Patents

Literature

104results about How to "Avoid hard clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet chemistry method for preparing lithium iron phosphate

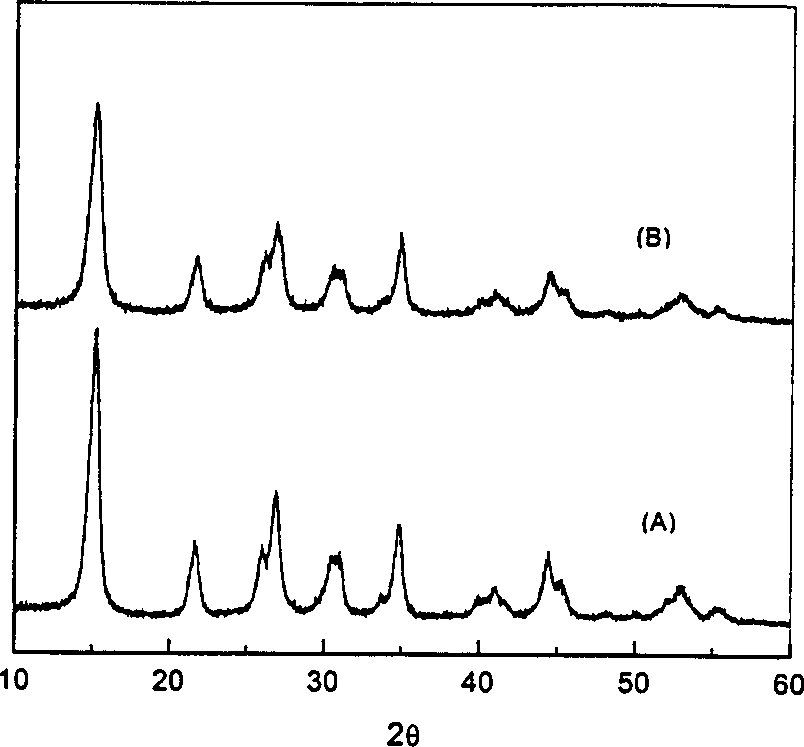

InactiveCN1431147AEasy to controlEvenly distributedElectrode thermal treatmentLi-accumulatorsChemical compositionLithium iron phosphate

A wet chemical process for preparing iron lithium phosphate includes mixing the solution or suspensions of Li source compound, Fe source compound, P source compound, doping element compound or electric conducting agent, and precipitant, reaction at 5-120 deg.C for 0.5-24 hr while stirring, filtering, washing, baking to obtain nano precursor, quickly heating to 500-800 deg.C in non-air or non-oxidizing atmosphere, calcining for 5-48 hr, and cooling. Its advantages are easy control, high uniformity and electric conductivity.

Owner:郑绵平

Method for preparing nano hydroxyapatite powder

InactiveCN101734635ANo pollution in the processNo harmNanostructure manufacturePhosphorus compoundsWater bathsPolyethylene glycol

The invention relates to a method for preparing nano hydroxyapatite powder, belonging to the field of the biomedical material. The method for preparing the nano hydroxyapatite powder comprises the following steps: adding the organic polymer of polyethylene glycol to the initial reactants of calcium nitrate and diammonium phosphate solution to adjust and control the morphologies of the products of reaction; adding aqueous ammonia to adjust the pH values of the products of reaction, and making the aqueous ammonia react with the products of reaction at different water bath temperature to synthesize nano hydroxyapatite precipitate, wherein the agglomeration of the synthesized nano hydroxyapatite precipitate can be inhibited by the polyethylene glycol functioning as the dispersant; freezing and drying synthesized nano hydroxyapatite precipitate slurry to obtain dry nano hydroxyapatite powder which contains by-products of reaction and polyethylene glycol, and calcinating the dry nano hydroxyapatite powder at high temperature to remove the by-products of reaction and the polyethylene glycol which are contained in the dry nano hydroxyapatite powder to obtain the nano hydroxyapatite powder which is in the shape of the ball or the rod and in the particle size of 10-100 nm and has high yield and good dispersion. The method for preparing the nano hydroxyapatite powder is simple, needs short preparing period, causes no poison and pollution and is suitable for industrial production.

