Patents

Literature

116results about How to "Good initial tack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive emulsion for environment-friendly textile gilding printing paste and preparation method thereof

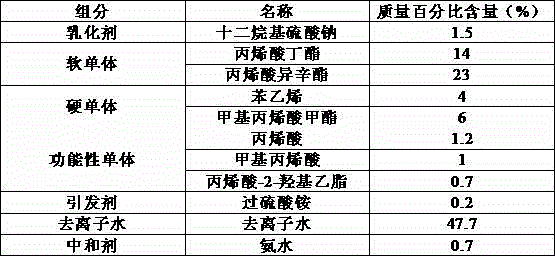

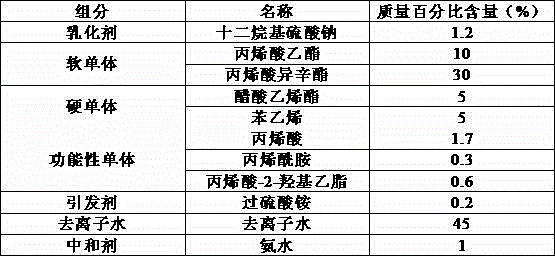

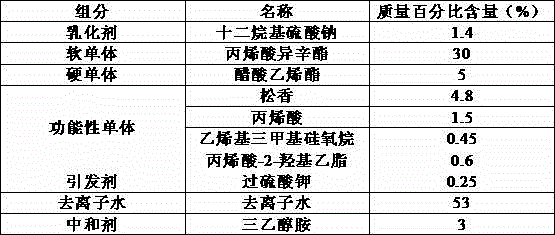

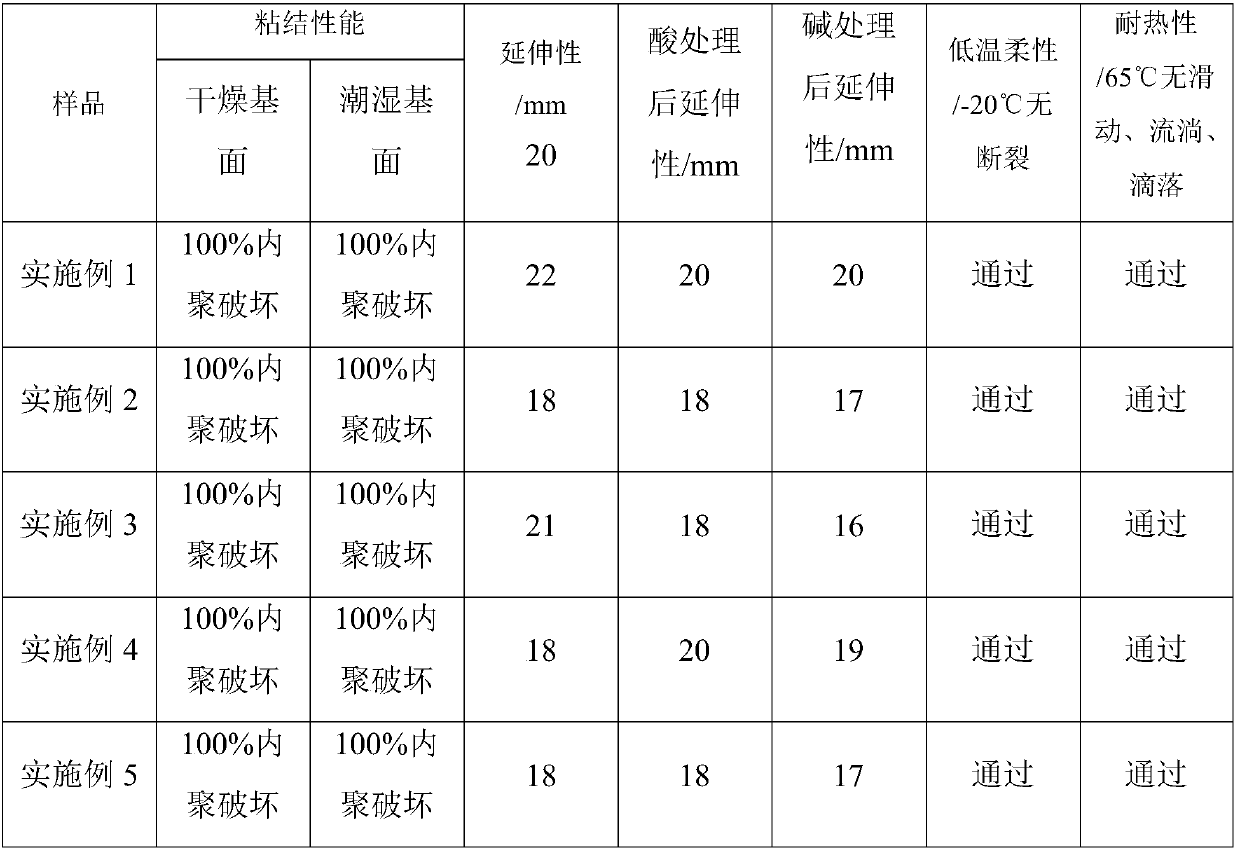

The invention discloses adhesive emulsion for environment-friendly textile gilding printing paste and a preparation method thereof. The emulsion consists of the following components in percentage by weight: 0.5-3% of emulsifier, 30-50% of soft monomer, 6-15% of hard monomer, 2-5% of functional monomer, 0.1-0.3% of initiator, 40-60% of deionized water and 0.5-2% of neutralizer. The adhesive is prepared into gilding paste and is used for bonding textile gilding foil; and the shortcomings of the products on the market of low net operability, hard handfeel, unsatisfactory firmness, easy color losing after washing, environmental pollution and the like are overcome. Through the invention, the prepared adhesive has excellent initial viscosity and sustained viscosity and good water resistance, and can realize good adhesive force against different textile fabrics; and meanwhile, the adhesive has good cohesion permanent viscosity, is environment-friendly without releasing toxic substances such as formaldehyde and the like, and does not contain the alkylphenol additives. The adhesive emulsion disclosed by the invention is suitable for the cold and hot gilding technology of manual or mechanical printing, is easy to operate, and has soft handfeel, no sand hole and high yield.

Owner:BAILIHE CHEM ZHONGSHAN

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Method for preparing modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive

InactiveCN103435760AGood pressure sensitivityImprove water resistanceGraft polymer adhesivesEpoxyPolyurethane dispersion

The invention discloses a method for preparing a modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The method comprises the following steps: adding polyisocyanate and low polymer polyhydric alcohol into reaction equipment, further adding a hydrophilic chain extender to react to obtain a polyurethane prepolymer, subsequently adding acrylic ester containing hydroxyl and a modified epoxy resin so as to obtain the modified polyurethane prepolymer; further adding a neutralizer to neutralize, adding water, subsequently dispersing by using a high-speed dispersing machine so as to obtain a modified waterborne polyurethane dispersoid; uniformly dripping acrylate monomer, a modified rosin resin and an initiating agent so as to obtain a modified waterborne polyurethane dispersoid; further adding a defoaming agent, and finally adding a curing agent additionally so as to obtain the modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The pressure-sensitive adhesive prepared through the method is high in primary adhesion property, release force, adhesion lasting property and high-temperature adhesion lasting property; a high-temperature-resistant pressure-sensitive adhesive tape prepared from the adhesive can meet the requirements of automobile and electronic industries. According to the invention, the preparation process is simple, the production period is short and the operation cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Adhesive tape used for solar cell assembly and preparation method thereof

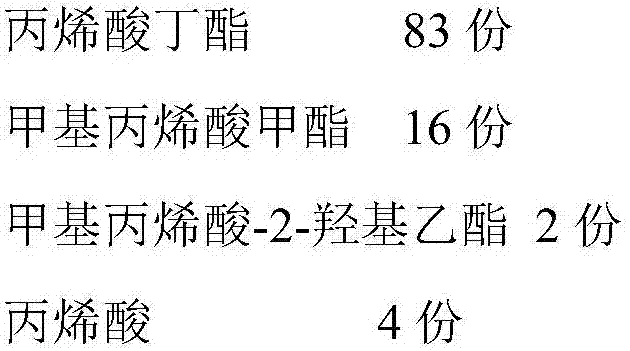

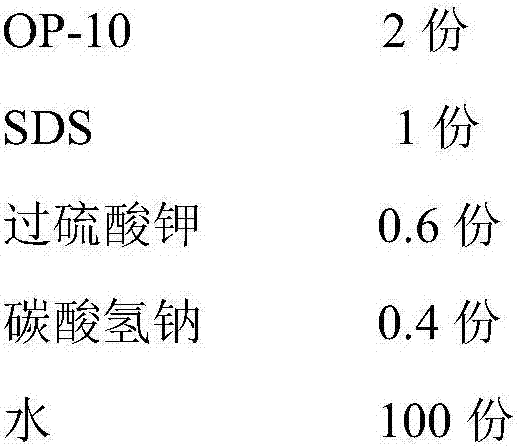

InactiveCN102816536AGood adhesionGood initial tackFilm/foil adhesivesEster polymer adhesivesAmmonium sulfateEmulsion

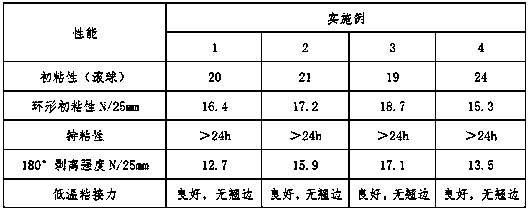

The invention relates to a double-sided adhesive tape, and specifically relates to the double-sided adhesive tape used for a solar cell assembly and a preparation method thereof. The double-sided adhesive tape comprises a substrate, an adhesive, a backlining and backlining glue, wherein the adhesive mainly comprises the following components of, by weight, 0.5-1 part of ammonium sulfate, 5-10 parts of methyl methacrylate, 55-65 parts of butyl acrylate, 20-30 parts of hydroxymethyl acrylamide, 1-2 parts of a composite emulsifier, 60-70 parts of a tackifying resin, 0.2-0.8 part of acrylic acid, 1-2 parts of hydroethyl methacrylate, 1-1.5 parts of 2-acrylamide-2-methylpro panesulfonic acid and 1-3 parts of 3-(methacryloxy)propyltrimethoxysilane. The preparation method comprises the steps of firstly pre-preparing a high-strength organosilicone and acrylate co-polymeric emulsion pressure-sensitive adhesive; and then performing operations of double roll reverse coating, drying, compositing, transferring and the like with a B-50 multifunctional coating machine, wherein both the font side and the back side of the backlining of the substrate are already coated by a layer of low-adhesivity backlining glue.

Owner:SUZHOU DATONG ADVANCED MATERIAL

Hot-melting pressure-sensitive adhesive for PVC (Polyvinyl Chloride) plastic floor tiles and preparation method thereof

InactiveCN101831263AIncrease stickinessLow costMineral oil hydrocarbon copolymer adhesivesPetroleum resinAntioxidant

The invention discloses a hot-melting pressure-sensitive adhesive for PVC (Polyvinyl Chloride) plastic floor tiles, comprising the following components in parts by weight: 5-10 parts of thermoplastic elastomer SBS792, 20-25 parts of thermoplastic elastomer SIS4211, 5-10 parts of petroleum resin ESCOREZ5020, 20-30 parts of petroleum resin ESCOREZ1000, 15-20 parts of petroleum resin ESCOREZ5000, 10-15 parts of rubber softening oil KN4010 and 0.2-0.5 part of composite antioxidant. The invention also discloses a preparation method of the PVC hot-melting pressure-sensitive adhesive. The hot-melting pressure-sensitive adhesive has better cohesive force and better initial viscosity even in winter; compared with an imported product, the hot-melting pressure-sensitive adhesive has low price and properties completely meeting the requirements.

