Patents

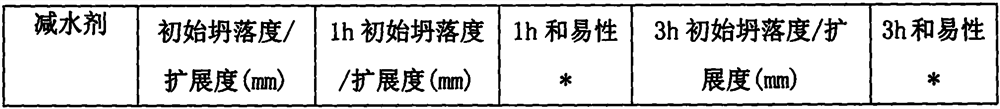

Literature

39results about How to "Moderate molecular weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol soluble polyacrylate resin and preparation method and application thereof

The invention discloses an alcohol soluble polyacrylate resin and a preparation method and an application thereof; the preparation method comprises the following steps: taking 260-800 parts of alcohols solvent, adding the solvent in a reaction kettle with a mixer, a reflux condenser, a heating jacket and a nitrogen covering layer, then heating the system to 70-150 DEG C, mixing the mixture for 10-30min; adding acrylic ester used as hard monomers, acrylic ester used as soft monomers, polar functional group monomers, organosilane monomers and initiator to react for 4-7h and obtain alcohol soluble polyacrylate resin. The alcohol soluble polyacrylate resin prepared by the method of the invention has no excitant odour, the number-average molar mass is 10,000-200,000, the molecular weight distribution is 1.1-4 and the Brookfield viscosity of the resin system is 100-5000cp. The coating which is prepared by mixing the resin with other pigments, fillers and assistants can be applied in glass, aluminium coil and polypropylene plastic for surface decoration and protective function.

Owner:SOUTH CHINA UNIV OF TECH

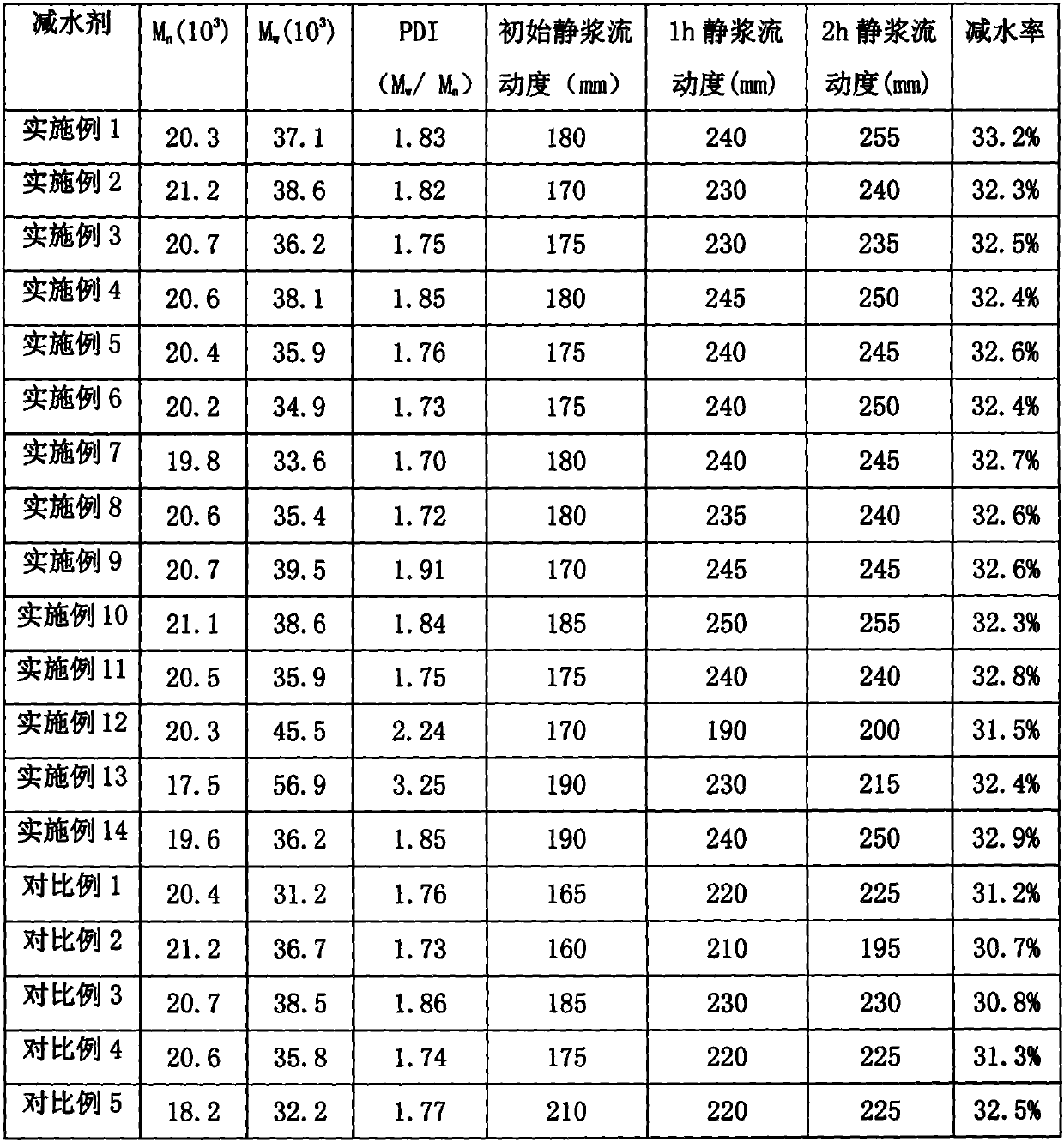

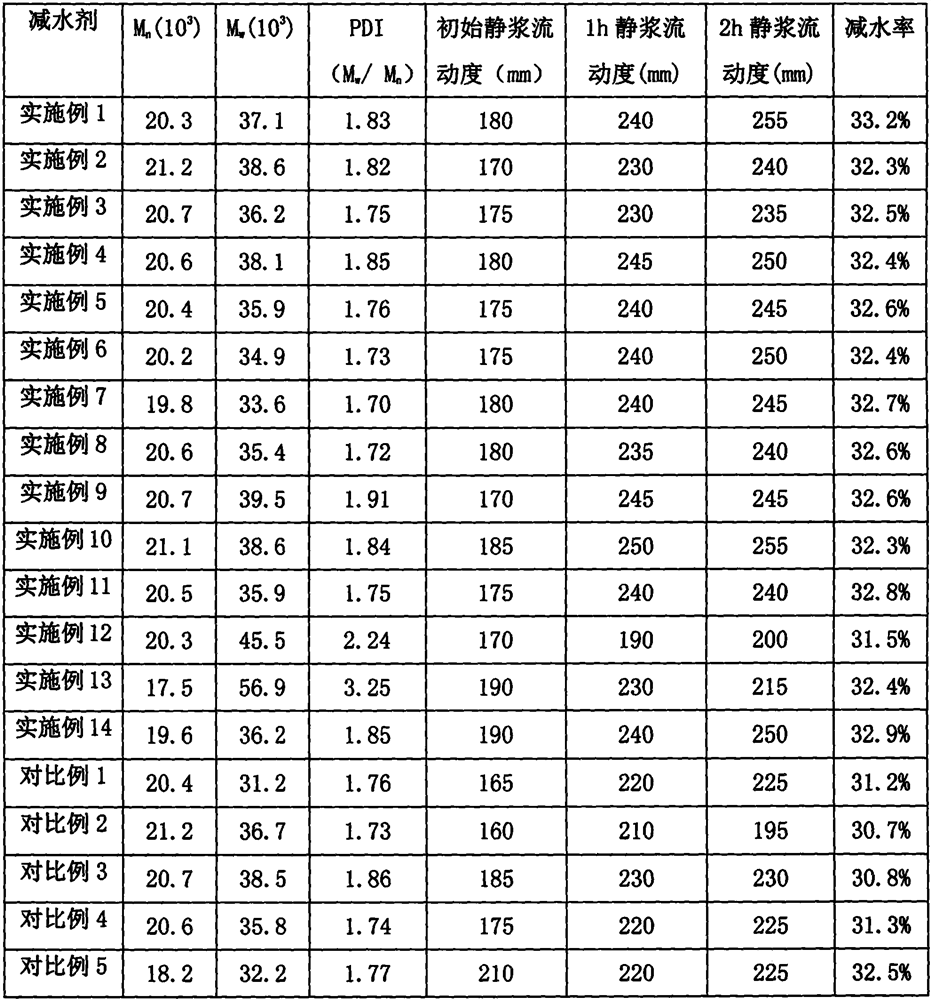

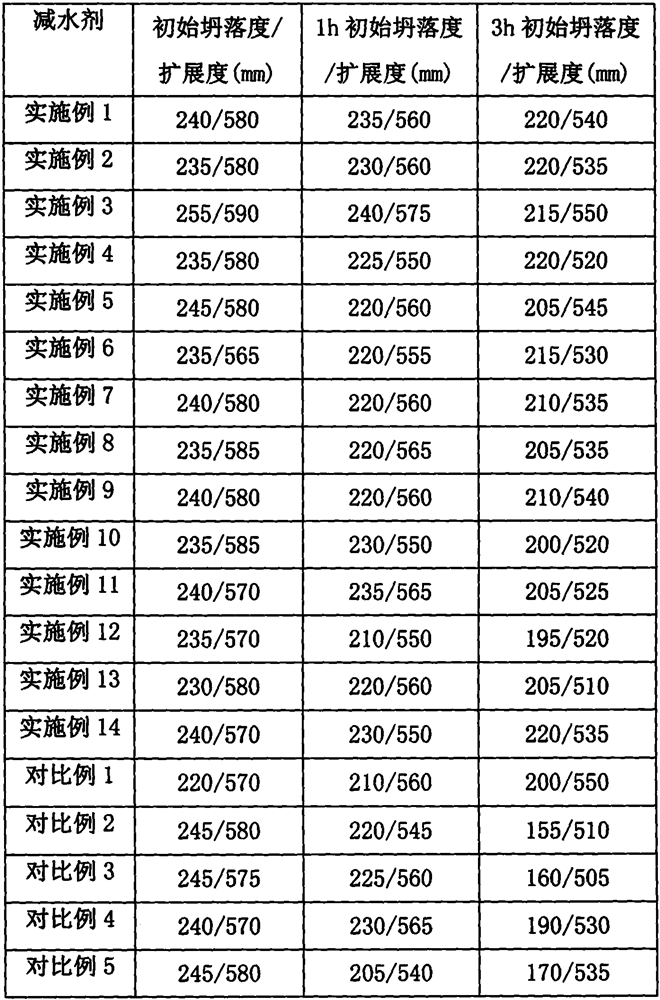

High-slump-retaining coagulation-retarding type polycarboxylate water reducing agent and preparation and application thereof

The invention discloses a high-slump-retaining coagulation-retarding type polycarboxylate water reducing agent and a preparation method and application thereof. The water reducing agent is prepared from, by molar part, 10-30 parts of small-molecule unsaturated carboxylic acid, 3-8 parts of ester of small-molecule unsaturated carboxylic acid, 1-5 parts of salt of small-molecule unsaturated carboxylic acid, 2-6 parts of polyethylene glycol diacrylate, 1-5 parts of an unsaturated polyether macromonomer, 8-20 parts of an acrylamide monomer, an initiator and a chain transferring agent, wherein theacrylamide monomer is a group consisting of three monomers including acrylamide (AM), 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 2-acryloylamino-2-phenylethanesulfonic acid (AMSS). The molecular structure of the water reducing agent is designed according to the construction demands for workability and slump retaining performance, and the high-slump-retaining coagulation-retarding type polycarboxylate water reducing agent with excellent comprehensive performance is finally obtained. During construction, a high water reducing rate can be achieved by applying a low dosage of the water reducing agent, the construction can be guaranteed, the slump retaining performance is excellent, the slump is basically not changed within 3 hours, and the water reducing agent has wide applicabilityin concrete construction.

Owner:深圳市五山新材料股份有限公司

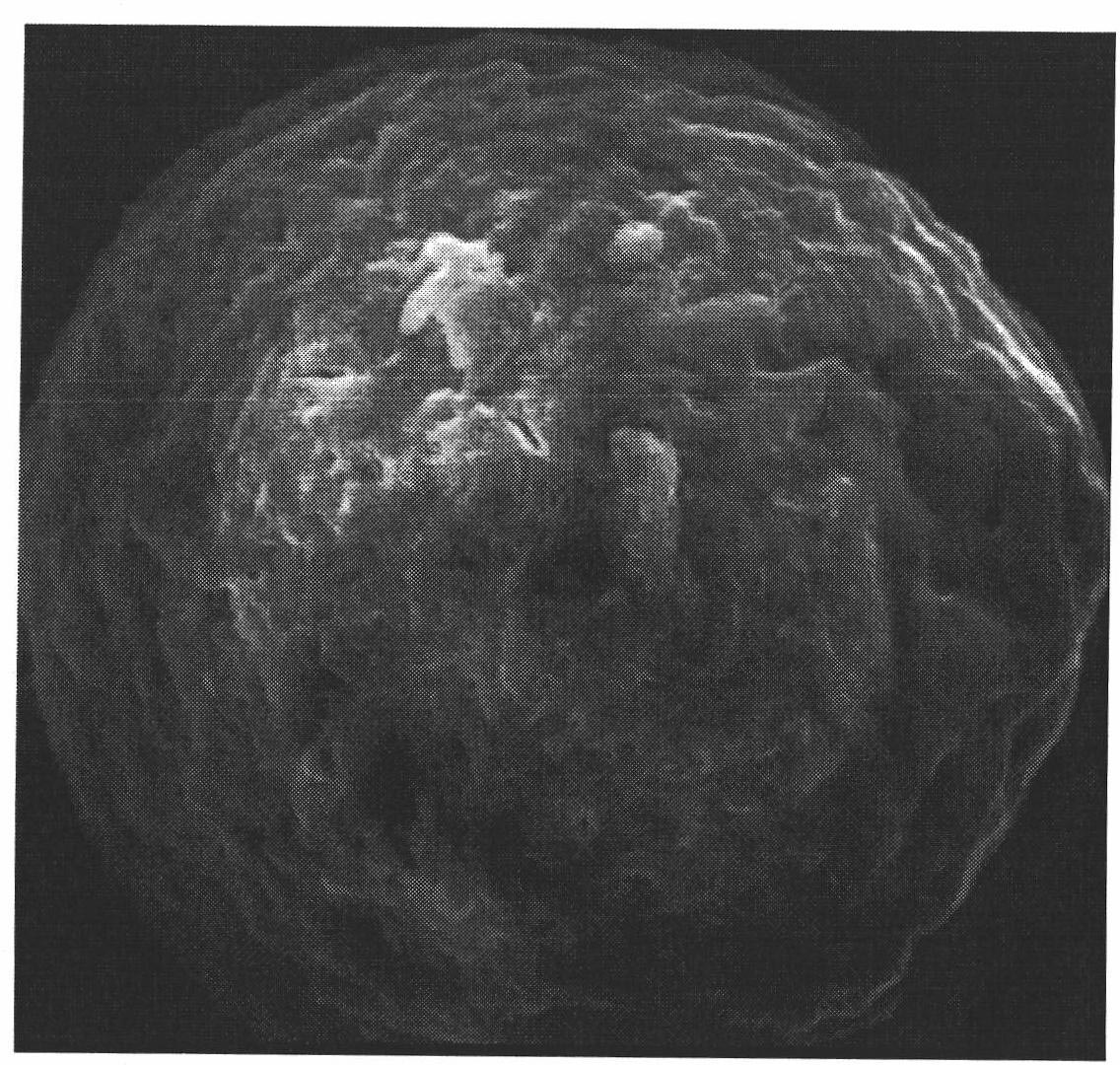

Olefin polymerization catalyst and preparation method thereof

InactiveCN102464731ASolve the poor sensitivity of hydrogen adjustmentSolve the problem that the molecular weight distribution of the product is too narrowHydrogenPolymer science

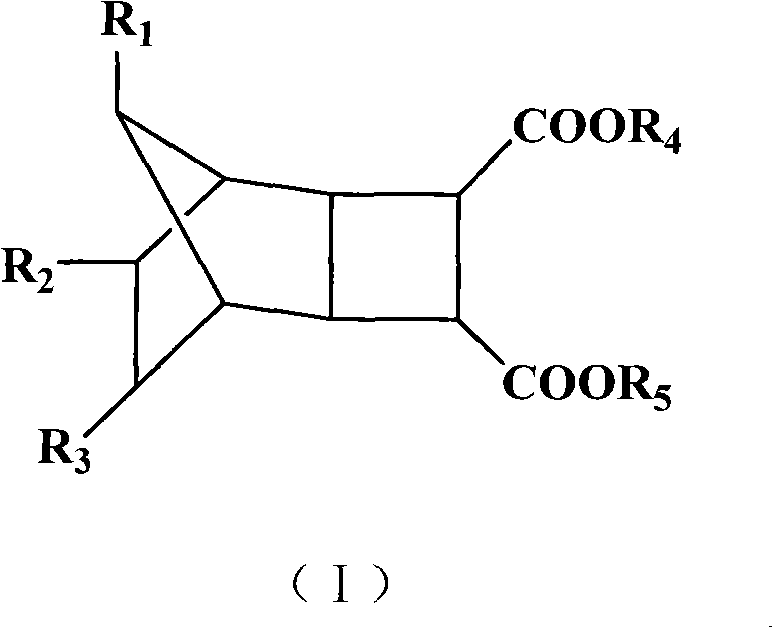

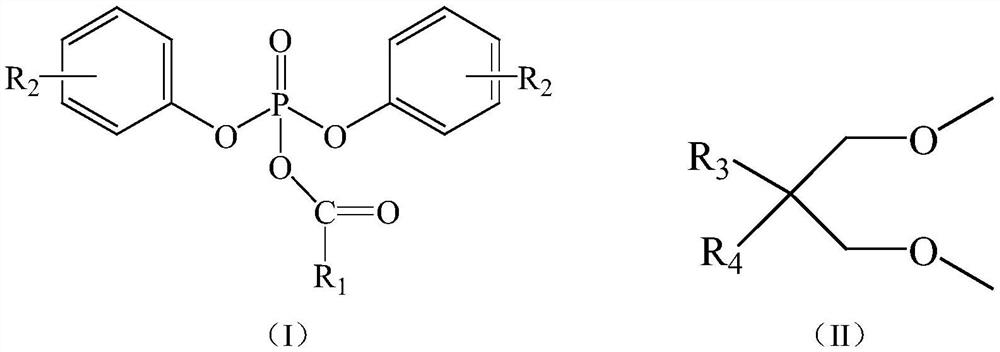

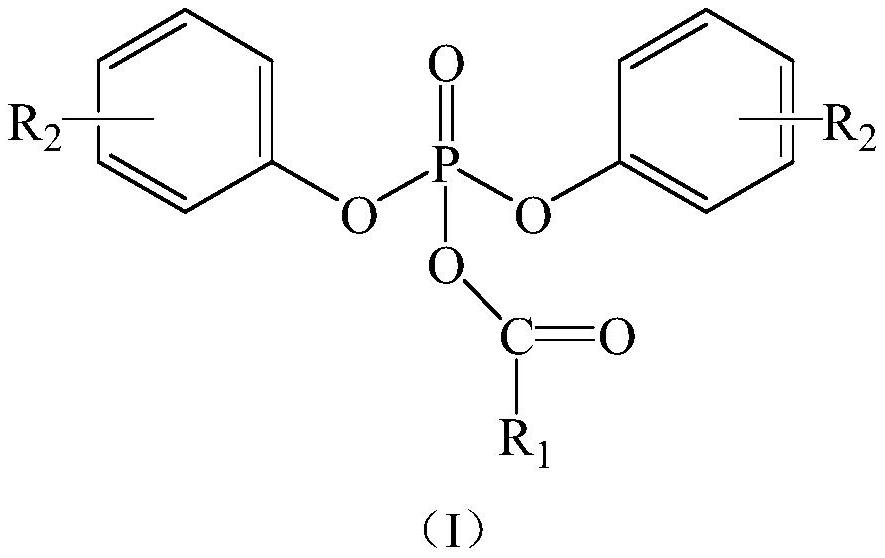

The invention discloses an olefin polymerization catalyst, which consists of two electron-donating compounds, including a polycyclic 1,4-diester compound shown as a general formula (I) and a phthalic acid ester compound and can be used for effectively solving the problems of poor hydrogen regulation sensitivity, over-narrow molecular weight distribution of a product and the like of a catalyst caused by separate use of an electron-donating compound. The average particle size of the obtained catalyst is 5-100 microns, and the specific surface area is more than 100 m<2> / g. The catalyst is approximately spherical, has high comprehensive performance, and can be well suitable for the requirements of slurry, gas-phase and mass propylene polymerization processes. The molecular weight distribution of an obtained polymerization product is appropriate.

