Corrugated steel plate confined concrete combination column and manufacturing method thereof

A technology for confining concrete and corrugated steel plates, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor confinement effect of core concrete, buckling of steel pipes, etc., and achieve superior mechanical properties, light weight, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

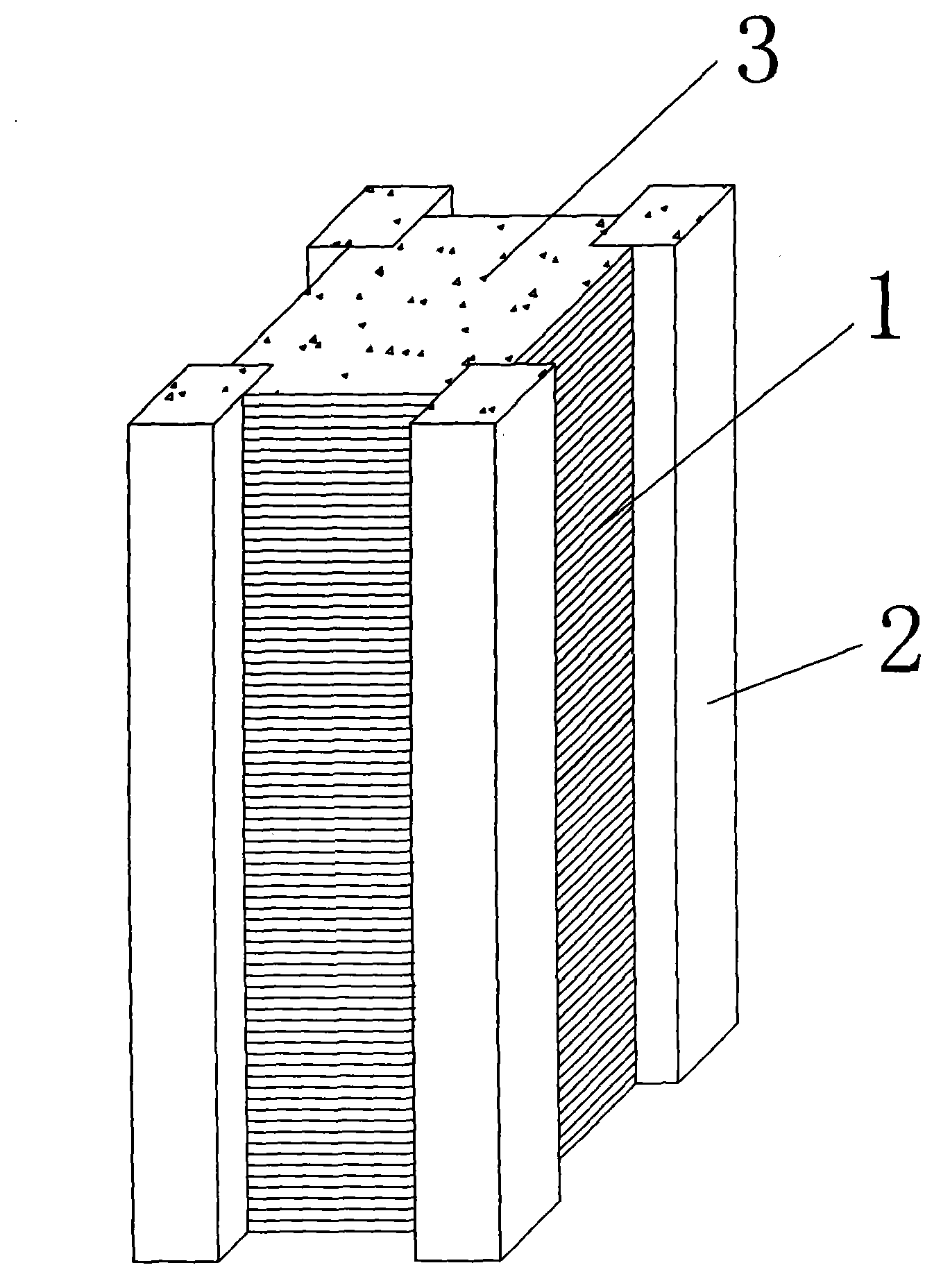

[0019] Such as figure 1 Shown is a corrugated steel plate confined concrete composite column. The composite column is formed by welding four corrugated steel plates 1 and four steel pipes 2 with a square cross section to form a quadrilateral pipe, wherein the four steel pipes 2 with a square cross section are located at the four vertices of the quadrilateral, and then between the quadrilateral pipe and the four square ( Or rectangular) steel pipe 2 is filled with concrete 3 and formed.

[0020] Its production method is as follows:

[0021] 1) Process corrugated steel plate 1 and square steel pipe 2 according to the designed size;

[0022] 2) A square steel pipe 2 is used as a corner and a corrugated steel plate 1 is welded to form a quadrilateral pipe, and the corrugated direction of the corrugated steel plate 1 is the same as the length direction of the quadrilateral pipe;

[0023] 3) Fill the concrete 3 in the quadrilateral pipe and the corner square steel pipe 1 .