Owner:江苏光辉粘合科技有限公司

Polybutadiene rubber modified waterborne polyurethane adhesive and preparation method thereof

ActiveCN103409101AIncrease elasticityImprove low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymer science

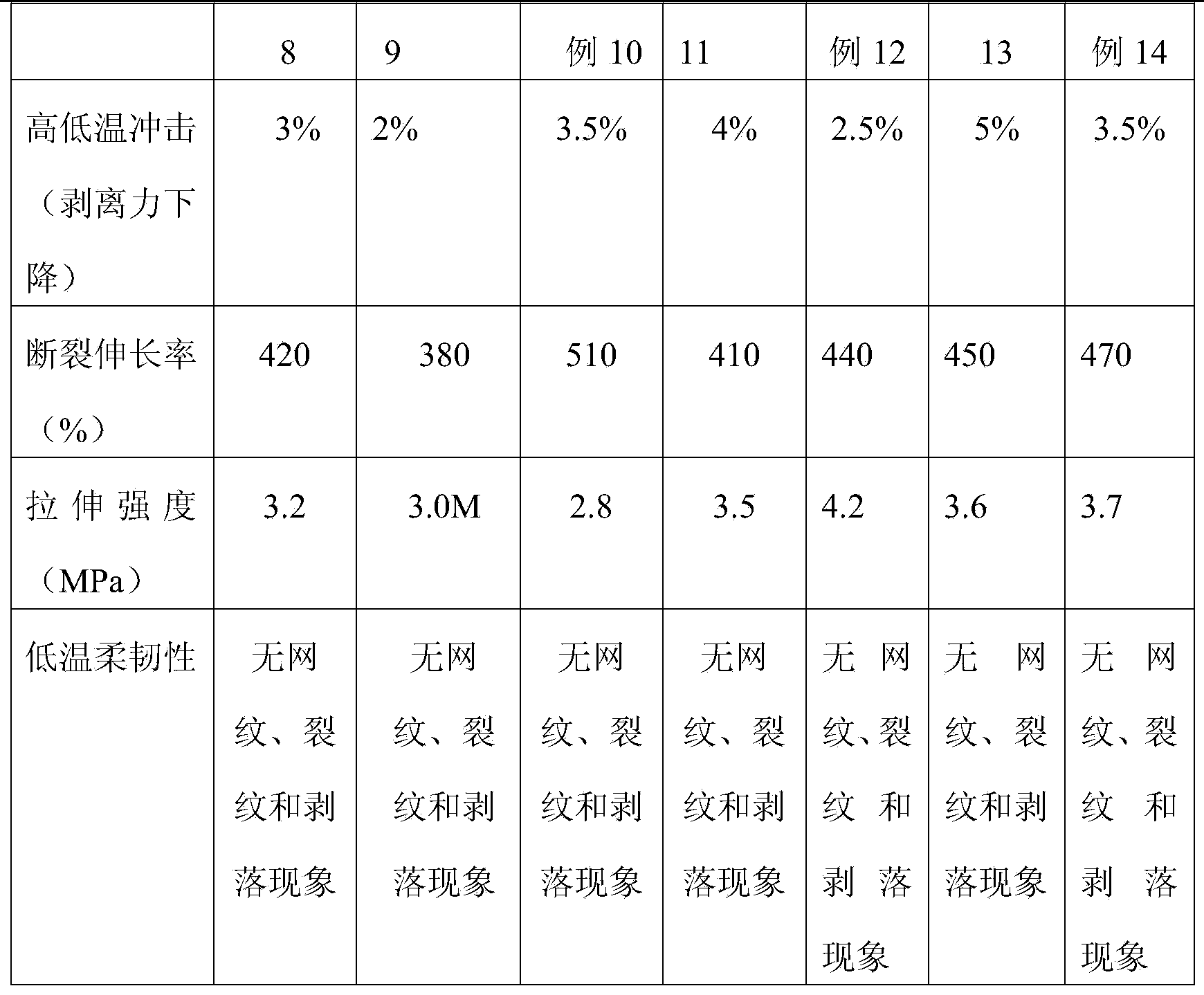

The invention discloses a polybutadiene rubber modified waterborne polyurethane adhesive and a preparation method thereof, which belong to the field of waterborne polyurethane adhesives and are used for solving the problems that an existing polybutadiene rubber modified waterborne polyurethane adhesive is high in thermal activation temperature, low in solid content and poor in primary viscosity and peeling strength. In order to solve the problems, the adhesive disclosed by the invention comprises the following components in parts by weight: 75-100 parts of polybutadiene rubber modified waterborne polyurethane, 3-5 parts of white carbon black, 0.2-0.5 part of 3-amino propyl triethoxysilane, 0.15-0.3 part of waterborne thickening agent, 8-15 parts of plasticizer and 3-7 parts of waterborne curing agent. The invention further provides a preparation method of the polybutadiene rubber modified waterborne polyurethane adhesive. After the adhesive disclosed by the invention is adhered with a sample and impacted for 5 cycles at a high-low temperature between -65 DEG C and 120 DEG C, the peeling strength is reduced by not more than 5%, the elongation at break is as high as 380%-510%, and the tensile strength is as high as 2.8 MPa-4.2MPa.

Owner:CHANGCHUN SANHUA IND

Preparation method of hydrosilylation/free radical dual-crosslinking organic silicon pressure-sensitive adhesive

InactiveCN103305179AGood initial tackIncrease stickinessNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitiveChemistry

The invention discloses a preparation method of a hydrosilylation / free radical dual-crosslinking organic silicon pressure-sensitive adhesive and relates to a preparation method of an organic silicon pressure-sensitive adhesive. The invention aims at solving the technical problem that the existing method for preparing organic silicon pressure-sensitive adhesive cannot be used for preparing a high-performance organic silicon pressure-sensitive adhesive with initial adhesion performance and permanent adhesion performance, high peel strength, a board using temperature range and a remarkable moisture-resistant anti-ageing effect. The preparation method of the hydrosilylation / free radical dual-crosslinking organic silicon pressure-sensitive adhesive comprises the following steps of: firstly, weighing materials; secondly, preparing condensed adhesive liquor; thirdly, preparing un-cross-linked organic silicon pressure-sensitive adhesive liquor; fourthly, preparing hydrosilylation / free radical dual-crosslinking organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive glue prepared by the preparation method disclosed by the invention can be applied in the fields of aviation, spaceflight, machinery, electronics, boats and the like.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Polyurethane adhesive and preparation method thereof

ActiveCN107858133AExcellent reworkabilityReduce tanglingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane elastomerMasterbatch

The invention provides a polyurethane adhesive and a preparation method thereof. The polyurethane adhesive is prepared from the following components in percentage by mass: 1.6 to 11.4 percent of hydroxyl polyurethane elastomer, 0 to 3.5 percent of flexibilizer, 0 to 2.8 percent of polymer modifier, 0.1 to 2.8 percent of reinforcing agent, 0 to 1.5 percent of aid and 88 to 97 percent of organic solvent. The adhesive has the advantages of low solid content, good rework ability, high initial viscosity, high peel strength, high shearing strength, good wettability and low cost of a substrate and the like; in addition, the adhesive has good high-temperature washing resistance, bending resistance and heat-resisting aging when being used for adhering shoe soles to vamps. The invention also provides the preparation method of the polyurethane adhesive; the preparation method comprises the steps of preparing polyurethane elastomer masterbatch, dissolving and the like; the process is simple.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Rosin modified composite resin and preparation method

InactiveCN102532495AReduce dosageGood initial tackPolyester coatingsPolymer scienceResin-Based Composite

The invention discloses a rosin modified composite resin, which comprises the following raw materials in part by weight: 60 to 80 parts of rosin, 3 to 10 parts of conjugated polyprotic acid, conjugated polyanhydride or mixture of conjugated polyprotic acid and conjugated polyanhydride, 8 to 18 parts of polyol, 0.3 to 2 parts of pre-antioxidant, and 5 to 25 parts of vegetable oil, fatty acid or mixture of vegetable oil and fatty acid. The preparation method disclosed by the invention is to prepare rosin modified composite resin with high toughness, excellent film forming leveling property, high weather resistance and less pollution by subjecting raw materials to addition, esterification, ester exchange and other special modification reactions to increase the weather resistance and oxidation resistance of a resin structure. The preparation method can reduce production cost and environment pollution, and solve the problems of medium brittleness, poor leveling property, low weather resistance, and the like.

Owner:NANJING HALIMA CHEM

Double-component aqueous adhesive for automotive interior and preparation method of double-component aqueous adhesive

ActiveCN110272705AHigh bonding strengthImprove heat resistancePolyureas/polyurethane adhesivesEpoxy resin adhesivesEpoxyHydrophilic monomer

The invention discloses a double-component aqueous adhesive for an automotive interior and a preparation method of the double-component aqueous adhesive. The adhesive is a double-component aqueous adhesive of which a component A is synthesized by firstly introducing sulfonate to a polyurethane prepolymer molecular chain from an oligomer polyhydric alcohol, a nonionic hydrophilic monomer, a polyisocyanate, a micromolecule chain extender, a sulfonate-containing hydrophilic chain extender or a polyhydric alcohol with a sulfonic group, adding certain amounts of a silane coupling agent and an epoxy resin, carrying out uniform stirring, adding water, carrying out stirring emulsification, adding an amino type chain extender, an epoxy group and -NCO after emulsification, and by carrying out a reaction so as to obtain a polyurethane emulsion with amino; a component is an aqueous epoxy resin; the component A and the component B are mixed according to a certain ratio; and an aqueous thickening agent is additionally used to adjust the viscosity of the emulsion to form a novel adhesive system for bonding automotive interior materials. The double-component aqueous adhesive has the characteristics of being good in primary viscosity, thermal resistance and environment change resistance stability and free of smell, and use requirements on the automotive interior materials can be met.

