Patents

Literature

38results about How to "Save the drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for extracting iodine from kelp

InactiveCN1840469ASave the drying processReduce manufacturing costHalogen/halogen-acidsMANNITOL/SORBITOLIodine

The disclosed method to extract I2 from kelp comprises: with fresh kelp as material, cutting up, adding 200wt% water to dip for 30-50min; putting soak into pond, adjusting pH value with alkali, while filling gas to stir and then filter to obtain the clear liquid with I2 and mannitol; acidifying and oxidizing to obtain dissociative I2 and then adsorb with basic anion exchange resin; desorbing the I2 on resin with Na2S2O3; adding strong H2SO4 and KClO3 to separate out coarse I2; cleaning, and refining with 25wt% strong H2SO4 at 140Deg to obtain the refined iodine. This invention reduces cost and source.

Owner:威海长青海洋科技股份有限公司

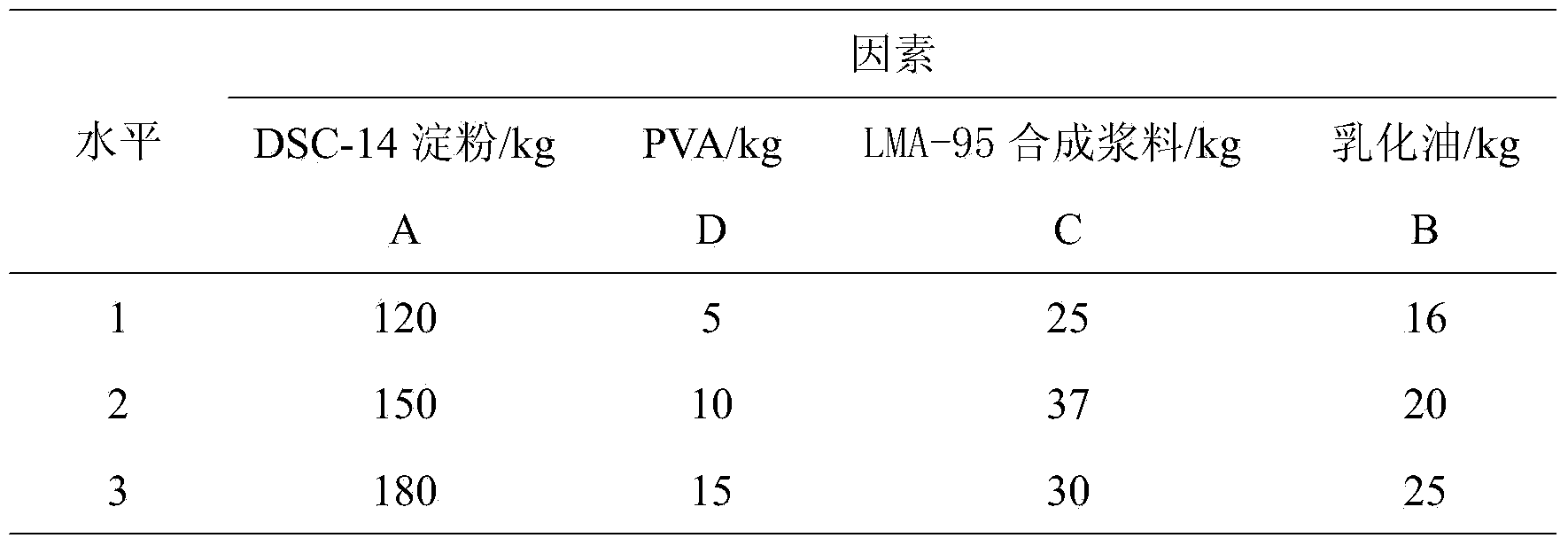

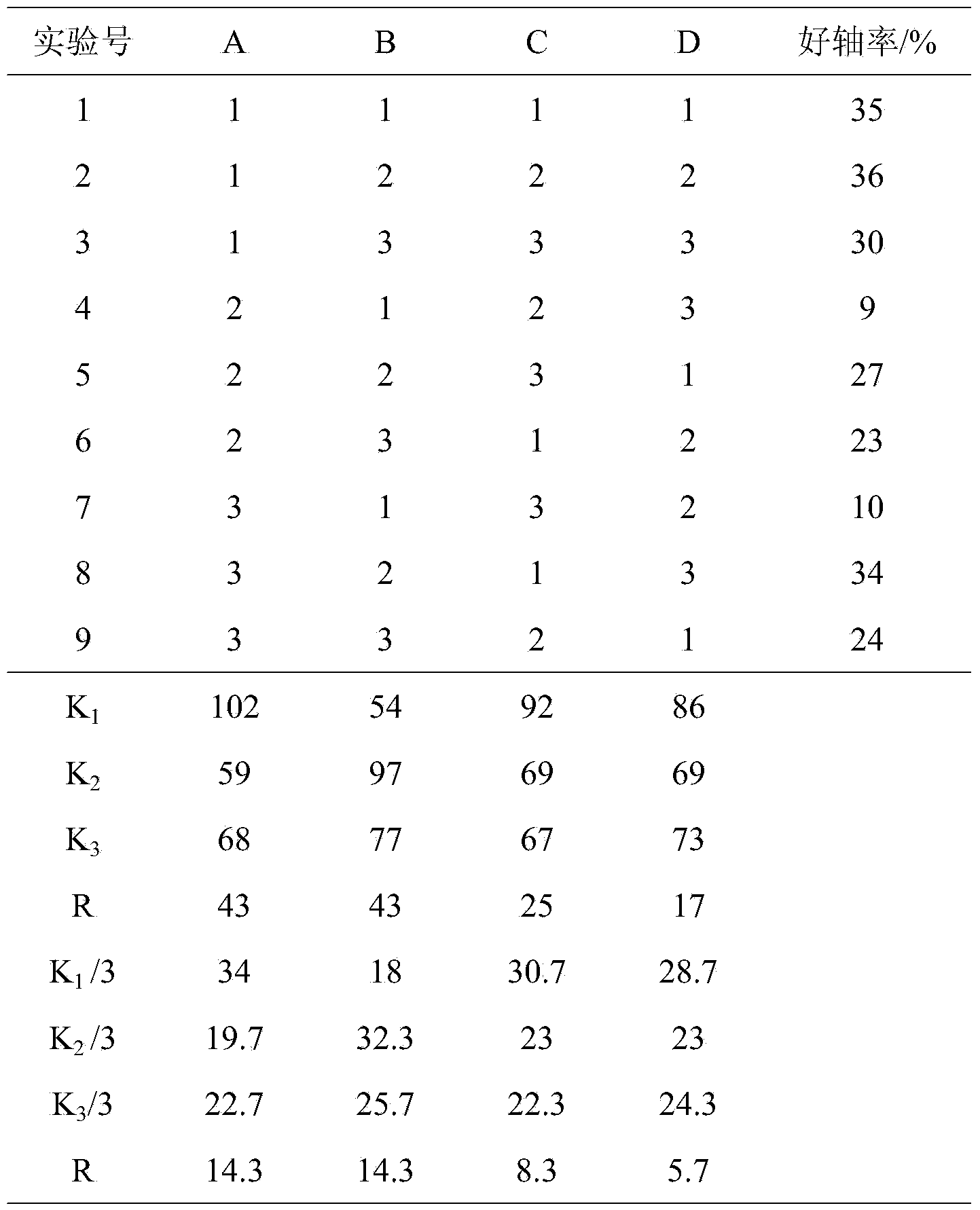

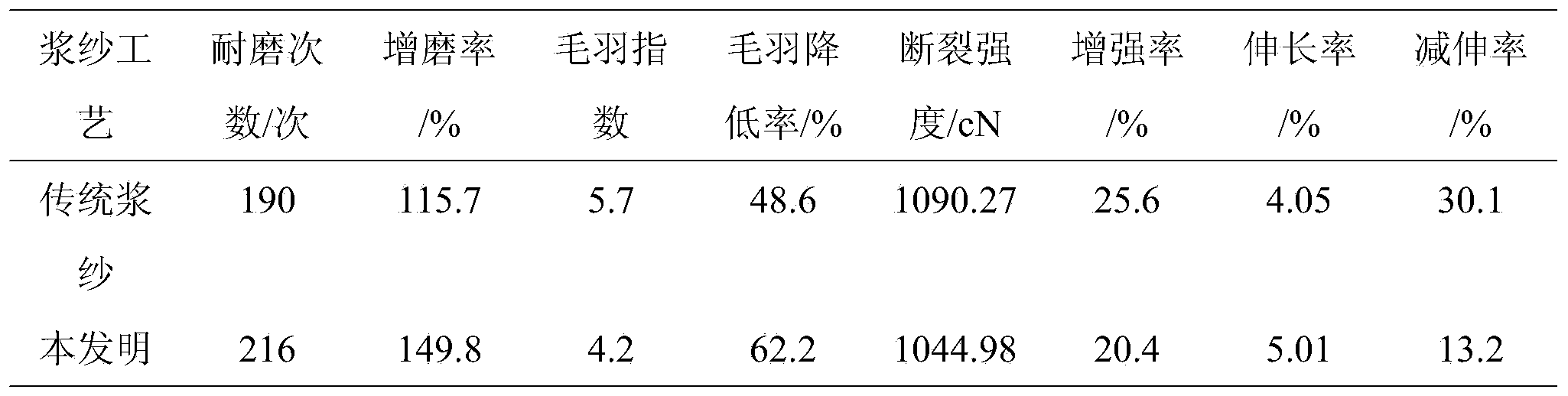

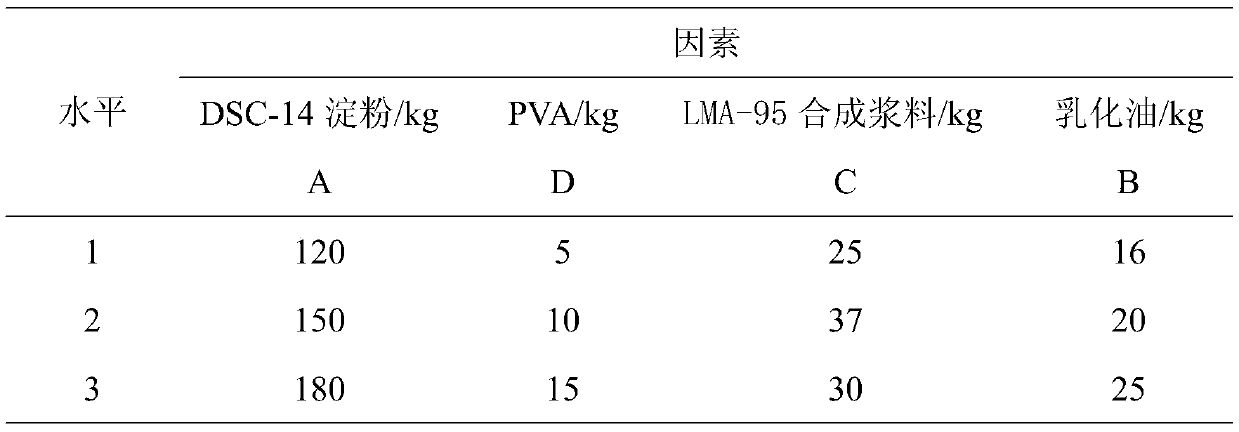

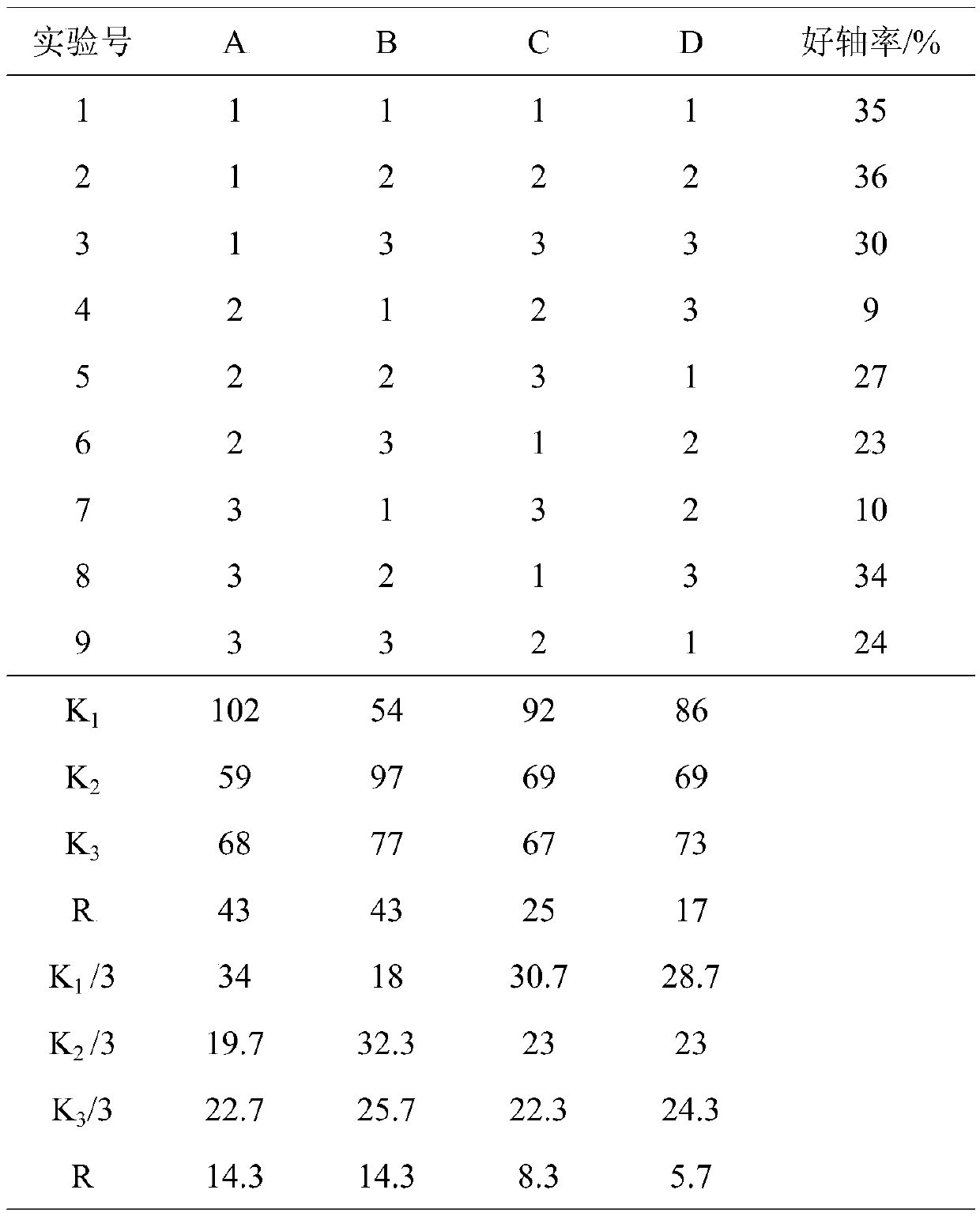

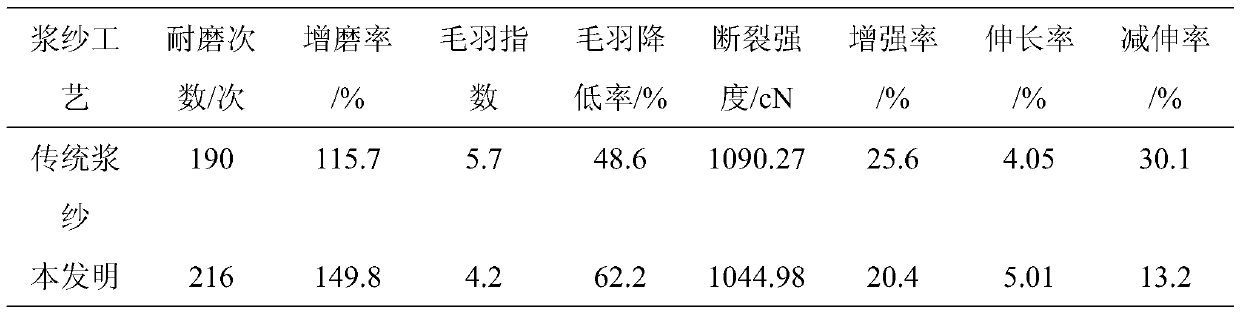

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Preparation method of anti-ultraviolet finishing agent for silk fabric

The invention discloses a preparation method of an anti-ultraviolet finishing agent for silk fabric. The preparation method comprises the following steps: filling 25-50mL of propylene glycol into a conical flask, dropwise adding 5-10mL of tetrabutyl titanate into the conical flask, introducing nitrogen gas with water at 60-80 DEG C and stirring for 30-60min; removing moisture in the conical flask by using a rotary evaporator at 80-100 DEG C, adding 5-10g of sodium stearate and 2-5g of hydroxyethyl cellulose into the conical flask, and carrying out water-bath ultrasonic treatment for 1-2h to obtain mixed paste; transferring the mixed paste in the conical flask into a high-speed dispersion machine, adding a wetting agent, a softening agent, a defoaming agent, a dispersing agent and a coupling agent, and stirring for 60-90min at 10000-15000r / min to obtain the anti-ultraviolet finishing agent for silk fabric. The anti-ultraviolet finishing agent for silk fabric has good heat resistance, is not easy to decompose when being heated, is non-toxic, is harmless to human body, has good biodegradability and facilitates environmental protection.

Owner:南通中宸印染有限公司

Solid state fermentation feed technology and related high-efficiency safe biological fermentation feed

