Patents

Literature

346results about How to "Not easy to mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

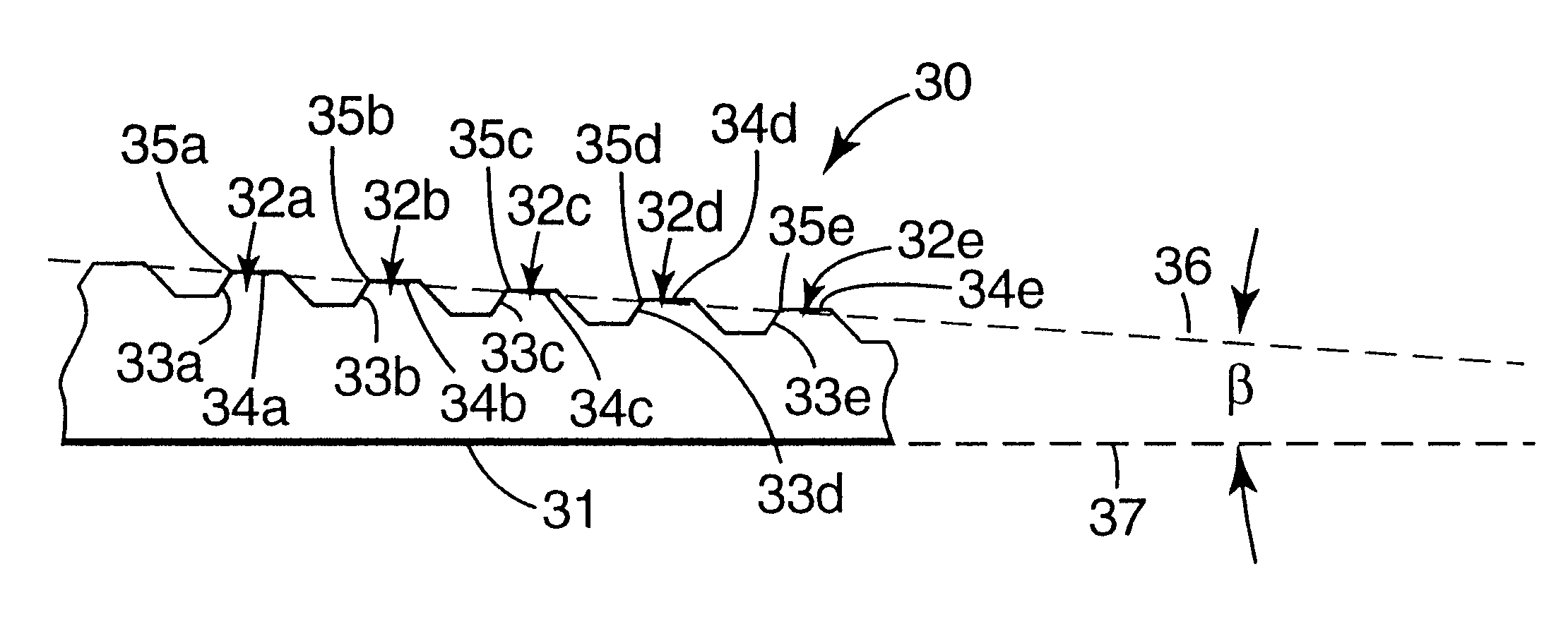

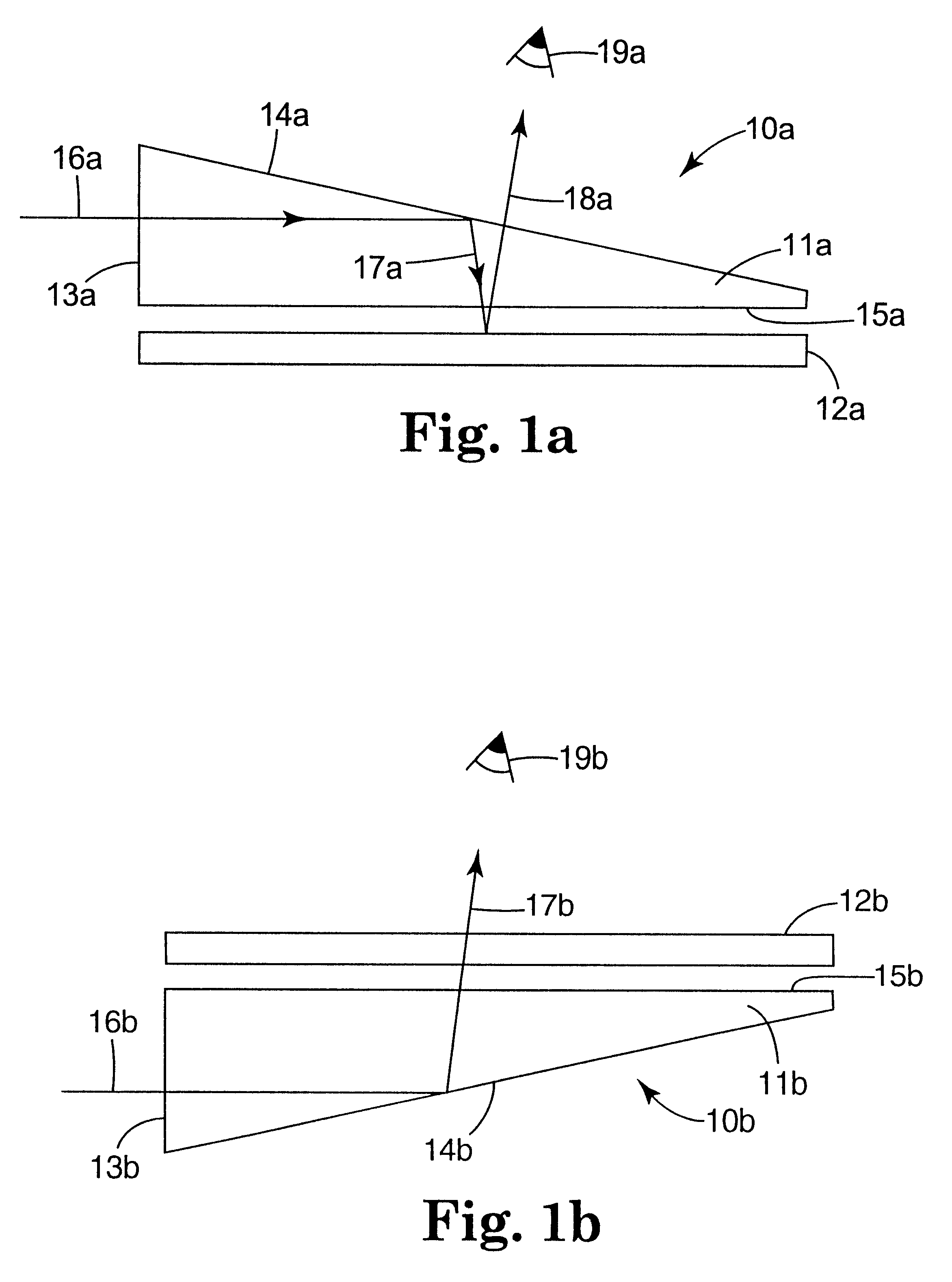

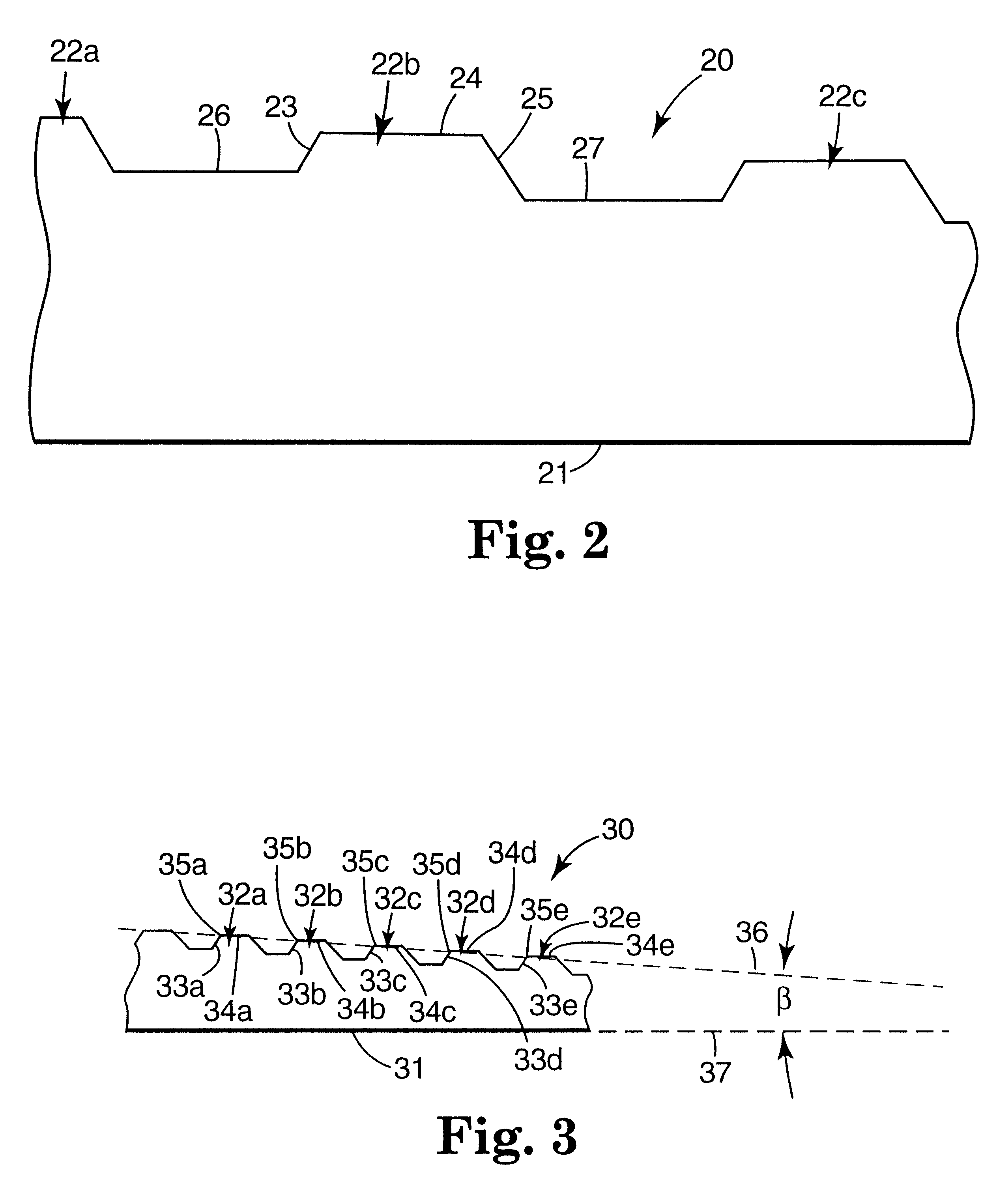

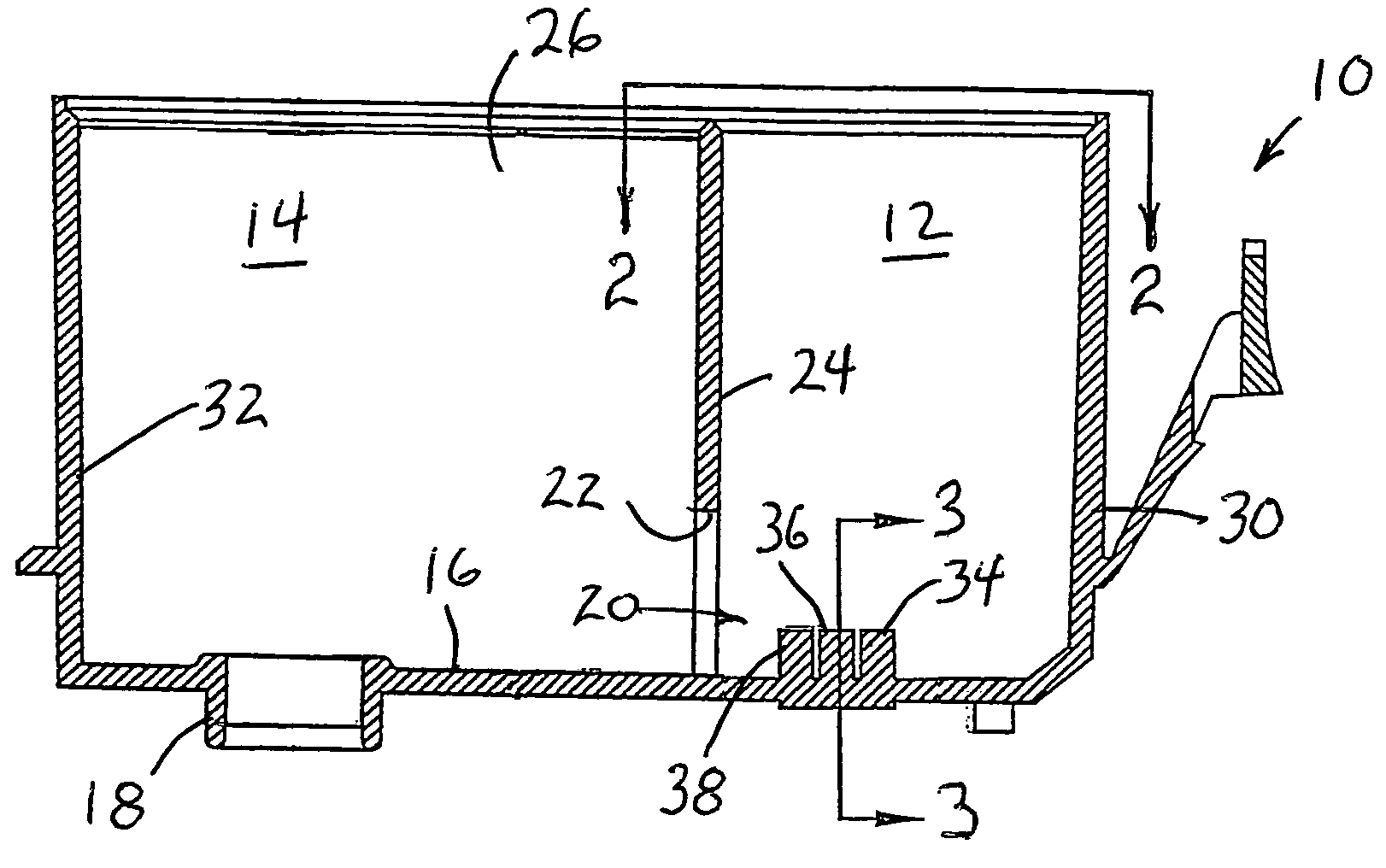

Wedge light extractor with risers

InactiveUS6347874B1Reduce power consumptionEfficient designMechanical apparatusPoint-like light sourceOptoelectronicsAvailable light

A wedge-shaped light extractor having a light-redirecting surface with a plurality of projections having a riser segment, a plateau segment, and a facet segment, with land segments flanking the projections. The projections improve extraction efficiency, thereby facilitating use of available light from a light source.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing orange peel tea

The invention relates to a method for preparing orange peel tea, comprising the following steps: 1) selecting matured Xinhui citrus reticulata 'Chachigan' fruit with complete peels, washing the fruit to be clean, peeling, removing flesh, putting the peels in a sunny place for drying, storing the orange peels under sealed condition after drying treatment, and then softening the orange peels; 2) sterilizing the softened orange peels by ozone and then disinsectizing at high temperature; 3) humidifying the orange peels obtained in step 2) for 7-8 hours by using moist air with humidity of 60-80% for further softening, and then pressing the orange peels for forming; 4) performing drying treatment and storing the orange peels under sealed condition for 2-5 months for primary fermentation, removing the orange peel tea after primary fermentation, humidifying for 5-6 hours by using moist air with the humidity of 60-80%, and then drying in a sunny place; 5) collecting the dried orange peel tea and then putting the dried orange peel tea in dry air with humidity of 30-50% for 4-5 hours for heat reduction; and 6) storing the treated orange peel tea under sealed condition again for natural fermentation. The orange peel tea fundamentally has no pesticide residue after several years of production, fermentation and aging, thus being a pure nature environment-friendly green health-care food.