Owner:SICHUAN UNIV

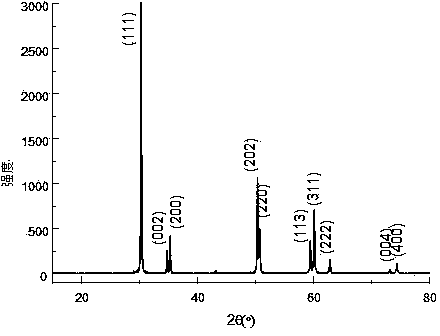

Yttria-stabilized zirconia powder and preparation method thereof

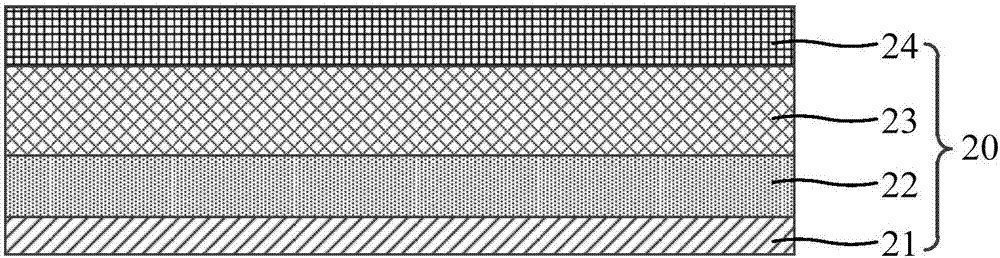

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

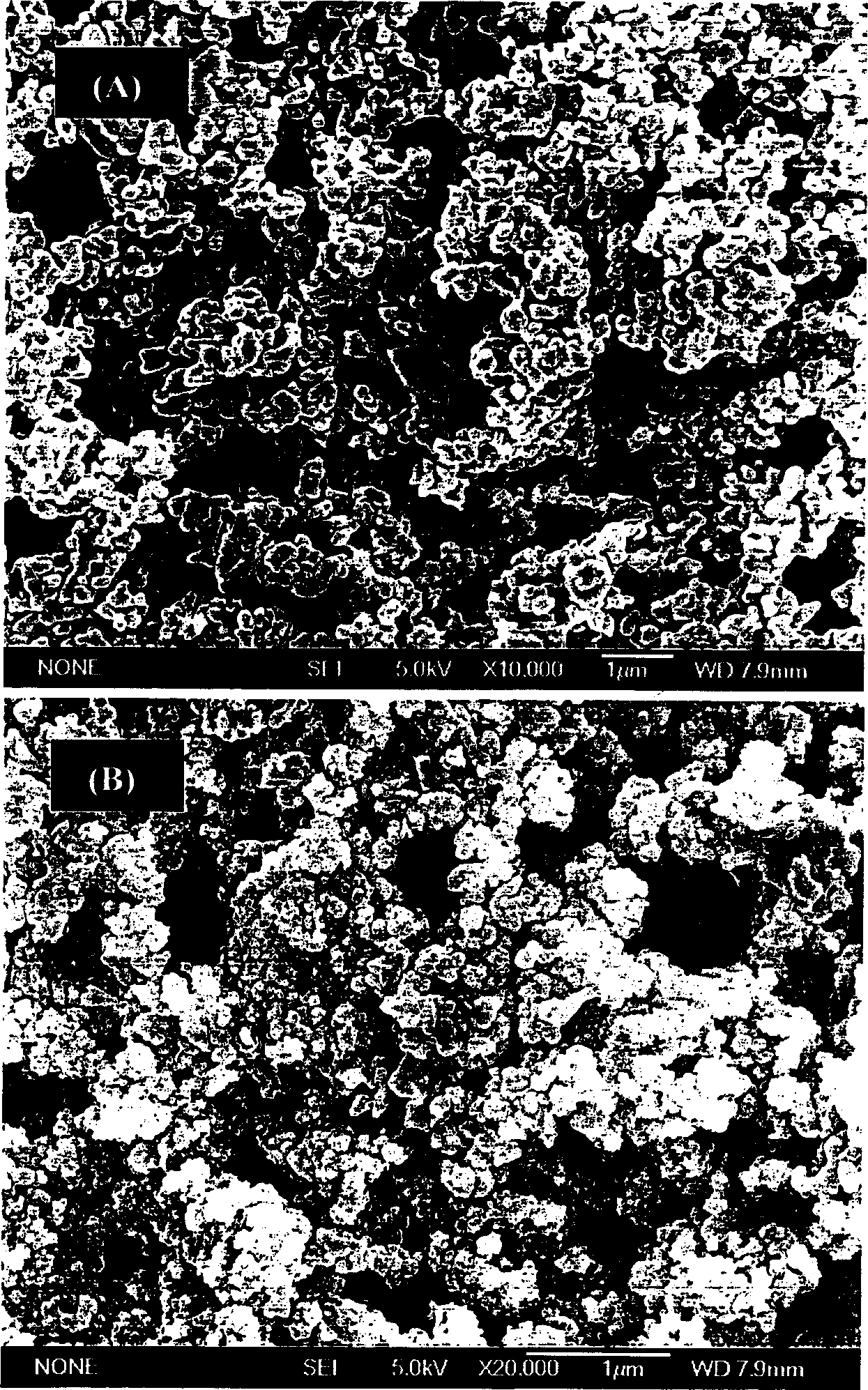

