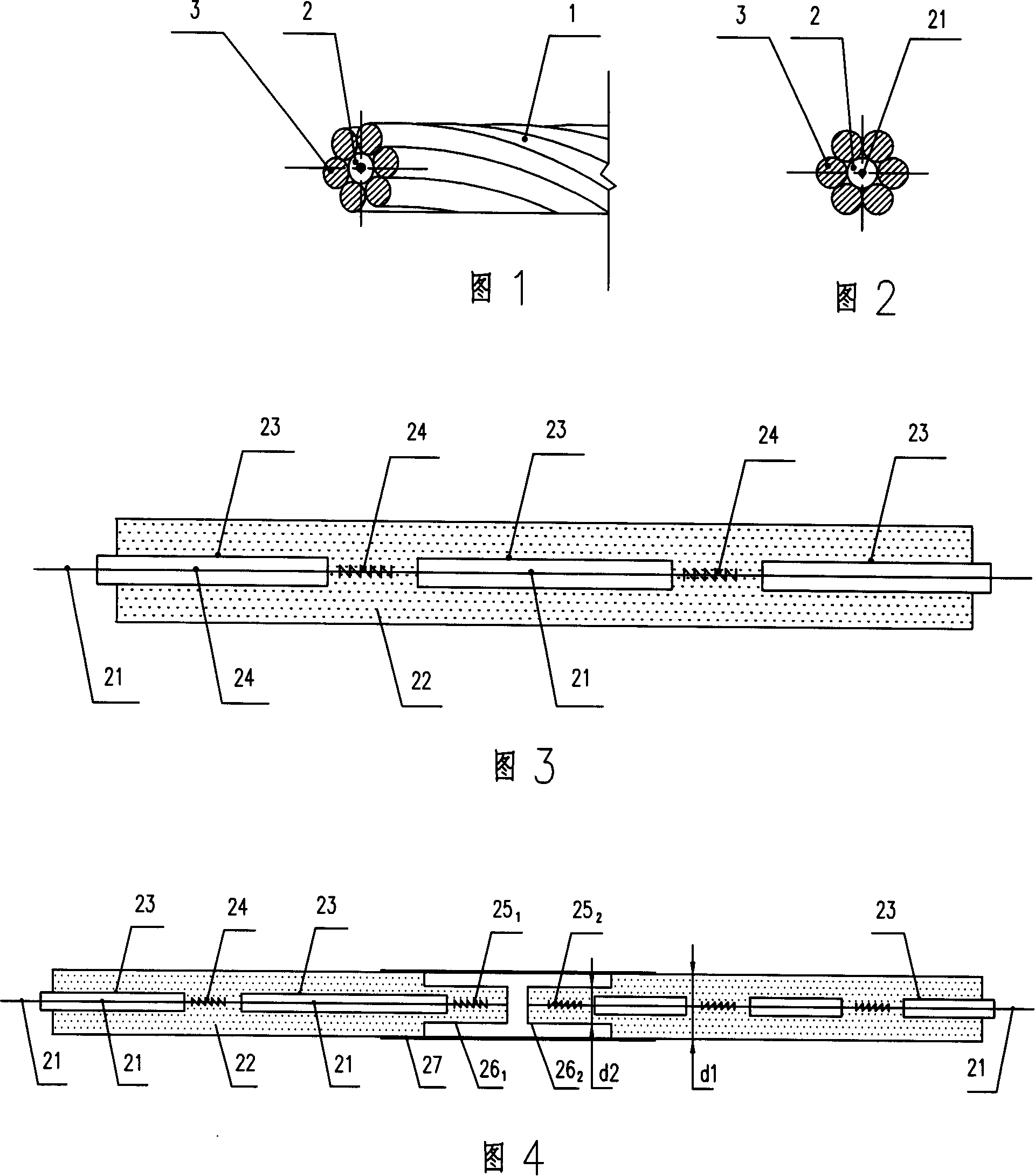

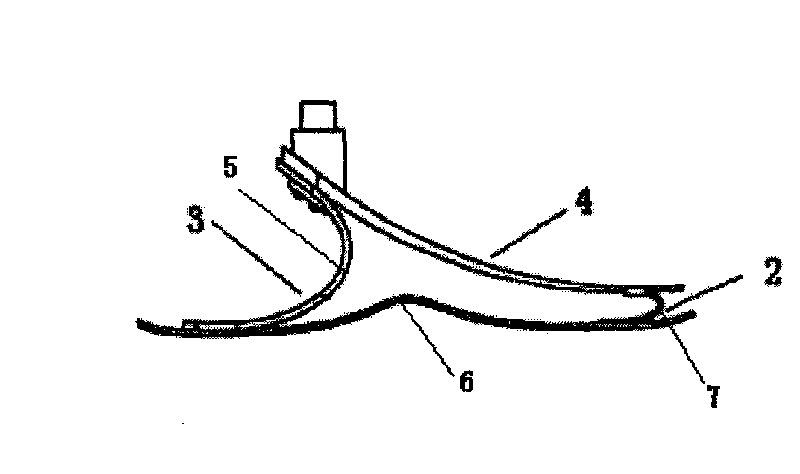

Optical fiber grating intelligent steel strand and its manufacture method

ActiveCN101210983AEffective protectionSo as not to damageForce measurement by measuring optical property variationCoupling light guidesGratingStress conditions

An intellectual steel strand for fiber lattice, which is molded by the stranding of central wire and wires around the central wire, the central wire is the enhanced composite intellectual rib of fiber lattice of a fiber lattice sensor; the intellectual rid comprises a fiber enhanced rid and fiber distributed along the lengthwise direction of the fiber enhanced rib, the fiber lattice sensor; a plastic sleeve is sleeved around the fiber without lattice, separates from the fiber and is connected with the fiber enhanced rib; the fiber transmitted by the fiber lattice sensor is led out from the head of the steel strand; a preparation method of the steel strand comprises the following steps of: firstly preparing the fiber lattice fiber enhanced composite intellectual rib; scattering stranding machines with the same length with the intellectual rib and substituting the central wire of the steel strand with fiber lattice fiber enhanced composite intellectual rib and finally molding the wire through stranding. The invented intellectual steel strand has self sensing property with all the advantages of fiber lattice, which can easily grasp the stress condition of the steel strand in the construction and service periods and instruct the tensioning of initial stress and the construction.

Owner:LIUZHOU OVM MASCH CO LTD

Process for forming artificial leg made of carbon fiber composite materials

The invention relates to a process for forming an artificial leg made of carbon fiber composite materials. The forming process comprises pre-soaked materials, cutting, paving, thermal forming, grinding and sand spraying, wherein the pre-soaked materials comprise one-way carbon fiber pre-soaked materials, 3K carbon fiber bundle woven fabric pre-soaked materials and a resin membrane, and the pre-soaked materials are cutting to needed shapes; in the paving link which is particularly important, the pre-soaked materials are adhered to a mould to form a pre-forming body in a paving mode, and in the paving process, an intermediate layer is arranged, the one-way carbon fiber pre-soaked materials are alternately paved along different directions and symmetrical to the intermediate layer, and the resin membrane is evenly melted by an electric iron and permeates into the pre-forming body; in the thermal forming link, the flat plate-like parts are formed by mould pressing, and the parts with a bigger radian are formed by bag pressing; and after demoulding, the formed artificial leg undergoes the grinding and the sand spraying treatments. The composite material artificial leg produced by the process has the advantages of high overall strength, light weight, fatigue resistance, good elasticity, good matching with a connecting piece, uniform geometric structure, good thermal stability, little amount of deformation and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Synthetic fiber paper containing polyphenyl sulfide and aromid fiber and producing method thereof

InactiveCN1974925AHigher than strongHigher than the moldNon-fibrous pulp additionCalendersPolymer scienceThermal expansion

The present invention belongs to the field of synthetic fibre paper. In particular, it relates to a kind of synthetic fibre paper made up by using aramid fiber as structural fiber and utilizing polyphenylene sulfide fiber or granules through the processes of adhesive bonding and finalization. Said synthetic fiber paper possesses the excellent properties of light weight, high strength, resisting high temperature, resisting fatigue, resisting chemical corrosion, resisting radiation, high specific modulus, low thermal-expansion coefficient and good biological compatibility, and can be extensively used in the fields of electromechanical technology and aerospace industry. Besides, said invention also provides a wet preparation method for producing said synthetic fiber paper.