Owner:PETROCHINA CO LTD

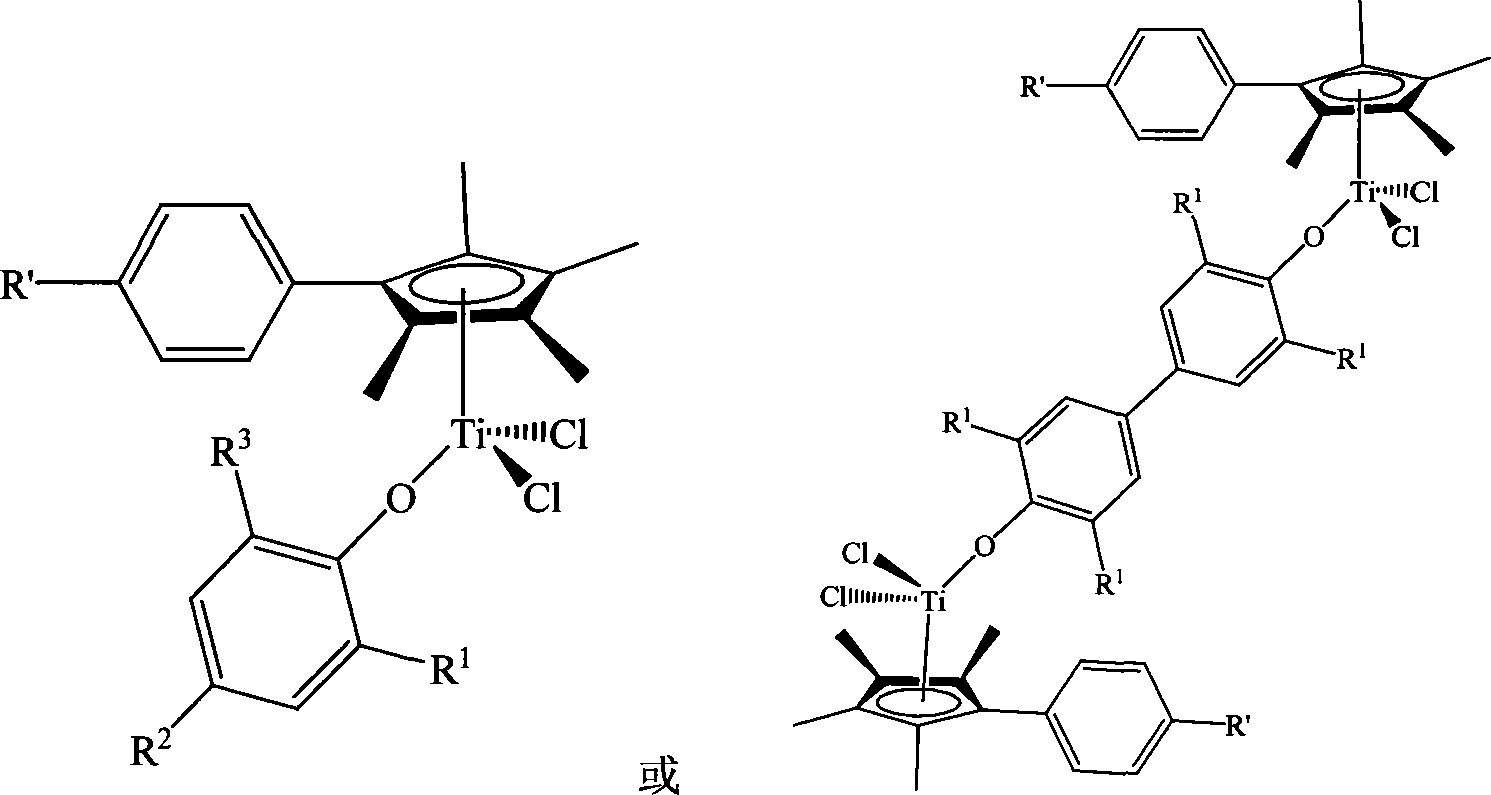

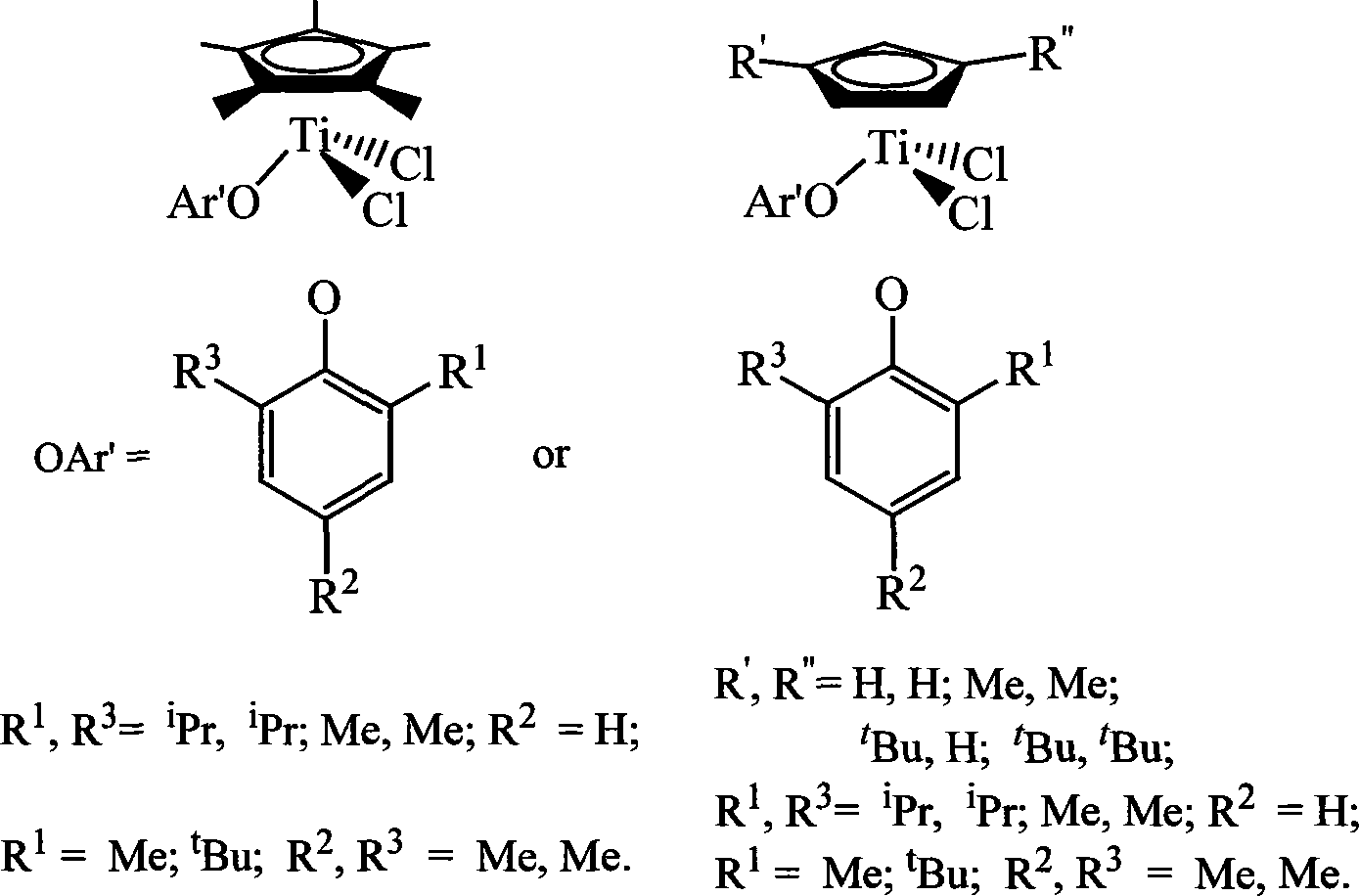

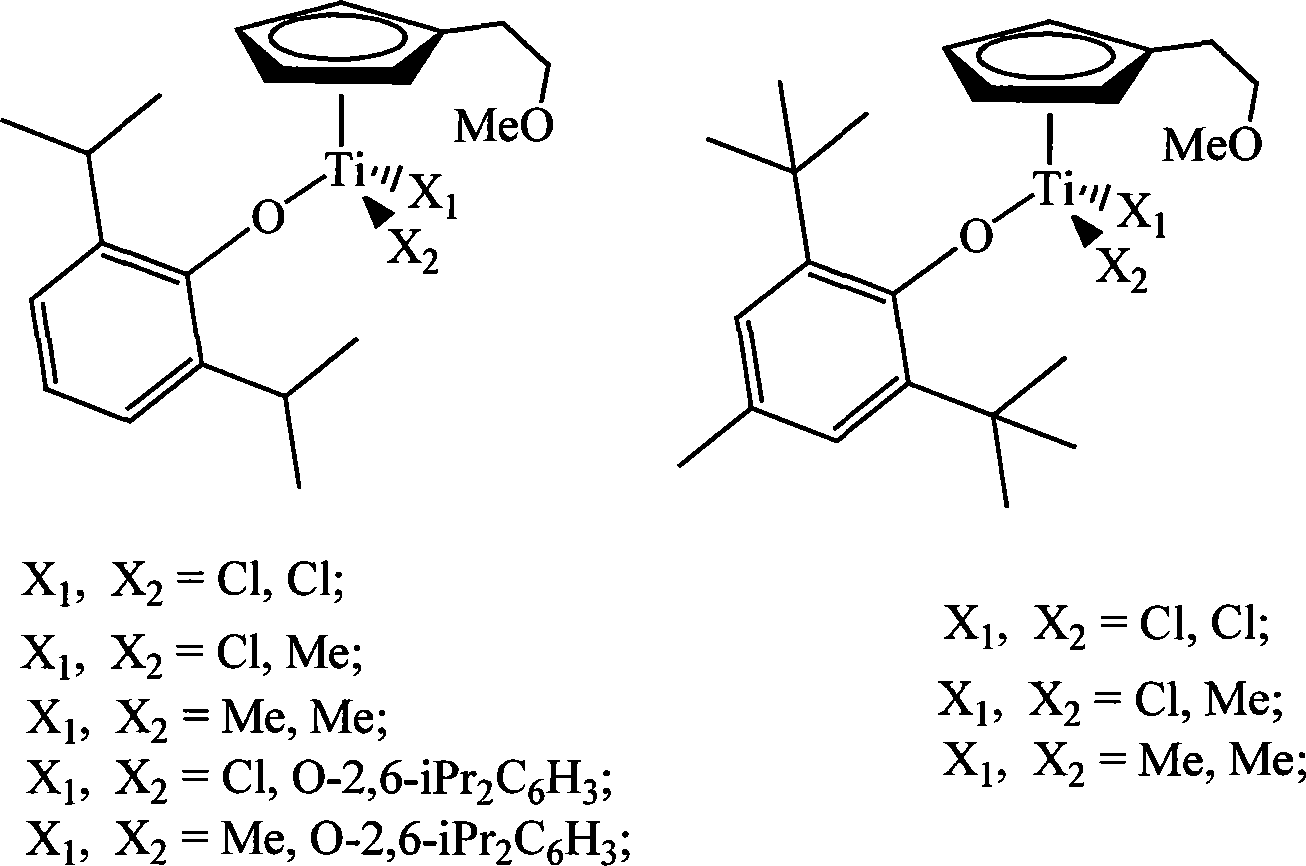

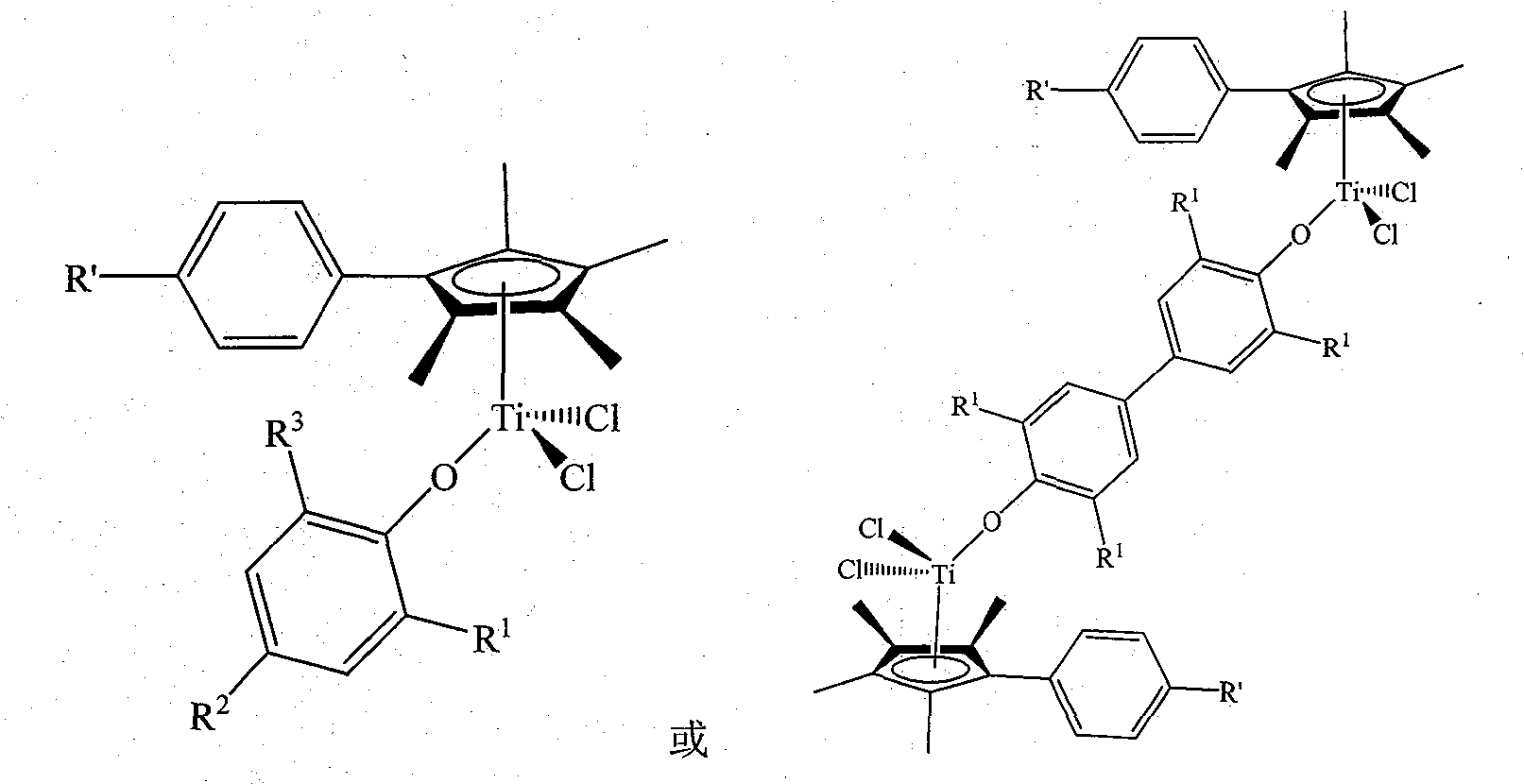

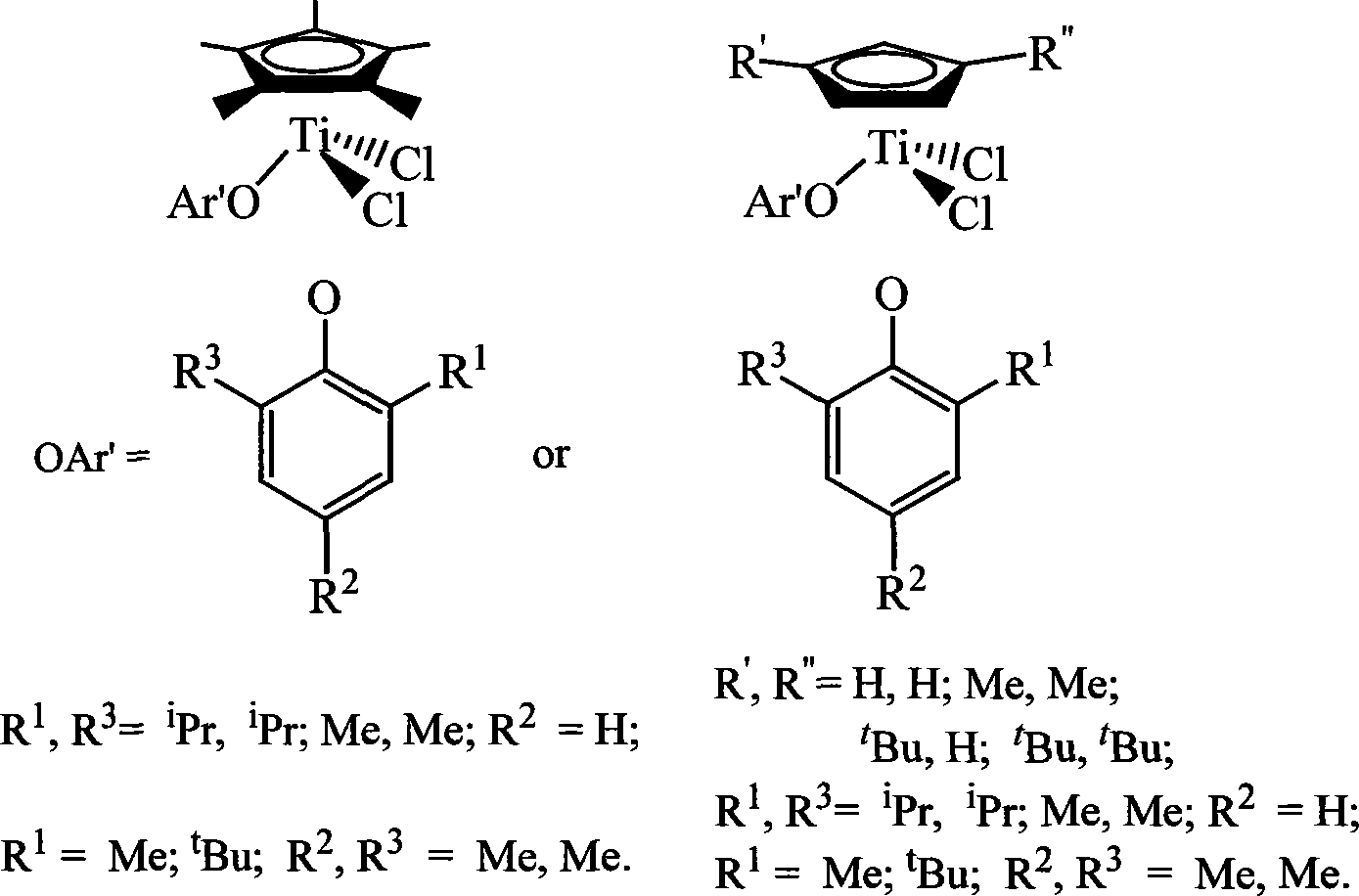

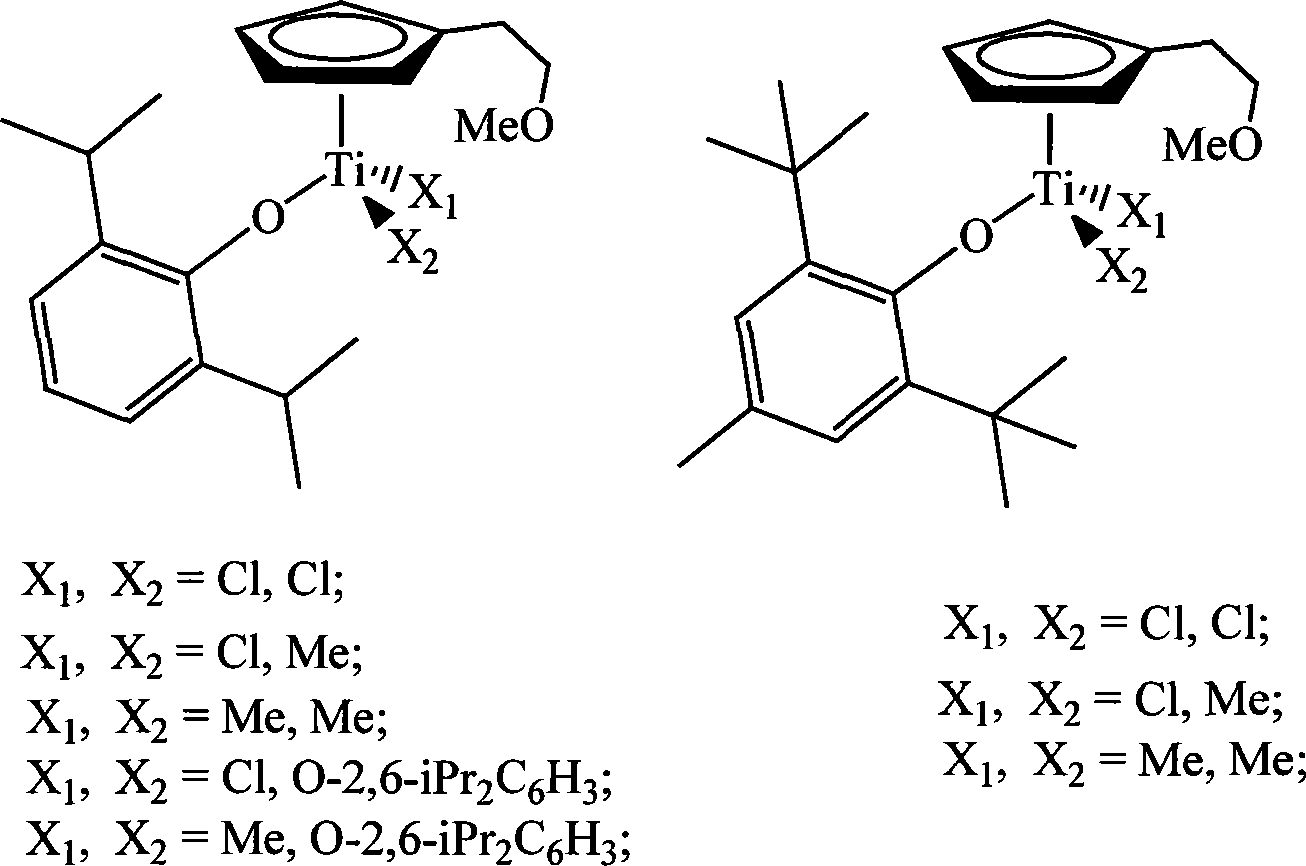

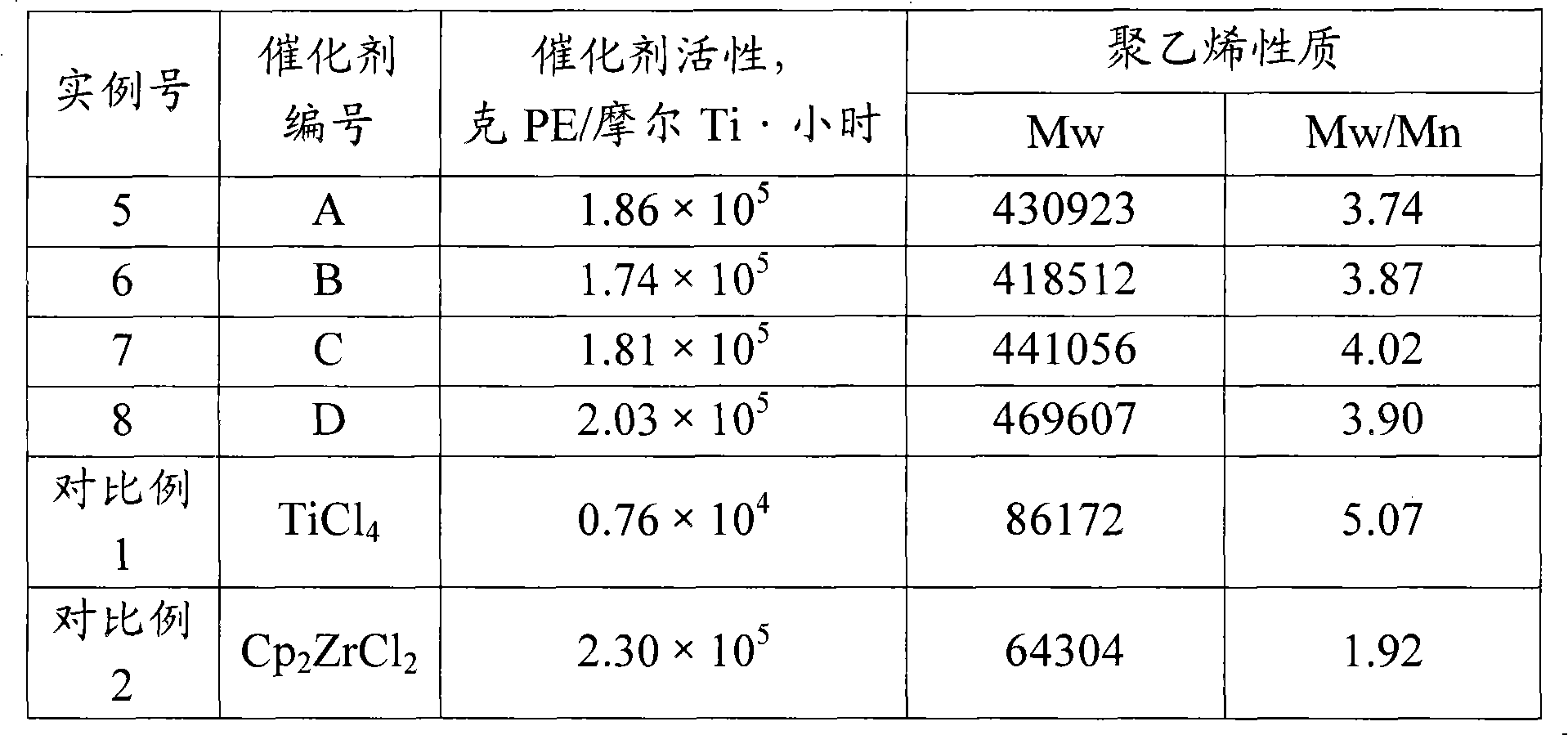

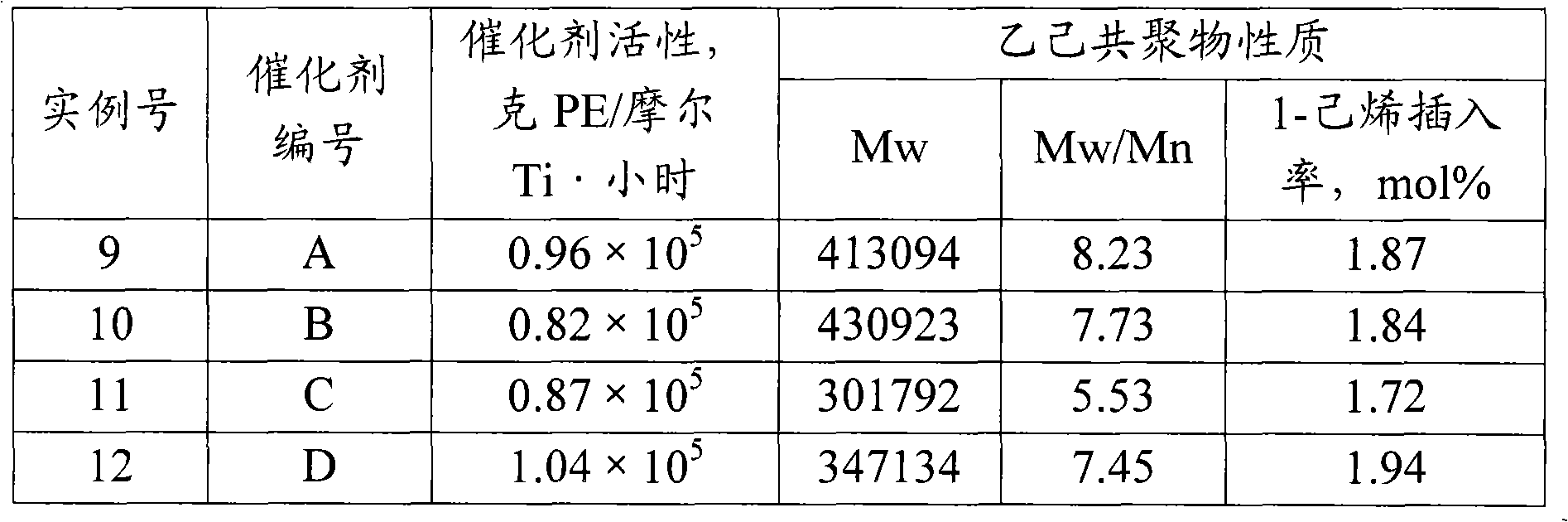

Non-bridged single/double-nucleus metallocene compound and uses thereof

InactiveCN101195644AHigh comonomer contentModerate molecular weight distributionMetallocenesTitanium chlorideOxygen

The invention relates to a non-bridge mono / bi-nuclear metallocene compound and a relative application olefin polymerization catalyst technical field. The compound contains 1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-(2, 4, 6-tertiary butyl phenoxy)-titanium chloride, and (3, 3', 5, 5'-quattuor isopropyl-4, 4'-biphenyl oxygen)-bi-[1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-titanium dichloride] or the like. The metallocene compound can be used as main catalyst, while alkyl aluminum is used as promoter, or organic boron compound and alkyl aluminum are assembled into a promoter system, to catalyze and synthesize high-molecular-weight atactic polypropylene with improved catalysis activity and polymer molecular weight, which can catalyze the polymerization of vinyl and alpha-olefin, to obtain the polymer with suitable molecular weight in narrow distribution and high co-monomer content.

Owner:JILIN UNIV

Preparation method of high-molecular sodium polyacrylate for water-absorbent resin

The invention discloses a preparation method of high-molecular sodium polyacrylate for water-absorbent resin. The preparation method includes the steps: (1) preparing sodium acrylate water solution; (2) emulsification; (3) polymerization reaction; (4) purification. The preparation method of the high-molecular sodium polyacrylate for the water-absorbent resin is simple and convenient to operate and easy to implement, the cost of raw materials is reduced is reduced by reversed emulsion polymerization, yield and purity of reactants are improved, and the obtained polyacrylic resin is transparent in appearance, stable in performance, moderate in molecular weight distribution and excellent in water absorptivity.