Owner:林炳光

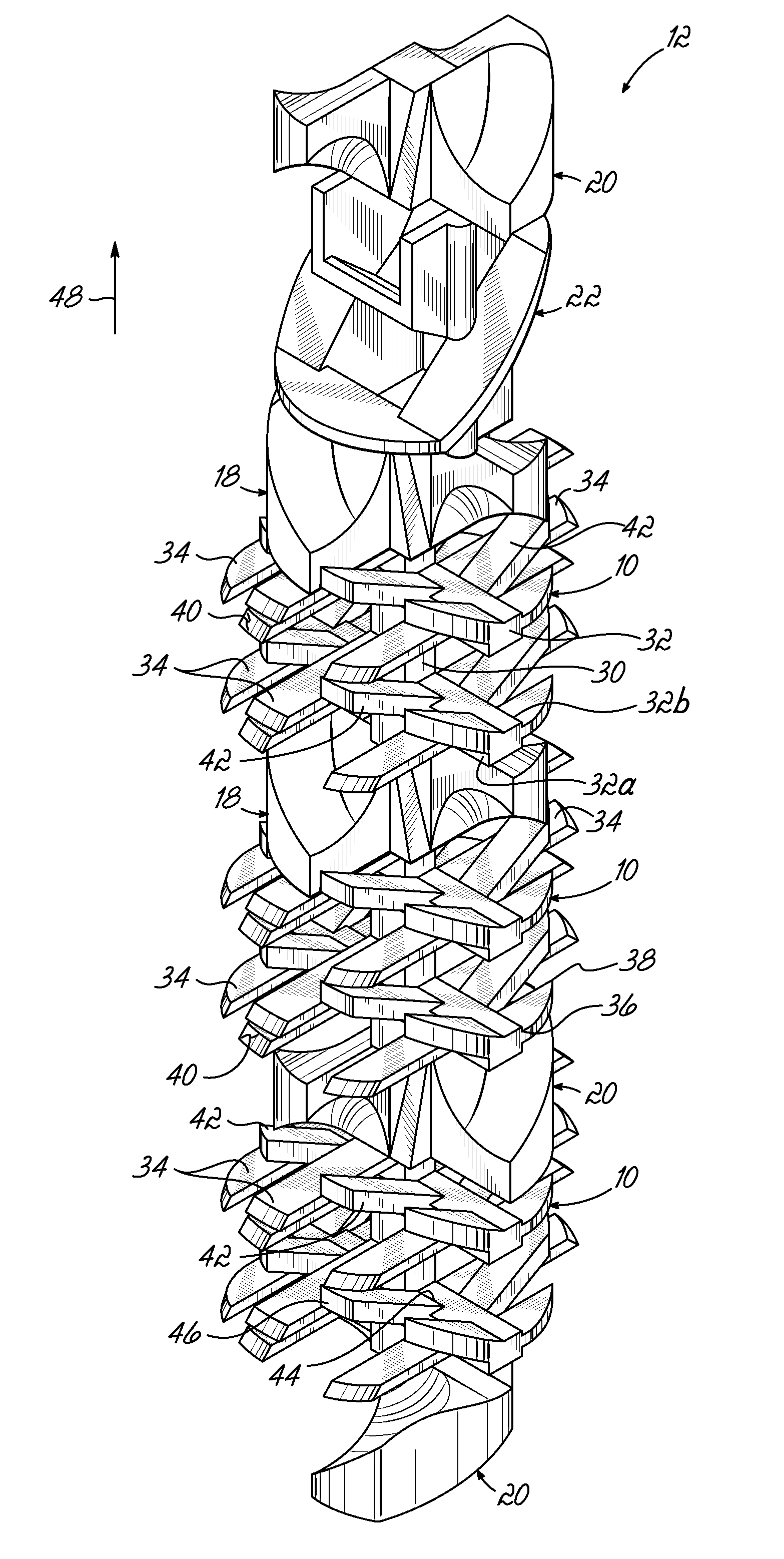

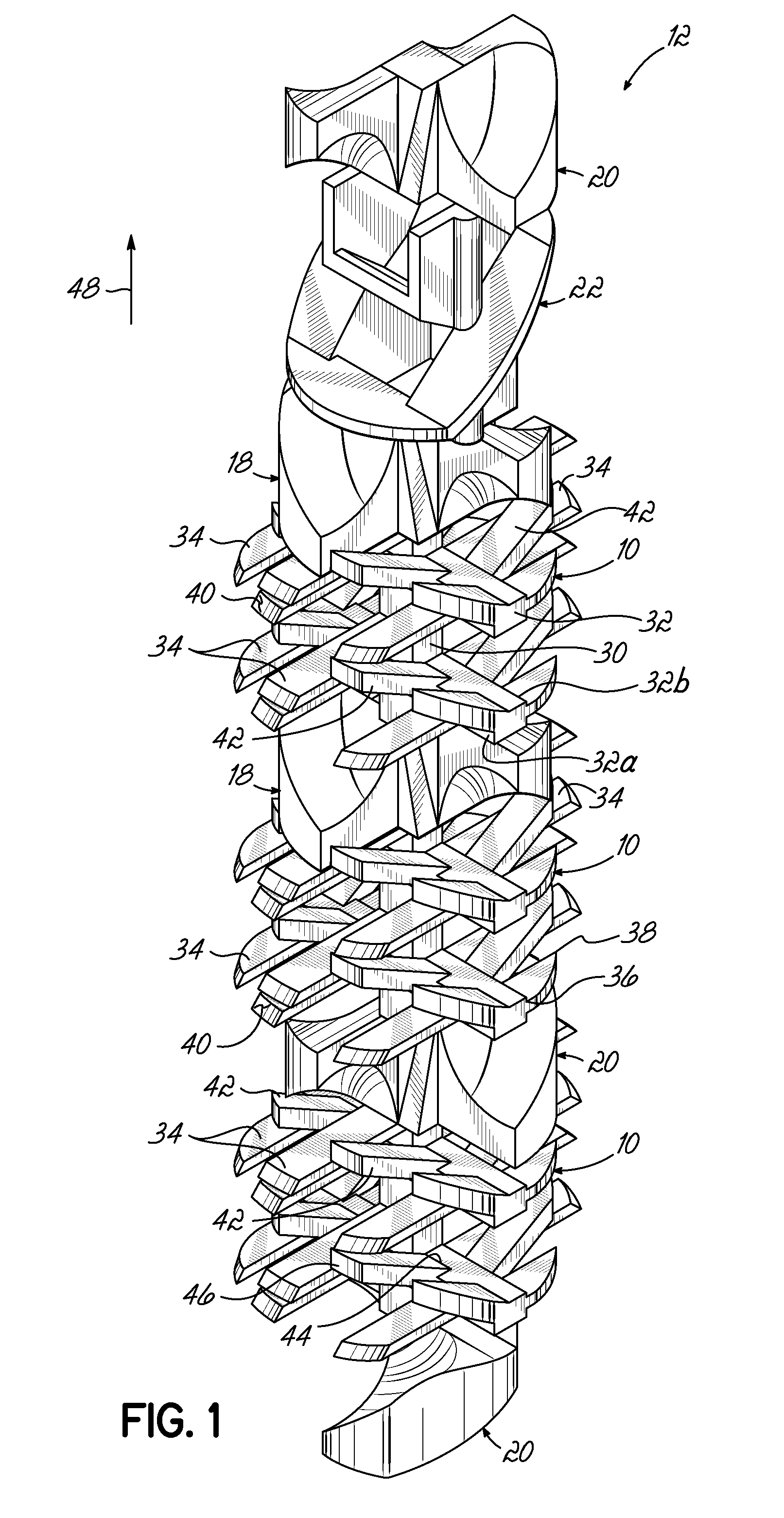

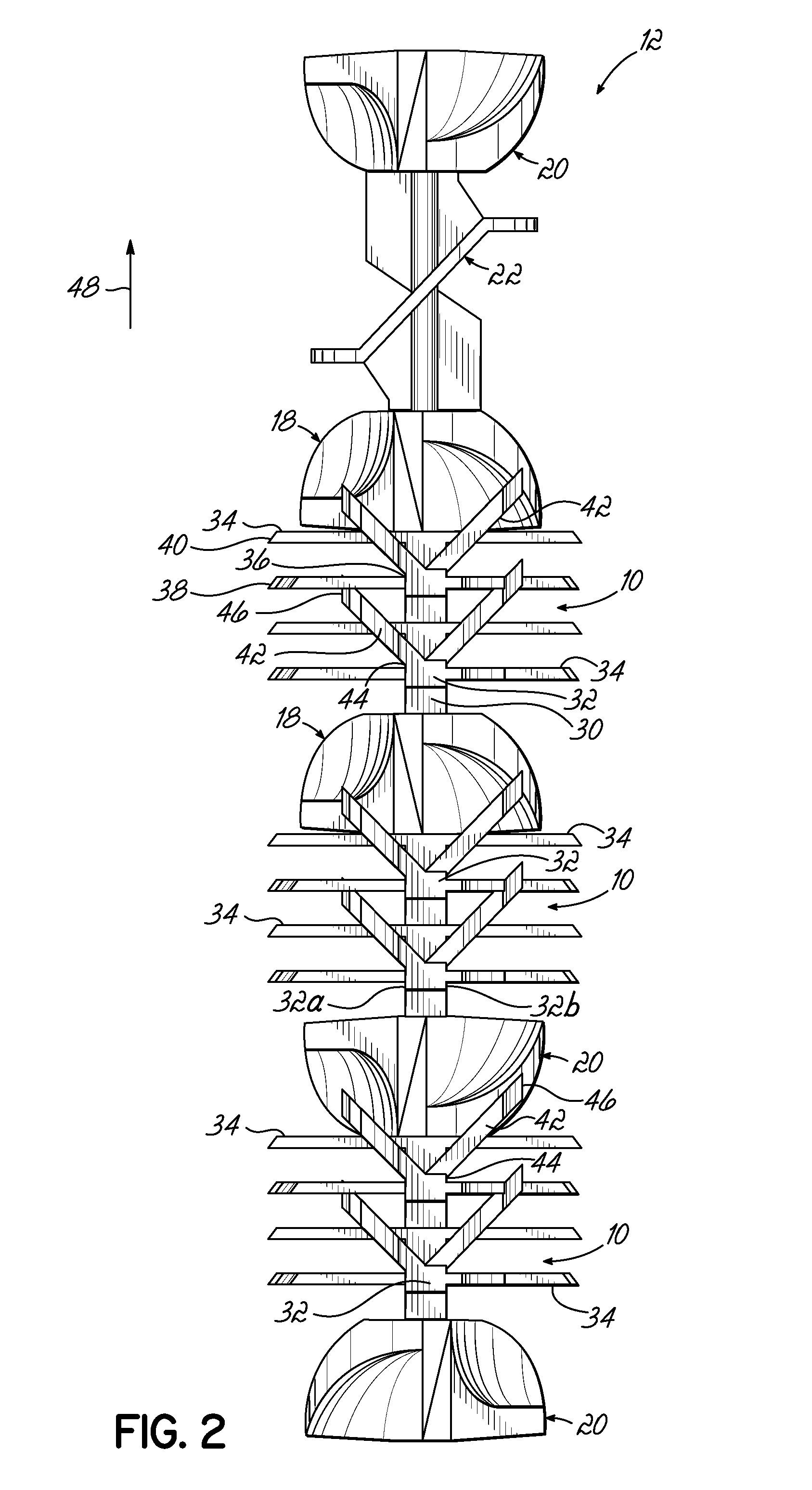

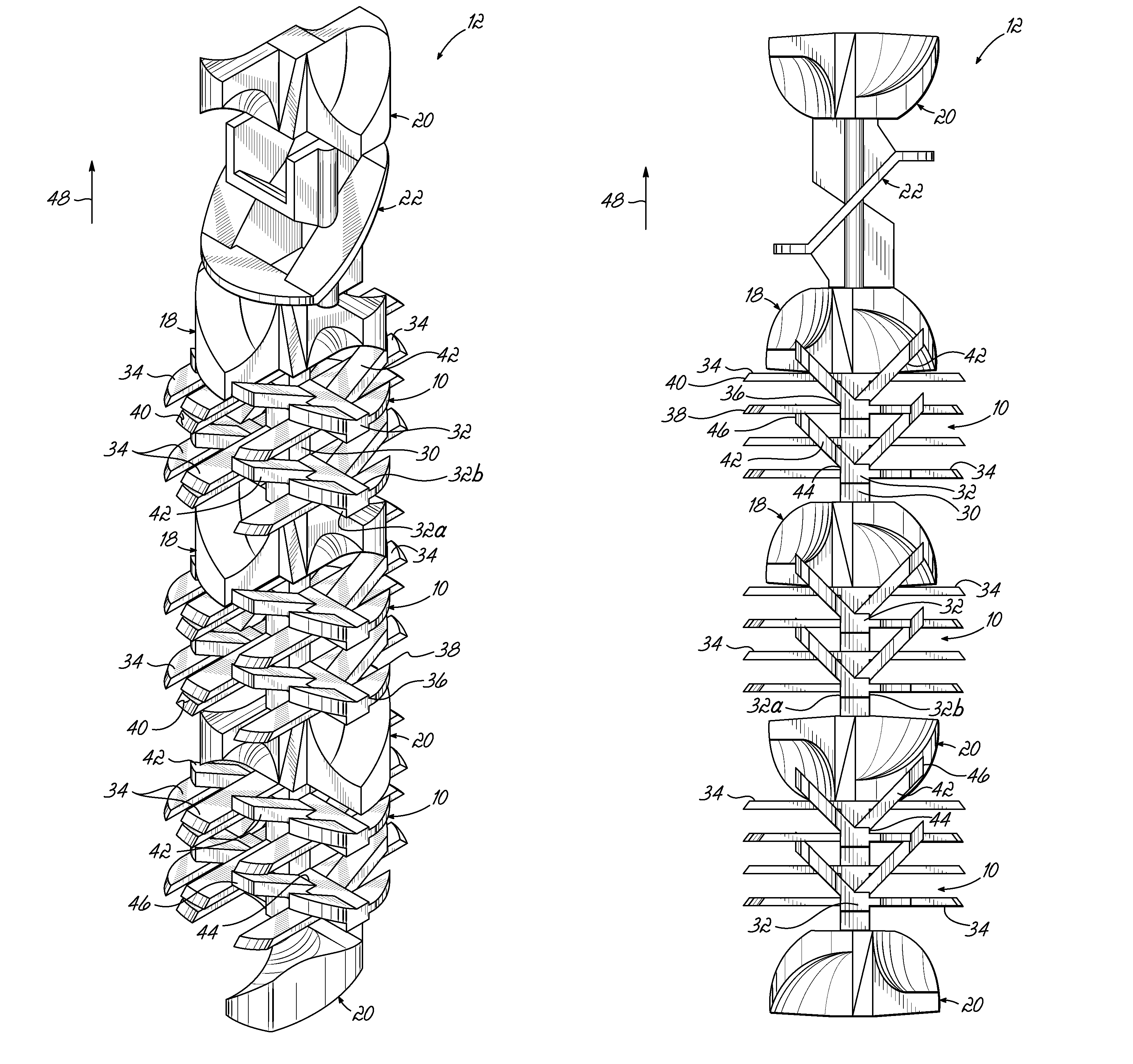

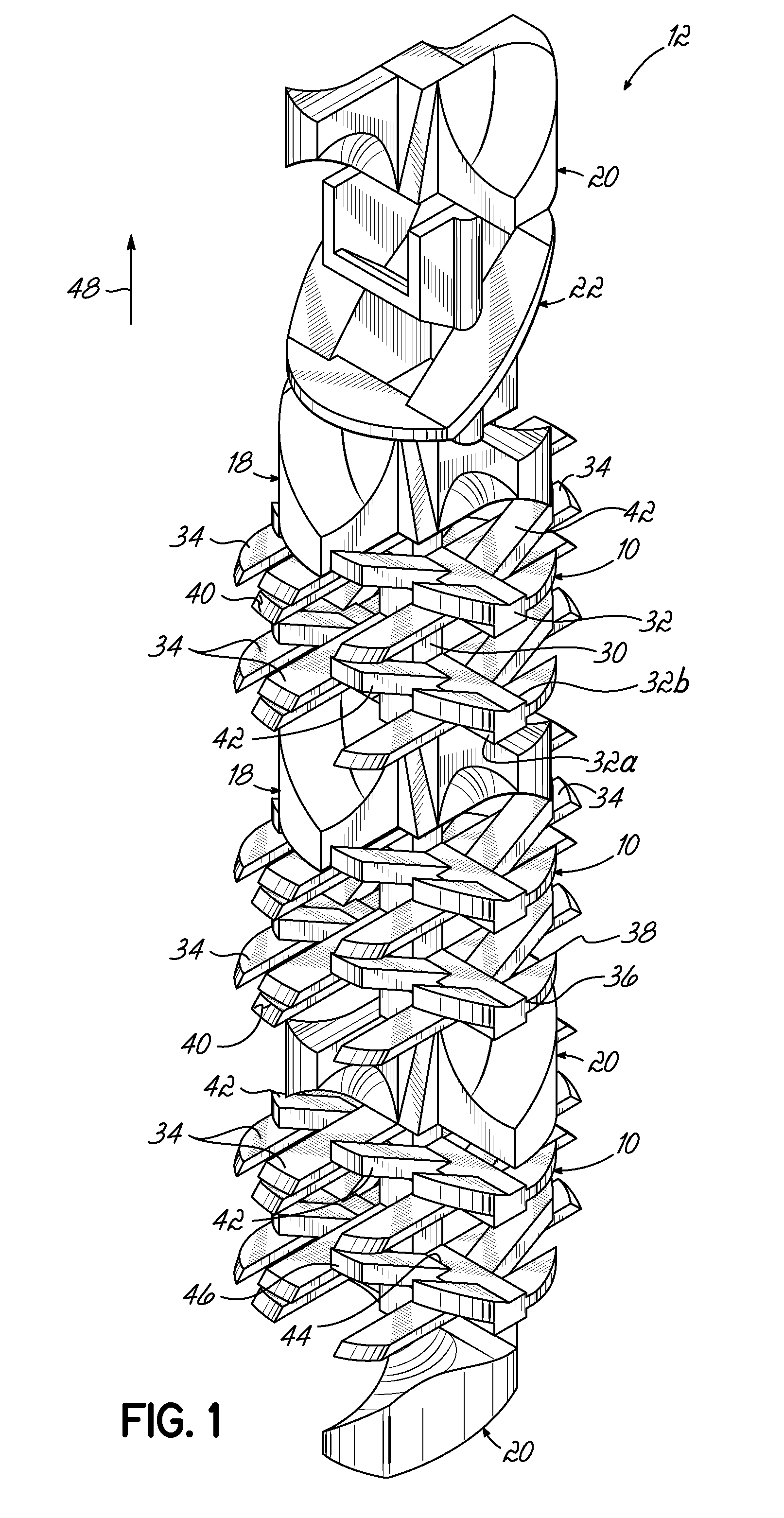

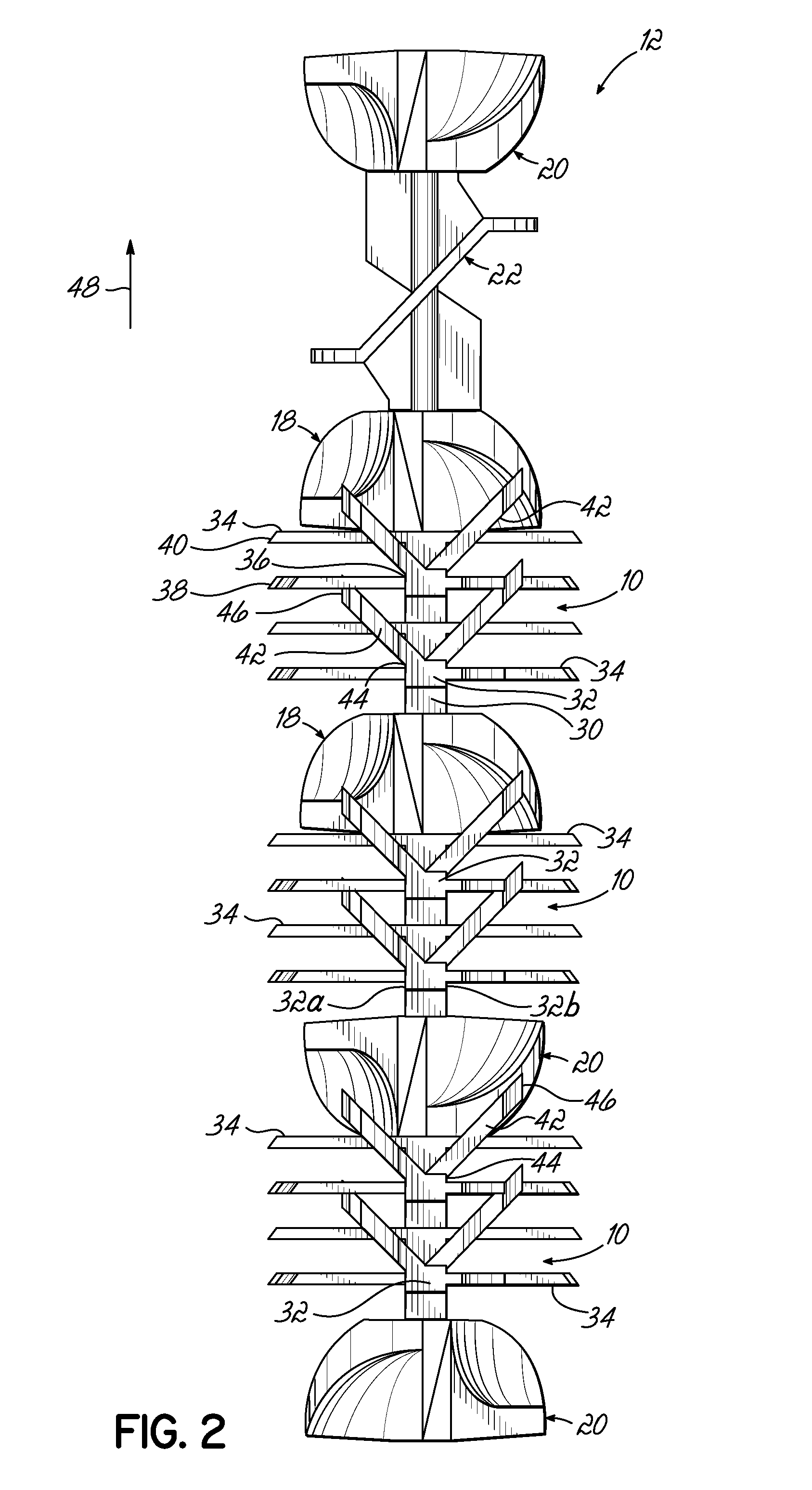

Reconfigurable mixing baffle for static mixer and method for making a static mixer

ActiveUS20130107660A1Improve deformationEasy to moveFlow mixersMetal rolling stand detailsEngineeringStatic mixer

A mixing baffle for mixing a fluid flow in a static mixer includes a mixing element support structure extending along a longitudinal direction and a first set of moveable mixing elements coupled to the mixing element support structure. The first set of moveable mixing elements is formed in a first configuration and moves to a second configuration when the mixing baffle is inserted into a tubular conduit. In the second configuration, the first set of moveable mixing elements is optimized for mixing fluids and defines a plurality of undercuts that are difficult to mold. The mixing baffle may also include a second set of stationary mixing elements that interlace with the first set of moveable mixing elements when the first set of moveable mixing elements moves to the second configuration.

