Patents

Literature

159results about How to "The process is simple and feasible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for isolation and purification of xanthophyll crystals from plant oleoresin

ActiveUS7271298B2Minimal use levelThe process is simple and feasibleOrganic chemistryAlcoholOrganic solvent

A process for isolation and purification of xanthophylls crystals from plant oleoresin is disclosed. The organic solvents involved in the process is no other than food grade alcohol. The process includes saponifying the plant oleoresin containing xanthophyll diesters, neutralizing the saponified reaction mixture with an acid and washing water-soluble impurities and other fat-soluble oil with warm water and alcohol, respectively. The process can improve purity and yield of products, by which the content and the recovery of xanthophylls are as high as 90% and 80% respectively. And the process is economical and easy to perform in industrial production.

Owner:ZHEJIANG MEDICINE CO LTD

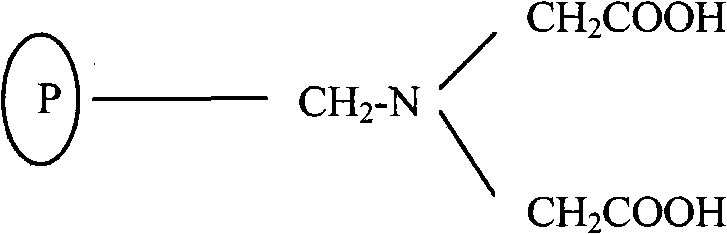

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Process for producing diesel oils of superior quality and low solidifying point from fraction oils

InactiveUS6413412B1Quality improvementRelaxing severityHydrocarbon oil crackingTreatment with hydrotreatment processesSingle stageChemistry

This invention discloses a single-stage process for producing diesel oils of superior quality and low solidifying point from fraction oils under controlled reaction conditions, comprising a hydrorefining step, optionally a hydroupgrading step and a hydrodewaxing step combined in series. The process of the invention is simplified, the operation is simple, the adaptability to feedstocks is good, and the quality of diesel oil product is improved, and when the hydroupgrading step is comprised, the cetane number of the product is further boosted. A hydrorefining catalyst having a higher content of NiO and good anti-coking performance and a hydroupgrading catalyst and hydrodewaxing catalyst having an adequate acidity and strong resistance to NH3 and H2S respectively are preferably used in the present invention to achieve better results.

Owner:CHINA PETROCHEMICAL CORP +1

Process for extracting iodine from kelp

InactiveCN1840469ASave the drying processReduce manufacturing costHalogen/halogen-acidsMANNITOL/SORBITOLIodine

The disclosed method to extract I2 from kelp comprises: with fresh kelp as material, cutting up, adding 200wt% water to dip for 30-50min; putting soak into pond, adjusting pH value with alkali, while filling gas to stir and then filter to obtain the clear liquid with I2 and mannitol; acidifying and oxidizing to obtain dissociative I2 and then adsorb with basic anion exchange resin; desorbing the I2 on resin with Na2S2O3; adding strong H2SO4 and KClO3 to separate out coarse I2; cleaning, and refining with 25wt% strong H2SO4 at 140Deg to obtain the refined iodine. This invention reduces cost and source.

Owner:威海长青海洋科技股份有限公司

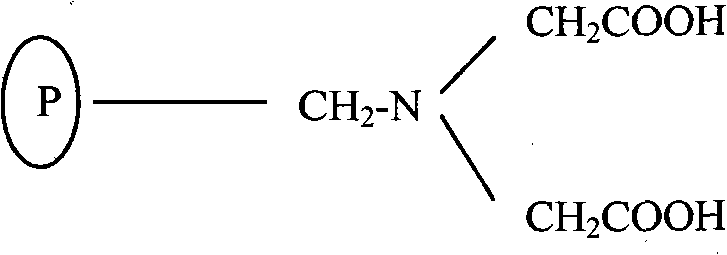

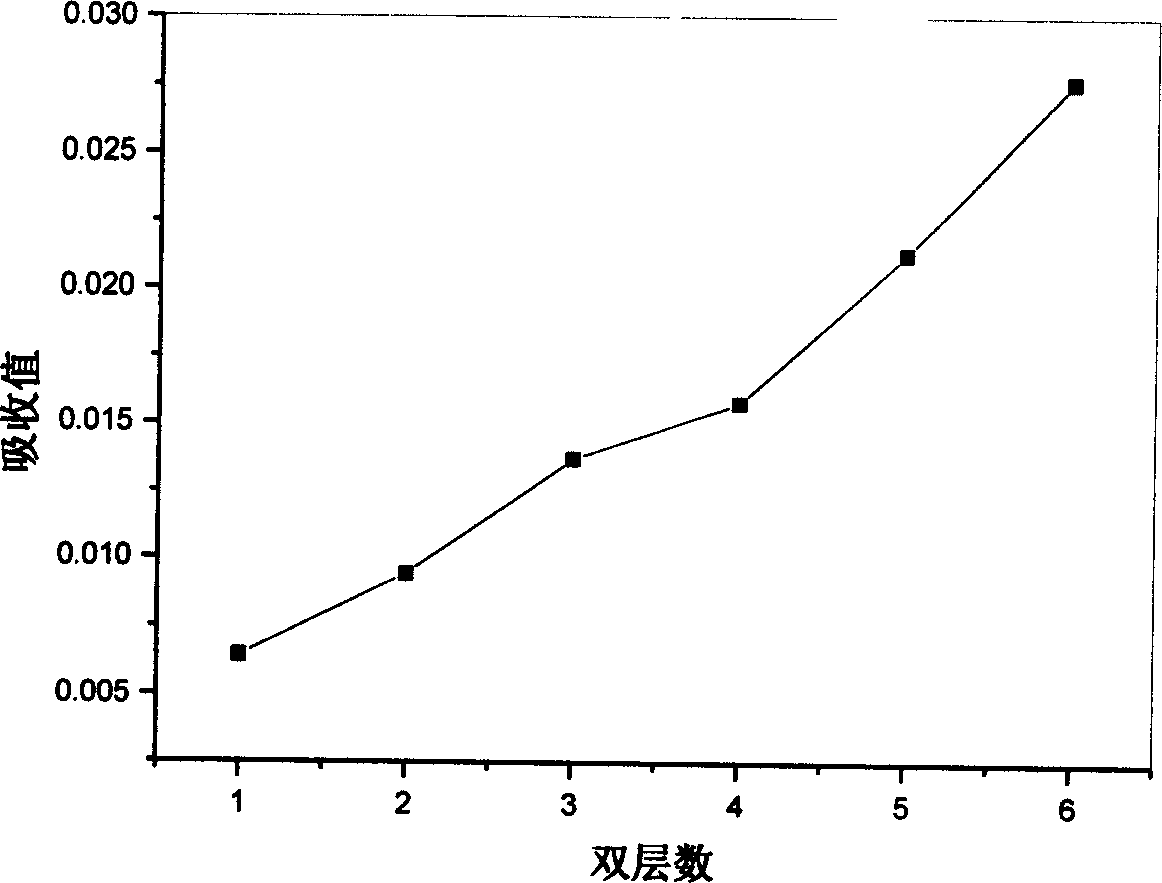

Method for layer-layer self-assembling and fixing biological active factor on tissue engineering material

InactiveCN1515324AThe process is simple and feasibleGood repeatabilityProsthesisPolyelectrolyteBioactive scaffold

The present invention discloses a method for fixing bioactive factor on tissue engineering material by adopting layer-layer self-assembling mode. The method utilizes the characteristics of that under the condition of a certain pH environment the natural bioactive factor is charged and adopts the layer-layer self-assembling mode of said bioactive factor and other polyelectrolyte with opposite charge to assemble the bioactive factor on the ionized material surface so as to obtain the tissue engineering material with biological activity. The method is suitable for modification of tissue engineering support with complex structure, and the constructed bioactive support can be extensively used in various tissue engineering fields.

Owner:ZHEJIANG UNIV

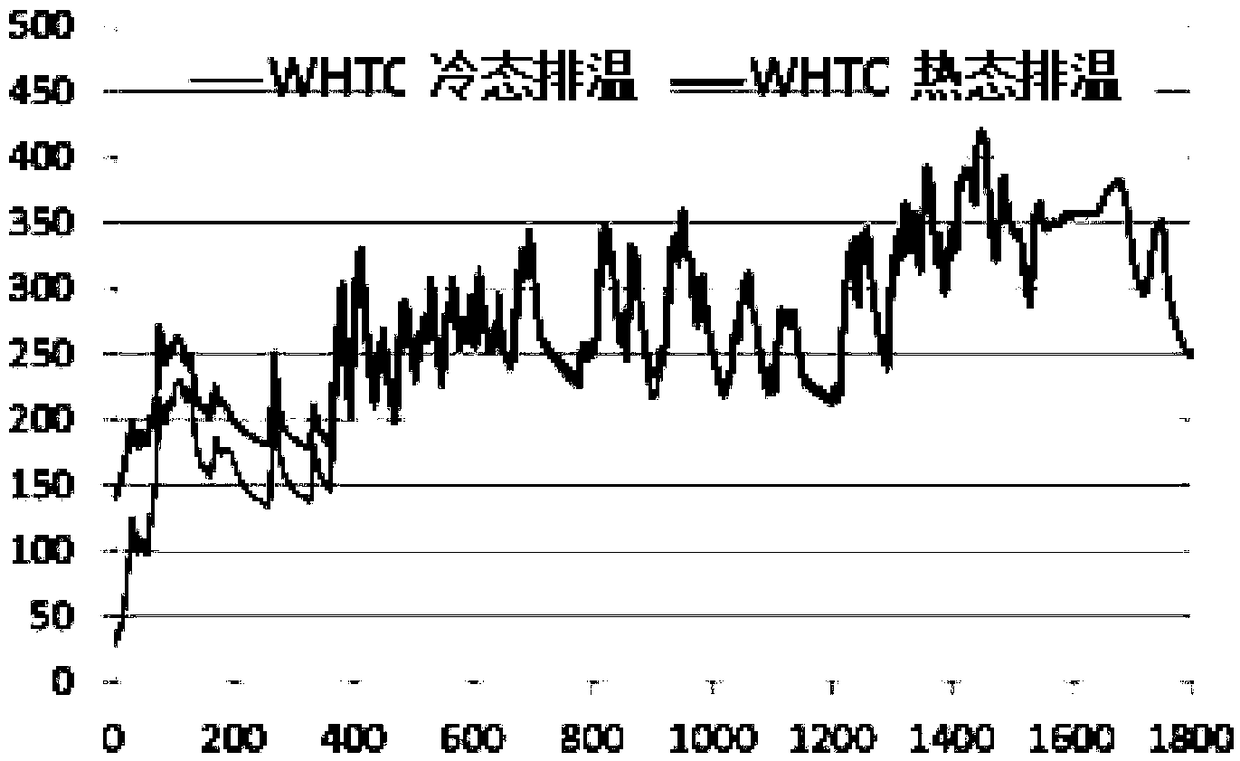

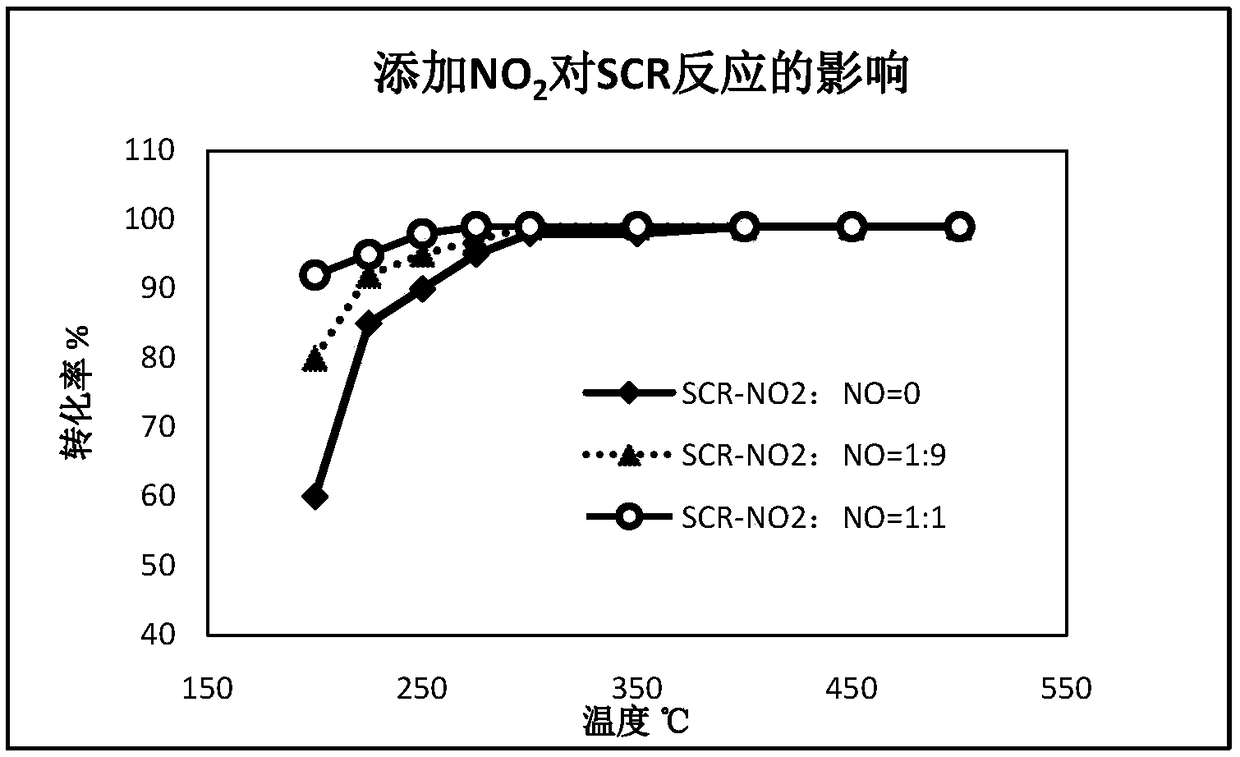

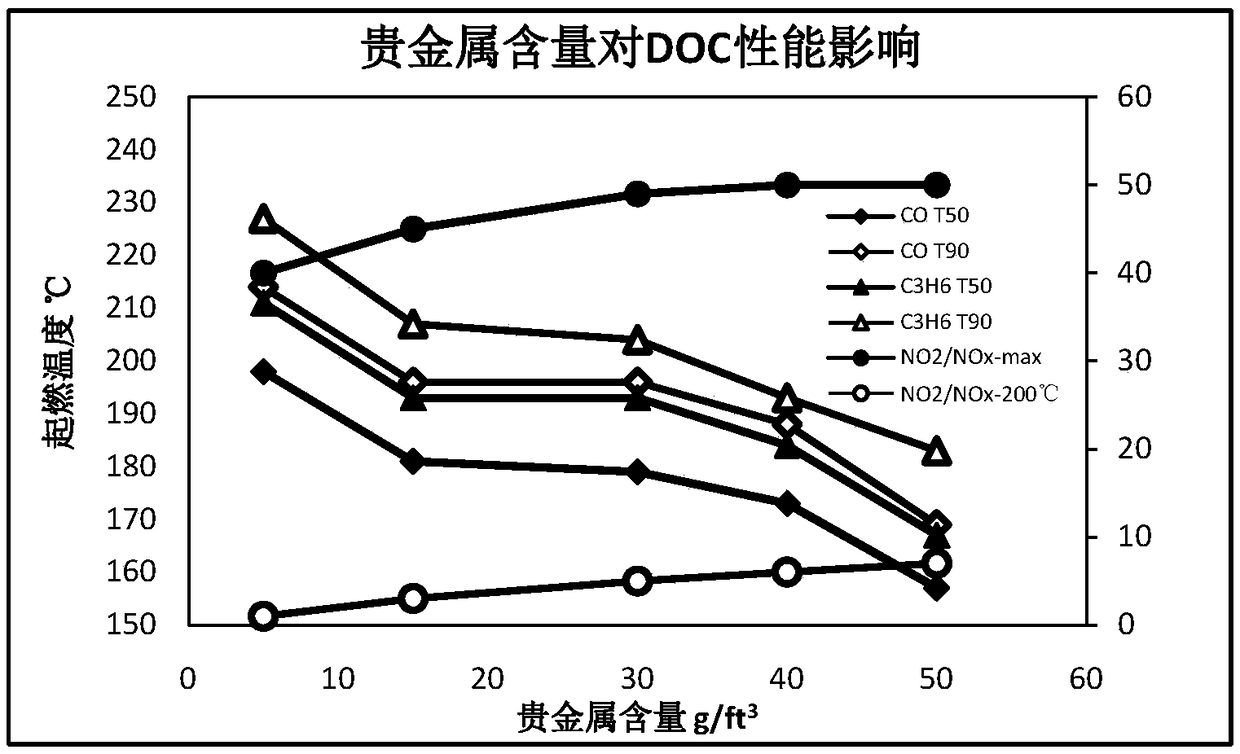

DOC matched with SCR and preparation method thereof

ActiveCN108927147AHigh NO oxidation performanceHigh adsorption oxidation to NO

<sub>2</sub>

s efficiencyGas treatmentMolecular sieve catalystsEngineeringPalladium

The invention relates to a diesel vehicle oxidization catalyst, which includes noble metals comprising, but not limited to one or more of Pt, Pd, Rh and the like. The diesel vehicle oxidization catalyst includes a front end and a rear end, wherein the palladium content of the front end is higher than that of the rear end. The oxidization DOC catalyst is matched with SCR and can oxidize NO into NO2at low temperature, so that catalytic initiation temperature of HC and CO is reduced as most as possible, and the capability of oxidizing NO into NO2 at a low temperature (200 DEG C) is enhanced. A corresponding method is also provided in the invention, which is easy to carry out and is low in cost.

Owner:SINOCAT ENVIRONMENTAL TECH

Compound feed for young crabs during their later stage, and its prepn. method

InactiveCN1911082AGood performanceAttractiveClimate change adaptationAnimal feeding stuffLarvaChemistry

A mixed forage for the later-phase larvae of scylla is prepared proportionally from protein, fat, fibers, Ca, P, and phosphatide through pulverizing, sieving, mixing, adding peptone, fish slurry and edible oil, mixing, modifying, granulating, drying and cooling.