Owner:陶世毅 +3

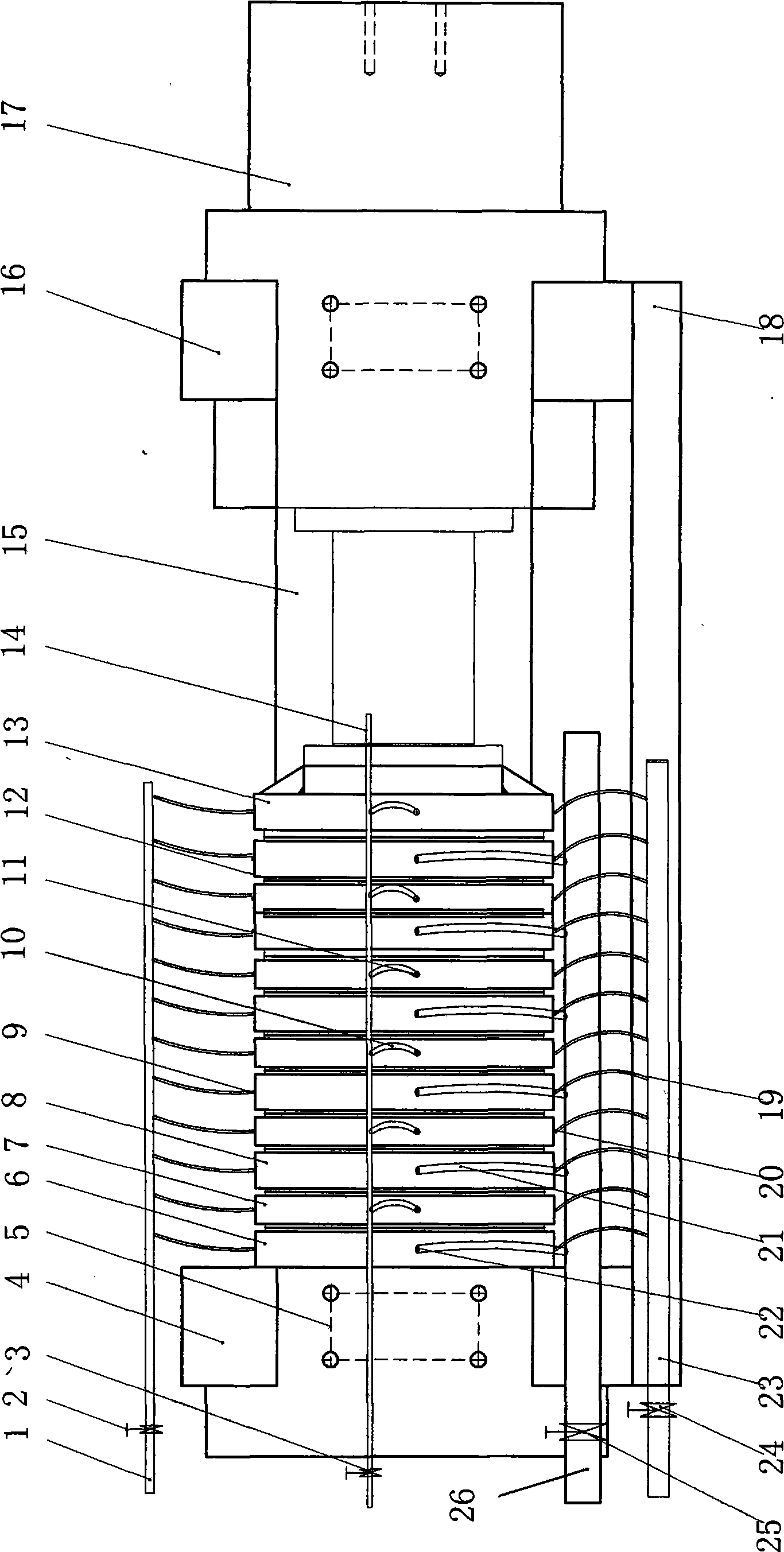

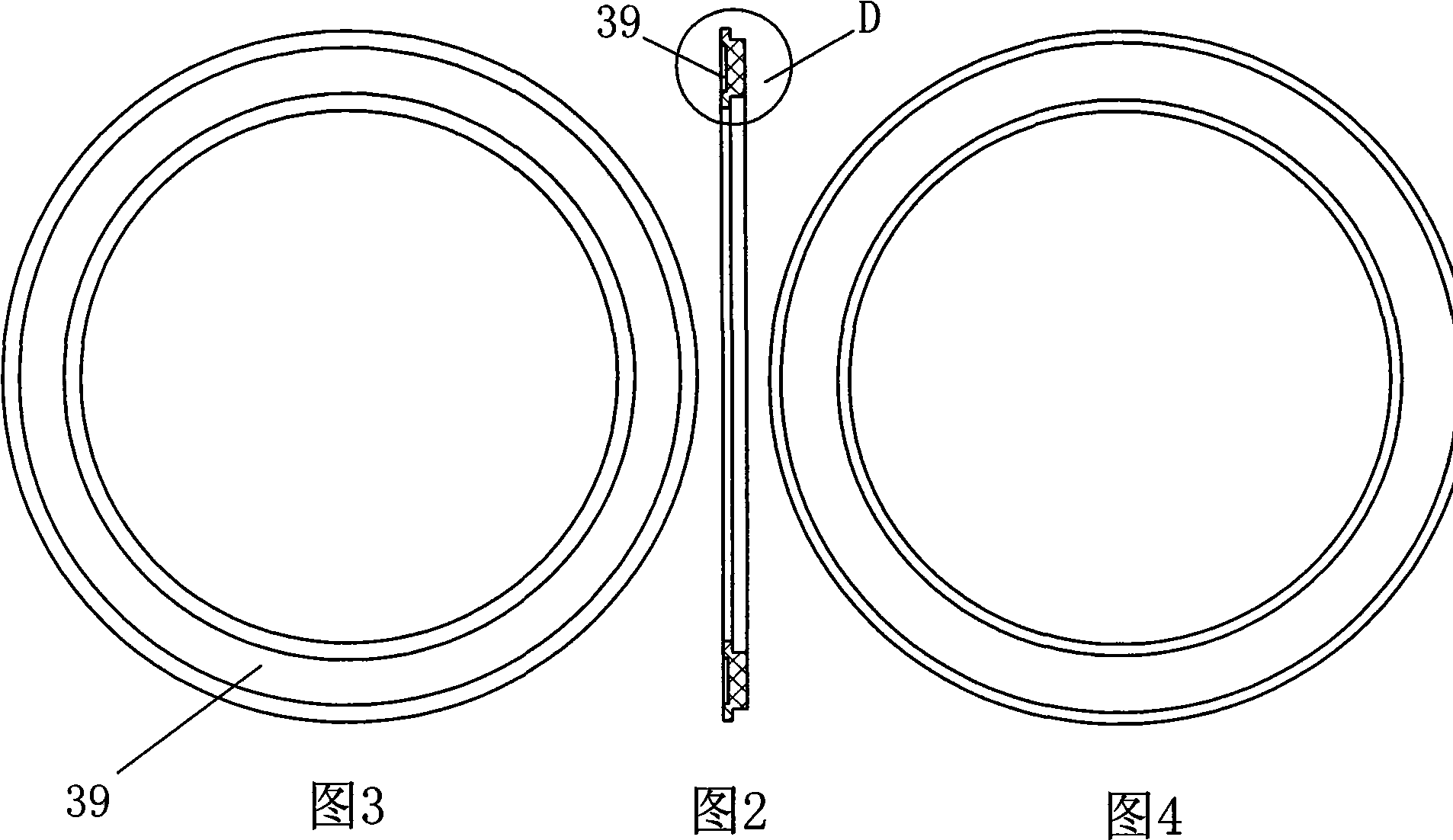

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

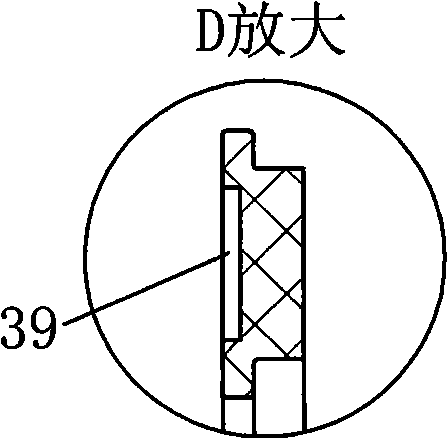

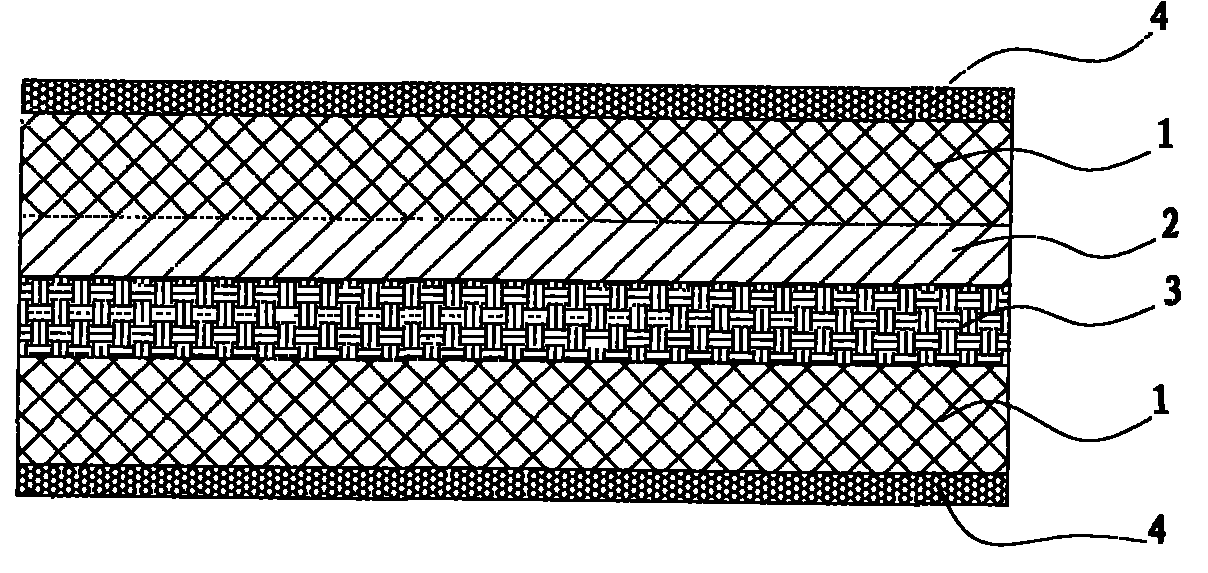

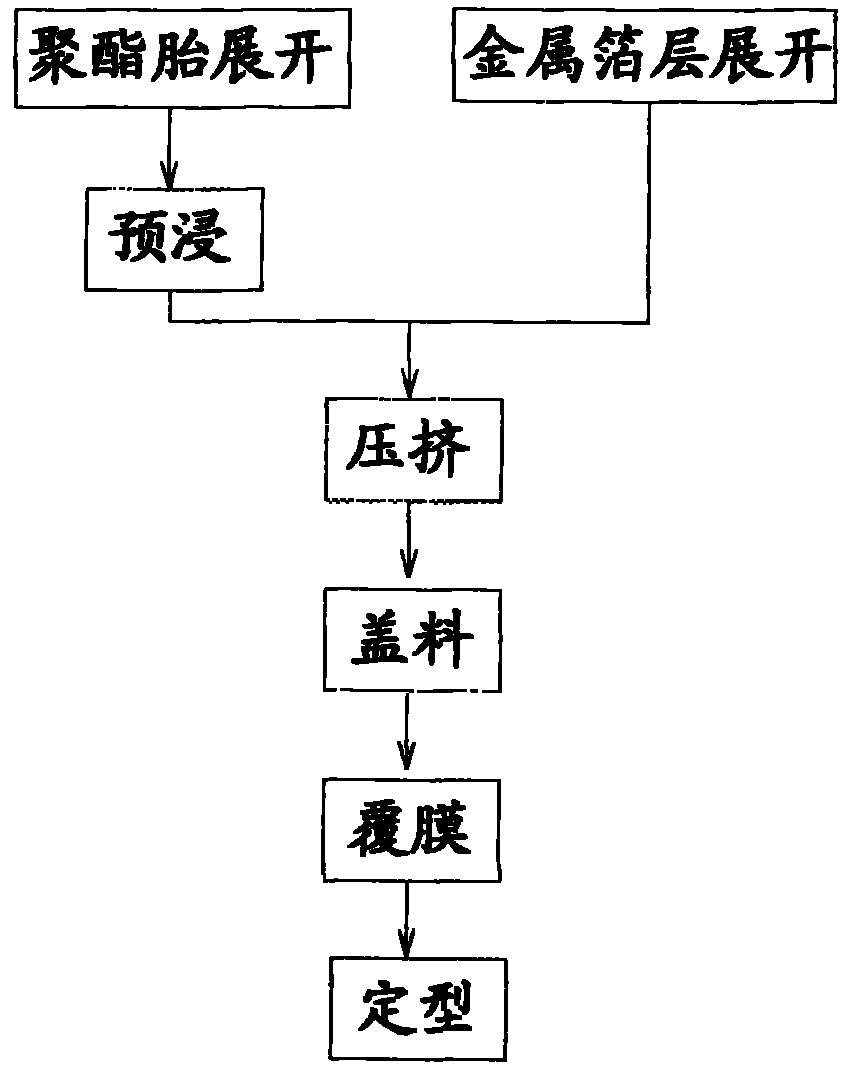

Root thorn-proof and waterproof coiled material and preparation technology

InactiveCN101818548APrevent penetrationDoes not affect growthLamination ancillary operationsRoof covering using flexible materialsPolyesterBituminous waterproofing

The invention provides a root thorn-proof and waterproof coiled material, which comprises a modified asphalt waterproof layer, a metal foil layer and a polyester tire, which are composited together. The polyester tire is presoaked by special modified asphalt. The root thorn-proof and waterproof coiled material is formed by the composite of the modified asphalt waterproof layer, the metal foil layer and the polyester tire, wherein the polyester tire is presoaked by the special modified asphalt, so that the root thorn-proof and waterproof coiled material has double functions of the water resistance and the penetration resistance of plant roots, can prevent from being penetrated by plant root hairs, and keeps the waterproof function for a long time.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

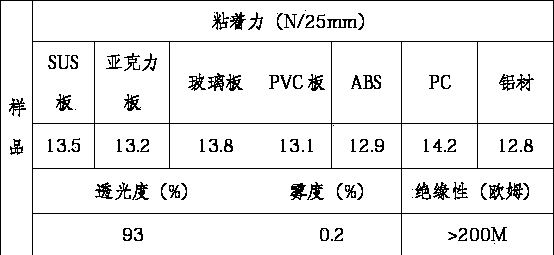

OCA optical adhesive tape and making method thereof

InactiveCN103588954AImprove performanceFast curingFilm/foil adhesivesPolyureas/polyurethane adhesivesPrepolymerChemistry

The invention mainly relates to an OCA optical adhesive tape and a making method thereof. The OCA optical adhesive tape sequentially comprises a light-peel PET release film layer, an optical adhesive layer and a heavy-peel PET release film layer from top to bottom, and the optical adhesive layer comprises, by weight, 100 parts of a polyurethane acrylate prepolymer, 2 parts of a compounding agent, 5 parts of an initiator, 2 parts of an accelerant, 0.3 parts of an accelerant aid and 0.01 parts of a stabilizer. The invention further relates to a making method of the polyurethane acrylate prepolymer. The OCA optical adhesive tape has a good bond property to various polar and non-polar materials comprising inorganic glass, organic plastic sheets, metals and the like.

Owner:常熟市富邦胶带有限责任公司

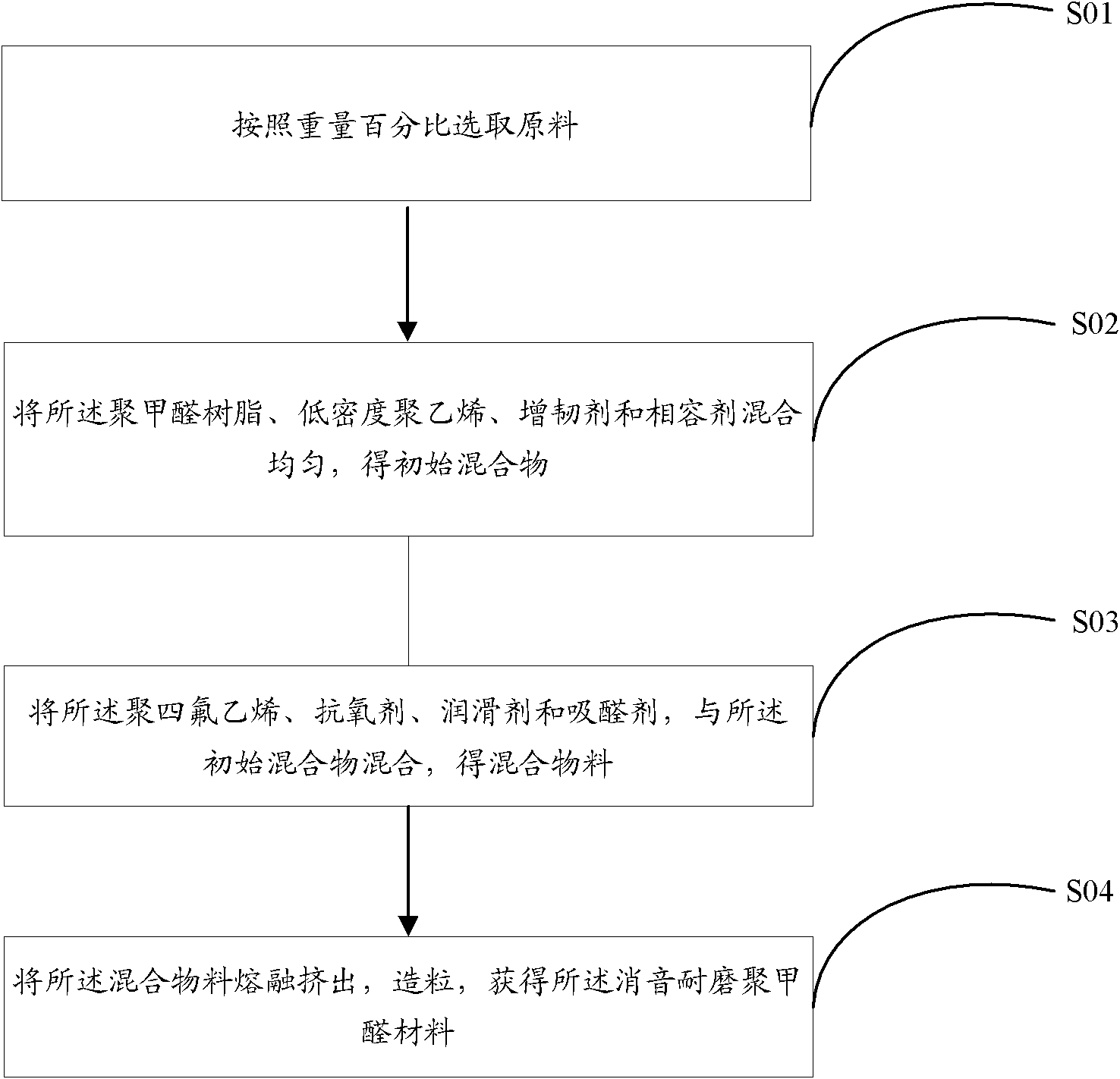

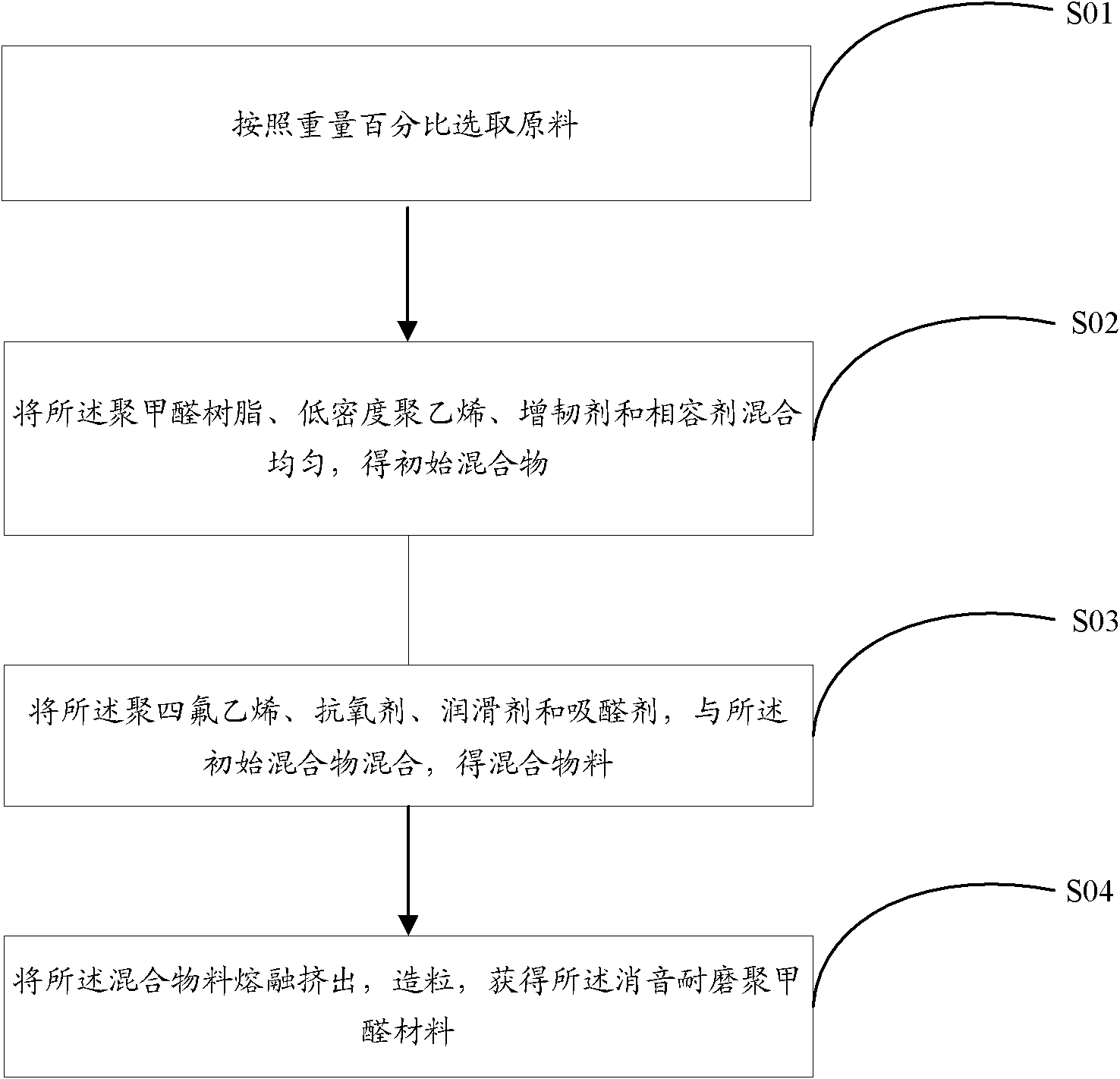

Sound-attenuating and wear-resistant polyformaldehyde material and preparation method thereof

The invention provides a sound-attenuating and wear-resistant polyformaldehyde material. The material comprises the following components in percentage by weight: 55 to 75 percent of polyformaldehyde resin, 5 to 10 percent of low density polyethylene, 3 to 10 percent of toughening agent, 10 to 20 percent of polytetrafluoroethylene, 2 to 5 percent of compatilizer, 0.2 to 0.4 percent of antioxidant, 0.2 to 0.6 percent of lubricating agent and 0.2 to 0.6 percent of aldehyde absorbing agent. The invention also provides a method for preparing the sound-attenuating and wear-resistant polyformaldehyde material. The sound-attenuating and wear-resistant polyformaldehyde material has high strength, dimensional stability, creep resistance, fatigue resistance, and high self-lubricating property, sound-attenuating property and wear resistance; and the preparation method for the material is simple, convenient to operate, high in benefit, low in cost and suitable for industrial production.

