Air drying grain bin

A granary and silo technology, applied in the field of grain storage equipment, can solve problems such as easy germination and mildew, road congestion, waste, etc., to ensure the quality of grain, reduce losses, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

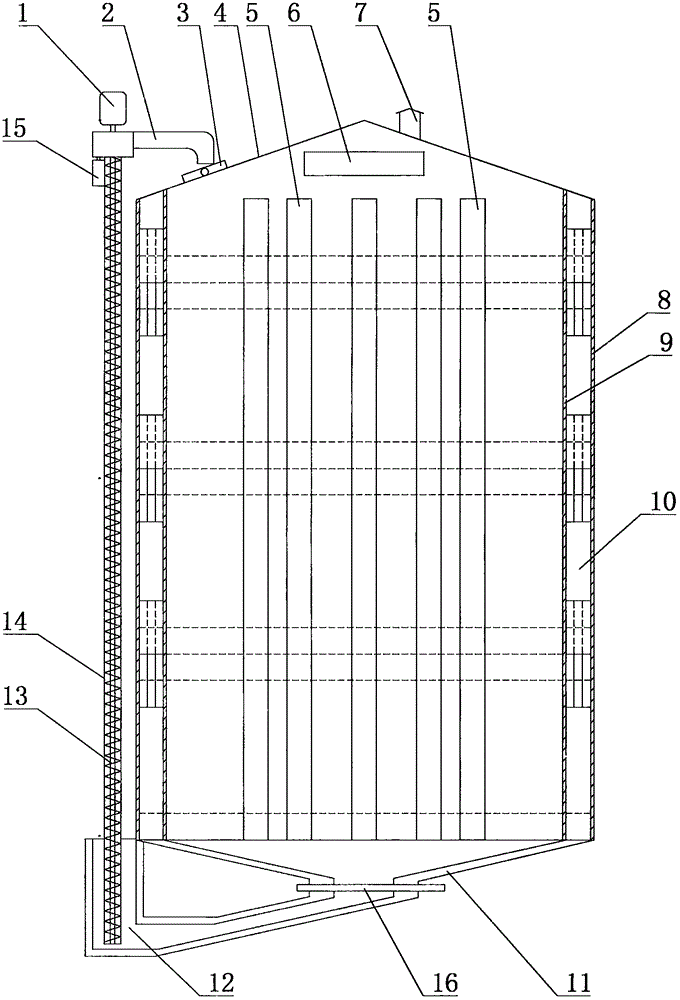

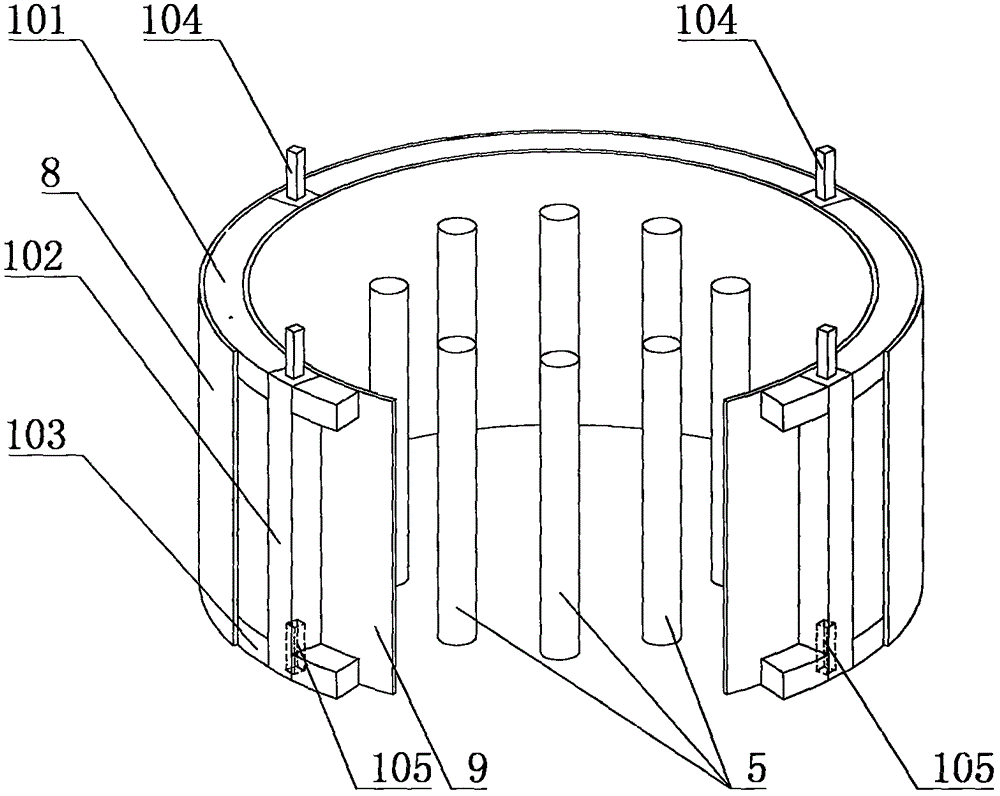

[0021] Example: as attached figure 1 to attach image 3 As shown, the air-dried granary includes a silo body, a silo roof 4 and a silo bottom. There are external ventilation holes, the roof 4 is provided with an air extractor 6 and an exhaust channel 7 connected to the exhaust port of the air extractor 6, and a number of air exhaust channels are provided below the air extractor 6 to penetrate the warehouse body from bottom to top. The ventilation pipe 5, the ventilation pipe 5 is fixedly placed in the warehouse body by the pipe frame, and the pipe wall of the ventilation pipe 5 is provided with an inner pipe ventilation hole. The apertures of the outer vent hole and the inner pipe vent hole are all smaller than the grain diameter. The pipe frame, the outer air vent and the inner pipe air vent are not shown in the accompanying drawings.

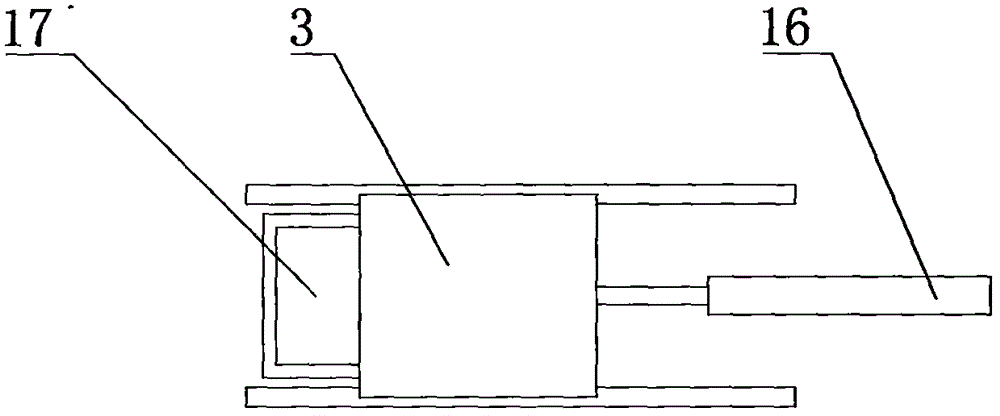

[0022] as attached figure 1 and 2 As shown, the warehouse roof 4 is provided with a grain inlet window 17, and the grain inlet window 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com