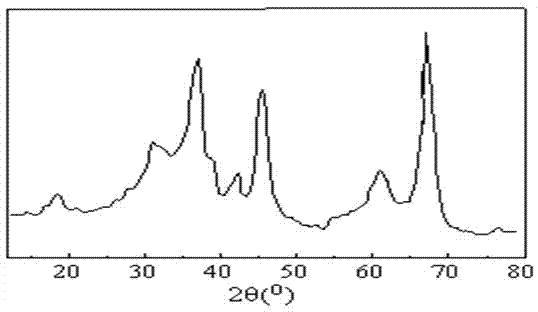

Preparation method of metallic nano powder

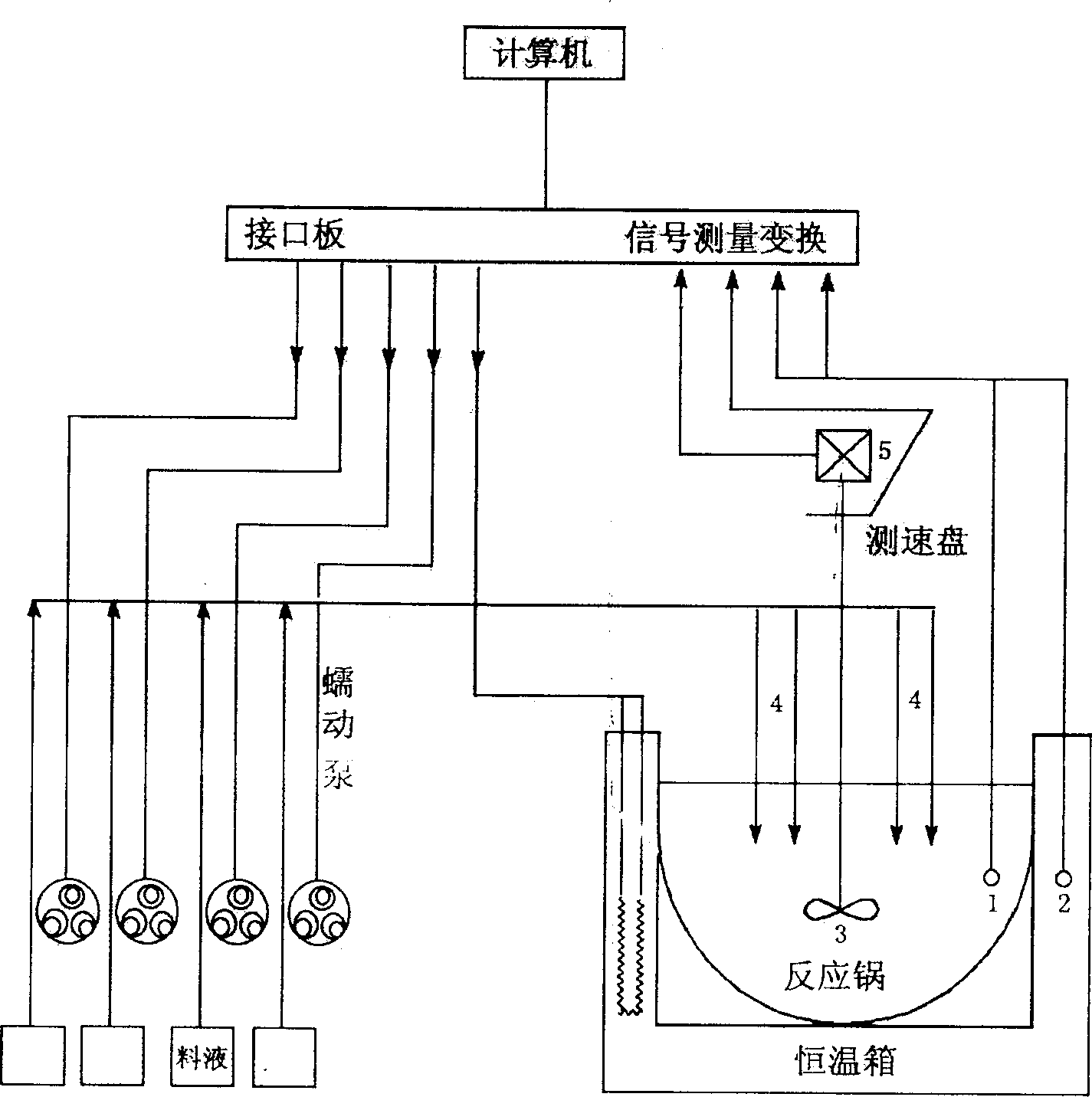

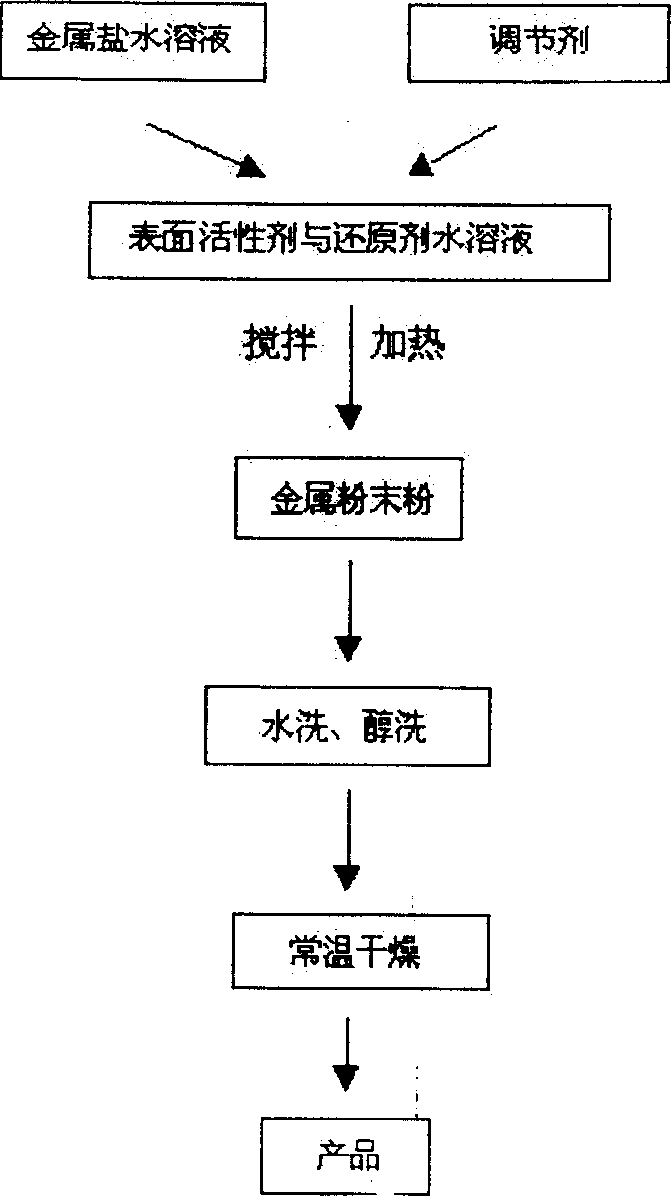

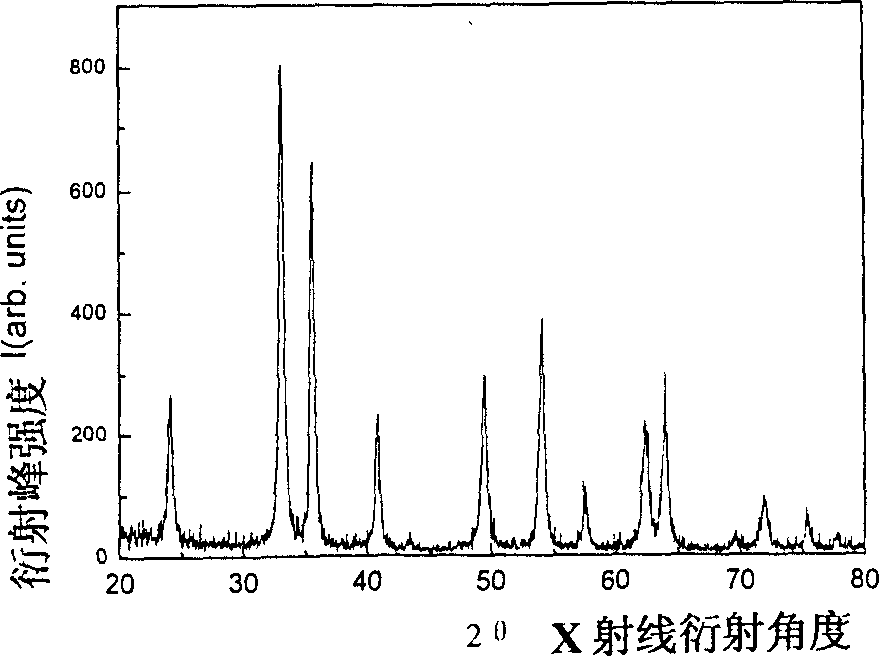