Owner:徐东

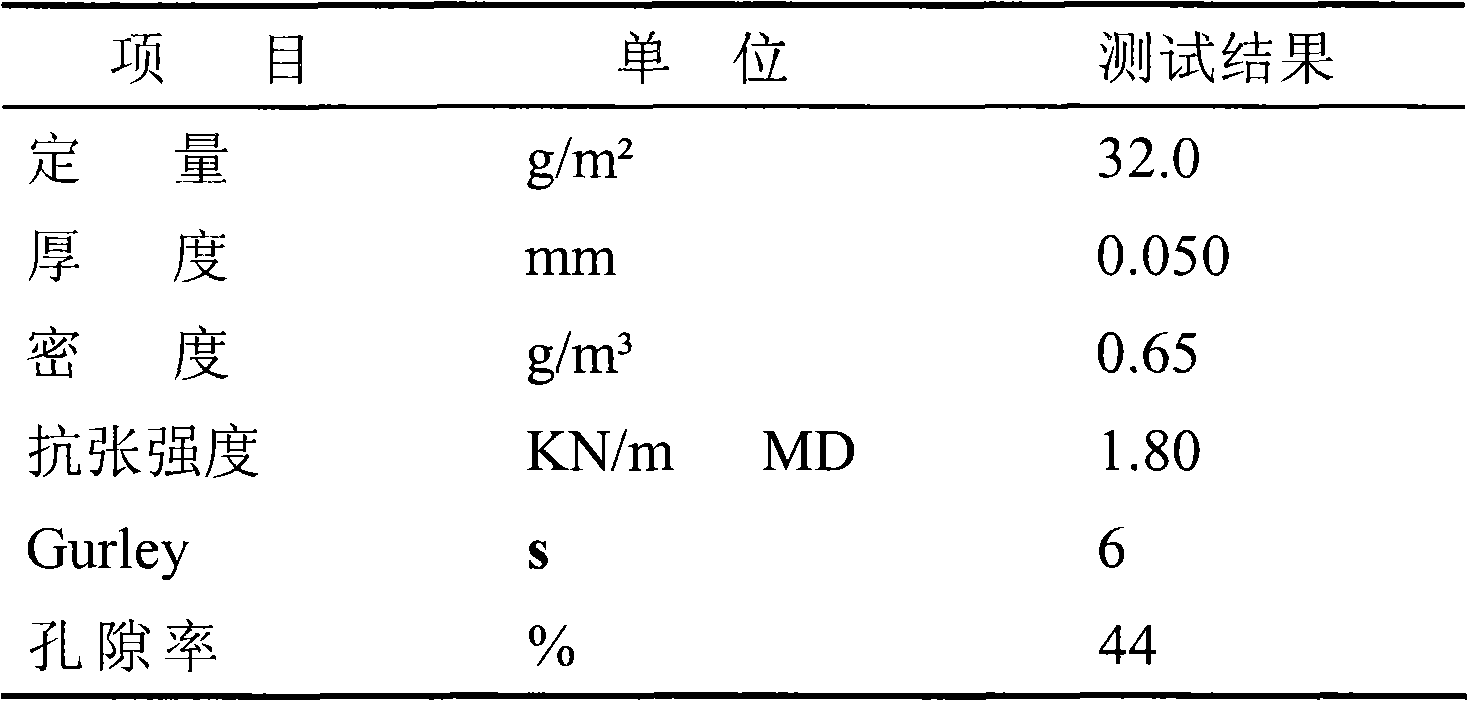

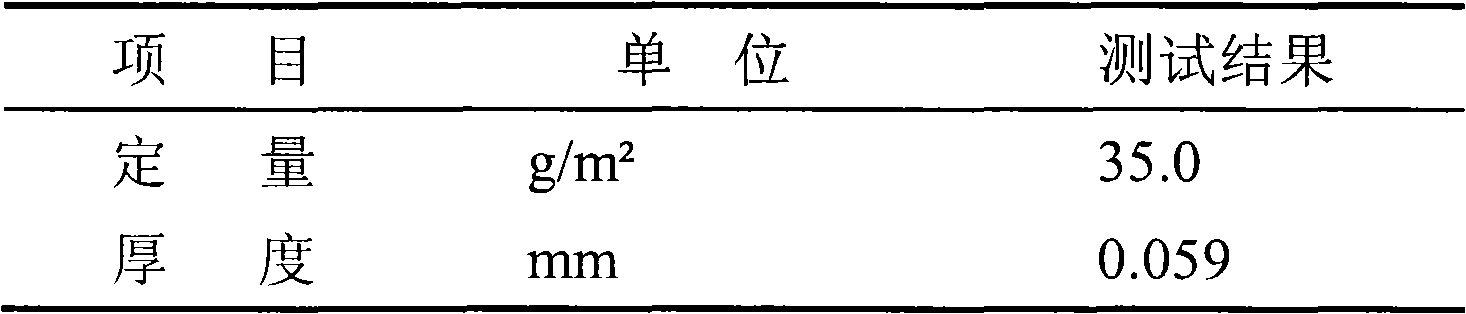

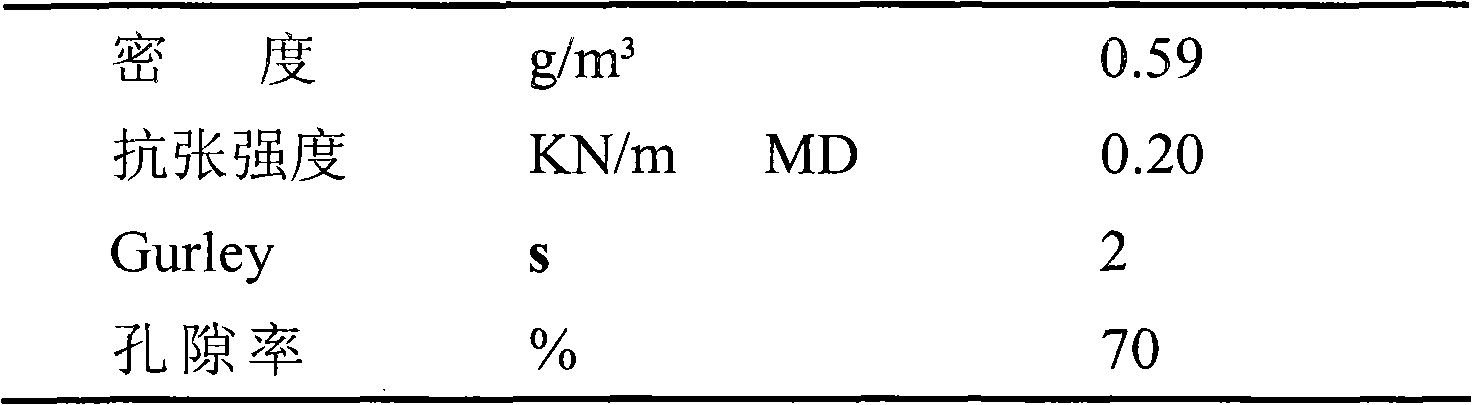

Battery diaphragm based on aramid fibre

InactiveCN101867030AOvercome the weakness of heat intoleranceProne to liquid-solid phase separationCell component detailsPorosityElectrical resistance and conductance

The invention discloses a battery diaphragm based on aramid fibre. The battery diaphragm is manufactured mainly from ultra-short aramid fibre in match with aramid fibre fibrid, and the specific requirements of air permeability and porosity of the battery diaphragm can be satisfied through adjusting fibre formula and molding process. The battery diaphragm can realize mechanical isolation function of the positive and negative poles of the battery, ensures low resistance and high ion electrical conductivity simultaneously, and has enough electrochemistry stability. Compared with traditional plastic diaphragm, the battery diaphragm in the invention has more excellent comprehensive properties, i.e. excellent heat resistance performance, high strength, fatigue resistance performance, low deformation, fire-resistant and flame retardant performance, chemical-corrosion resistance performance and the like. The battery diaphragm in the invention can be widely applied to the manufacturing of various ion batteries.

Owner:深圳昊天龙邦复合材料有限公司

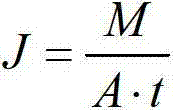

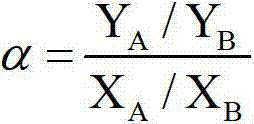

Preparation method of polyurethane pervaporation phenol/water separating membrane compounded by inorganic particles

InactiveCN103084077AHigh temperature resistantHigh temperature resistanceDistillationFiberDiphenylmethane

The invention discloses a preparation method of a polyurethane pervaporation phenol / water separating membrane compounded by inorganic particles, and belongs to the field of pervaporation membrane separation. The polyurethane membrane basic material is obtained by polymerizing and mixing monomer hydroxyl-terminated polybutadiene, toluene diisocynate, 4,4'-diamine diphenylmethane solution, cyclodextrin and silica or carbon fiber powder. The preparation method comprises the following steps: reacting hydroxyl-terminated polybutadiene with toluene diisocynate to obtain blocked prepolymer, then adding 4,4'-diamine diphenylmethane solution and cyclodextrin as chain extenders to perform the chain extension, and adding inorganic modified particle silica or carbon fiber powder (using N,N-dimethylacetamide as solvent) to obtain prepolymer solution of polyurethane; casting the solution on a polyfluortetraethylene plate to form a membrane, solidifying for 1-1.5 hours at room temperature, and moving the membrane to an oven at 80 DEG C to thermally treat to obtain the polyurethane membrane compounded by inorganic particles. The preparation method disclosed by the invention is simple in process, and the prepared membrane has good heat and chemical stability and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Medlar fruit wine with health care function, and preparation method thereof

InactiveCN103173319AWith health functionWith hypolipidemicAmphibian material medical ingredientsAnthropod material medical ingredientsMedicinal herbsFruit wine

The invention relates to a medlar fruit wine with a health care function, and a preparation method of the medlar fruit wine; the medlar fruit wine is characterized by being prepared by mixing medicine raw materials containing medlar and cured rice according to the weight ratio of 1: (8-12), fermenting the mixture and brewing. The preparation method of the medlar fruit wine comprises the following steps of: cleaning and drying the medicine raw materials, mixing and grinding; mixing the ground medicine raw materials with the cured rice according to the weight ratio of 1: (8-12), then adding a fermentation filler into the mixture, and carrying out mixed fermentation for 80-130 days to form fermented stock wine; after that, adding white spirit into the fermented stock wine, and continuously fermenting for 20-40 days; and when the alcohol content meets the requirement, filtering and sterilizing the fermented product to obtain the medlar fruit wine with the health care function. The medlar fruit wine with the health care function has the characteristics of being high in nutritional ingredients, high in yeast acid element content, high in unsaturated fatty acid content and high in content of other beneficial components, and can be used for reducing the blood fat and the blood sugar content after being drunk for a long time. Furthermore, the medlar fruit wine with the health care function also has the characteristics of being simple in preparation method, easy to implement, etc.

Owner:NINGXIA TIANCHUN LIQUOR IND

Preparation method of polyester-nylon parallel composite elastic fiber

ActiveCN110644073AIncrease melt viscosityPromote charcoalFlame-proof filament manufactureMelt spinning methodsPolyesterFiber

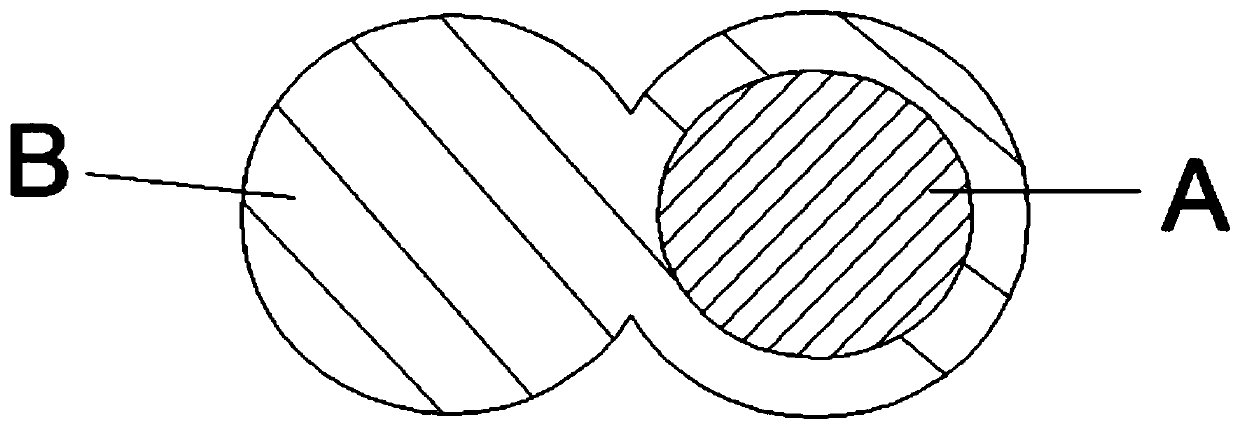

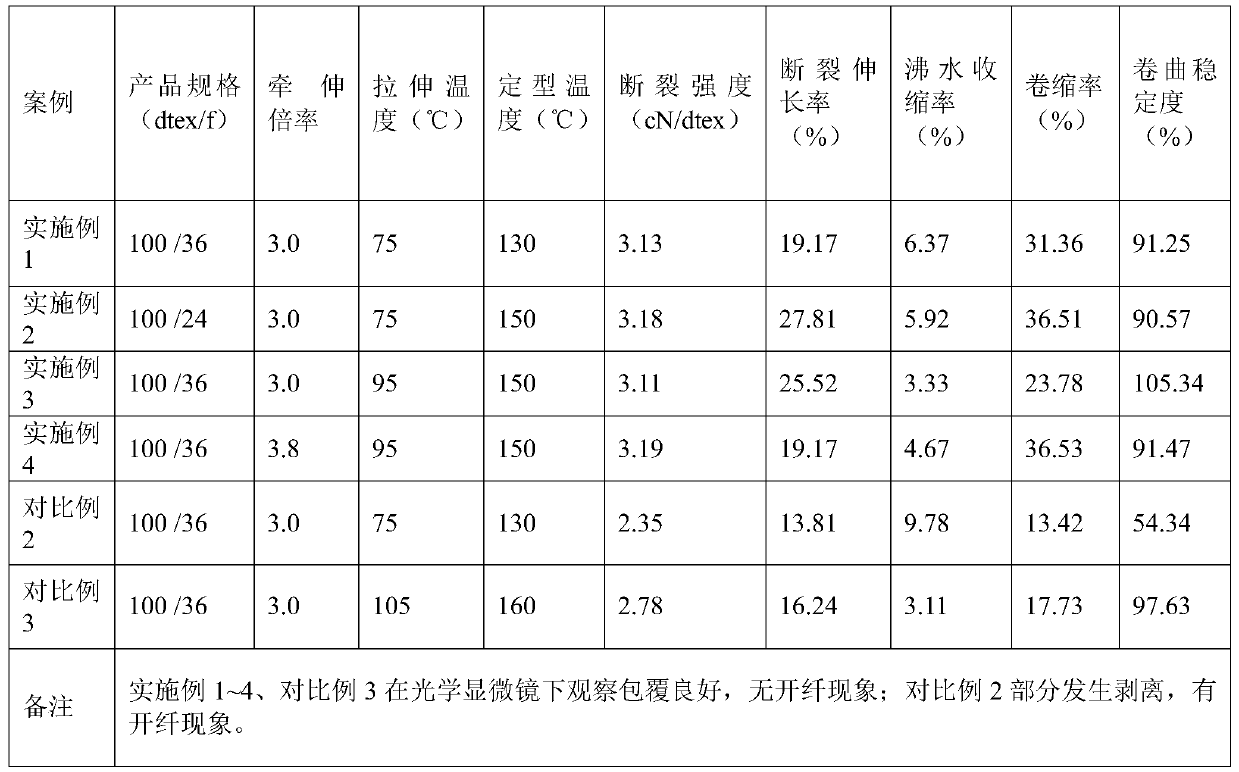

The invention relates to the field of chemical fibers and discloses a preparation method of a polyester-nylon parallel composite elastic fiber, wherein PET (polyethylene terephthalate) and nylon 6 aretaken as two parallel components, then the PET and nylon 6 are respectively subjected to melt extrusion through a screw extruder, the melts enter a two-component composite spinning assembly and a skin-core composite spinneret plate with a special design, and the sprayed melt is cooled, the cooled melt is oiled, and the oiled material is stretched and shaped and wound to obtain the polyester-nylonparallel composite elastic fiber, having the advantages of moisture absorption, air permeability, pilling resistance, bulkiness, high elasticity, fabric stiffness and the like. Compared with the current polyester-nylon composite fibers, the polyester-nylon composite fiber has better elasticity, and higher added value, and the problem of fiber opening of parallel polyester-nylon composite fibers is solved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