Owner:诚和环境科技(苏州)有限公司

Supported non-metallocene catalyst and its preparation method and use

The invention relates to a supported non-metallocene catalyst and its preparation method and use. The supported non-metallocene catalyst has the characteristics of simple and feasible processes and obvious comonomer effects. A polyolefin product prepared by the supported non-metallocene catalyst is especially suitable as a raw material which can be directly used for preparing chlorinated polyolefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of light-color modified petroleum resin with low softening point

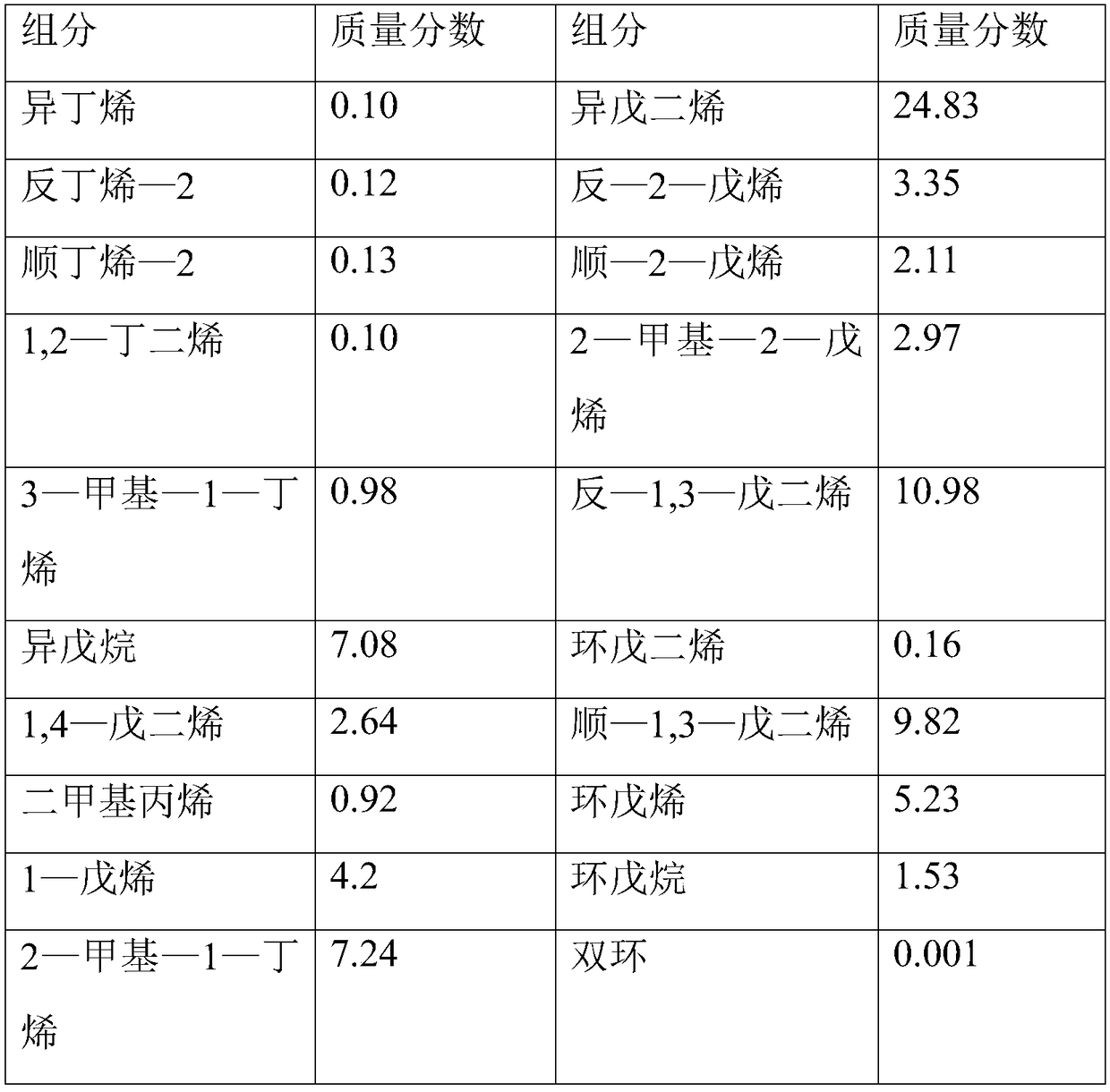

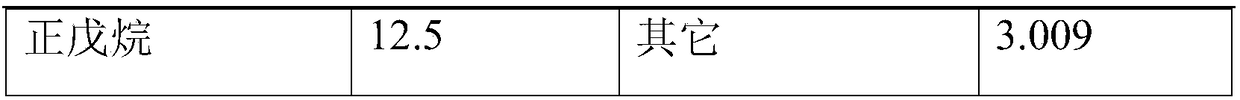

The invention belongs to the technical field of petroleum resin, and particularly relates to a preparation method of light-color modified petroleum resin with low softening point. The preparation method of the light-color modified petroleum resin with low softening point comprises the following steps of pretreating the byproduct of C5 fraction twice to remove cyclopentadiene and dicyclopentadiene,so as to obtain a mixture which has lower content of cyclopentadiene and contains multiple types of diolefin, monoolefine and alkene, wherein the C5 fraction byproduct is produced in the petroleum cracking process for preparing the ethylene; selecting one or multiple of aromatic vinyl monomers as a polymer modifying agent, selecting a compound catalyst, enabling the olefin in the C5 fraction andthe aromatic vinyl monomers to generate polymerizing reaction under the certain polymerizing condition, effectively controlling the heat of the polymerizing reaction, and slowly performing the reaction, so as to prepare the light-color modified petroleum resin with low softening point with the advantages of stable quality, excellent property and moderate molecular weight.