Owner:XIAMEN UNIV

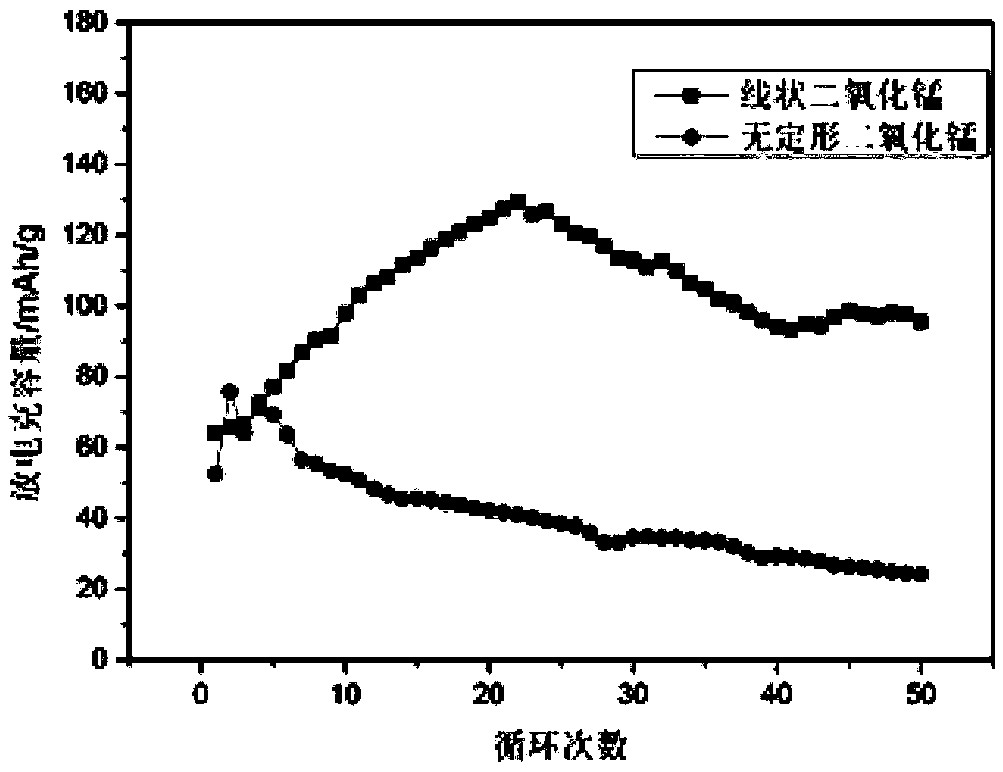

A rechargeable zinc-manganese battery and a preparation method thereof

InactiveCN109148877AThe process is simple and feasibleGood experimental reproducibilitySecondary cellsPositive electrodesUltrasound attenuationAspect ratio

The invention provides a rechargeable zinc-manganese battery and a preparation method thereof. A positive electrode adopts a linear alpha-MnO2 material to replace a traditional amorphous manganese dioxide material, and the linear alpha-MnO2 material has a uniform structure. The large tunnels and vacancies in MnO2 increase the contact between the active material and the electrode, reduce the internal resistance of the battery, and improve the diffusivity of protons. The larger aspect ratio of MnO2 can make the preferred orientation degree of the material higher, thus improving the rate performance of the battery. Stable structure, not easy to collapse, the activity can be maintained at a high level, the decay rate is slow, more conducive to the battery cycle performance. In accordance withthat present invention, the preparation method of the alpha-MnO2 material is simple and feasible, the experimental reproducibility is good, the raw materials used are cheap and easy to obtain, the linear alpha-MnO2 material has a uniform structure, large aspect ratio, and stable structure, and is not easy to collapse and slow in attenuation rate.

Owner:桑顿新能源科技(长沙)有限公司

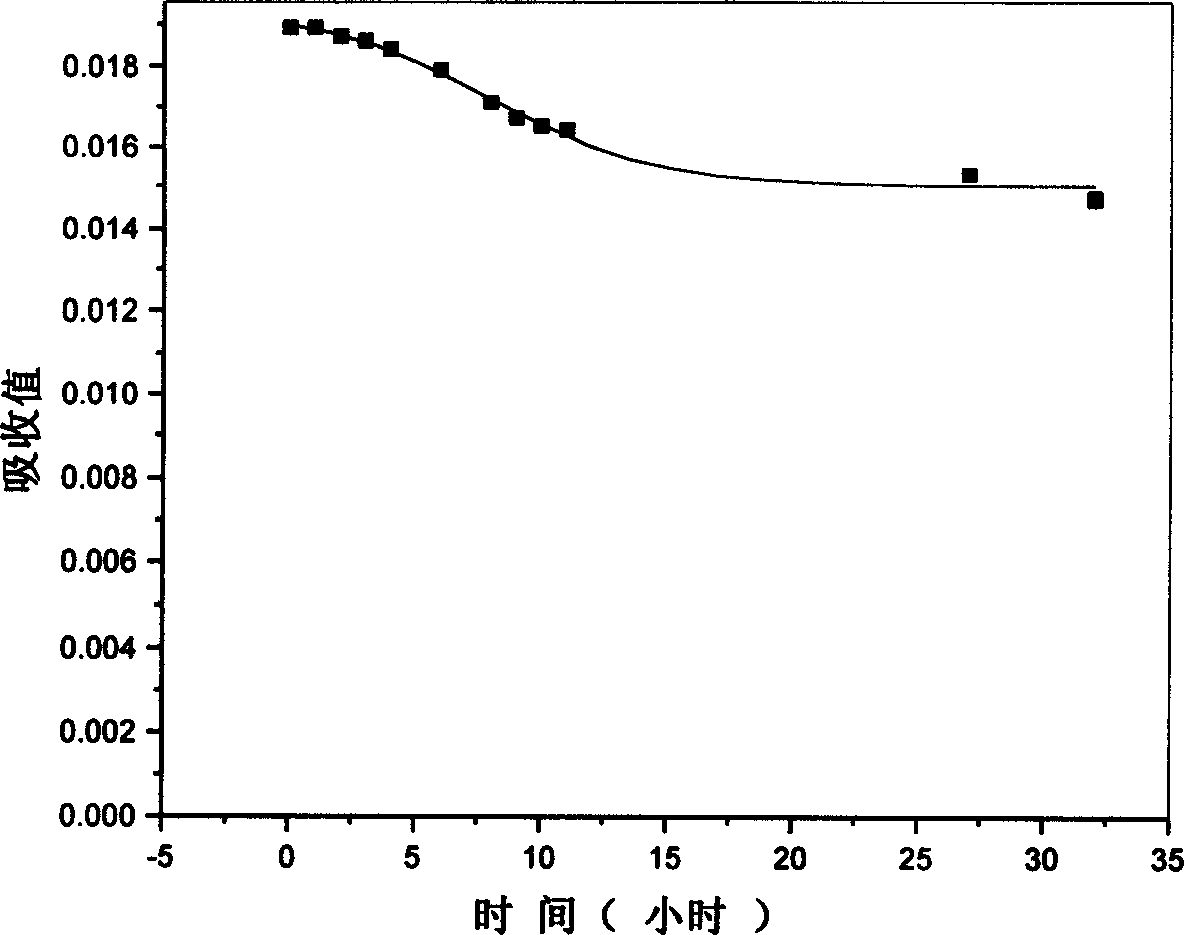

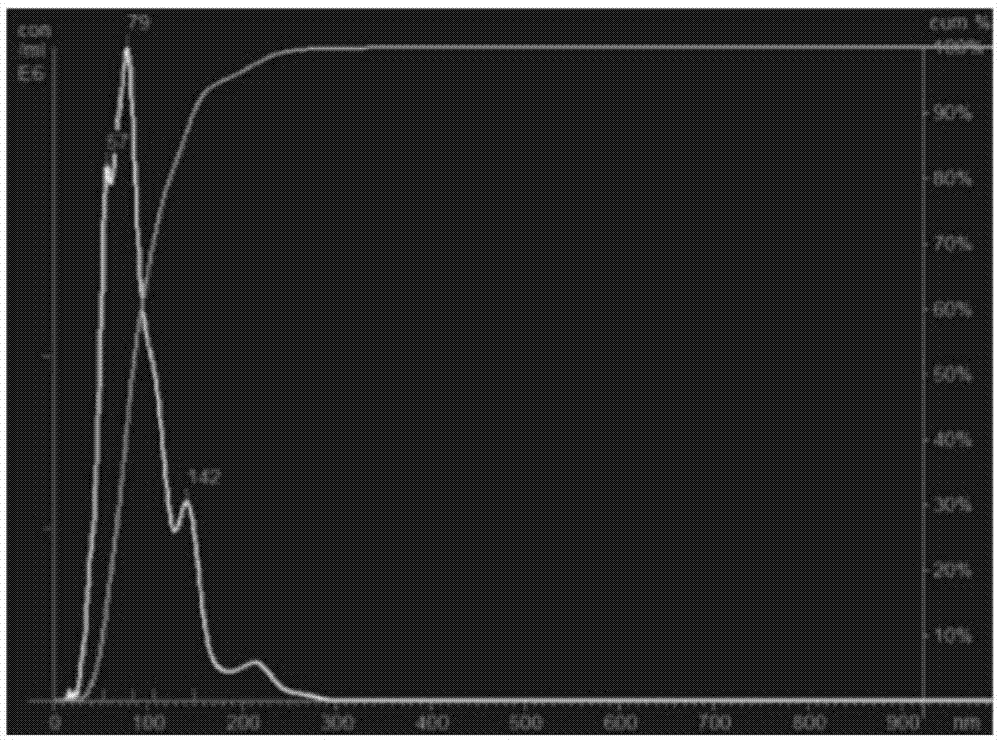

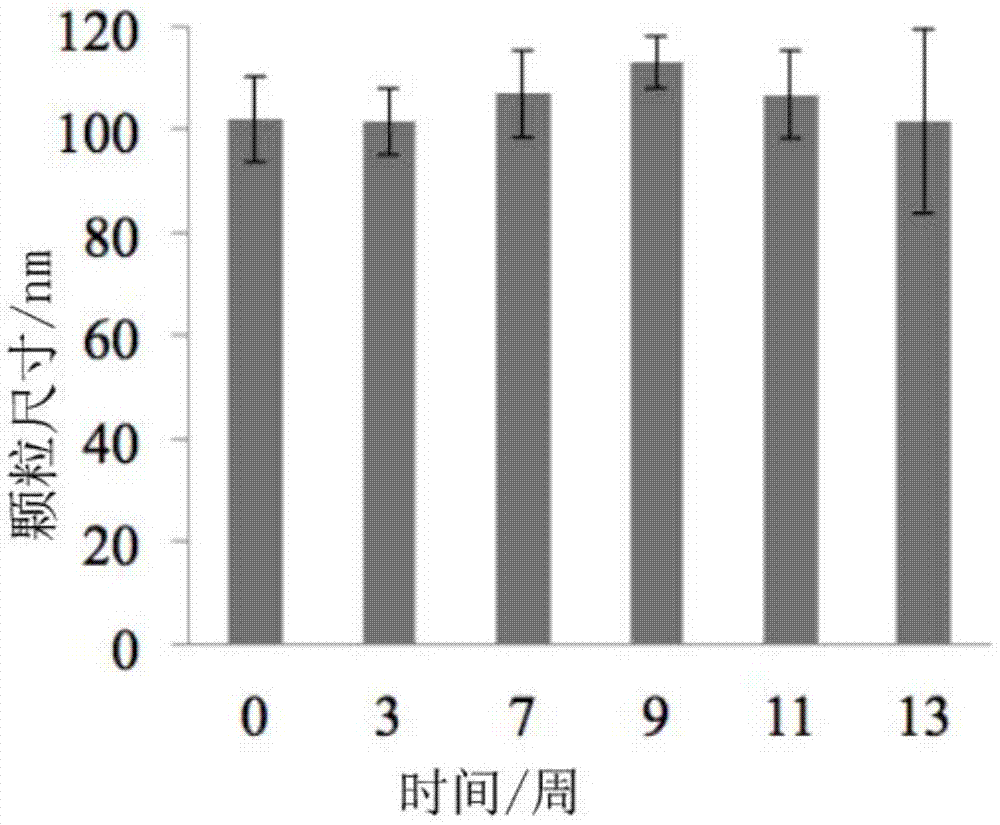

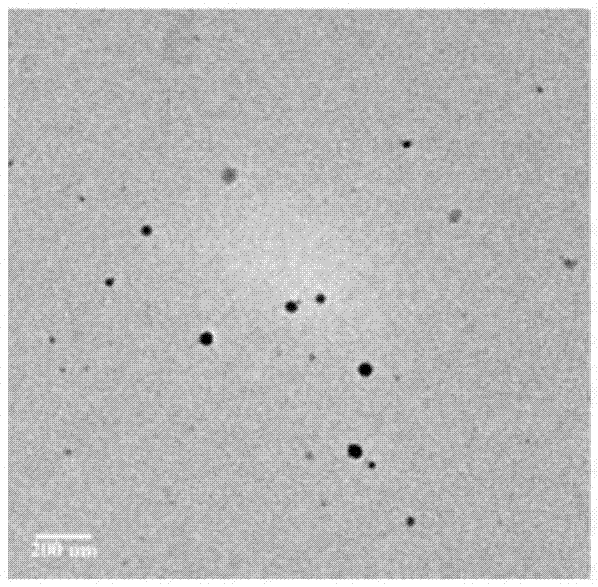

Nanometer selenium hydrosol having antitumor activity, preparation method, preservation method and applications thereof

ActiveCN107412280AStrong physical adsorption capacityAvoid Agglomeration and PrecipitationPeptide/protein ingredientsSolution deliverySide effectCancer cell

The present invention relates to the technical field of nanometer selenium hydrosols, particularly to a nanometer selenium hydrosol having antitumor activity, a preparation method, a preservation method and applications thereof, wherein the hydrosol at least contains nanometer selenium with a concentration of 0.5-5.0 mmol / L, and Coriolus versicolor polysaccharide protein with a concentration of 100.0-600.0 mg / L. The preparation method at least comprises: S01, adding a solution containing selenium ions and / or selenous ions to a Coriolus versicolor polysaccharide protein aqueous solution; S02, adding a reducing agent solution to the mixed solution obtained in the step S01 in a dropwise manner, and shaking; and S03, carrying out volume metering on the product obtained after the reducing reaction, and carrying out dialysis treatment. According to the present invention, the hydrosol is stable at a temperature of 2-10 DEG C; and the Coriolus versicolor polysaccharide protein has the hydrophilic hydroxyl and the hydrophilic amino, and the two groups can enhance the affinity between the nanometer selenium and the cancer cells, and can improve the uptake on the nanometer selenium by tumor cells so as to achieve the whole treatment effect of medication dosage reducing, treatment effect improving and less toxic-side effect, such that the effective scheme is provided for the combination chemotherapy of cancers in the clinic.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST +2