Owner:YANTAI UNIV

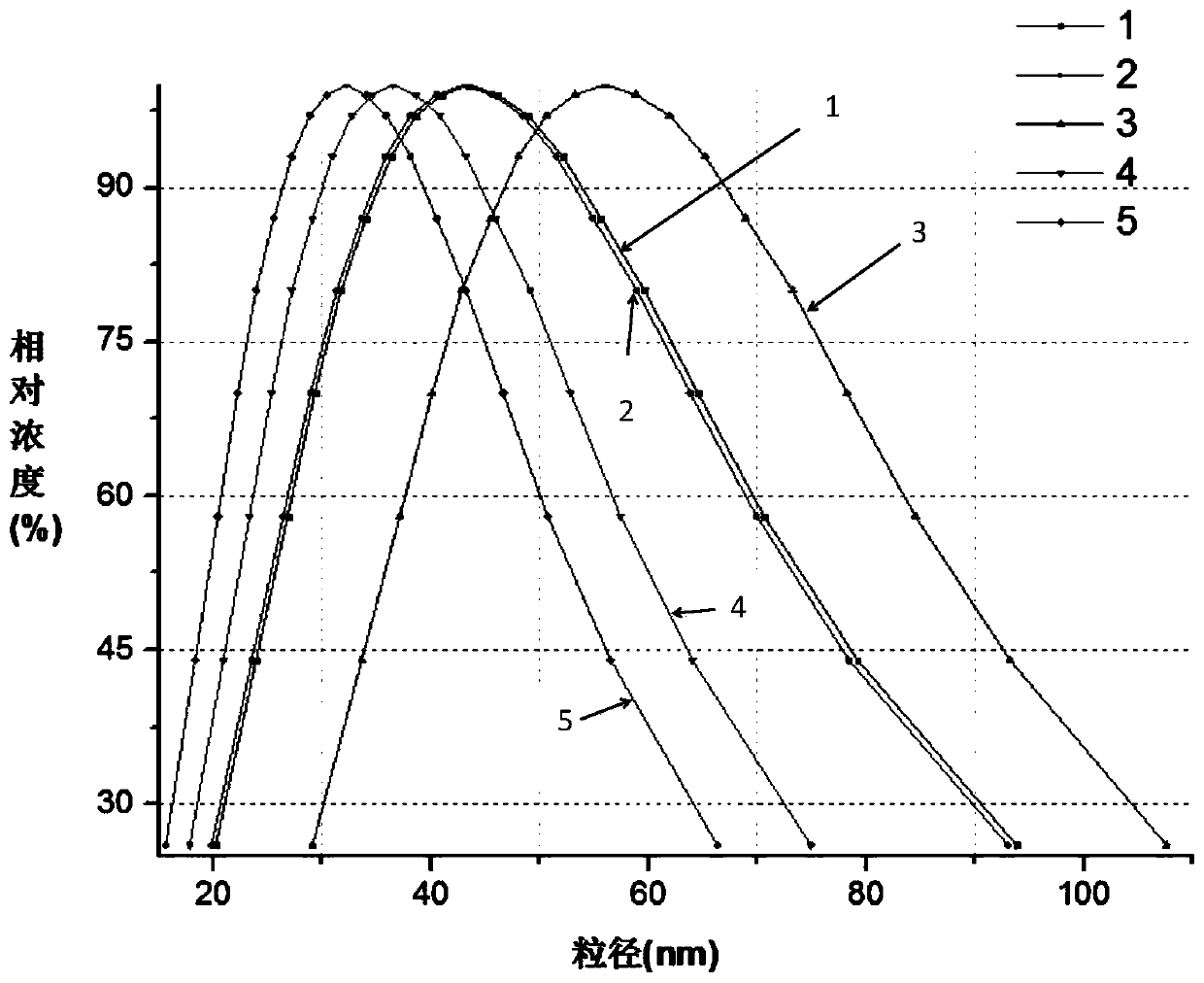

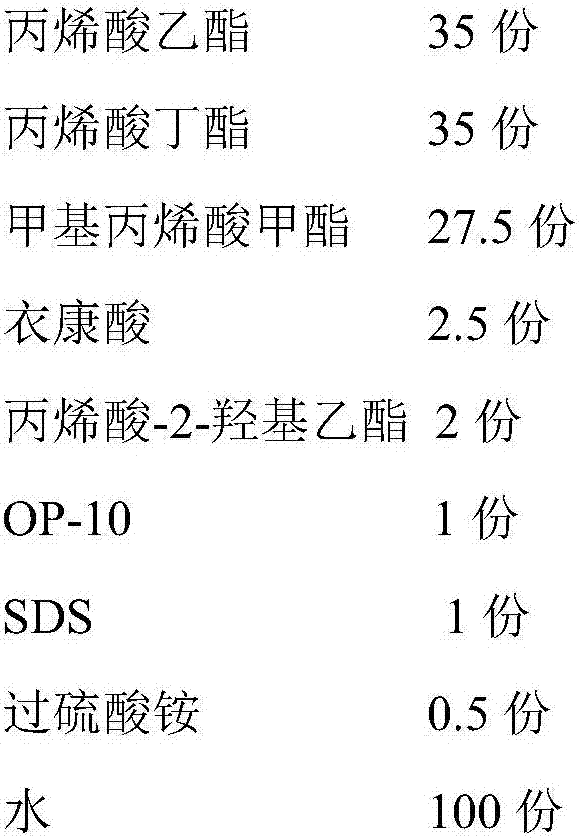

Preparation method of polystyrene-acrylate core-shell composite emulsion

The invention discloses a preparation method of a polystyrene-acrylate core-shell composite emulsion, belongs to the emulsion preparation field, and solves the problems of adhesion resistance, poor heat resistance and the like of a thermoplastic polystyrene-acrylate random copolymer in the prior art. The preparation method is as follows: 1, weighing raw materials; 2, adding distilled water into a reactor, heating up, adding a compound emulsifier, a pH buffer and then part of a mixed vinyl monomer for emulsifying, adding part of an initiator, heating up to react until no reflux exists to obtain a seed emulsion; 3, continuing heating up, dripping off the rest of the mixed vinyl monomer, synchronously adding part of the initiator, after the dripping of the part of the initiator, keeping warm to obtain a core structure emulsion; 4, dripping a mixed acrylate monomer to the core structure emulsion, in the mixed monomer dripping process, adding part of the initiator, after dripping of the part of the initiator, adding the rest of the initiator, keeping warm, then cooling, adding ammonia water, stirring, further cooling, and filtering. The preparation method is applied in the fields of wood veneering, interior decoration, textiles and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Composite transfer adhesive for high-brightness reflective fabric and preparation method thereof

ActiveCN103881630AGood initial tackImprove cohesive strengthGraft polymer adhesivesAdhesive cementPolymer science

The invention discloses a composite transfer adhesive for a high-brightness reflective fabric. The composite transfer adhesive is prepared from raw materials comprising the following components in parts by weight: 50-70 parts of acrylate soft monomer, 10-40 parts of acrylate hard monomer, 3-12 parts of acrylate functional monomer, 0.2-1 part of initiator and 180-190 parts of solvent. The invention also discloses a preparation method of the composite transfer adhesive. The composite transfer adhesive has the beneficial effects that only low-toxicity ethyl acetate is adopted to serve as a solvent; the composite transfer adhesive for the high-brightness reflective fabric is synthesized by adopting a graft copolymerization method, so that high initial stickness is kept, and the holding power is greatly improved; the rubbing resistance and washing resistance applied to the high-brightness reflective fabric are far higher than those of random copolymer. A method for adding the initiators in batches is adopted, and the influence on the product performance in a traditional dripping mode due to the inconsistent dripping speed is avoided.

Owner:中节能(达州)新材料有限公司

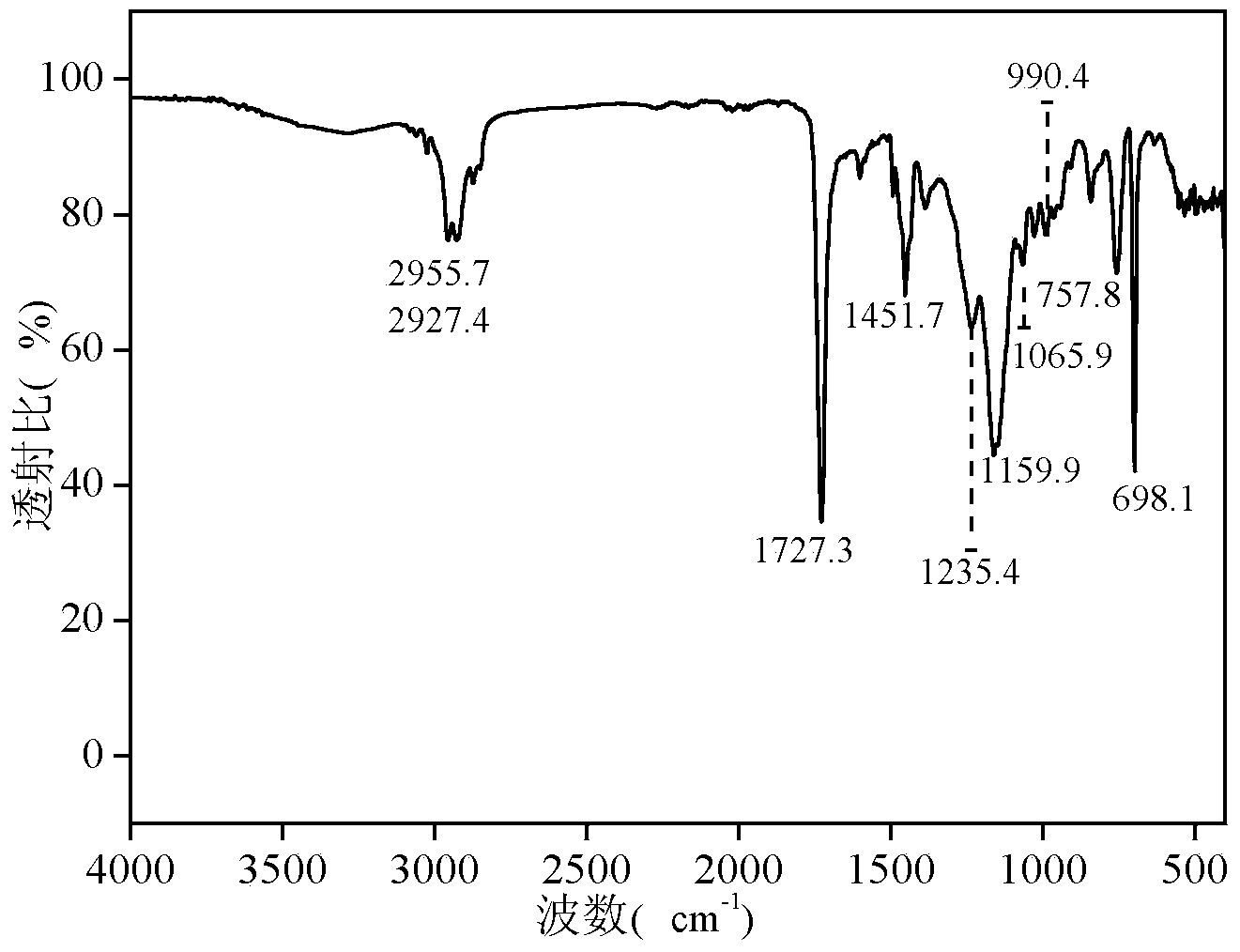

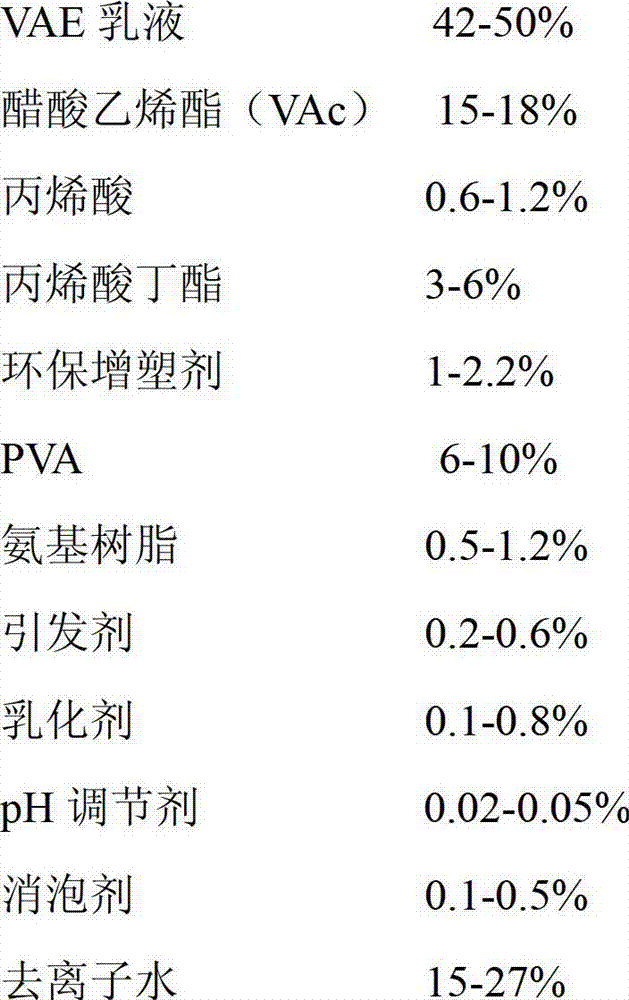

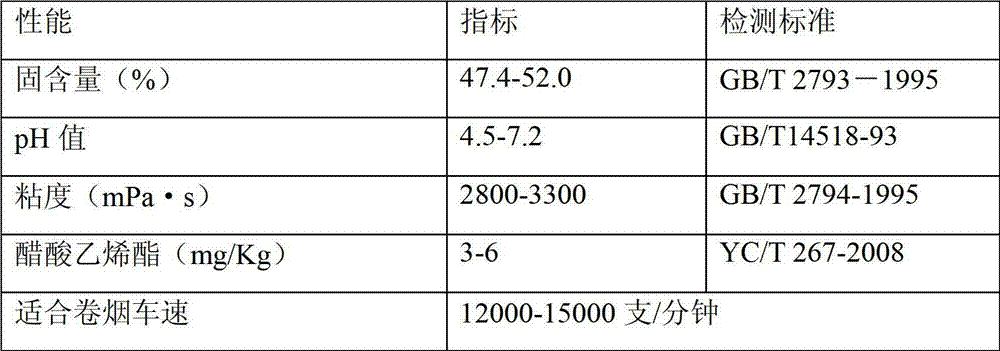

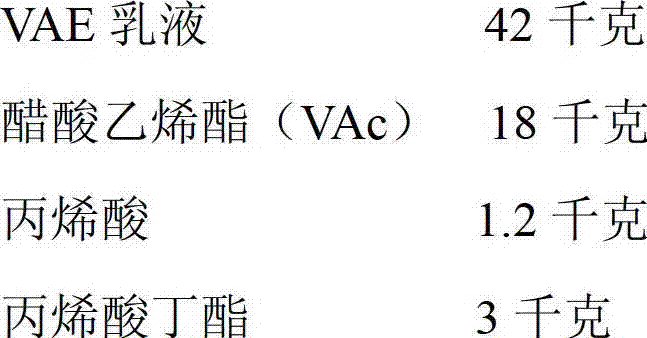

Environment-friendly high-speed cigarette holder glue for cigarettes and preparation method thereof

ActiveCN103045136AResidue reductionImprove initial tack performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCarvacryl acetateBond strength

The invention discloses environment-friendly high-speed cigarette holder glue for cigarettes and a preparation method thereof. The environment-friendly high-speed cigarette holder glue adopts VAE emulsion as a base material; and vinyl acetate, acrylic acid and butyl acrylate are added to implement polymerization and modification; plasticizer adopts environment-friendly plasticizer; and hydroxyl of PVA is sealed end by using amino resin. The obtained high-speed cigarette holder glue hardly contains aldehydes materials and phthalates materials which are harmful to human bodies; the monomer residual volume of vinyl acetate is low; the solid content is in a range of 47.4-52.0 percent; and the viscosity is in a range of 2,800-3,300 mPa / s; the glue has excellent early adhesiveness, bonding strength and water resistance, and is suitable for high-speed cigarette making machines with the speed of 12,000-15,000 piece / minute.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Solvent type repair adhesive special for ancient Chinese ink cultural relics and preparation thereof

InactiveCN101503612AMaintain propertiesReinforcedProtein adhesivesGlue/gelatin preparationPotassium persulfateButyl acetate