InactiveCN105767530AAlleviate the plight of humans and animals competing for foodIncrease added valueFood processingAnimal feeding stuffBiotechnologyRapeseed

The present invention provides solid state fermentation feed technology and a related high-efficiency safe biological fermentation feed. The technology includes the following steps: rapeseed meal, cottonseed meal and miscellaneous meal are pulverized, supplemented with wheat bran to be blended, and inoculated with a compound fermentation broth containing Saccharomyces cerevisiae, Bacillus subtilis, Aspergillus oryzae and Lactobacillus plantarum to be evenly mixed, the mixture is packed in a packaging bag with an antimicrobial safety film, and the packaging bag is sealed; and finally, the packaged mixture is transferred to a constant temperature fermentation room to be stacked, with the temperature of the constant temperature fermentation room maintained at 25-30 DEG C and the stacking fermentation time of 48-72 hours. The present invention is simple in production process, makes full use of the rapeseed meal, the cottonseed meal and the miscellaneous meal to perform biological fermentation, and the fermentation feed can reduce anti-nutritional factors, and is rich in nutrition.

Owner:武汉明天生物科技有限公司

Method for continuously preparing crystalline silicon solar cell PN (Positive-Negative) junction and antireflection film

InactiveCN102005508ASave the drying processOmit to removeFinal product manufactureSemiconductor devicesPhysicsSilicon nitride

The invention discloses a method for continuously preparing a crystalline silicon solar cell PN (Positive-Negative) junction and antireflection film. The method comprises the following steps of depositing a phosphor-doped (or boron-doped) silicon nitride antireflection film on a P-type (or N-type) silicon wafer which is cleaned and etched by using a plasma enhanced chemical vapor deposition technology, carrying out conventional annealing treatment at high temperature so that part phosphor (or boron) in the silicon nitride layer is diffused to the P-type (or N-type) silicon wafer, and forming a PN junction on the surface of the silicon wafer. The method is compatible with the industrialized crystalline silicon solar cell production process, does not need complex POC13 or BBr3 diffusion and the subsequent step of removing phosphorus silicon or boron silicon glass, has simpler production process and is suitable for low-cost batch production.

Owner:HUNAN UNIV

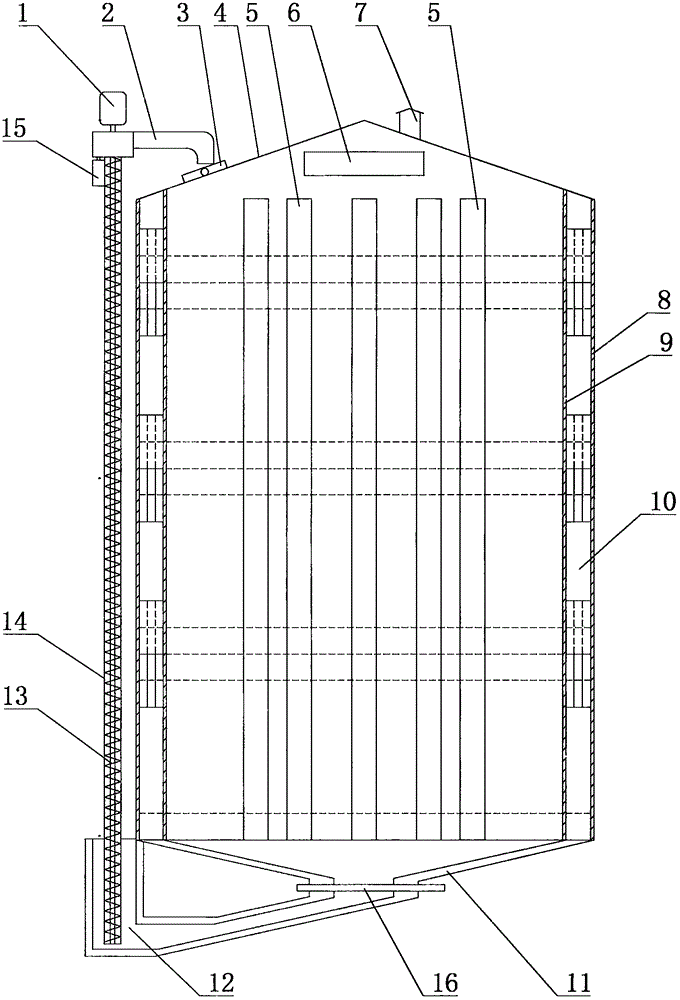

Air drying grain bin

InactiveCN107172978AReduce lossShorten the timeAgriculture tools and machinesHarvested fruit hanging devicesFood contactEngineering

