Preparation method of light-color modified petroleum resin with low softening point

A low softening point, petroleum resin technology, applied in the field of petroleum resin, can solve the problems of rising softening point of resin, and achieve the effects of easy polymerization, improved resin yield and expensive raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020]A kind of preparation method of light-colored low-softening point modified petroleum resin, comprises the following steps: 1, the preparation of raw material, chooses the by-product C5 fraction of petroleum cracking to make ethylene and refines C5 after pretreatment as raw material; Choose aromatic vinyl monomer One or more of them account for 5% to 50% of the refined C5 raw material in terms of mass percentage as a polymerization modifier; the aromatic vinyl monomer of the polymerization modifier is selected from styrene, α-methylbenzene One or several kinds of aromatic vinyl monomers such as ethylene, p-methylstyrene, ethylstyrene, tert-butylstyrene, etc.; choose a composite catalyst accounting for 0.2-3.0% of the total raw material amount calculated by mass percentage , the composite catalyst is solid AlCl 3 The catalyst is added to the solvent, and the electron donor is added under stirring to form a liquid catalyst; 2. The above raw materials are added to the solven...

Embodiment 1

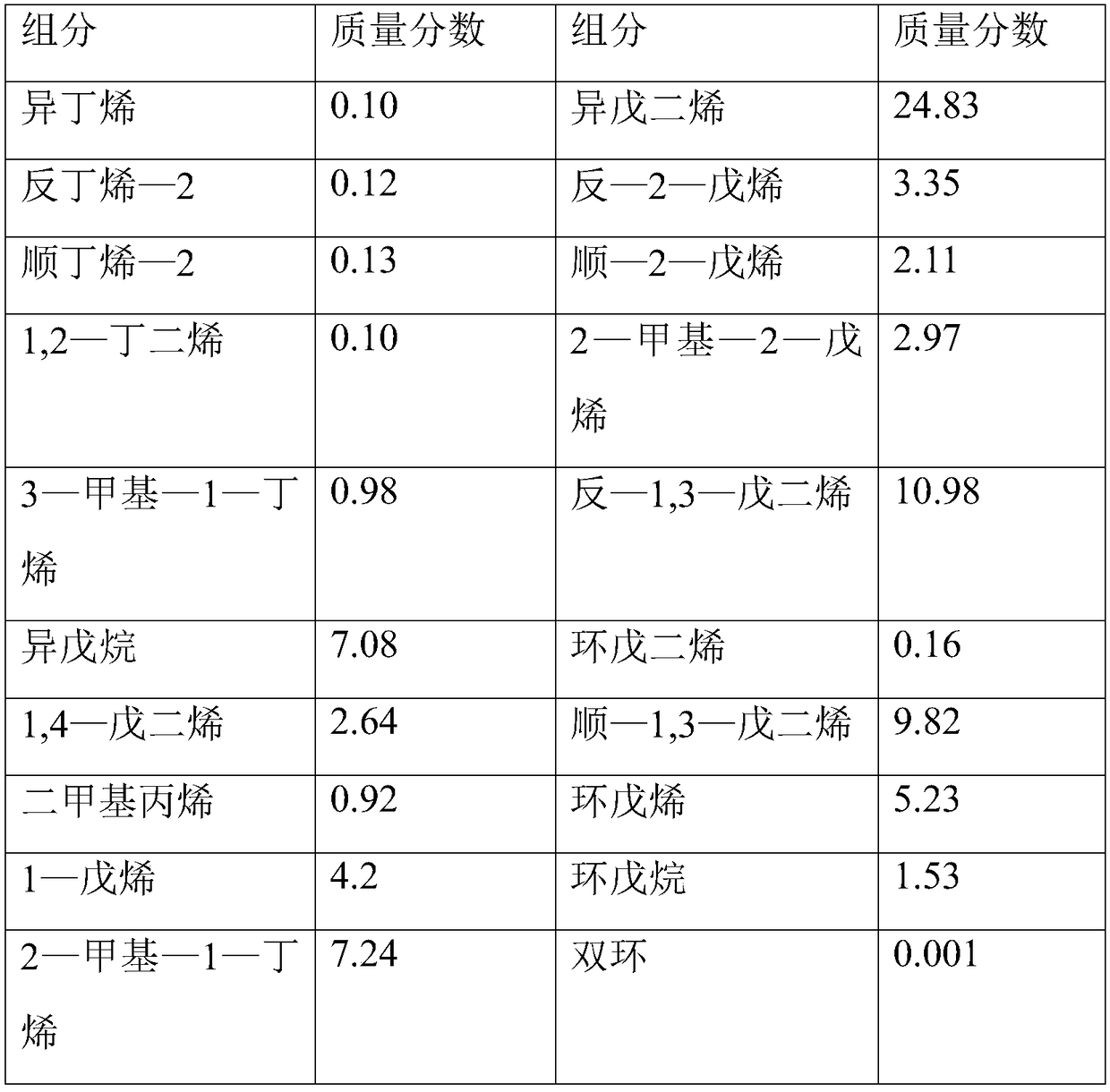

[0024] Add 500 g of xylene and 18 g of self-made composite catalyst in the reaction kettle and stir evenly, then mix 1000 g of the pretreated polymerization raw material C5 cut (see Table 1) and 240 g of methyl styrene and drop them into the catalyst system, and control the dropwise Acceleration, keep the reaction temperature at about 60°C, and the reaction time is 3h; after the reaction, the polymerization liquid is washed twice with water and once with alkali, and the polymerization liquid after removing the catalyst is distilled at 220°C under normal pressure to distill out low-boiling fractions, and then in The oligomer was removed by vacuum distillation at 230°C to obtain a light-colored low softening point modified petroleum resin with a yield of 68%, a color number (Fe-Co) of 2#, a softening point of 21°C and a molecular weight distribution of 1.32. See Table 1 for the composition table of the C5 fraction of the polymerization raw material after pretreatment.