The invention relates to an adhesive special for solvent-based ancient ink and a preparation method thereof, and belongs to an adhesive for protecting and restoring ancient ink cultural relics. The adhesive comprises the following components by weight percentage: 8 to 11 percent of gelatin, 25 to 30 percent of water, 45 to 50 percent of butyl acetate, 5 to 7 percent of acrylonitrile, 5 to 7 percent of butyl acrylate, 0.2 to 0.4 percent of zinc oxide nano-powder (treated), 3 to 5 percent of emulsifier (span-80), and 0.1 to 0.3 percent of initiator (ammonium persulfate or potassium persulfate). The adhesive is a repair adhesive special for the ancient ink, which is solvent-based, has good compatibility with a body material of the ancient ink, strong affinity, and no damage phenomena such as swelling, dissolution and the like, and has the characteristics of higher adhesive strength, aging resistance, mildew proofing and antibacterium and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

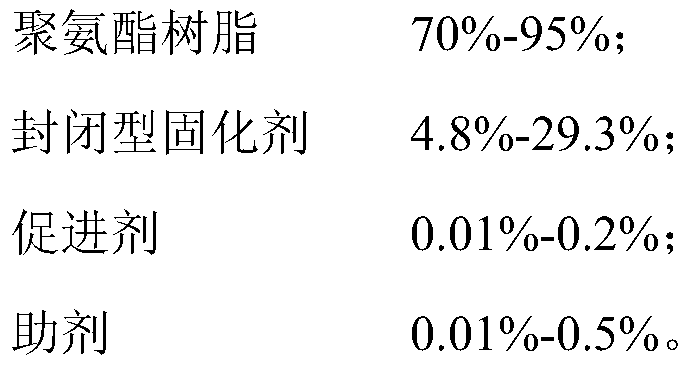

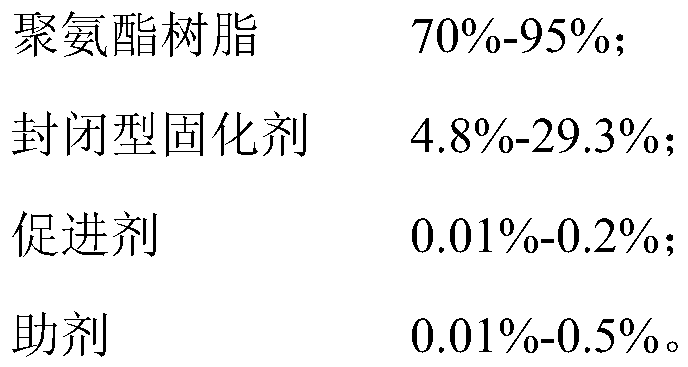

Latent single-component polyurethane hot melt adhesive, preparation method thereof and adhesive film

ActiveCN111100592AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention relates to the field of polymer adhesives, in particular to a latent single-component polyurethane hot melt adhesive, a preparation method thereof and an adhesive film. The latent single-component polyurethane hot melt adhesive comprises the following components (by weight): 70%-95% of polyurethane resin, 4.8%-29.3% of a closed curing agent, 0.01%-0.2% of an accelerant, and 0.01%-0.5% of an auxiliary agent. The latent single-component polyurethane hot melt adhesive disclosed by the invention has good bonding strength, heat resistance, hydrolysis resistance and the like; the preparation method is simple in process, low in cost and high in preparation efficiency, and has a prospect in industrial production; a latent single-component polyurethane adhesive film obtained by curingthe latent single-component polyurethane hot melt adhesive has good initial adhesion, excellent final adhesion and storage stability; and the product can be widely used in woodworking, textile, outdoor clothing, automobiles, electronics, household appliances and other industries.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

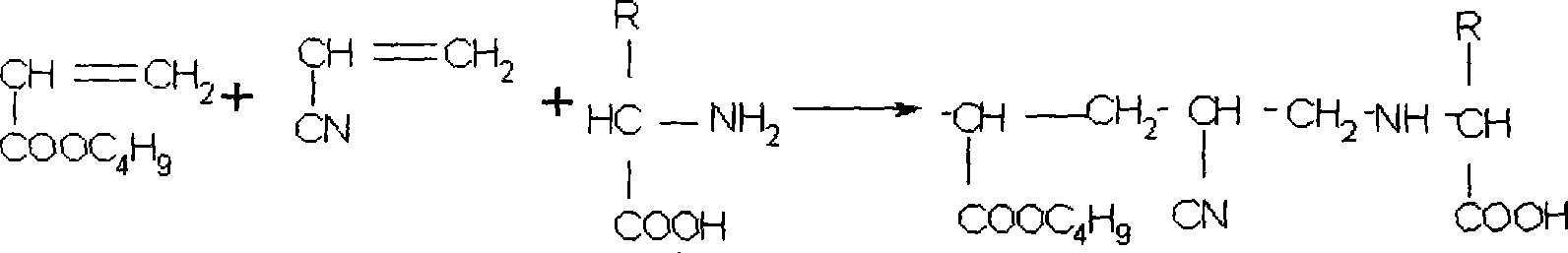

Polymer dispersion comprising particles of polyurethane and a copolymer or terpolymer produced by emulsion polymerization of olefinically unsaturated monomers

InactiveUS6924336B2Reduce usageImprove balanceOrganic non-macromolecular adhesiveCellulose adhesivesAdhesiveCrystallinity

A polymer dispersion comprising an aqueous, continuous phase and dispersed particles of polyurethane, which is based on organic, non-aromatic isocyanates with a functionality of at least 2, said polyurethane having a high degree of crystallinity and whose crystalline phase has a melting point between 25 and 70° C., and a copolymer and / or terpolymer having a Tg (glass transition temperature) between −20 and +50° C. obtainable by emulsion polymerization of ethylenically unsaturated monomeric materials containing only C, H, O and / or N atoms, which monomeric materials comprise from 0.5 to 15 percent on the total of monomeric materials of monomers containing at least one nitrile group, in a weight ratio between 50:50 and 10:90 (polyurethane to emulsion polymer), in which the particles of the dispersion are in the form of multiphase particles comprising said polyurethane and said copolymer and / or terpolymer and which dispersion is obtainable by emulsion polymerization of the monomeric materials in the presence of the polyurethane dispersion, said eventual polymer dispersion having a solids content of 30 to 70%. The invention also comprises the use of these dispersions as an adhesive, especially for heat seal laminating, preferably for 3-D(imensional) Laminating. The dispersion is also useful as a size for glass fibers.

Owner:CELANESE INT CORP

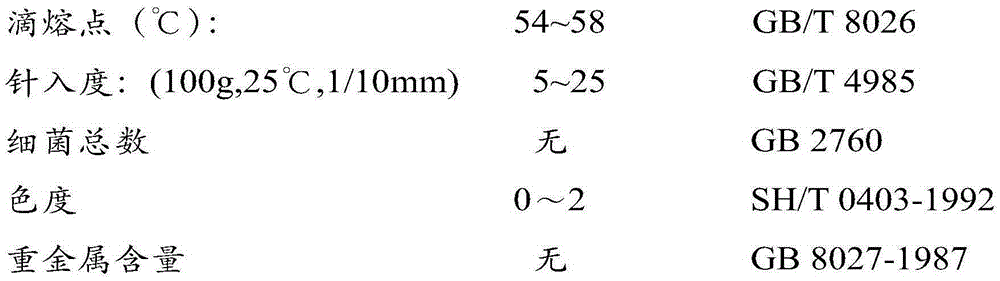

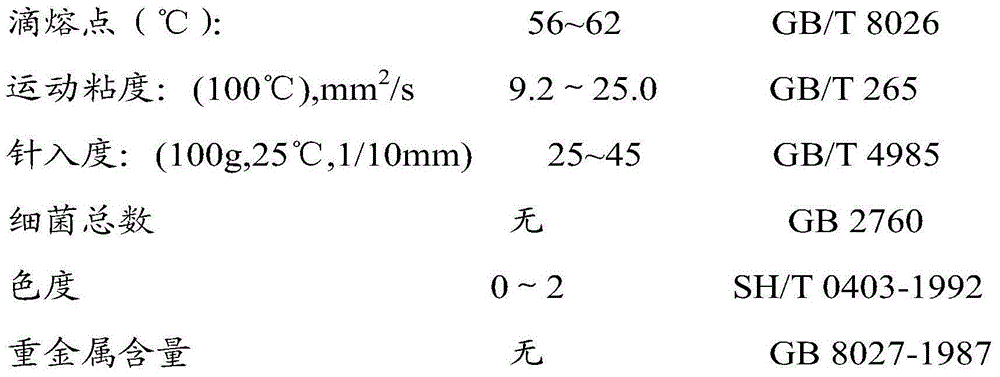

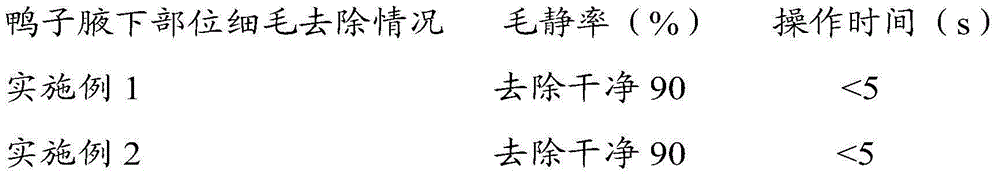

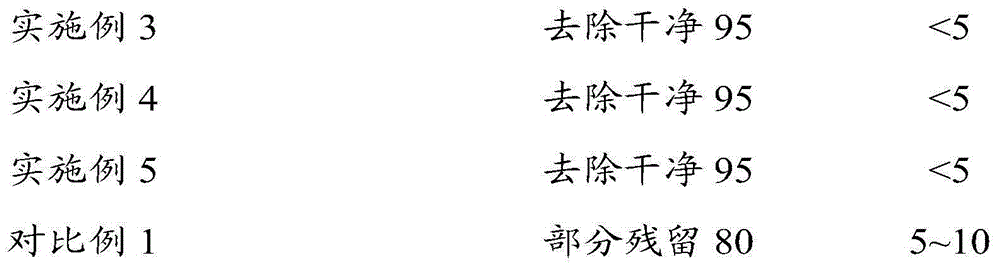

Solid depilatory wax for human bodies, and preparation method thereof

The invention relates to a depilatory wax, and concretely provides a solid depilatory wax for human bodies, and a preparation method thereof. The solid depilatory wax for human bodies comprises a tackifier, a plasticizer, a flexibilizer, a film forming agent, a stabilizer and a waxy substance. The preparation method of the solid depilatory wax comprises the following steps: heating the waxy substance for fusing, adding the tackifier, the plasticizer, the flexibilizer, the film forming agent and the stabilizer, and stirring until uniform mixing. The solid depilatory wax for human bodies has good adhesion, good film forming ability and good toughness, so the solid depilatory wax has a high depilation effect, has a very good removal effect on hair in positions difficult to process, such as underarm hair and bikini hair; and the solid depilatory wax for human bodies also has the advantages of good peeling effect, no skin sticking, and convenient and fast operation. The method has the advantages of simple process, convenient operation, and convenience for large scale production.