Owner:NORDSON CORP

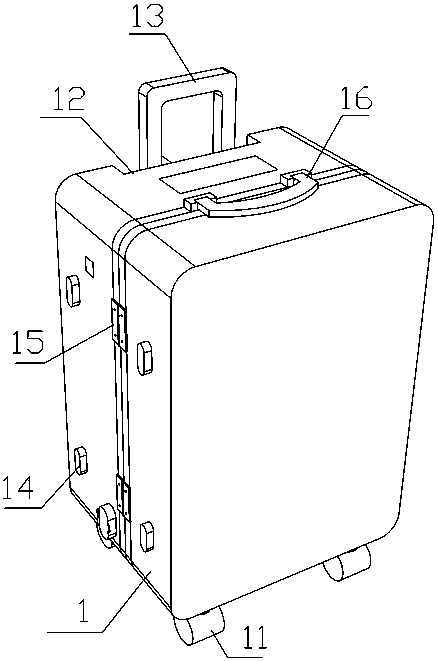

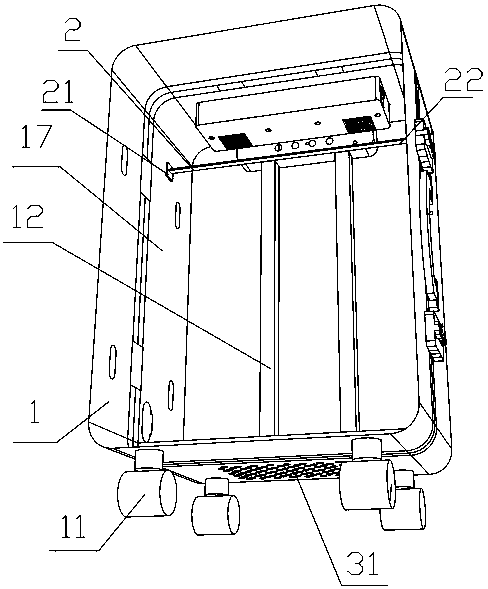

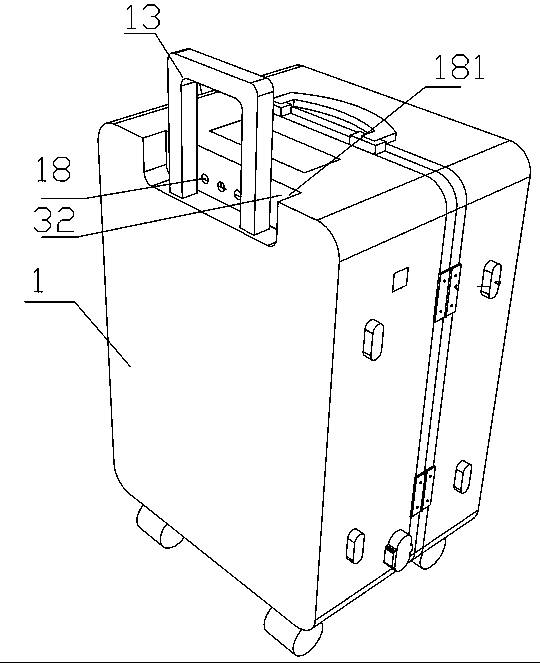

Intelligent draw-bar box

The invention relates to the field of case storage designing and in particular relates to an intelligent draw-bar box. According to the technical scheme of the invention, the intelligent draw-bar boxcomprises a box body, wherein walking wheels are arranged on the bottom surface of the box body; a draw-bar groove is formed in the box body; a telescopic draw-bar which can be pulled out from the draw-bar groove is arranged on the box body; a holding groove is formed in the box body; a surface plate is arranged on the box body; the surface plate comprises a control panel and a control main board;the control panel is connected with the control main board through a signal wire; a display screen and a temperature / humidity sensor for detecting temperatures and humidity are arranged on the control panel; a positioning module and a buzzer are arranged on the control main board. The invention aims to provide the draw-bar box, sterilization design and drying design are arranged in the draw-bar box, wet clothes can be rapidly dried in the draw-bar box, sterilization treatment can be also implemented, mold can be avoided, and the draw-bar box is clean and sanitary.

Owner:广德君安达消防科技有限公司

Method for making unartificial yeast

ActiveCN103503938AHigh nutritional valueHas a health effectFungiPre-baking dough treatmentBiotechnologyNutritive values

The invention discloses a method for making unartificial yeast. Raisins, banana peels and hawk tea are used for preparing yeast liquid and the unartificial yeast made of the yeast liquid has high nutrition values and has the function of healthcare to some extent. The unartificial yeast made with the method is stable in quality, long in storage time, not prone to mildew, and rich in necessary components including amino acid, vitamins, mineral substances and other components of the human body and has the efficacies of stimulating appetite, digesting food, reliving bloating, resolving toxin and dispersing swelling, refreshing, developing intelligence, improving eyesight, invigorating the stomach, stopping diarrhea, stopping belching and the like. Bread made with the unartificial yeast is better in flavor, higher in nutrition value, and meanwhile, capable of prolonging the optimal flavor time of the bread. People can taste unique food aromas of the unartificial yeast.

Owner:南通银琪生物科技有限公司

Environment protection type multifunction architecture adhesion agent and method for producing the same

ActiveCN101220250AImprove performancePromote degradationMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholAdhesive

The invention discloses an environment friendly and multi-functional building adhesive and the preparation method thereof, and is characterized in that: 4 to 5 percent of polyvinyl alcohol and 42 to 59.2 percent of water are taken by weight percentage, stired and heated to 80 plus or minus 2 DEG C until the polyvinyl alcohol is dissolved completely, then cooled to 70 plus or minus 2 DEG C, added with 10 to 20 percent of vinyl acetate-ethylene co-polymer emulsion and 0.4 to 0.6 percent of emulsifying agent; then the mixture is heated to 70 plus or minus 2 DEG C, added with 25 to 30 percent of winyl acetic ester and 0.5 to 1.5 percent of acrylic monomer, and further added with part of 0.25 to 0.3 percent of evocating agent which accounts for 35 to 45 percent of total amount of the evocating agent to carry out emulsion polymerization; the temperature is maintained at 70 plus or minus 2 DEG C, then the residual evocating agent which accounts for 55 to 65 percent of total amount thereof is added; the temperature is kept for 1-2 hours until no nomoner reflows, then the temperature raises to 90 plus or minus 2 DEG C, kept for 30 to 40 minutes, and finally reduced to 50 plus or minus 2 DEG C; the PH value is adjusted and the product is finished after stirring evenly. The invention has the advantages of steady performance, low viscosity coefficient, convenient operation, good stickiness property, good elasticity property, excellent film forming and water-proof property, high drying speed, uneasy going moldy and high biological degradability.

Owner:YANJIAN GRP CO LTD

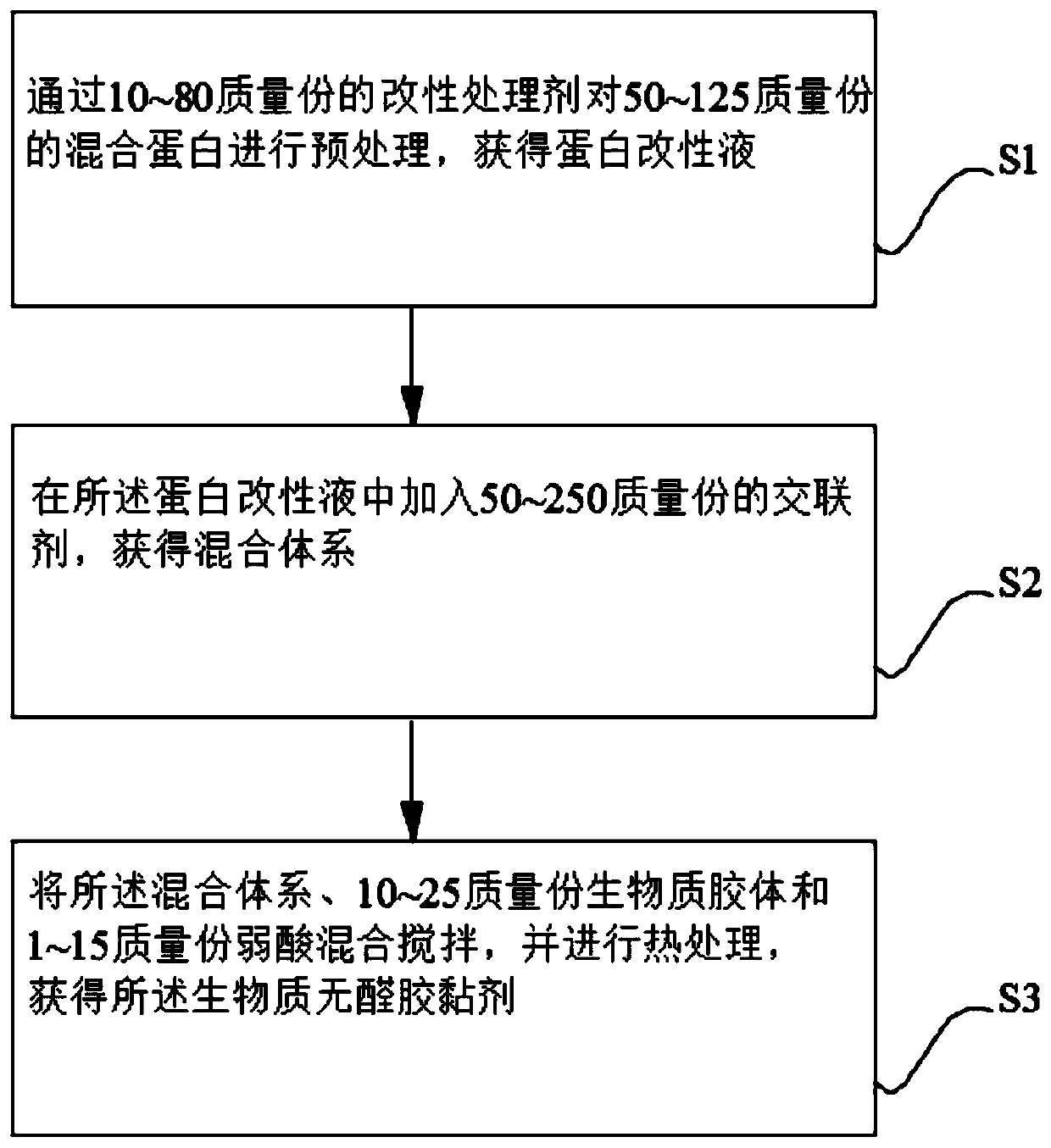

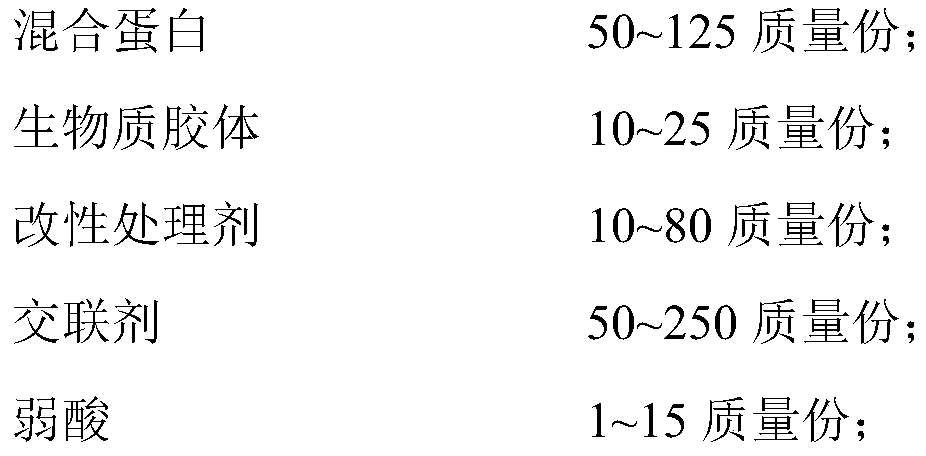

Biomass formaldehyde-free adhesive for artificial board and preparation method thereof

ActiveCN110922941AStable structureAchieve stabilizationProtein adhesivesPolyureas/polyurethane adhesivesAdhesiveCross linker

The invention discloses a biomass formaldehyde-free adhesive for an artificial board and a preparation method thereof. The biomass formaldehyde-free adhesive comprises mixed protein, biomass colloid,a modification treatment agent, a cross-linking agent, weak acid and the like. The biomass formaldehyde-free adhesive has the advantages of zero formaldehyde, high bonding strength, good water resistance, good anti-mildew effect, easiness in sizing and the like.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

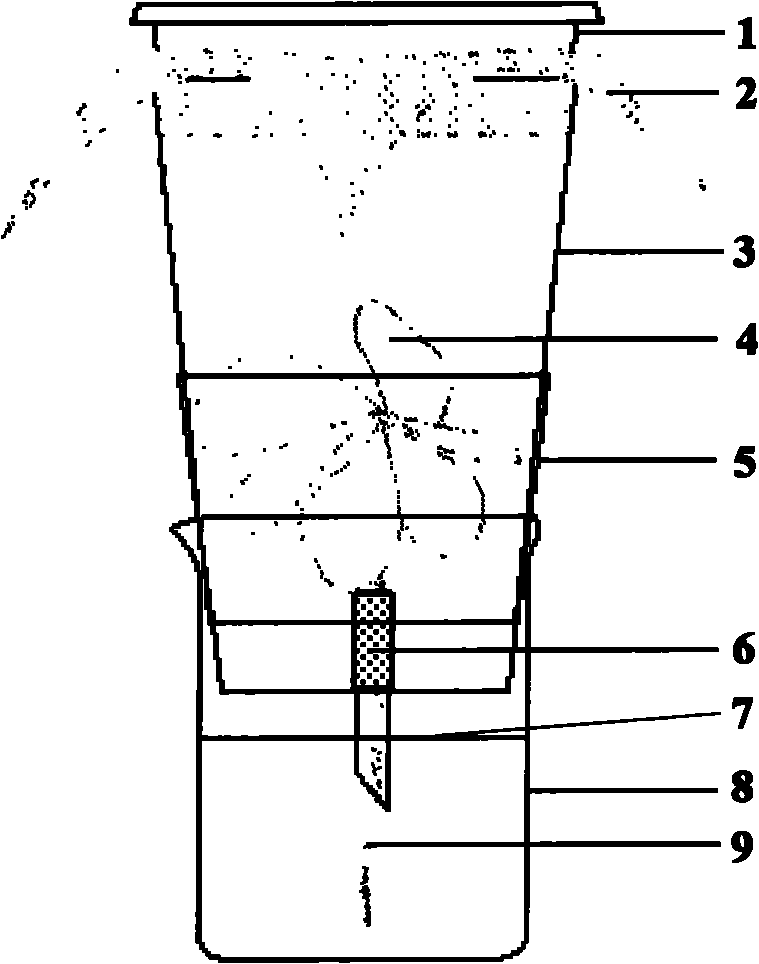

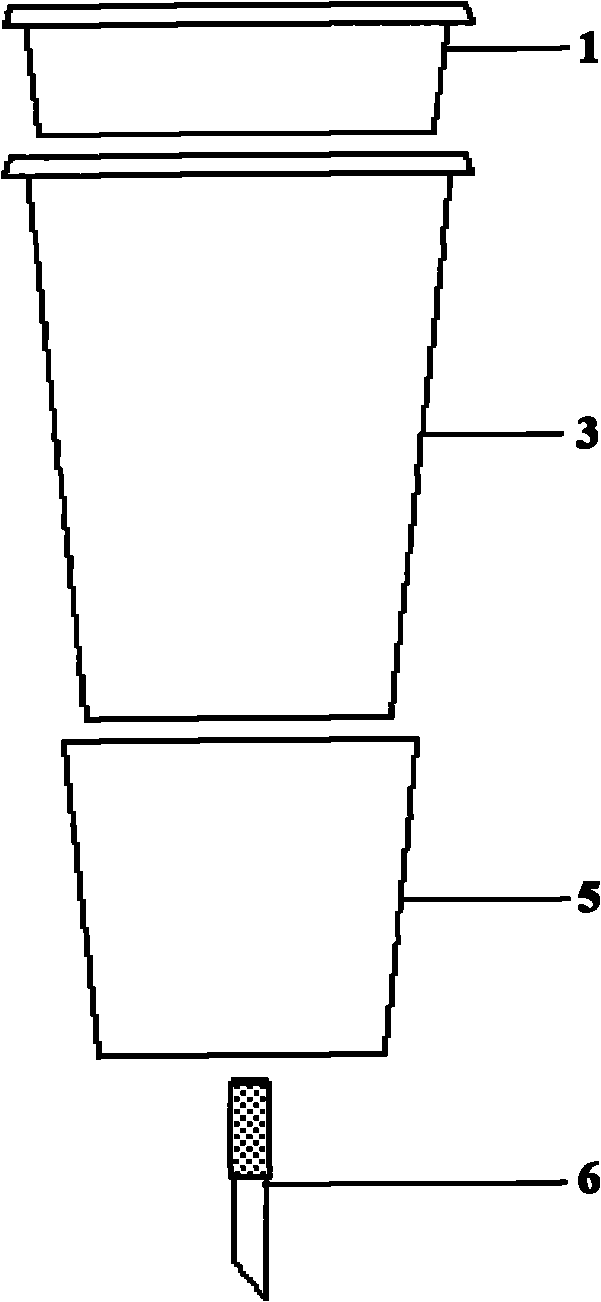

Tetranychina harti feeder

InactiveCN101810155AAvoid deathPrevent escape from disappearanceAnimal husbandryMicroscopic observationEngineering

The invention relates to a Tetranychina harti feeder, which belongs to the technical field of entomology experiment. The feeder consists of an upper feeding chamber and a lower water pool. Safflower oxalis leaf isolated leaf with petiole is vertically planted into the feeder. The blade in which the mite is cultivated is hung in the feeding chamber. The petiole enters under the water level of the water pool through a petiole inserting pipe at the bottom of the feeding chamber. When the Tetranychina harti is fed by the feeder, the blade part of the safflower oxalis leaf is free from the preserving liquid, therefore the blade is difficult to yellow and mildew, the blade surface is dry, and the mite can freely move on the blade, and has natural living state. The feeding chamber is manufactured by a disposable plastic cup, a gauge and the like, and has the advantages of sealing property, permeability and light transmission; and the microenvironment in which the mite is cultivated is consistent with the set feeding condition. Each component of the feeder is easy to disassemble and assemble, therefore the microscopic observation and replacement of the blade are convenient.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