Owner:PUYANG RUISEN GASOLINEEUM RESINS +1

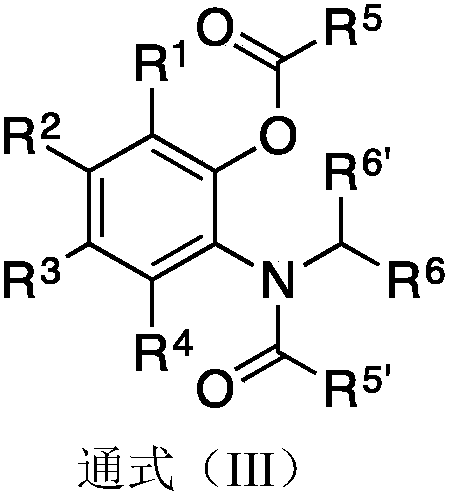

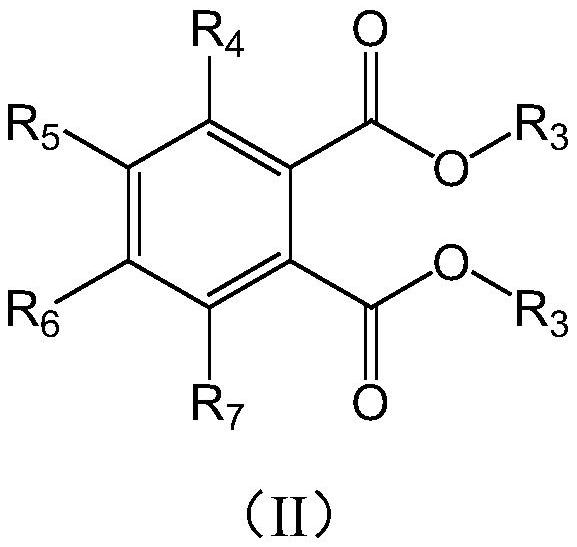

Solid catalyst component used for olefin polymerization, and catalyst and application thereof

ActiveCN108517022AHigh activityOvercome the disadvantage of narrow molecular weight distributionElectron donorElectronegativity

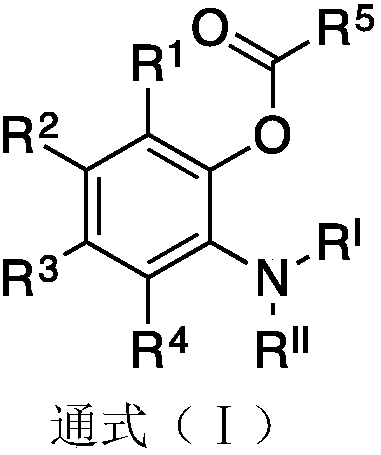

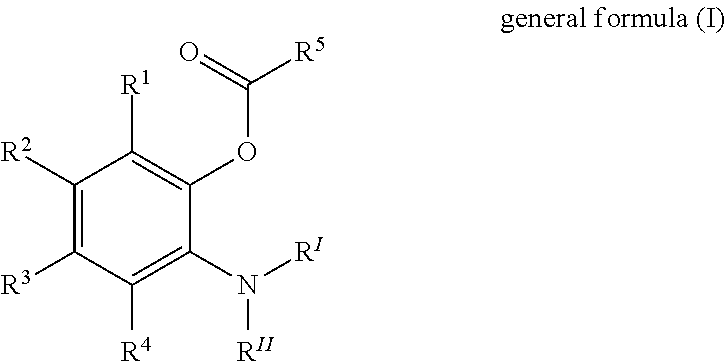

The invention provides a solid catalyst component used for olefin polymerization. The solid catalyst component includes Mg, Ti, halogen and at least two electron donor; one electron donor is 2-substituted amino-phenyl ester compound A selected from a general formula (I), and the other electron donor is selected from a Lewis alkali compound B containing one or more electronegative groups. A catalyst containing the solid catalyst component and an application of the catalyst in olefin polymerization, especially in propylene polymerization, are also disclosed. The catalyst has high activity; highisotacticity and wide molecular weight distribution polypropylene can be obtained; high isotacticity polypropylene can also be obtained without external electron donors; high activity can still be maintained when Al / Ti and Al / Si are reduced or polymerization time is prolonged during polymerization; and the solid catalyst component is suitable for manufacturing low ash polymers.

Owner:BEIJING LIHE TECH

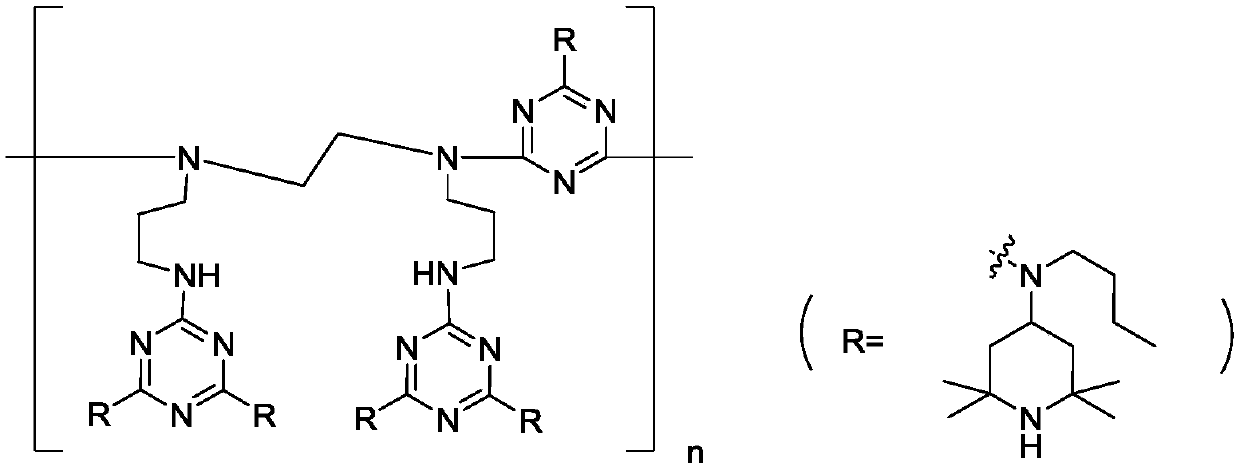

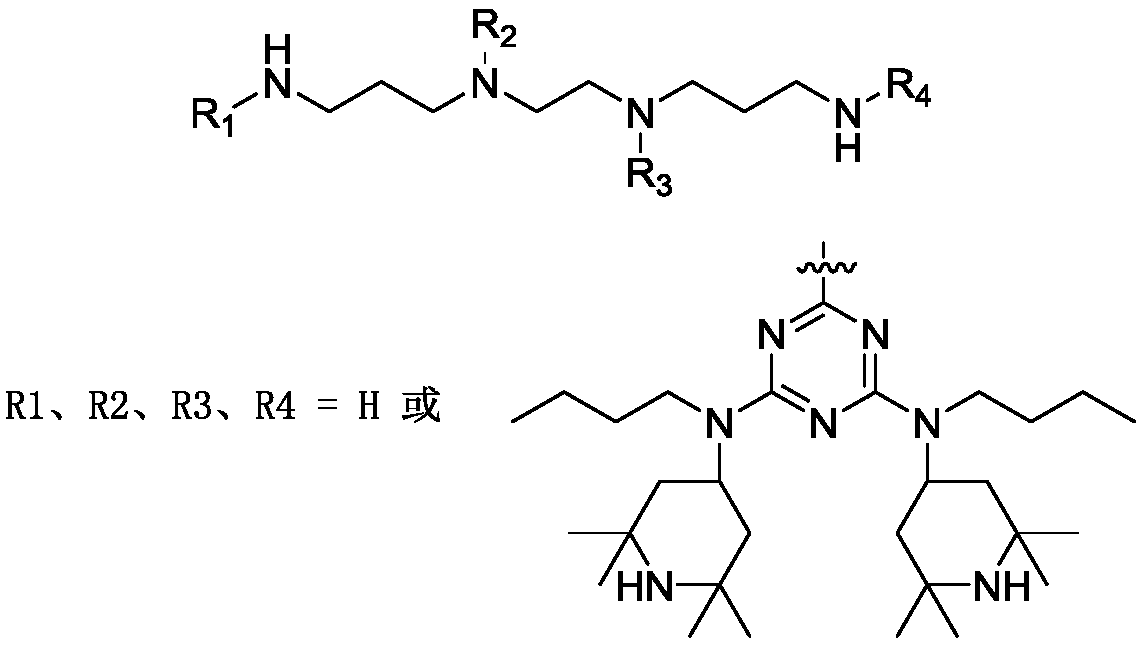

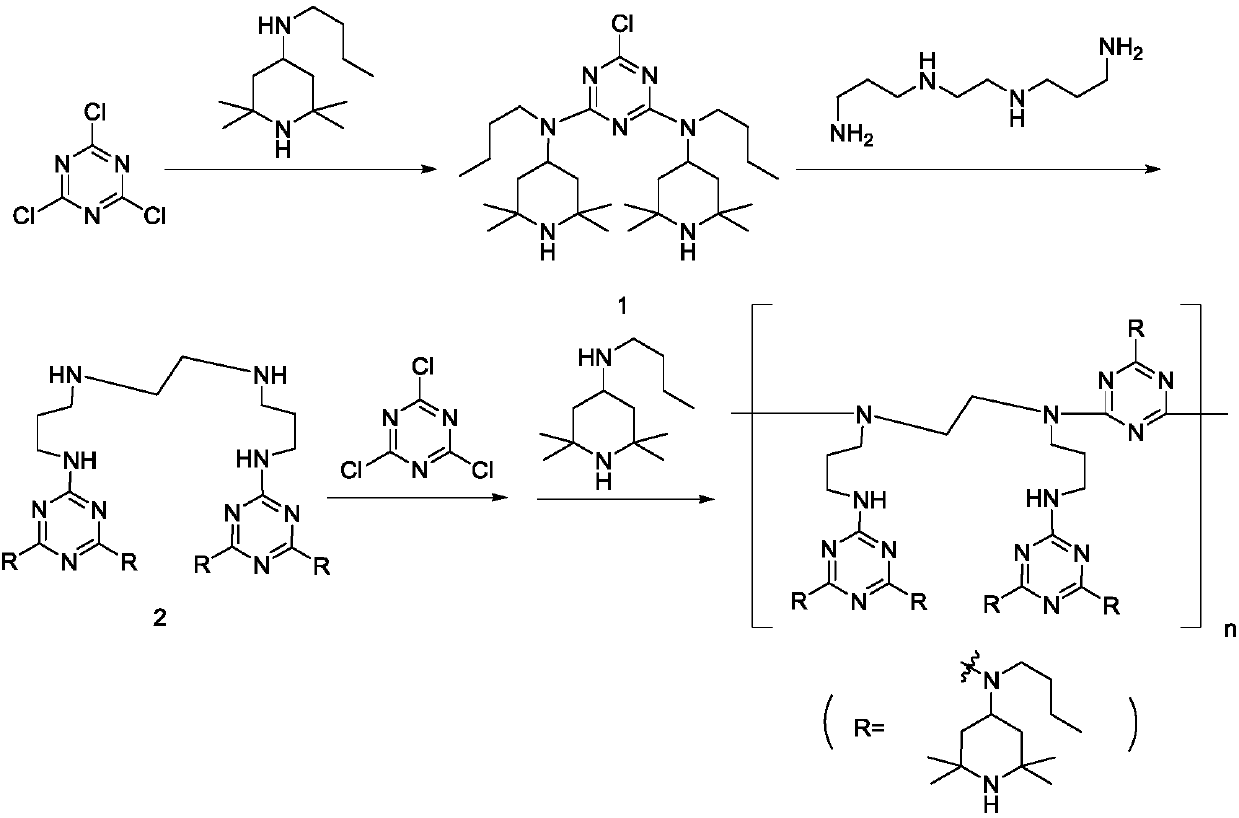

Polymeric hindered amine light stabilizer HA-88 and preparation method of polymeric hindered amine light stabilizer HA-88 intermediate

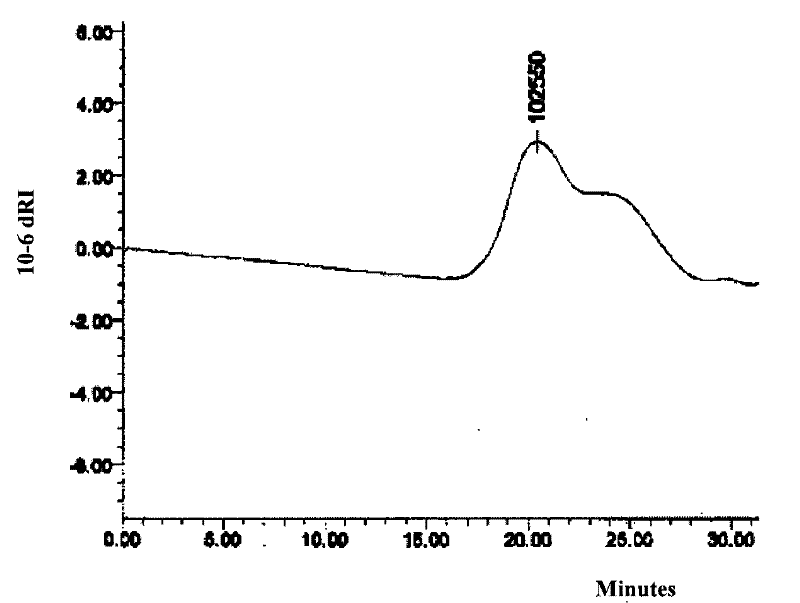

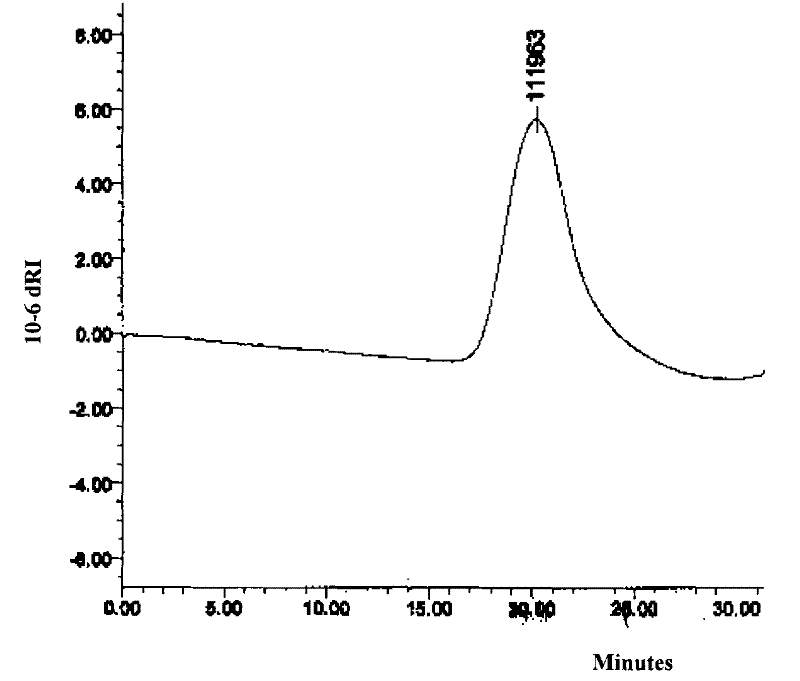

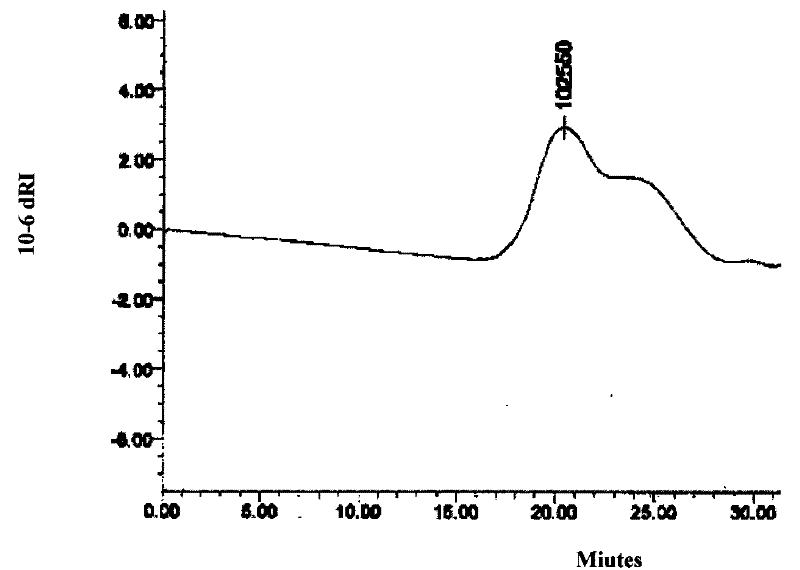

ActiveCN109535128AHigh Molecular Weight DistributionModerate molecular weight distributionOrganic chemistryHindered amine light stabilizersWeight distribution

The invention relates to a polymeric hindered amine light stabilizer HA-88 and a preparation method of a polymeric hindered amine light stabilizer HA-88 intermediate. The method is characterized in that firstly, N-butyl-2,2,6,6-tetramethyl-4-piperidinamine is reacted with cyanuric chloride; after the reaction is finished, the obtained reaction liquid is dropwise added into an N,N'-bis(3-aminopropyl) ethylenediamine solution; after the dropwise adding is completed, alkali metal hydroxide or salt is added as a catalyst; reaction is performed in a backflow state. The mild reaction conditions areused; by using different feeding methods and sequences, the molecular weight distribution of the intermediate can be obviously improved; the disubstituted substance content of N,N'-bis(3-aminopropyl)ethylenediamine is obviously increased; the condition of mixed ingredients of the product synthesized by the existing process is greatly reduced; the intermediate can be directly applied to HA-88 synthesis without post treatment; the dispersion index of the prepared HA-88 is relatively low; the molecular weight distribution is proper; the product quality is high; the application effect is prominent.