Owner:GUANGZHOU DEXIN WAX PROD

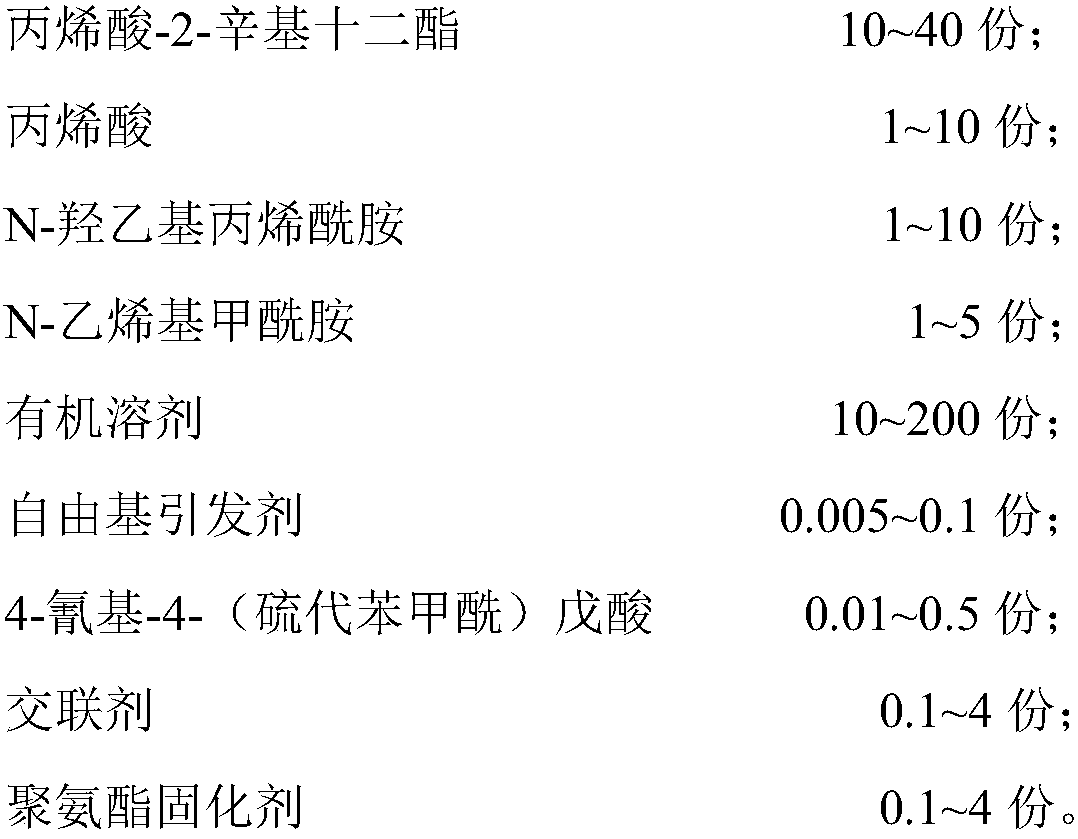

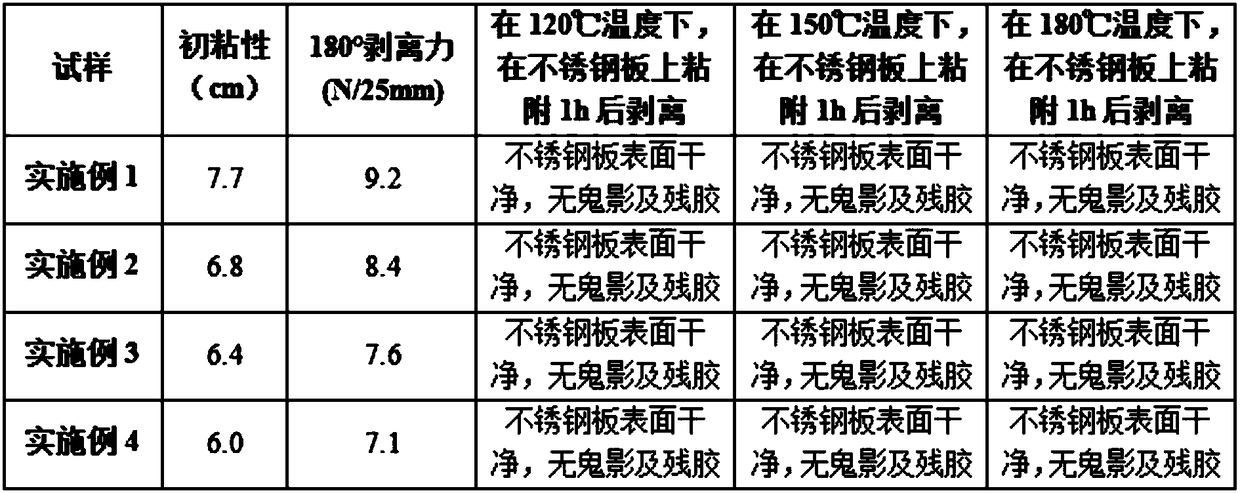

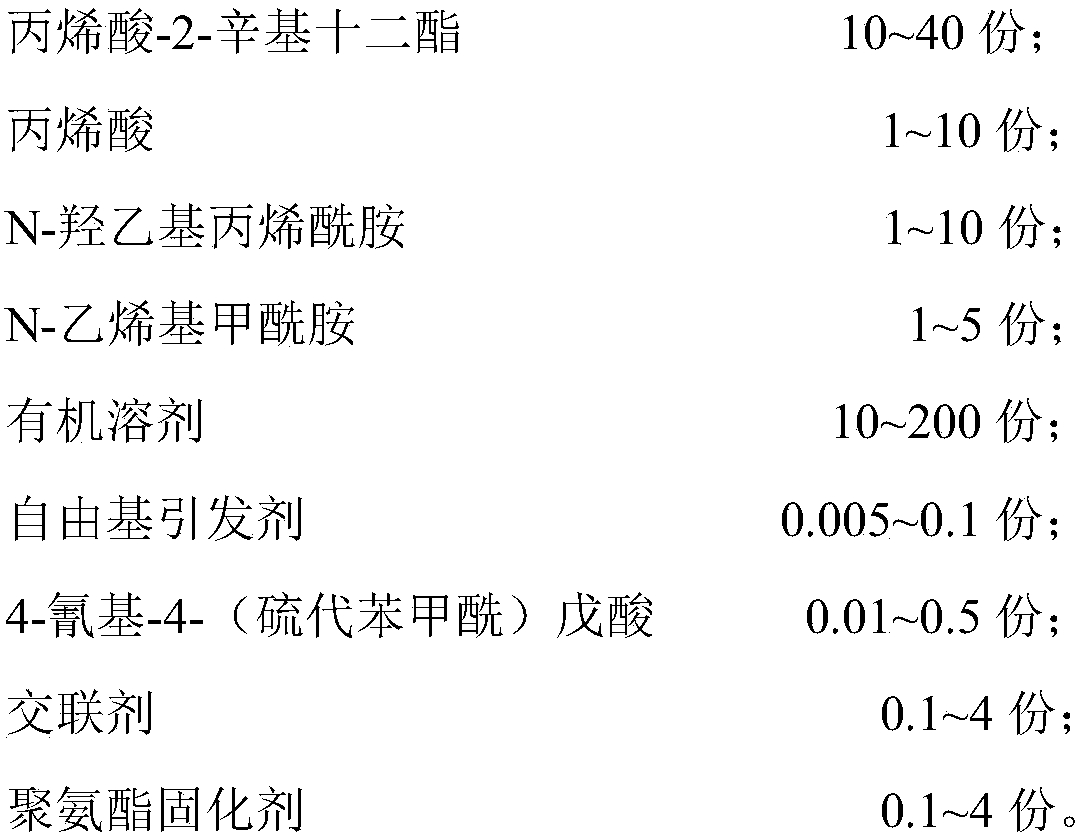

High temperature resistant pressure sensitive adhesive with excellent performance, pressure sensitive adhesive tape and preparation method thereof

ActiveCN108559427AExcellent compatibility and adaptabilityGood initial tackAmide/imide polymer adhesivesEster polymer adhesivesPressure sensitiveMonomer

The invention discloses a high temperature resistant pressure sensitive adhesive with excellent performance. By utilizing the compounding of acrylic-2-octyldodecyl ester and N-vinylformamide, a high temperature resistant monomer and an adhesion promoting function monomer have an efficient synergistic effect and exhibit excellent compatibility and adaptability, other raw material components are further adjusted to obtain a higher degree of adaptation, and a controlled active polymerization method (RAFT polymerization) is adopted for polymerization reaction to obtain the high temperature resistant pressure sensitive adhesive with excellent performance; the number-average molecular weight Mn of the high temperature resistant pressure sensitive adhesive is 50,000-500,000, the molecular polydispersity coefficient is 1.0-1.3, the glass transition temperature Tg is -45-5 DEG C, and the technical problems of poor high temperature resistance and poor stability of a traditional solvent-based acrylic pressure sensitive adhesive are effectively solved. The invention further discloses a preparation method of the pressure sensitive adhesive and a pressure sensitive adhesive tape using the same and a preparation method thereof.

Owner:GUANGDONG DONGLI NEW MATERIALS SCI & TECH CO LTD

Waterproof and highly-elastic foamable pure acrylic emulsion, and foamed material prepared therefrom

The invention discloses a waterproof and highly-elastic foamable pure acrylic emulsion, and a foamed material prepared therefrom. The pure acrylic emulsion with good washability and excellent viscoelasticity is synthesized through a pre-emulsifying semi-continuous seed emulsion polymerization method by selecting the kinds of a soft monomer, a hard monomer and a functional monomer and adjusting the ratio of the monomers. The synthesized emulsion has the characteristics of good initial viscosity, high solid content, good washability and high resiliency after being foamed and combined, can be used as a polyurethane substitute, can be used in carpet flocking and car foot mats, and has a high demand.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Epilating wax for living stock and preparation method of epilating wax

The invention provides epilating wax for the living stock and a preparation method of the epilating wax and belongs to the technical field of food processing auxiliaries. The epilating wax for the living stock is mainly prepared from a tackifier, a plasticizer, a flexibilizer, a film-forming agent, a stabilizer and a wax substance. The wax substance is heated and melted, then the tackifier, the plasticizer, the flexibilizer, the film-forming agent and the stabilizer are added to the wax substance, stirred and mixed uniformly, and accordingly, the epilating wax for the living stock is prepared. The epilating wax for the living stock has good adhesive force, good film-forming performance, good rigidity and high epilating rate, has a good removal effect on feather or fur at parts where the feather or fur is difficult to deal with, such as fine feather under winds, and also has a good peeling effect, and efficient epilating can be realized at higher operation efficiency of a worker or a wax peeling machine. The method is simple in process and convenient to operate and facilitates large-scale production.

Owner:广东德馨新材料科技股份有限公司

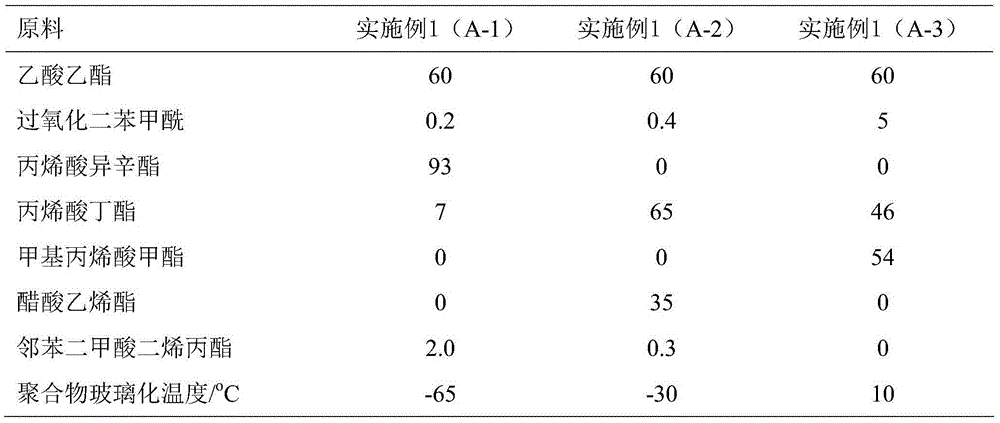

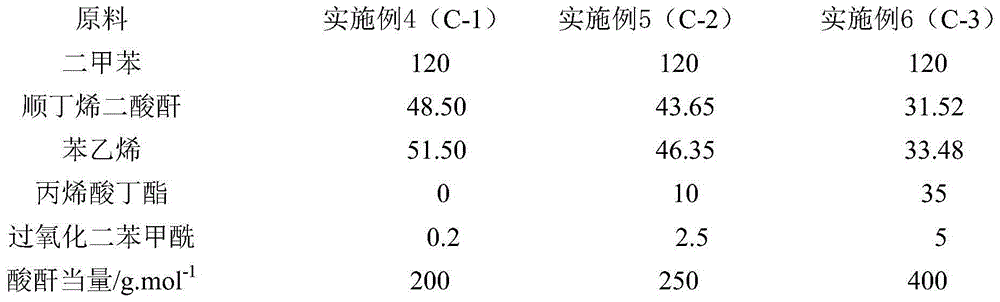

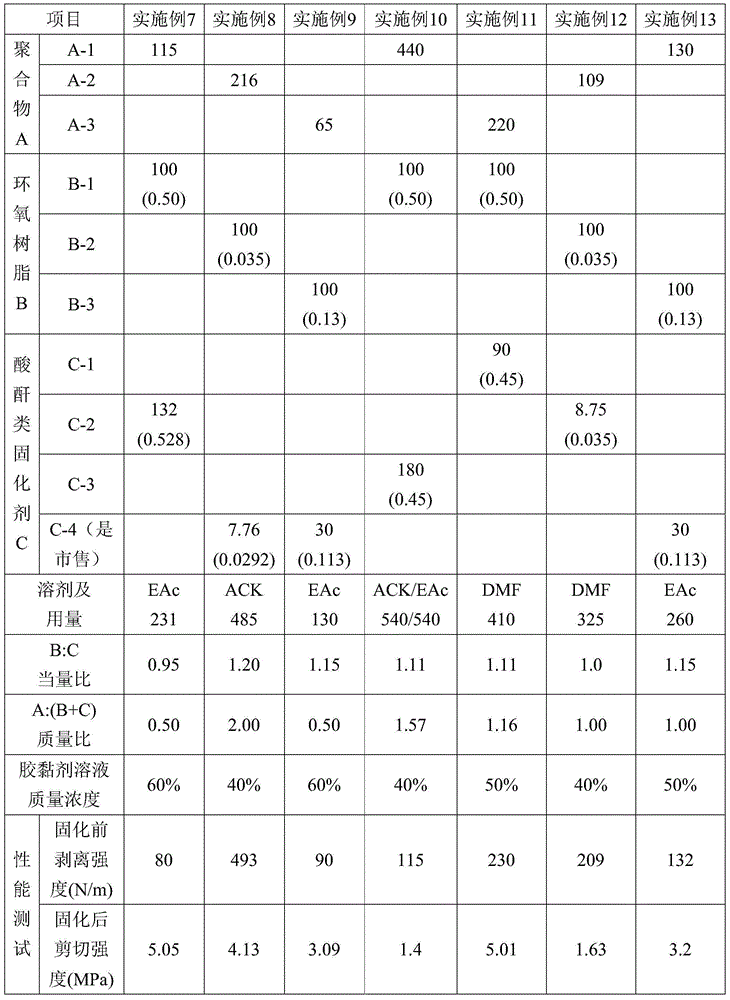

Self-curing polyacrylate-epoxy resin adhesive as well as preparation method and application of self-curing polyacrylate-epoxy resin adhesive

InactiveCN103980847AGood initial tackHigh bonding strengthEster polymer adhesivesEpoxy resin adhesivesSolventGlass transition

The invention discloses a self-curing polyacrylate-epoxy resin adhesive as well as a preparation method and application of the self-curing polyacrylate-epoxy resin adhesive. The preparation method comprises the steps of (1) weighing a polyacrylic polymer (A) with the glass transition temperature of 65 DEG C below zero to 10 DEG C, epoxy resin (B) and an acid anhydride curing agent (C), wherein the molar ratio of (B) to (C) is 0.95-1.2, and the mass ratio of (A) to (B+C) is 0.5-2.0; (2) dissolving (A), (B) and (C) into a solvent to prepare a solution with the mass concentration of 40-60%. The self-curing polyacrylate-epoxy resin adhesive disclosed by the invention has favorable initial adhesion at normal temperature and can be cured after being applied to a high-temperature environment so as to have favorable bonding strength. The method disclosed by the invention is simple in preparation. The adhesive is independently packaged so as to be convenient to use.