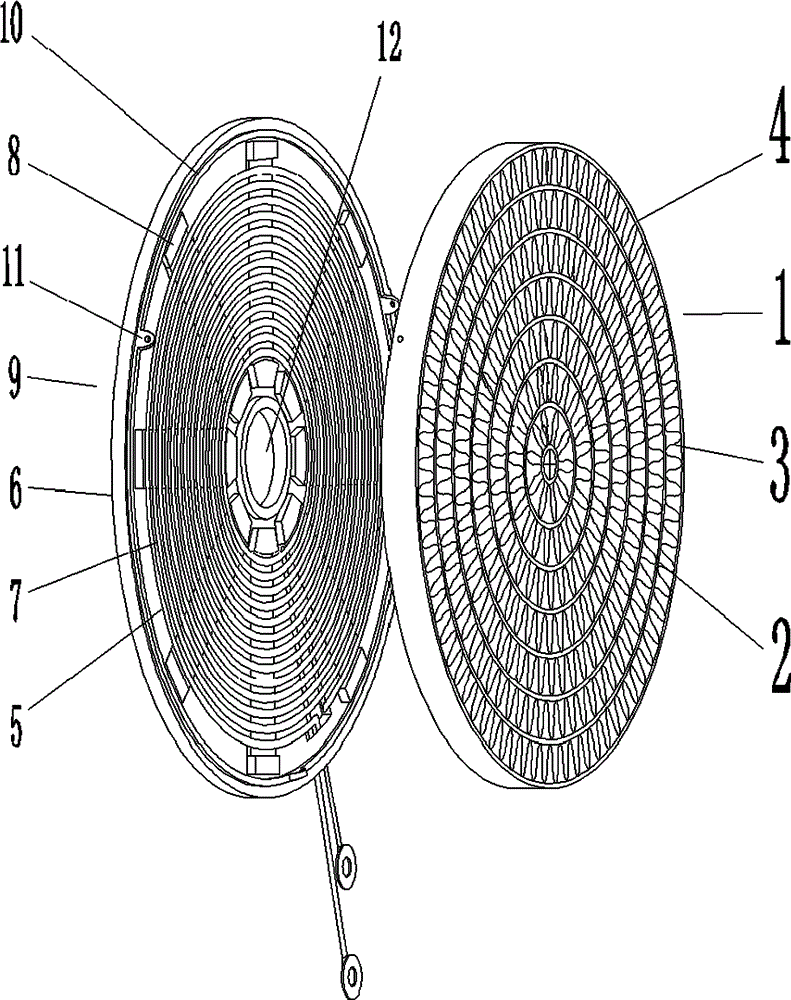

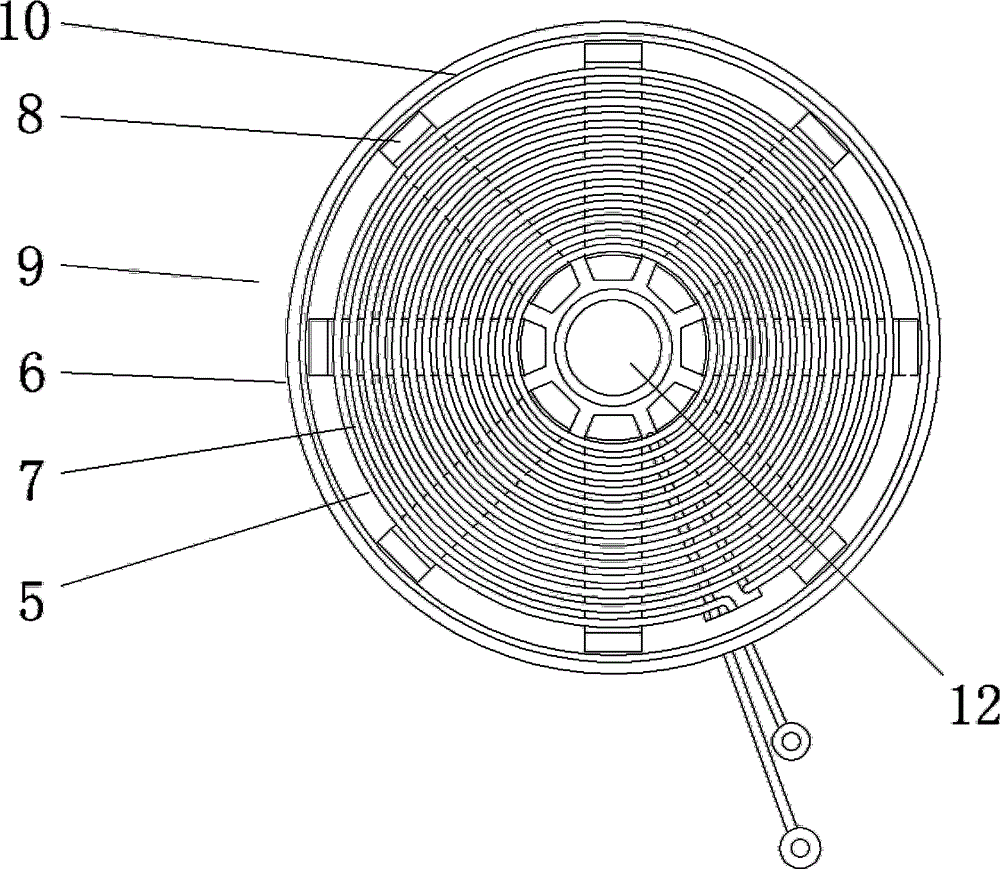

Electromagnetic heating device

InactiveCN104566602AFast heatingNot easy to rustCoil arrangementsLighting and heating apparatusHoneycombEngineering

The invention discloses an electromagnetic heating device. A metal honeycomb heating body capable of carrying out electromagnetic induction is assembled at the position of a coil surface of an electromagnetic induction heating wire coil; the wire coil is provided with a through gap convenient for ventilating; wind which is conveyed or led by a fan sequentially penetrates through the wire coil and the honeycomb heating body and warm wind is sent out when the metal honeycomb heating body emits heat because of electromagnetic induction. The electromagnetic heating device can be applied to wind warming technologies in a plurality of industries and household wind warming electric appliance products, and has the advantages of long service life, low energy consumption, fast temperature rise, no electric shock and thinning, and is not crushed.

Owner:彭萍芳

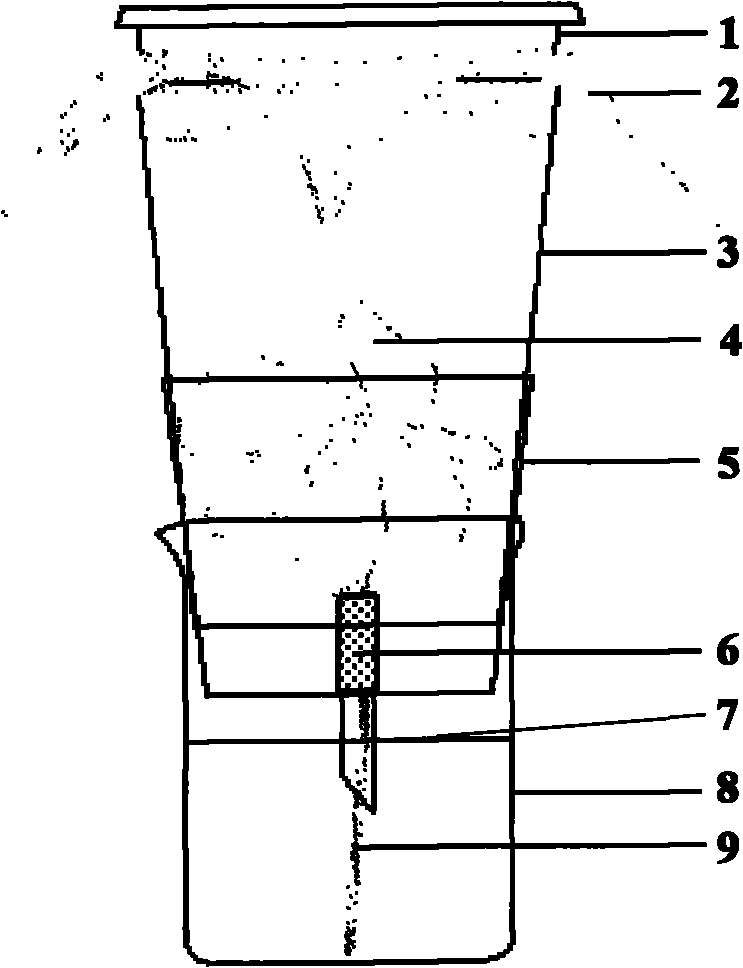

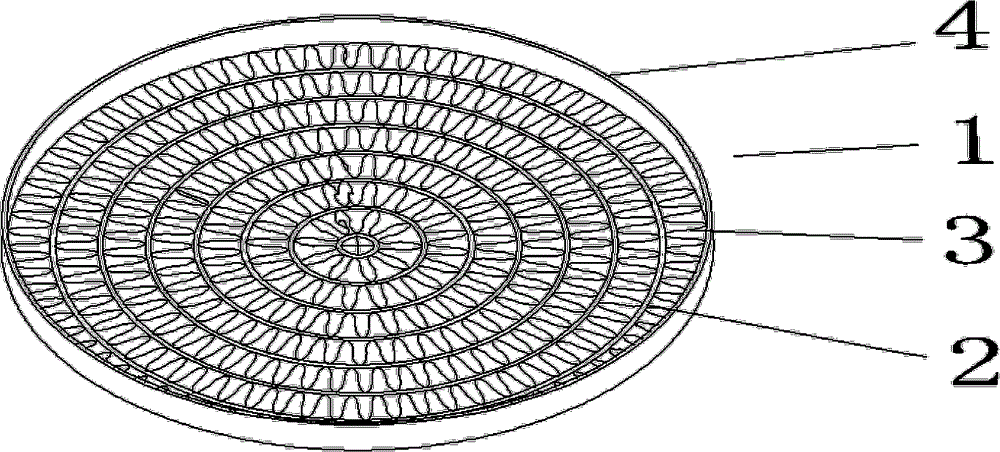

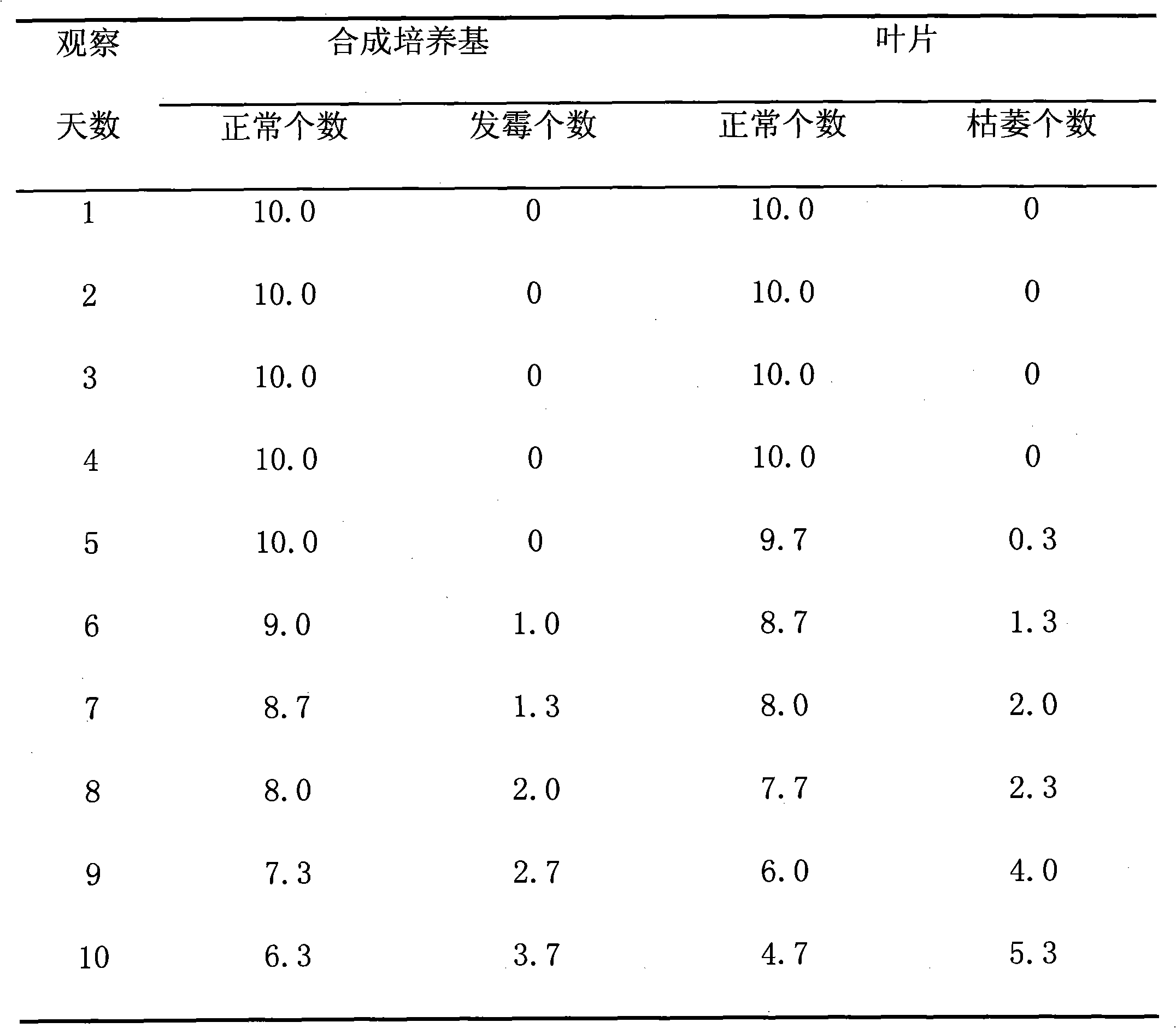

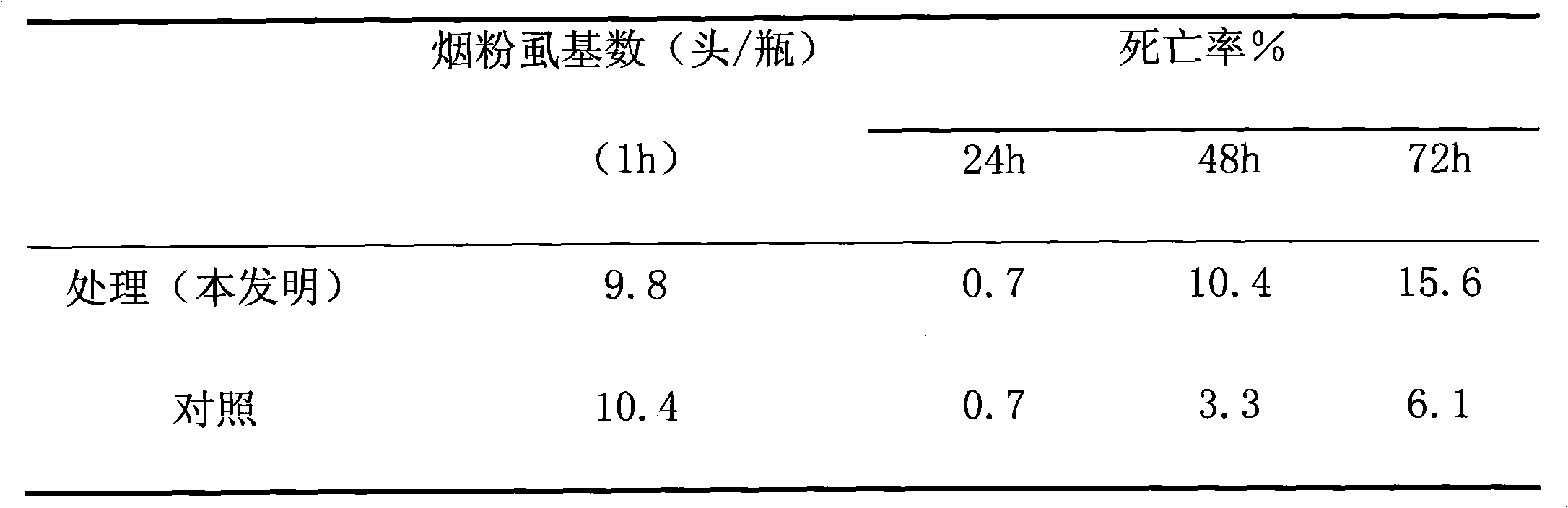

Method for measuring virulence by feeding Bemisia tabaci Gennadius imago

InactiveCN102037933AAvoid deathReduce dosagePlant tissue cultureHorticulture methodsVirulenceBiology

The invention discloses a method for measuring virulence by feeding Bemisia tabaci Gennadius imago, belonging to the technical field of insect feeding. The method comprises: (1) preparing and sterilizing a synthetic medium; (2) processing leaves by a medicament, and disinfecting and planting petioles; (3) adsorbing and releasing the Bemisia tabaci Gennadius imago; and (4) feeding, observing and the like. The invention can truly simulate the growing situation of leaves on plants, and can prolong the freshness of the leaves, and the medium has small possibility of going mouldy, thus effectively preventing the test imago of the Bemisia tabaci Gennadius from dying in a non-virulence mode; the contrast Bemisia tabaci Gennadius can normally survive within 72 hours of normal virulence measurement to obtain the standardization of the experiment test imago. The method is suitable for the requirements on measuring virulence by feeding Bemisia tabaci Gennadius imago for flowers, vegetables and cash crops.