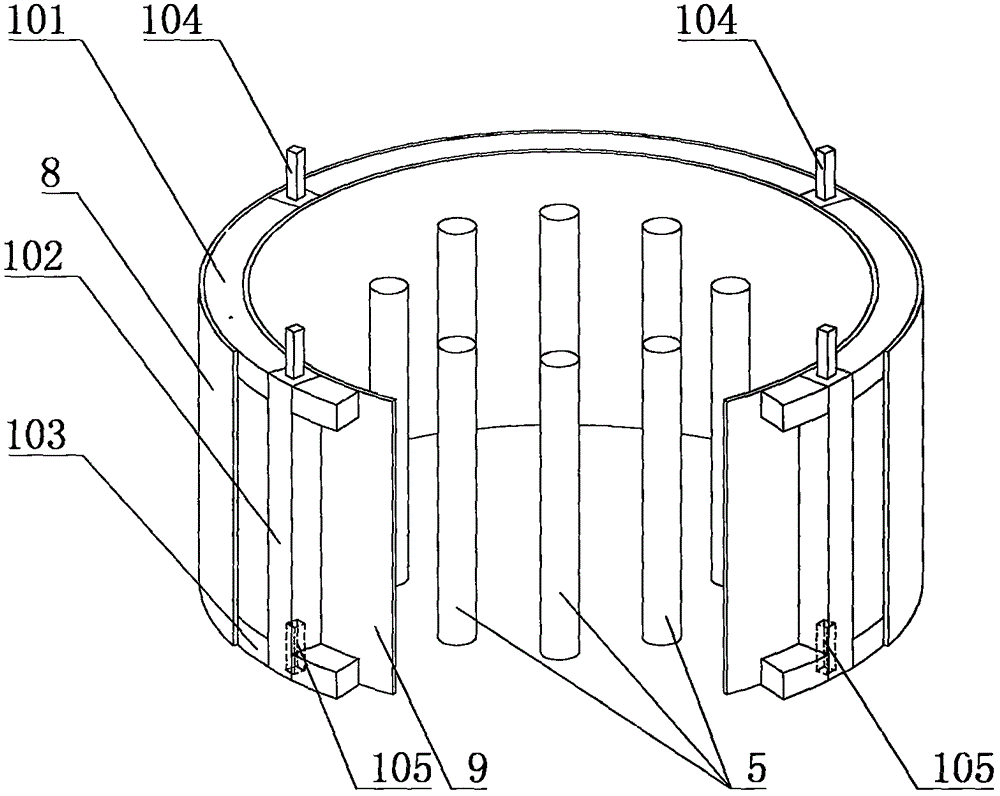

The invention provides an air-dried granary, comprising a bin body, a bin top and a bin bottom, the inside of the bin body is covered with an inner bin board, the inner bin board is provided with external ventilation holes, and the bin top is provided with an air extraction Machine and the exhaust channel connected with the exhaust port of the air extractor, several ventilating pipes are arranged below the air extractor, and the inner pipe vent holes are arranged on the wall of the ventilating pipe. The invention can directly store the newly harvested grain through the integrated structure of temperature and humidity automatic monitoring, automatic ventilation, drying and storage, and the new grain with high moisture content will be dried quickly in the granary, eliminating the steps of drying and multiple transfers, reducing It not only saves time, but also improves the efficiency and ensures the quality of grain.

Owner:马建海

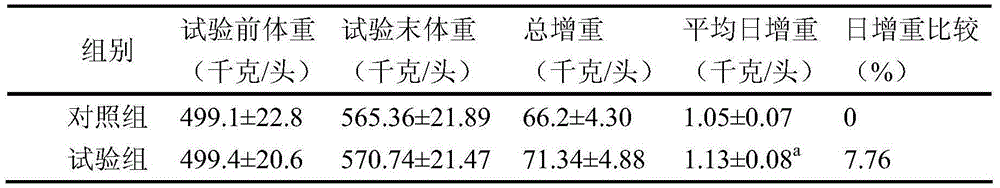

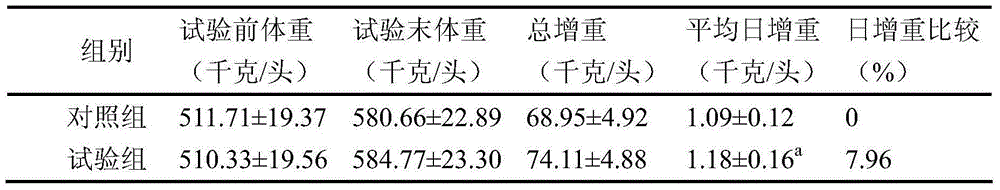

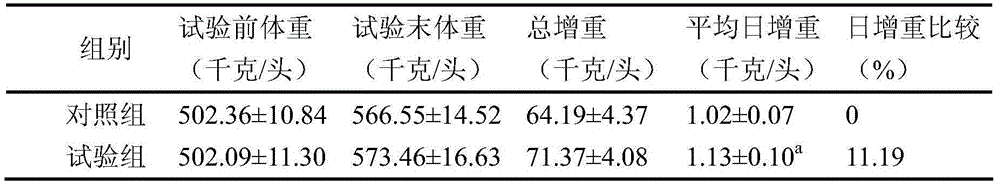

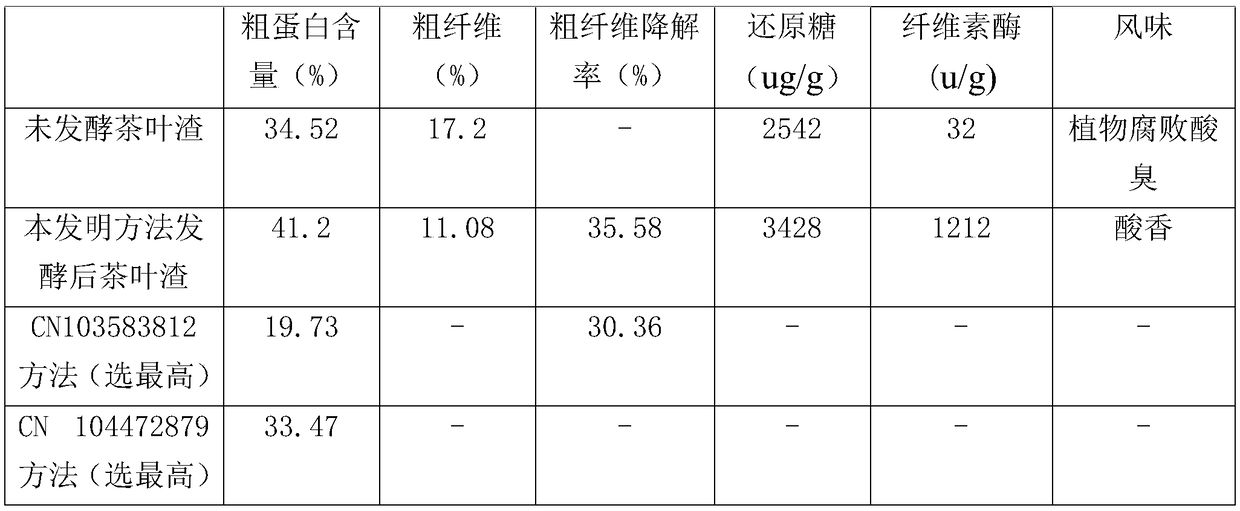

Cordyceps militaris culture medium fermented feed and preparation method thereof

ActiveCN105028897AFor long-term storageIncrease production capacityFood processingAnimal feeding stuffBiotechnologyBacillus cereus

The invention discloses a cordyceps militaris culture medium fermented feed and a preparation method thereof. The preparation method comprises the following steps: adding corn bran, brewer's grain and candy pomace into a fresh cordyceps militaris culture medium, crushing, uniformly mixing, inoculating microorganism lactic acid bacteria and bacillus cereus during the mixing process, regulating the moisture content to be 35-45%, carrying out anaerobic fermentation, so as to obtain the cordyceps militaris culture medium fermented feed after fermentation maturity; the fermented feed can completely replace corn in concentrated feeding stuff for flocks and herds. According to the cordyceps militaris culture medium fermented feed and the preparation method thereof, provided by the invention, the fresh cordyceps militaris culture medium is subjected to anaerobic fermentation treatment, and the fermentation temperature is lower than 40 DEG C, so that high-temperature drying is avoided, function materials in the culture medium are protected, the drying process is avoided, the drying cost is avoided, besides, the fresh cordyceps militaris culture medium can be preserved for a long time under a low pH and anaerobic environment, the production performance of cattle and sheep is improved by the cordyceps militaris culture medium fermented feed after fermentation under the action of the function materials contained in the fermented feed such as cordycepic acid, probiotics, enzyme and an acidifier.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI +1

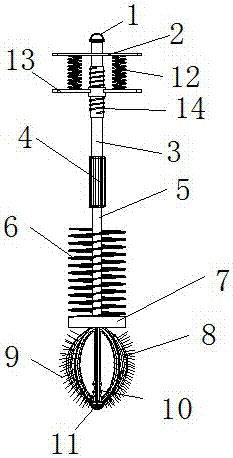

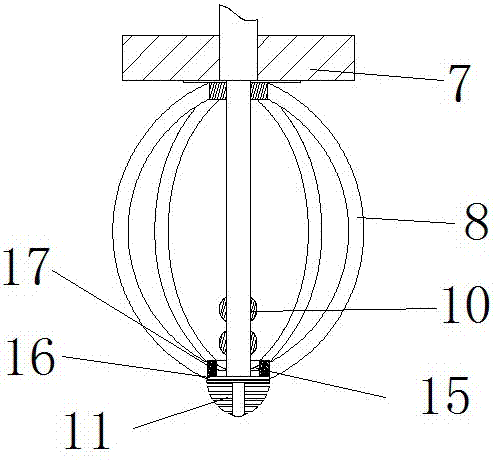

Telescopic test-tube brush for agricultural strain culturing

InactiveCN107319732ASimple structureFunction increaseBrush bodiesBristleAgricultural engineeringEngineering

The invention discloses a telescopic test-tube brush for agricultural strain culturing. The telescopic test-tube brush comprises a main hollow rod and an extension rod, and a hanging ring is arranged on the upper surface of the main hollow rod. The telescopic test-tube brush for agricultural strain culturing is simple in structure, diversified in functions, convenient to operate and capable of bringing convenience to a tester in cleaning of test tubes; by the aid of the hanging ring, the telescopic test-tube brush can be hung at a position, which is convenient for the tester to fetch and use; by the aid of a system formed by combination of a spring, a hollow screw rod and the like, the test tubes can be cleaned semi-automatically, thus effort is saved and cleaning time is saved greatly; by the aid of the extension rod which is adjustable telescopically, convenience in use of the telescopic test-tube brush is increased, a radian of an elastic rod can be adjusted according to the size and the shape of the test tube, and applicability of the telescopic test-tube brush is enhanced; by the aids of a semi-spherical sponge and an annular sponge pad which are arranged on the extension rod, water left on an inner wall of the test tube after cleaning can be absorbed completely, airing of the test tube after cleaning is omitted, and convenience in use of the telescopic test-tube brush is further increased.