Owner:TIANJIN UNIV

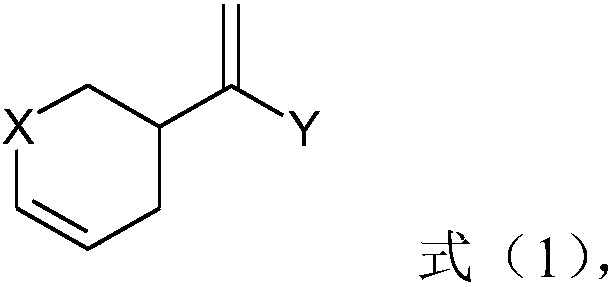

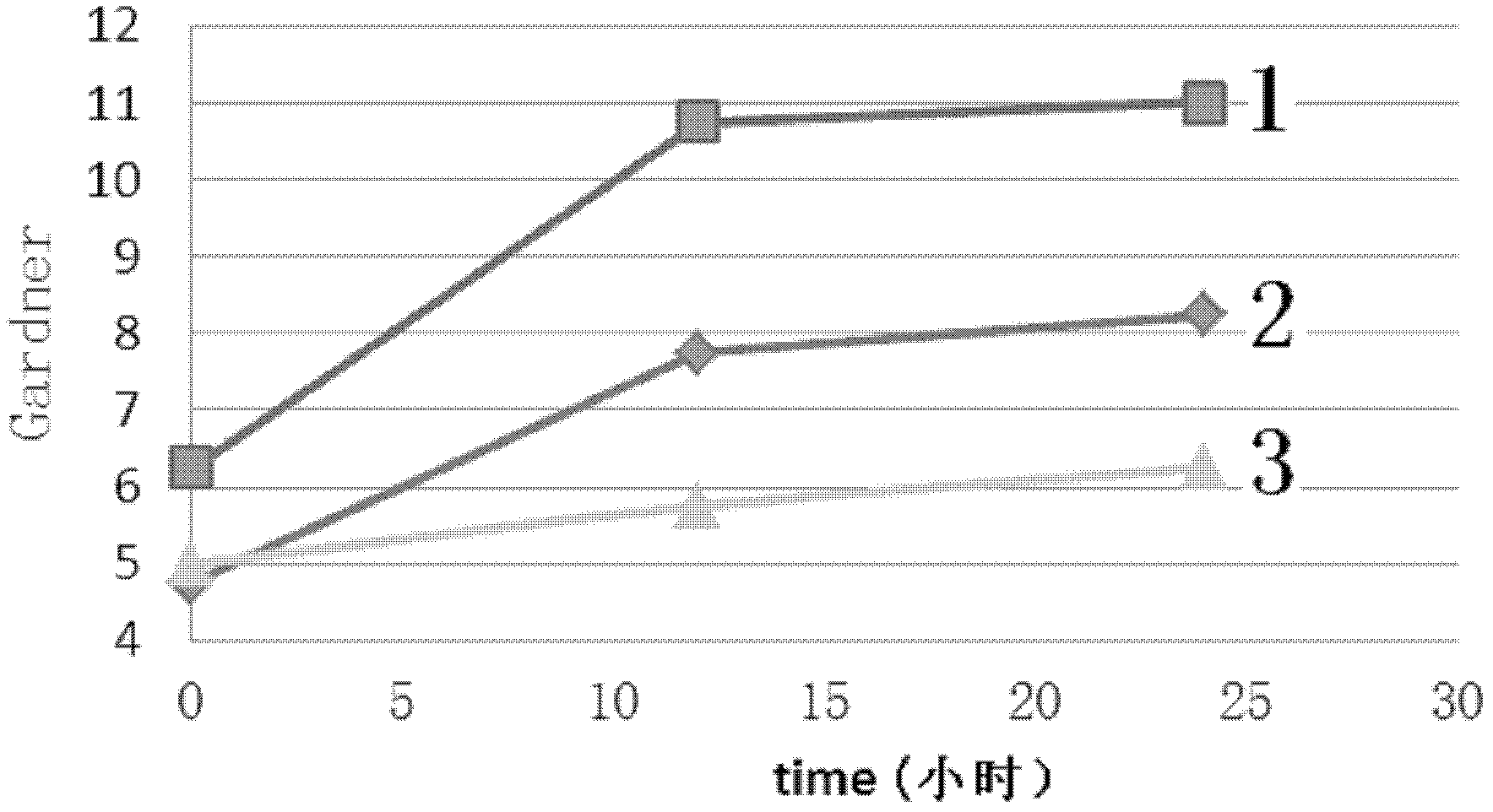

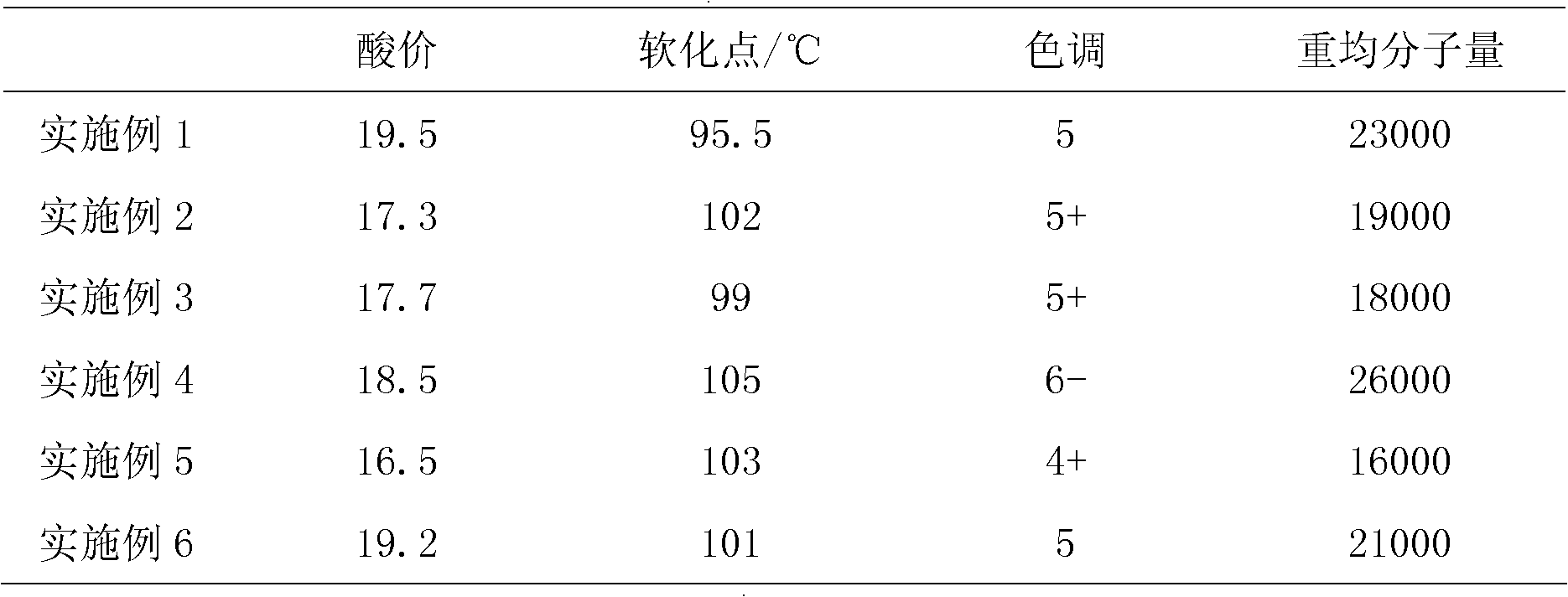

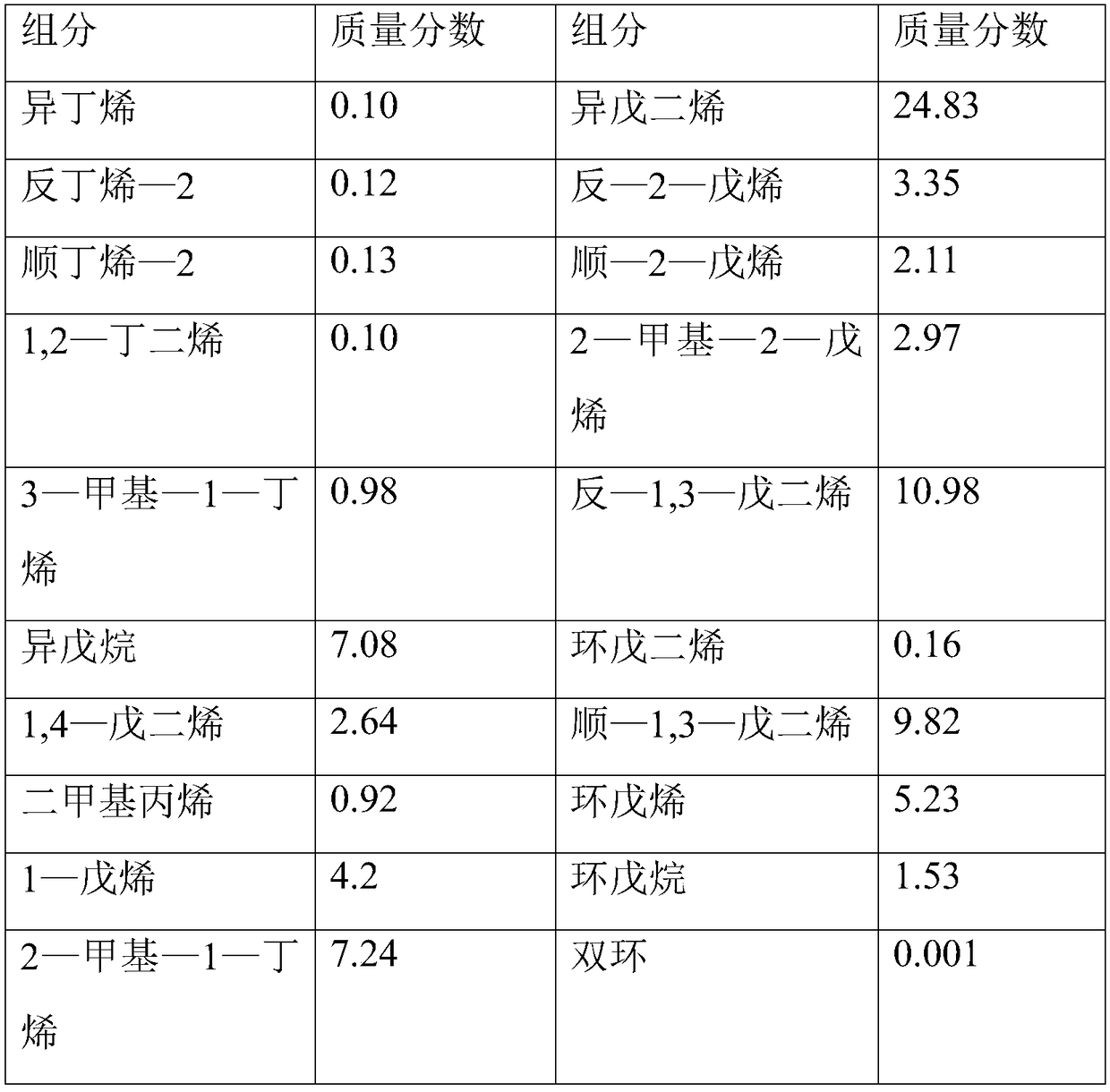

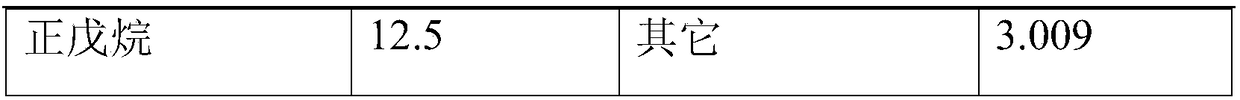

Preparation method of light-color modified petroleum resin with low softening point

The invention belongs to the technical field of petroleum resin, and particularly relates to a preparation method of light-color modified petroleum resin with low softening point. The preparation method of the light-color modified petroleum resin with low softening point comprises the following steps of pretreating the byproduct of C5 fraction twice to remove cyclopentadiene and dicyclopentadiene,so as to obtain a mixture which has lower content of cyclopentadiene and contains multiple types of diolefin, monoolefine and alkene, wherein the C5 fraction byproduct is produced in the petroleum cracking process for preparing the ethylene; selecting one or multiple of aromatic vinyl monomers as a polymer modifying agent, selecting a compound catalyst, enabling the olefin in the C5 fraction andthe aromatic vinyl monomers to generate polymerizing reaction under the certain polymerizing condition, effectively controlling the heat of the polymerizing reaction, and slowly performing the reaction, so as to prepare the light-color modified petroleum resin with low softening point with the advantages of stable quality, excellent property and moderate molecular weight.