Owner:ZHEJIANG XIAOSHAN COTTON & FLAX RES INST

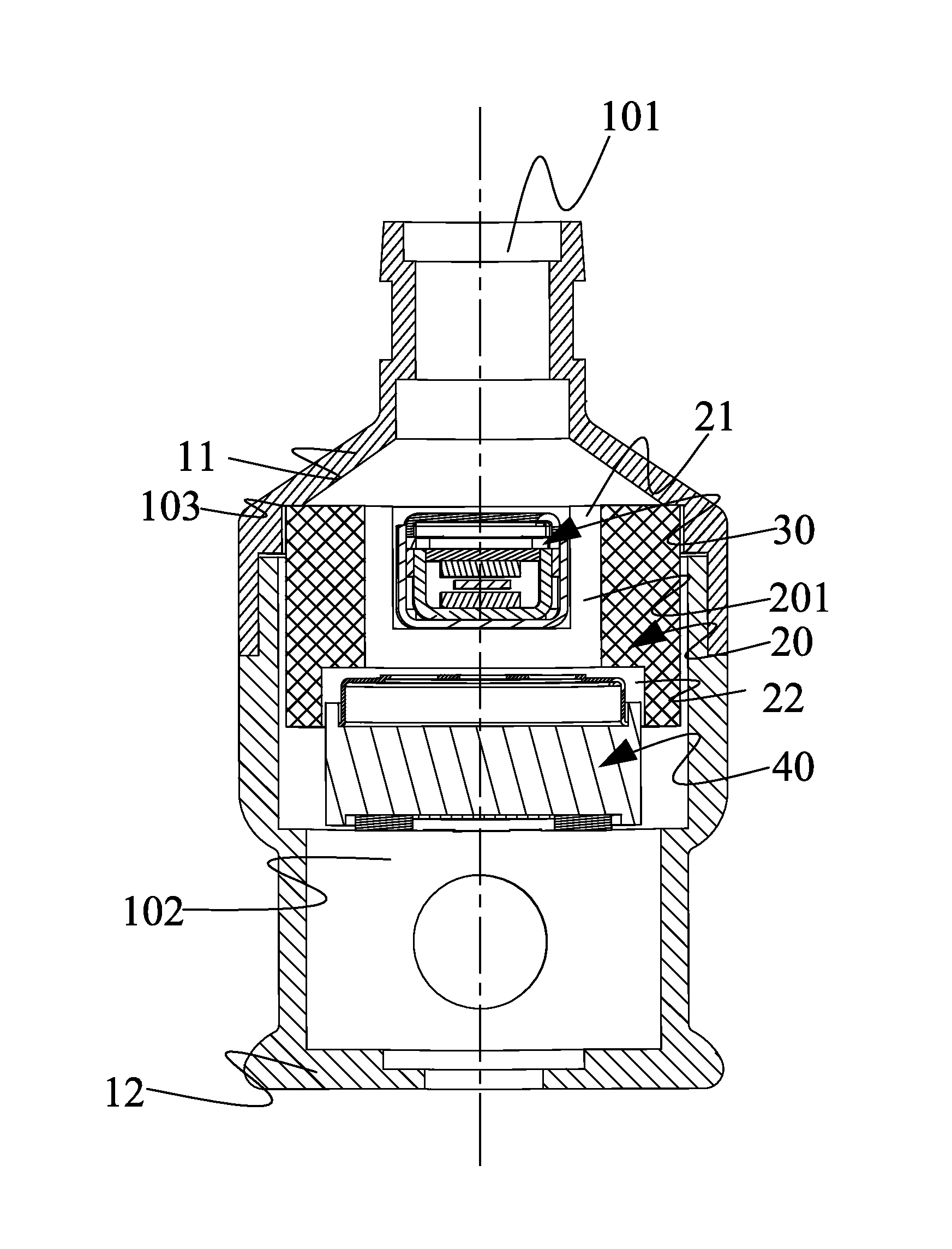

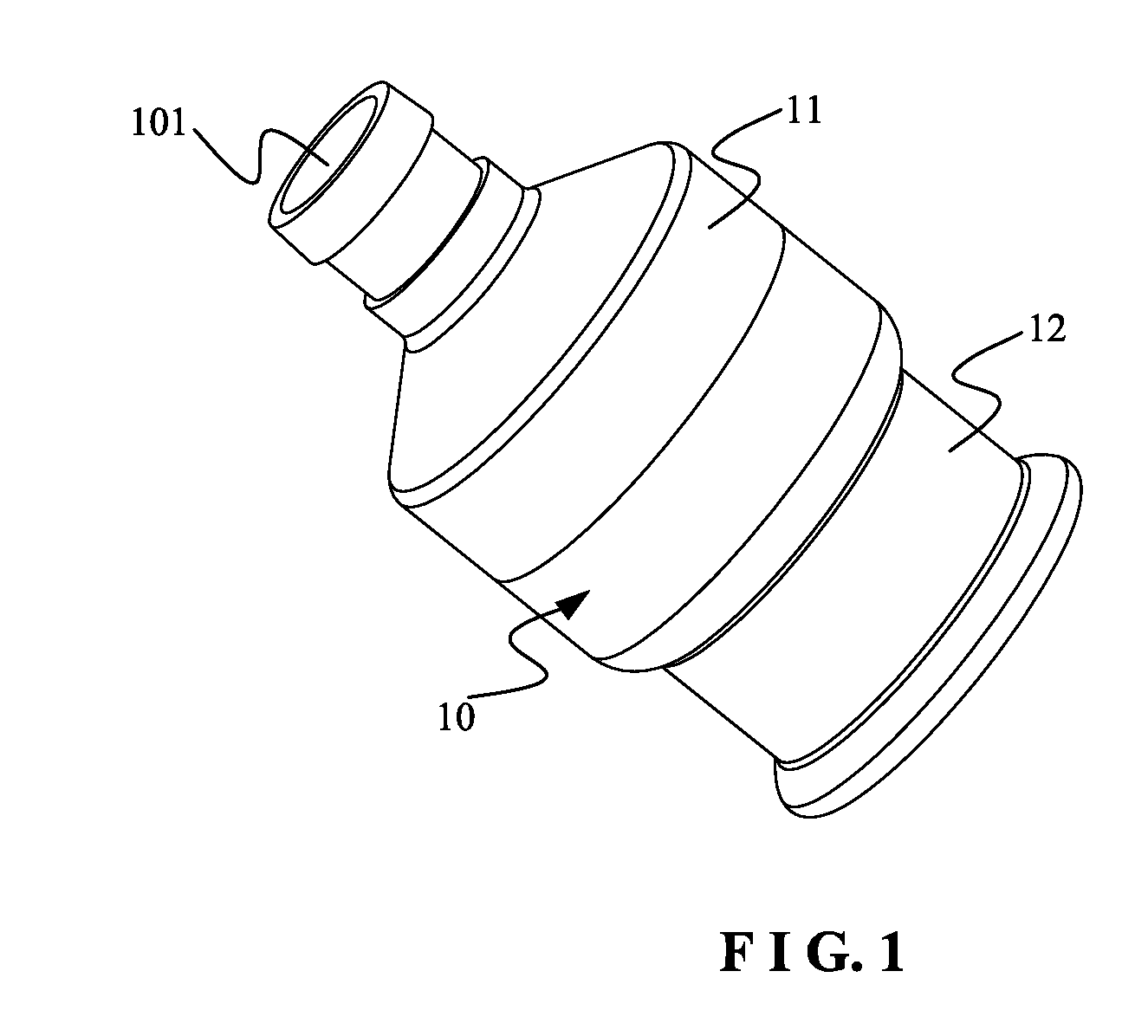

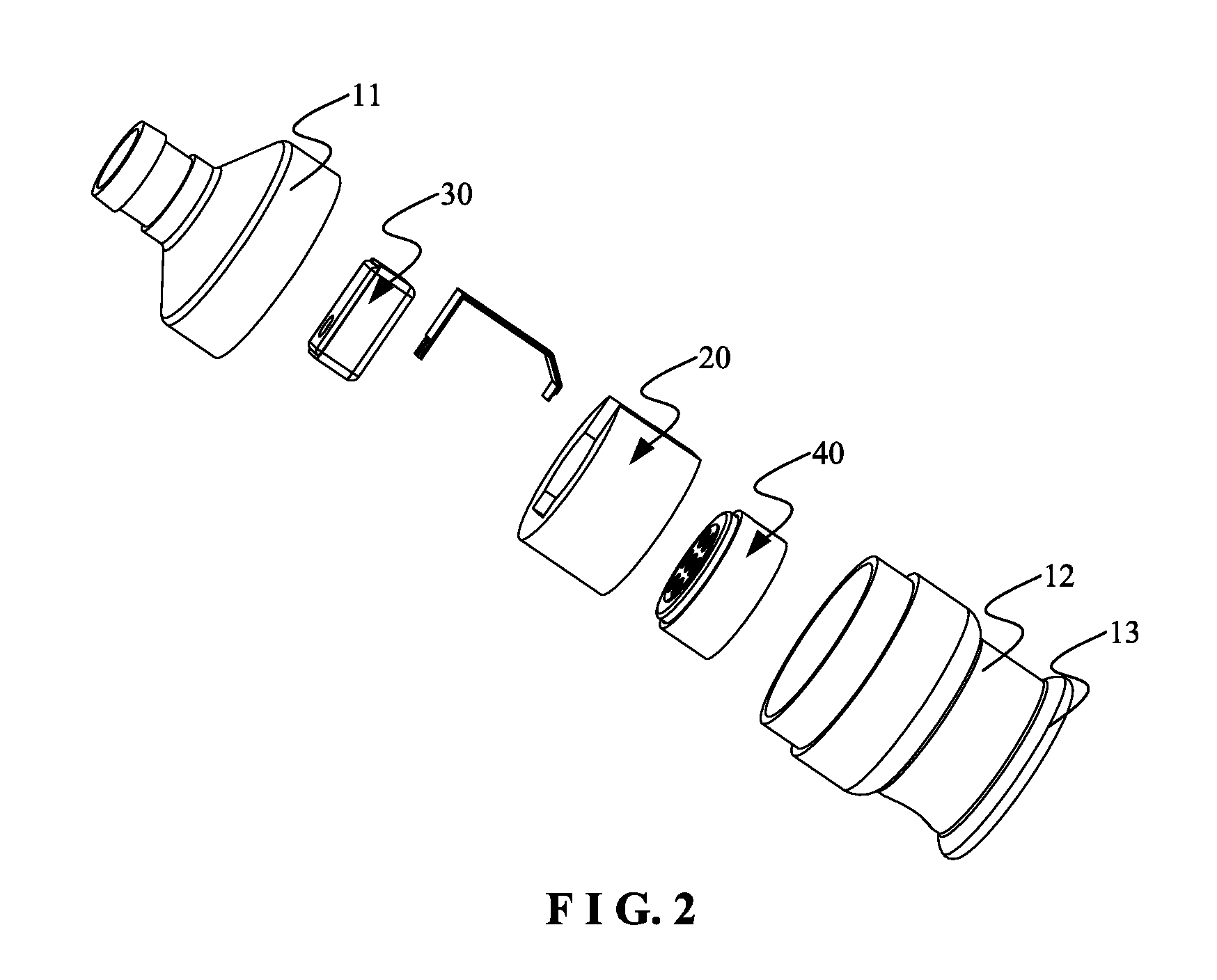

Earphone with dual loudspeakers

ActiveUS20150304763A1Cost of of difficultyNot easy to moldTransducers for sound channels pluralityEarpiece/earphone attachmentsEngineeringHeadphones

An earphone with dual loudspeakers includes a casing, a retaining member, a tweeter, and a woofer. The casing has a first sound outlet passage and an accommodation space therein. The retaining member is installed in the accommodation space. Two ends of the retaining member are formed with a first accommodation cavity and a second accommodation cavity, respectively. The tweeter and the woofer are respectively installed in the first and second accommodation cavities and then installed in the casing. The tweeter has a sound outlet side facing the first sound outlet passage. A second sound outlet passage is formed between the outer wall of the tweeter and the inner wall of the first accommodation cavity. The second sound outlet passage communicates with the first sound outlet passage. The woofer has a sound outlet side facing the second sound outlet passage.

Owner:DONGGUAN TRANSOUND ELECTRONICS

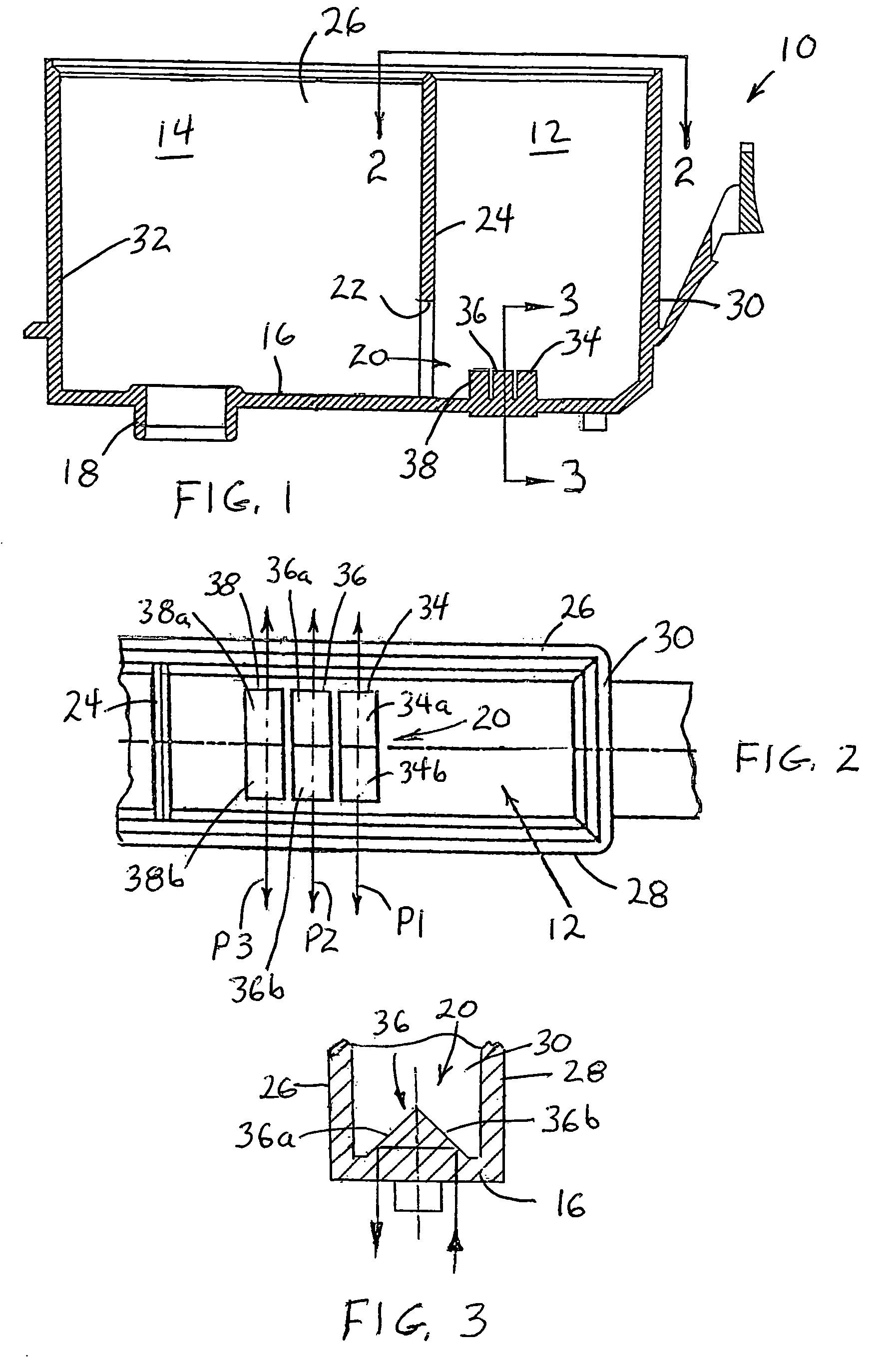

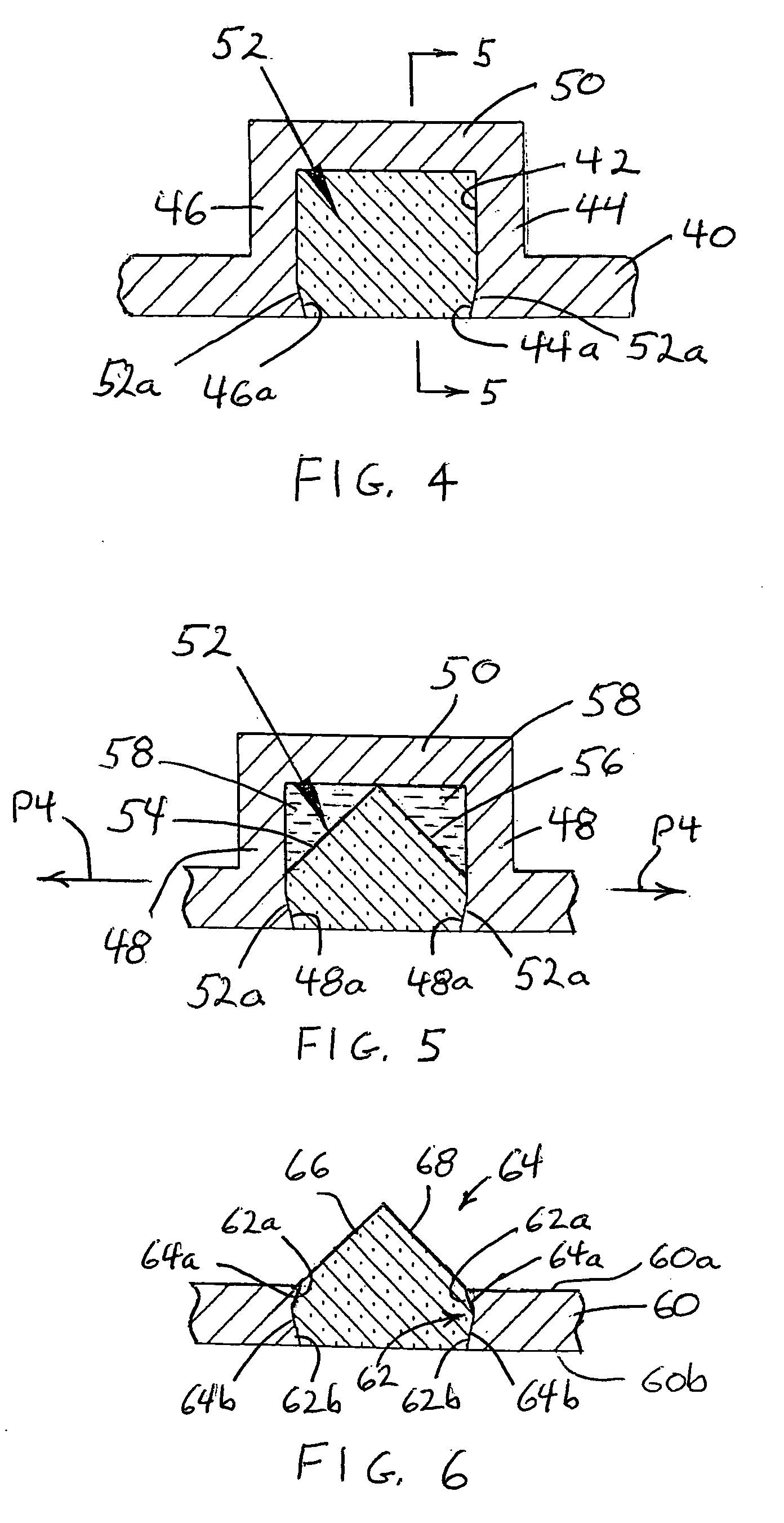

Optical ink level detecting arrangements for ink cartridges

An ink container shell for an ink jet cartridge has an ink chamber provided with an optical ink detection device in the form of a single or multi-segment prism having interface surfaces for reflecting light in a scan plane from a first to a second exterior area relative to the container shell when an ink level in the chamber recedes to a given level. The multi-segment prism provides for scanning a cartridge in different scanning planes. Either a single prism or the multi-segment prism can be separate from the cartridge and interengaged therewith by a snap-fit.

Owner:NU KOTE INT

Reconfigurable mixing baffle for static mixer and method for making a static mixer

InactiveUS9242214B2Improve deformationEasy to moveFlow mixersMetal rolling stand detailsStatic mixerMechanical engineering

A mixing baffle for mixing a fluid flow in a static mixer includes a mixing element support structure extending along a longitudinal direction and a first set of moveable mixing elements coupled to the mixing element support structure. The first set of moveable mixing elements is formed in a first configuration and moves to a second configuration when the mixing baffle is inserted into a tubular conduit. In the second configuration, the first set of moveable mixing elements is optimized for mixing fluids and defines a plurality of undercuts that are difficult to mold. The mixing baffle may also include a second set of stationary mixing elements that interlace with the first set of moveable mixing elements when the first set of moveable mixing elements moves to the second configuration.

Owner:NORDSON CORP

Water-based colour paste for printing ink

InactiveCN104004416ANot volatileNo effect on growthPigment pastesEnvironmental resistanceWater based

The invention relates to the technical field of water-based colour paste and provides water-based colour paste which is environmentally friendly, non-toxic, good in dispersing performance, strong in tinting strength and resistant to light, does not become thick, has anti-ultraviolet ray property, good weatherability and resistance to chemical attack and does not get mildew. The water-based colour paste is prepared from the following raw materials in parts by weight: 50-60 parts of pigment, 4-6 parts of wetting agent, 9-12 parts of dispersing agent, 6-10 parts of antioxidant, 0.3-0.45 part of antiseptic, 0.3-0.5 part of mildew preventive, 0.5-0.7 part of water-based defoaming agent, 6-8 parts of thickening and anti-settling agnet, 6-10 parts of ultraviolet light absorber and 30-60 parts of deionized water.

Owner:FUJIAN PROVINCE HUAPU NEW MATERIALS

Tamperproof protective method for Word file

InactiveCN102385680AImplement tamper protectionIngenious ideaDigital data protectionOperational systemWord processing

The invention provides a tamperproof protective method for a Word file, wherein the invention mainly includes the following steps: a TrueType word forming program is utilized to form new characters as a watermark signal, the watermark characters are embedded into the Word file to form a tamperproof protected file, a cipher key produced during forming the new characters is used for detecting the watermark in the tamperproof protected file in the computer, and the file can be judged to be whether tampered according to the change of the watermark. As the designed integration of the TrueType word forming program in the conventional universal Windows operation system, the display characteristics of the Windows word stock, and certain functions of the Word word processing program enables the word file to be protected in a tamperproof way, the tamperproof protective method for the Word file has ingenious conception and simple method, can be used easily by anyone familiar with Windows operation, is highly universal and easy to operate, and has low cost.