Owner:许昌农科种业有限公司

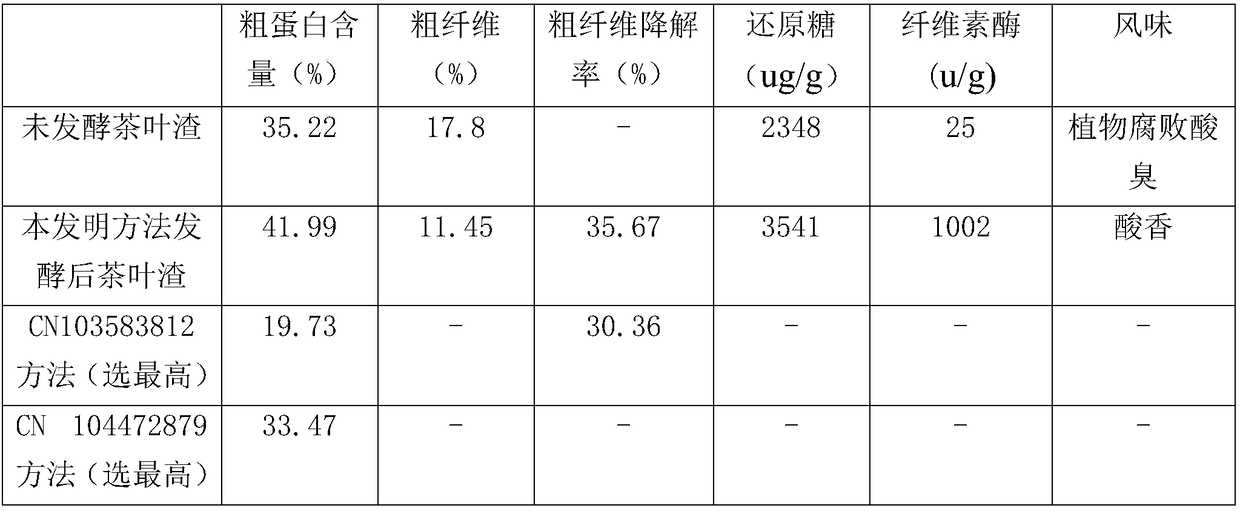

Method for preparing feed raw materials by solid state fermentation of tea dregs

The invention discloses a method for preparing feed raw materials by solid state fermentation of tea dregs, and relates to the field of feed processing. The method is as follows: mixing tea dregs, bean pulp, bran, molasses and composite trace elements as fermentation substrate according to a certain mass ratio, adjusting water content, adding 4 kinds of bacteria such as bacillus subtilis, saccharomyces cerevisiae, aspergillus niger and lactic acid bacteria, controlling fermentation conditions, and performing enzymolysis and aerobic and anaerobic combined fermentation to obtain the product. According to the tea dreg solid state fermentation feed produced by the method of the invention, the method effectively reduces the crude fiber content of the tea dregs, improves the protein content, andis suitable for industrial production of feeds.

Owner:ZHEJIANG UNIV

Rotary type quick glue spraying device with instant drying function

InactiveCN111111987AShorten the timeImprove glue spraying efficiency and qualityPretreated surfacesLiquid spraying apparatusMetal cylinderEngineering

The invention discloses a rotary type quick glue spraying device with an instant drying function. The device comprises a base, wherein an L-shaped fixing frame is arranged on the outer wall of one side of the top of the base, a support is arranged on the outer wall of one side of the top of the L-shaped fixing frame, an installation groove is formed in the outer wall of one side of the top of thesupport, a motor is clamped in the installation groove, a fan is arranged at the output end of the motor, an L-shaped placing groove is formed in the outer wall of the top of the L-shaped fixing frame, a fixing barrel is welded on the inner wall of the bottom of the L-shaped placing groove, a baffle is arranged on the outer circumferential wall of one side of the fixing barrel, through holes distributed at equal distances are formed in the outer circumferential wall of the fixing barrel, a stepping motor is arranged on the outer top wall of one side, close to the L-shaped fixing frame, of thebase, and an output shaft of the stepping motor is connected with a rotating shaft through a coupler. According to the rotary type quick glue spraying device with the instant drying function, the drying work is effectively carried out in time, so that the process of putting a metal cylinder workpiece into drying equipment for drying is omitted, the time is saved, and the glue spraying efficiency and quality of the integral device are also improved.

Owner:GUANGDONG ORIENT RESIN

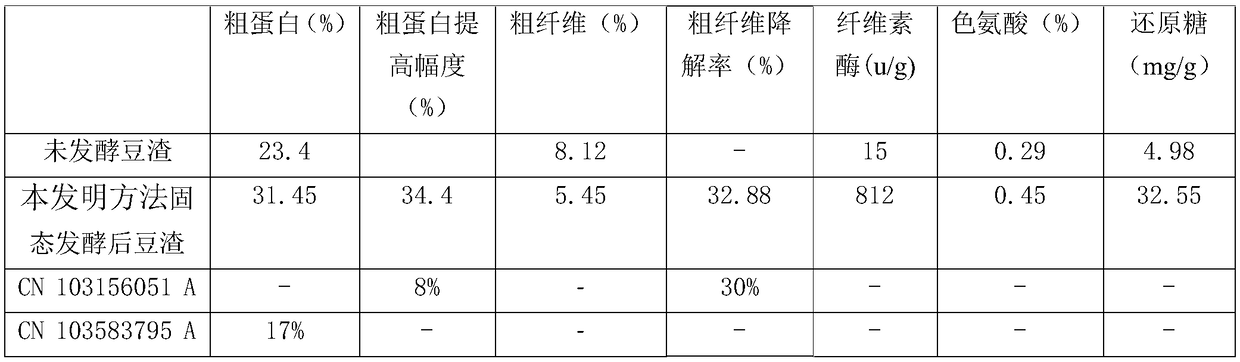

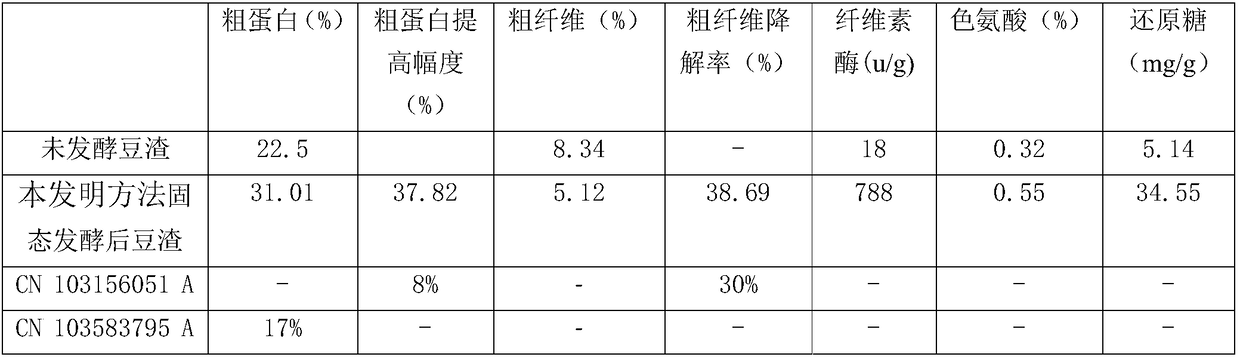

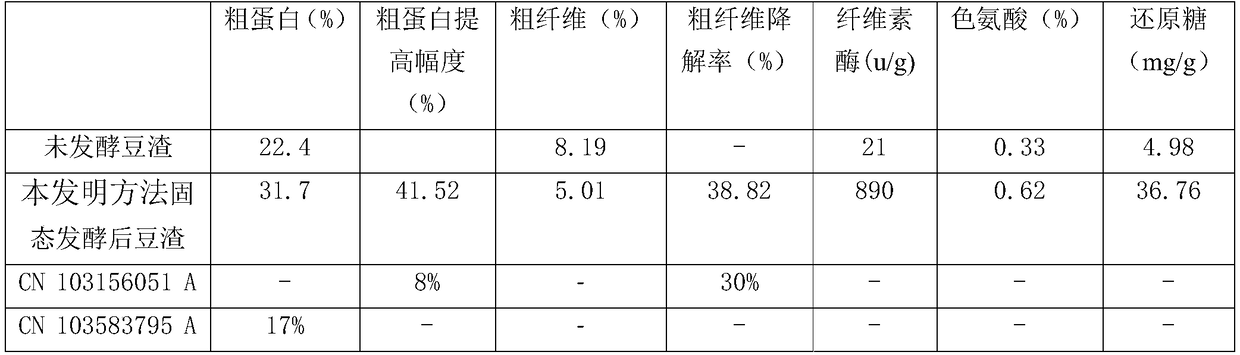

Method for preparing microbial cultures through solid state fermentation of bean dregs

The invention relates to a method for preparing microbial cultures through solid state fermentation of bean dregs, and relates to the field of feed processing. The method comprises the following stepsof taking bean dregs, amino acid residues, bran, molasses and composite trace elements in a certain mass ratio, performing mixing to obtain a mixture as a fermentation substrate, regulating the moisture content, adding 3 kinds of bactera of corynebacterium glutamicum, aspergillus oryzae, plant lactobacillus and the like, controlling fermentation condition, and adopting combination of enzymolysis,aerobic fermentation and anaerobic fermentation so as to obtain the products namely the microbial cultures. When the method disclosed by the invention is used for producing the microbial cultures through solid state fermentation of bean dregs, the content of insoluble dietary fibers in the bean dregs is effectively reduced, the protein content is increased, and the method is suitable for industrial production of feeds.

Owner:ZHEJIANG UNIV

A kind of denim warp yarn sizing size and sizing process

ActiveCN103966849BImprove wear resistanceImprove surface propertiesFibre treatmentSlurryPulp and paper industry

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Mask of three-layer structure

InactiveCN104705841AThe overall structure is simpleLow costBreathing filtersProtective garmentEngineeringLife saving

The invention discloses a mask of a three-layer structure. The mask comprises a mask body and mask bands. The mask bands are arranged on the two sides of the mask body, and a length adjusting mechanism is arranged on each mask band. The mask body sequentially comprises an inner mask cloth, a detachable filter component and an outer mask cloth. The detachable filter component comprises a PM 2.5 filter layer and an adsorption layer. The mask of the three-layer structure is simple in structure, low in cost and easy to manufacture; the filter component can filter out impurities, toxic gas and PM2.5 in external air; the filter component can be taken out and reused after being aired and disinfected, the situation that secondary pollution is caused to the inhaled air due to the fact that the mask body is not cleaned thoroughly is prevented, and the process of cleaning and airing the mask body is omitted. The mask of the three-layer structure has the functions of filtration, health care and life saving.