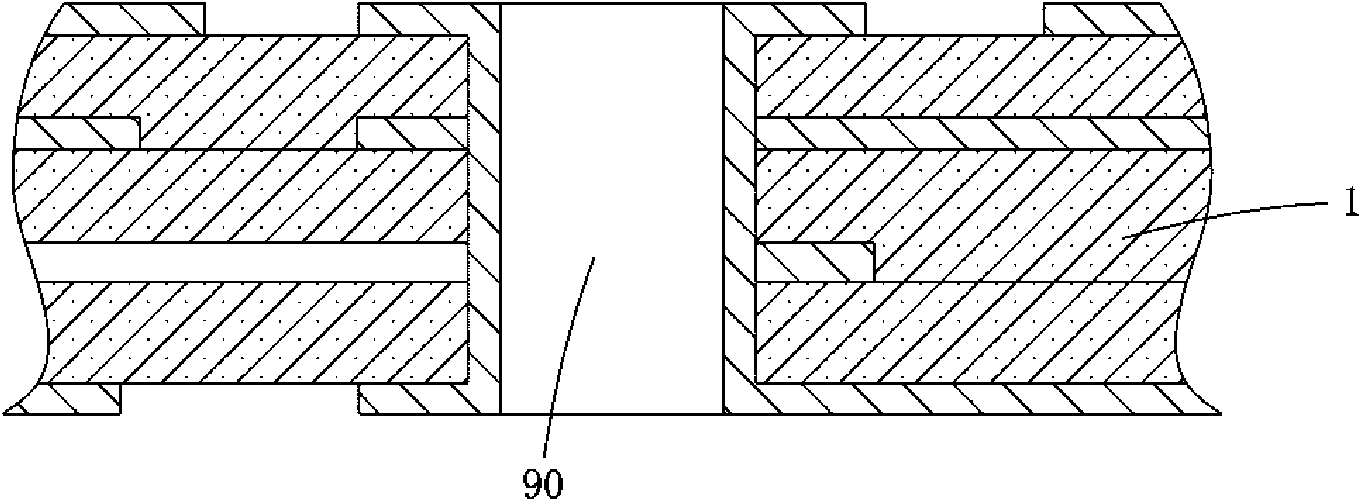

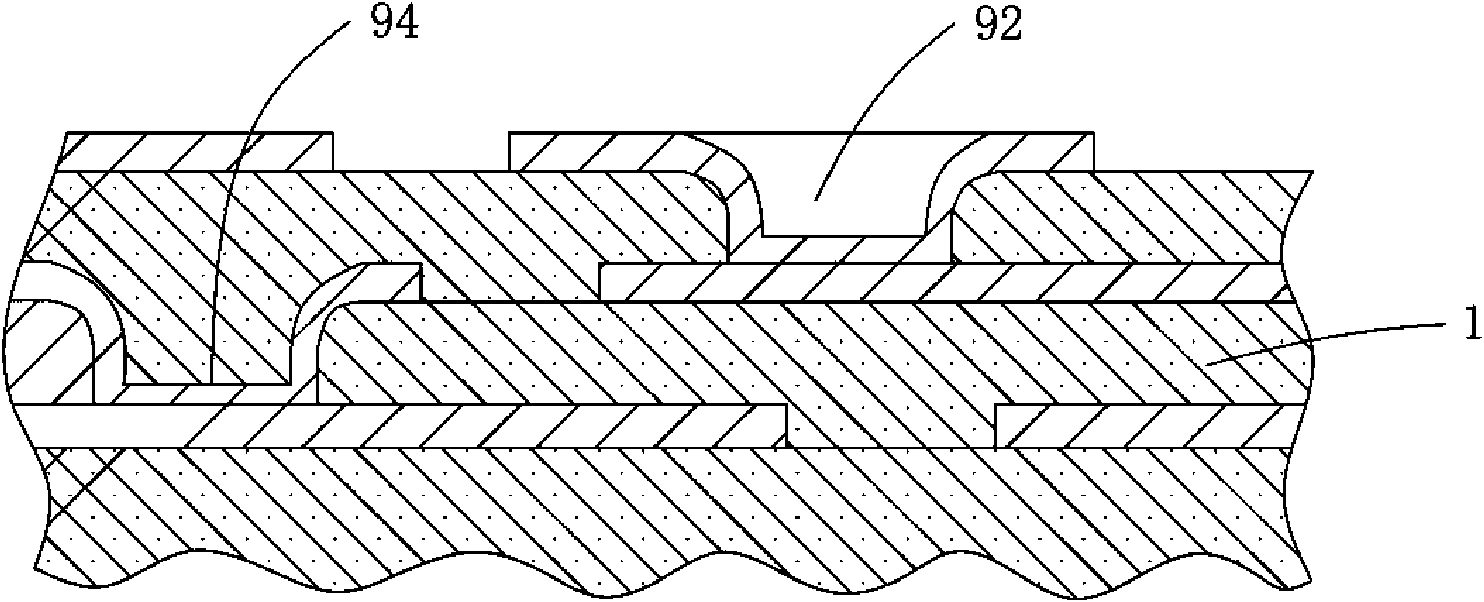

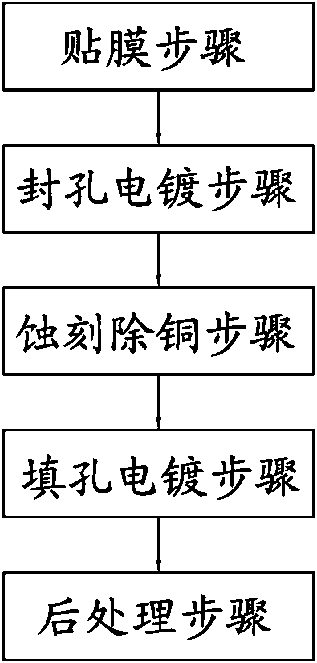

Method for molding via hole of printed circuit board

ActiveCN101605434AReduce area occupationExcellent electrical performancePrinted element electric connection formationCopper highEngineering

The invention relates to a method for molding a via hole of a printed circuit board, which comprises the steps of: film attachment, in which the surfaces of upper and lower surface copper layers of an insulating dielectric layer drilled with the via hole are attached with photosensitive films, and the positions, which correspond to the via hole, on the photosensitive films are provided with film openings; hole-sealing electroplating, in which an orifice end, which is near a first surface, of the via hole is closed through a copper electroplating process on the first surface of the insulating dielectric layer; hole-filling electroplating, in which the via hole is completely filled with copper, and the filled copper is connected with the surface copper layer of a second surface of the insulating dielectric layer, namely the connection of solid via holes between upper and lower adjacent line layer patterns is realized; and the post-treatment, in which the two surfaces of the insulating dielectric layer are subjected to subsequent treatment respectively, and a level conducting surface which is convenient for implementing subsequent pattern line production working procedures is obtained by removing the photosensitive films, removing the filled copper higher than the surface copper layers, and leveling the board surface. The method has the advantages of simple, convenient and feasible process, low cost, and small area occupation, and upper and lower corresponding line rackets of the hole are integrally preserved, are not damaged by the via hole and have good electrical properties.

Owner:美龙翔微电子科技(深圳)有限公司

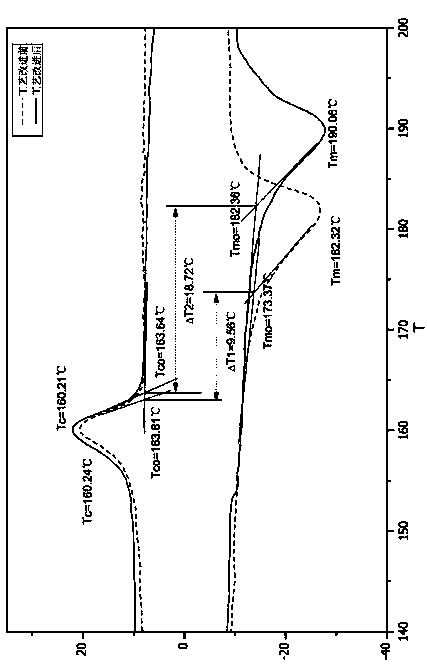

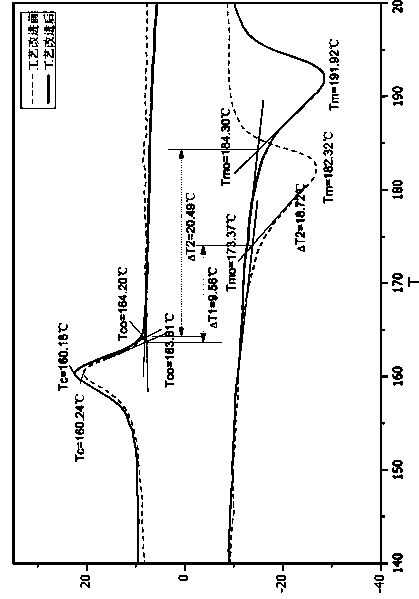

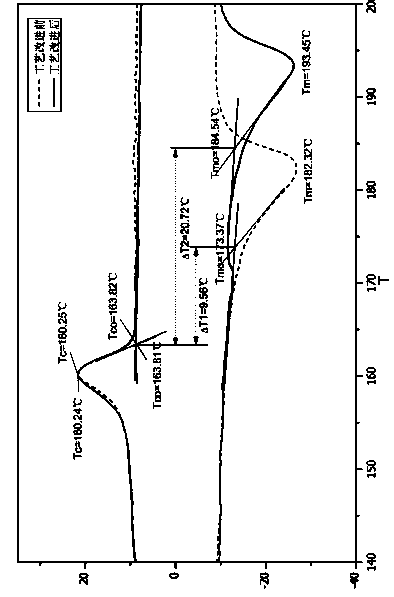

Polyamide powder for laser sintering and preparation method thereof

ActiveCN104385608AThe process is simple and feasibleGood sphericitySelective laser sinteringPolyamide

The invention discloses a polyamide powder for laser sintering and a preparation method thereof. The preparation method is characterized by comprising rapidly cooling a polyamide solution to a temperature lower than the crystallization temperature of polyamide by 15-20 DEG C, then heating to the crystallization temperature of polyamide, and slowly cooling until polyamide powder is precipitated. The difference value of the initial melting temperature Tmo and the initial crystallization temperature Tco of polyamide powder prepared by employing the method is increased, the powder is narrow in particle size distribution and good in fluidity, and the polyamide powder is especially suitable for selective laser sintering.

Owner:HUNAN FARSOON HIGH TECH CO LTD

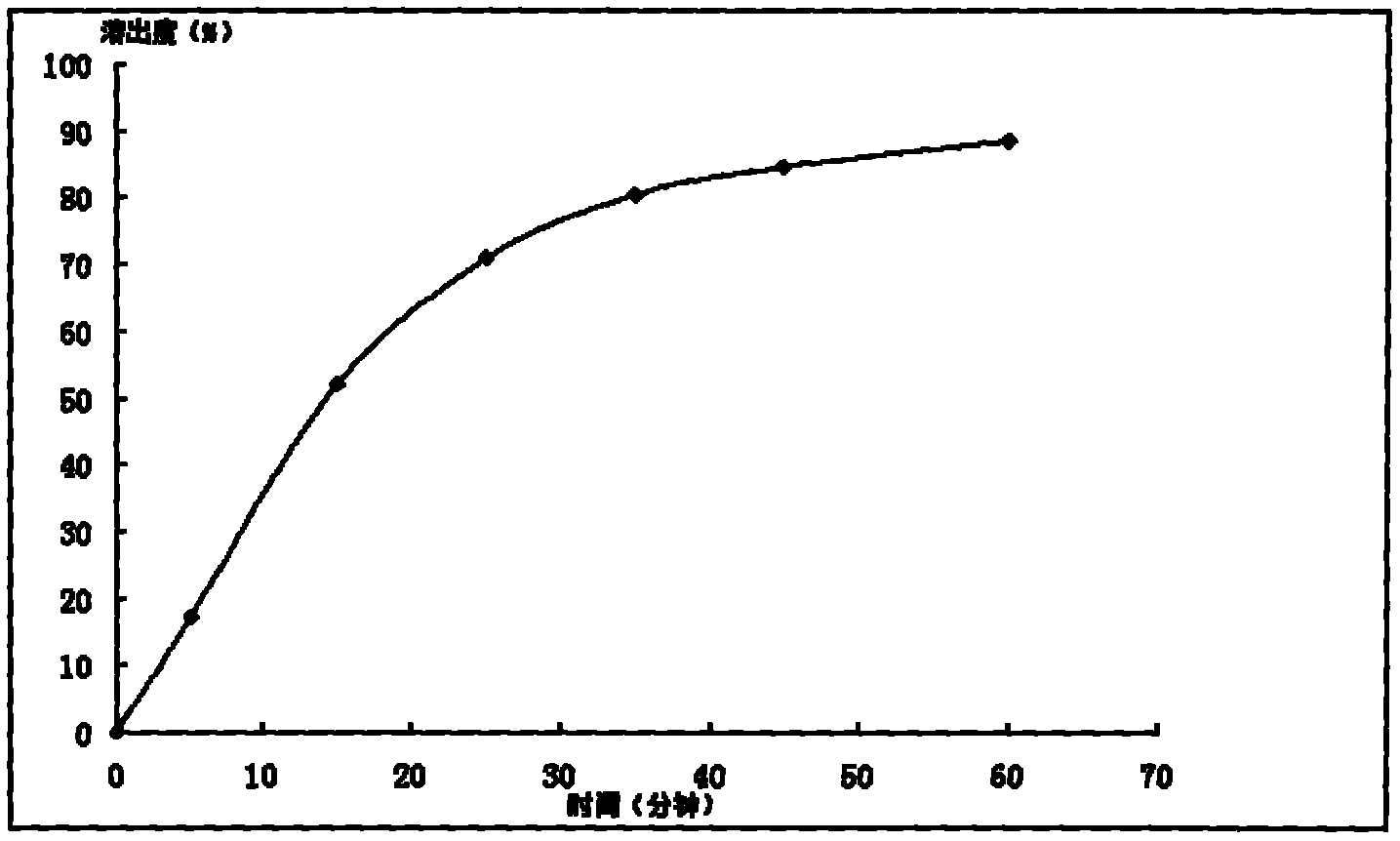

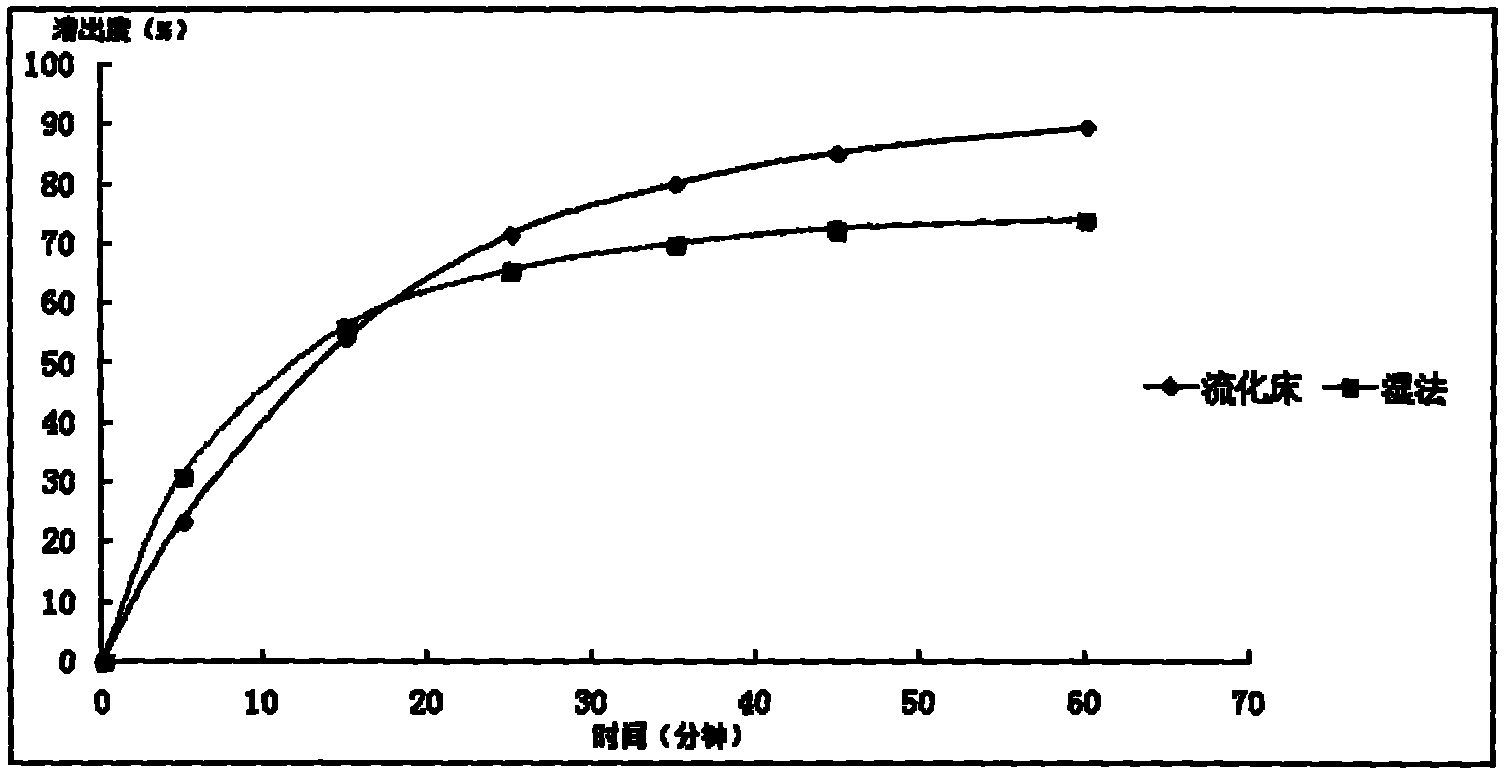

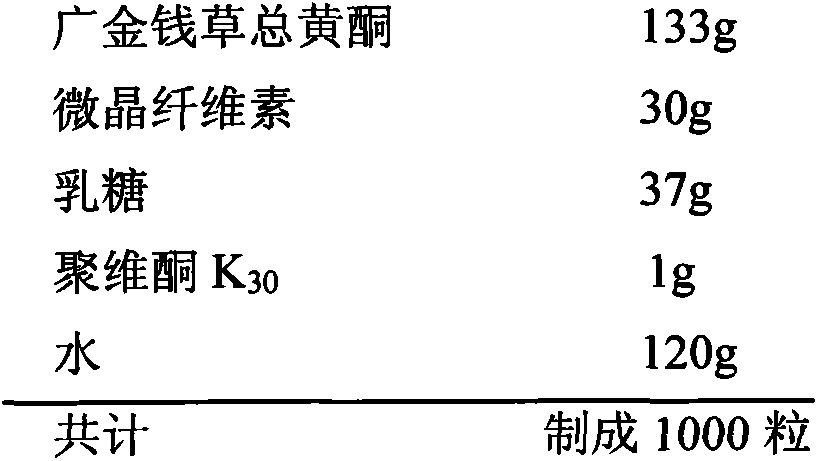

General flavanone capsule of desmodium styracifolium and preparation method and application thereof

InactiveCN103893246AHigh dissolution rateGood quality and stabilityUrinary disorderGranular deliveryAlcoholMedicine

The invention provides a general flavanone capsule of desmodium styracifolium and a preparation method and application thereof, wherein the general flavanone capsule of the desmodium styracifolium comprises total flavanone of the desmodium styracifolium, which is an alcohol extract of the desmodium styracifolium, and pharmaceutically acceptable medicinal excipients. The general flavanone capsule of the desmodium styracifolium disclosed by the invention has the characteristics of being explicit in effective material basis, controllable in quality standard, good in drug dissolution degree, good in quality stability, significant in pharmacology and drug efficacy, less in dosage, safe and convenient to take, and completely applicable to industrial massive production.