Owner:RIANLON +3

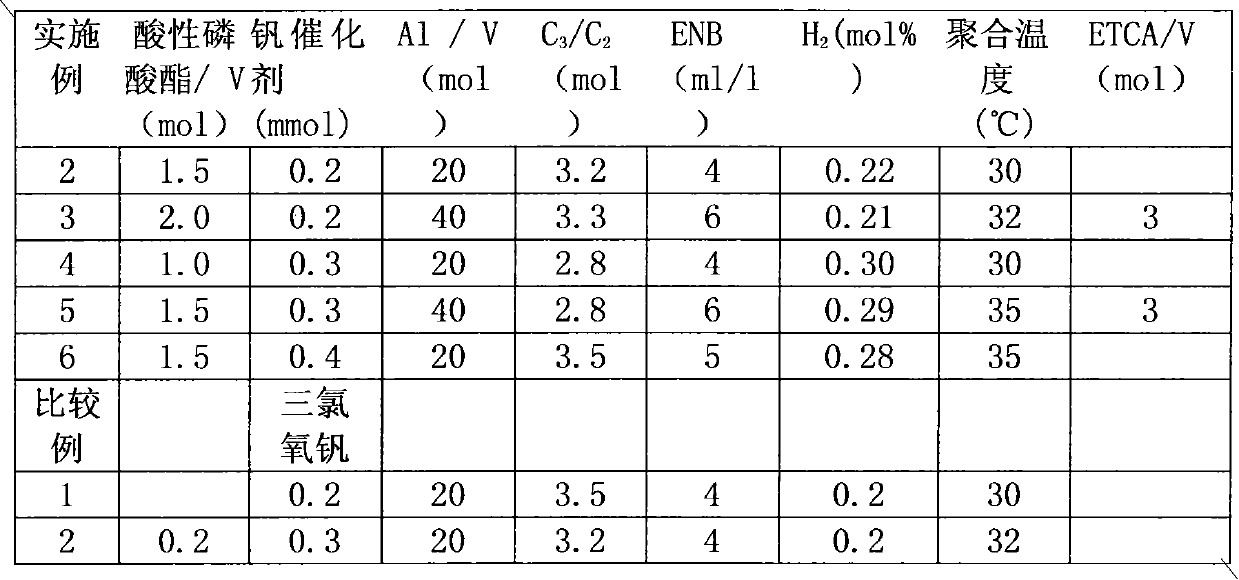

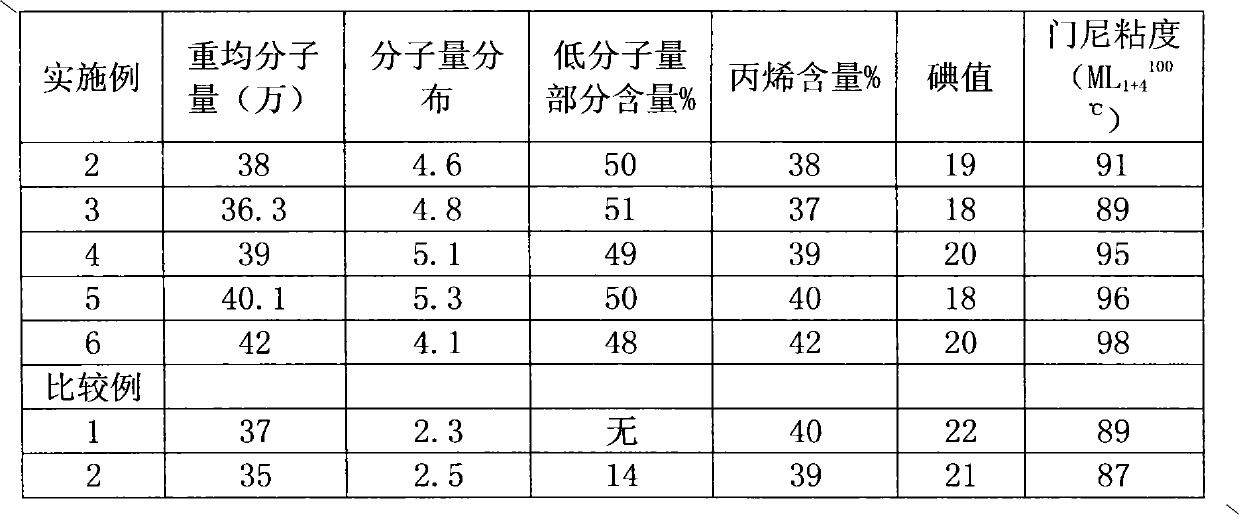

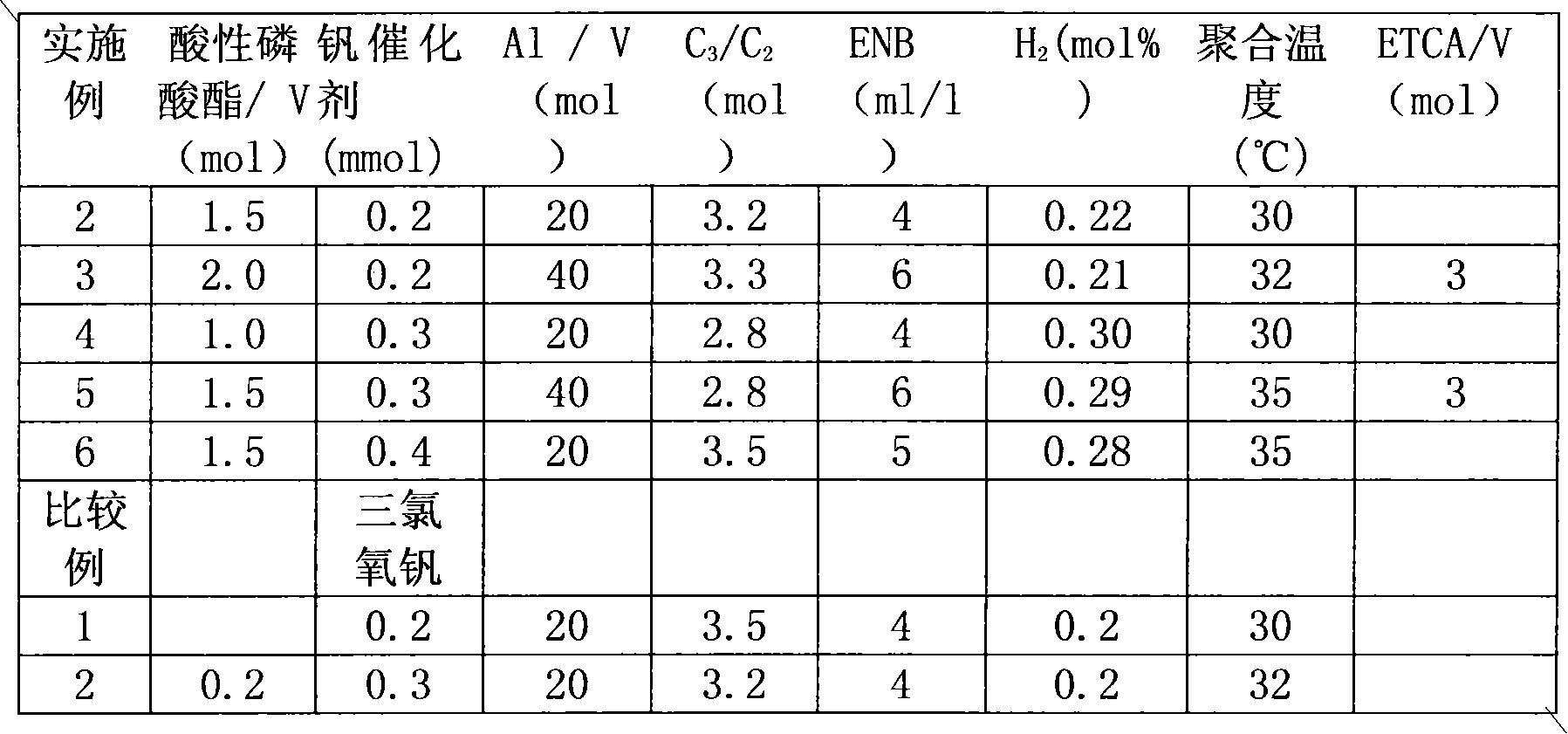

Synthesis method of bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer

ActiveCN102558414AHigh Mooney viscosityModerate molecular weight distributionPhosphateSynthesis methods

The invention relates to a synthesis method of a bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer, which comprises the following steps: introducing a gas mixture of ethylene, propylene and hydrogen into a reaction kettle, adding a primary catalyst, a cocatalyst and an activating agent, and adding the non-conjugated diene for polymerization at 25-45 DEG C under the pressure of 0.3-0.6 MPa. The propylene / ethylene mol ratio is 1-6; the hydrogen accounts for 0.05-0.5 mol% in the comonomer; the addition amount of the non-conjugated diene in every 1000mL of hexane is 2-10mL; the acidic-phosphate modified vanadium compound is used as the primary catalyst, the halogenated alkyl aluminum is used as the cocatalyst, and the mol ratio of Al in the cocatalyst to V in the primary catalyst is (1-100) / 1; the activating agent is ethyl trichloroacetate, and the mol ratio of the activating agent and the vanadium compound is (1-10) / 1; and the copolymer has high Mooney viscosity and moderate molecular weight distribution, and is used in processing rubber of automobile seals.

Owner:PETROCHINA CO LTD

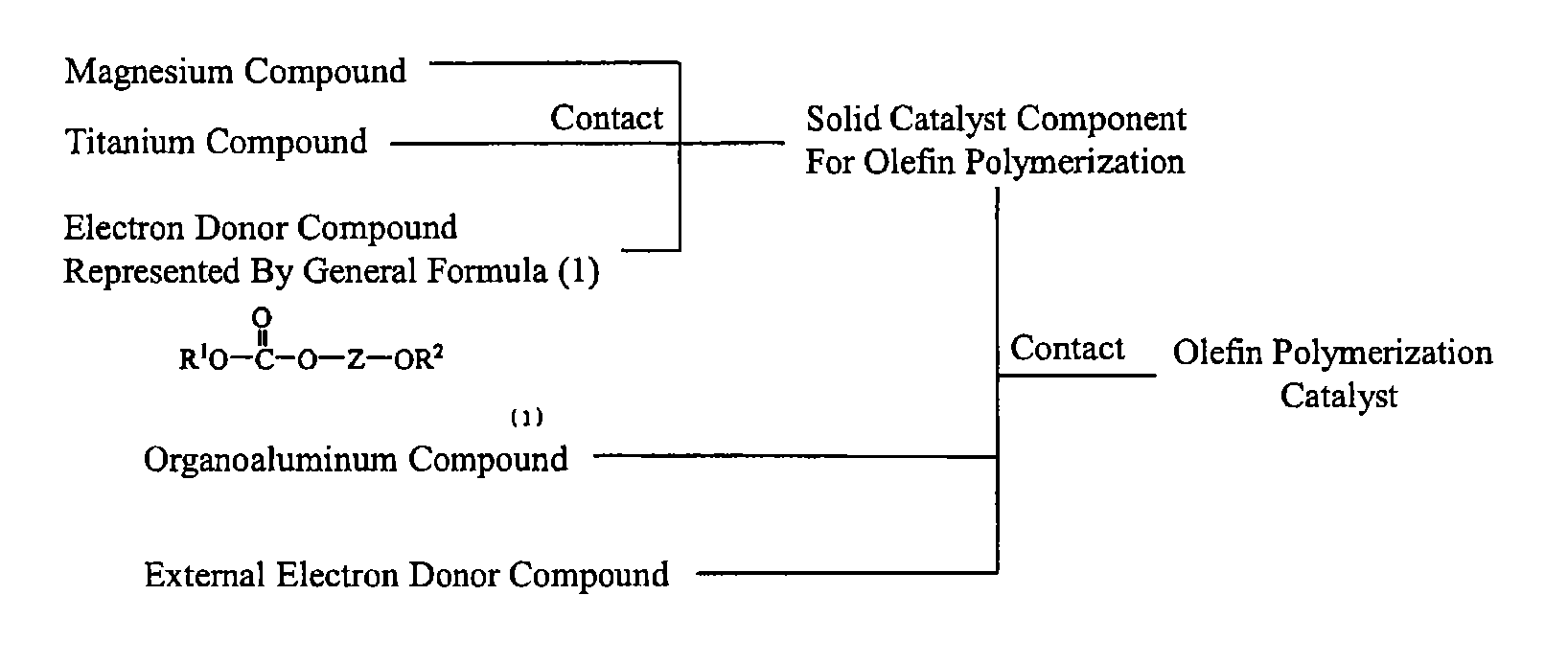

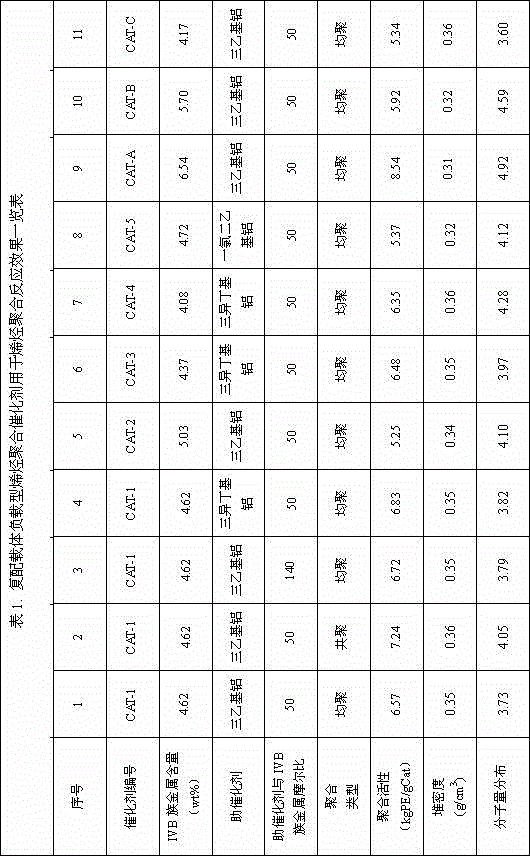

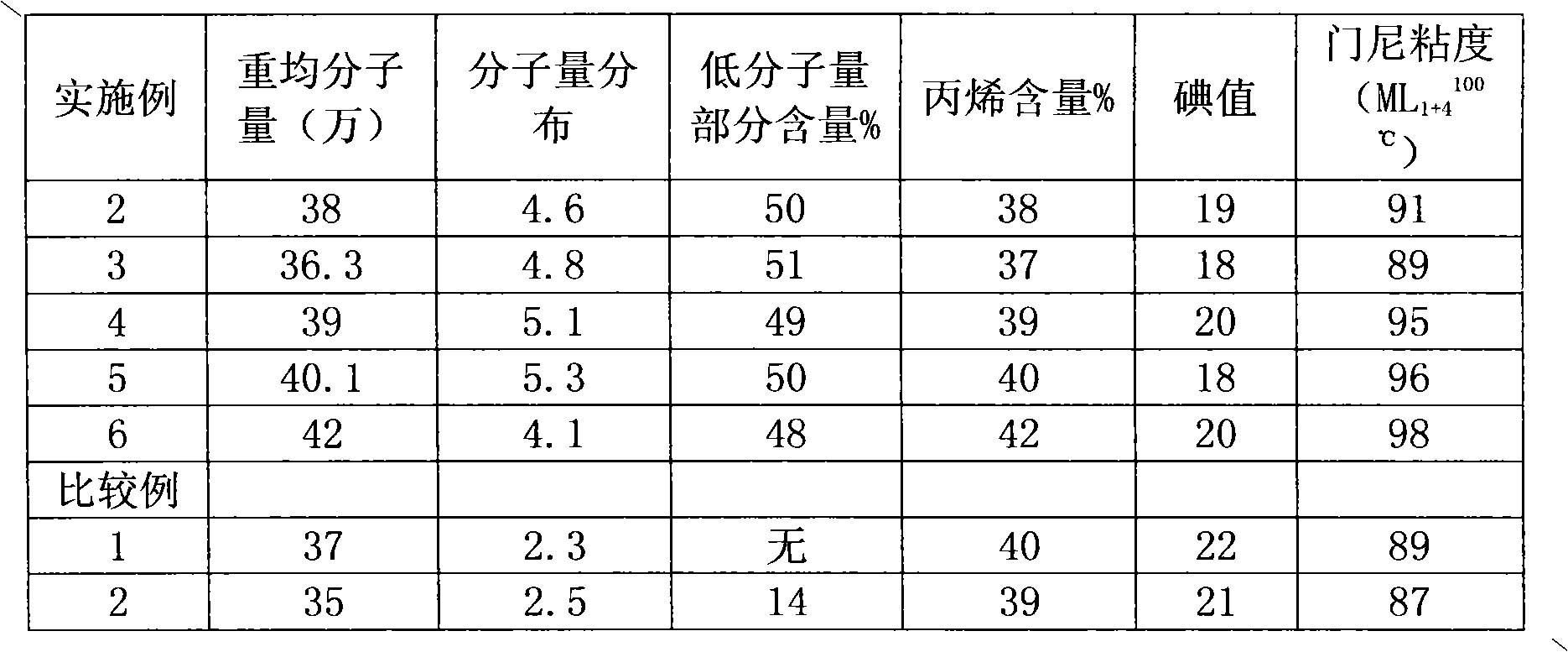

Solid catalyst component for polymerization of olefin, catalyst for polymerization of olefin, and method for producing olefin polymer

A solid catalyst component for olefin polymerization includes titanium, magnesium, a halogen, and a compound represented by the following formula (1): R1O—C(═O)—O—Z—OR2, and an olefin polymerization catalyst includes the solid catalyst component, an organoaluminum compound, and an optional external electron donor compound. An olefin polymer that has a moderate molecular weight distribution while maintaining high stereoregularity can be produced by utilizing the solid catalyst component and the olefin polymerization catalyst.