Owner:XIAN UNIV OF SCI & TECH

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

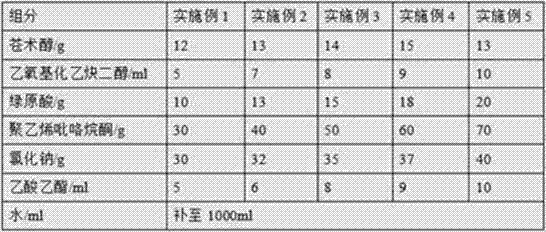

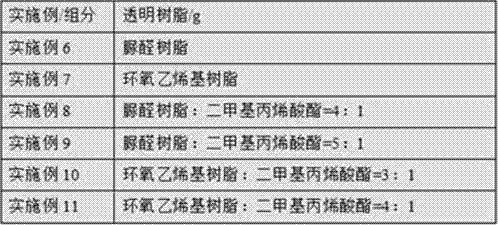

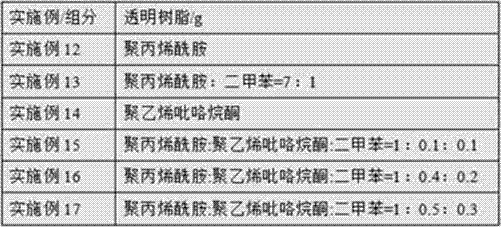

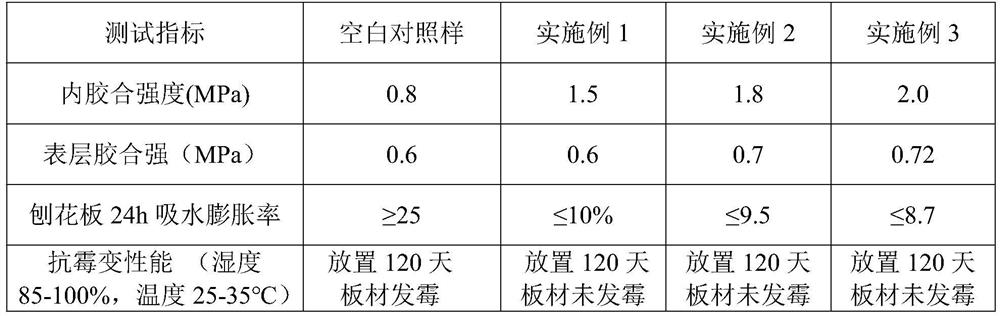

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

Biomass formaldehyde-free adhesive as well as preparation method and application method thereof

ActiveCN112322254AGood initial tackEasy to apply glueProtein adhesivesStarch adhesivesAntibacterial actionCellulose

The invention relates to the technical field of formaldehyde-free adhesive processing, in particular to a biomass formaldehyde-free adhesive based on a cellulose extracting solution as well as a preparation method and an application method thereof. Plant fibers with a natural antibacterial effect are used as main materials, a cellulose aqueous solution is prepared through physical crushing, pretreatment activation, dissolution and acetylation treatment, and compounding is performed through plant protein powder, a cross-linking agent, a curing agent and a tackifying aid. A biomass cellulose adhesive with good initial viscosity, easy gluing, water resistance and excellent natural antibacterial property of the prepared plate can be obtained, the mildewing condition of a glued layer of the glued plate is greatly improved, and the biomass formaldehyde-free adhesive prepared from the cellulose extracting solution has the advantages of wide raw material source, low preparation cost, environment friendliness, and no pollution, natural resources can be fully utilized, the dependence of the wood adhesive on petroleum resources is reduced, high-valued utilization of plant fibers with a natural antibacterial effect can be realized, and the adhesive has important significance for environmental protection.

Owner:NANNING KETIAN SHUIXING TECH LTD CO +2

Chemical fertilizer for flowers and plants and preparation method thereof

PendingCN107216191ANot easy to moldImprove qualityAlkali orthophosphate fertiliserExcrement fertilisersCelluloseVegetable oil

The invention discloses a chemical fertilizer for flowers and plants. The chemical fertilizer for flowers and plants is composed of the following components in parts by weight: 10-30 parts of vegetable oil cakes, 5-20 parts of cow dung, 10-15 parts of humic acid powder, 25-35 parts of pine needle soil, 0.1-0.5 part of lauryl dimethyl amine oxide, 8-15 parts of ground phosphate rock, 20-30 parts of traditional Chinese medicine residues, 2-10 parts of biological bacteria, 10-35 parts of cellulose homogenate, 0.2-1 part of a water-retaining agent, 2-4 parts of an anti-blocking agent and 20-80 parts of water. The invention also discloses a preparation method of the chemical fertilizer. By fermenting a matrix by the chemical fertilizer, nutrients are favorably released to a flower and plant plot soil. Nutrients in the chemical fertilizer are rich and can promote growth of the flowers and plants and keep the vitality.

Owner:兰溪市普润斯水产养殖技术有限公司

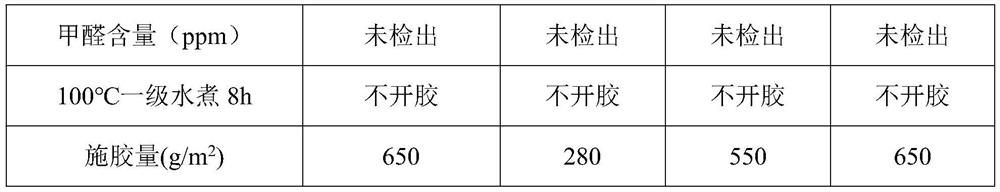

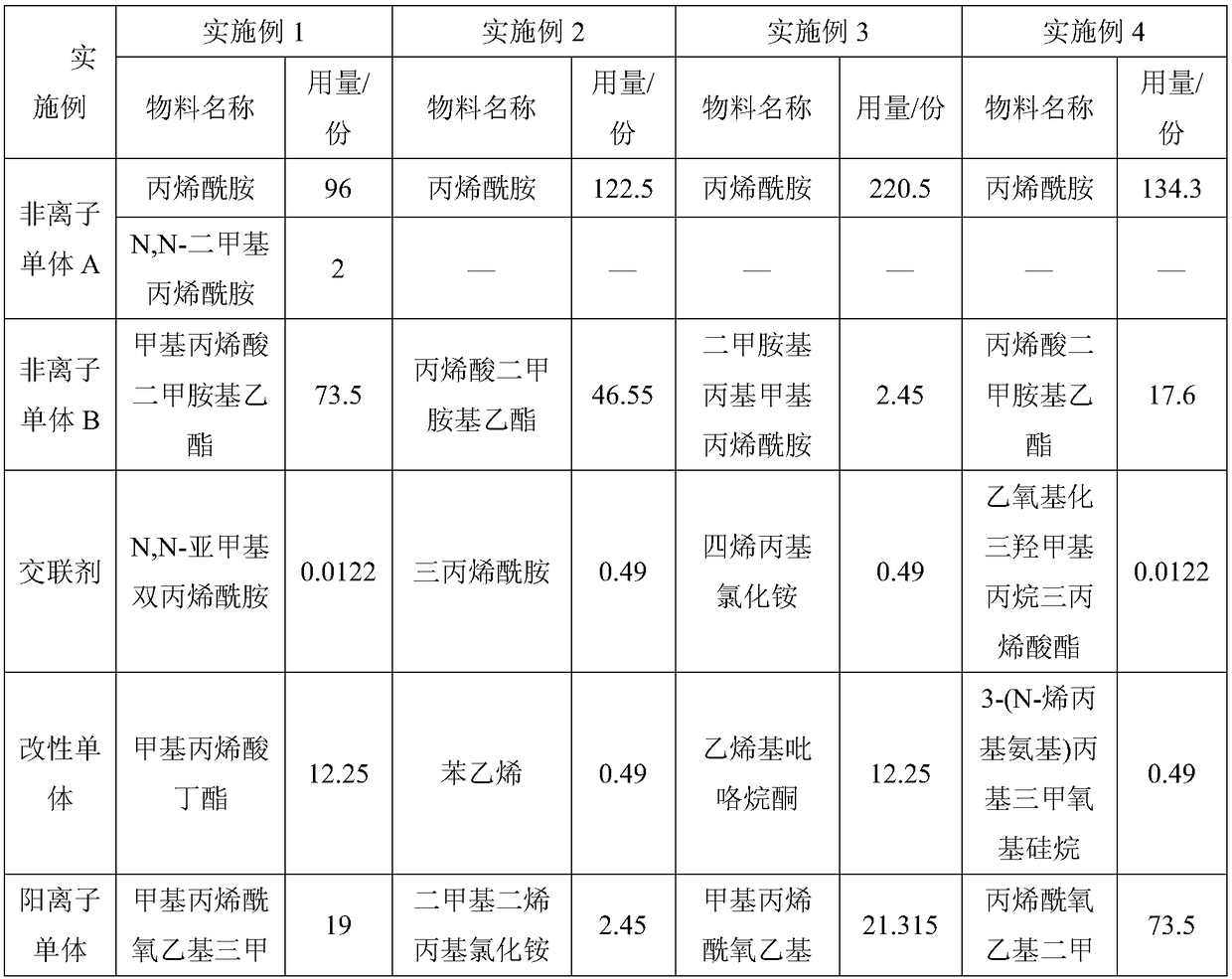

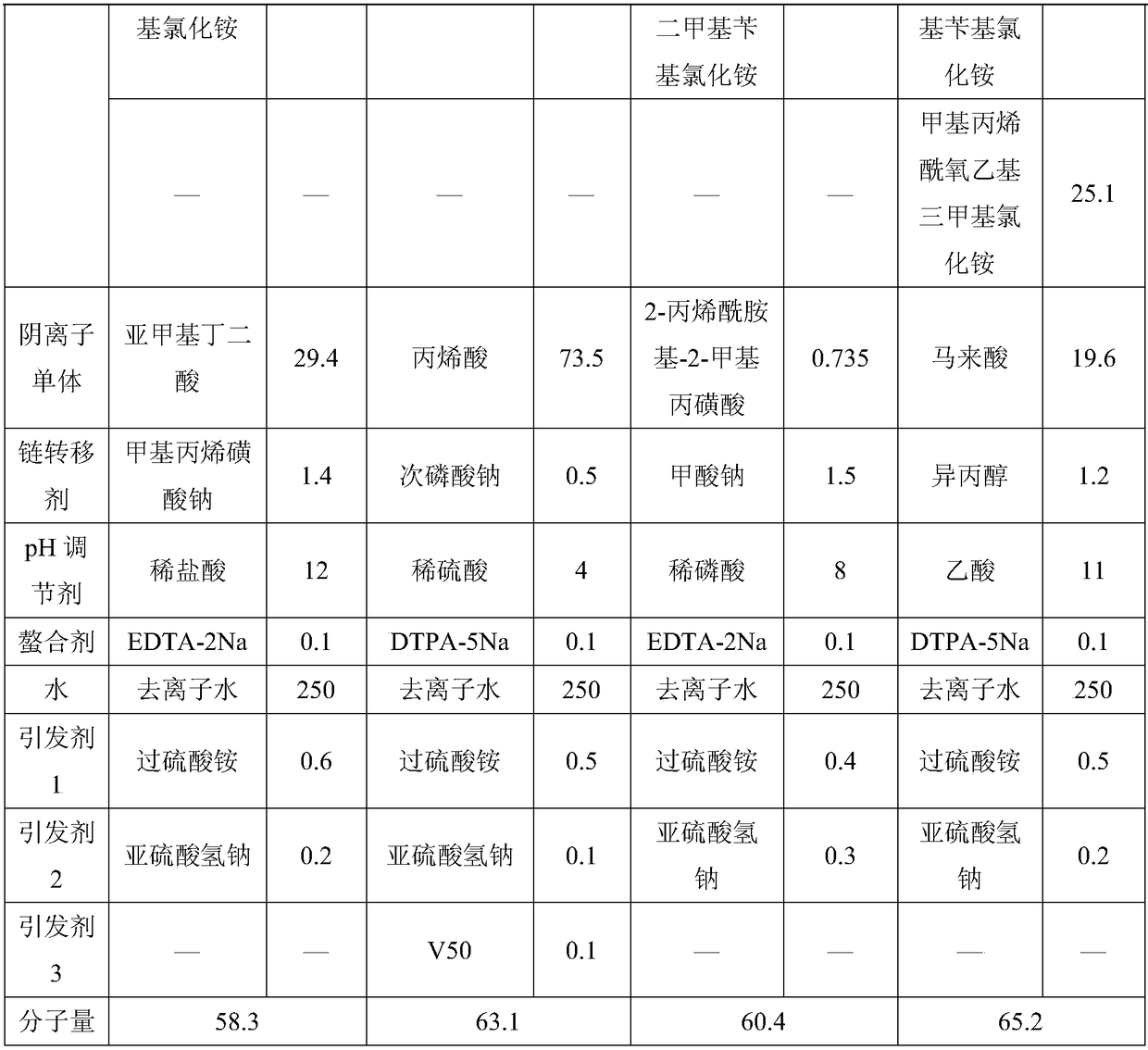

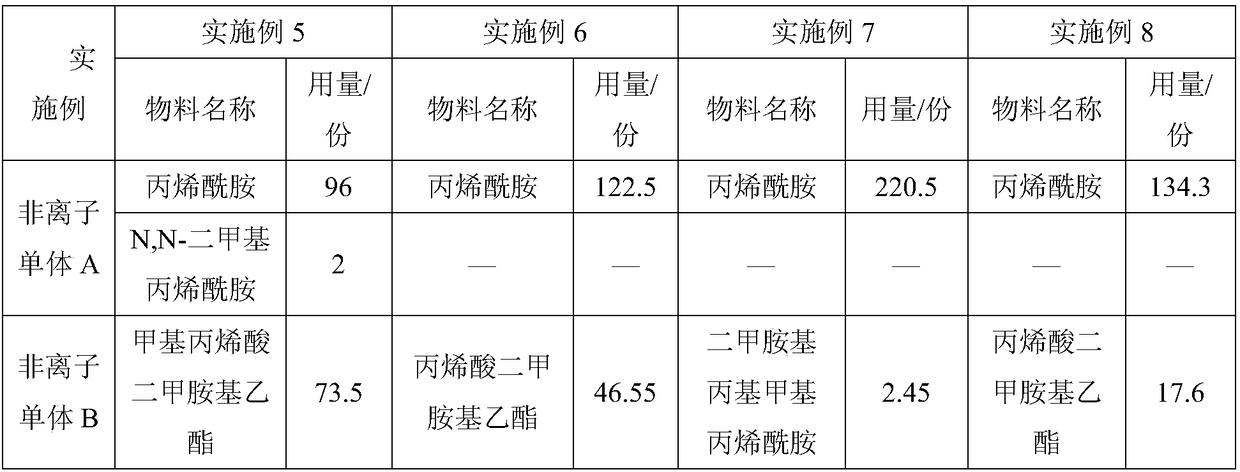

Crosslinking modified type water-soluble solid polyacrylamide and application thereof

The invention discloses crosslinking modified type water-soluble solid polyacrylamide. The water-soluble solid polyacrylamide is at least formed through chain copolymerization of six monomers including a nonionic monomer A, a nonionic monomer B, a crosslinking agent, a modified monomer, a cationic monomer and an anionic monomer. The problems that a water-soluble amphoteric polyacrylamide product has low molecular weight, low effective substance content, poor storage stability, short expiration date and the like are solved, and a product with higher molecular weight can be obtained and is highin effective substance content, low transportation cost and not prone to hydrolysis and mildewing. The invention also discloses an application of the crosslinking modified type water-soluble solid polyacrylamide in enhancement and / or modification of natural fiber materials or semi-synthetic fiber materials and can promote improvement of drainability and help strength improvement.

Owner:JIANGSU FEYMER TECH

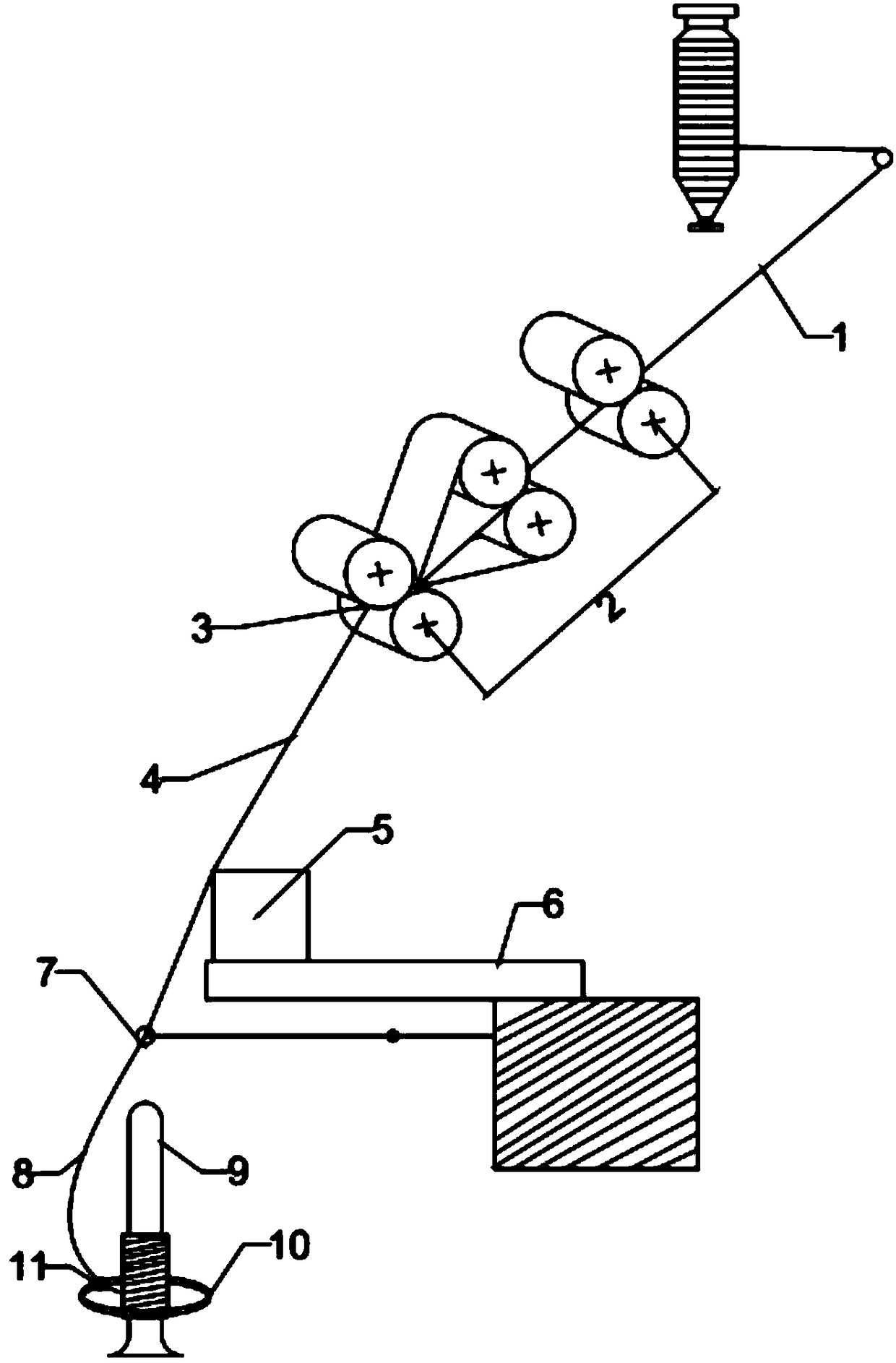

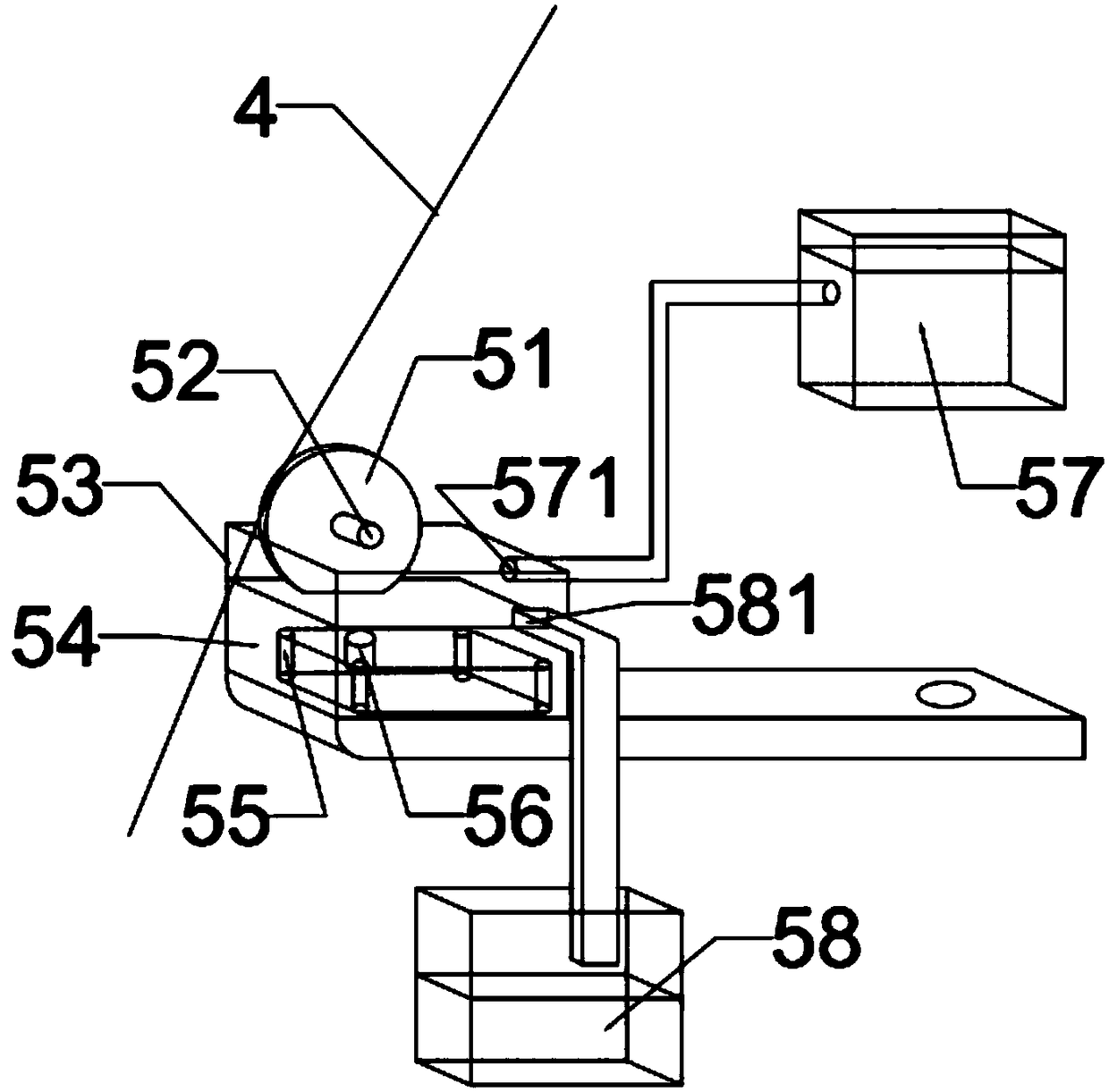

Online sizing spinning machine and sizing method of cellulose fiber yarn at room temperature