Owner:张小英 +1

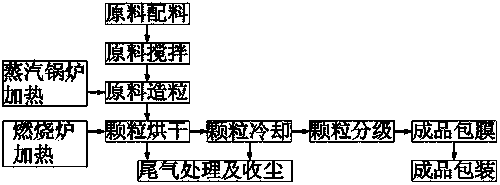

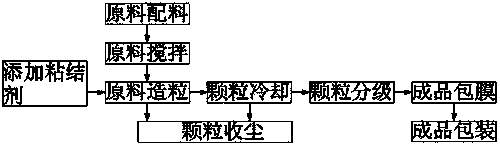

Novel compound fertilizer production process

InactiveCN105254394AHigh ball rateSave the drying processFertilizer mixturesPhosphatePhosphoric acid

The invention discloses a novel compound fertilizer production process. The novel compound fertilizer production process comprises the following procedures: batching of raw materials; stirring of the raw materials; granulation of the raw materials; cooling of particles; dust collection of the particles; grading of the particles; coating of a finished product; packaging of the finished product; etc. The process is characterized in that in the procedure of batching of the raw materials, urea, monoammonium phosphate and potassium chloride are used as the raw materials; and in the procedure of granulation of the raw materials, a binder composed of magnesium oxide powder and a phosphoric acid solution is added into a granulator in proportion. Compared with the prior art, the invention has the following advantages: the compound fertilizer production process is simplified; compound fertilizer production efficiency is improved; equipment cost is reduced; energy consumption is lowered; and environmental pollution is decreased.

Owner:汤阴环美制动器材有限公司

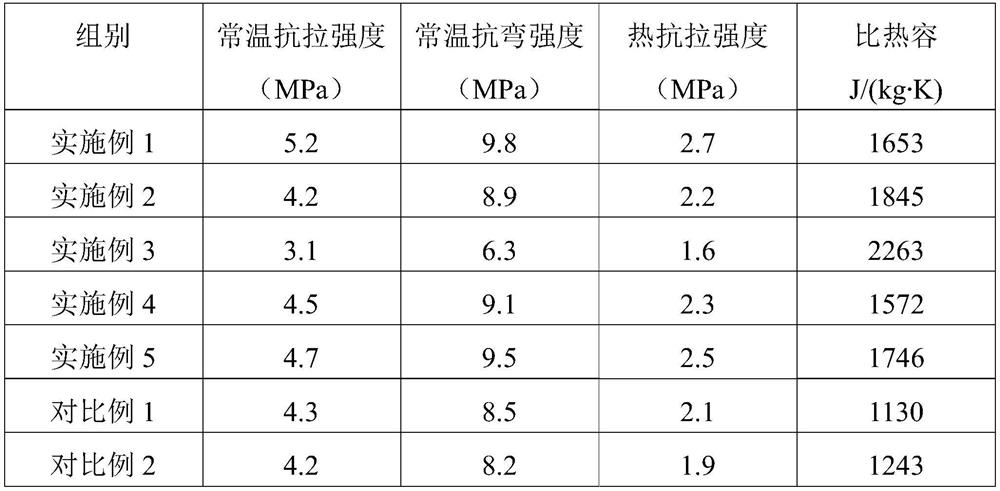

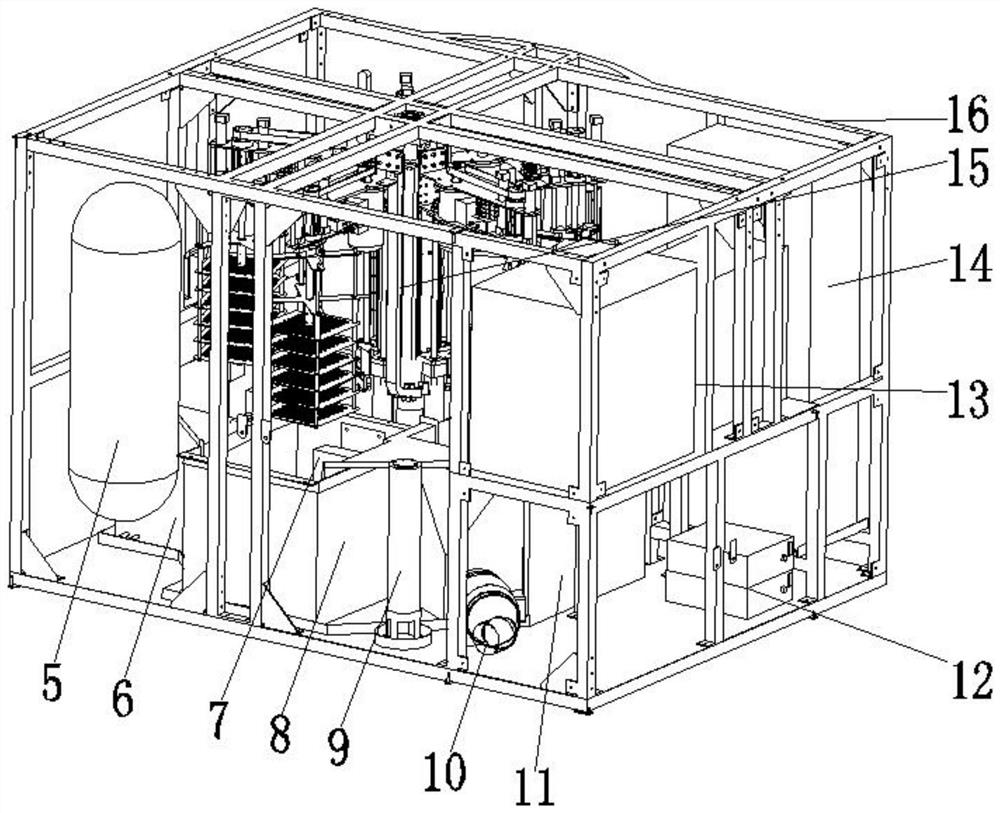

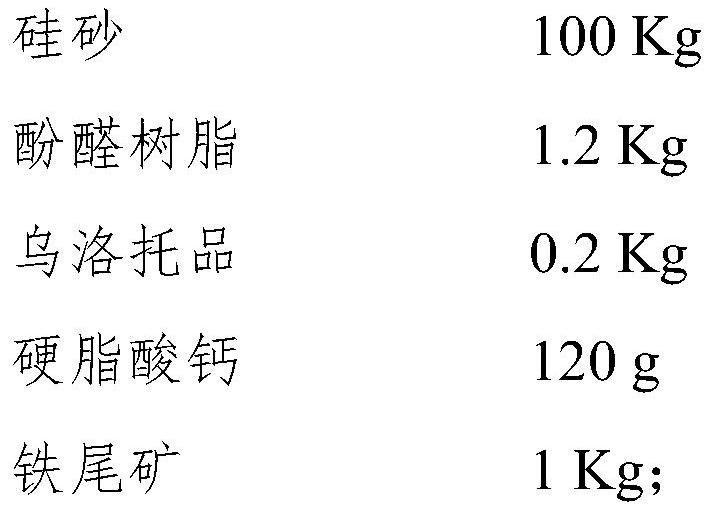

Self-heat-absorption precoated sand and preparation method thereof

ActiveCN113770297AImprove heat resistanceIncrease productivityFoundry mouldsFoundry coresFerrochromeFire retardant

The invention relates to self-heat-absorption precoated sand and a preparation method thereof. The self-heat-absorption precoated sand is prepared from the following raw materials in parts by weight: 96-98 parts of silica sand, 1-3 parts of phenolic resin, 0.1-0.6 part of a curing agent, 0.05-0.3 part of a lubricant, 0.096-0.98 part of a heat absorption auxiliary agent and 0.096-0.98 part of a flame retardant. The precoated sand has the advantages that the heat absorption auxiliary agent is added into the precoated sand, heat of high-temperature molten metal during solidification is absorbed through a self-heat-absorption chemical reaction, so that the heat resistance of the precoated sand is improved. Compared with a traditional ferrochrome sand chilling material, the cost advantage is obvious, the working procedures of brushing paint on a sand core and drying are omitted, and the purposes of reducing cost and improving efficiency are achieved; the surface of the precoated sand is coated with the heat absorption auxiliary agent, so that the conventional performance of the precoated sand is not affected; and according to the precoated sand prepared through the method, castings can achieve different effects in different solidification stages, and the special requirement that common silica sand can be used for ultra-large steel castings is met.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Method for preparing microbial cultures through solid state fermentation of shrimp shells

PendingCN109198176ALow costReduce pollutionFood processingAnimal feeding stuffBiotechnologyLactarius

The invention relates to a method for preparing microbial cultures through solid state fermentation of shrimp shells, and relates to the field of feed processing. The method comprises the following steps of taking shrimp shells, soybean meal, bran and composite trace elements in a certain mass ratio, performing mixing to obtain a mixture as a fermentation substrate, regulating the moisture content, adding 3 kinds of bacteria of phaffia rhodozyma, bacillus subtilis, plant lactobacillus and the like, controlling fermentation condition, and adopting combination of aerobic fermentation and anaerobic fermentation so as to obtain the products namely the microbial cultures. When the method disclosed by the invention is used for producing the microbial cultures through solid state fermentation ofshrimp shells, the possibility that chitin in the shrimp shells is converted into functional chitosan is effectively reduced, the protein content is increased, and the method is suitable for industrial production of feeds.

Owner:ZHEJIANG UNIV

Traditional Chinese medicine bacterial fertilizer produced by utilizing traditional Chinese medicine waste residues and preparation method thereof

PendingCN112898076ARealize comprehensive utilizationSolve tough problemsCalcareous fertilisersMagnesium fertilisersBiotechnologyPulp and paper industry

The invention provides a traditional Chinese medicine bacterial fertilizer produced by utilizing traditional Chinese medicine waste residues. The traditional Chinese medicine bacterial fertilizer comprises the following raw materials in parts by weight: 60-80 parts of traditional Chinese medicine waste residues with water content of 70-80%; 20-40 parts of a wet auxiliary material with a water content of 50%-75%; 30-50 parts of a dry auxiliary material with a water content of 0.1%-20%; 5-10 parts of trace elements; 5-10 parts of a fermentation inoculant; 1-2 parts of beneficial viable bacteria; and 5-10 parts of potassium fulvate. The preparation method of the traditional Chinese medicine bacterial fertilizer comprises the following steps: determining a ratio, mixing materials, fermenting, crushing and refining, granulating and supplementing bacteria. The traditional Chinese medicine waste residues serve as fermentation main materials, the water content of the fermentation raw materials is controlled within a suitable range by adding the dry auxiliary materials and the wet auxiliary materials, the drying link is omitted in the middle, the fermentation time is greatly shortened, the energy consumption and the labor cost are saved, and meanwhile the preparation method is not limited by regions and weather and is wider in applicability.