Owner:TOHO TITANIUM CO LTD

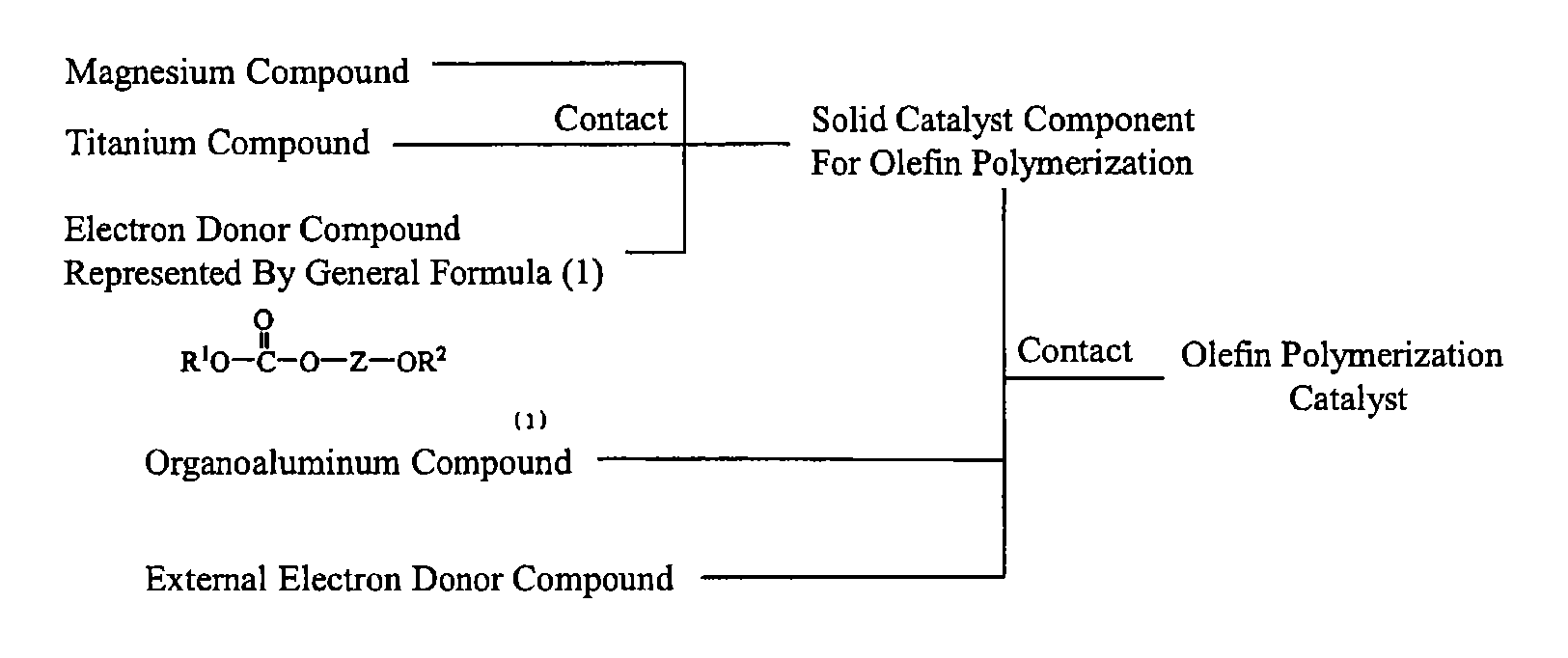

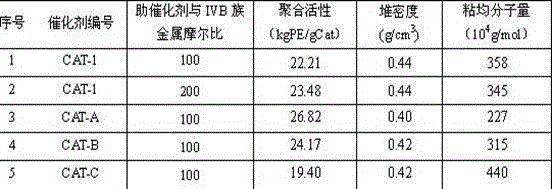

Preparation method and application of compounded carrier supported olefin polymerization catalyst

The invention relates to a preparation method and application of a compounded carrier supported olefin polymerization catalyst. The method is characterized in that a compounded carrier formed by a magnesium compound and a porous carrier is treated through a silicon-containing compound and a chemical treating agent containing group IVB (titanium, zirconium and hafnium) metal halides, and filtering, washing and drying are then carried out to obtain the compounded carrier supported olefin polymerization catalyst. The catalyst exhibits a high polymerization activity when used for olefin polymerization, and an obtained polymer achieves a high bulk density, uniform particle distribution, as well as moderate molecular weight distribution. The catalyst is particularly suitable for the manufacture of ultra-high molecular weight polyethylene.

Owner:TIANJIN XIQING DISTRICT RUNTIAN JINCHENG TECH DEV

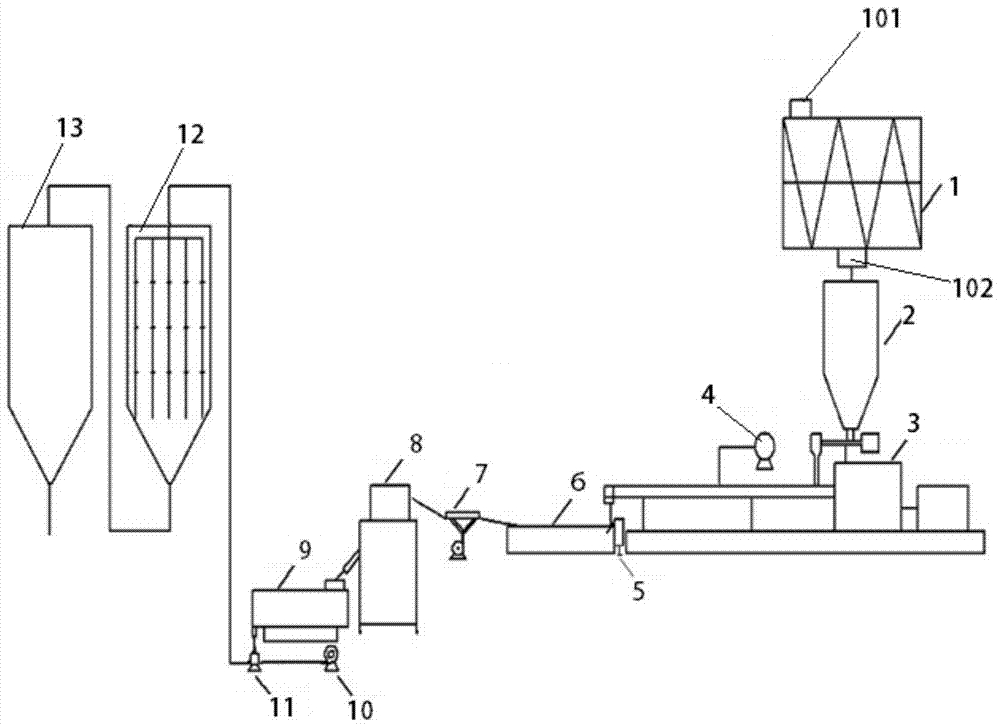

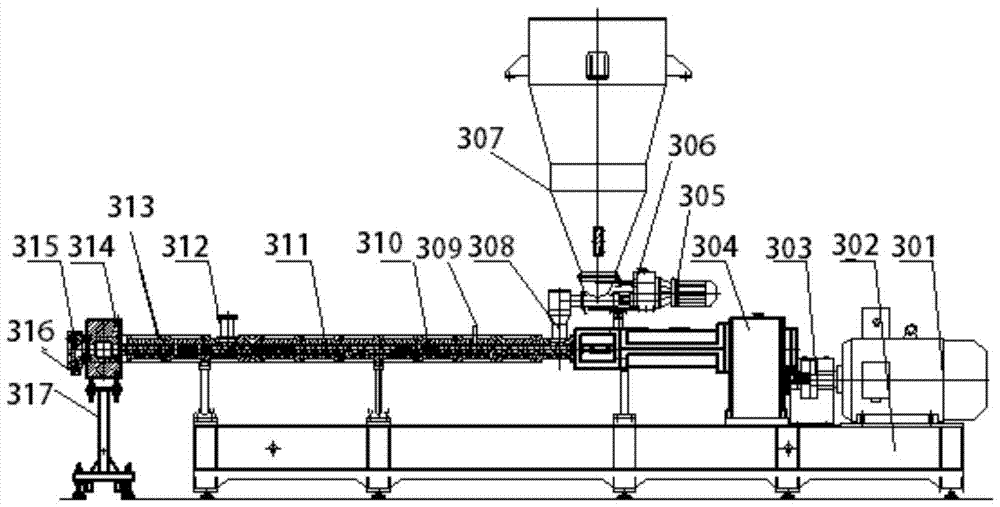

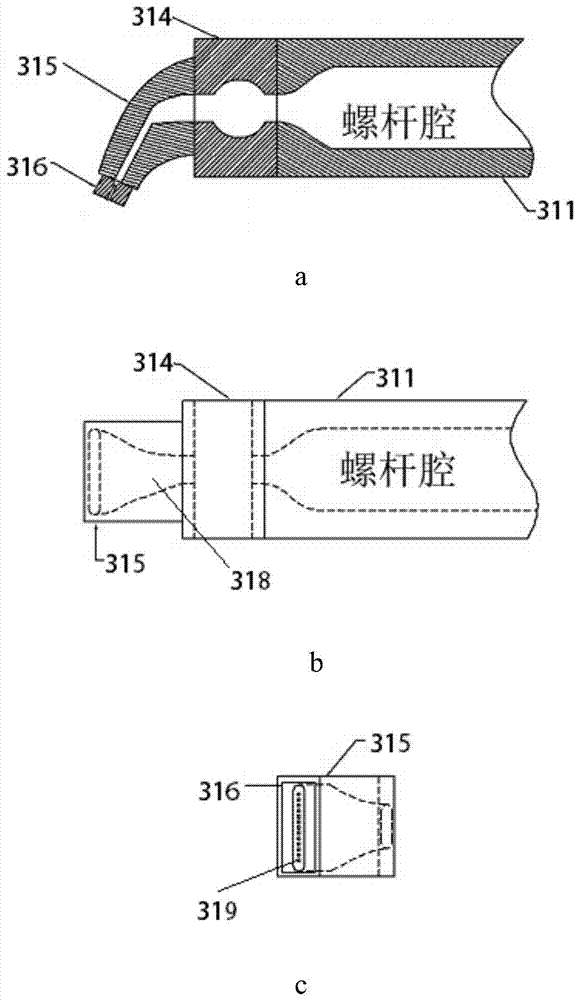

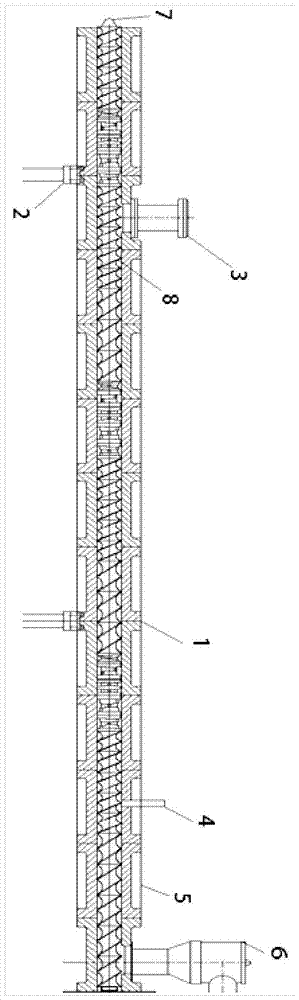

A kind of production method and production equipment of polypropylene melt-blown non-woven special material

The invention discloses a production method and production equipment for special materials for high-grade polypropylene melt-blown non-woven fabrics. For every 100 kilograms of polypropylene, 50-200 grams of long-acting stabilizers and 25-200 grams of short-acting stabilizers are added to achieve high temperature resistance and stability. 25-160 grams of lubricant, 20-100 grams of lubricant; the mixer stirs, feeds to the extruder, and reacts in the screw reaction section of the twin-screw extruder; the production equipment, including the mixer, mixes uniform raw materials from mixing The material outlet goes down to the middle silo, and the bottom outlet of the middle silo is connected to the inlet of the extruder. The extruder has a twin-screw structure. The extruder sends the processed material to the cooling water tank through the inclined water tank for cooling, and then in the air dryer Air-dried, granulated in a granulator, screened by a vibrating sieve, and sent to a homogenizing blending tank through a rotary feeder. The invention has the beneficial effects of mixing evenly, solving the molding problem of high-fluidity melt index polypropylene, and being suitable for conventional production.

Owner:HUNAN SHENGJIN NEW MATERIAL

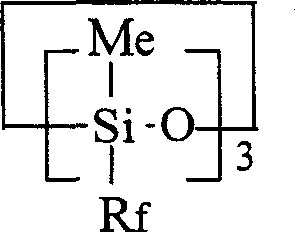

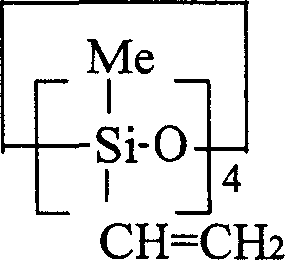

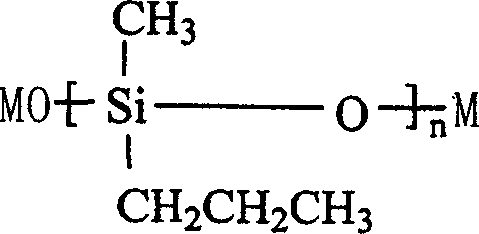

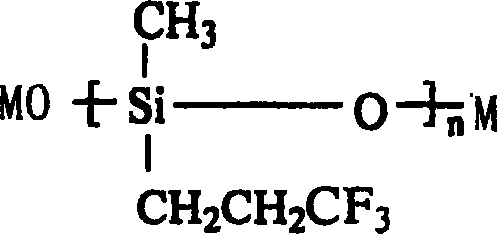

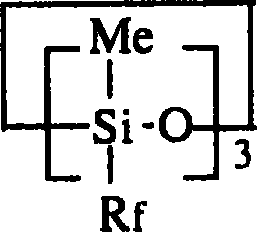

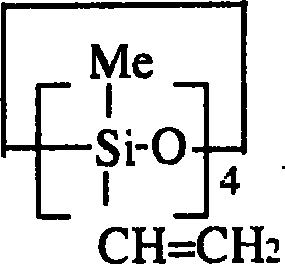

Fluorine-silicon compounded rubber stock and method for making same

ActiveCN1302048CHigh molecular weightModerate molecular weight distributionSolventUltimate tensile strength

The invention provides a silicofluoride mixed glue. The invention mainly comprises silicofluoride, white carbon black, scale control agent, heat stabilizer, curing agent and so on. The vulcanised silicofluoride mixed glue possesses properties of high hot strength, good low and high temperature resistance, perfect solvent resistance and oil resistance. The invention also discloses the method for manufacturing silicofluoride mixed glue.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

A high slump retarding polycarboxylate superplasticizer and its preparation and application

The invention discloses a high slump retarding polycarboxylate water reducer and its preparation method and application. The water reducer is prepared from the following raw materials in molar parts: 10-30 parts of small molecule unsaturated carboxylic acid, 3‑8 parts of esters of small molecular unsaturated carboxylic acids, 1‑5 parts of salts of small molecular unsaturated carboxylic acids, 2‑6 parts of polyethylene glycol diacrylate, 1‑5 parts of unsaturated polyether macromonomers , 8-20 parts of acrylamide monomer, initiator and chain transfer agent; wherein said acrylamide monomer is acrylamide (AM), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 2 ‑acrylamido‑2‑phenylethanesulfonic acid (AMSS) is a group of three monomers. The molecular structure of the superplasticizer is designed according to the ease and slump retention of the construction requirements, and finally a high-slump retention and retardation polycarboxylate superplasticizer with excellent comprehensive performance is obtained. In construction, a low dosage can achieve a higher water reducer The water rate can ensure the construction, and the slump retention is excellent, and the slump is basically not lost within 3 hours, and it has wide applicability in concrete construction.

Owner:深圳市五山新材料股份有限公司

Non-bridged single/double-nucleus metallocene compound and uses thereof

InactiveCN101195644BHigh comonomer contentModerate molecular weight distributionMetallocenesTitanium chlorideOrganic Boron Compounds

The invention relates to a non-bridge mono / bi-nuclear metallocene compound and a relative application olefin polymerization catalyst technical field. The compound contains 1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-(2, 4, 6-tertiary butyl phenoxy)-titanium chloride, and (3, 3', 5, 5'-quattuor isopropyl-4, 4'-biphenyl oxygen)-bi-[1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-titanium dichloride] or the like. The metallocene compound can be used as main catalyst, while alkyl aluminum is used as promoter, or organic boron compound and alkyl aluminum are assembled into a promoter system, to catalyze and synthesize high-molecular-weight atactic polypropylene with improved catalysis activity and polymer molecular weight, which can catalyze the polymerization of vinyl and alpha-olefin, to obtain the polymer with suitable molecular weight in narrow distribution and high co-monomer content.

