New process for painting container of engineering dump truck

A technology of dump truck and new process, applied in the field of coating process of automobile engineering cargo box, can solve the problems of unstable product quality, low production efficiency, complex process, etc., and achieves small footprint, improved product quality, and simple process workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

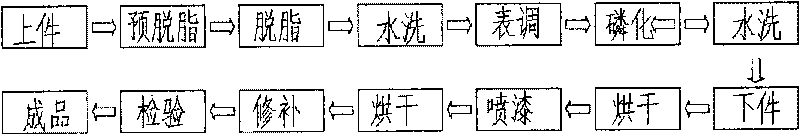

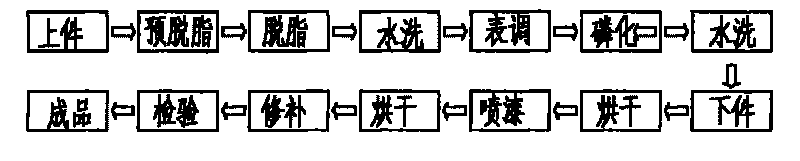

[0028] Such as figure 1 As shown, a new process for painting the cargo box of an engineering dump truck, the process includes the following steps:

[0029] Step 1: Loading, open the rear door panel of the engineering dump truck container and fix the position of the rear door panel, and then send the engineering dump truck container into the chemical tank of the self-propelled hoist circulation conveying system. The method of fully immersing the container of the engineering dump truck in the chemical tank is to run the self-propelled hoist circulation conveying system to the middle limit point of the chemical tank and then stop. / 3 When immersed in the tank liquid, the cargo box just forms a 20-30 degree inclination angle with the liquid surface, and then the two self-propelled hoists descend at the same time. After reaching the set position, the self-propelled hoist at the rear door panel end stops descending, and the other self-propelled hoist continues to descend to the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com