Owner:天津市农业科学院

3C product charging connector shell highlight process

ActiveCN108312048AReduce damageImproved dimensional stabilityEdge grinding machinesPolishing machinesElectrical and Electronics engineeringFlow time

The invention discloses a 3C product charging connector shell highlight process. The 3C product charging connector shell highlight process comprises following steps that firstly, a CNC numerical control device is adopted to machine a charging connector shell; secondly, grinding stone I and the charging connector shell obtained in the first step are added into a grinding bucket of a rolling grinding machine according to the proportion to be subject to rolling grinding, and the ground charging connector shell is cleaned and dried; thirdly, the charging connector shell obtained in the second stepis subject to sand blasting treatment; fourthly, grinding stone II and the charging connector shell obtained in the third step are added into the grinding bucket of the rolling grinding machine according to the proportion to be ground. The 3C product charging connector shell highlight process has the good highlight effect, the product yield and the stability can be improved, the machining flow time can be shortened, manpower is saved, material losses are reduced, product production cost is reduced, and the product market competitiveness is improved.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Novel process for extracting honeysuckle juice

InactiveCN103083383AReduce lossCutting costsCosmetic preparationsToilet preparationsNatural resourceElectricity

The invention discloses a novel process for extracting honeysuckle juice, and relates to the field of a process for extracting plant juice. The process comprises the following steps of: 1, squeezing fresh honeysuckle into paste in a container; 2, separating out juice in a filter screen of 200 meshes through a centrifuge; 3, depositing at 0-10 DEG C for 20-24 hours; and 4, after depositing, filtering for the second time through a filter plate. The novel process disclosed by the invention can greatly reduce loss of various beneficial components, and air-curing, decocting and drying processes are saved, so that corresponding expenditures on coal, alcohol, water and electricity, labor and the like of the processed are greatly saved. And the novel process saves usage amount of the honeysuckle, improves use value of the honeysuckle and reduces waste of natural resource.

Owner:陈汉林

Drying-free granulating process of composite fertilizer

ActiveCN103449940AEasy to addHigh ball rateFertiliser formsFertilizer mixturesPhosphoric acidFertilizer

The invention provides a drying-free granulating process of a composite fertilizer. The granulating process comprises the following process links of preparing raw materials, mixing the raw materials, granulating the raw materials, cooling the granules, collecting dust from the granules, grading the granules, enveloping the finished product with a film, packaging the finished product and the like. The drying-free granulating process is characterized in that the raw materials in the process link of preparing the raw materials include urea, monoammonium phosphate and potassium chloride; and in the process link of granulating the raw materials, a binding agent consisting of a magnesium oxide powder and a phosphoric acid solution is added into a granulator according to a certain proportion. Compared with the prior part, the process for producing the composite fertilizer has the advantages that the process flow is simplified, the production efficiency of the composite fertilizer is improved, the equipment cost is reduced, the energy consumption is reduced, and simultaneously, the environment pollution can also be reduced.

Owner:滁州华冶机电科技有限公司

A kind of production method of ultraviolet absorber bp-3

ActiveCN111302920BAvoid discharge pollutionImprove efficiencyOrganic compound preparationCarbonyl compound preparation by hydrolysisBenzyl chlorideSolvent

The present invention relates to a production method of ultraviolet absorber BP-3, which specifically comprises the following steps: S1: Condensation reaction: put solvent and resorcinol into the reaction kettle, stir and heat up, then add trichlorobenzyl, keep warm and carry out condensation Reaction; S2: hydrolysis stratification and material transfer: add deionized water to the reaction product of S1, hydrolysis reaction, stand and stratify, the upper water layer is applied mechanically, and the lower layer material is transferred to another reaction kettle with solvent and water; S3: esterification Reaction: Add sodium carbonate and dimethyl sulfate to the reaction kettle containing the lower layer materials in S2, and keep warm for reaction; S4: Prepare finished product: centrifugally filter the product after the esterification reaction, and pack the filtered sodium sulfate by-product, The filtrate is evaporated to recover the solvent, and the solvent is used mechanically. The material after the solvent is evaporated is sequentially rectified, refined, centrifuged, and dried to obtain the finished product. The production process adopted in this application makes the production of BP-3 more concise, smooth, and safer, reduces the production cost by more than 40%, and brings considerable profits to the enterprise. At the same time, the production process is cleaner, more efficient, and more friendly to the environment.