Owner:JILIN UNIV

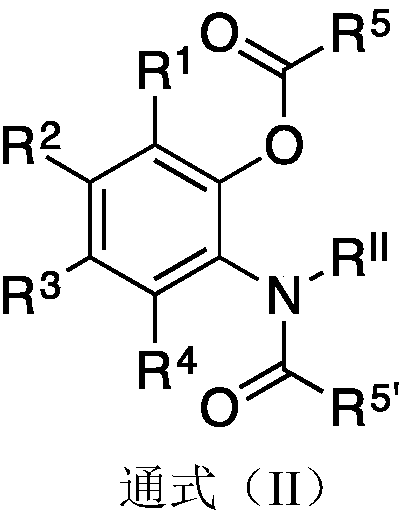

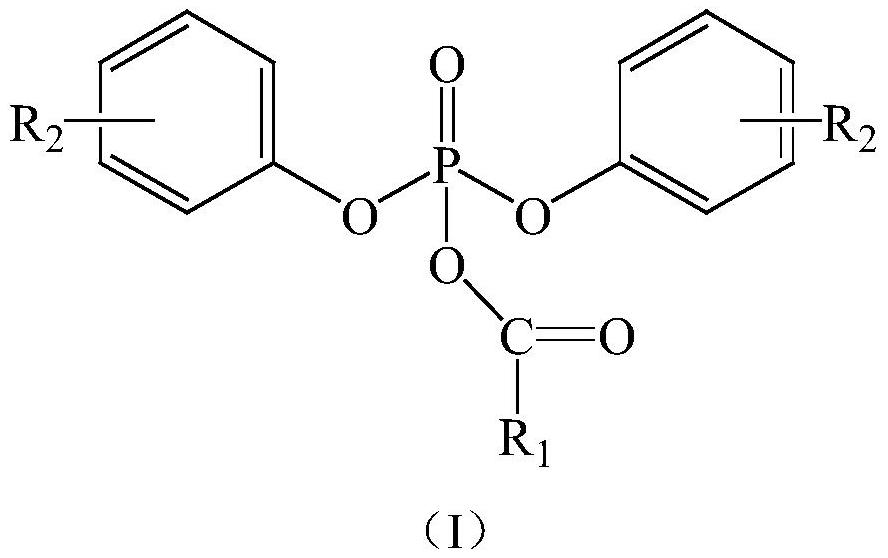

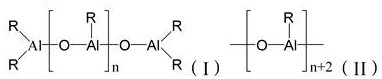

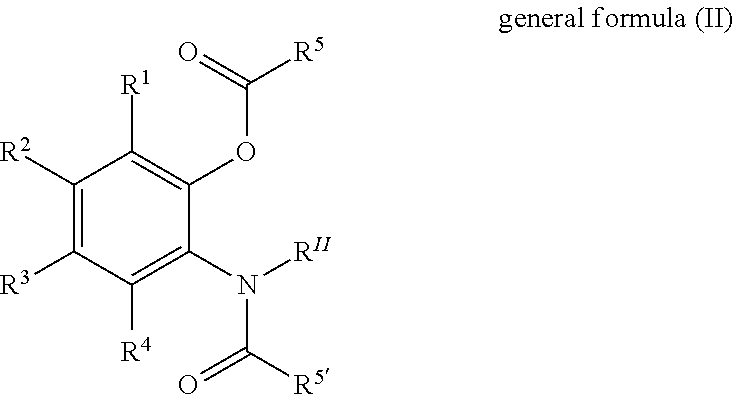

Solid catalyst component and catalyst system for producing polymers

PendingCN113929797AHigh activityGood hydrogen sensitivityBulk chemical productionStereospecificityElectron donor

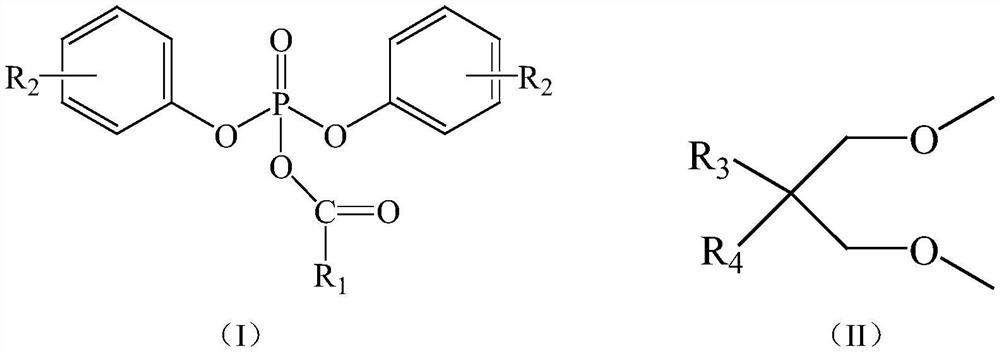

The invention discloses a solid catalyst component for producing polymers. The solid catalyst component comprises magnesium, titanium, halogen and internal electron donor compounds, and the internal electron compounds comprise a first internal electron donor compound as shown in a general formula (I) and a second internal electron donor compound as shown in a general formula (II). The invention also provides a catalyst system comprising the solid catalyst component. When the catalyst component provided by the invention is used for propylene polymerization reaction, polymerization activity is high, stereospecificity is good, hydrogen regulation sensitivity is good, and the molecular weight distribution of the obtained polymers is moderate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Twin-screw extruder suitable for the production of special materials for melt-blown non-woven fabrics

Owner:HUNAN SHENGJIN NEW MATERIAL

Synthesis method of bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer

ActiveCN102558414BHigh Mooney viscosityModerate molecular weight distributionPhosphateSynthesis methods

The invention relates to a synthesis method of a bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer, which comprises the following steps: introducing a gas mixture of ethylene, propylene and hydrogen into a reaction kettle, adding a primary catalyst, a cocatalyst and an activating agent, and adding the non-conjugated diene for polymerization at 25-45 DEG C under the pressure of 0.3-0.6 MPa. The propylene / ethylene mol ratio is 1-6; the hydrogen accounts for 0.05-0.5 mol% in the comonomer; the addition amount of the non-conjugated diene in every 1000mL of hexane is 2-10mL; the acidic-phosphate modified vanadium compound is used as the primary catalyst, the halogenated alkyl aluminum is used as the cocatalyst, and the mol ratio of Al in the cocatalyst to V in the primary catalyst is (1-100) / 1; the activating agent is ethyl trichloroacetate, and the mol ratio of the activating agent and the vanadium compound is (1-10) / 1; and the copolymer has high Mooney viscosity and moderate molecular weight distribution, and is used in processing rubber of automobile seals.

Owner:PETROCHINA CO LTD

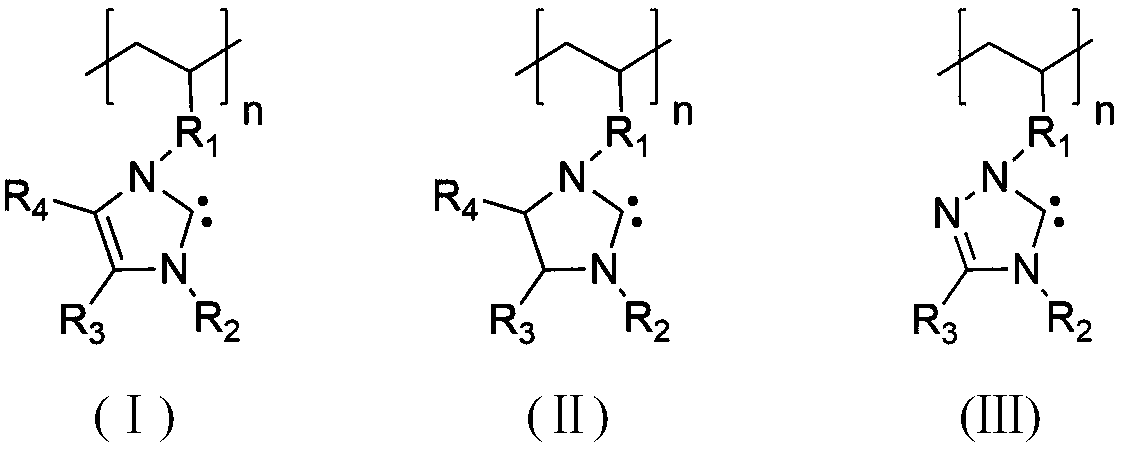

Method for synthesizing brush-like polymers based on poly(n-heterocyclic carbene) structure self-catalyzed self-initiated ring-opening and the prepared brush-like polymers

ActiveCN107057047BHigh graft densityModerate molecular weight distributionPolymer sciencePtru catalyst

The invention discloses a method based on autocatalysis self-initiation ring opening of a poly(N-heterocylic carbene) structure to synthesize a brush polymer. The method includes: under inert gas shielding, adding annular monomer capable of being in ring opening polymerization under catalytic action of N-heterocylic carbene into an organic solution containing poly(N-heterocylic carbene), wherein a molar ratio of poly(N-heterocylic carbene) repetitive unit to at least one annular monomer is 1:1-1000, reaction temperature is minus 80 DEG C-120 DEG C, and reaction time is 10s-48h. The invention further discloses the brush polymer of a poly(N-heterocylic carbene) carbon dioxide adduct structure obtained by adding carbon dioxide to terminate reaction in the method. More brush polymers various in structure can be obtained by repeating the method. The method is simple in step, an initiator is not needed, a catalyst is metal-free, and the obtained polymer is narrow in molecular weight distribution, controllable in structure, high in grafting density and wide in application range.

Owner:SICHUAN UNIV

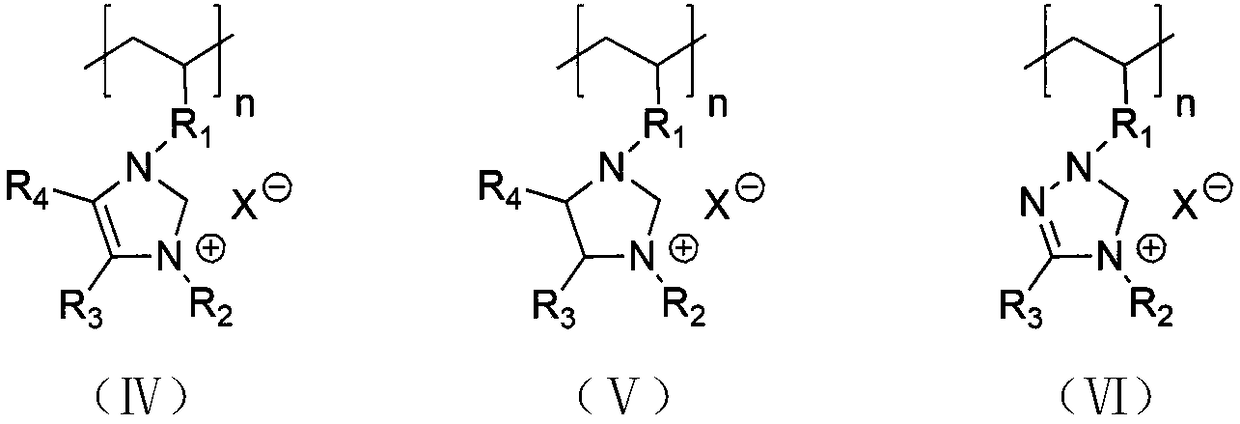

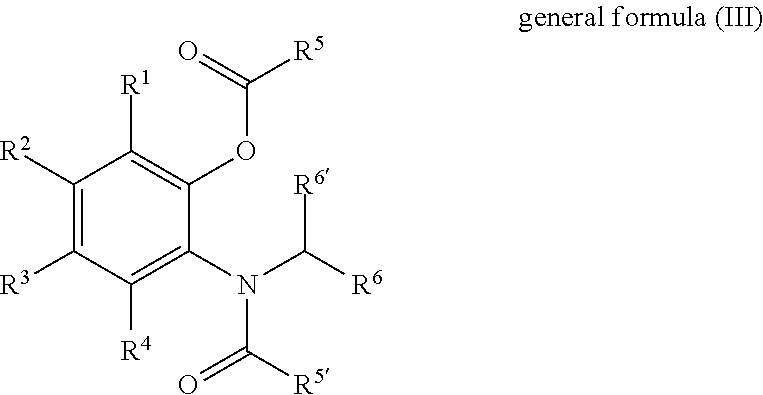

Catalyst component for olefin polymerization, catalyst system and application

ActiveCN113929799AHigh activityGood hydrogen sensitivityBulk chemical productionPolymer sciencePtru catalyst

The invention discloses a catalyst component for olefin polymerization. The catalyst component comprises magnesium, titanium, halogen and internal electron donor compounds, wherein the internal electron donor compounds comprise a first internal electron donor compound as shown in a general formula (I) and other second internal electron donor compounds containing lone pair electrons, such as a phthalate compound as shown in a general formula (II). The invention also discloses a catalyst system for olefin polymerization. The solid catalyst component provided by the invention has high activity and better hydrogen regulation sensitivity when being used for propylene polymerization; the obtained polypropylene resin has good stereoregularity; the molecular weight distribution of the polymer is moderate; and the comprehensive performance of the catalyst is excellent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of bimodal-distribution ethylene-alpha-alkene-non-conjugated dialkene random copolymer

ActiveCN101838365BHigh Mooney viscosityModerate molecular weight distributionSynthesis methodsMooney viscosity

The present invention relates to a synthesis method of a bimodal-distribution ethylene-alpha-alkene-non-conjugated dialkene random copolymer. The method comprises the following steps: a high-molecular weight part ethylene-propylene copolymer is synthesized from ethylene, propylene and hydrogen (the mol ratio is 1:1.0-3.0:0.15-0.30) and ethidene norbornylene 2-5 mL / L hexane; a low-molecular weight part ethylene-propylene copolymer is synthesized from the ethylene, the propylene and the hydrogen (the mol ratio is 1:3.0-4.5:0.9-2.0) and ethidene norbornylene 8-12 mL / L hexane; the main catalyst is soluble vanadium complex, and the cocatalyst is ethylaluminium sesquichloride; the mol ratio of Al to V is 1-100; the activating agent for the low-molecular weight part is ethyl trichloroacetate; and the mass ratio of the high-molecular weight part ethylene-propylene copolymer to the low-molecular weight part ethylene-propylene copolymer is 80 / 20-40 / 60. The copolymer has the advantages of high Mooney viscosity and moderate molecular weight distribution, and can be used for processing rubber for automobile gland strips.

Owner:PETROCHINA CO LTD

Catalyst composition and preparation method of fluorine silicon contained polymer

The invention discloses a catalyst combination that includes silanolate compound and F contained organo-silicon low molecular polymer that is selected from methyl fluoride silicone oil, hydroxyl silicone oil, and vinyl silicone oil. The weight rate of the silanolate compound and the Fl contained organo-silicon is from 1:1 to 50:1. The invention also discloses the method to make Fl contained silanol by using the catalyst compound.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

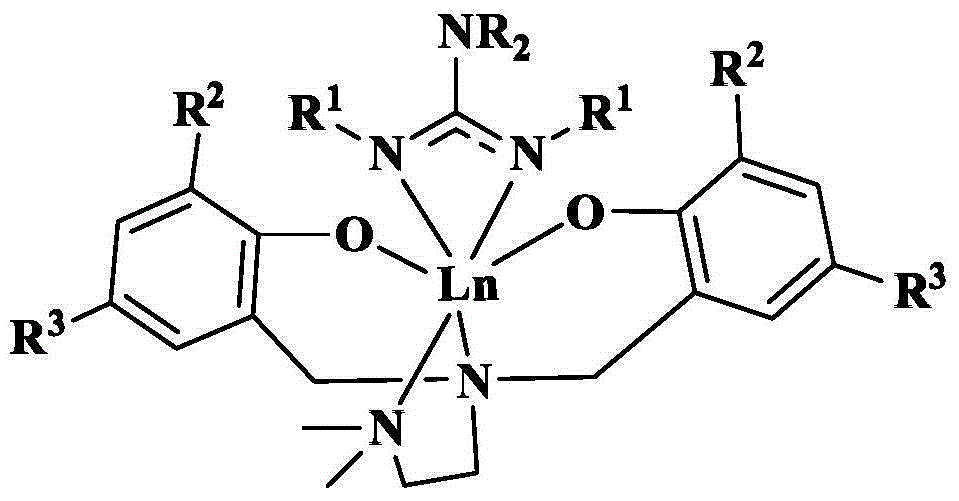

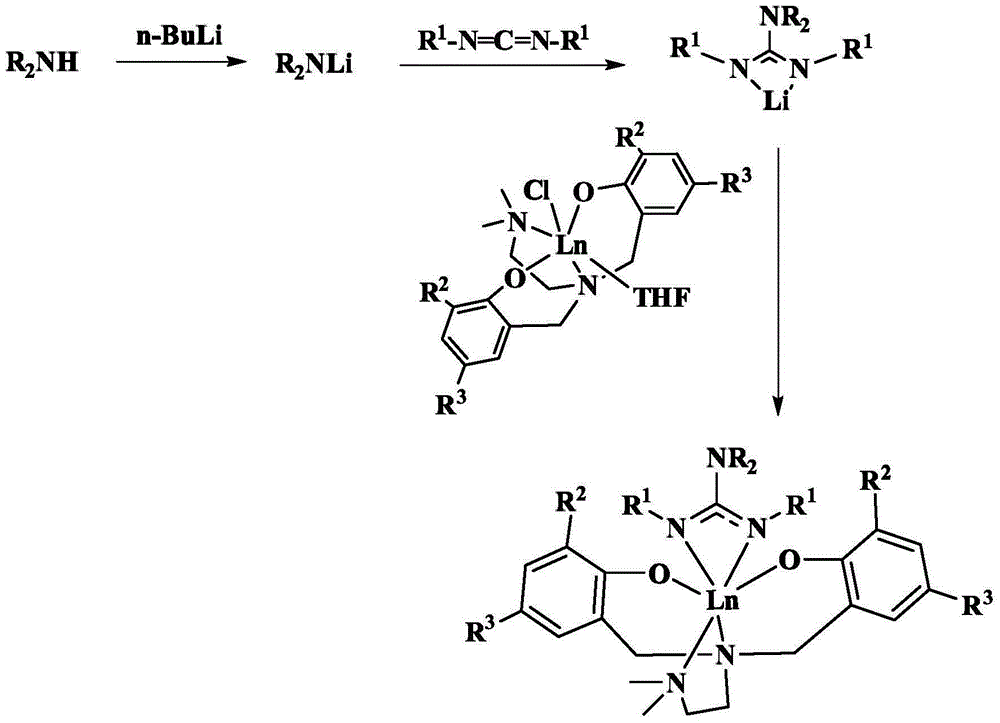

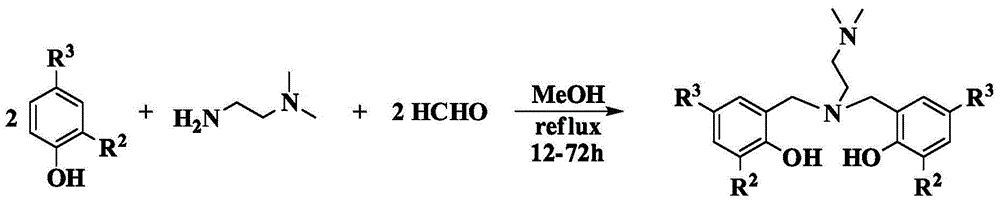

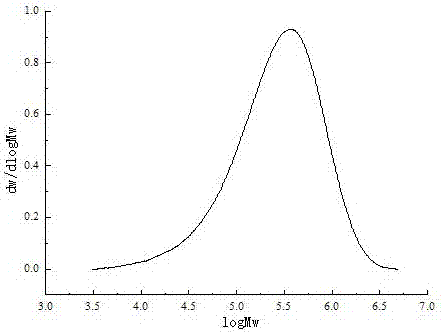

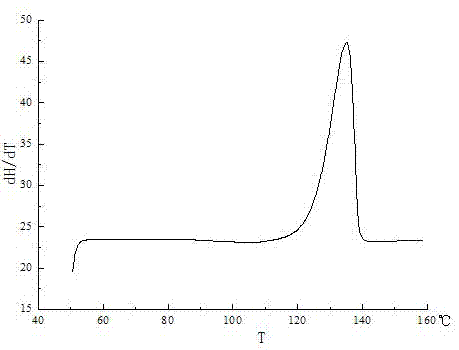

Amine bridged bisaryloxy rare earth metal guanidinium compound and its preparation method and application

InactiveCN103483362BEasy to synthesizeClear structureGroup 3/13 element organic compoundsRare earth metal compoundsKetone

Owner:SUZHOU UNIV

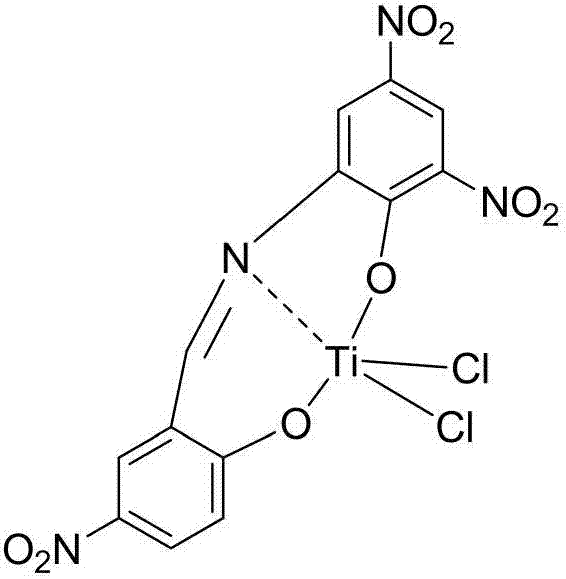

Titanium complex containing polynitro-substituent phenoxyimine ligand, preparation method and use

ActiveCN104693233BIncrease electropositivityReduce unit consumptionTitanium organic compoundsPhenyl groupTitanium tetrachloride

The invention discloses a titanium complex containing a polynitro-substituent phenoxyimine ligand, a preparation method and an application. Its preparation method is obtained by the reaction of phenoxyimine ligand with polynitro-substituent and titanium tetrachloride in dichloromethane solvent through coordination and dehydrochlorination, while ligand L is obtained from 4,6-di Nitro‑2‑aminophenol and 5‑nitrosalicylaldehyde are prepared in high yield through condensation reaction. The invention has the characteristics of cheap and easy-to-obtain raw materials and low preparation cost, and the prepared titanium complex C containing polynitro-substituent phenoxyimine ligands needs less activating dose when catalyzing ethylene polymerization, and can catalyze ethylene polymerization. It has the characteristics of ultra-high activity, high polymerization temperature resistance and long activity time, less cooling water consumption during polymerization reaction, moderate molecular weight distribution of catalytic polymerization products and high molecular weight of polymerization products, and has broad industrial application prospects.