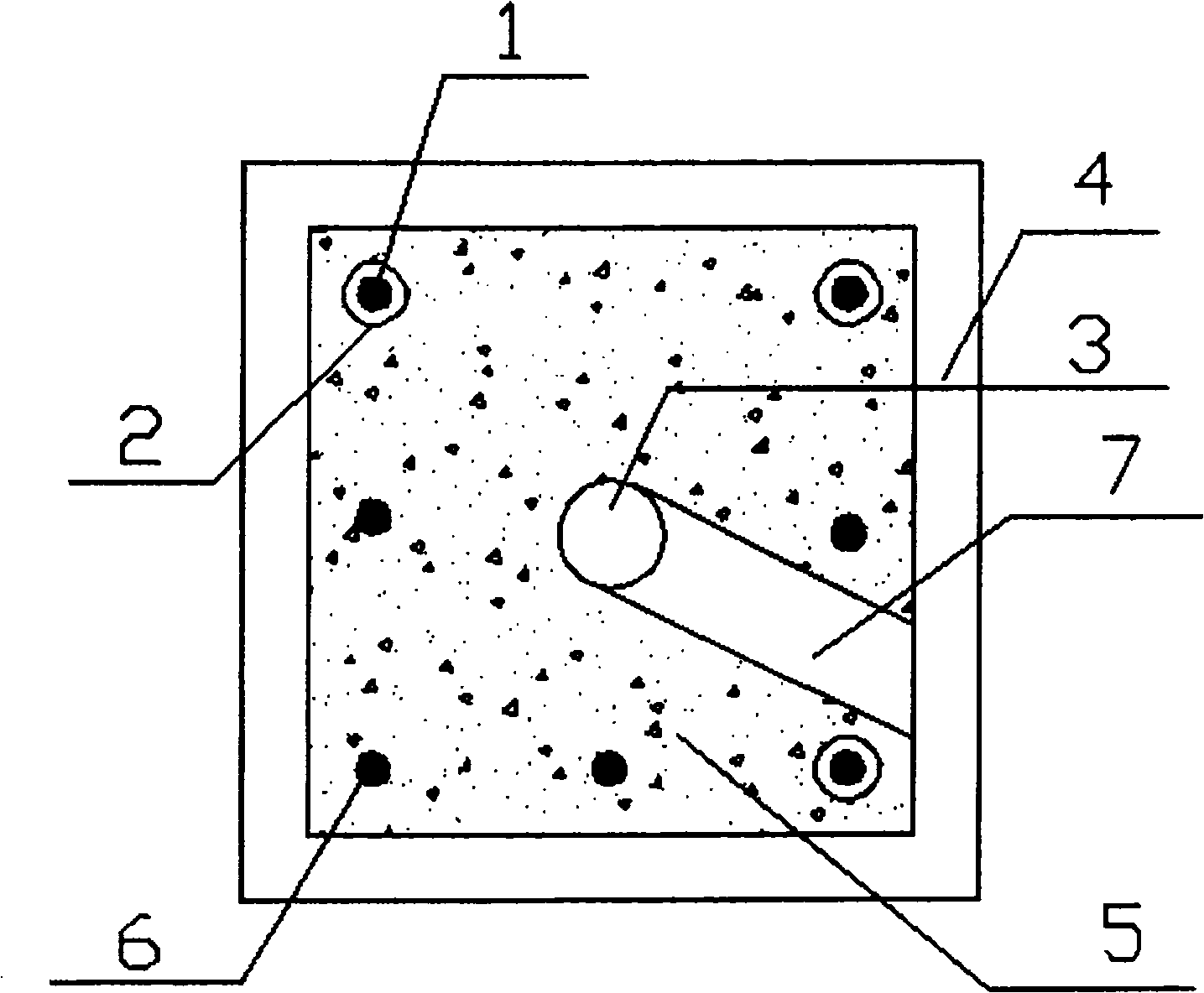

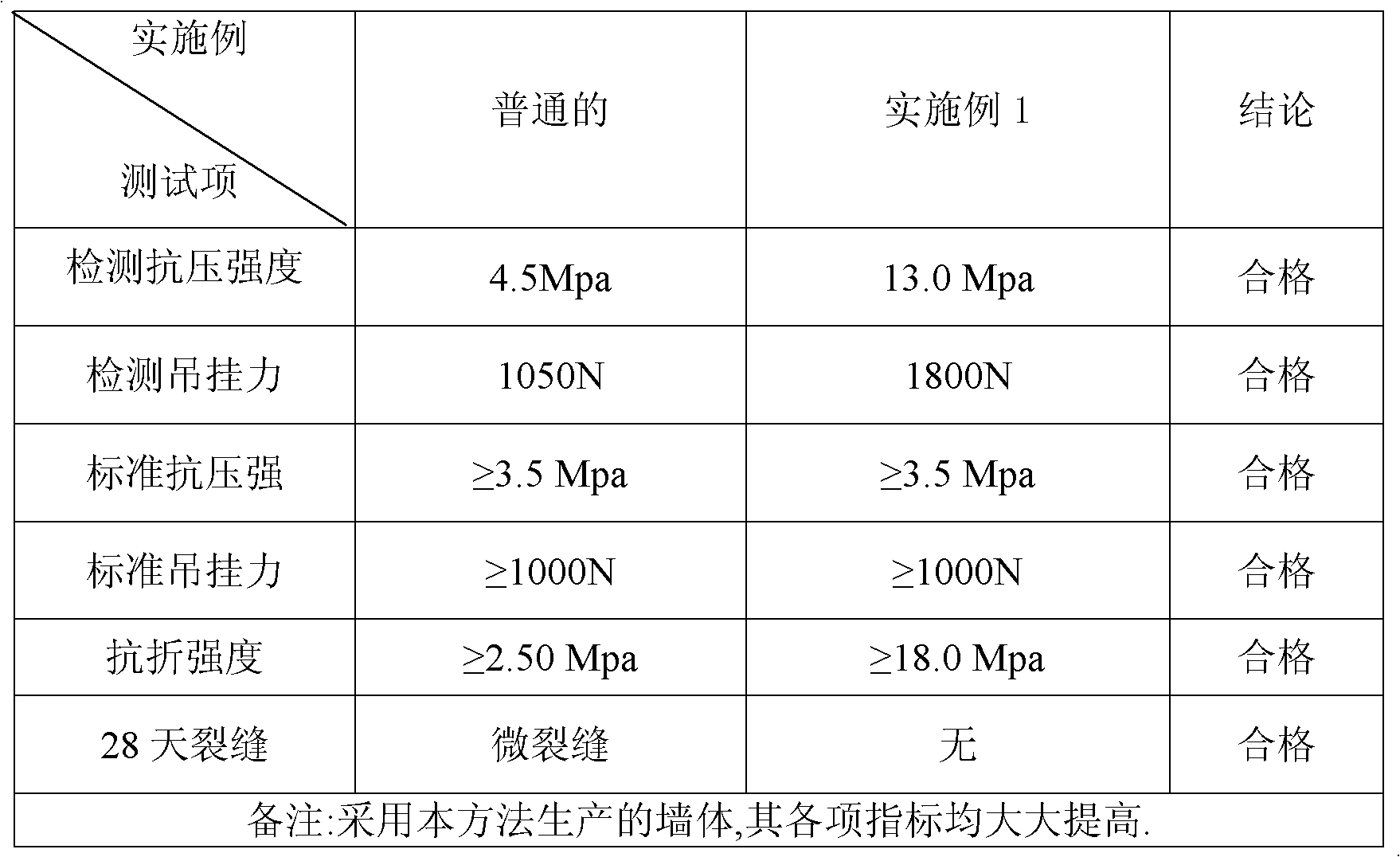

Steel plate concrete column and construction method

InactiveCN102061780AImpact resistantFatigue resistantStrutsBuilding material handlingShock resistanceRebar

The invention discloses a steel plate concrete column and a construction method, and the method is characterized in that a plastic skin aluminum core lead wire is built in on a steel bar before concrete is poured, unhardened concrete is heated by utilizing an electromagnetic inductive method, and when the concrete is hardened, the shrinkage of a steel plate is greater than that of the concrete, i.e., prestressing force is applied to a steel tube by the concrete. Before the concrete is poured, an inbuilt conducting tube is connected with an anode power supply, the steel bar is connected with a negative power source, the power source is switched on in the process of pouring the concrete, and free water in the concrete is discharged through different electric potential distributions formed in the concrete. The steel plate concrete column provided by the invetnion has the advantages of high intensity, light weight, good plasticity, shock resistance, fatigue resistance, and the like; and the construction method provided by the invention has the characteristics that templates are omitted, labor and materials are saved, the construction is convenient, no season restriction exists, and the like.

Owner:虞建放

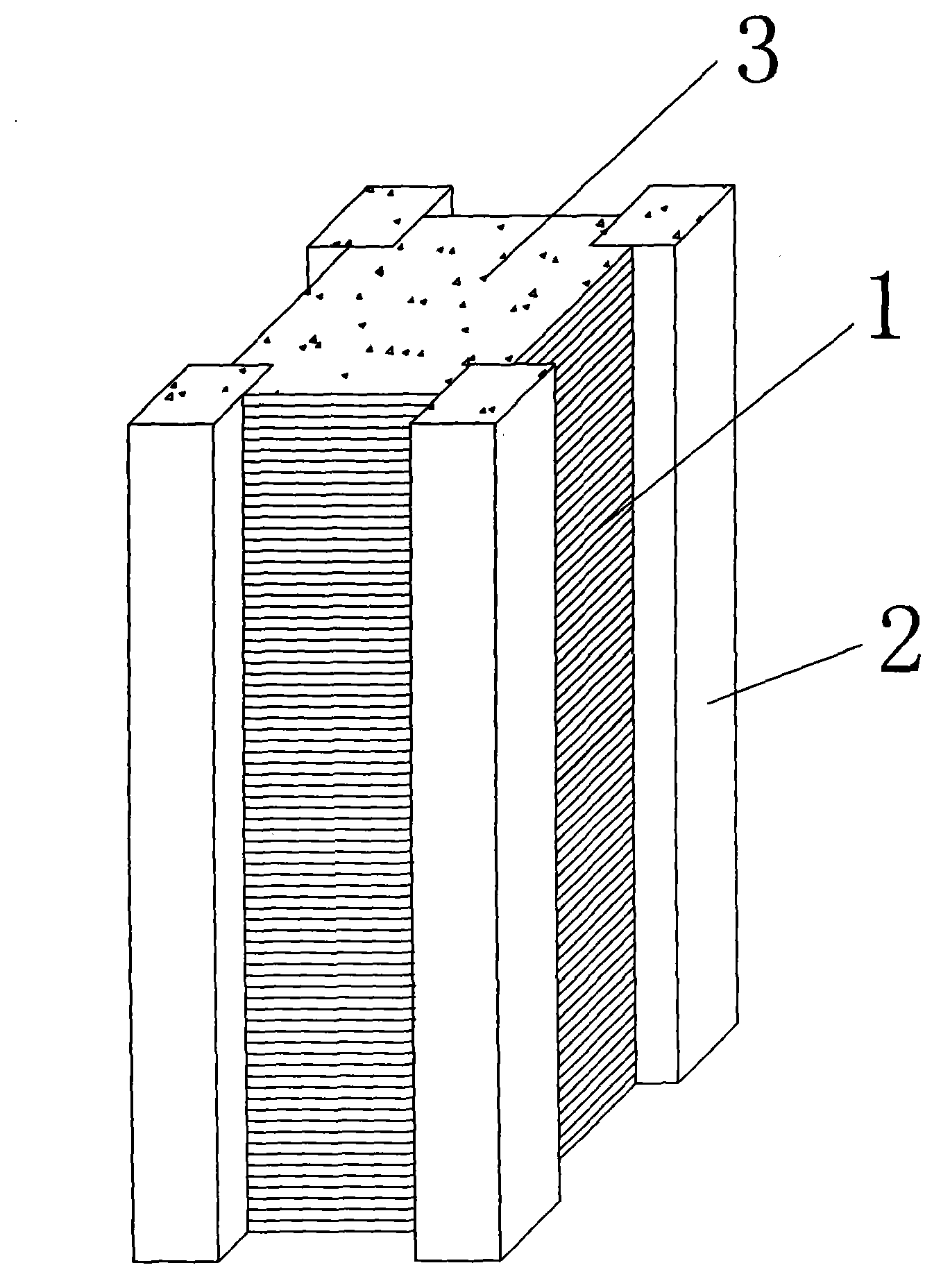

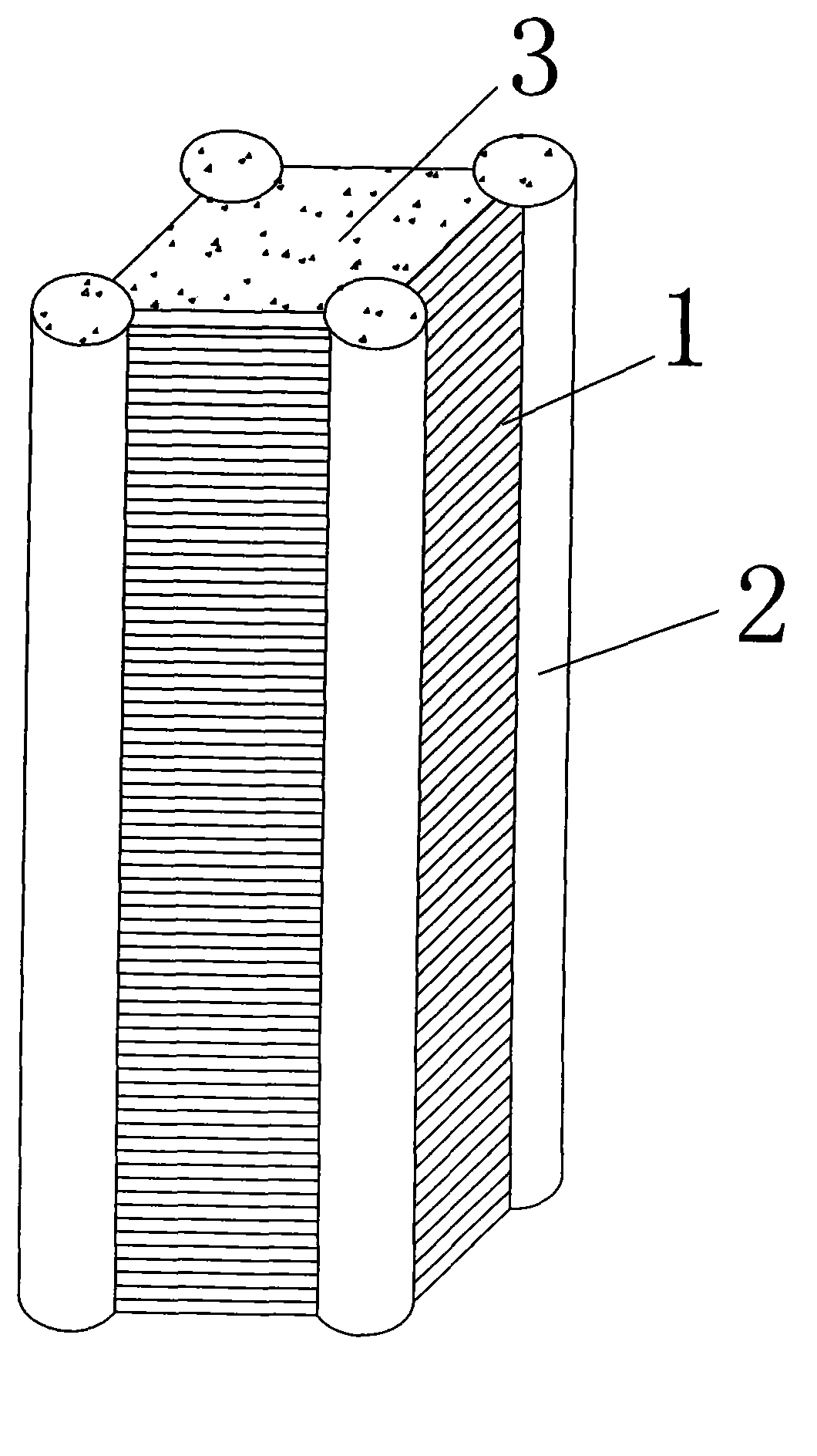

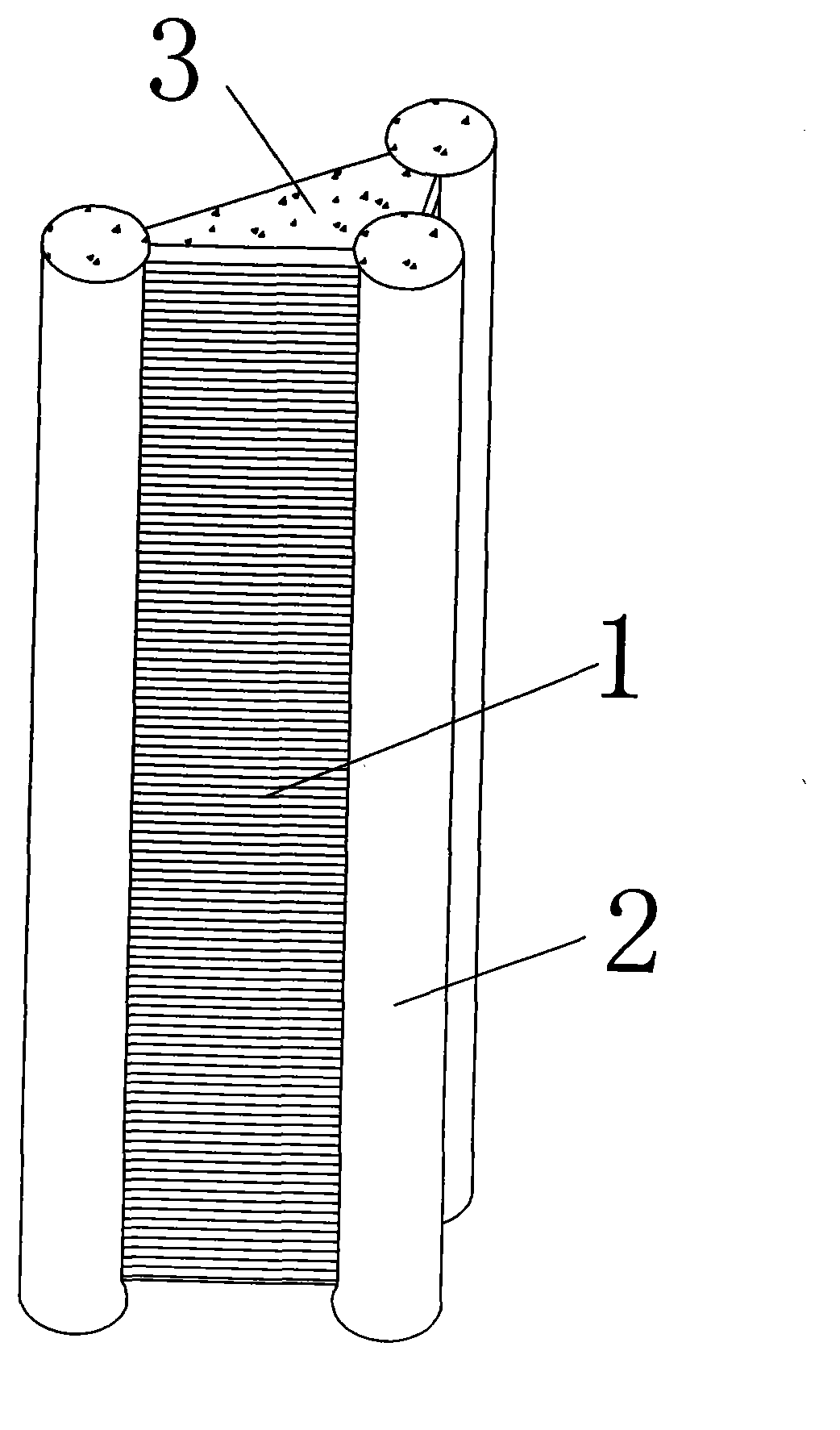

Corrugated steel plate confined concrete combination column and manufacturing method thereof

InactiveCN103015632AFatigue resistantImpact resistantStrutsPillarsSheet steelUltimate tensile strength

The invention discloses a corrugated steel plate confined concrete combination column which is a polygon tube formed by using a plurality of corrugated steel plates and a plurality of steel tubes as turning corners, wherein the corrugation directions of the corrugated steel plates are identical to the length direction of the polygon tube; and concrete is further filled into the polygon tube and the corners so as to manufacture the combination column. In addition to the excellent mechanical property of the conventional steel tube concrete, the combination column further has the following remarkable advantages that the load born by corrugated steel plate bears in the corrugation direction is small, so that the strength of the corrugated steel plate is mainly for providing annular restraint on the core concrete, then the compression bearing capacity of the core concrete is greatly improved, the compression bearing capacity of the combination column is improved to a large extent, the material is saved, and the engineering cost is reduced; the outer rigidity of the plane of the corrugated steel plate is large, and the corrugated steel plate is unlikely to bulge under the transverse expansion deformation action of the core concrete, so that the effective annual restraint of the corrugated steel plate to the core concrete is increased, and the compression bearing capacity of the combination column is further improved.