InactiveCN108893896ALess hairyReduce the number of rootsFibre treatmentDrafting machinesYarnRoom temperature

The invention belongs to the technical field of ring spinning, and relates to an online sizing spinning machine and sizing method of cellulose fiber yarn at room temperature. The sizing spinning machine comprises a ring spinning frame and a sizing device; the sizing device is fixed on the ring spinning frame through a fixed plate, and the sizing device is located between a front roller clamp and ayarn guide hook of the ring spinning frame, and a yarn twisting section output from the front roller clamp is sized through the sizing device. A motor is connected with a pulping guide roller througha rotor shaft and drives the pulping guide roller to rotate; the bottom of the pulping guide roller is immersed in the slurry of the lower pulp groove. A circulating device is fixed at the bottom ofthe pulp groove. The online sizing spinning machine of cellulose fiber yarn at room temperature adds an on-line sizing device to the yarn twisting section between the front roller clamp and the yarn guide hook, combines the environmental friendly grout which is suitable for the normal temperature single yarn sizing of cellulose fiber yarn and carries out the sizing process on the yarn twisting section between the front roller clamp and the yarn guide hook, the spinning process is combined with the sizing procedure, and the obtained fine yarns can be used directly for weaving.

Owner:JIANGNAN UNIV

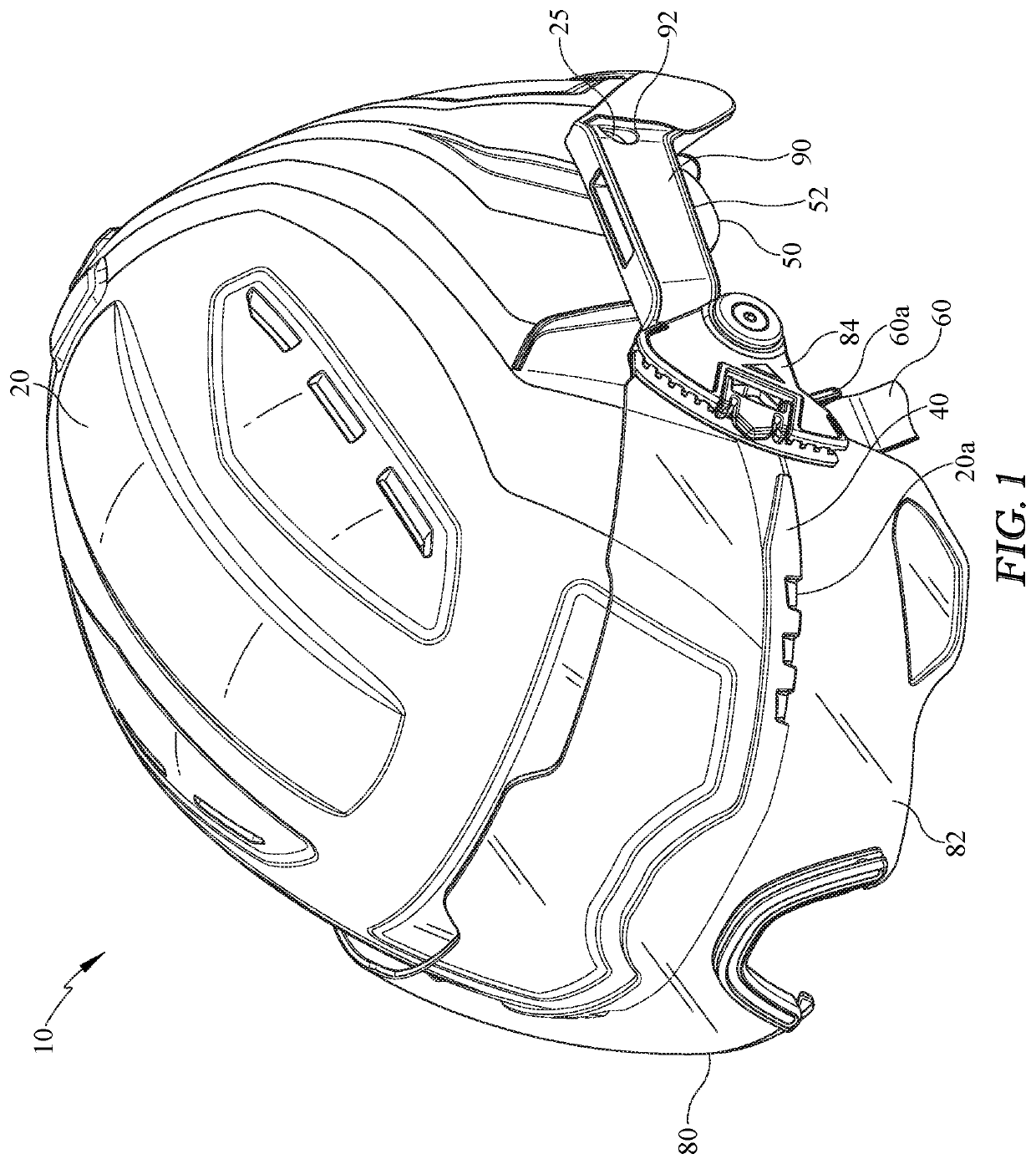

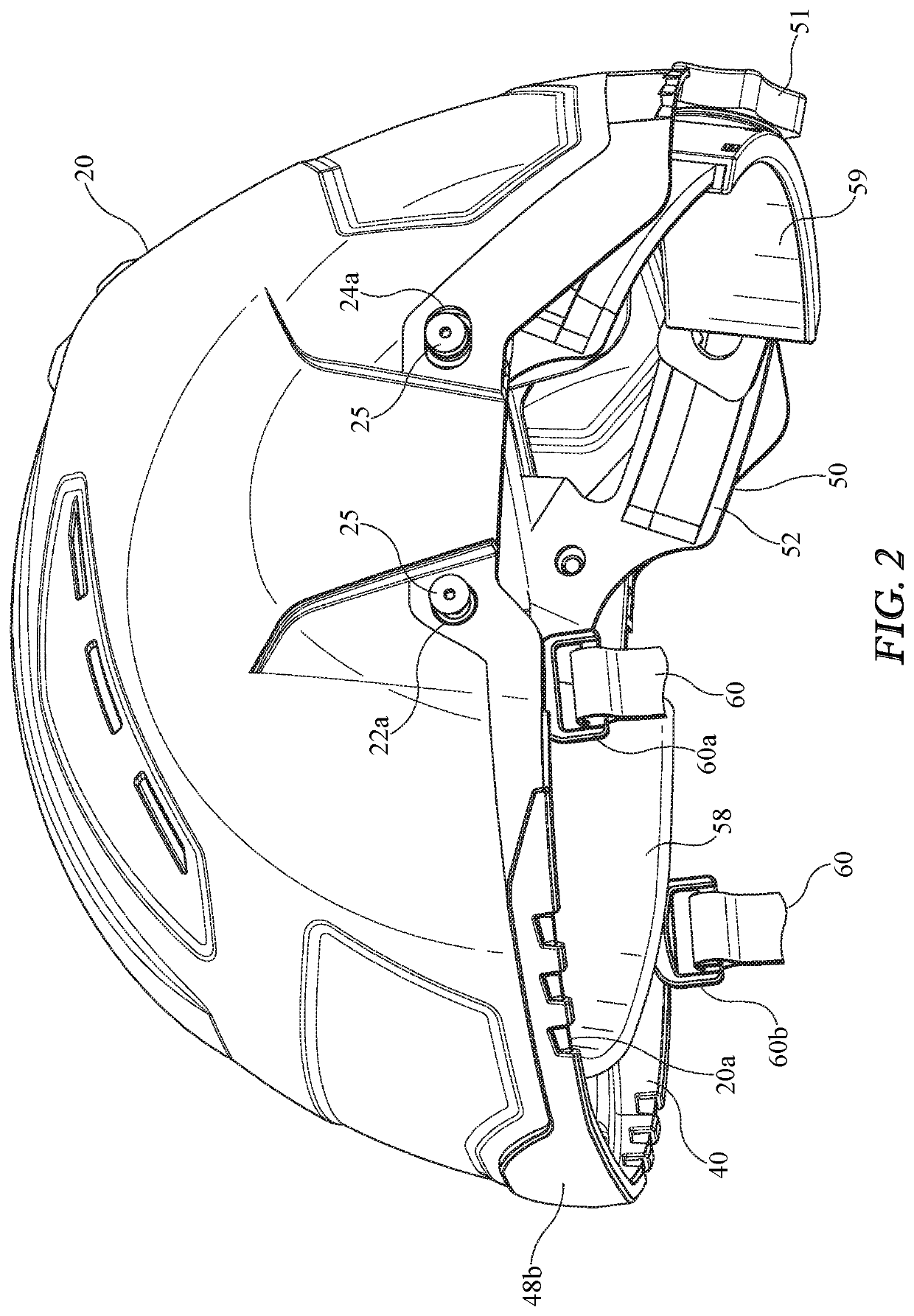

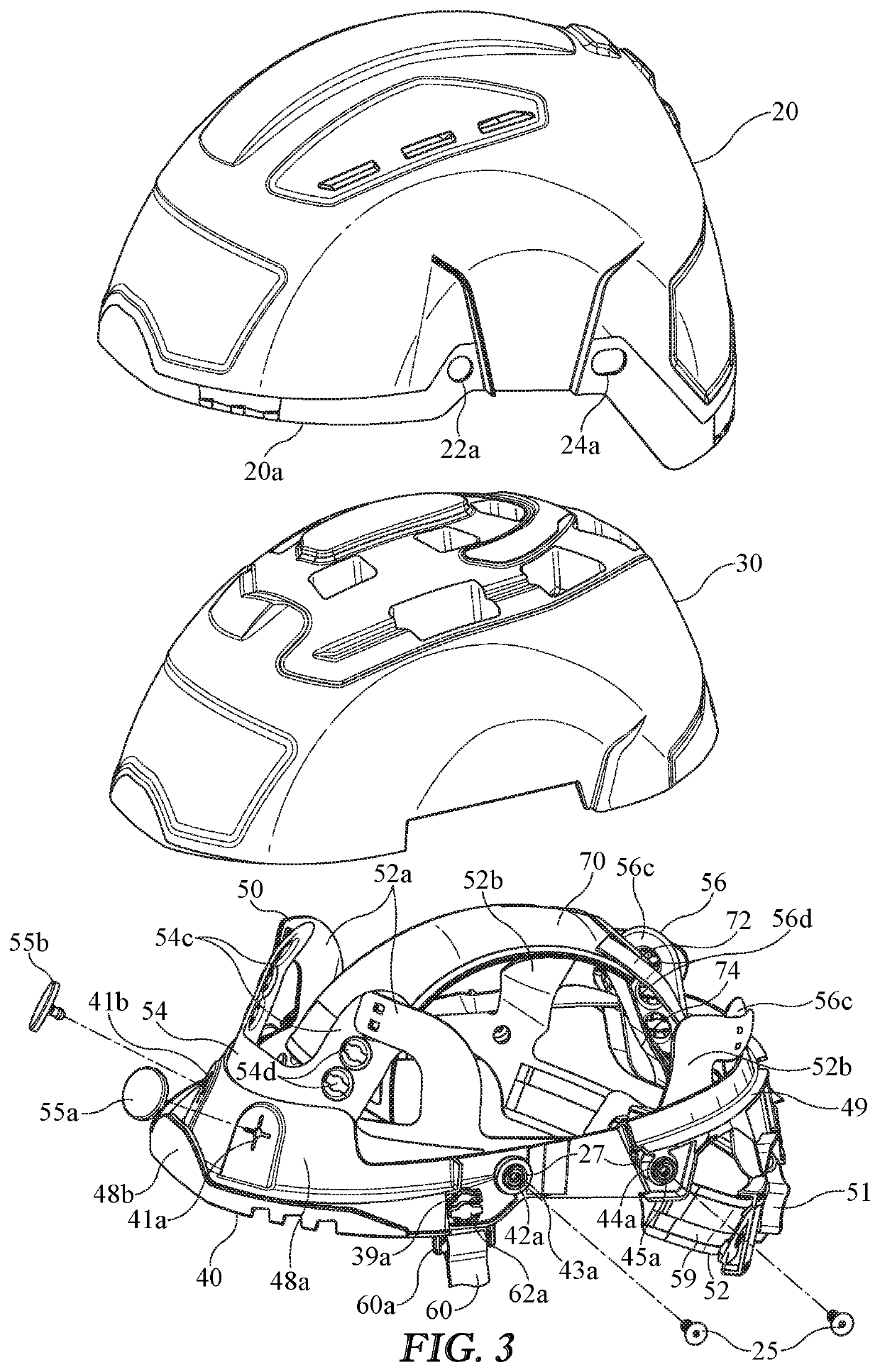

Protective helmet with attachment ring

InactiveUS20210037905A1Weaken energyMaintain positionHelmetsHelmet coversStructural engineeringMechanical engineering

A protective helmet adapted to receive and protect the head of a wearer includes an outer shell and an attachment ring removably secured to the outer shell, such that the attachment ring can be selectively attached to or detached and removed from the outer shell. The outer shell is shaped to protect the head of the wearer of the protective helmet and defines a bottom opening and an internal cavity for receiving the head of the wearer. The attachment ring acts as a point of attachment for, and thus secures, one or more components of the protective helmet configured to engage the head of the wearer, such that the components secured to the attachment ring are transported with the attachment ring when the attachment ring is detached and removed from the outer shell.

Owner:E D BULLARD

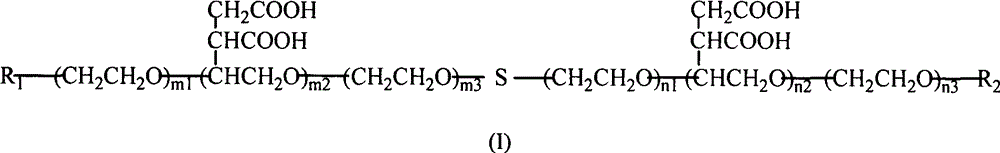

Efficient aqueous pigment dispersant

InactiveCN102974267AGood dispersion effectLittle environmental hazardTransportation and packagingInksFatty alcoholPOLYOXYETHYLENE ETHER

The invention relates to an auxiliary agent for a pigment, which is particularly suitable for dispersing the pigment, has good dispersion performance and high stability, and belongs to the field of application of a fine chemistry industry. A dispersant is prepared from fatty alcohol-polyoxyethylene ether, fatty alcohol-polyoxyethylene ether monoester, fatty alcohol-polyoxyethylene ether diester, carboxylated fatty alcohol-polyoxyethylene ether, carboxylated fatty alcohol-polyoxyethylene ether monoester and carboxylated fatty alcohol-polyoxyethylene ether diester. The dispersant is easily and biologically degraded and meets ecological and green and environment-friendly requirements; and a unique molecular chain structure can better disperse the pigment and can keep the pigment stable.

Owner:JIANGNAN UNIV

Mould-proof honeycomb packaging carton and preparation method thereof

InactiveCN105951507ASimple methodImprove breathabilityEnvelopes/bags making machineryPaper/cardboardFiberHoneycomb

The invention discloses a mould-proof honeycomb packaging carton and a preparation method thereof. The preparation method comprises the steps that pulp, chemical fibers, tin dimethyl, Cason, trimethoprim and a dispersing agent are stirred and mixed to obtain pulp M; the pulp M is dehydrated and formed, and the mould-proof honeycomb packaging carton is obtained through the hot-pressing technology. The problem that a common packaging carton is poor in gas permeability and mould-proof cavity, and consequently objects contained in the packaging carton are prone to bacterium breeding and moulding is solved.

Owner:铜陵锋帆彩色印务有限公司

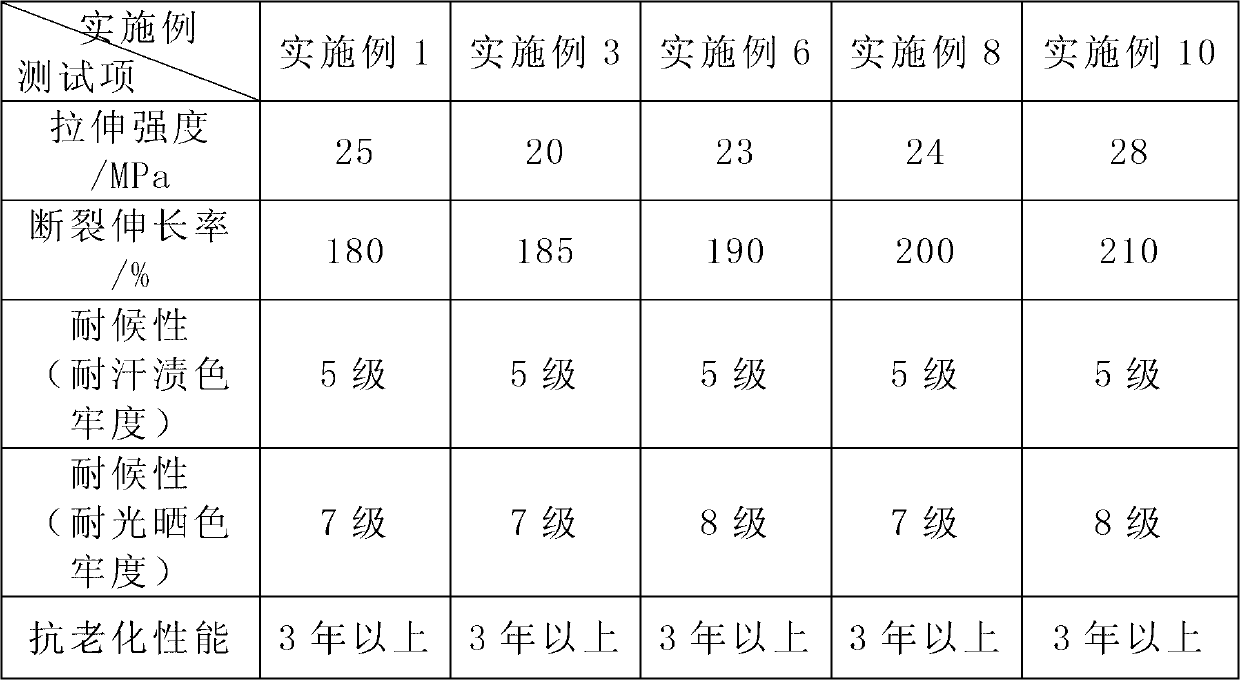

Polyvinyl chloride (PVC) composite material for Textilene cloth

The invention relates to a polyvinyl chloride (PVC) composite material for Textilene cloth, which belongs to the technical field of high polymer materials. In order to overcome the technical problems existing in the prior art adopting bisphenol A to realize a PVC composite material with high oxidization resistance and high aging resistance, the invention provides a PVC composite material for Textilene cloth. The PVC composite material comprises following components in parts by weight: 100 parts of PVC, 2.0 to 4.0 parts of chelating agent, 10 to 20 parts of environment-friendly plasticizer, 5.0 to 10 parts of corn starch, 2.0 to 5.0 parts of fire retardant, 0.3 to 1.0 part of weather-resisting agent and 1 to 3 parts of antioxidant; and the PVC composite material also comprises one or more of lubricant, dispersant or antibacterial agent. The PVC composite material has advantages of good oxidization resistance, good plasticizing effect, long anti-aging time, good mechanic performance and no toxic bisphenol A. Moreover, yarns which are produced by the PVC composite material have good abrasion performance.