Owner:HUBEI MEIKAI CHEM

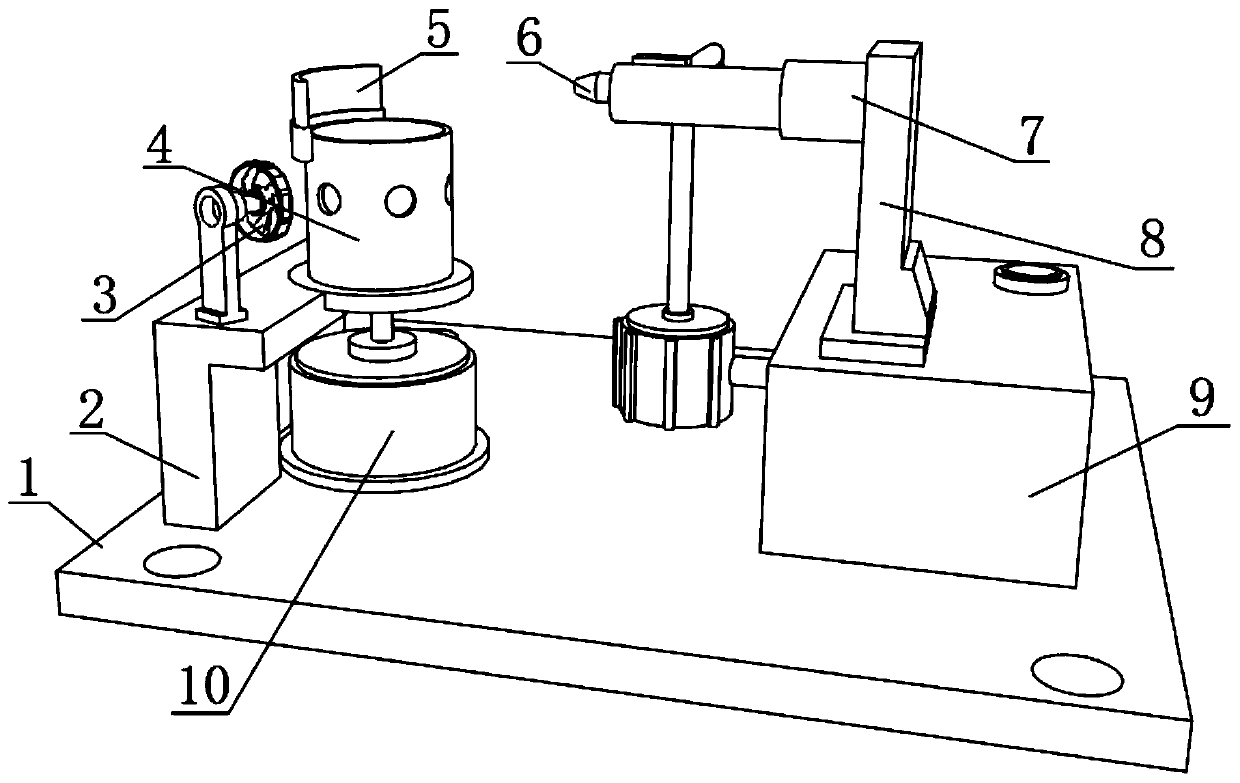

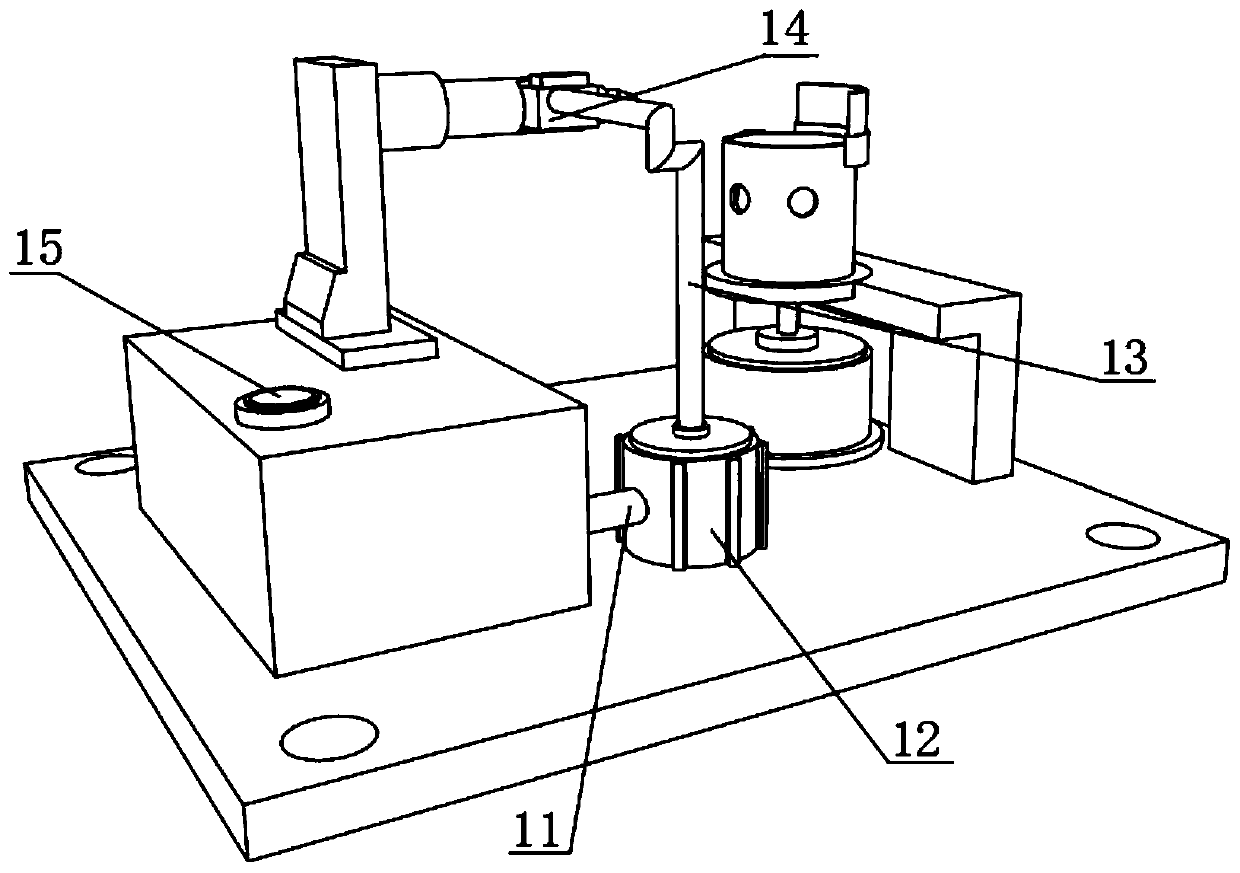

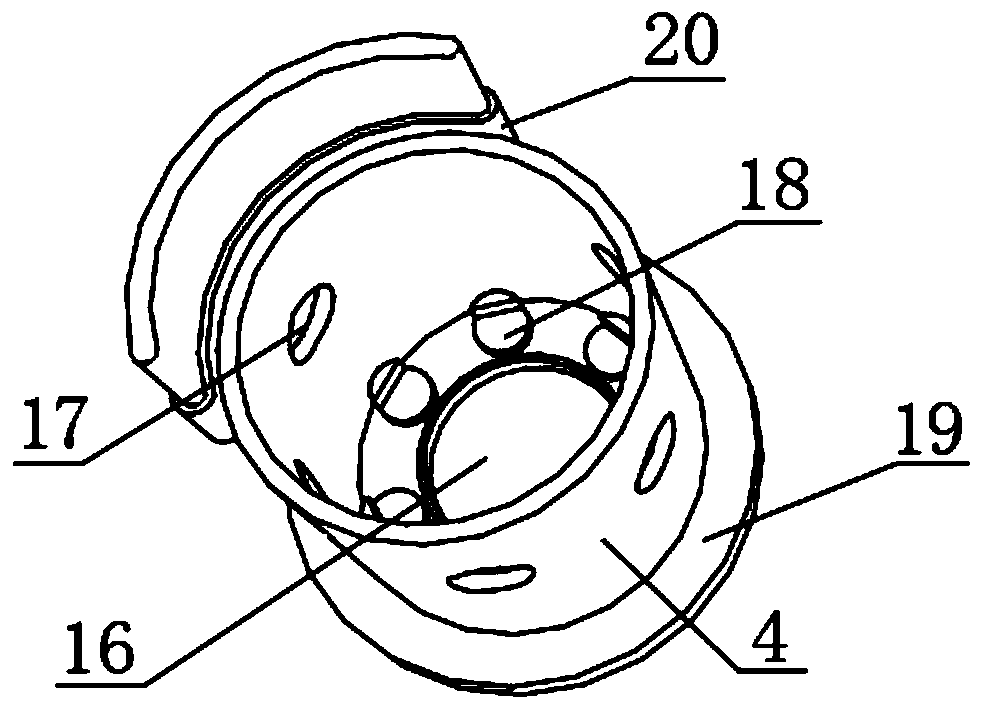

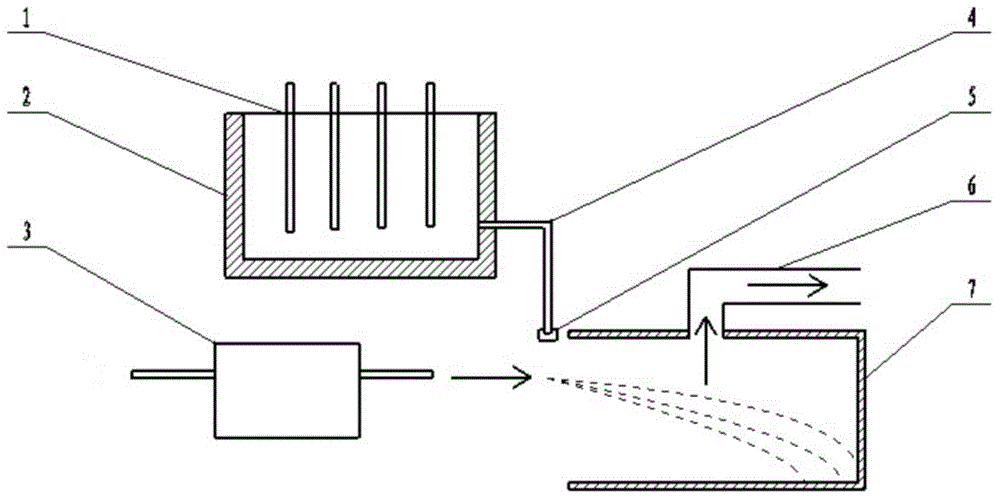

Preparation method and device of tin powder for organic tin production

The invention discloses a preparation method and device of tin powder for organic tin production. The method comprises the following steps: (a) heating and melting a tin ingot, and preparing molten tin; (b) enabling the molten tin to enter a dispersion chamber through a tin flowing channel, supplying air to the molten tin to disperse the molten tin, and sucking the air at the top of the dispersion chamber; (c) cooling the dispersed molten tin in the dispersion chamber to prepare the tin powder. The device comprises a tin melting furnace, a tin flowing pipe, an air compressor, the dispersion chamber and an air suction fan, wherein the tin melting furnace is arranged above the dispersion chamber; an inlet of the tin flowing pipe is connected with the tin melting furnace; an outlet of the tin flowing pipe is arranged at an inlet of the dispersion chamber; the air compressor is arranged at the joint of the outlet of the tin flowing pipe and the inlet of the dispersion chamber; the air suction fan is arranged at the top of the dispersion chamber. According to the method and the device for organic tin production, the molten tin powder is dispersed and cooled by adopting the air, so that the relatively large particle diameter of the tin powder can be controlled, the surface of the tin powder is prevented from being oxidized, the energy consumption is low, the efficiency is high, and the molten tin is discharged smoothly.

Owner:HUBEI NANXING CHEM GENERAL FACTORY

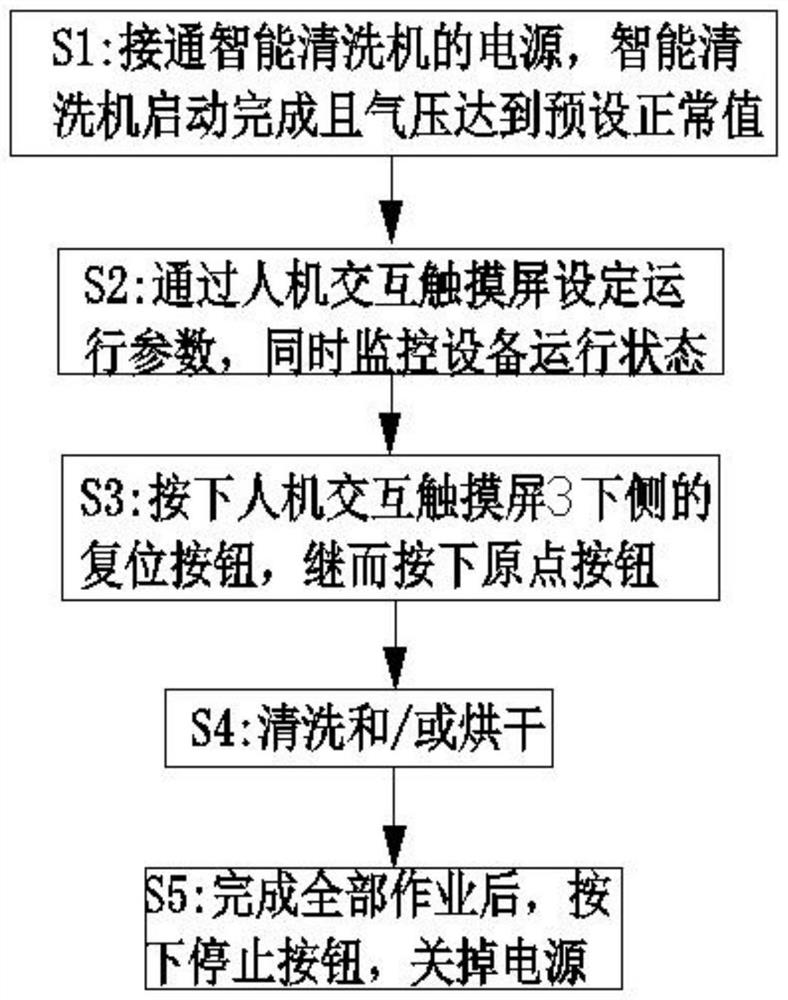

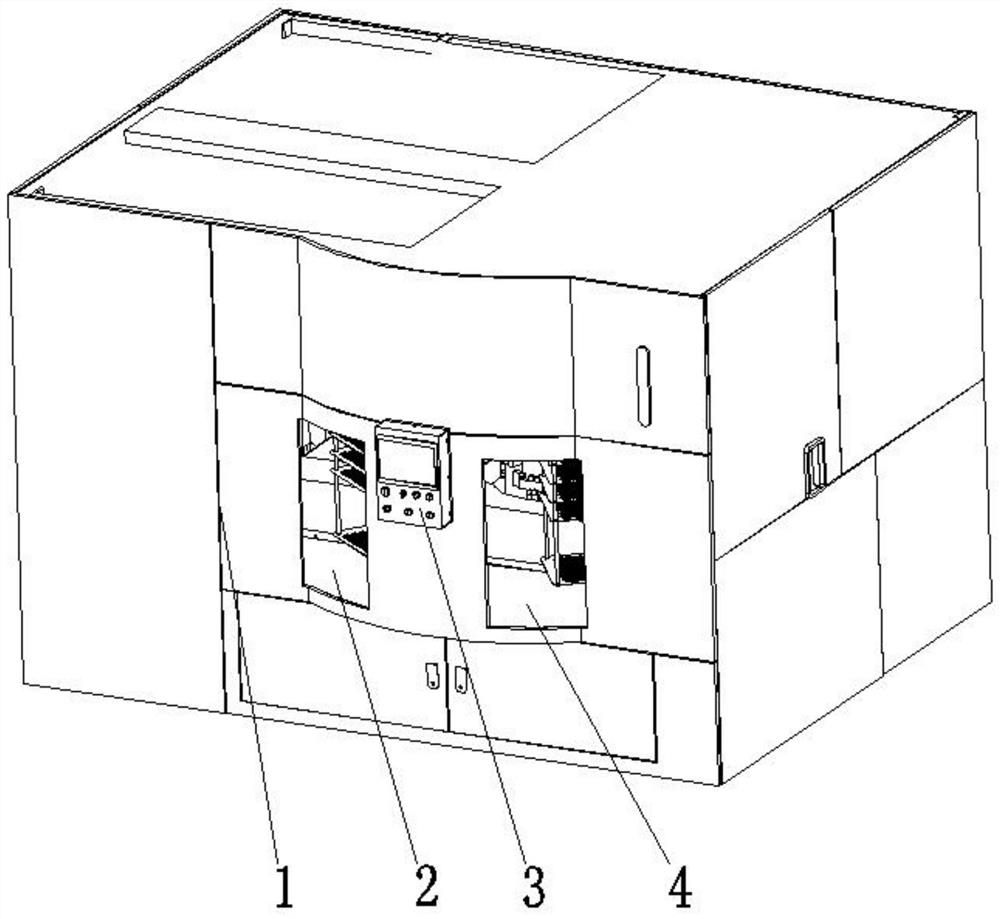

Intelligent cleaning and drying method

PendingCN114082708ASave the drying processEasy to adjustHollow article cleaningDrying gas arrangementsProcess engineeringTouchscreen

An intelligent cleaning and drying method is characterized by comprising the following steps that 1 the power supply of an intelligent cleaning machine is switched on, the intelligent cleaning machine is started, and an air compressor unit is started till the air pressure reaches a preset normal value; 2 operating parameters are set through a man-machine interaction touch screen, and meanwhile the operating state of equipment is monitored; 3 a reset button on the lower side of the man-machine interaction touch screen is pressed down, then an original point button is pressed down, and the intelligent cleaning machine returns to the original point position; 4 cleaning and / or drying are / is carried out until all baskets are cleaned; and 5 after all operations are completed, a stop button is pressed, and the power supply is turned off. The device is simple in structure, easy and convenient to operate and good in cleaning effect, the cleaning amount per hour can reach 700 or more, the basket can be cleaned, various basket-shaped objects can be cleaned, the stability is good, the ultrasonic washing function and the drying function are achieved, the airing process of the washed objects is omitted, secondary pollution is avoided, meanwhile, the airing space and time are saved, the working efficiency is improved, and the labor cost is reduced.