Owner:CHINA UNIV OF MINING & TECH

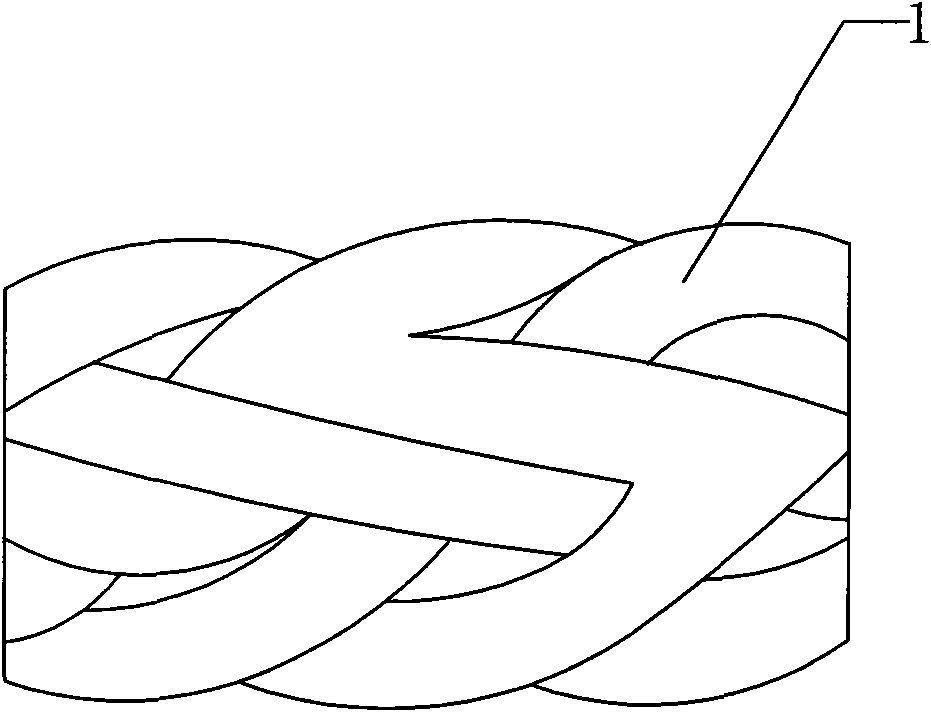

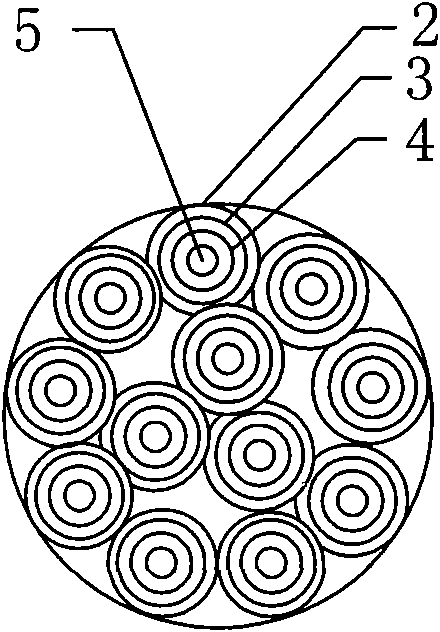

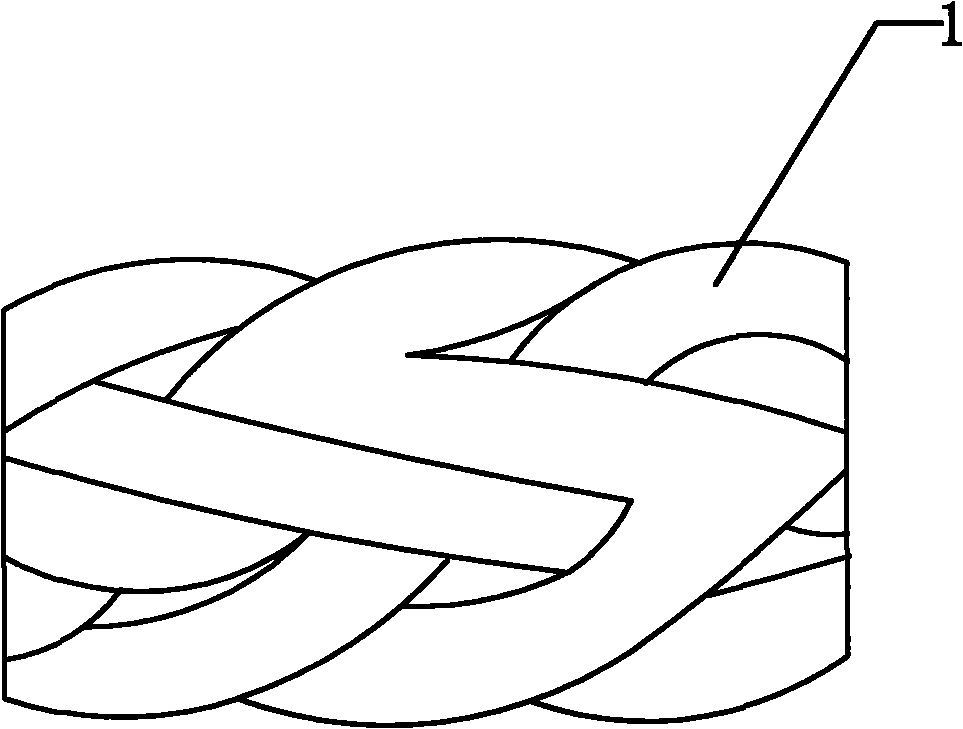

Polyester and polypropylene compound mooring rope and preparation process thereof

The invention relates to a polyester and polypropylene compound mooring rope and a preparation process thereof. The polyester and polypropylene compound mooring rope comprises twelve strands which are knitted into a whole, wherein six strands are used as left twisted strands and other six twisted strands are used as right twisted strands; the strands comprise outer layers, intermediate layers, inner layers and core layers which are formed by twisting and other polyester and polypropylene fiber twisting wires; the preparation process comprises the following steps: (1) selecting raw materials; (2) twisting wires; (3) producing strands; and (4) forming ropes. The invention has the beneficial effects that the mooring rope not only has the characteristics of low density, light weight, high strength, favorable specific modulus and impact resistance and the like which are the same as the characteristics of like products, but also has the performances of corrosion resistance, fatigue resistance, wear resistance, heat resistance, high melting point, ultraviolet ray resistance and the like; the wear resistance is about 8 percent higher than that of the like products, the fracture strength is 10 percent higher than that of the like products, the compressive strength is high and the structure is reasonable, attractive and practical.

Owner:浙江四兄绳业有限公司

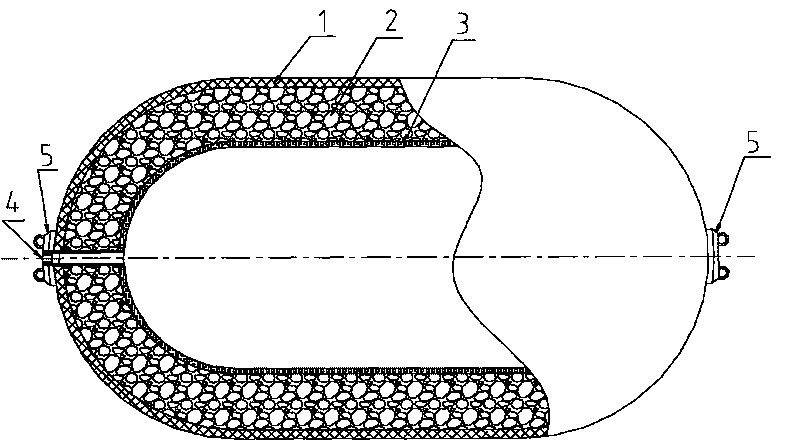

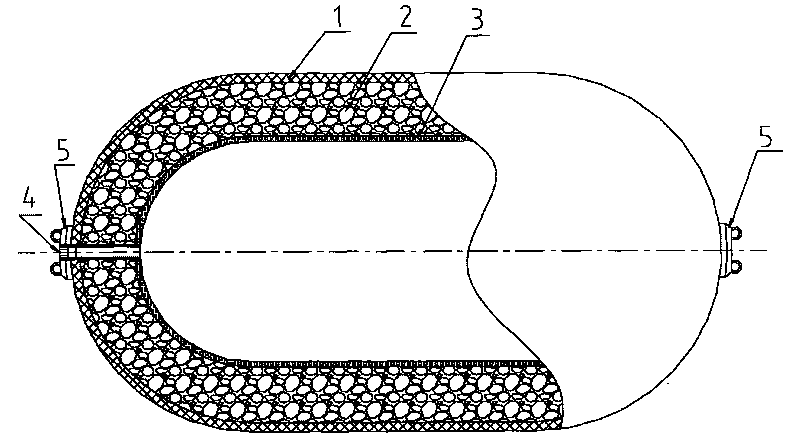

Combined type fender

InactiveCN101698424AAnti-agingExtended service lifeVessel cleaningClimate change adaptationEnergy absorptionEngineering

The invention relates to a combined type fender, which is a protective device to be used in docks, shipping and oceanographic engineering. The combined type fender is characterized by consisting of a shell, a buffering protective layer and a liner. The combined type fender integrates the advantages of various fenders, has the characteristics of toughness, extrusion resistance, fatigue resistance, ageing resistance and long service life of a fender taking rubber as a buffering medium, and avoids the disadvantages that the weight is large, the fender cannot float on a water surface, energy absorption is less and counter-force is large; the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force and pricking resistance which are possessed by a fender taking a foaming material as the buffering medium, and avoids the disadvantages of slow response speed and short service life; and in addition, the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force, quick response speed, capability to backpressure adjustment on the energy absorption and the counter-force and the like which are possessed by an air inflation type fender taking gas as the buffering medium, and avoids the defects that the combined type fender is easy for pricking, aging and air leakage, and needs to be maintained frequently.

Owner:钟爱民

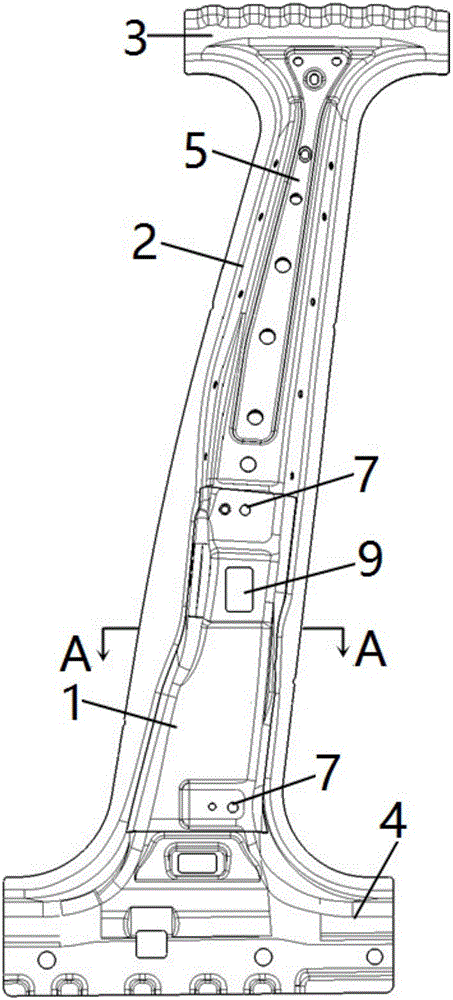

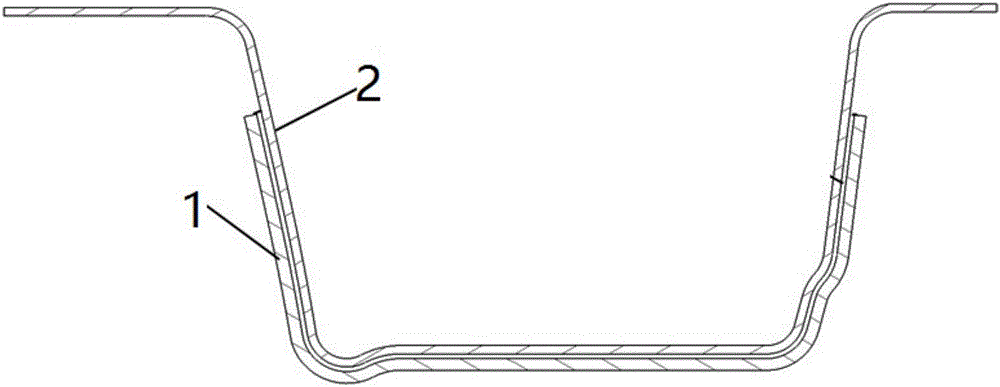

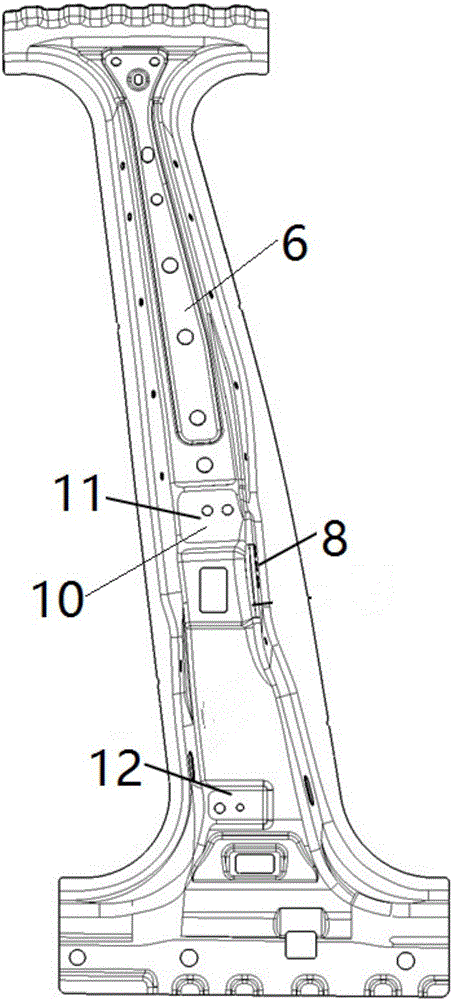

Automobile B column reinforcing plate assembly

The invention provides an automobile B column reinforcing plate assembly applied to the technical field of parts and components for an automobile body. A supporting outer plate (1) of the automobile B column reinforcing plate assembly adopts a structure made of carbon fiber materials; a reinforcing inner plate (2) adopts a structure made of steel plate materials; the supporting outer plate (1) and the reinforcing inner plate (2) are fixedly connected together; and the automobile B column reinforcing plate assembly is fixed on the automobile body. The automobile B column reinforcing plate assembly disclosed by the invention is simple in structure; through the composite design of the carbon fiber materials and the steel plate, the integrated intensity of the automobile B column reinforcing plate assembly is effectively improved, so that when the automobile collides, the side colliding safety of the automobile is improved; and besides, the weight of the automobile body is reduced, the purpose of reducing weight is achieved, and the performance requirements of the complete automobile are met.