Owner:PUYANG RUISEN GASOLINEEUM RESINS +1

Waterborne polyurethane adhesive composition and preparing method thereof

InactiveCN105482765AImprove water resistanceHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a waterborne polyurethane adhesive composition and a preparing method thereof. The composition is prepared from, by weight, 40-70 parts of modified polyurethane, 2-8 parts of a flatting agent, 1.5-4 parts of a waterborne wetting agent, 1-5 parts of a filling agent, 0.5-2 parts of a penetrating agent, 2-6 parts of a curing agent, 10-15 parts of waterborne cosolvent, 4-20 parts of a crosslinking agent, 3-10 parts of an antioxidant and 2-5 parts of fire retardant. The waterborne polyurethane adhesive composition is high in bonding strength, initial bonding strength and peeling strength and has dirt resistance, flame retardance and other good properties, and meanwhile the preparing method is simple in process and low in cost.

Owner:潘庆辉

Adhesive resin for aluminum ceiling

ActiveCN111117524AGood compatibilityIncrease polarityCovering/liningsSynthetic resin layered productsPolymer scienceReaction speed

The invention discloses an adhesive resin for an aluminum ceiling. According to the adhesive resin for the aluminum ceiling, high impact polystyrene (HIPS) is introduced into a formula system, so thatseparation between polar and non-polar materials in the adhesive resin is effectively improved; the bonding reaction speed is favorably improved; and the styrene-isoprene-styrene copolymer (SIS) is further introduced and can be matched with HIPS to greatly improve the infiltration effect on aluminum, and the overall compatibility of the system is enhanced, so that the material has good initial adhesion performance in the processing process, and the adhesion speed and the adhesion strength are improved.

Owner:HEYUAN PLG MATERIALS

Production method of modified casein label adhesive

InactiveCN101928531AImprove water resistanceImprove curing speedProtein adhesivesStarch adhesivesAdhesiveCarton

The invention relates to a production method of a modified casein label adhesive, comprising the following steps: firstly, dissolving polyvinyl alcohol in water under high temperature to obtain polyvinyl alcohol solution; secondly, dissolving borax and casein to obtain casein solution; thirdly, gelatinizing corn starch at 80-85 DEG C to obtain gelatinized corn starch; and finally mixing the polyvinyl alcohol solution with the casein solution and stirring the solutions at 70-75 DEG C to react, sequentially adding dispersing agents, gelatinized corn starch, mixed chelating agents, sorbic acid and disodium hydrogen phosphate to reaction solution and obtaining the finished casein label adhesive after uniform mixing. The invention uses two heavy metal salts as crosslinking agents to modify the casein label adhesive, thus effectively improving the water resistance and the curing rate of the casein label adhesive. The modified casein label adhesive can be widely applicable to manual and mechanical label package of the boxes for food, drinks and cigarette, especially to labeling machines of beer.

Owner:NORTHWEST NORMAL UNIVERSITY

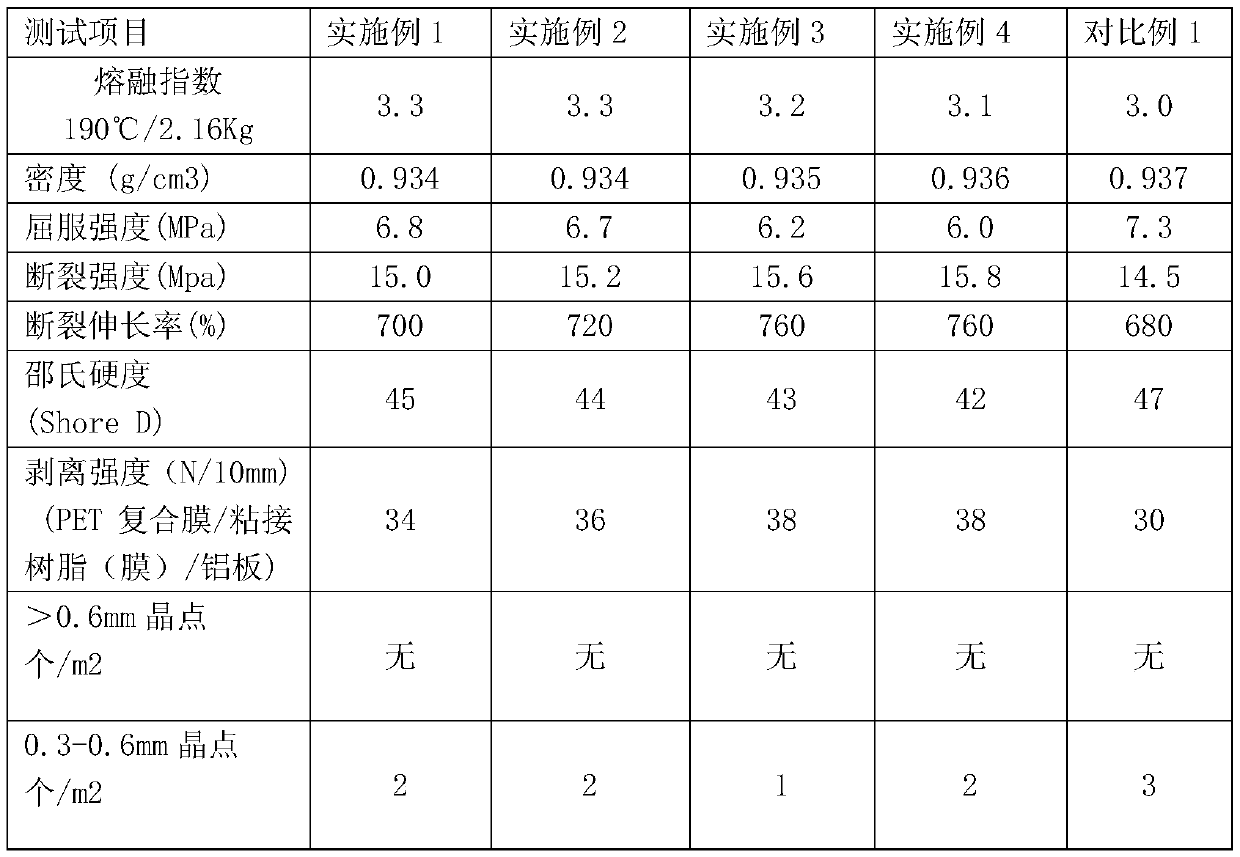

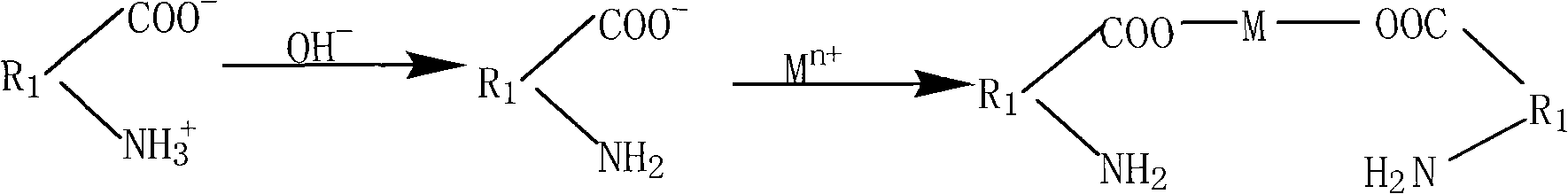

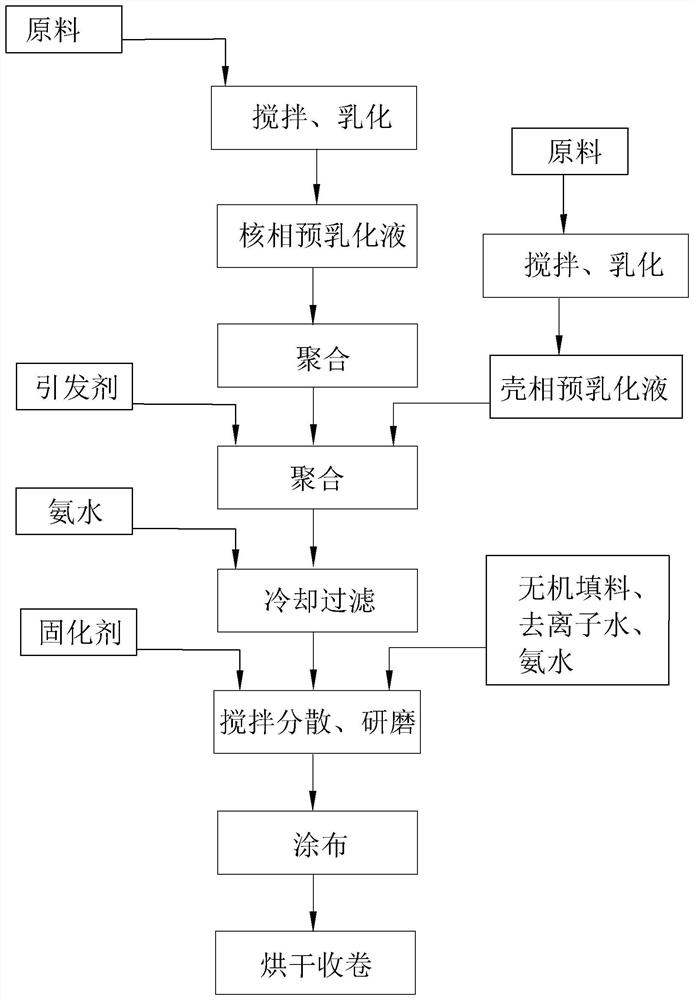

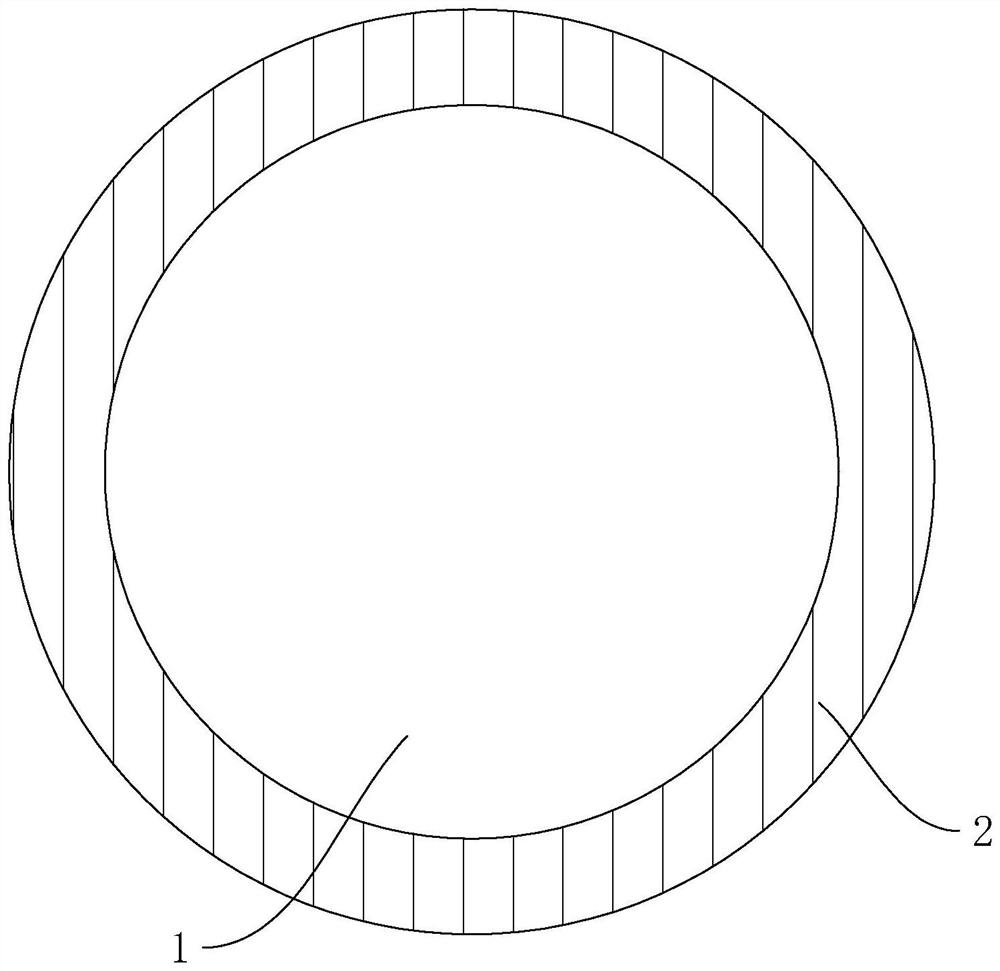

Pure adhesive film with core-shell structure and preparation method thereof

PendingCN113980587AImprove heat resistanceHigh peel strengthFilm/foil adhesives without carriersFilm/foil adhesive release linersPolymer scienceFlexible circuits

