Method for preparing microbial cultures through solid state fermentation of bean dregs

A microbial culture and solid-state fermentation technology, applied in the field of feed, can solve problems such as environmental pollution and high production costs, and achieve the effects of reducing production costs, reducing pollution, and eliminating drying links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

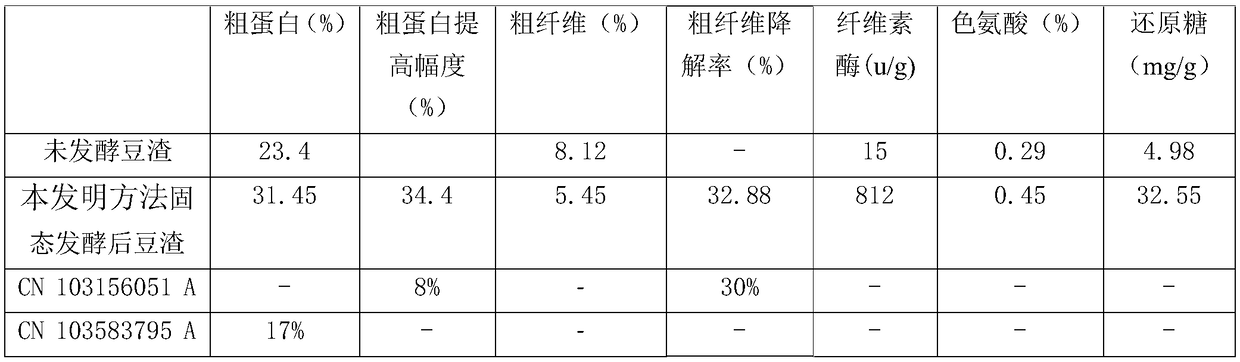

Embodiment 1

[0022] Embodiment 1: Prepare the soybean dregs solid-state fermented feed material of the present embodiment according to the following method:

[0023] (1) Bean dregs steam explosion sterilization treatment: put the bean dregs into the steam explosion tank, feed 2.1Mpa steam into the steam explosion tank, keep for 2.5min, open the steam explosion valve, and obtain the bean dregs after the steam explosion;

[0024] (2) Dehydration: the tea leaves after steam explosion are extruded or dried by equipment, so that the moisture content is controlled at 55% by mass fraction;

[0025] (3) Preparation of fermentation substrate: 71.97 parts by weight of dehydrated bean dregs, 8 parts by weight of bran, 10 parts by weight of lysine residue, 10 parts by weight of molasses, and 0.03 parts by weight of compound trace elements are fully mixed to make a fermentation substrate; Said compound trace element is made up of 2 parts by weight FeS0 4 ·7H 2 0, 0.9 parts by weight MnS0 4 , 0.8 par...

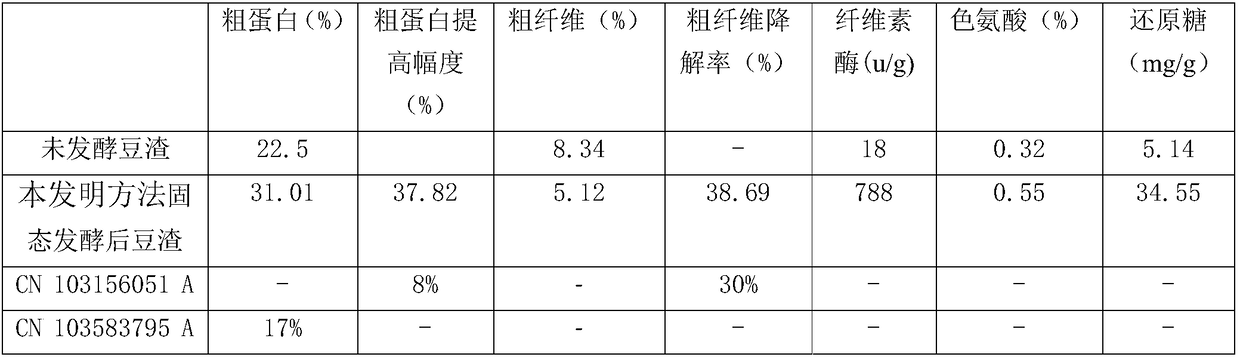

Embodiment 2

[0032] Embodiment 2: Prepare the soybean dregs solid-state fermented feed material of the present embodiment according to the following method:

[0033] (1) Bean dregs steam explosion sterilization treatment: put the bean dregs into the steam explosion tank, feed 2.5Mpa steam into the steam explosion tank, keep for 3min, open the steam explosion valve, and obtain the bean dregs after steam explosion;

[0034] (2) Dehydration: the bean dregs after steam explosion are extruded or dried by equipment, so that the moisture content is controlled at 50%;

[0035] (3) Fermentation substrate preparation: 68.96 parts by weight of dehydrated bean dregs, 10 parts by weight of bran, 10 parts by weight of glutamic acid residue, 11 parts by weight of molasses, and 0.04 parts by weight of compound trace elements are fully mixed to make a fermentation substrate; Composite trace element consists of 3 parts by weight FeS0 4 ·7H 2 0,1 parts by weight MnS0 4 , 0.9 parts by weight ZnS0 4 , 1.1 ...

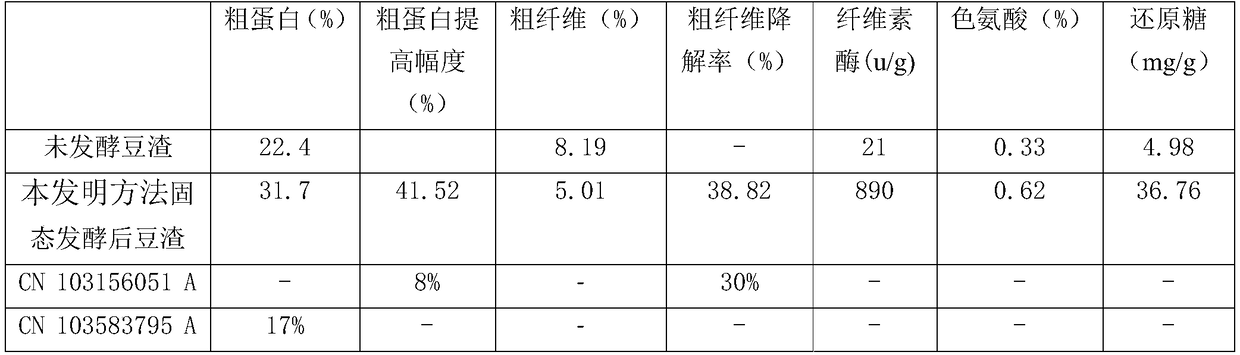

Embodiment 3

[0042] Embodiment 3: Prepare the bean dregs solid-state fermented feed material of the present embodiment according to the following method:

[0043] (1) Bean dregs steam explosion sterilization treatment: put the bean dregs into the steam explosion tank, feed 3Mpa steam into the steam explosion tank, keep for 4min, open the steam explosion valve, and obtain the bean dregs after the steam explosion;

[0044] (2) Dehydration: the bean dregs after steam explosion are extruded or dried by equipment, so that the moisture content is controlled at 55% by mass;

[0045] (3) Preparation of fermentation substrate: 84 parts by weight of dehydrated bean dregs, 10 parts by weight of bran, 15 parts by weight of lysine residue, 12 parts by weight of molasses, and 0.05 parts by weight of compound trace elements are fully mixed to make a fermentation substrate; Said compound trace element is made of 2.3 parts by weight FeS0 4 ·7H 2 0, 0.9 parts by weight MnS0 4 , 0.8 parts by weight ZnS0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com