Method for preparing high-performance concrete and application

A high-performance concrete and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems affecting the development and promotion of high-performance concrete and high-performance concrete products, and the engineering or products of corrosive steel bars , Concrete products are easy to crack and other problems, to improve the molding speed and production efficiency, not easy to corrode and mildew, and overcome the effect of low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

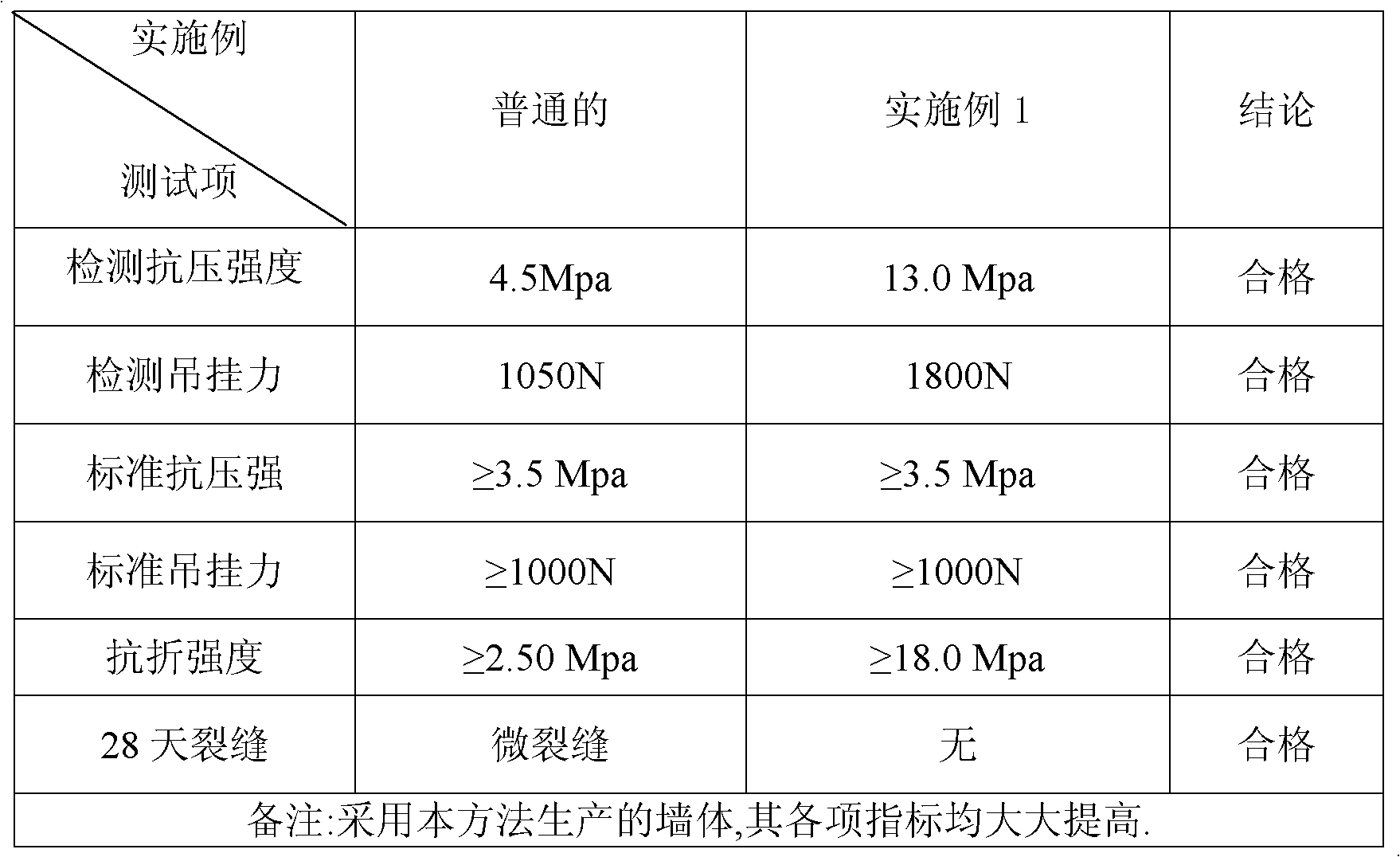

Embodiment 1

[0021] Production of lightweight wall materials for construction with a length of 3200mm, a plate thickness of 90mm, and a core hole of 42mm, that is, lightweight slats:

[0022] 1) Design the concrete mix ratio according to the requirements of concrete strength grade, frost resistance, crack resistance, flexural resistance and impermeability; prepare concrete raw materials: fine aggregate, cementitious material, admixture, coarse aggregate and engineering fiber,

[0023] 2) Feeding: Put fine aggregate, engineering fiber and cementitious material into the mixer in turn, and then stir for more than 30 seconds to make the engineering fiber evenly distributed and obtain the mixed material; among them, when inputting the engineering fiber, it is best to put Engineered fibers fall on the surface of the fine aggregate;

[0024] 3) Mortar making: put water into the mixer, then stir with the mixed material obtained in step 2), and mix evenly to obtain mortar, wherein the amount of wat...

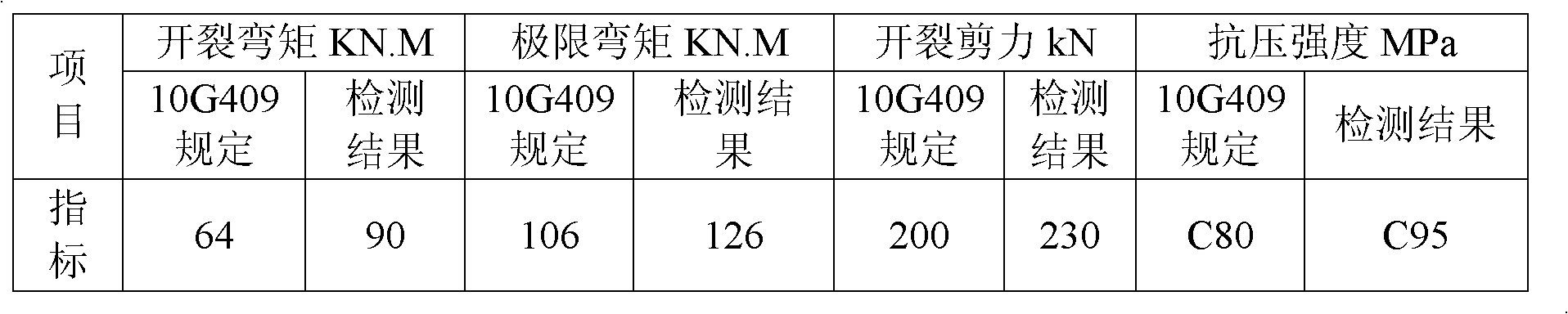

Embodiment 2

[0032] To produce prestressed high-strength concrete pipe piles of AB type piles with a length of 10 meters, a diameter of 400mm, and a wall thickness of 95mm, the specific method is as follows:

[0033] 1) Prepare concrete raw materials: fine aggregate, cementitious material, admixture, coarse aggregate and engineering fiber, and design the concrete mix ratio according to the requirements of concrete strength grade, frost resistance, crack resistance, flexural resistance and impermeability;

[0034] 2) Feeding: Put fine aggregate, engineering fiber and cementitious material into the mixer in turn, and then stir for more than 45 seconds to distribute the engineering fiber evenly to obtain a mixed material; among them, when putting in the engineering fiber, it is best to put Engineered fibers fall on the surface of the fine aggregate;

[0035] 3) Mortar making: put water into the mixer, then stir with the mixed material obtained in step 2), and mix evenly to obtain mortar, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com