Owner:TAIZHOU DONGHAI PLASTIC PRODS MFG

Composition capable of forming yellowing-free, low-hardness polyurethane elastomer, and method for producing yellowing-free, low-hardness polyurethane elastomer using the same

The present invention provides a thermosetting polyurethane elastomer that is yellowing-free, has low hardness and does not give rise to bleeding without using any plasticizer, has little tack, and exhibits small changes in hardness with temperature.This is achieved by a composition forming a yellowing-free, low-hardness polyurethane elastomer, containing no plasticizer and having (A) an isocyanate-terminated prepolymer and (B) a polyester polyol, wherein the isocyanate-terminated prepolymer (A) is an isocyanate-terminated prepolymer obtained by reacting hexamethylene diisocyanate with a glycol having an alkyl group as a side chain and having a molecular weight no greater than 500, and the polyester polyol (B) is a polyester polyol obtained from trimethylolpropane, 3-methyl-1,5-pentanediol and adipic acid, and having an average number of functional groups of 2.5 to 3.5 and a number average molecular weight of 800 to 5,000.

Owner:NIPPON POLYURETHANE IND CO LTD

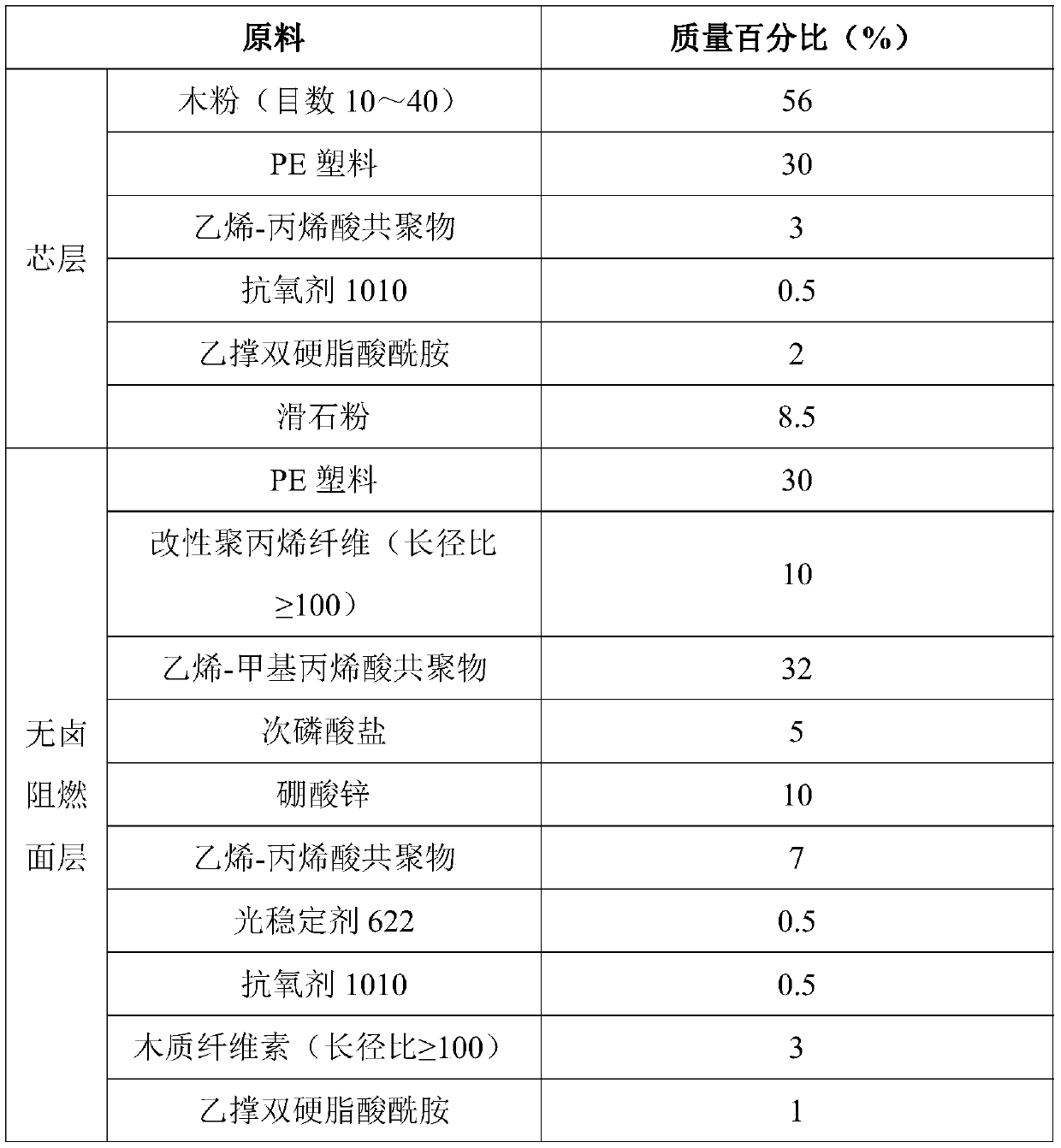

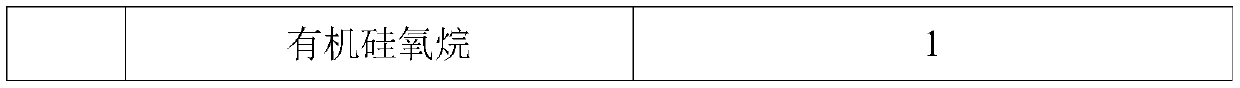

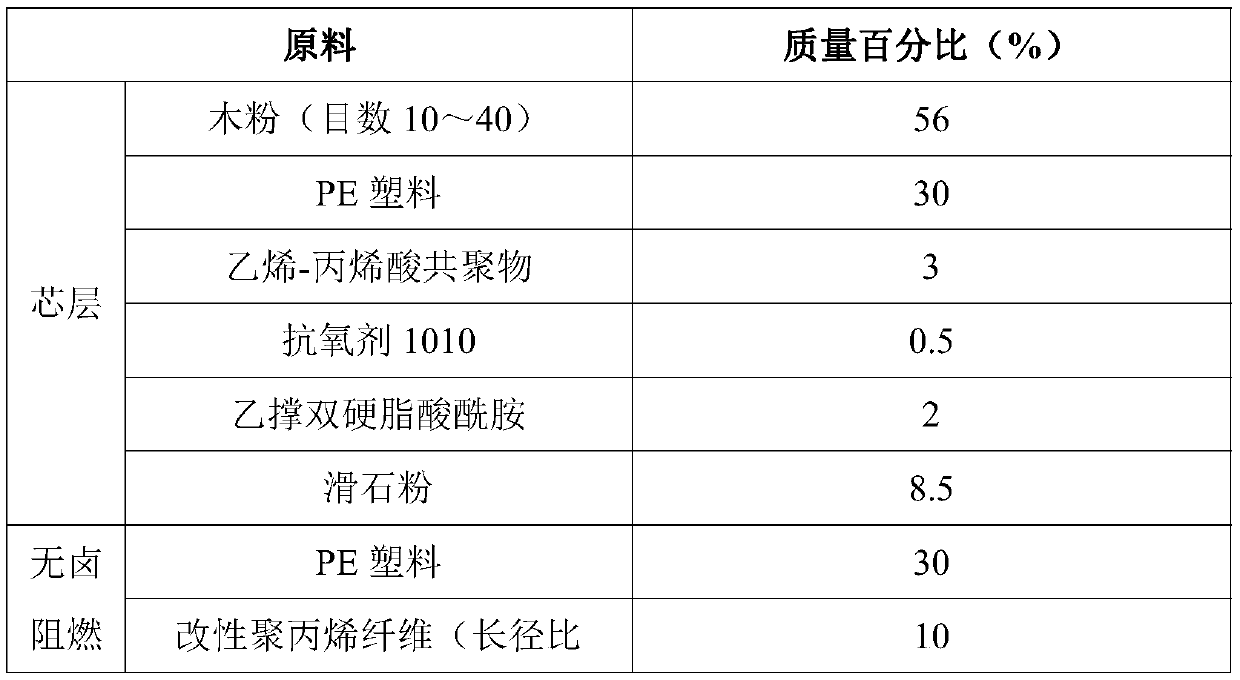

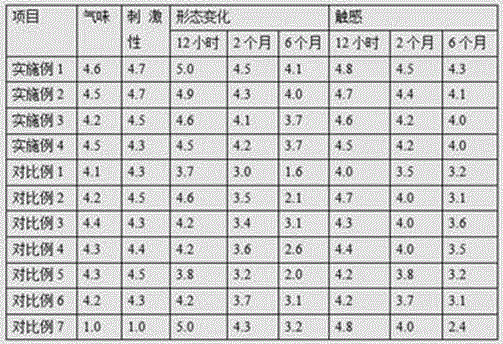

Halogen-free flame-retardant wood-plastic co-extrusion composite material and preparation method thereof

InactiveCN111070824AImprove flame retardant performanceHigh strengthSynthetic resin layered productsWood layered productsZinc boratePlant fibre

The invention discloses a halogen-free flame-retardant wood-plastic co-extrusion composite material and a preparation method thereof. The halogen-free flame-retardant wood-plastic co-extrusion composite material comprises a core layer and a halogen-free flame-retardant surface layer for coating the core layer, wherein the core layer comprises plant fibers, PE plastic, a compatilizer, an antioxidant, a lubricant and an inorganic filler, and the halogen-free flame-retardant surface layer comprises PE plastic, modified polypropylene fibers, an ethylene-methacrylic acid copolymer, hypophosphite, zinc borate, an interface modifier, a light stabilizer, an antioxidant and other auxiliaries. The halogen-free flame-retardant wood-plastic co-extrusion composite material disclosed by the invention isvery simple to prepare, the core layer granules and the halogen-free flame-retardant surface layer granules are firstly prepared respectively, and then co-extrusion molding is carried out. The halogen-free flame-retardant wood-plastic co-extrusion composite material has the advantages of excellent flame retardancy, high strength, excellent impact resistance, high hardness, favorable wear resistance, low water absorptivity, favorable aging resistance, favorable wear resistance, favorable scratch resistance, high wood texture and favorable antiskid effect, and is not easy to fade or mildew whenbeing used outdoors.

Owner:广州康森新材料科技有限公司 +1

Toothbrush with sucker

The invention relates to a toothbrush with a sucker, which is characterized in that the handle end of the toothbrush is additionally provided with a sucker design. Because the sucker is positioned in the toothbrush handle, the toothbrush can be uprightly put in general to have good ventilation and difficult mildew generation, and can save limited space, such as a washroom. The toothbrush consists of a toothbrush main body and the sucker in the handle, the toothbrush main body and the sucker can be designed into a whole and can also be connected into a whole without any limited mode. When the toothbrush is produced, the prepared sucker with relative size and the toothbrush are poured into a whole through integrally molding; or a clamp position is reserved on the toothbrush, the sucker is clamped in the toothbrush, the sucker and the toothbrush are connected into a whole, and therefore, when damaged, one of the toothbrush main body and the sucker can be replaced by a new one so that the toothbrush with the sucker saves the cost and is simple and durable.

Owner:吴士成

Preserving stationary liquid for pathological tissues

InactiveCN106689120AImprove hygroscopicityReasonable combinationDead animal preservationChemistrySpecimen Handling

Owner:NANYANG MEDICAL COLLEGE

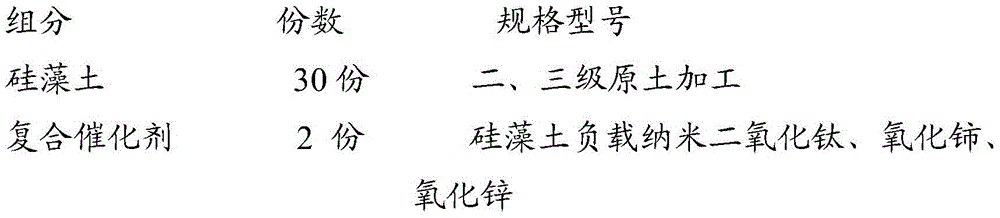

Baking-free diatomite ecological brick and preparation method thereof

ActiveCN105622017ANot easy to moldGood antibacterial and antifungal effectCeramicwareCalciumAntibacterial agent

The invention discloses a baking-free diatomite ecological brick and a preparation method thereof. The baking-free diatomite ecological brick comprises the following raw materials in parts by weight: 20-50 parts of diatomite, 1-3 parts of a composite catalyst, 1-3 parts of a nano silver antibacterial agent, 30-50 parts of white cement, 1-3 parts of wood fiber, 10-30 parts of ground calcium carbonate, 10-30 parts of talcum powder, 0.1-0.3 part of HPMC, 1-5 parts of pigment and 30-90 parts of water. The baking-free diatomite ecological brick is produced by the processes of mixing the raw materials, slurrying, pouring, vibrating, maintaining, demolding, grinding, checking and packaging. Compared with the diatom ooze decoration wall material, the strength, the water resistance and the service life of the diatomite ecological brick are significantly improved; the baking-free diatomite ecological brick is convenient to construct, short in period and high in efficiency; the baking-free diatomite ecological brick is produced by taking an inorganic cementitious material as a base material through a pouring process; the baking-free diatomite ecological brick can be maintained and cured at the normal temperature; the process is simplified on the basis that the advantages of the diatomite ecological brick are retained; the energy consumption is reduced; the equipment investment and the construction investment are reduced.

Owner:营口盼盼硅藻材料集团有限公司

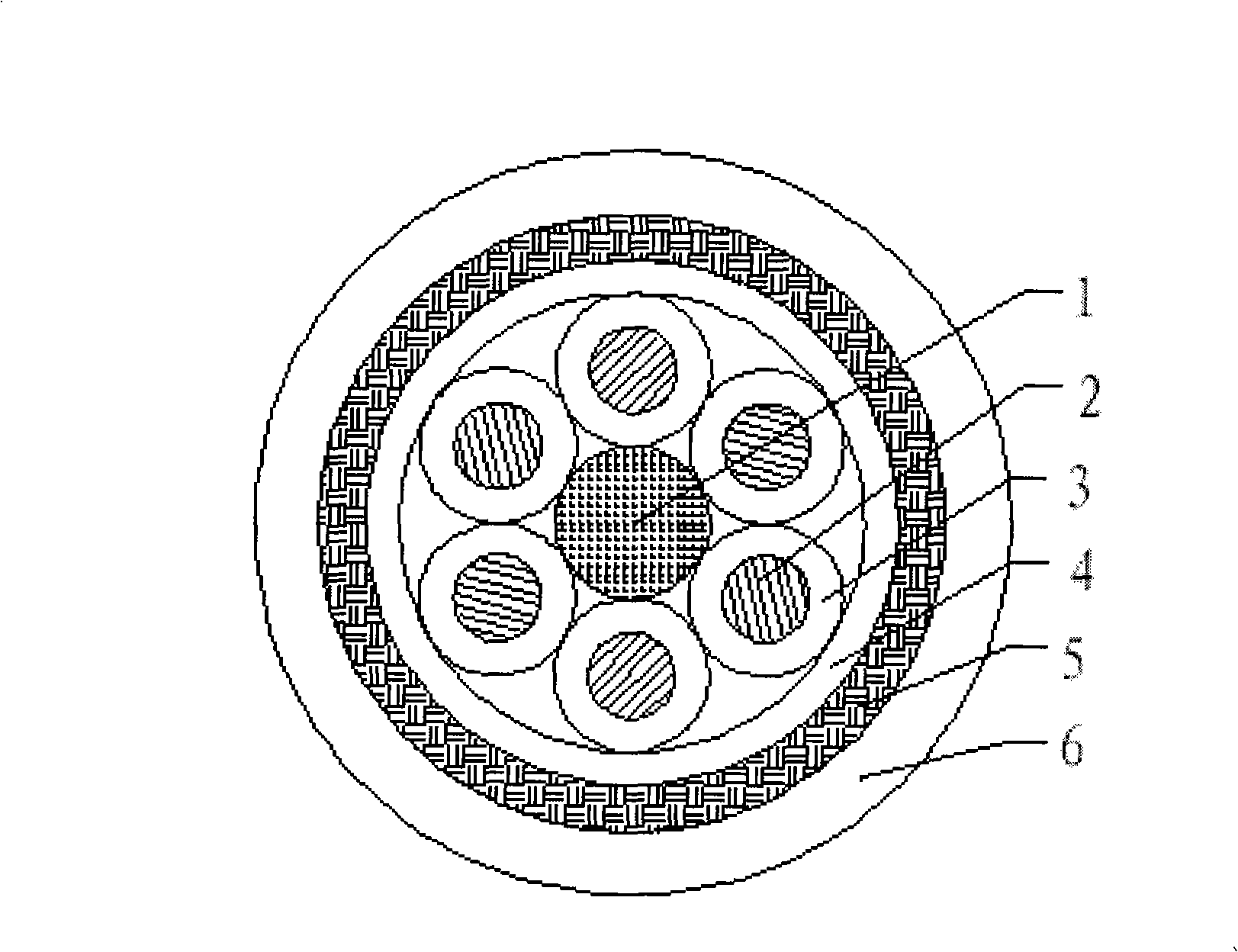

Underwater magnet measurement cable for ship

InactiveCN101345101ARequirements for difficult underwater magnetic measurement systemMeet the requirements of underwater magnetic measurement systemSubmarine cablesInsulated conductorsInsulation layerUnderwater

The invention provides an underground magnetic-measuring cable used for ships, belonging to the cable manufacture technique, and relating to improvement to the underground magnetic-measuring cable used for the ships. The underground magnetic-measuring cable comprises 6-18 insulated wire cores, a knitting shielding layer (5) and an external protection sleeve (6); the underground magnetic-measuring cable is characterized in that the center of the insulated wire core is provided with an aramid-reinforced filling core (1); the insulated layer (3) adopts a thermal-plastic vulcanized rubber insulation layer; a waterproof belt (4) is enwound on the external surface of the cable consisting of all the insulated wire cores; the external surface of the waterproof belt (4) is wrapped with the knitting shielding layer (5); the external protection sleeve (6) adopts a polyurethane external protection sleeve.

Owner:安徽宏源特种电缆集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com