Supported non-metallocene catalyst and its preparation method and use

A technology of non-metallocene and non-metallocene ligands, applied in the field of non-metallocene catalysts, can solve the problems of not finding or showing the application of chlorinated polyethylene raw materials, etc., and achieving the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

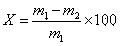

Image

Examples

Embodiment 1

[0285] The alkoxy magnesium ball adopts diethoxy magnesium ball (sphericity is 1.42, bulk density is 0.32g / cm 3 , and the average particle size is 420 microns), the contact solvent is n-octane, and the chemical treatment agent is titanium tetrachloride. The non-metallocene ligand adopts the structure compound of.

[0286] Weigh 5g of diethoxymagnesium spheres and non-metallocene ligands, add n-heptane solvent, stir at 300rpm for 30min and heat to 90 o C makes the system disperse evenly, then in the reaction system, titanium tetrachloride is added dropwise at a uniform speed, and the time of dropping is 2 hours, and after the dropwise addition is completed, continue at 90 o The reaction was stirred at C for 6 hours, filtered, washed 3 times with hexane, each time 60 ml of hexane was used, and vacuum-dried at room temperature to obtain a supported non-metallocene catalyst.

[0287] The ratio is as follows: the ratio of diethoxy magnesium spheres to n-heptane is 1mol: 1000ml...

Embodiment 2

[0290] Basically the same as Example 1, but with the following changes:

[0291] Non-metallocene ligands use , the contact solvent was changed to heptane, and the chemical treatment agent was changed to zirconium tetrachloride (TiBr 4 ), the reaction temperature was changed to 85 o C, continue at 85 after the dropwise addition o The reaction was stirred at C for 10 hours.

[0292] The ratio is as follows: the ratio of alkoxymagnesium spheres to contact solvent is 1mol: 1500ml; the molar ratio of alkoxymagnesium spheres to non-metallocene ligands is 1: 0.015; the molar ratio of alkoxymagnesium spheres to chemical treatment agent It is 1:3.

[0293] Supported non-metallocene catalysts are designated CAT-2.

Embodiment 3

[0295] Basically the same as Example 1, but with the following changes:

[0296] Alkoxymagnesium spheres are changed to dipropoxymagnesium spheres (Mg(OPr) 2 ) (sphericity is 1.83, bulk density is 0.40g / cm 3 , and the average particle size is 530 μm), the non-metallocene ligand adopts , the contact solvent was changed to ethylbenzene, and the reaction temperature was changed to 95 o C, continue at 95 after the dropwise addition o The reaction was stirred at C for 4 hours.

[0297] The ratio is as follows: the ratio of alkoxymagnesium spheres to contact solvent is 1mol: 2000ml; the molar ratio of alkoxymagnesium spheres to non-metallocene ligands is 1:0.02; the molar ratio of alkoxymagnesium spheres to chemical treatment agent It is 1:5.

[0298] Supported non-metallocene catalysts are designated CAT-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com