Embodiment 2

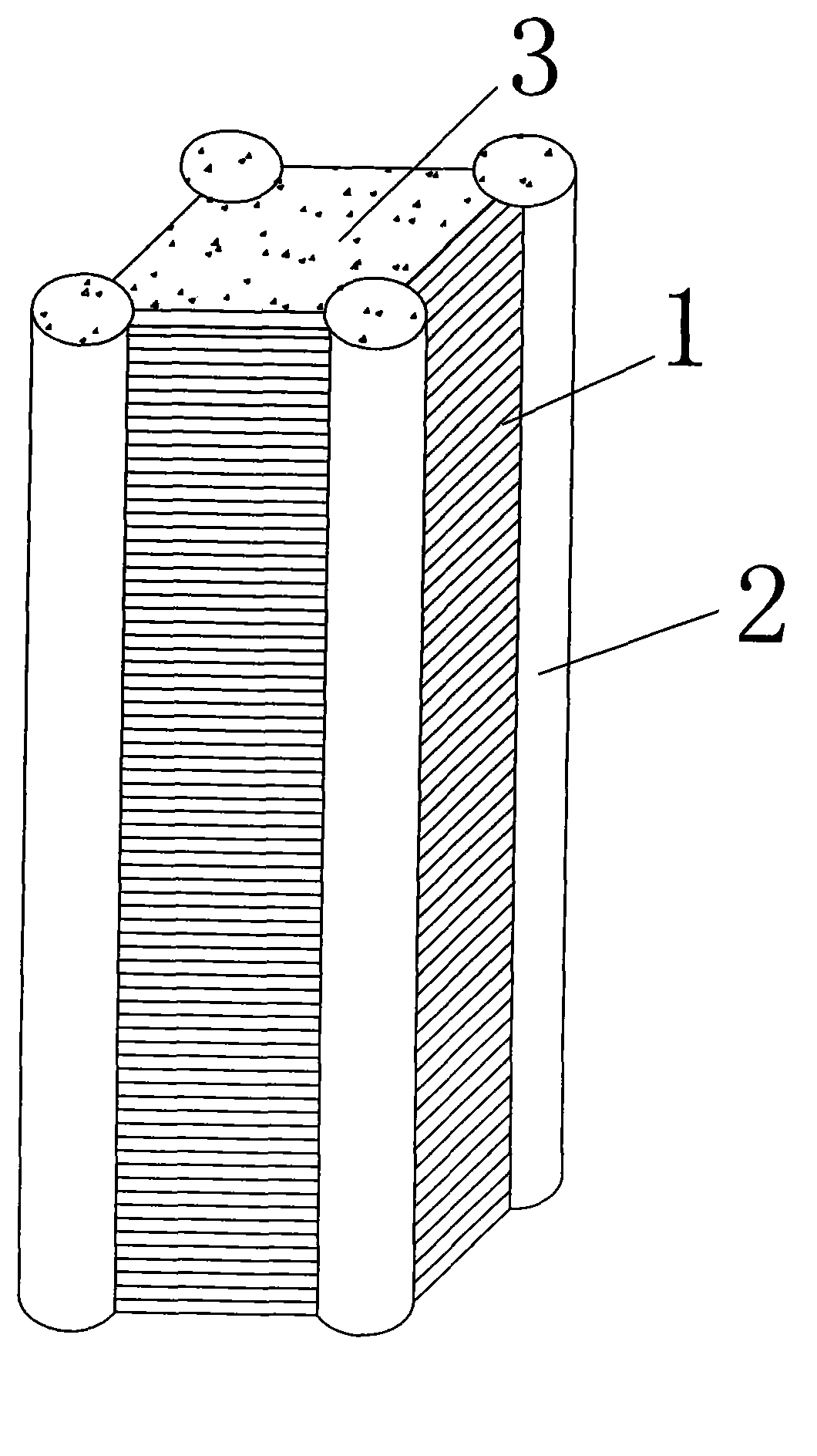

[0025] Such as figure 2 Shown is another corrugated steel plate confined concrete composite column. The composite column is formed by welding four corrugated steel plates 1 and four circular steel pipes 2 to form a quadrilateral pipe, wherein the four circular steel pipes 2 are located at the four vertices (i.e. corners) of the quadrilateral, and then the quadrilateral pipe and the four The circular steel pipe 2 is filled with concrete 3 and formed. Its production method is as follows:

[0026] 1) Process the corrugated steel plate 1 and the circular steel pipe 2 according to the designed size;

[0027] 2) The circular steel pipe 2 is used as the corner and the corrugated steel plate 1 is welded to form a quadrilateral pipe, and the corrugated direction of the corrugated steel plate 1 is the same as the length direction of the quadrilateral pipe;

[0028] 3) Concrete 3 is filled in the square pipe and the round steel pipe 1 at the corner.