The invention relates to the technical field of flexible circuit boards, and particularly discloses a pure adhesive film with a core-shell structure and a preparation method thereof. The preparation method of the polyacrylate pure adhesive film with the core-shell structure comprises the steps: pre-emulsifying to prepare a core-phase pre-emulsion and a shell-phase pre-emulsion, then adding a cross-linking agent, polymerizing to prepare a polymerized emulsion with the core-shell structure, and then adding a curing agent, an inorganic filler and the like to prepare an adhesive; and finally coating a first release film with the adhesive, carrying out thermocompression bonding on the first release film and a second release film, and rolling to obtain the pure adhesive film with the core-shell structure. The prepared pure adhesive film with the core-shell structure has the advantages of high heat-resistant stability and high peel strength, is free of performance defects, is suitable for market popularization and use, and meets market requirements.

Owner:深圳市科泰顺科技有限公司

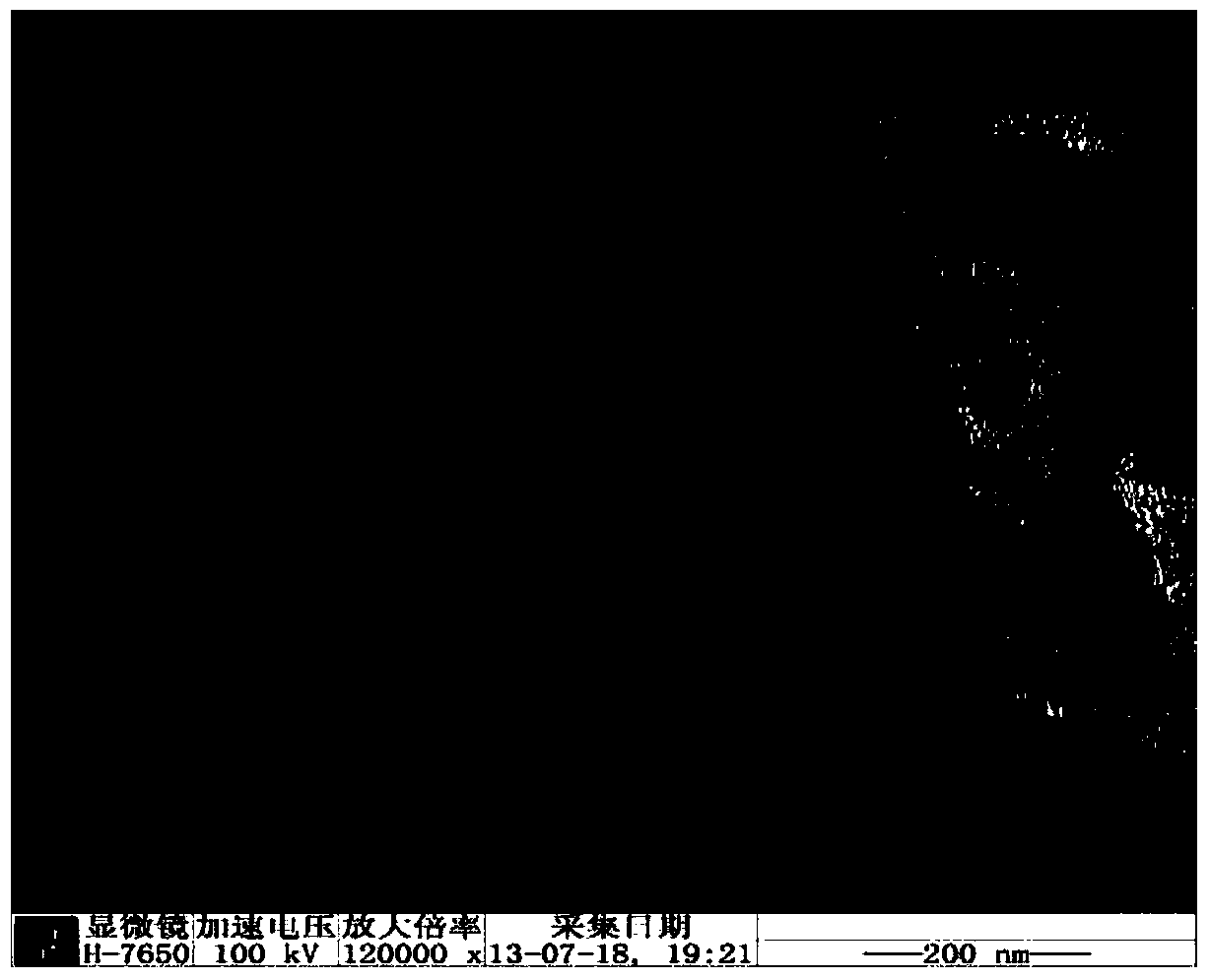

Ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive and preparation method thereof

ActiveCN111187586AGood initial tackGood bonding strengthPressure sensitive film/foil adhesivesGraft polymer adhesivesPolymer scienceFunctional monomer

The invention relates to an ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive. The ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive is prepared from the following rawmaterials in parts by weight: 70-120 parts of an acrylate monomer, 1-5 parts of a functional monomer, 1-5 parts of an internal crosslinking monomer, 1-15 parts of liquid tackifying resin, 0.3-2 partsof an emulsifier, 0.2-1 part of an initiator, 0.05-0.3 part of a reducing agent, 0.05-1 part of a wetting agent, 0.05-1 part of a defoaming agent and 70-130 parts of deionized water. According to theinvention, the submicron liquid tackifying resin is creatively prepared and is used as a seed for emulsion polymerization, and the tackifying resin is wrapped in latex particles, so a special core-shell structure is formed, with a core being the tackifying resin and a shell being polyacrylate; the core and the shell are fused with each other in the process of film forming, so a formed adhesive film has excellent initial adhesion, bonding strength and temperature resistance; and a ratio of the core to the shell is adjustable, a performance range is wide, a new idea is provided for solving the defect of poor comprehensive performance of water-based acrylate pressure-sensitive adhesives, and the adhesive can be popularized and used in a large range.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

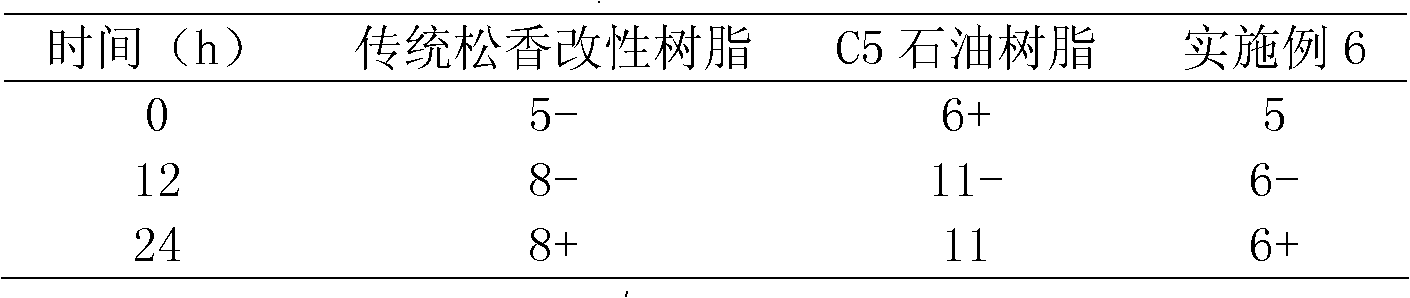

Sulfonic acid type water-based polyurethane pressure-sensitive adhesive and preparation method thereof

InactiveCN109401712AImprove hydrophilicityWell mixedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPolymer science

The invention discloses a sulfonic acid type water-based polyurethane pressure-sensitive adhesive and a preparation method thereof. The sulfonic acid type water-based polyurethane pressure-sensitive adhesive takes a polymer composed of isocyanate, polymer diatomic alcohol, small molecular polyhydric alcohol and a chain extender as a main body of the pressure-sensitive adhesive, takes deionized water as a solvent, is free of toluene and other organic solvents, and is nontoxic, pollution-free and environment-friendly; the chain extender, a stabilizer, a regulator and a blocking agent are also added; a mixture of 8-naphthylamine-1,6-disulfonate sodium, 1,4-bis(butyryloxy)-2-butene and sodium N-tris(hydroxymethyl)methyl-3-aminopropane sulfonate is selected as the chain extender; under combinedaction of the three substances, a good chain extending effect is achieved, the length of a polymer is extended, the structure of the polymer is adjusted, and the chain extender has a synergistic effect with the polymer main body; and meanwhile, the prepared pressure-sensitive adhesive has certain temperature tolerance, the finally prepared pressure-sensitive adhesive has high initial viscosity and strong holding power, and the application range of the water-based polyurethane pressure-sensitive adhesive is greatly extended.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

Heat conduction type polyacrylate pressure-sensitive adhesive and preparation method thereof

InactiveCN107523242AFacilitate cross-linkingImprove water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesMethacrylateCarboxylic salt

The invention discloses a heat conduction type polyacrylate pressure-sensitive adhesive and a preparation method thereof. A polyacrylate emulsion is prepared from components in parts by weight as follows: 40-58 parts of lauryl acrylate, 50-70 parts of ethyl methacrylate, 24-36 parts of 3-methacryloxypropyltrimethoxysilane, 10-15 parts of N-tert-octylacrylamide, 6-9 parts of N-acryloylmorpholine, 6-8 parts of methyl myristate alpha-sodium sulfonate, 9-14 parts of sodium polyoxyethylene lauryl ether carboxylate, 30-50 parts of itaconic acid and 32-45 parts of acrylic acid. The heat conduction type polyacrylate pressure-sensitive adhesive has good heat conduction performance, can transfer heat rapidly, has good initial adhesion and strong holding power, can keep stable performance for a long time and is non-toxic, environmentally friendly and wider in application range.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Antibacterial mould-proof polyurethane dual-component compound adhesive

InactiveCN108034398AImprove antibacterial propertiesImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhosphonium saltAdhesive

The invention discloses an antibacterial mould-proof polyurethane dual-component compound adhesive which is prepared from a component A and a component B, wherein a weight ratio of the component A tothe component B is (80 to 90) to (10 to 20); the component A is prepared from the raw materials in parts by weight: 30 to 45 parts of polyurethane prepolymer, 0.3 to 2 parts of diisononyl phthalate, 0.5 to 3.5 parts of cyclic carbonate, 10 to 25 parts of graphene, 2 to 10 parts of montmorillonite, 30 to 45 parts of carbon black, 1 to 3.5 parts of silver-loaded hydroxyapatite, 0.02 to 0.5 part of antioxidant and 0.2 to 1.5 parts of ultraviolet light absorber; the component B is prepared from the raw materials in parts by weight: 6 to 12 parts of palm oil polyhydric alcohols, 1 to 3 parts of amino silane coupling agent, 2 to 5 parts of stannous octoate, 2 to 10 parts of modified phosphonium salt sterilizing agent, 0.2 to 1.5 parts of rosin resin and 0.3 to 2 parts of triethanolamine. The antibacterial mould-proof polyurethane dual-component compound adhesive disclosed by the invention has the advantages of excellent bonding strength and good antibacterial mould-proof performance.

Owner:阜阳市龙建包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com