Owner:杭州都凌汽车研发有限公司

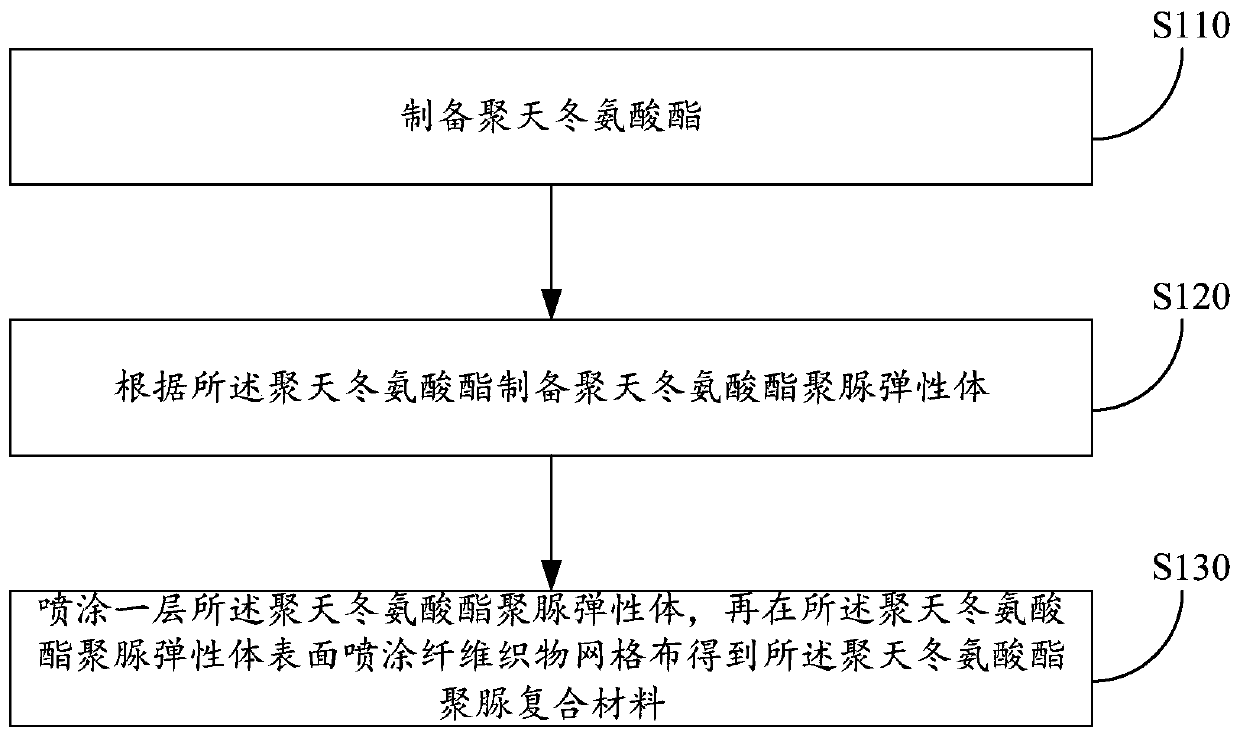

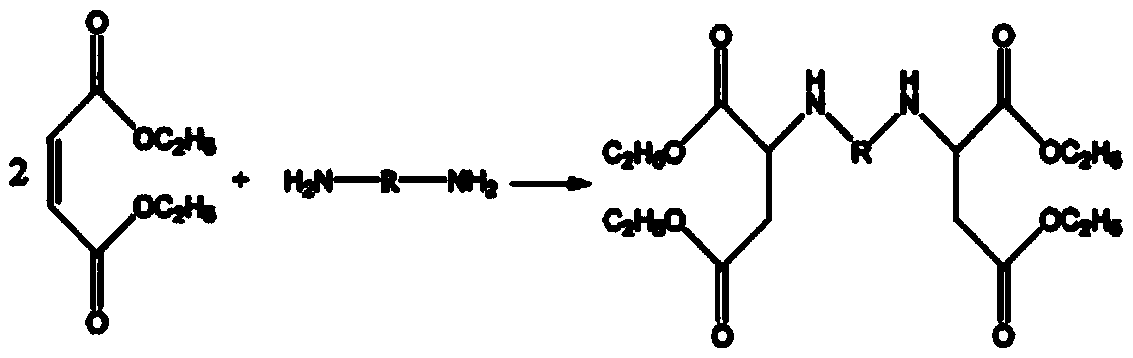

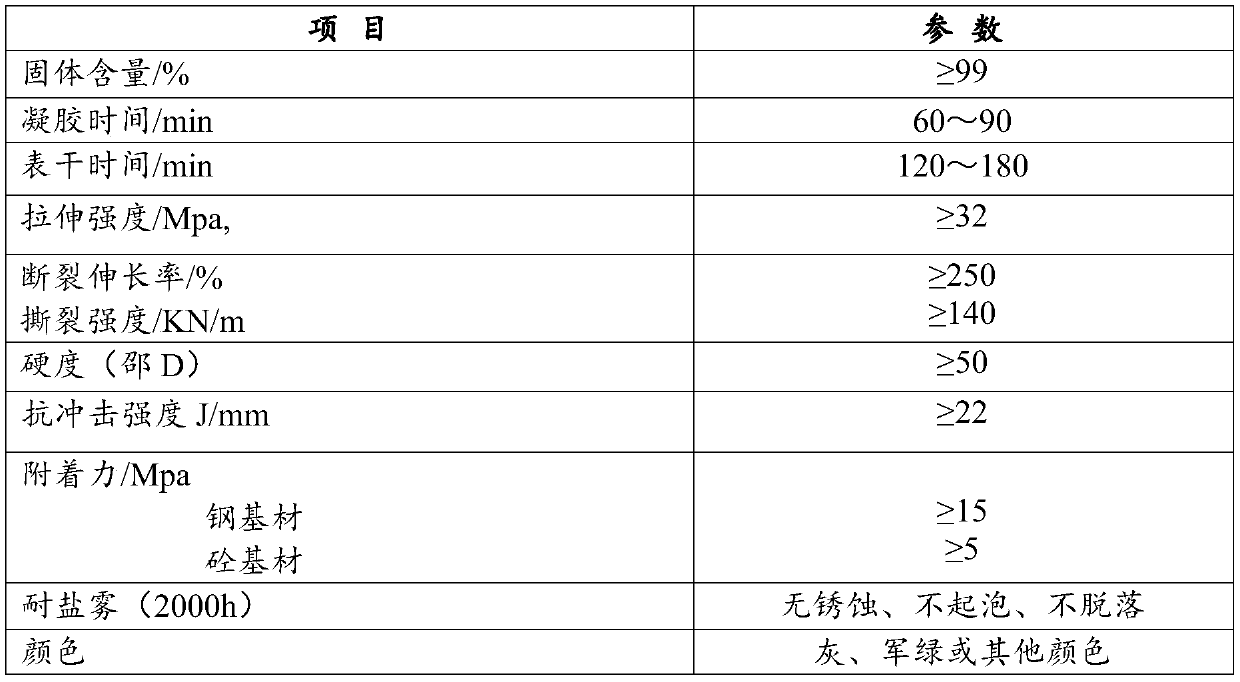

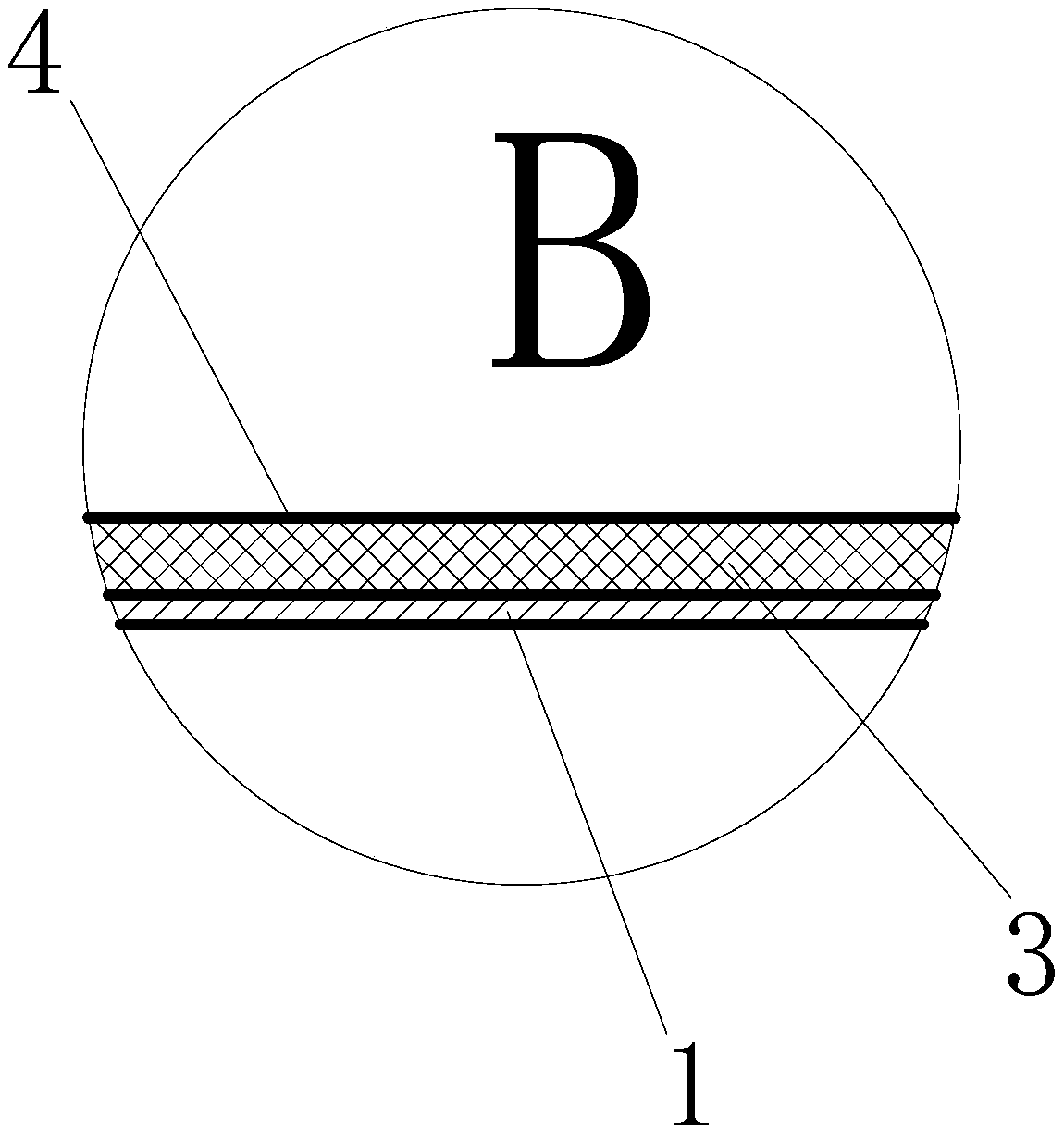

Polyaspartic acid ester polyurea composite material and preparation method thereof

The invention discloses a preparation method of a polyaspartic acid ester polyurea composite material. The composite material is prepared by compounding an explosion-proof polyaspartic acid ester polyurea elastomer and a porous energy-absorbing fiber fabric mesh cloth, the polyaspartic acid ester polyurea elastomer is anti-explosive, wear-resistant, impact-resistant and fatigue-resistant, and is an energy-absorbing reinforcing material, the porous fiber fabric mesh cloth is light, energy-absorbing, vibration-reducing and tear-resistant, and is an energy-absorbing reinforcing material, the polyaspartic acid ester polyurea composite material obtained by compounding the explosion-proof polyaspartic acid ester polyurea elastomer and the porous energy-absorbing fiber fabric mesh cloth has properties such as explosion resistance, energy-absorbing properties, vibration-reducing properties and impact resistance, can be used in military facilities and explosion-proof energy-absorbing protective equipment, can resist shock waves and debris generated by explosion, and meets basic requirements of military equipment.

Owner:QINGDAO AIR NEW MATERIALS

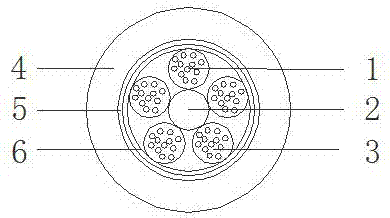

Low-water-adsorbing cable material for high-speed railway motor train unit and preparation method of low-water-adsorbing cable material

InactiveCN104804301ALow water absorptionImprove water resistancePlastic/resin/waxes insulatorsInsulated cablesVinyl etherAlpha-phenylindole

The invention discloses a low-water-absorbing cable material for a high-speed railway motor train unit and a preparation method of the Low-water-adsorbing cable material. The low-water-absorbing cable material for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 81 to 92 parts of polypropylene, 43 to 55 parts of polybutylene terephthalate, 27 to 39 parts of poly (vinyl chloride co-isobutyl vinyl ether), 3 to 5 parts of vaseline, 22 to 26 parts of crystal silicon micro-powder, 4 to 6 parts of triethoxy-1H,1H,2H,2H-tridecafluoro-n-octylsilane, 1 to 2 parts of 4-hydroxybenzoic acid hydrazide, 3 to 4 parts of zinc pyrrolidone carboxylic acid, 2 to 3 parts of stannous octoate, 4 to 6 parts of glyceryl tristearate, 15 to 20 parts of calcined kaolin, 3 to 4 parts of lead maleate tribasic, 1 to 2 parts of alpha-phenylindole, 21 to 27 parts of a composite fire retardant, and 1.5 to 2.5 parts of an anti-oxidant 1520. The cable material produced by the preparation method provided by the invention is low in water absorption and superior in water resistance, further has excellent performance such as high intensity, excellent thermal stability, shock resistance, aging resistance, corrosion resistance, fatigue resistance, environment friendliness and flame retardance, and the like, and has a very wide application prospect.

Owner:ANHUI KANGLIYA CO LTD

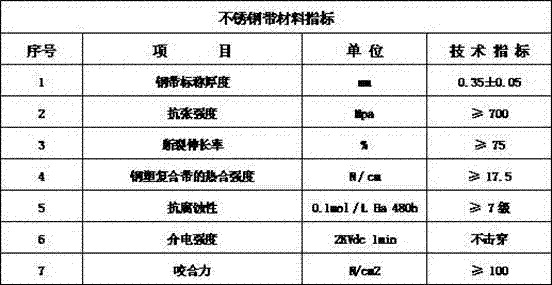

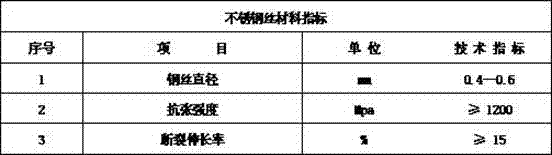

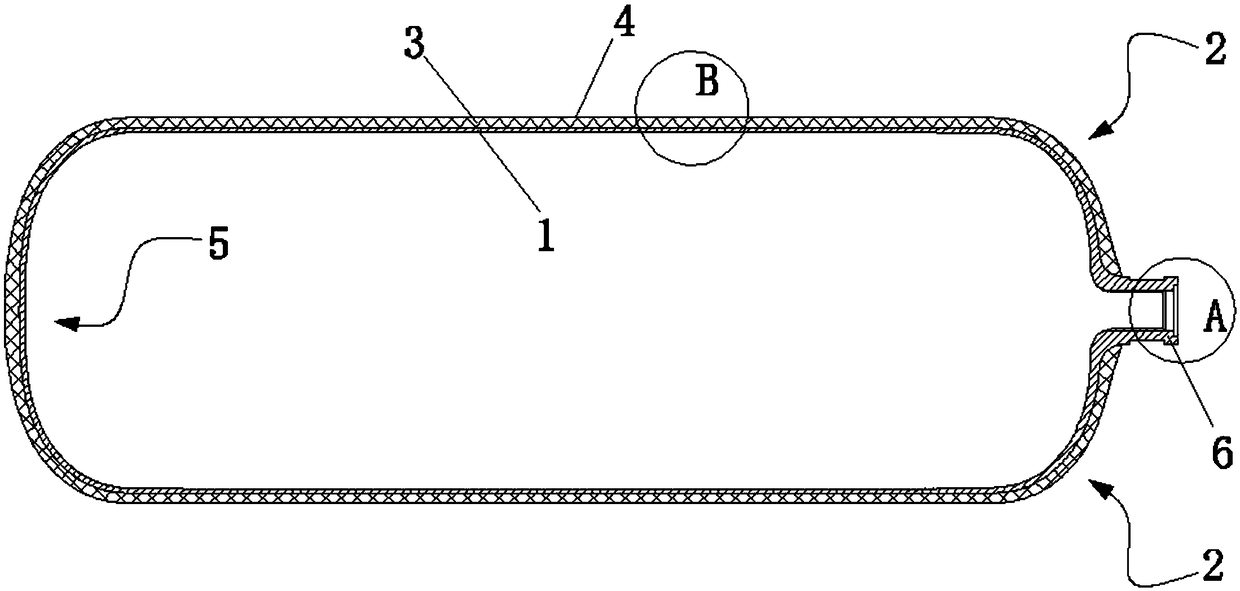

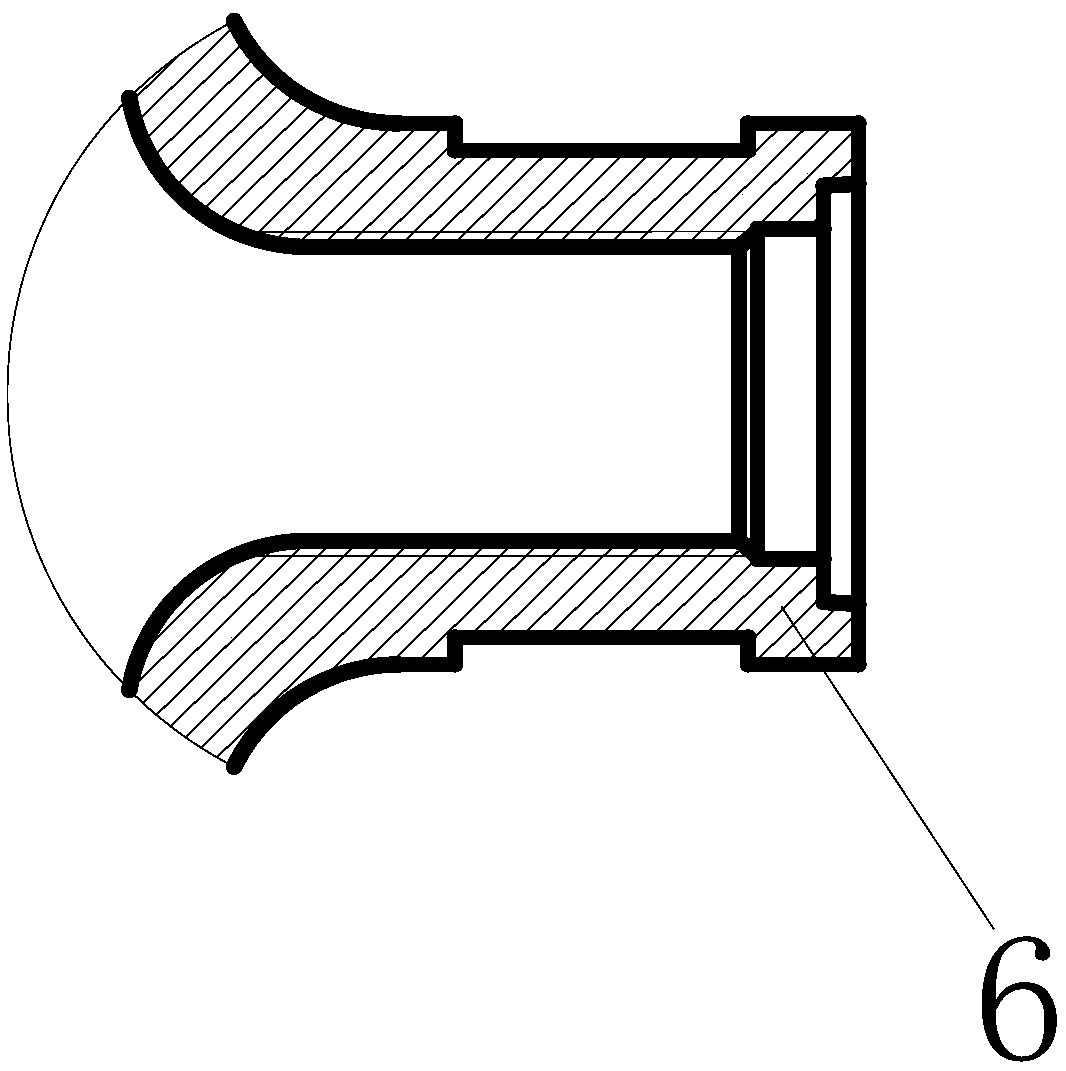

Rat-proof optical cable, preparation method thereof, and outer sheath material of rat-proof optical cable

The invention provides a rat-proof optical cable, a preparation method thereof, and an outer sheath material of the rat-proof optical cable. The rat-proof optical cable comprises a cable core which is formed by stranding a central reinforcement piece and a plurality of beam tubes around the reinforcement piece, and the beam tubes are internally provided with a plurality of optical fibers. The cable core is wrapped by a stainless steel belt, and an outer sheath is extruded at the outermost layer of the cable core. The stainless steel belt is a lipped stainless steel belt with the lipped width of 5mm and the height of 2.5mm, and firstly hot melt adhesive is injected into the joint of the lipped steel belt and then the lipped stainless steel belt is wrapped by multiple stainless steel wires with the diameter of 0.4mm. According to the rat-proof optical cable provided by the invention, under the premise of ensuring structural strength and tensile performance, the bite of rats is effectively prevented, the preparation method is simple and convenient, and the outer sheath used by the optical cable has the effects of wear resistance, low smoke, non halogen, and rat control.

