Baking-free diatomite ecological brick and preparation method thereof

A production method and technology of ecological bricks, applied in the field of decorative materials, can solve problems such as high construction skills requirements, energy pollutant discharge, and long construction period, and achieve the effects of improving antibacterial and anti-mildew performance, increasing service life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

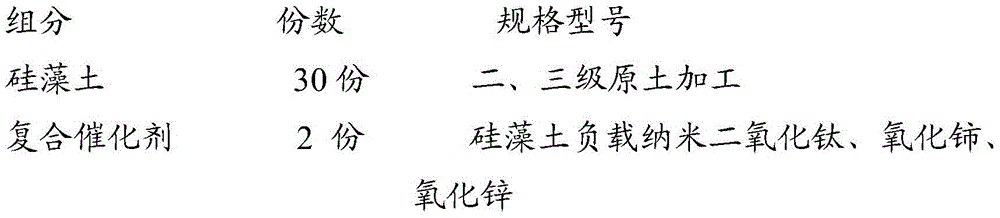

[0030] Components:

[0031]

[0032]

[0033] Preparation:

[0034] Measure all the components except water according to the above proportions, add them into the powder mixer, stir for 30 minutes and mix until the powder is uniform.

[0035] Add 54 parts of water into the pulping tank, add the mixed powder under stirring, and after adding the powder, stir for 20 minutes until the slurry is uniform.

[0036] Inject the slurry into the prefabricated mold, scrape the mold, and shake on the shaking platform.

[0037] Cured for 7 days at a temperature of 15°C-25°C and a relative humidity of 40%-60%, demolded, and cured for 21 days at a temperature of 15°C-25°C and a relative humidity of 40%-60%, and polished.

[0038] After the product has passed the inspection, the finished bricks are pasted on the grid cloth coated with pressure-sensitive adhesive, put into cartons, and put into storage.

Embodiment 2

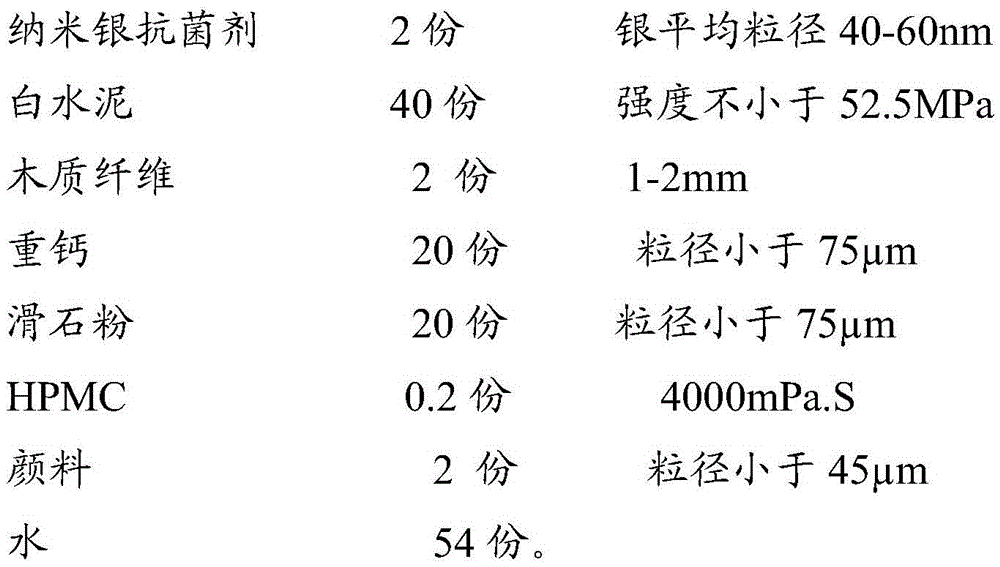

[0040] Raw material components:

[0041]

[0042]

[0043] Preparation:

[0044] Measure all the components except water according to the above proportions, add them into the powder mixer, stir for 30 minutes and mix until the powder is uniform.

[0045] Add 90 parts of water to the pulping tank, add the mixed powder under stirring, and after adding the powder, stir for 20 minutes until the slurry is uniform.

[0046] Inject the slurry into the prefabricated mold, scrape the mold, and shake on the shaking platform.

[0047] Cured for 7 days under the conditions of temperature 15℃-25℃, relative humidity 40%-60%, demoulding, and curing for 21 days under the conditions of temperature 15℃-25℃, relative humidity 40%-60%, demoulding, sanded.

[0048] After the product has passed the inspection, the finished bricks are pasted on the grid cloth coated with pressure-sensitive adhesive, put into cartons, and put into storage.

Embodiment 3

[0050] Raw material components:

[0051]

[0052] Preparation:

[0053] Measure all the components except water according to the above proportions, add them into the powder mixer, stir for 30 minutes and mix until the powder is uniform.

[0054] Add 30 parts of water to the pulping tank, add the mixed powder under stirring, and after adding the powder, stir for 20 minutes until the slurry is uniform.

[0055] Inject the slurry into the prefabricated mold, scrape the mold, and shake on the shaking platform.

[0056]Cured for 7 days at a temperature of 15°C-25°C and a relative humidity of 40%-60%, demolded, and cured for 21 days at a temperature of 15°C-25°C and a relative humidity of 40%-60%, demolded, sanded.

[0057] After the product has passed the inspection, the finished bricks are pasted on the grid cloth coated with pressure-sensitive adhesive, put into cartons, and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com