Embodiment 3

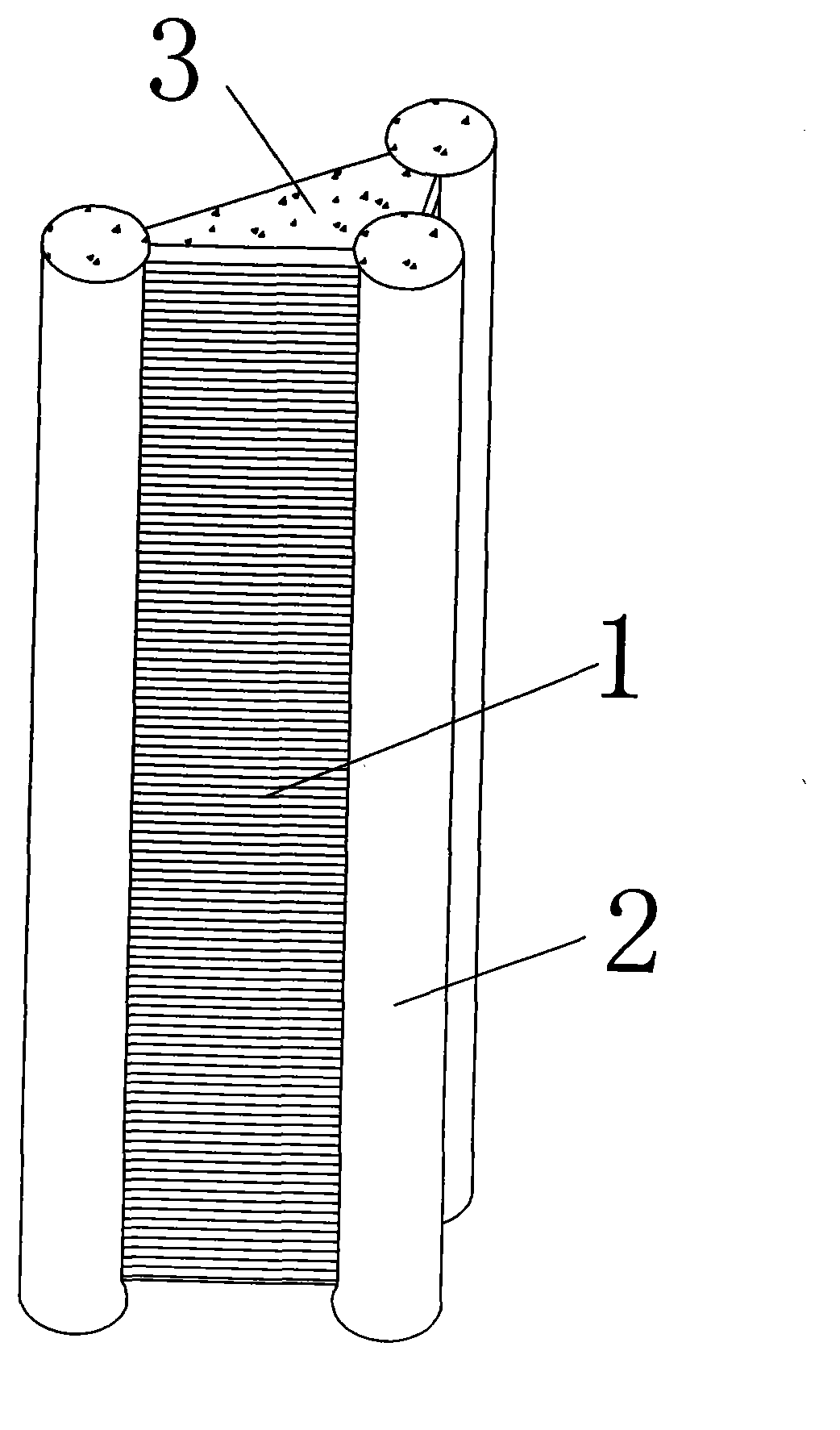

[0030] Such as image 3 Shown is another corrugated steel plate confined concrete composite column. The composite column is composed of three corrugated steel plates 1 and three circular steel pipes 2 welded to form a triangular pipe, wherein the three circular steel pipes 2 are located at the three vertices of the triangle, and then the triangular pipe and the Three circular steel pipes 2 are filled with concrete 3 to form. Its production method is as follows:

[0031] 4) Process the corrugated steel plate 1 and the circular steel pipe 2 according to the designed size;

[0032] 5) The round steel pipe 2 is used as the corner and the corrugated steel plate 1 is welded to form a triangular pipe, and the corrugated steel plate 1 has the same corrugated direction as the length direction of the triangular pipe;

[0033] 6) Concrete 3 is filled in the triangular pipe and the round steel pipe 1 at the corner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com