Owner:武汉科技大学资产经营有限公司

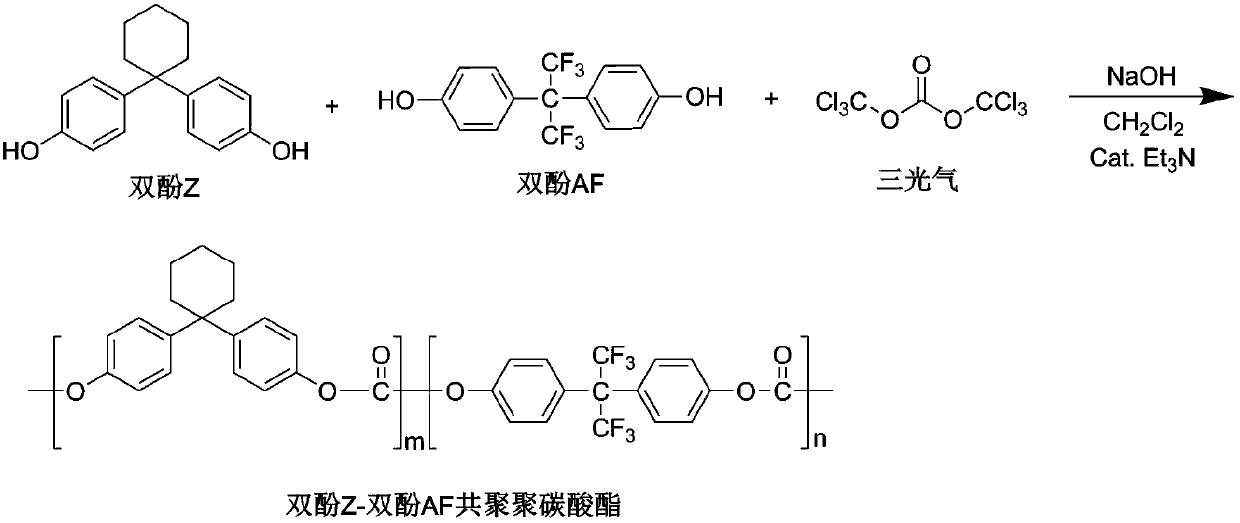

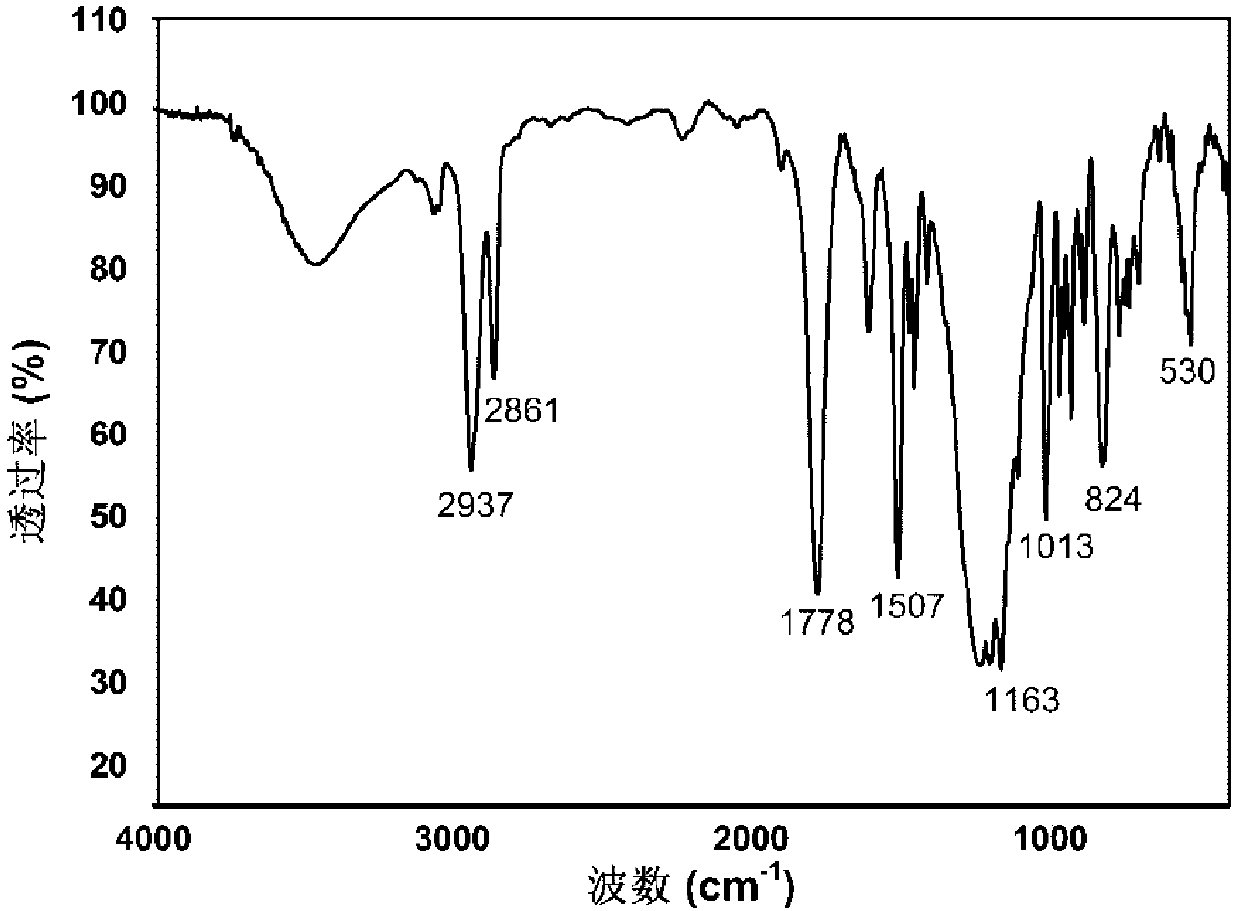

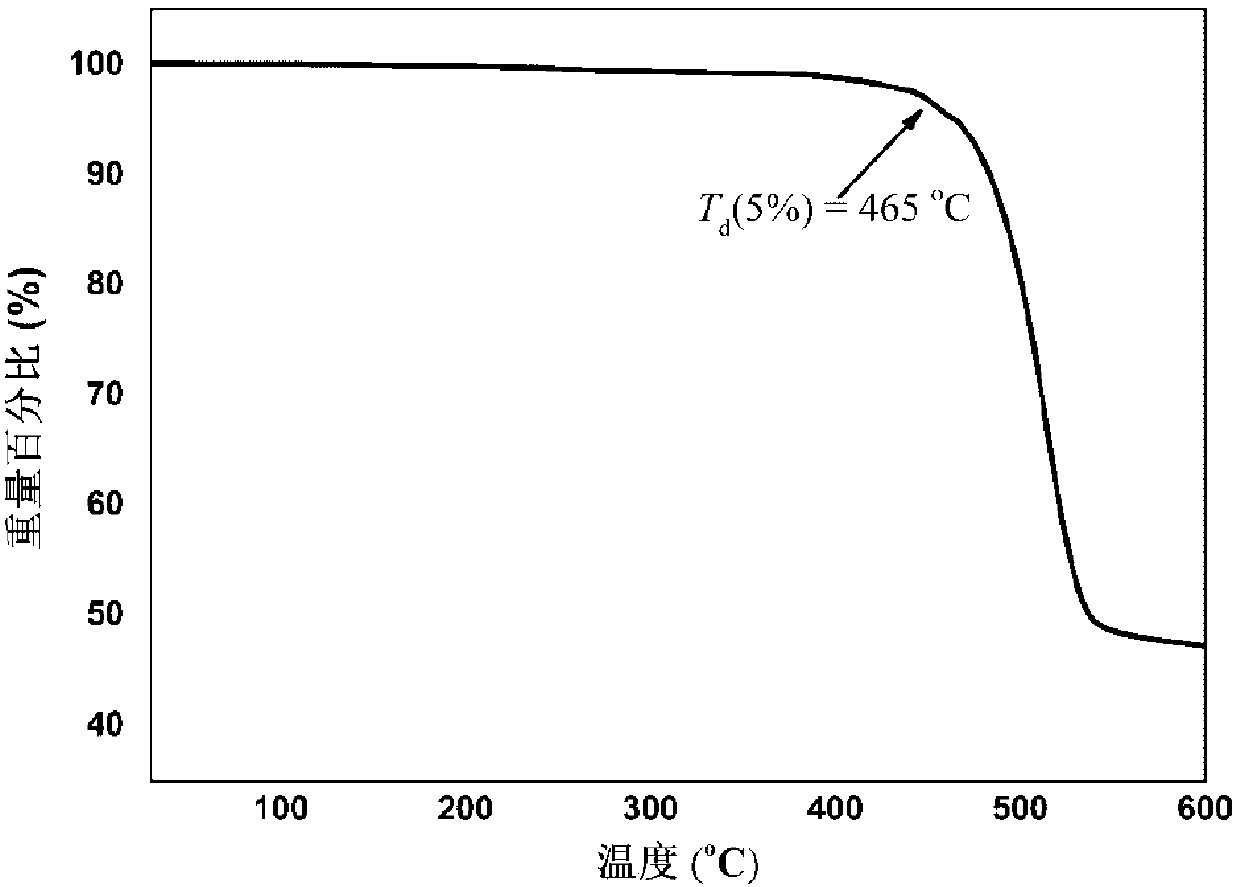

A kind of bisphenol Z-bisphenol AF copolycarbonate binding resin and its preparation method and application

ActiveCN105860048BImprove solubilityModerate molecular weight distributionElectrography/magnetographyAdhesivesSolubilityPolymer science

The invention relates to bisphenol Z-bisphenol AF copolymer polycarbonate adhesive resin as well as a preparation method and application thereof. Bisphenol Z and bisphenol AF are copolymerized in a certain proportion to prepare binary copolymer polycarbonate; and according to needs of different solubility, the bisphenol Z, the bisphenol AF and triphosgene in different proportions are copolymerized to prepare the bisphenol Z-bisphenol AF copolymer polycarbonate. According to the bisphenol Z-bisphenol AF copolymer polycarbonate, the binary copolymer polycarbonate prepared by copolymerizing the bisphenol Z, the bisphenol AF and the triphosgene is proper in molecular weight distribution, is relatively good in solubility, and is relatively low in cost; and the binary copolymer polycarbonate is used as adhesive resin of a carrier transmission material for preparing a carrier transmission layer of an organic optical conductor.

Owner:JIANGSU UNIV OF TECH

Catalyst for polymerization of olefins, preparation method thereof and applications

ActiveCN101333267AModerate molecular weight distributionPreparation raw materials are cheap and easy to obtainPolyolefinTitanium

An olefin polymerization catalyst, containing the following ingredients:(1) solid catalyst with general formula of TiAlmMgpClq(OR)s(MgCl2)t*n(THF), wherein R is an alkyl from C2-C4, m is 0-2, p is 0-10, q is 4-10, s is 3-14, t is 0.5-1.5 and n is 2-13; and (2) auxiliary catalyst of alkyl aluminum selected from alkyl aluminum or modified alkyl aluminum. The Moore ratio of aluminium in the auxiliary catalyst to titanium in the solid catalyst is 150-1000:1. The raw materials for preparing olefin polymerization catalyst are cheap and easy to get, the preparation process is simple, and the olefin polymerization catalyst can be applied in olefin polymerization to get polyolefines in appropriate molecular weight range.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol soluble polyacrylate resin and preparation method and application thereof

The invention discloses an alcohol soluble polyacrylate resin and a preparation method and an application thereof; the preparation method comprises the following steps: taking 260-800 parts of alcohols solvent, adding the solvent in a reaction kettle with a mixer, a reflux condenser, a heating jacket and a nitrogen covering layer, then heating the system to 70-150 DEG C, mixing the mixture for 10-30min; adding acrylic ester used as hard monomers, acrylic ester used as soft monomers, polar functional group monomers, organosilane monomers and initiator to react for 4-7h and obtain alcohol soluble polyacrylate resin. The alcohol soluble polyacrylate resin prepared by the method of the invention has no excitant odour, the number-average molar mass is 10,000-200,000, the molecular weight distribution is 1.1-4 and the Brookfield viscosity of the resin system is 100-5000cp. The coating which is prepared by mixing the resin with other pigments, fillers and assistants can be applied in glass, aluminium coil and polypropylene plastic for surface decoration and protective function.

Owner:SOUTH CHINA UNIV OF TECH

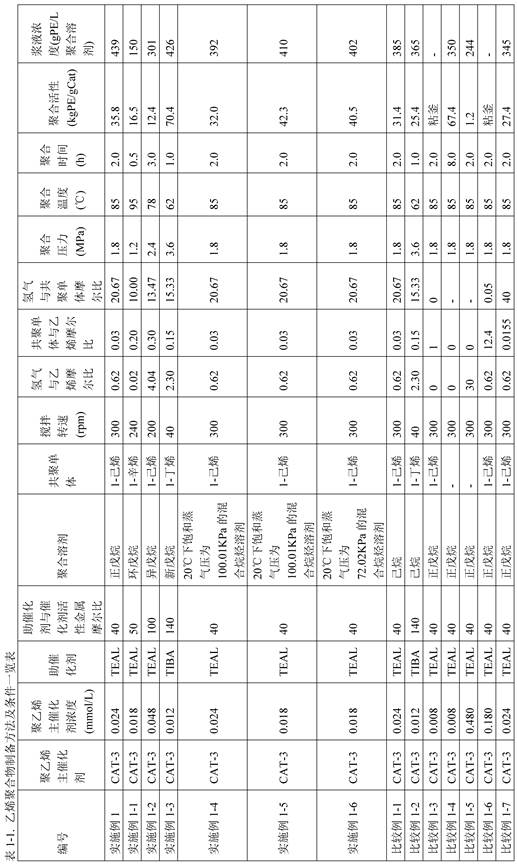

Ethylene polymer and preparation method thereof

PendingCN114507311AIncrease true densityModerate molecular weight distributionBulk chemical productionPoly ethyleneAlkane

The invention relates to an ethylene polymer and a preparation method thereof. The ethylene polymer has an average particle size of 50-3000 [mu] m, a bulk density of 0.28-0.55 g / cm < 3 >, a true density of 0.930-0.980 g / cm < 3 >, a melt index of 0.01-2500 g / 10 min under a load of 2.16 Kg at 190 DEG C, a crystallinity of 30-90%, a melting point of 105-147 DEG C, a comonomer molar insertion rate of 0.01-5 mol%, a weight-average molecular weight of 20,000-400,000 g / mol, and a molecular weight distribution of 1.8-10. In the preparation method, an alkane solvent with a boiling point of 5-55 DEG C or a mixed alkane solvent with saturated vapor pressure of 20-150KPa at 20 DEG C is used as a polymerization solvent, and under the condition that the molar ratio of hydrogen to ethylene is (0.01-20): 1, preferably (0.015-10): 1, and the molar ratio of hydrogen to a comonomer is (8-30): 1, preferably (10-25): 1, the polymerization reaction is carried out for 1-2 hours under the existence of a polyethylene catalytic system. A raw material comprising ethylene, hydrogen and a comonomer is subjected to kettle slurry polymerization to produce an ethylene polymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid catalyst component for use in olefin polymerisation, catalyst, and application thereof

ActiveUS20200071430A1Increase isotacticity and particle propertyStrong coordinationPolymer sciencePtru catalyst

Provided in the present invention is a solid catalyst component for use in olefin polymerisation, comprising Mg, Ti, a halogen, and at least one electron donor, the electron donor being a 2-substituted amino-phenyl ester compound selected from general formula (I). Also disclosed in the present invention are a catalyst comprising the solid catalyst component, and an application for the catalyst in olefin polymerisation, particularly in propylene polymerization. Also provided in the present invention is a high activity catalyst, said catalyst being able to obtain polypropylene of high isotacticity and wide molecular weight distribution, and not requiring an external electron donor to obtain high isotacticity polypropylene; during polymerization, Al / Ti and Al / Si are reduced, the polymerization time is lengthened, and high activity can still be maintained, suitable for producing low-ash polymers.

Owner:BEIJING LIHE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com