Owner:HUMANWELL HEALTHCARE GRP +1

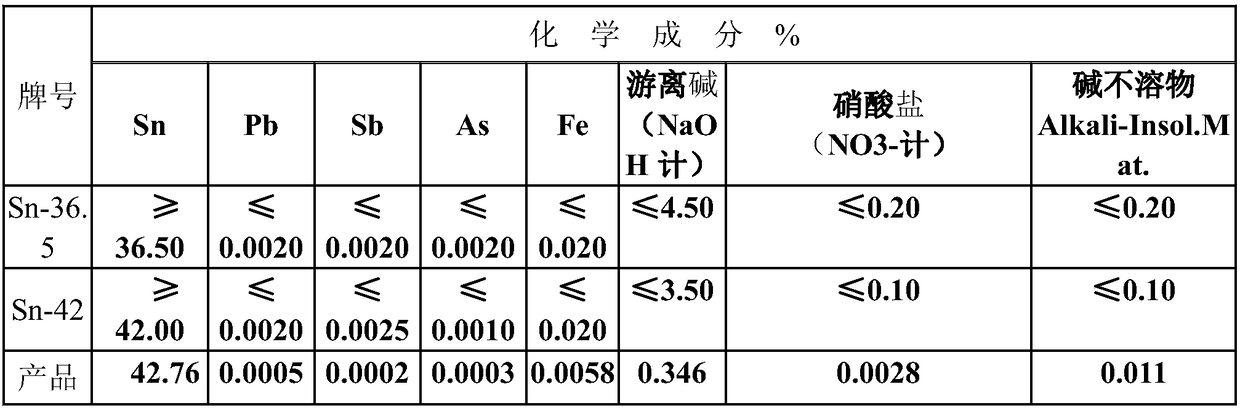

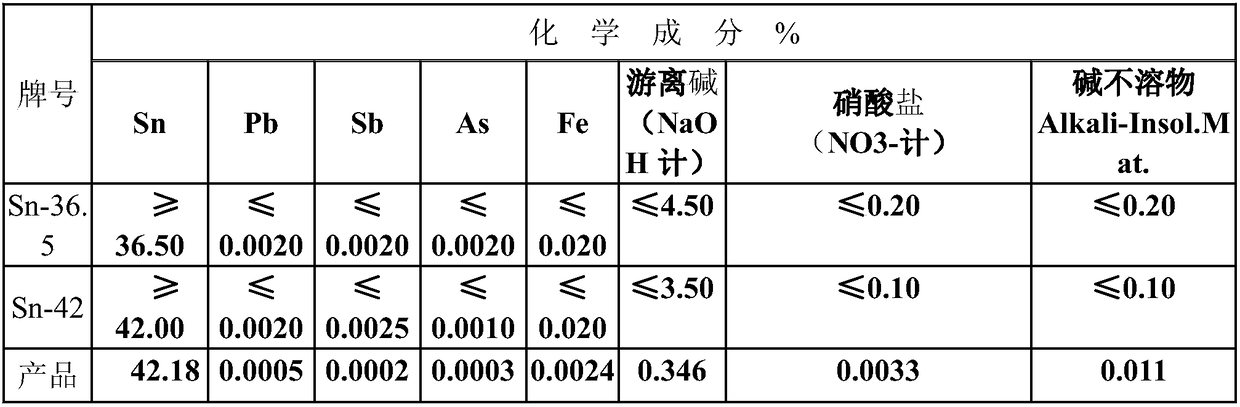

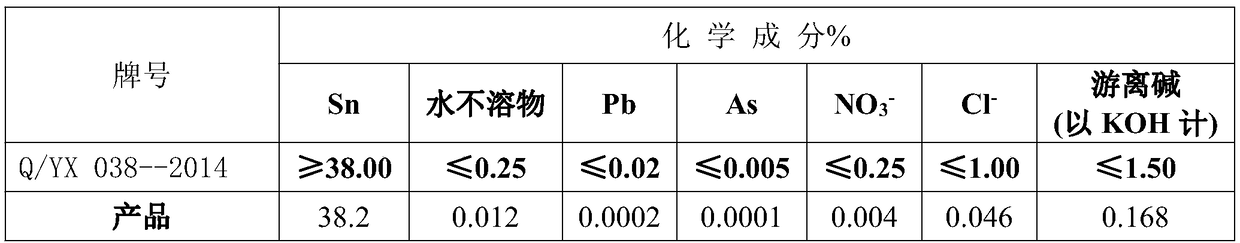

Method for treating tin-copper slag through whole wet method

ActiveCN108359805AThe process is simple and feasibleReduce manufacturing costProcess efficiency improvementAntimonyLiquid solid

The invention discloses a method for treating tin-copper slag through a whole wet method. The method comprises the following steps of: performing oxygen-pressure alkaline leaching on tin-copper slag through sodium hydroxide or potassium hydroxide, wherein a liquid-solid mass ratio is (3-12) to 1, initial alkaline concentration of alkaline liquor is 60-200g / l, reaction temperature ranges from 110 DEG C to 150 DEG C, reaction is performed for 2-6 hours, and reaction pressure is 1-2 MPa; getting leach liquor which is a sodium stannate solution or a potassium stannate solution, adding tin to replace stibium and copper, adding sodium sulfide to remove lead, purifying the solution, evaporating, concentrating, cooling and crystallizing the purified solution to obtain a stannate product; washing leach residues, performing sulfuric acid normal-pressure leaching, and separately generating a secondary leach liquor copper sulfate solution and secondary leach residue tin concentrate, wherein acidity of H2SO4 is 50-150g / l, a liquid-solid mass ratio is (2-10) to 1, and a leaching temperature is 40-95 DEG C; evaporating, concentrating, cooling and crystallizing the copper sulfate solution to obtain a copper sulfate product, drying and returning the tin concentrate to a tin smelting system. The method can generate a stannate product, and also can effectively separate copper in the tin-copper slag.

Owner:云南锡业研究院有限公司

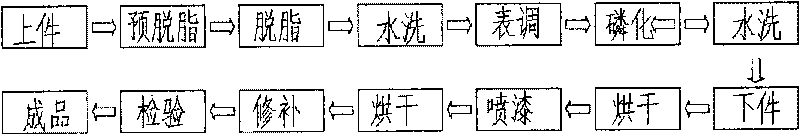

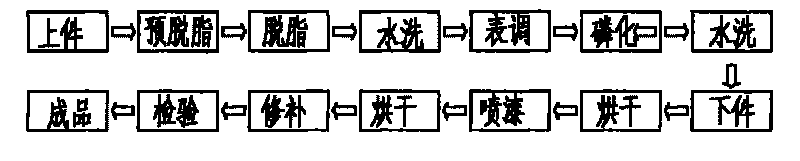

New process for painting container of engineering dump truck

ActiveCN101733240ASolve the phosphating methodReduce manufacturing costPretreated surfacesCoatingsSmall footprintEngineering

The invention provides a new process for painting a container of an engineering dump truck, which comprises the following processes of pre-degreasing, degreasing, washing, surface adjusting, phosphating, washing, drying and spraying paint integrating primer with finishing paint. The paint integrating the primer with the finishing paint is sprayed after the container of the engineering dump truck is phosphated integrally so as to simplify the conventional double-spraying and double-drying process for the container of the engineering dump truck. The new process integrally phosphates the container of the engineering dump truck, simplifies the conventional double-spraying and double-drying process for the container of the engineering dump truck by using the paint integrating the primer with the finishing paint, provides a pretreatment process and a single-spraying and single-drying process for the engineering container of the vehicle, and has the advantages of less investment, small occupied area, low operating and maintenance cost, simple and practicable process, improvement on product quality, reduction in production cost and the like.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

Chinese Medicine Hair-blackening Preparation and Formula and Preparation Method Therefor

InactiveUS20130121941A1Penetrate into skin quicklyQuick and good effectCosmetic preparationsHair cosmeticsGinger RhizomeLigusticum chuanxiong

A preparation having the effect of blackening hair and a method for the preparation thereof, the preparation containing extracts of fresh ginger, huangqi (Radix astragali), heshouwu (Polygonum multiflorum), black sesame, danggui (Angelica sinensis), goujizi (Chinese wolfberry), chuanqiong (Ligusticum chuanxiong), danshen (Salvia miltiorrhiza), wild chrysanthemum, red dates, black beans, walnuts, white mulberry root-bark, nuzhenzi (Fructus ligustri lucidi), hanliancao (Eclipta prostrata), mulberry fruit, black-bone chicken and duck fat, and also containing 65% ethanol solution and 40% ethanol solution, the whole being variously subjected to techniques of mixing, grinding, maceration and extraction to produce a thick ointment composition. The preparation is suitable for all hair and scalp types, and when used after washing of the hair produces no allergic reactions or toxic side-effects, allowing the medicinal elements swiftly to penetrate and be absorbed by the skin to achieve blackening of the hair with quickly visible results. The hair is blackened and nourished, cost is low and the preparation technique is simple.

Owner:YUAN ZHIXIAN

Preparation process for microbial preparation for repairing nitrotoluene contaminated soil

ActiveCN104694427AThe process is simple and feasibleGood processing effectBacteriaContaminated soil reclamationBiomassContaminated soils

The invention belongs to the technical field of microorganisms and discloses a preparation process for a microbial preparation for repairing nitrotoluene contaminated soil. The preparation process comprises the following steps: mixing and uniformly mixing a compound bacterial solution with biomass organic substances, culturing for 12 hours at 30 DEG C, adding auxiliary materials and natural minerals, and stirring; finally, drying at a low temperature to obtain the microbial preparation. The preparation process disclosed by the invention is simple and feasible; the prepared microbial preparation can be used for effectively treating nitrotoluene contaminated soil, is good in treatment effect and low in cost.

Owner:青岛新地原生物科技有限公司

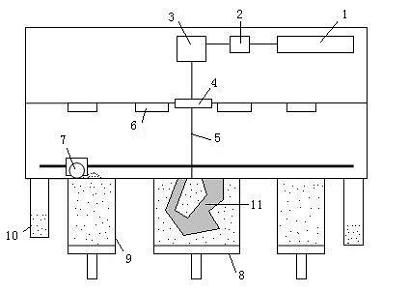

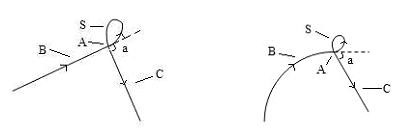

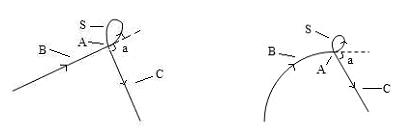

Selective laser sintering scanning method

ActiveCN102172774AUniform laser scanning intensityGuaranteed qualityIncreasing energy efficiencySelective laser sinteringLaser scanning

The invention discloses a selective laser sintering scanning method. When a sharp corner is met in a selective laser sintering process, a sealed curved-form empty jump is adopted to change the scanning direction, and the scanning speeds at the front and back of the corner are guaranteed to be consistent, thus uniform laser scanning intensity and scanning accuracy of the sharp corner are guaranteed.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Process for recycling asphalt from asphalt mixture

InactiveCN103711058AEliminate the effects ofImprove solubilityRoads maintainenceTrichloroethyleneAsphalt

The invention discloses a process for recycling asphalt from an asphalt mixture. The process comprises three steps of impurities removal, asphalt extraction and distillation and recovery of an asphalt solution, and thus recovered asphalt can be obtained. An asphalt-trichloro ethylene solution is vacuumized to reduce pressure and heated to accelerate evaporation; the evaporated trichloro ethylene is condensed after being contacted with circulating water and enters a solvent-recovering bottle so as to be separated from the asphalt; a distilling flask is kept in a vacuum state, so that secondary ageing of the asphalt can be prevented; and the process is simple and practicable in steps and has very good popularization value.

Owner:LIUZHOU BOZE SCI & TECH

Productive method for food put in live bamboo body to assimilate nutriment and fragrance

InactiveCN1385115AThe process is simple and feasibleFull of nutritionFood preservationNutrientNutritious food

The production method of food which can be stored in the live bamboo and absorb nutrients and fragrance of bamboo includes the following steps: preparing food, using injection or hole-opening mode toinjet the food into the between of bamboo joints of growing bamboo, sealing the opened hole, making the bamboo plant in which the food is held naturally grow for 10 days to 5 years, then chopping thebamboo plant and sawing off two ends of the between of bamboo joints in which the food is held so as to obtain the invented bamboo fragrance nutrient food, which rich nutrients and unique taste.

