Preparation method and device of tin powder for organic tin production

A preparation device and a technology for organotin are applied in the field of preparation of tin powder for organotin production, can solve problems such as unfavorable use, easy failure, too fine tin powder, etc., and achieve the effects of improving efficiency, avoiding oxidation and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

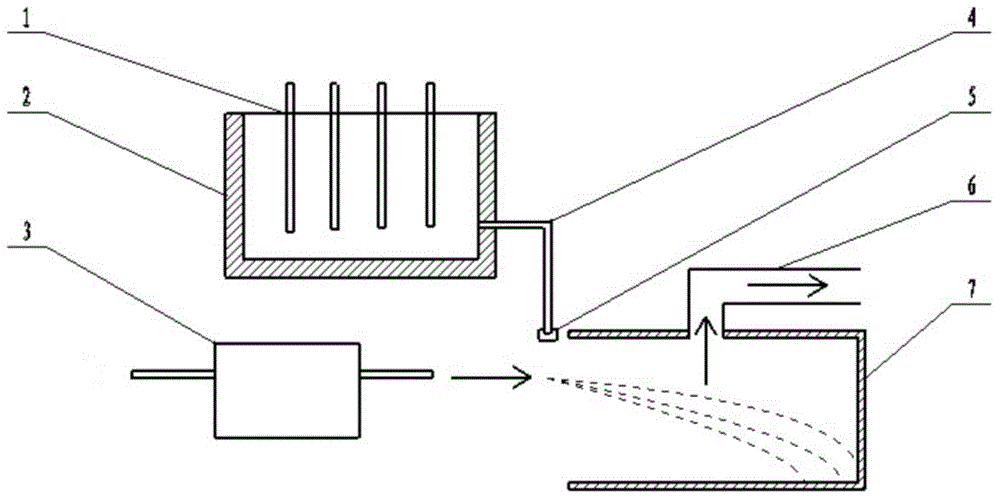

[0029] A kind of tin powder preparation method for organotin production provided by the invention comprises the following steps:

[0030] (a) Melt the tin ingot with a stainless steel heating tube in a carbon steel furnace, and adjust the temperature between 320°C and 350°C to prepare molten tin.

[0031] (b) Let the molten tin pass through the tin flow channel equipped with a dispersing device, and guide it into the dispersing chamber; when the molten tin passes through the dispersing device, supply air to the molten tin, and the air volume is set at 18m 3 / min to 20m 3 / min, the wind pressure is 3500Pa to 3800Pa, to disperse the molten tin flowing from the leakage hole; the top of the dispersion chamber is ventilated to take away the heat in time. The purpose of the frequency converter in practice is 25Hz ~ 30Hz.

[0032] (c) Use cold dry compressed air to blow the uncooled dispersed tin powder to obtain tin powder for the production of organotin. The specification of the ...

Embodiment 1

[0043] A method for preparing tin powder for organotin production, comprising the following steps:

[0044] (a) In a carbon steel furnace, use a stainless steel heating tube to melt the tin ingot, and use an intelligent instrument to automatically adjust the temperature to maintain it at 320°C to obtain molten tin.

[0045] (b) Open the discharge valve so that the molten tin passes through the tin flow channel equipped with a dispersing device and enters the dispersing chamber; when the molten tin passes through the dispersing device, air is supplied to the molten tin, and the air volume is set at 18m 3 / min, with a wind pressure of 3500Pa, to disperse the molten tin flowing down from the leakage hole; a 7.5Kw exhaust fan is used to force ventilation at the top of the dispersion chamber, and the heat is removed in time. For the purpose of taking away heat, the inverter frequency is 25Hz.

[0046] (c) Use cold dry compressed air to blow the uncooled dispersed tin powder to obt...

Embodiment 2

[0056] A method for preparing tin powder for organotin production, comprising the following steps:

[0057] (a) In a carbon steel furnace, use a stainless steel heating tube to melt the tin ingot, and use an intelligent instrument to automatically adjust the temperature to maintain it at 340 ° C to obtain molten tin.

[0058] (b) Open the discharge valve so that the molten tin passes through the tin flow channel equipped with a dispersing device and enters the dispersing chamber; when the molten tin passes through the dispersing device, air is supplied to the molten tin, and the air volume is set at 20m 3 / min, with a wind pressure of 3800Pa, to disperse the molten tin flowing down from the leakage hole; a 7.5Kw exhaust fan is used to force ventilation at the top of the dispersion chamber, and the heat is taken away in time. For the purpose of taking away heat, the inverter frequency is 28Hz.

[0059] (c) Use cold dry compressed air to blow the uncooled dispersed tin powder t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com