Owner:浙江克拿德电子有限公司

Production method of ultraviolet light absorber BP-3

ActiveCN111302920AAvoid discharge pollutionImprove efficiencyOrganic compound preparationCarbonyl compound preparation by hydrolysisUltraviolet lightsHeat conservation

The invention relates to a production method of an ultraviolet light absorber BP-3, which specifically comprises the following steps: S1, condensation reaction: adding a solvent and resorcinol into areaction kettle, stirring, heating, adding benzyl trichloride, keeping the temperature, and carrying out condensation reaction, S2, hydrolysis layering and material transferring: adding deionized water into a reaction product obtained in the step S1, carrying out hydrolysis reaction, standing for layering, applying an upper water layer, and transferring a lower-layer material into another reactionkettle with water as a solvent, S3, esterification reaction: adding sodium carbonate and dimethyl sulfate into the reaction kettle containing the lower-layer material in S2, and carrying out heat preservation reaction, and S4, finished product preparation: centrifugally filtering a product after esterification reaction, packaging a filtered sodium sulfate byproduct, evaporating filtrate to recover the solvent, applying the solvent, and sequentially rectifying, refining, centrifuging and drying the material from which the solvent is evaporated to obtain the finished product. According to the production process adopted by the invention, the production of the BP-3 becomes simpler, smoother and safer, the production cost is reduced by 40% or above, considerable profits are brought to enterprises, and meanwhile, the production process is cleaner, more efficient and more environment-friendly.

Owner:HUBEI MEIKAI CHEM

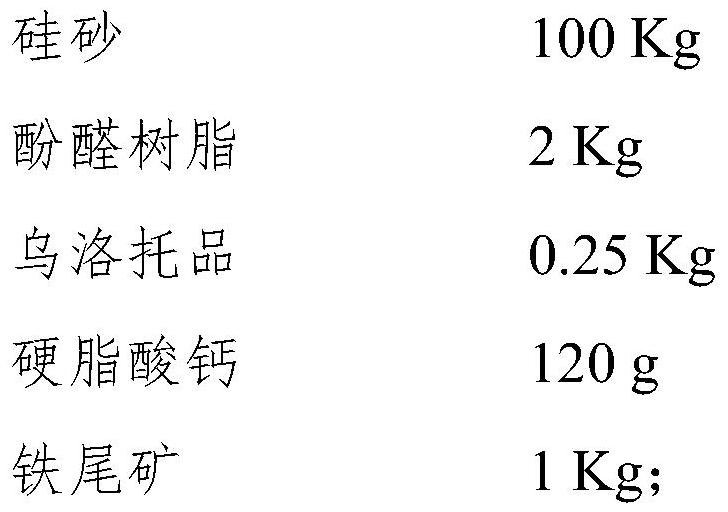

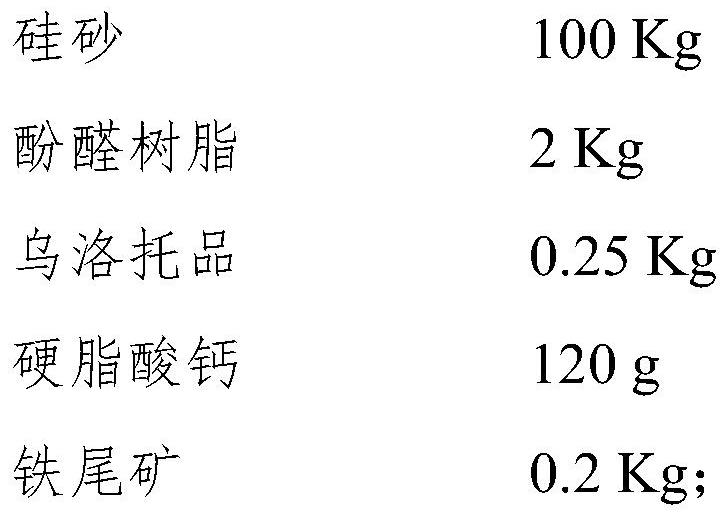

Environment-friendly heat-resistant precoated sand as well as preparation method and application thereof

PendingCN114346164AImprove heat resistanceSave the drying processFoundry mouldsFoundry coresFirming agentIron oxide

The invention discloses environment-friendly heat-resistant precoated sand and a preparation method and application thereof.The environment-friendly heat-resistant precoated sand comprises silica sand, phenolic resin, a curing agent, a lubricating agent and iron tailings, the adding amount mass ratio of the silica sand to the phenolic resin is 96-98: 1-3, and the adding amount of the iron tailings accounts for 0.1-1.2 wt% of the silica sand; the preparation method comprises the following steps: uniformly mixing the silica sand of which the surface is sequentially coated with the phenolic resin layer and the curing agent layer with the iron tailing powder of which the particle size is less than 500 meshes, and then uniformly mixing with the lubricant. The iron tailing auxiliary agent is adopted to treat the precoated sand and can replace a fireproof coating and an iron oxide auxiliary agent so as to improve the heat resistance of the precoated sand, the cost advantage is obvious, the processes of coating and drying of a sand core are omitted, the cost is reduced, and the efficiency is improved; according to the environment-friendly heat-resistant precoated sand, the surfaces of the precoated sand grains are evenly coated with the iron tailings, and the conventional performance of the precoated sand is not affected.

Owner:通辽市仁创铸造材料有限公司

A high-gloss process for charging interface shells of 3c products

ActiveCN108312048BAvoid damageSave the drying processEdge grinding machinesPolishing machinesNumerical controlSand blasting

The invention discloses a 3C product charging connector shell highlight process. The 3C product charging connector shell highlight process comprises following steps that firstly, a CNC numerical control device is adopted to machine a charging connector shell; secondly, grinding stone I and the charging connector shell obtained in the first step are added into a grinding bucket of a rolling grinding machine according to the proportion to be subject to rolling grinding, and the ground charging connector shell is cleaned and dried; thirdly, the charging connector shell obtained in the second stepis subject to sand blasting treatment; fourthly, grinding stone II and the charging connector shell obtained in the third step are added into the grinding bucket of the rolling grinding machine according to the proportion to be ground. The 3C product charging connector shell highlight process has the good highlight effect, the product yield and the stability can be improved, the machining flow time can be shortened, manpower is saved, material losses are reduced, product production cost is reduced, and the product market competitiveness is improved.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

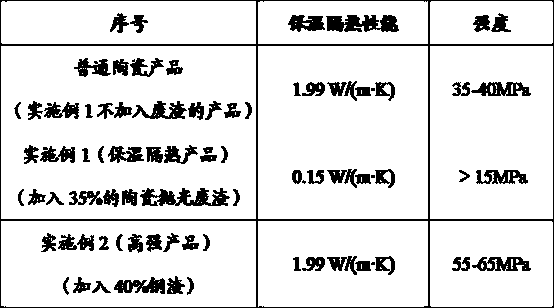

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340BReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingBrick

The invention discloses a building ceramics prepared by using industrial solid waste slag dry method and its technology, which comprises 30-60% of solid waste slag, 40-70% of ceramic raw materials and 1-3% of ceramic additives in terms of mass percentage. Wherein, the ceramic raw material is selected from one or more compositions of clay raw materials, feldspar raw materials or talc, and the ceramic additives are sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate , Sodium humate, Sodium lignosulfonate, Disodium EDTA, EDTA, or a combination of several. The solid waste slag has finer particles after pretreatment. It is mixed with the spray-dried ingredients by dry mixing method and then directly used for brick pressing or put into the silo for standby, which reduces the energy consumption of ball milling and degumming costs, and saves the need for humidification. Granules and fluidized bed drying, and the formula can be quickly adjusted according to the functional characteristics of the product. The process control is simple, and the product has good properties such as thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

Method for continuously preparing crystalline silicon solar cell PN (Positive-Negative) junction and antireflection film

InactiveCN102005508BSave the drying processOmit to removeFinal product manufactureSemiconductor devicesSilicon solar cellPhysics

The invention discloses a method for continuously preparing a crystalline silicon solar cell PN (Positive-Negative) junction and antireflection film. The method comprises the following steps of depositing a phosphor-doped (or boron-doped) silicon nitride antireflection film on a P-type (or N-type) silicon wafer which is cleaned and etched by using a plasma enhanced chemical vapor deposition technology, carrying out conventional annealing treatment at high temperature so that part phosphor (or boron) in the silicon nitride layer is diffused to the P-type (or N-type) silicon wafer, and forming a PN junction on the surface of the silicon wafer. The method is compatible with the industrialized crystalline silicon solar cell production process, does not need complex POC13 or BBr3 diffusion andthe subsequent step of removing phosphorus silicon or boron silicon glass, has simpler production process and is suitable for low-cost batch production.

Owner:HUNAN UNIV

Wire drawing online precoating process

InactiveCN110434042AShorten the lengthSave the drying processPretreated surfacesCoatingsTubing typesEnergy consumption

The invention relates to a wire drawing online precoating process, relates to the technical field of wire drawing production, and aims to solve the problems that an existing groove type soaking coating process is high in energy consumption, low in coating uniformity, and relatively high in production cost, the wire drawing efficiency of an existing before-drawing online coating process is restricted by online coating, and the working efficiency is low. A method comprises the following steps of replacing a groove type soaking process or a before-drawing online coating process with an online coating process during the wire drawing preparation process, annealing a cold-drawn steel wire to obtain an annealed steel wire, then transferring the annealed steel wire into a multi-tube type continuous online coating machine for coating, performing wire blowing after coating, drying after wire blowing, and taking up after drying, thereby completing the wire drawing online precoating. The wire drawing online precoating process can be obtained.

Owner:HARBIN WELL WELDING CO LTD +1

Konilite wet ball milling-paint integrated preparation method

The invention discloses a konilite wet ball milling-paint integrated preparation method. The konilite used as the main raw material is firstly subjected to wet ball milling to obtain the konilite ultrafine slurry, and other powder slurries are added in the paint preparation link to obtain the konilite-base paint; the coated film is bright and fine; and the method solves the problem of paint pollution caused by wearing iron powder since the konilite with high hardness can easily wear and damage the sand mill in the paint sanding link.

Owner:GUIZHOU LIANHE NEW BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com