Owner:李盛秋

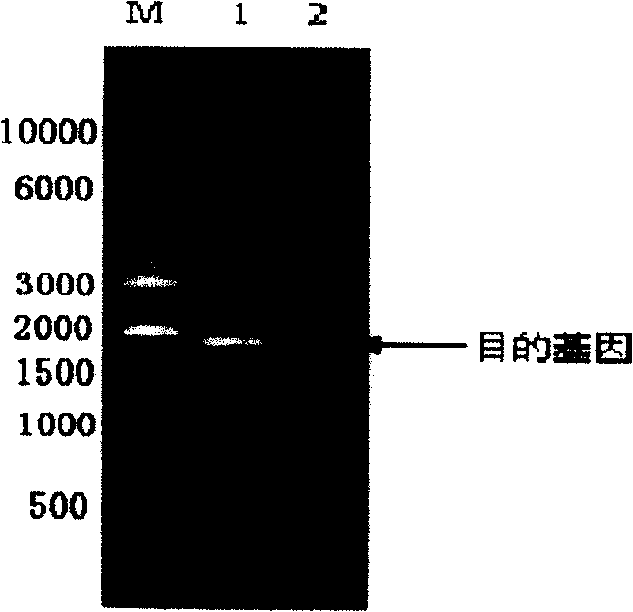

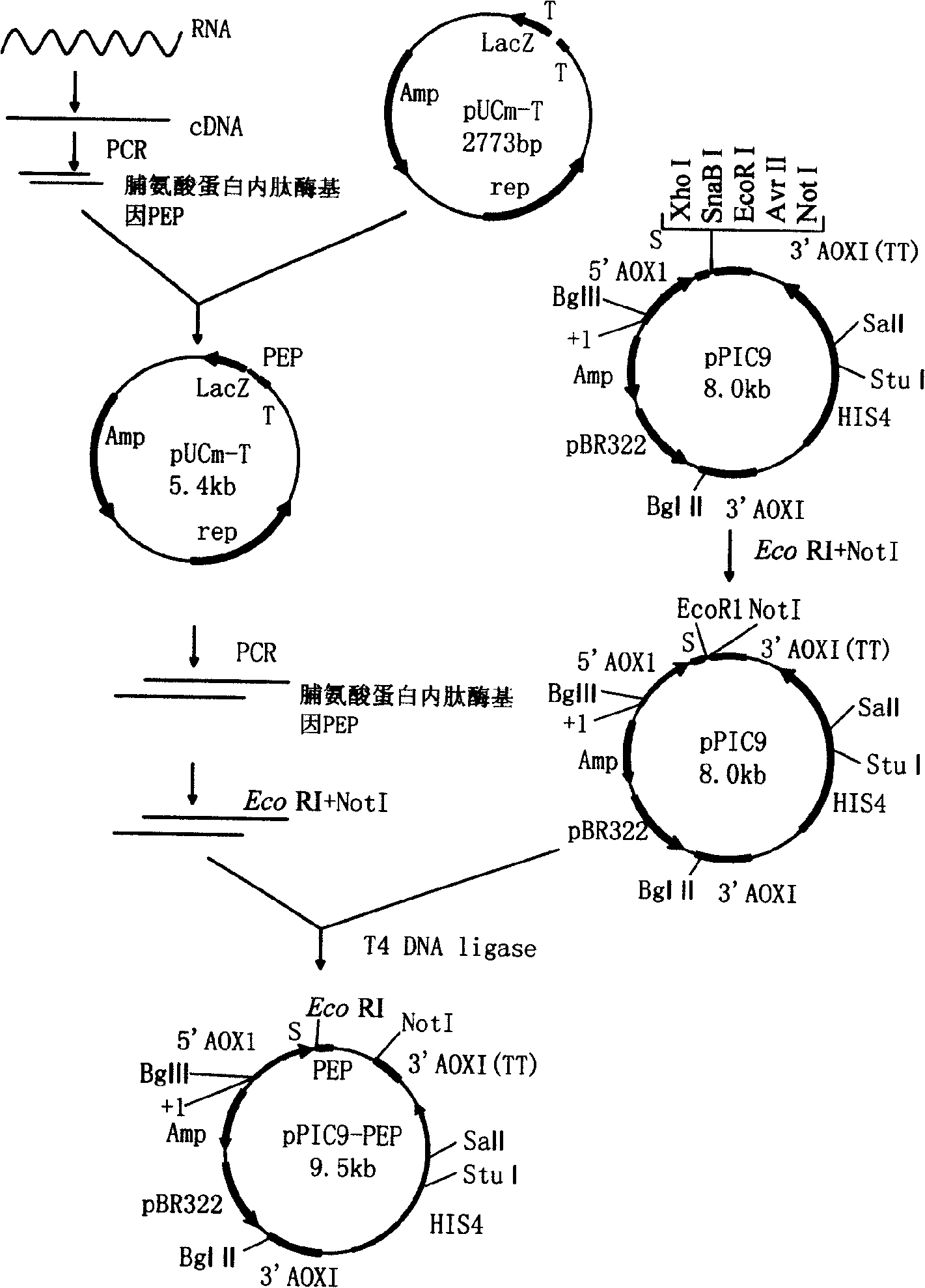

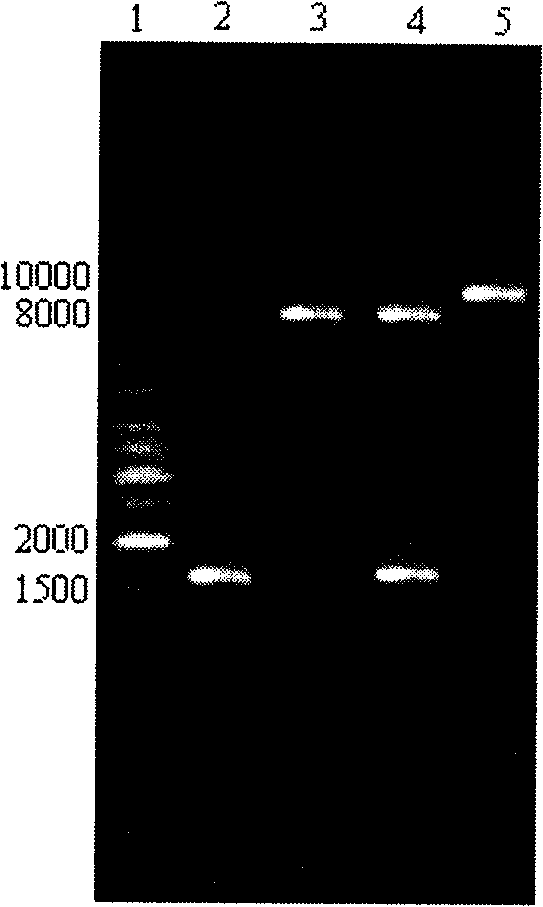

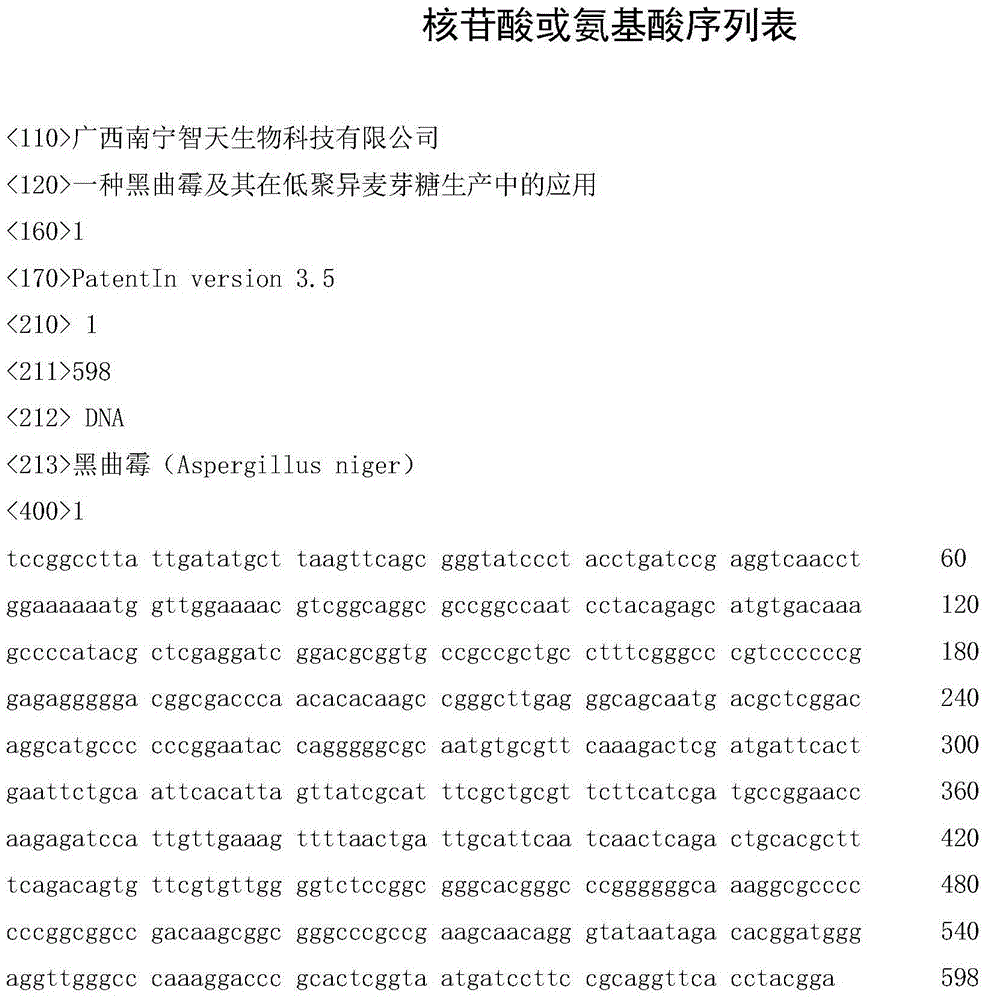

Aspergillus niger proline protein endopeptidase and preparation method thereof

InactiveCN101294153AThe process is simple and feasibleImprove efficiencyHydrolasesFermentationEndopeptidaseGenetic engineering

The invention relates to Aspergillus niger proline-specific endoprotease and the preparation method thereof, which belong to the field of genetic engineering and enzymology. The Aspergillus niger proline-specific endoprotease is selected from amino acid sequence of Aspergillus niger proline-specific endoprotease with a sequence code of SEQ ID No.2, wherein the amino acid sequence has nucleotide sequences represented by the first to the 1,581 in SEQ ID No.1, and has polypeptides of amino acid sequence represented by SEQ ID No.2. Test shows that haze protein bands with molecular weight of 8 to 14 kDa are disappeared completely after SDS-polyacrylamide gel electrophoresis detection of beer protein added with PEP, which shows that the haze activity protein rich in proline residues is hydrolyzed completely by PEP, and primarily testifies that proline-specific endoprotease can specifically cut protein and proline residues at carbon terminal of a peptide chain, and can eliminate cold haze substance in beer.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

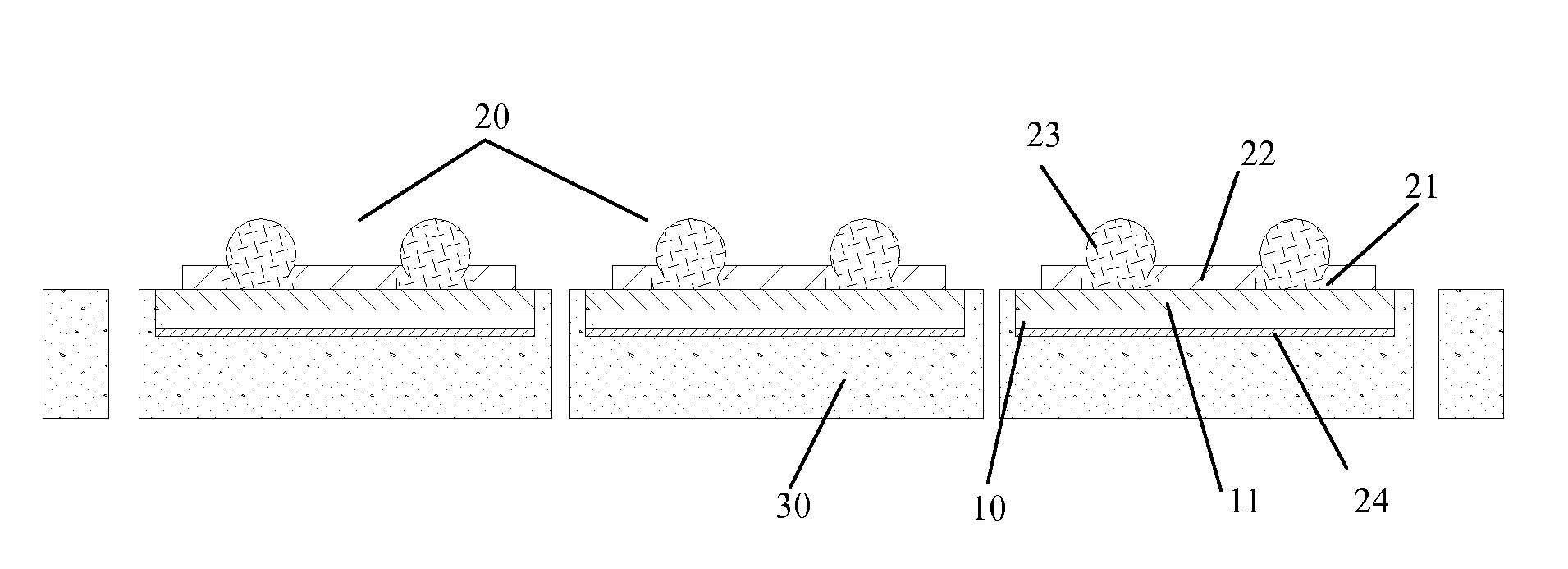

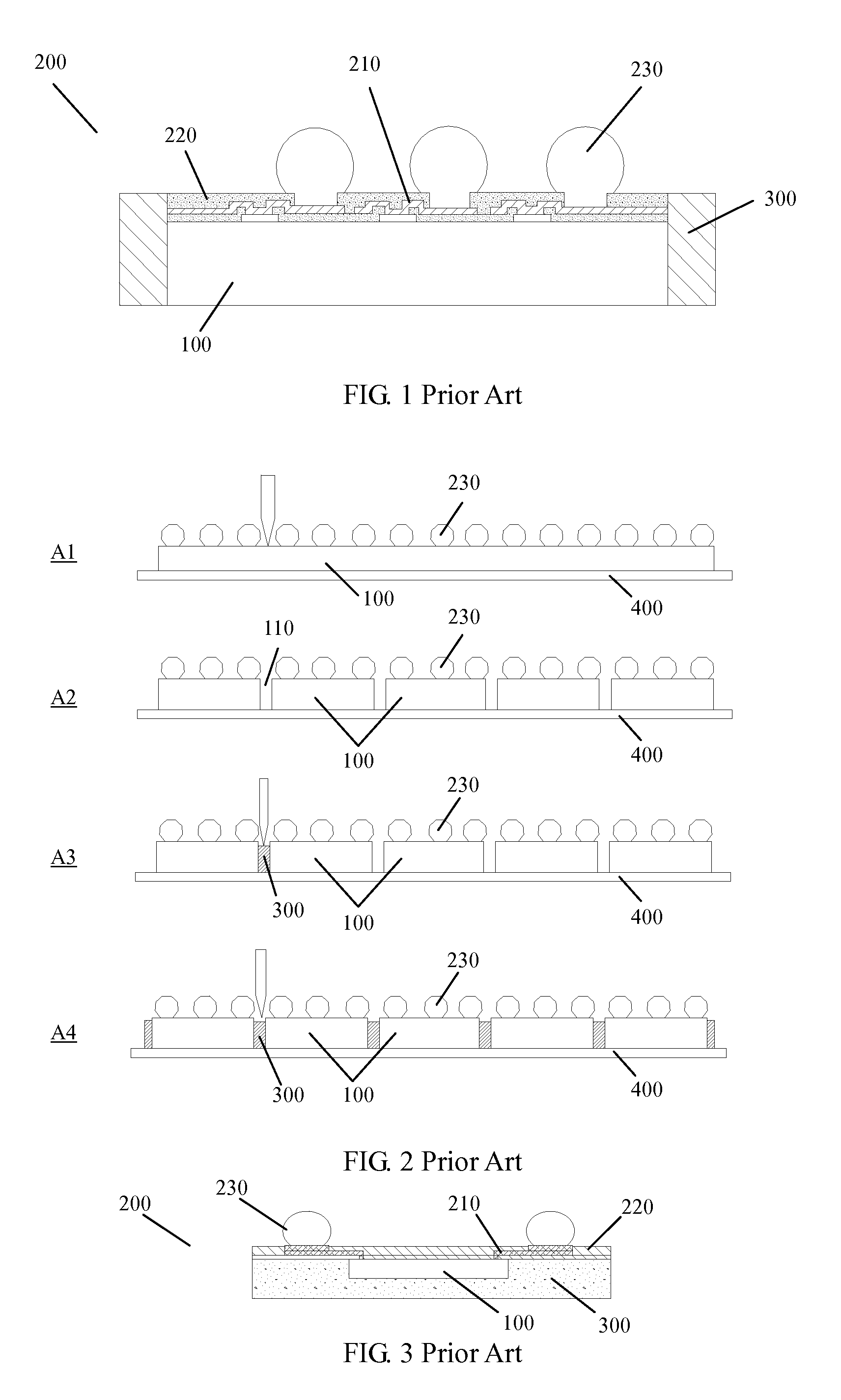

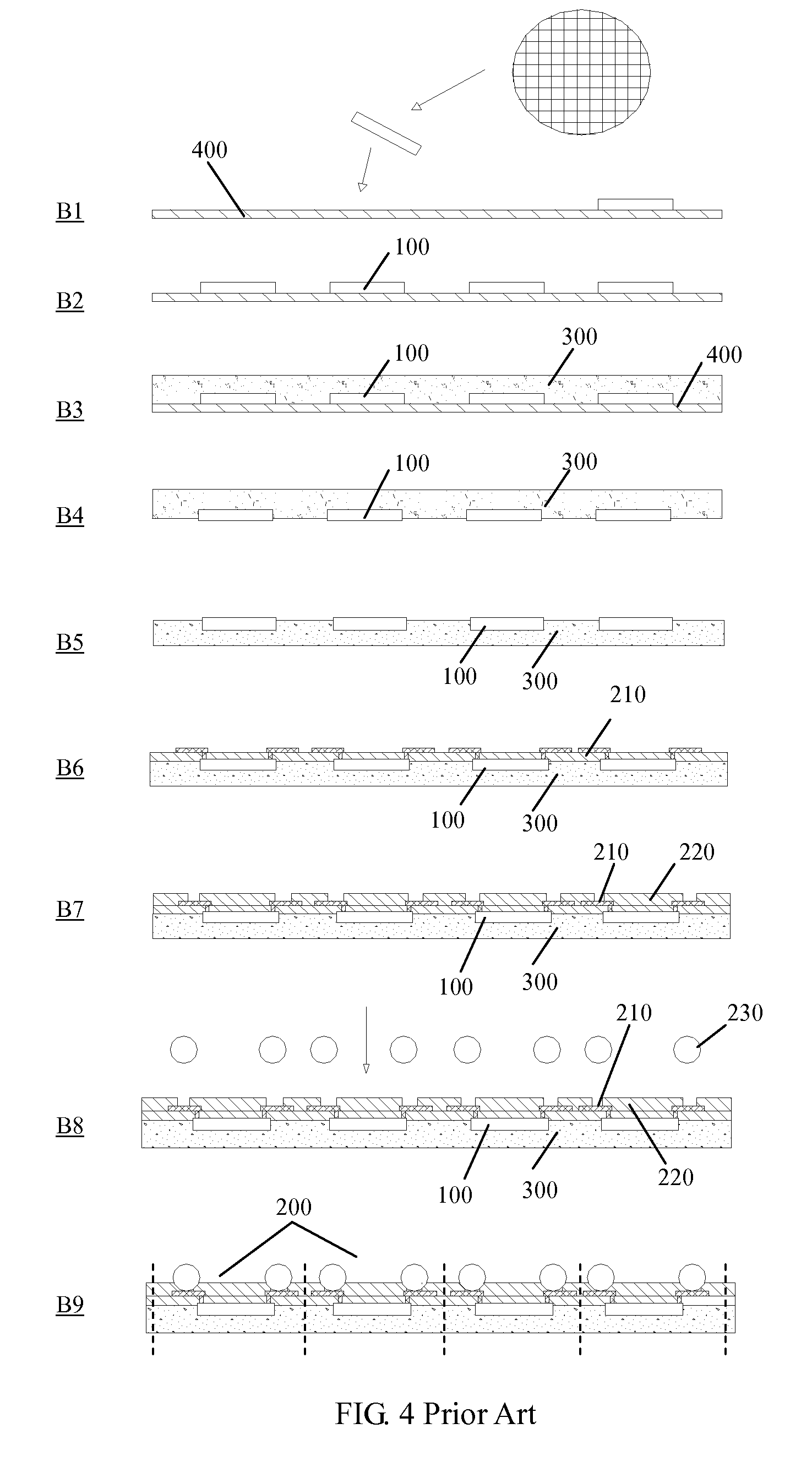

Wafer level packaging method of encapsulating the bottom and side of a semiconductor chip

ActiveUS8486803B2Improve ductilityKeep the distanceSemiconductor/solid-state device detailsSolid-state devicesShell moldingDicing tape

A chip-scale packaging method, with bottom and side of a semiconductor chip encapsulated, includes the following steps: attaching backside of a thinned semiconductor wafer to a dicing tape; separating individual chips by cutting from front side of the wafer at scribe line but not cut through the dicing tape; flipping and attaching the wafer onto a top surface of a double-sided tape, then removing the dicing tape; attaching bottom surface of the double-sided tape on a supporting plate; filling the space between adjacent chips and covering the whole wafer backside with a molding material; flipping the whole structure and remove the supporting plate; placing solder balls at corresponding positions on electrodes of each chip and performing backflow treatment; finally separating individual chip packages by cutting through molding material at the space between adjacent chip packages with molding material encapsulating the bottom and side of each individual semiconductor chip.

Owner:ALPHA & OMEGA SEMICON INC

Lithium bis(oxalato)borate preparation method

InactiveCN109232629AThe process is simple and feasibleLower impedanceGroup 3/13 element organic compoundsChemistryCalcium hydroxide

The invention provides a lithium bis(oxalato)borate preparation method. The preparation method comprises the steps: weighing lithium hydroxide, oxalic acid and boric acid according to a certain molarratio; then respectively drying lithium hydroxide, oxalic acid and boric acid; then putting the dried lithium hydroxide, oxalic acid and boric acid into a ball mill to be evenly ball milled to form amixture; then dry pressing the mixture into pieces under the certain pressure P; then putting into a container; reacting under the vacuum environment with a temperature as 105 to 130 DEG C for 5 to 8h; then putting into the vacuum environment with a temperature as 140 to 170 DEG C to react for 12 to 24 h to prepare a lithium bis(oxalato)borate crude product; then grinding the lithium bis(oxalato)borate crude product into powder; fully dissolving into distilled anhydrous acetonitrile; filtering to obtain filtrate; evaporating and concentrating the filtrate until the residual liquid is 1 to 2%of the total amount of the filtrate; finally, pouring the residual liquid and drying a product which is prepared by evaporating and concentrating the filtrate to obtain lithium bis(oxalato)borate. According to the method disclosed by the invention, a technology is simple, the raw materials are cheap and easy to obtain, and the purity of the prepared product is extremely high.