[0025] T...

Embodiment 2

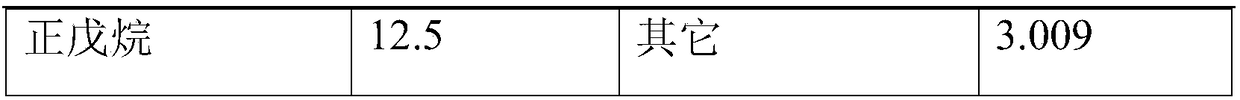

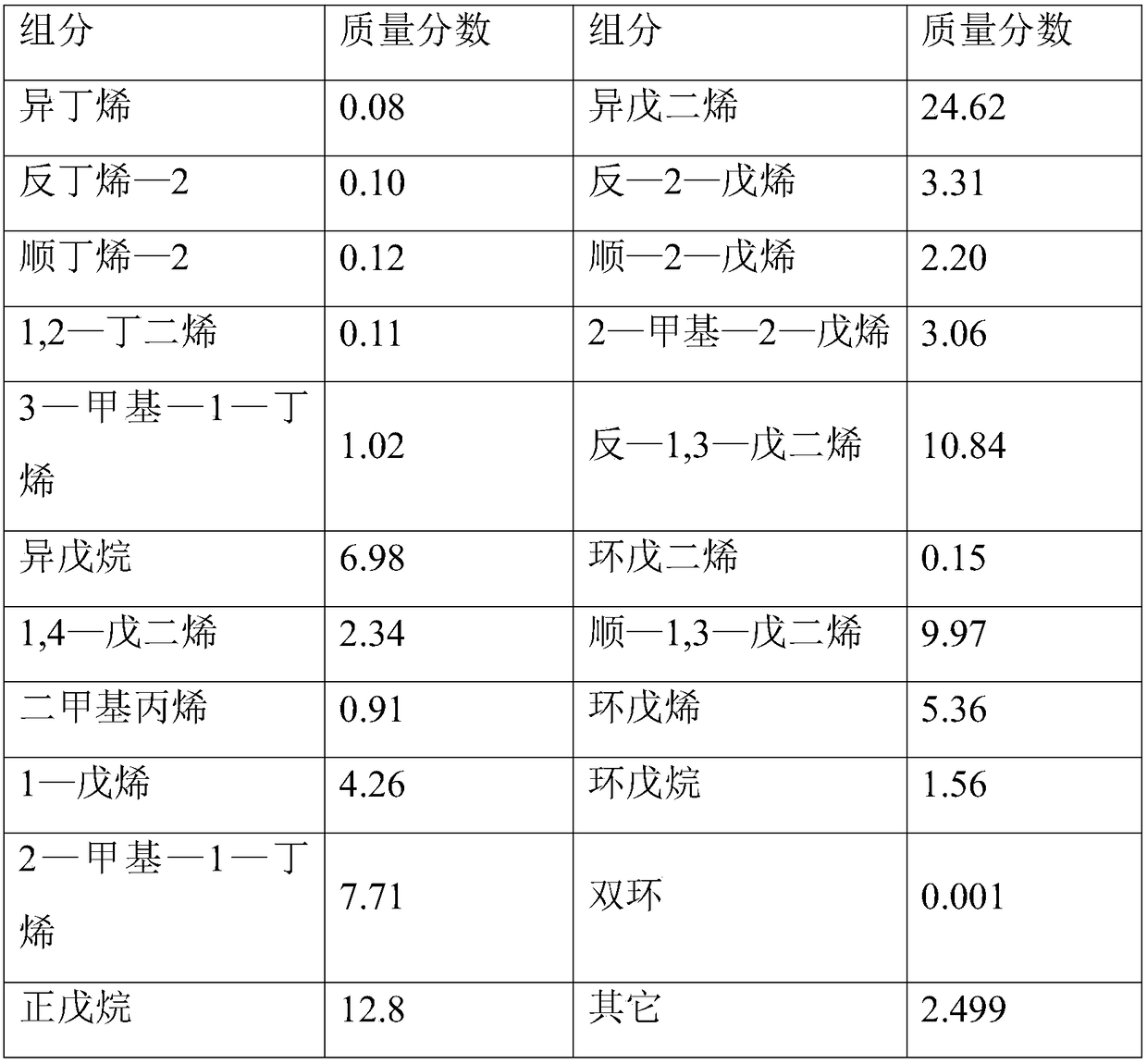

[0029] Add 500 g of xylene and 20 g of self-made composite catalyst in the reaction kettle and stir evenly, then mix 1200 g of the pretreated polymerization raw material C5 fraction (see Table 1) and 240 g of methyl styrene and drop them into the catalyst system, and control the dropwise Acceleration, keep the reaction temperature at about 65°C, and the reaction time is 4h; after the reaction, the polymerization solution is washed twice with water and once with alkali, and the polymerization solution after removing the catalyst is distilled at 220°C under normal pressure to distill out low-boiling fractions, and then in The oligomers were removed by vacuum distillation at 230°C to obtain a light-colored low softening point modified petroleum resin with a yield of 72%, a color number (Fe-Co) of 2#, a softening point of 18°C and a molecular weight distribution of 1.35. See Table 2 for the composition table of the C5 fraction of the polymerization raw material after pretreatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com