Selective laser sintering scanning method

A technology of laser sintering and scanning method, which is applied in the field of laser scanning, which can solve the problems of very high matching between scanning speed and laser power, reducing the accuracy of parts, and uneven laser intensity, so as to achieve uniform laser scanning intensity and ensure product quality , The effect of consistent scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

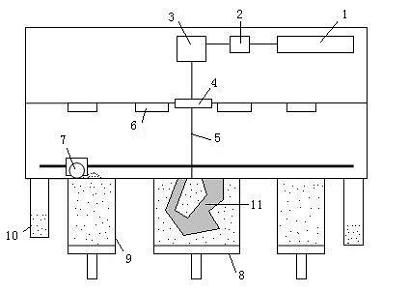

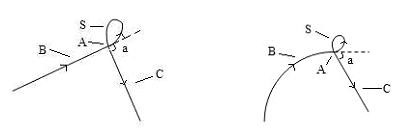

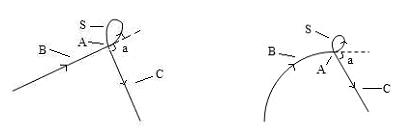

[0011] The equipment that the inventive method adopts is as figure 1 As shown, in the SLS equipment, the powder feeding device 9 sends a certain amount of powder to the worktable, and after the powder is preheated, the powder spreading roller 7 evenly spreads the powder on the upper surface of the molded part 11 in the working cylinder 8 , the excess powder is recovered to the overflow powder cylinder 10, the heating device 6 heats the laid powder to a temperature just below the sintering point of the powder, the laser beam 5 emitted from the laser 1 is reflected by the prism 2 to the vibrating mirror system 3, and vibrates The mirror system 3 controls the laser beam 5 to pass through the laser window 4 to the working table for filling and scanning sintering of the cross-section powder of the workpiece 11 . Such as figure 2 As shown in -4, a is the sharp corner of the laser scanning. The laser scans to the vertex A at a constant speed along the side B with the speed v and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com