Owner:湖南科霸汽车动力电池有限责任公司

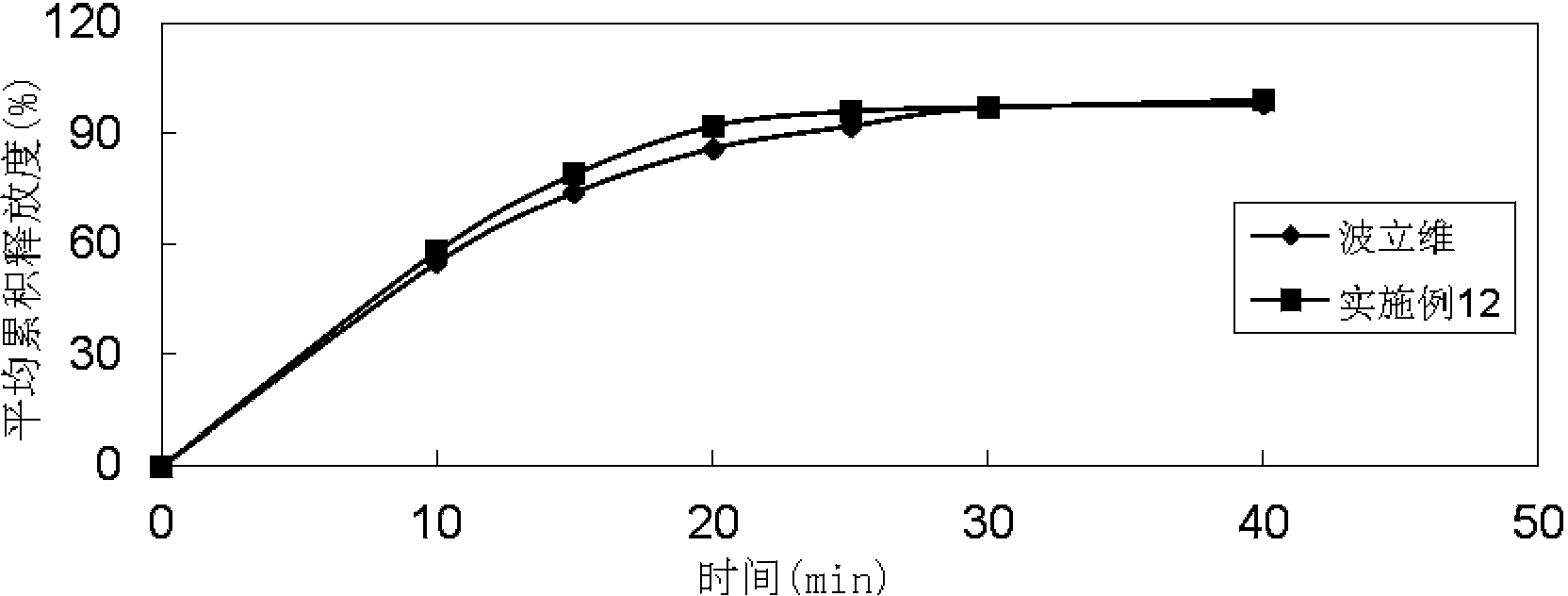

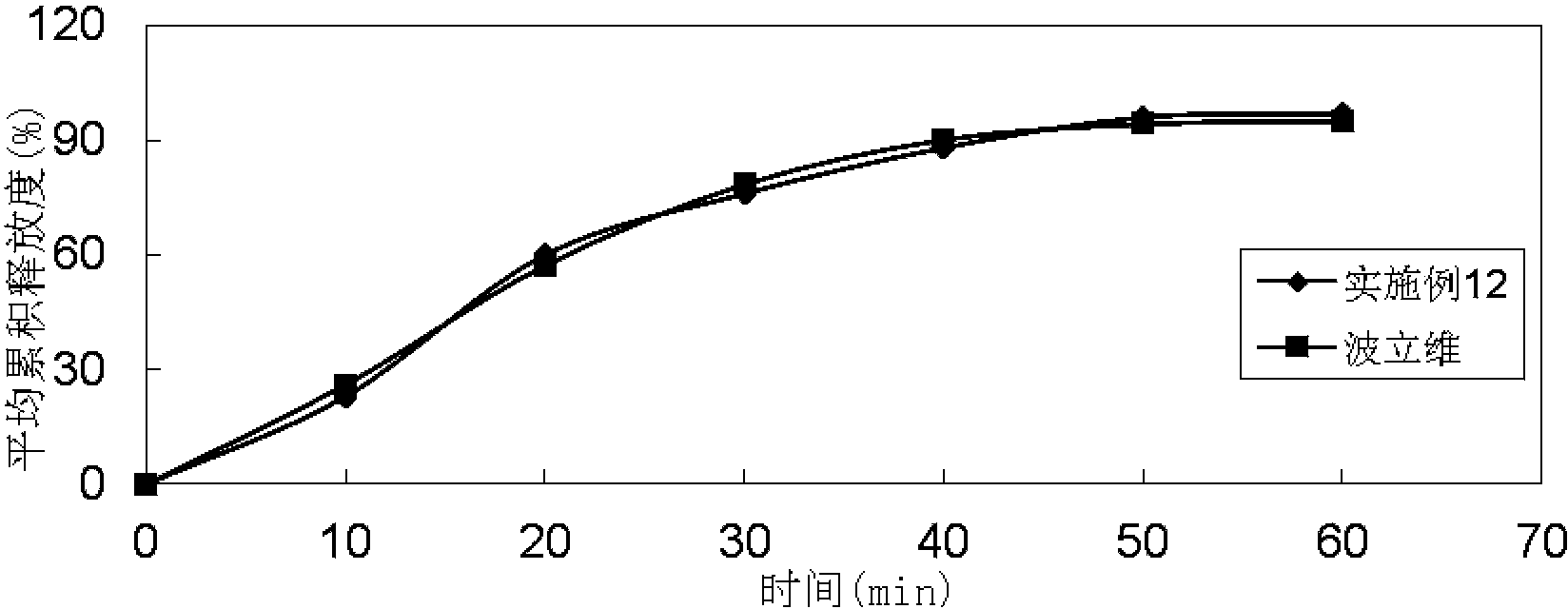

Clopidogrel tablet and preparation method thereof

InactiveCN103877056AAvoid the phenomenon of melting and aggravating stickingGood compatibilityOrganic active ingredientsInorganic non-active ingredientsCoated tabletsMANNITOL/SORBITOL

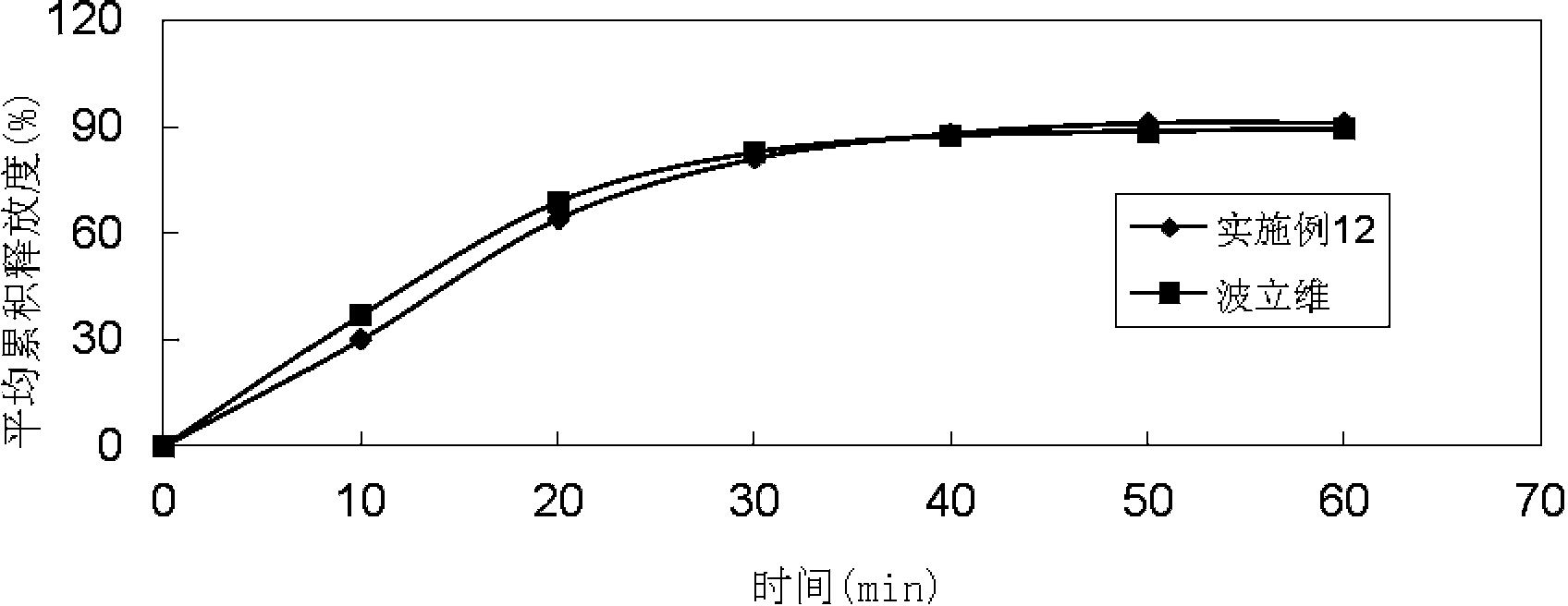

The invention discloses a clopidogrel tablet and a preparation method thereof. The clopidogrel tablet is a coated tablet which consists of a clopidogrel table body and a coating material, wherein the clopidogrel table body comprises the following ingredients in parts by weight of clopidogrel free alkali: 75 parts of pharmaceutically acceptable salt of clopidogrel, 6-9 parts of sodium stearyl fumarate, 3-6 parts of talcum powder, 90-135 parts of diluent, 2-6 parts of bonding agent and 7-17 parts of disintegrating agent, wherein the diluent is made of combined mannitol and microcrystalline cellulose in a weight ratio of (2:1)-(1:1); the weight of the coating material accounts for 2.7-3.3% of the weight of the clopidogrel tablet. By adopting the clopidogrel tablet, not only is the problem of sticking in the tabletting process solved, but also the mixed lubricant and clopidogrel have good compatibility, the phenomena that active ingredients are degraded or the configuration is inversed are avoided, and the clopidogrel tablet is high in stability, good in quality, and high in similarity in dissolving behavior to that of an original triturate plavix.

Owner:WUHAN SUNRISE BIO PHARMA SCI & TECH

Electronic device, shell, electrochromic module and packaging method thereof

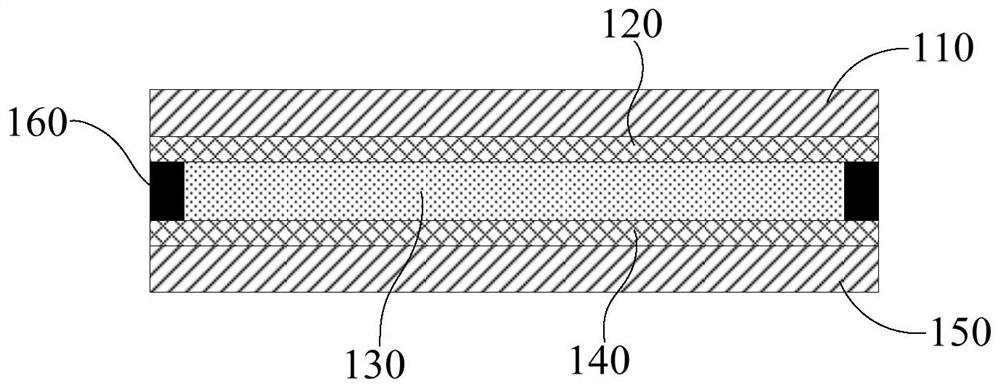

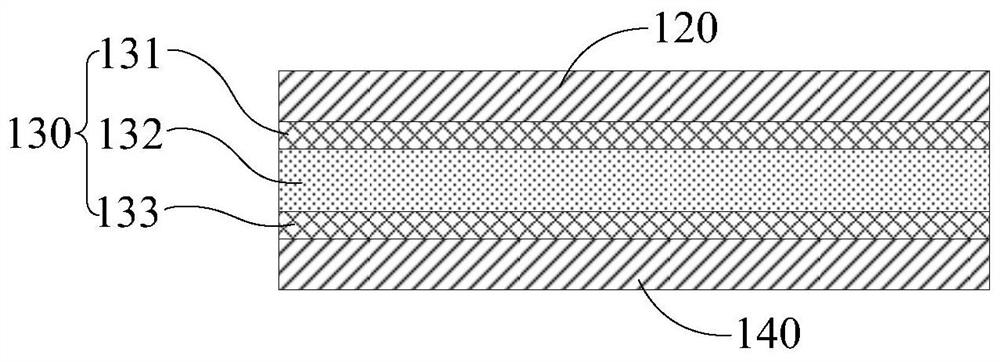

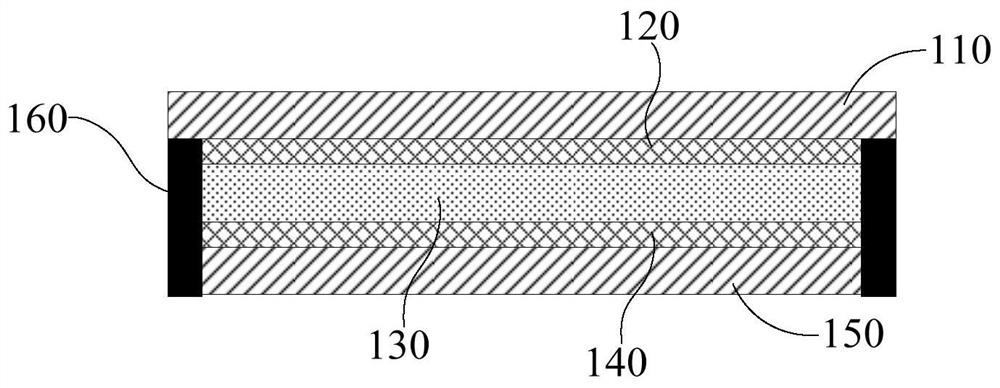

ActiveCN112147827AImprove package reliabilityThe process is simple and feasibleCasings/cabinets/drawers detailsNon-linear opticsEngineeringElectrochromism

The invention provides a packaging method of an electrochromic module. The packaging method comprises the following steps of: providing a laminated structure, wherein the laminated structure comprisesa first substrate, a first conductive layer, a color-changing material layer, a second conductive layer and a second substrate which are sequentially laminated; forming a groove in the laminated structure, wherein the groove penetrates through the second substrate, the second conductive layer, the color-changing material layer and the first conductive layer; and forming a sealant in the groove. The packaging method of the electrochromic module provided by the embodiment of the invention is simple, convenient and feasible in process, and the formed rubber frame structure is high in packaging reliability and is compatible with a front-end process flexible electrochromic film material (semi-finished product) process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Pharmaceutical composition as well as preparation method and application thereof

InactiveCN103893247AEffective treatmentSpontaneous activity influencePowder deliveryOrganic active ingredientsActive componentDesmodium styracifolium

The invention provides a medicinal composition as well as a preparation method and application thereof. The pharmaceutical composition is a medicinal preparation for clinical administration, which is prepared from desmodium styracifolium general flavone extract serving as an active component and pharmaceutically acceptable medicinal auxiliaries. The composition can be used for preparing clinical treatment medicament for clearing damp-heat, promoting diuresis and expelling stone (damp-heat stagnation).