Owner:JIANGSU TRIGIANT TECH +1

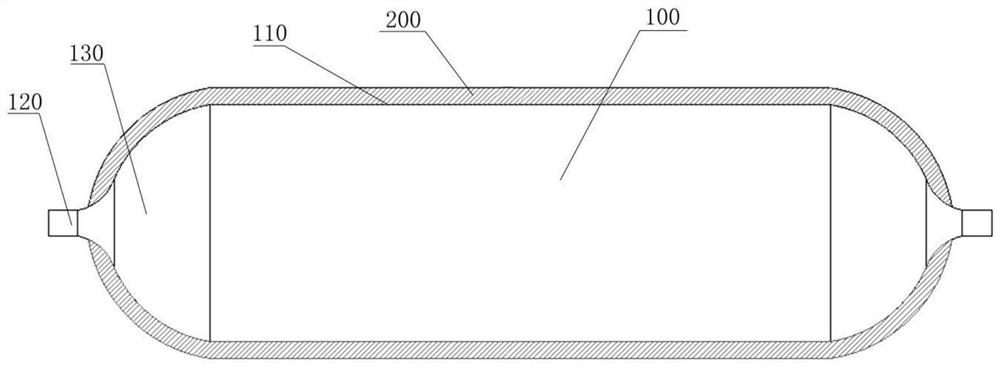

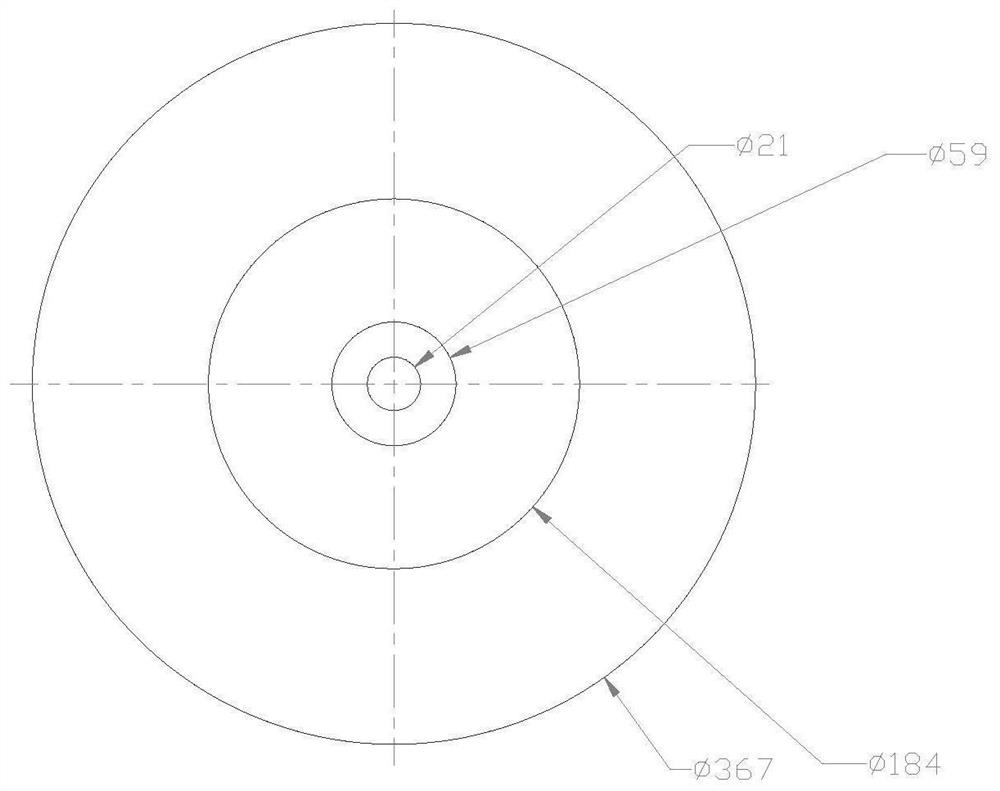

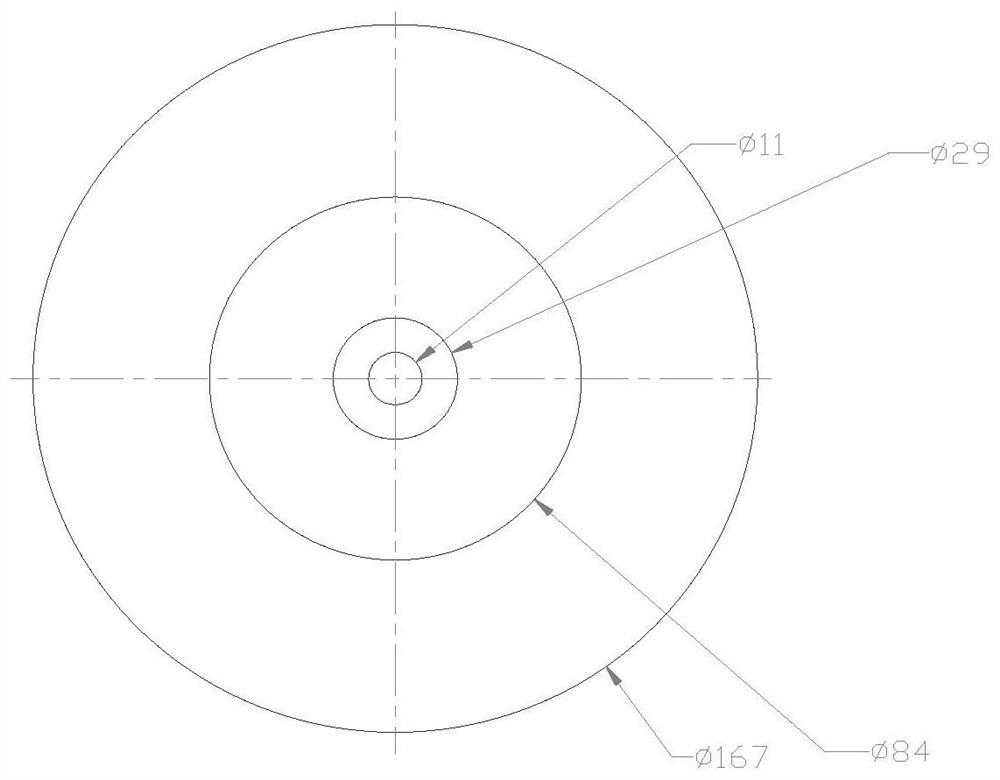

High-pressure gas storage cylinder of fuel cell unmanned aerial vehicle and preparation method thereof

PendingCN108758324ASimple structureScientific and reasonable designVessel manufacturingVessel geometry/arrangement/sizeAutomotive engineeringHigh weight

The invention discloses a high-pressure gas storage cylinder of a fuel cell unmanned aerial vehicle and a preparation method thereof and solves the problem that the endurance performance of the unmanned aerial vehicle is seriously influenced due to high weight and low hydrogen storage density per unit weight in the prior art. The high-pressure gas storage cylinder of the fuel cell unmanned aerialvehicle is punched, drawn and molded by aluminum plates; the high-pressure gas storage cylinder comprises a front sealing head and a rear sealing head which are respectively molded at the front and the rear end and also comprises an aluminum inner container used for storing hydrogen gas, a cylinder opening formed in the front sealing head and a strength layer, wherein the strength layer is prepared from a carbon fiber-epoxy system composite material and is crossed, folded and wound on the outer wall of the aluminum inner container through circular, longitudinal, and spiral manners. The preparation method of the high-pressure gas storage cylinder comprises the following steps: step one, manufacturing the aluminum inner container; step two, winding the strength layer; and step three, coatinga photocurable resin layer. The high-pressure gas storage cylinder is simple in structure, scientific and reasonable in design, convenient to use, light in weight, excellent in pressure-resistant property and excellent in fatigue property, and is capable of effectively improving the endurance performance of the unmanned aerial vehicle.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

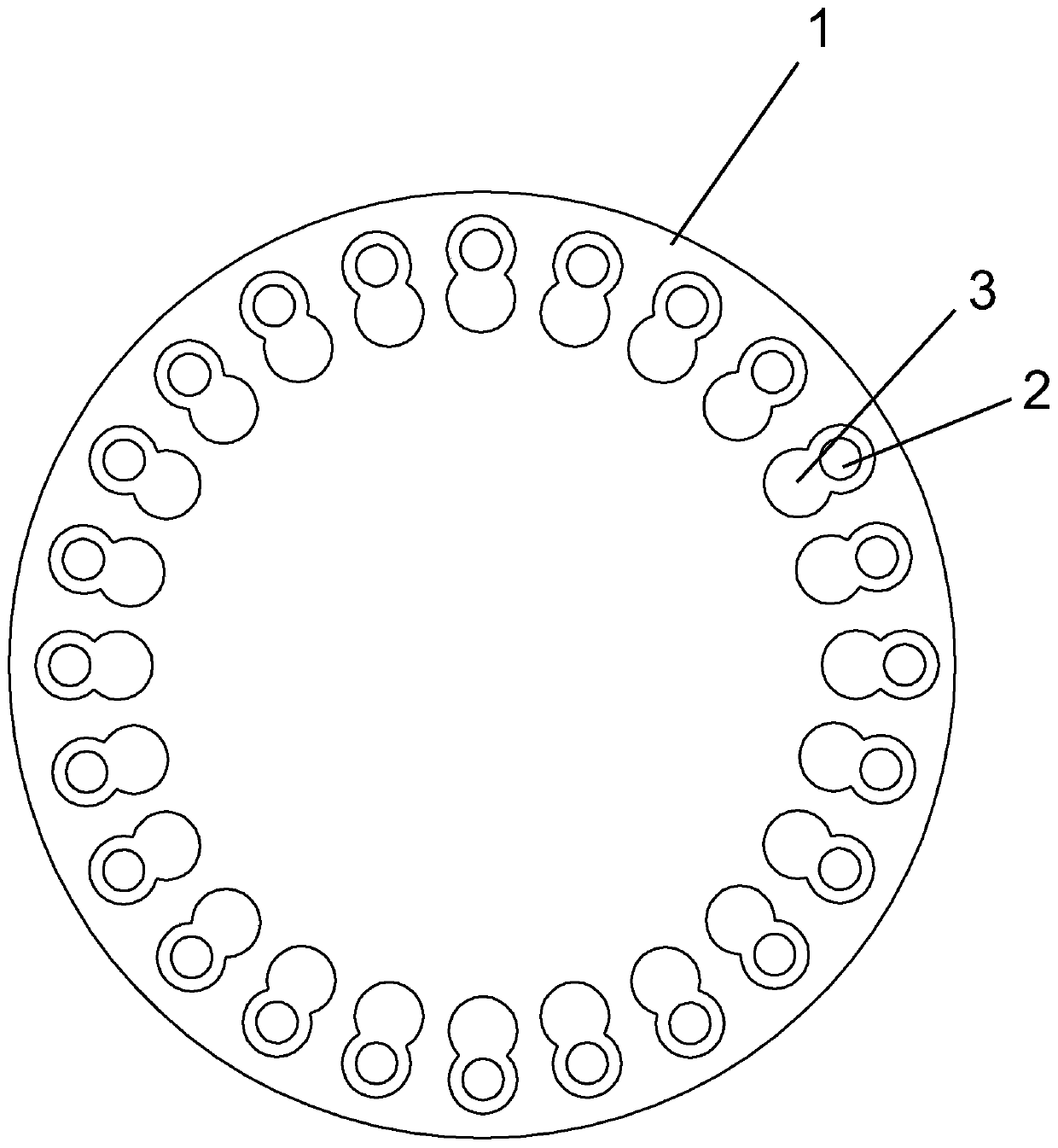

Fiber composite material high-pressure hydrogen storage cylinder and preparation method thereof

The invention provides a fiber composite material high-pressure hydrogen storage cylinder and a preparation method thereof. The preparation method comprises the steps that S100, a cylinder inner container is provided, and the cylinder inner container comprises an inner container body and a cylinder opening; S200, fiber yarns are adopted to conduct two-dimensional multi-spindle weaving on the outer surface of the cylinder inner container, so that a composite material weaving layer comprising multiple layers of fiber two-dimensional fabric is formed, the weaving angle of the fiber two-dimensional fabric at the position of the inner container body is 56-67 degrees, and the weaving angle of the fiber two-dimensional fabric at the position of the cylinder opening is 15-55 degrees; S300, in the composite material weaving layer, a sewing thread in the axis direction of the cylinder is additionally arranged between every 3-5 layers of adjacent fiber two-dimensional fabric for fixing, and a woven preformed body is obtained; and S400, resin is adopted to cure the woven preformed body through a vacuum bag vacuum resin infusion method, and the fiber composite material high-pressure hydrogen storage cylinder with the fiber composite material layer is obtained. The fiber composite material high-pressure hydrogen storage cylinder is light in weight, high in strength, resistant to fatigue, large in structural rigidity and good in high and low temperature impact resistance stability.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

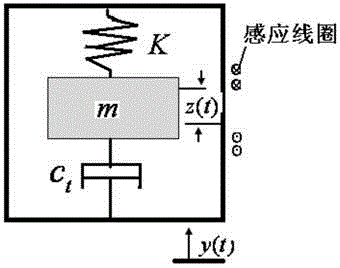

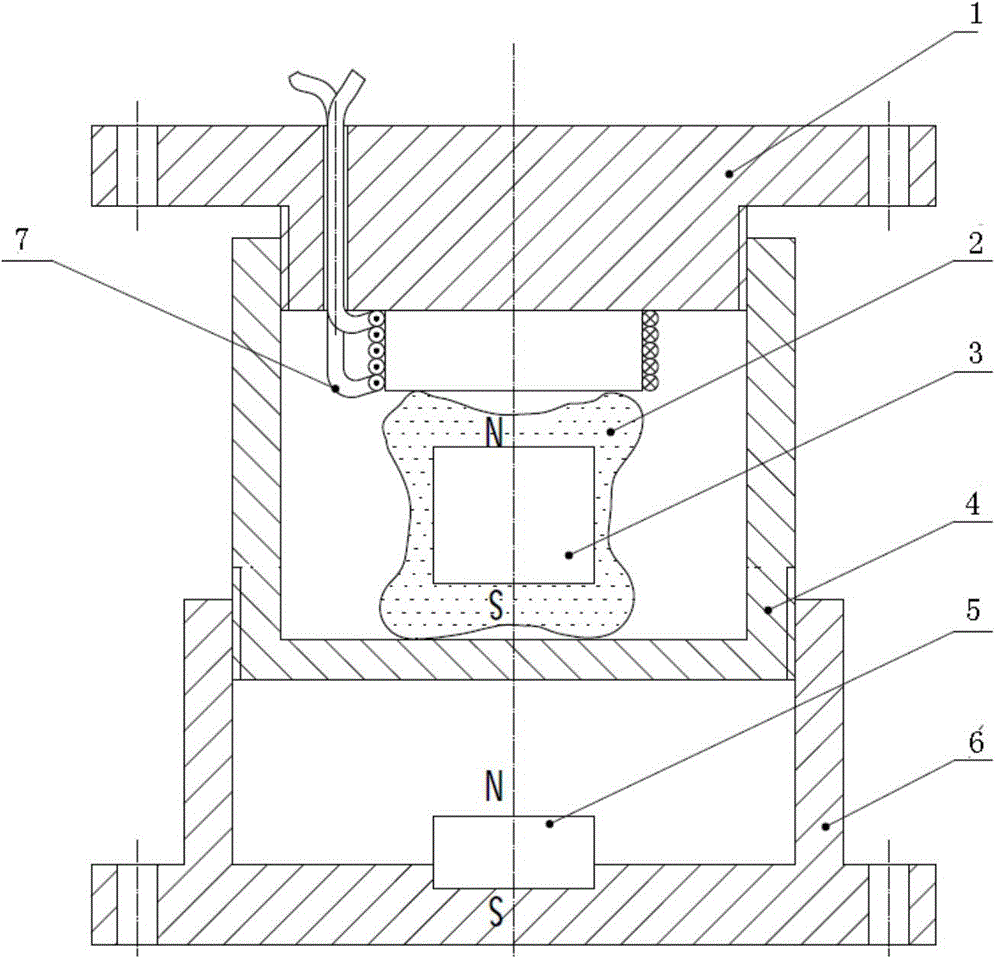

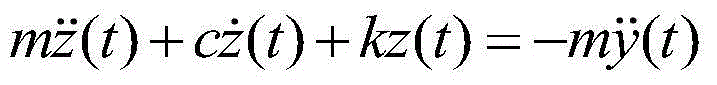

Planar vibration energy collector adopting magnetic liquid and permanent magnet combined structure

InactiveCN104393736ASimple structureFatigue resistantDynamo-electric machinesMagnetic liquidsMagnetic flux

The invention relates to a planar vibration energy collector adopting a magnetic liquid and permanent magnet combined structure. A vibration pick-up system of the collector is formed by a columnar permanent magnet with two ends absorbing magnetic liquid and a permanent magnetic piece which is arranged on the external side of a casing; attraction between permanent magnet materials is served as restoring force; the columnar permanent magnet which suspends inside the casing due to absorption of the magnetic liquid is served as an inertia mass block to respond to the exterior vibration; an induction coil winds a stepped cylinder on the internal side of the end cover, magnetic flux inside the induction coil changes along with relative movement of the permanent magnet inside the casing to induce electric energy and achieve collection of vibrational energy. The planar vibration energy collector adopting the magnetic liquid and permanent magnet combined structure is simple in structure, strong in practicability, fatigue resistant and can efficiently collect vibration energy in various planar forms.

