Preparation method of steel rod of rod mill

A rod mill and steel rod technology, applied in the field of wear-resistant materials, can solve problems such as low production efficiency, high production cost, and high labor intensity, and achieve the effects of improving efficiency, low cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

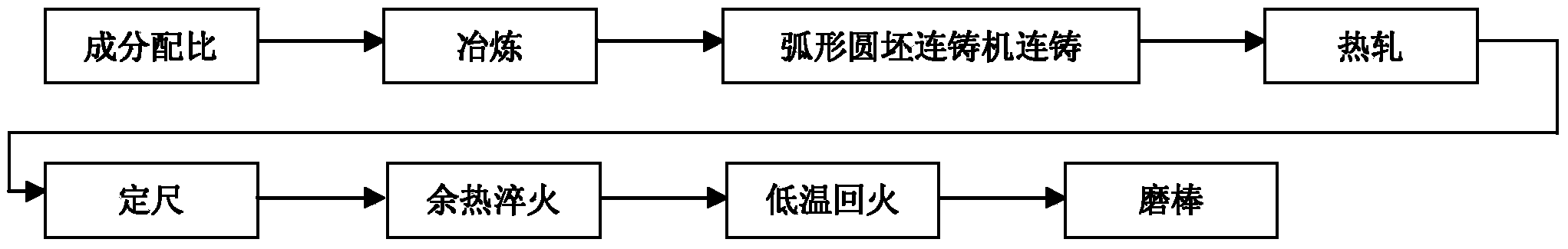

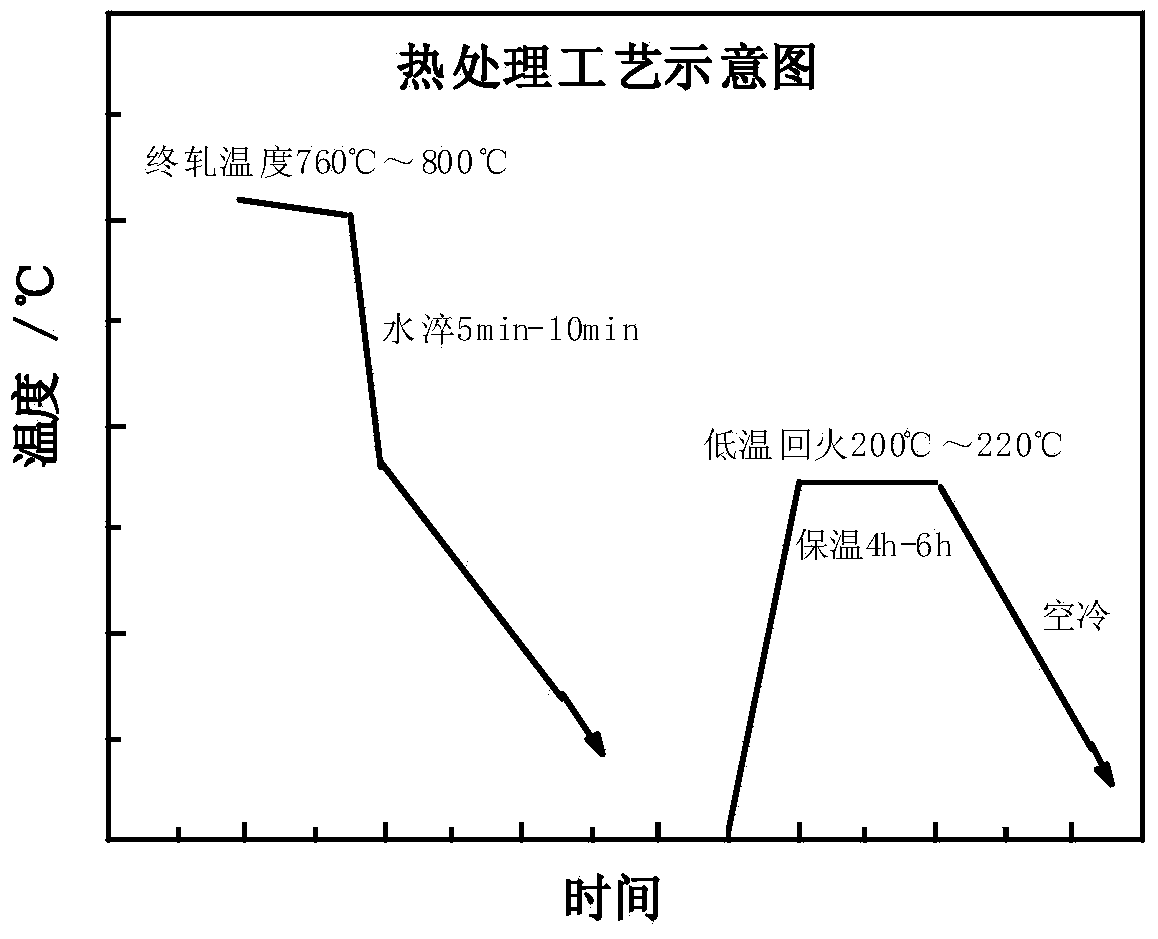

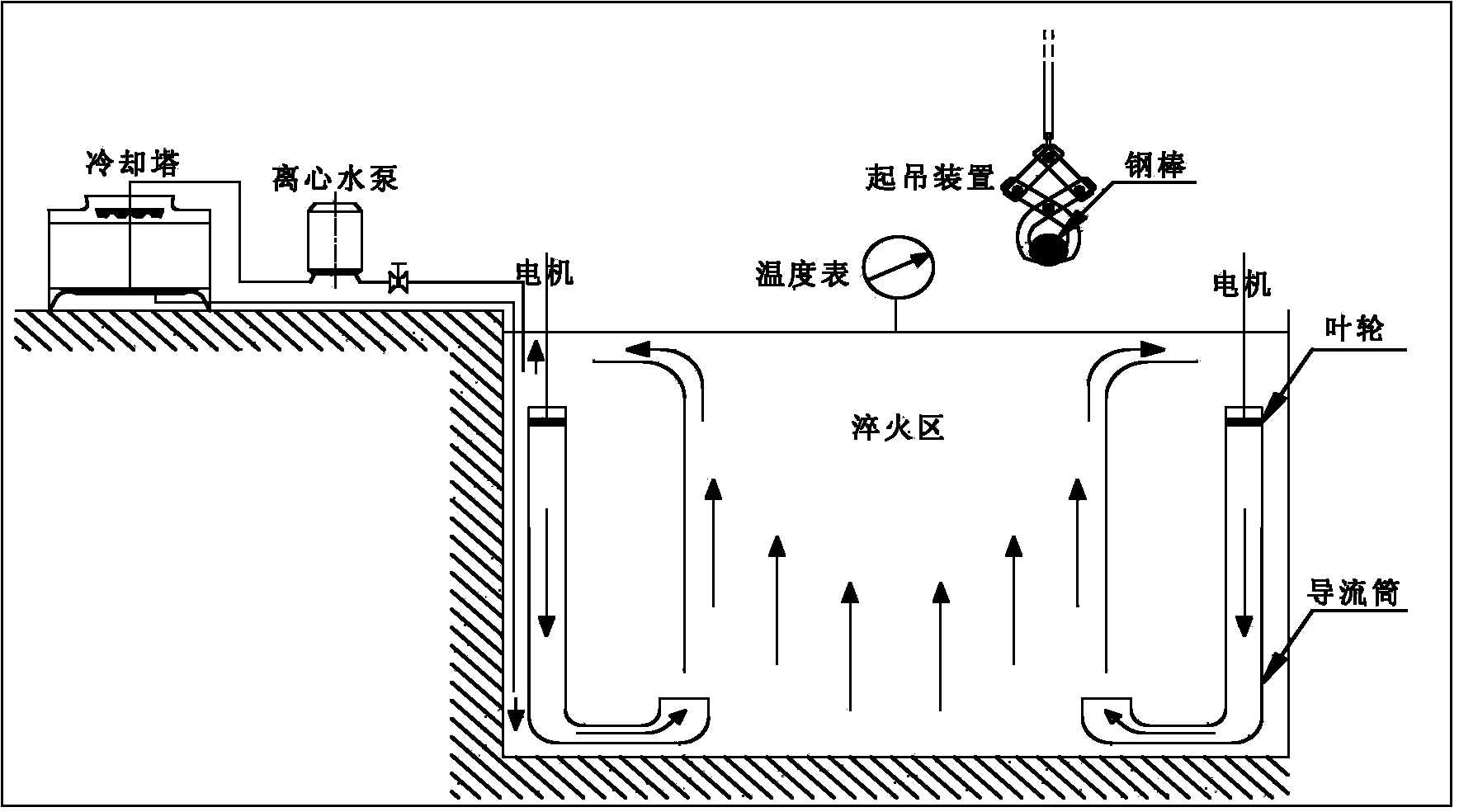

Method used

Image

Examples

Embodiment 1

[0043] Size: According to the size parameters of the MBS1530 rod mill: cylinder diameter 1500mm, cylinder length 3000mm, it is determined that the rod mill size is 2850mm in length and 105mm in diameter.

[0044] Composition: mass percentage according to C: 0.6-0.85%, Si: 0.17-0.37%, Mn: 0.7-1.2%, P: ≤0.035%, S: ≤0.035%, Cr: ≤0.6%, Nb: 0.01-0.02% Proportion;

[0045] 1) Smelting: In order to ensure the quality requirements, smelting, continuous casting, and hot rolling are carried out by large steel mills. Firstly, the composition is proportioned according to the mass percentage of the chemical composition of the steel rod of the rod mill. Converter-LF furnace technology can be used for molten steel smelting. In this process, the composition ratio must be accurate, and the content of S, P and other impurity elements must be strictly controlled;

[0046] 2) Continuous casting: After the smelting is completed, the continuous casting operation is carried out on the arc-shaped r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com