Owner:HUMANWELL HEALTHCARE GRP +1

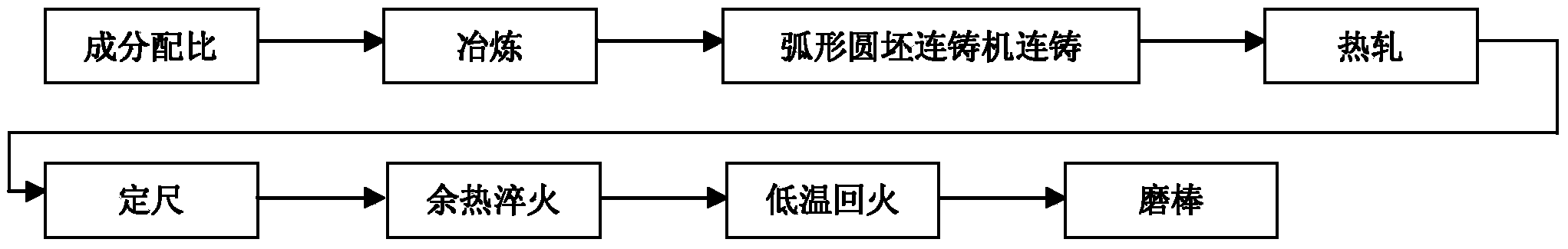

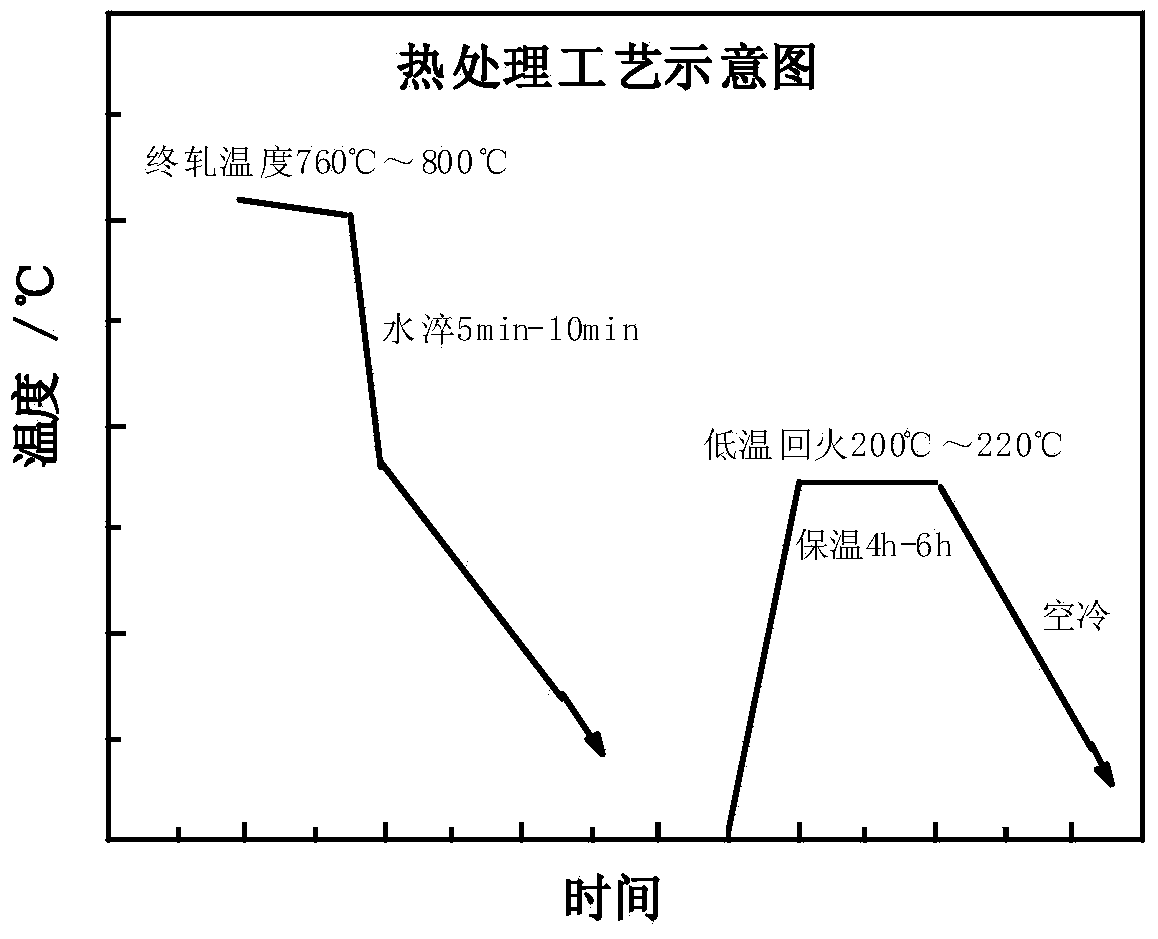

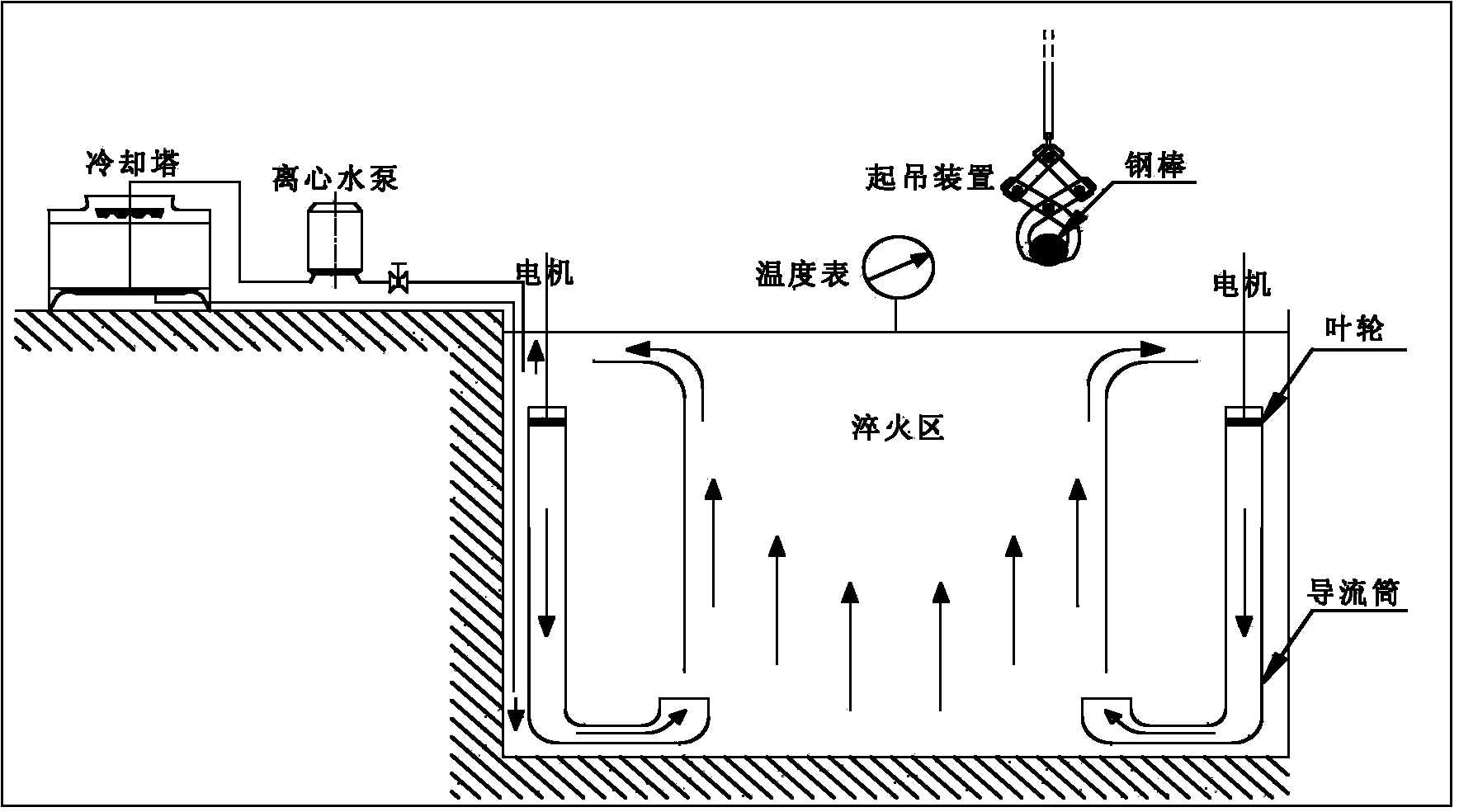

Preparation method of steel rod of rod mill

The invention discloses a preparation method of a steel rod of a rod mill, belonging to the field of wear-resistant materials. The steel rod of the rod mill comprises the following components in percentage by mass: 0.6-0.85% of C, 0.17-0.37% of Si, 0.7-1.2% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, less than or equal to 0.6% of Cr and 0.01-0.02% of Nb. The preparation method of a grinding rod comprises the steps of smelting, continuously casting a round billet, and rolling round steel with the diameter of 50-120mm and the fixed length of 2-7m by using a TMCP (Thermal Mechanical Controlled Process); directly quenching in water for 5-10min by utilizing waste heat after rolling; then, tempering at low temperature. The method can be used for obtaining the grinding rod which has gradient hardness, the surface hardness of HRC60 and the core hardness of HB200 and the steel rod which is high in surface hardness, good in wear resistance, relatively high in core toughness and favorable in matching between hardness and toughness. The method disclosed by the invention is simple in process, high in efficiency, low in energy consumption, low in cost and capable of realizing actual industrial production and application.

Owner:UNIV OF SCI & TECH BEIJING

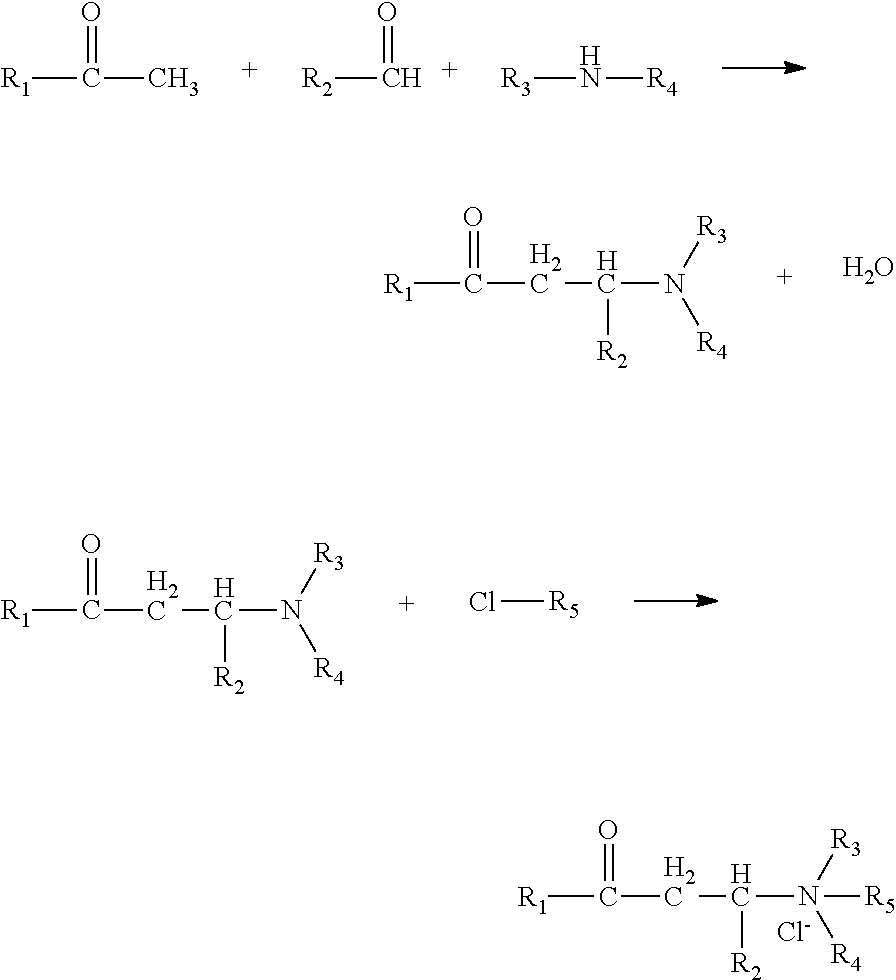

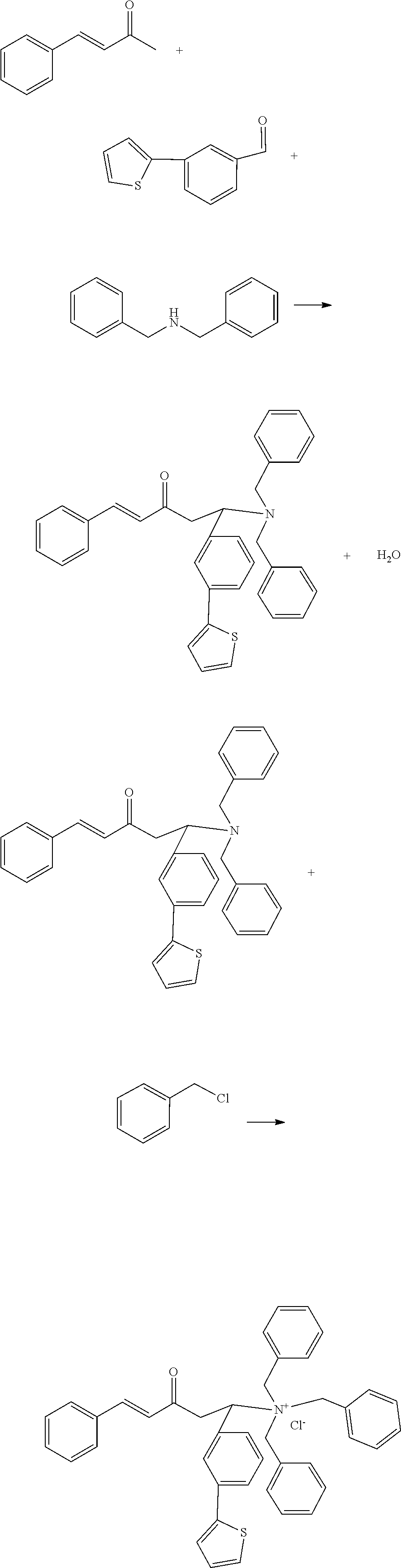

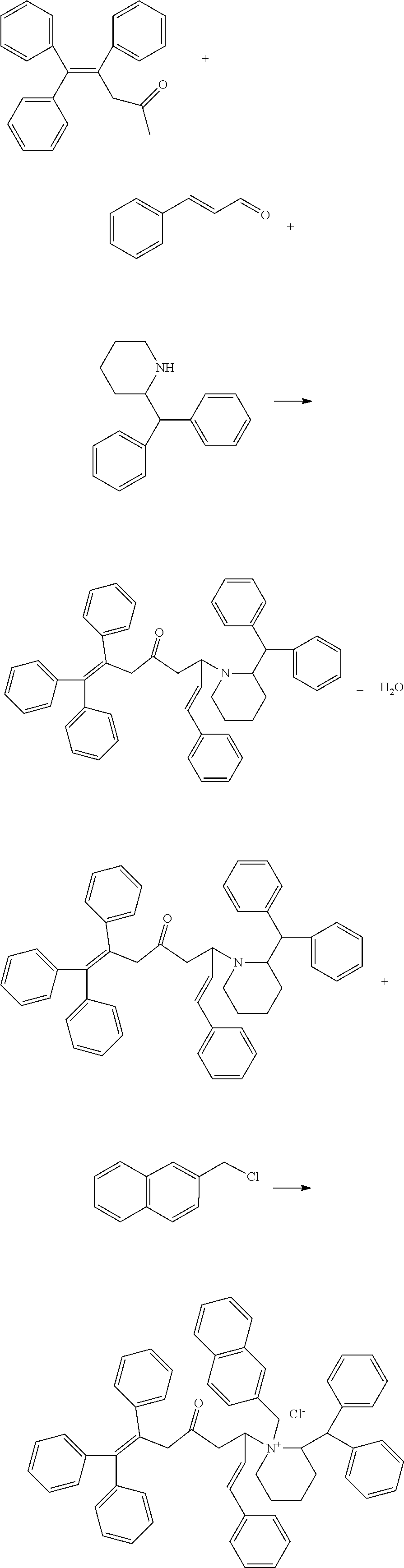

Process for preparing mannich base quaternary ammonium salt high-temperature resistant corrosion inhibitor and applications thereof

ActiveUS20200331856A1Good dispersibilityImprove solubilityOrganic chemistryDrilling compositionPhenethylaminesKetone

The present invention discloses a process for preparing a Mannich base quaternary ammonium salt high-temperature resistant corrosion inhibitor and applications thereof. The preparation process comprises the following steps: (1) dissolve an amine substance indole, benzhydrylpiperidine, diphenylethylamine, dibenzylamine or diisopropanolamine into an organic solvent, slowly add an aldehyde substance 3-(2-thienyl)benzaldehyde or cinnamaldehyde, then place in a constant-temperature water bath, stir to react at 60-80° C. for 1 to 3 hours, then add a ketone substance benzalacetone, diphenylstyryl acetone or 1,1-diphenylacetone, adjust the reaction system pH to 3 to 4 using a hydrochloric acid solution, and then react for 7 to 10 hours; after cooled to room temperature, perform distillation under a reduced pressure to remove the solvent, to obtain a Mannich base; (2) dissolve the Mannich base in an organic solvent, add quaternizing reagent chloromethylnaphthalene, benzyl chloride or triphenylchloromethane, then react at 70-90° C. for 14-16 h, after cooled to room temperature, perform distillation under a reduced pressure. The process is simple and feasible, and its raw material is non-toxic, safe and environmental-friendly, and the prepared corrosion inhibitor has obvious resistance to the acid corrosion of carbon steels in oil-gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

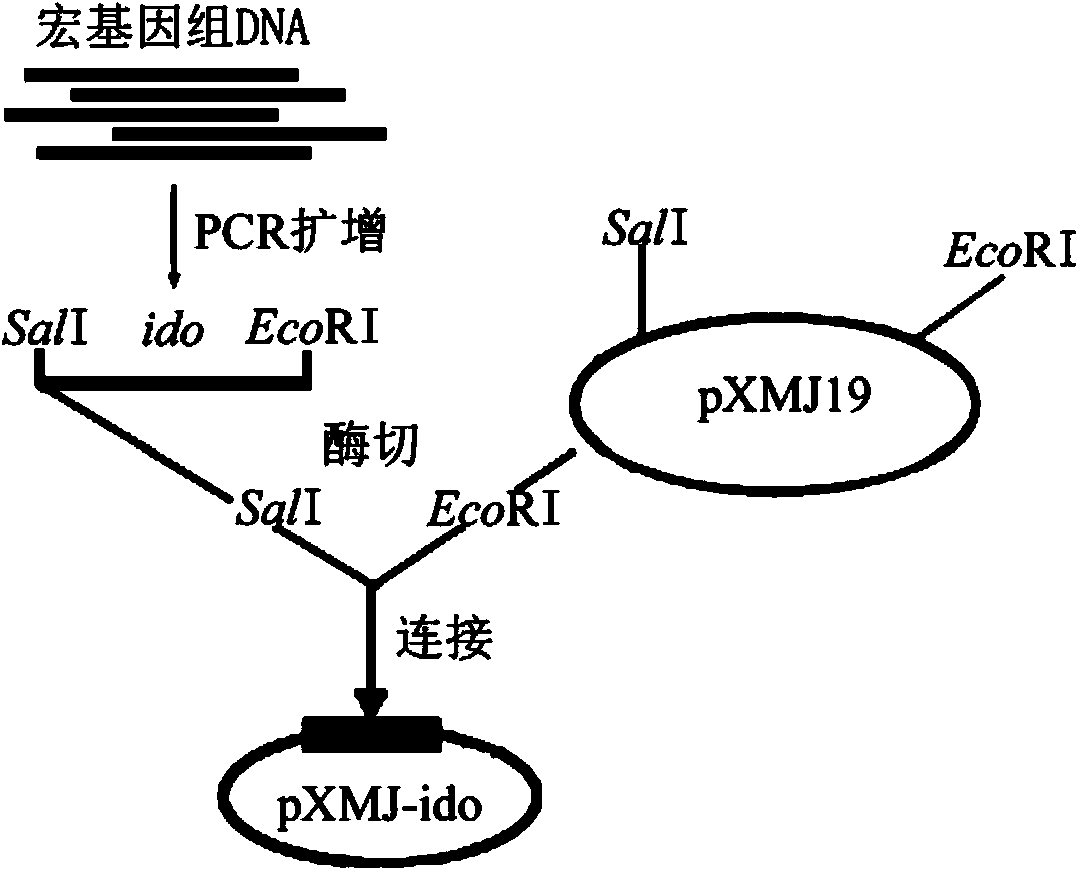

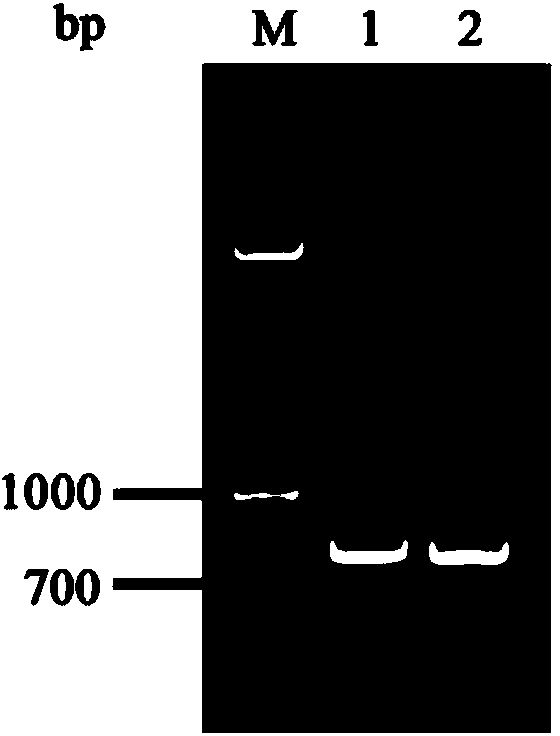

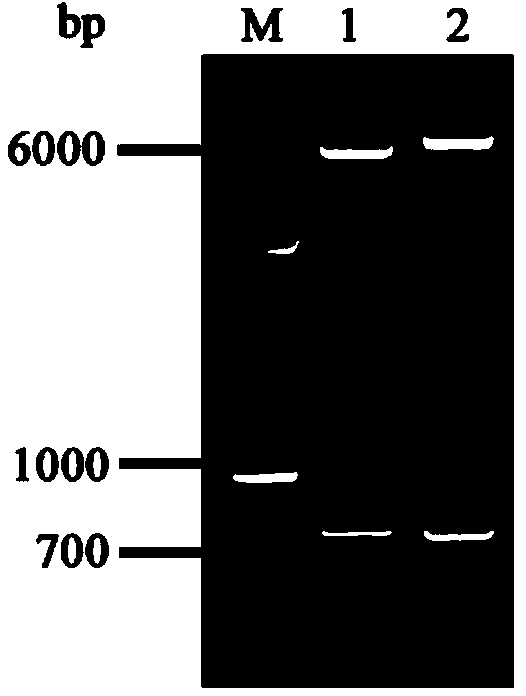

L-isoleucine hydroxylase gene as well as genetically engineered bacterium and application of L-isoleucine hydroxylase gene