Owner:BEIJING JIAOTONG UNIV

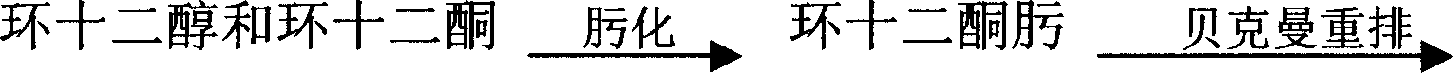

Long carbon chain nylon hot melt glue and its synthesis method

InactiveCN1493639AStrong and wear-resistantImpact resistantAdhesivesPolymer scienceSynthesis methods

A hot-fusible adhesive of C13-C18 polyamide with long carbon chain is prepared from the dibasic acid prepared by fermenting method through synthesizing. Its advantages are high adhesion, softness and size stability, and excellent resistance to water washing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal-panel polyurethane solid-solid phase transition energy-storage lightweight wall plate

InactiveCN102127948AReduce weightHigh strengthBuilding componentsHeat-exchange elementsInsulation layerEngineering

The invention relates to a preparation method of a metal-panel polyurethane solid-solid phase transition energy-storage lightweight wall plate. The metal-panel polyurethane solid-solid phase transition energy-storage lightweight wall plate prepared by the method is significantly improved in building energy saving when compared to traditional metal-panel polyurethane wall plates, and the wall plate prepared by the method not only has the outstanding advantages of light weight, great intensity, high stiffness, heat insulation, sound insulation, fatigue tolerance, and the like, but also has the characteristic of solid-solid phase transition energy storage. The material can be widely applicable to building energy saving, can be used as a wall material for movable board house, a heat-insulation layer inside and outside a building, a indoor baffle, etc.

Owner:洪伟

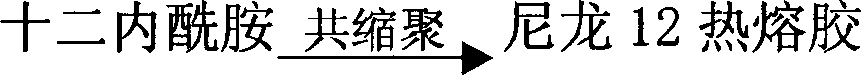

Method for preparing high-performance concrete and application

The invention discloses a method for preparing high-performance concrete and application. The method comprises the following steps of: designing a concrete mixing proportion; sequentially adding fine aggregate, engineering fibers and gel material into a stirrer, and stirring till the engineering fibers are uniformly distributed; and adding water to prepare mortar, adding coarse aggregate, stirring uniformly, and adding an admixture to obtain the high-performance concrete required by design. The prepared high-performance concrete can be used for preparing high-performance concrete products. The method is simple and convenient for processing; the length of the utilized engineering fibers is easily controlled, so that the concrete has good workability, the forming velocity and the production efficiency are improved, the concrete has the advantages of tensile resistance, shearing resistance, cracking resistance, fatigue resistance, high toughness and the like, and concrete cracks caused by temperature stress can be reduced; the microstructure of the cement slurry is improved, and the compactness of the concrete is increased, so that the strength and the durability of the concrete are improved, and the service life of the concrete is prolonged; and the concrete has good safety and economic and social benefits.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Wood plastic composite material with anti-bacterial function and preparation method

The invention relates to a wood plastic composite material with an anti-bacterial function. The wood plastic composite material is characterized in that raw materials for preparing the wood plastic composite material comprise the following components in parts by weight: 15-40 parts of wheat and rice straw, 1-15 parts of sweet wormwood and 1-3 parts of sweet wormwood extract. The wood plastic composite material has the traditional characteristics of high strength, high elasticity, high toughness, fatigue resistance and the like, has the advantages of being anti-bacterial and mould-proof and enhancing aroma without additionally adding a chemical antibacterial agent and an aroma enhancer, can well meet the needs of places having bacteriostatic requirements, such as hospitals and kindergartens, meanwhile is good for increasing the needs of the market on the raw materials of the sweet wormwood, the wheat and rice straw and the like, and promotes the comprehensive utilization of agricultural straw.

Owner:SUZHOU TANGJI BIOTECH CO LTD

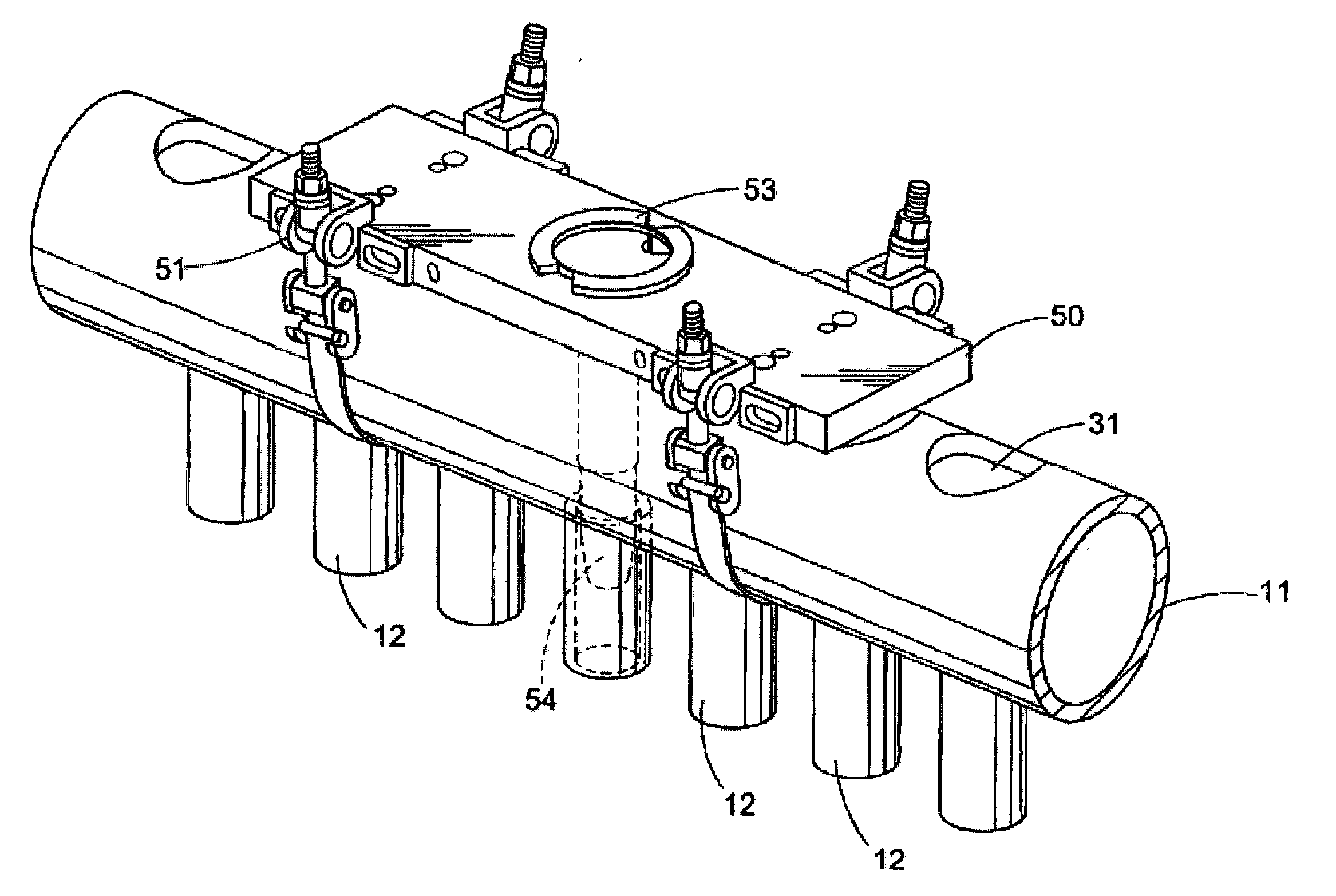

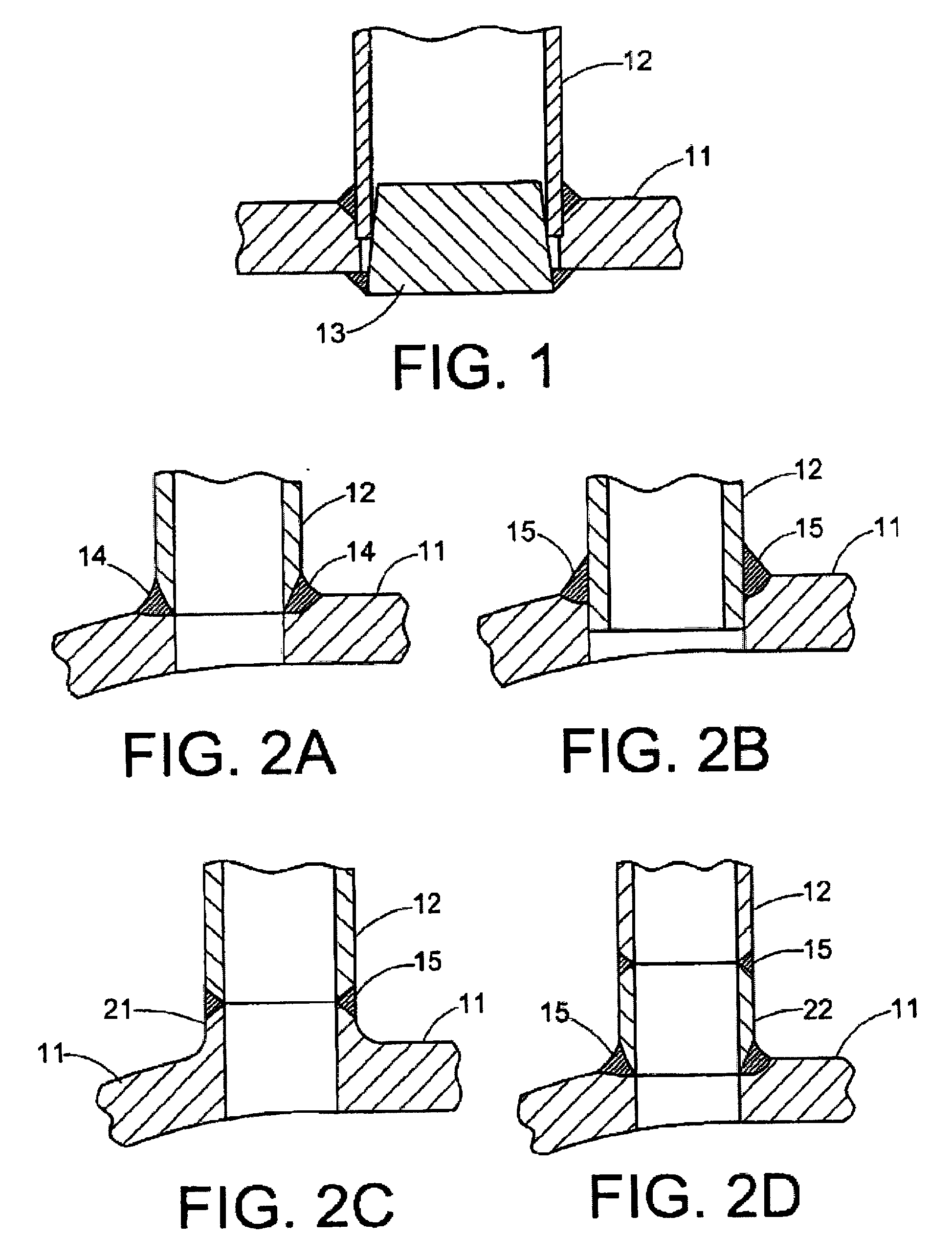

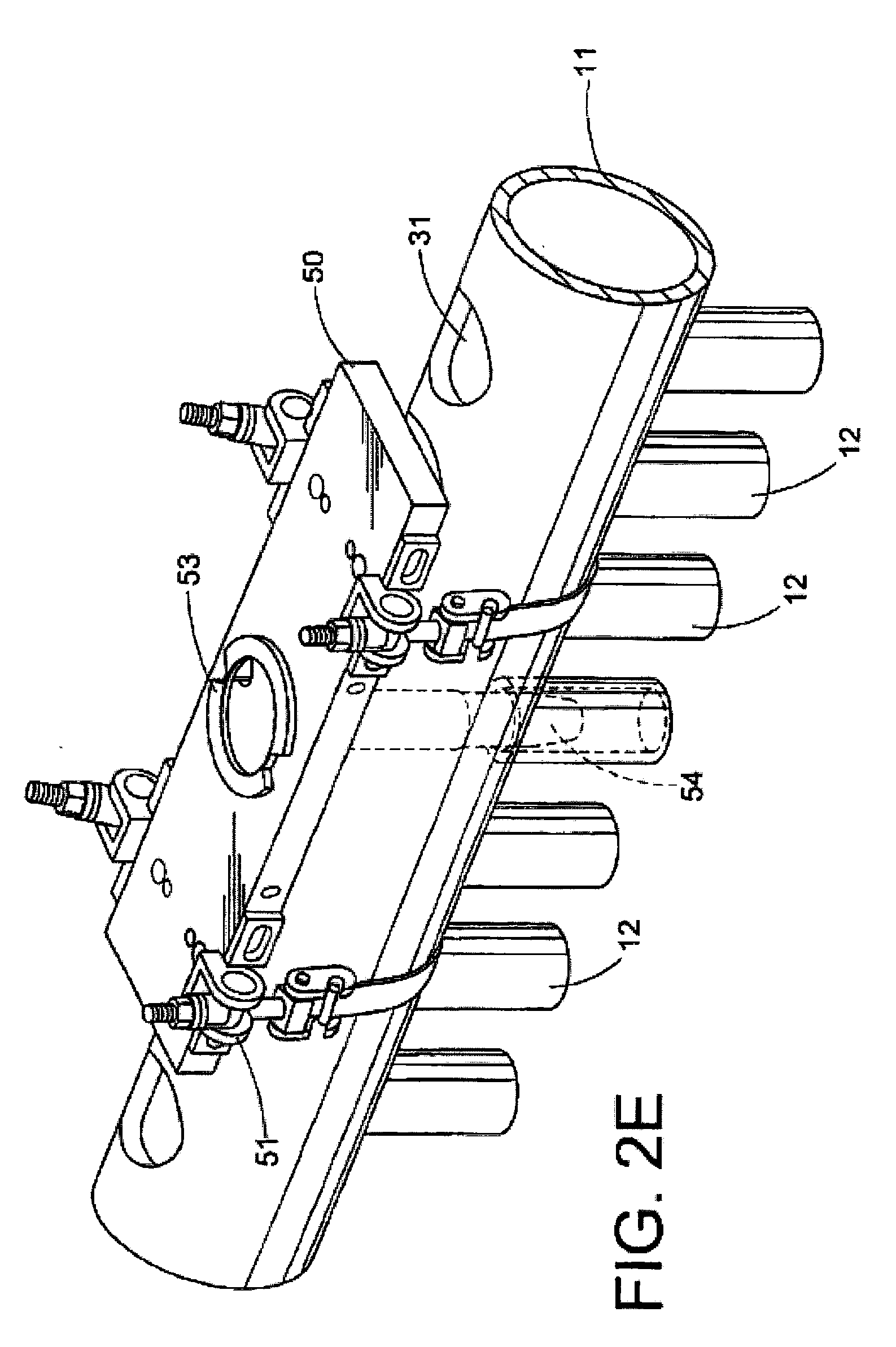

Method for repairing heat recovery steam generator tube-to-header damage

InactiveUS20090223053A1Reduce the numberShorten the timeWelding/cutting auxillary devicesArc welding apparatusEngineeringHeat recovery steam generator

A method for repairing a heat recovery steam generator (HSRG) header to tube attachment damage, includes providing an access window in the header opposite the damaged header to tube attachment location; removing the header to tube attachment damage; inserting a tapered stub tube into a header penetration centered axially immediately over the tube; effecting a profile weld between the header and the tapered stub tube at the header penetration from the inside surface of the header; welding the tapered stub tube to the existing tube through the header inside diameter; welding shut the access window; and completing a post weld heat treatment of all the welds.

Owner:ELECTRIC POWER RES INST INC

Machining method for modifying spheroidal graphite cast iron well lid

InactiveCN109023030AHigh tensile strengthHigh compressive strengthProcess efficiency improvementDuctile ironMachining

The invention relates to a machining method for modifying a spheroidal graphite cast iron well lid. The machining method is characterized in that modification is carried out with an alloying means, the micro-structure of spheroidal graphite cast iron can be improved, and the mechanical performance of the spheroidal graphite cast iron can be further improved. A powder spheroidizing agent is adoptedfor spheroidizing treatment, the absorption rate is obviously increased, and the production cost can be reduced. A nucleating agent is added step by step, so that the nucleating effect is improved.

Owner:安徽大来机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com