ActiveCN103865940AImprove conversion efficiencySimple processBacteriaMicroorganism based processesChemical synthesisHydroxylase gene

The invention belongs to the technical field of biology and particularly relates to an L-isoleucine hydroxylase gene capable of specifically catalyzing L-isoleucine to generate (2S, 3R, 4S)-4-hydroxyisoleucine and a genetically engineered bacterium containing the gene. When the bacterium is used for producing (2S, 3R, 4S)-4-hydroxyisoleucine, defects such as low extraction ratio, difficulty in separation and purification, high raw material quality demand, high cost and the like existing in an extraction method can be overcome; the problems of harsh reaction conditions, more steps, difficulty in separation and low yield existing in a chemical synthesis method can be solved; the problems of low conversion rate and large-quantity alpha-aminobutyric acid and other byproduct production existing in an enzyme method can be solved, 4-hydroxyisoleucine with only one configuration, i.e., (2S, 3R, 4S)-4-hydroxyisoleucine, exists in a fermentation solution, and the conversion efficiency is further increased by using an L-isoleucine hydroxylase encoding gene over-expression method, so that the aims of simplifying processes and reducing the production cost are achieved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aspergillus niger and application in production of isomaltose hypgather

ActiveCN104877911ASimple nutritional requirementsThe cultivation method is simpleFungiMicroorganism based processesAlgluceraseIsomaltooligosaccharide

The invention discloses an aspergillus niger which is classified and named aspergillus niger M1 with the preservation number being CCTCC NO: M2014421. The preservation date is September 23nd, 2014, and the preservation department is China Center for Type Culture Collection. Alpha-glucosidase produced by the aspergillus niger M1 strain is endoenzyme, and the aspergillus niger M1 strain can produce isomaltose hypgather containing more than 65% of active trisaccharide (IG+P+IG3) under the condition of high temperature. The required reaction time of preparing IMO-500 type isomaltose hypgather containing 35% of active trisaccharide is only half of the reaction time of preparing the isomaltose hypgather containing more than 65% of active trisaccharide. The alpha-glucosidase produced by the strain has advantages of excellent temperature characteristic, short glucoside conversion time, high content of the active trisaccharide in the product and the like.

Owner:GUANGXI NANNING ZHITIAN BIOTECH

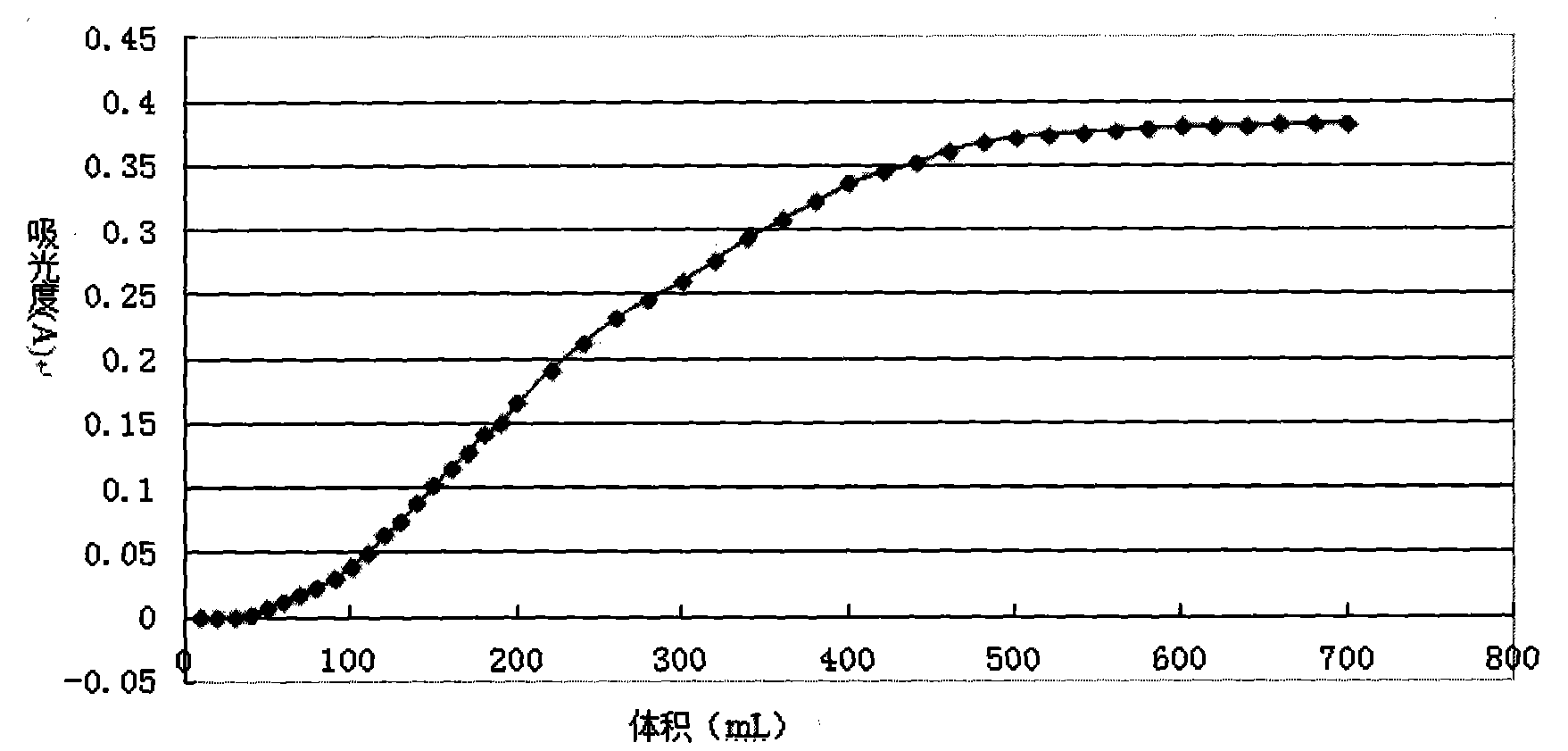

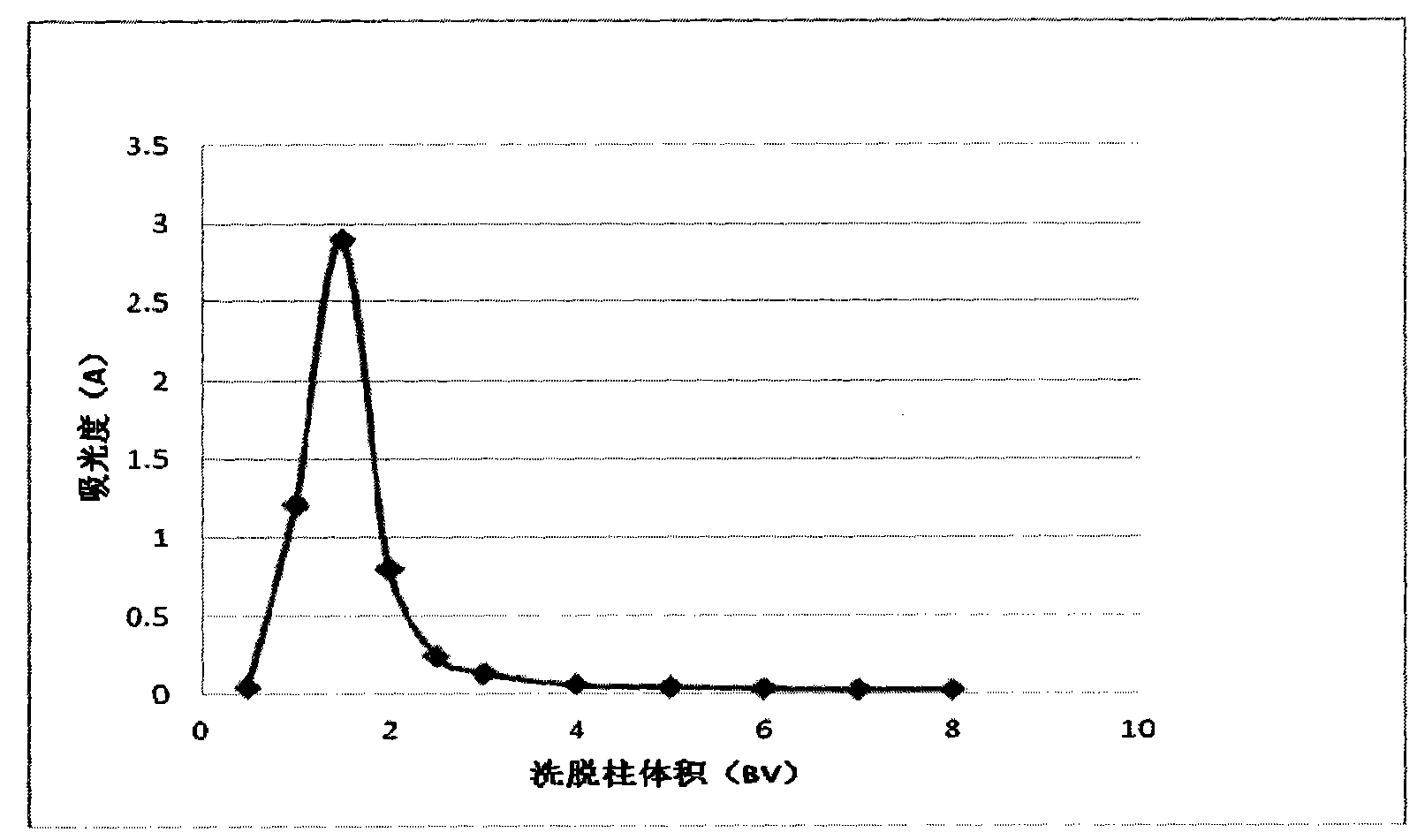

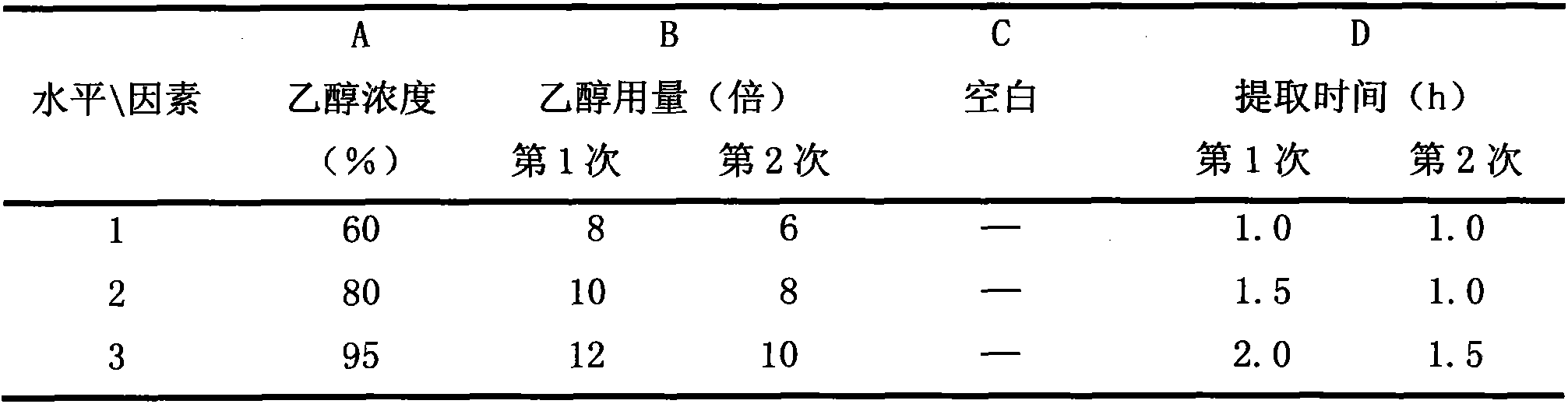

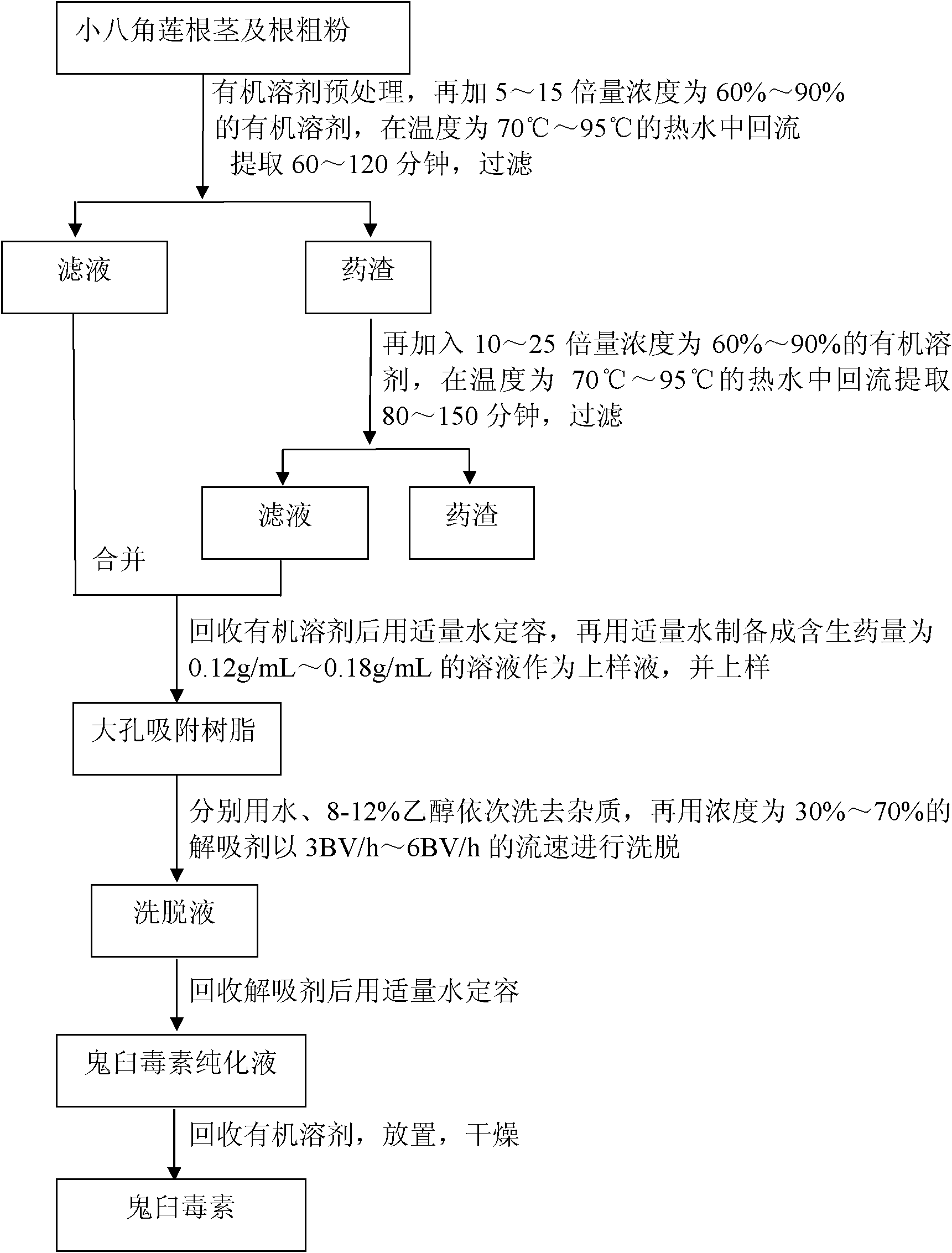

Process for extracting and purifying podophyllotoxin from Dysosma difformis

InactiveCN101974008AThe process is simple and feasibleSimple processOrganic chemistryRefluxOrganic solvent

The invention relates to a process for extracting and purifying podophyllotoxin from Dysosma difformis, which comprises the following steps: crushing rhizomes of the Dysosma difformis into coarse powder, pretreating the Dysosma difformis coarse powder with organic solvents, extracting with hot water by reflux, continuously extracting filter residue by hot reflux, filtering again, merging the two filtrates, recovering the organic solvents, adding a defined amount of water to maintain a constant volume so as to obtain a podophyllotoxin extracting solution; and preparing the podophyllotoxin extracting solution into a solution the crude drug content of which is 0.12-0.18g / mL, selecting a purified macroporous adsorptive resin as the adsorption column resin to sufficiently adsorb the solution acting as a sample solution, respectively and sequentially washing off impurities with water and 10% ethanol, eluting with a strippant, collecting the eluted part, recovering the strippant, and adding a defined amount of water to maintain a constant volume so as to obtain a podophyllotoxin purified solution. The organic solvents used in the process are nonpoisonous and can be recovered, and no three wastes polluting the environment are produced. The whole process is green and environment friendly and has the advantages of simple operation and easy industrialization, and the purity of the podophyllotoxin obtained by the process is above 98%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com