A process for preparing nano-class metal particles by dual-pouring method features that under the existance of protector and regulator, the metallic salt is reduced by reducing agent to obtain one ormore (30-100 nm) metallic particles. Its advantages are high dispersity, easy control of diameter, high output rate up to 95%, and preparing the particles of more metals by a single equipment.

Owner:TIANJIN ZHONGKE PHYSICAL & CHEM NEW MATERIAL TECH CO LTD

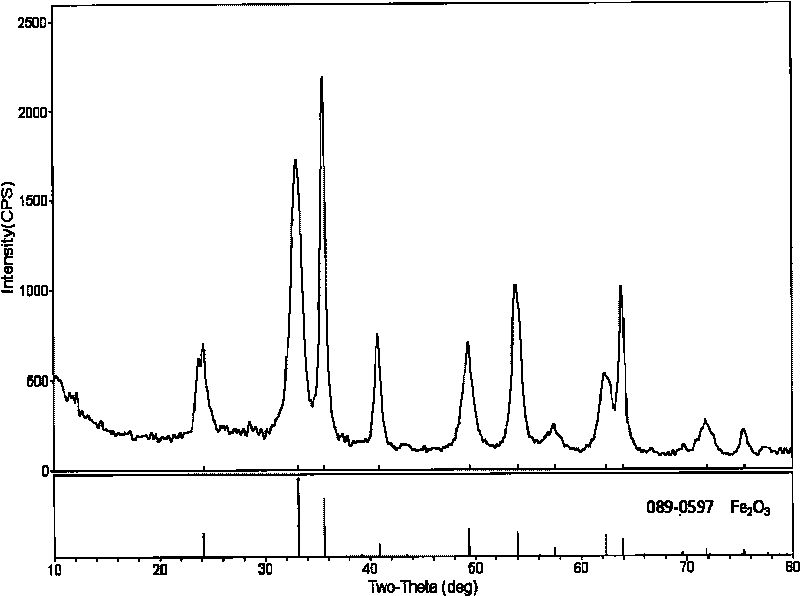

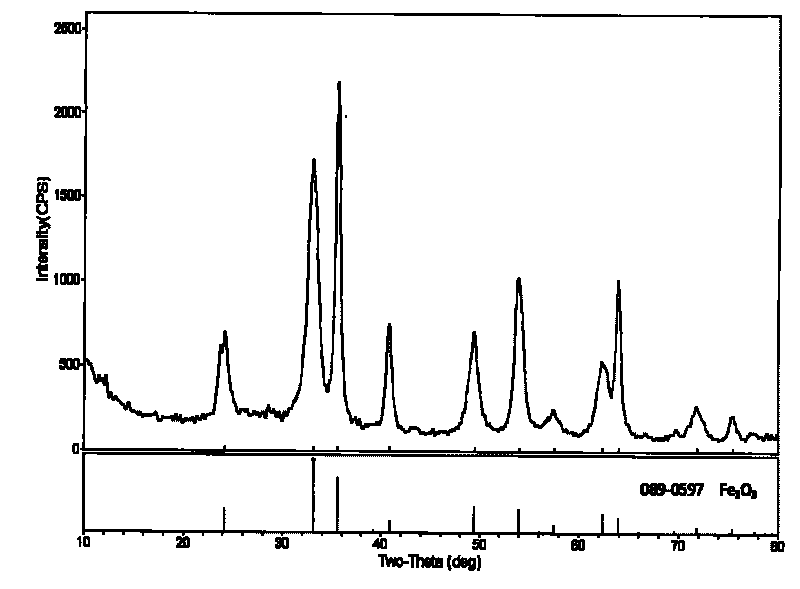

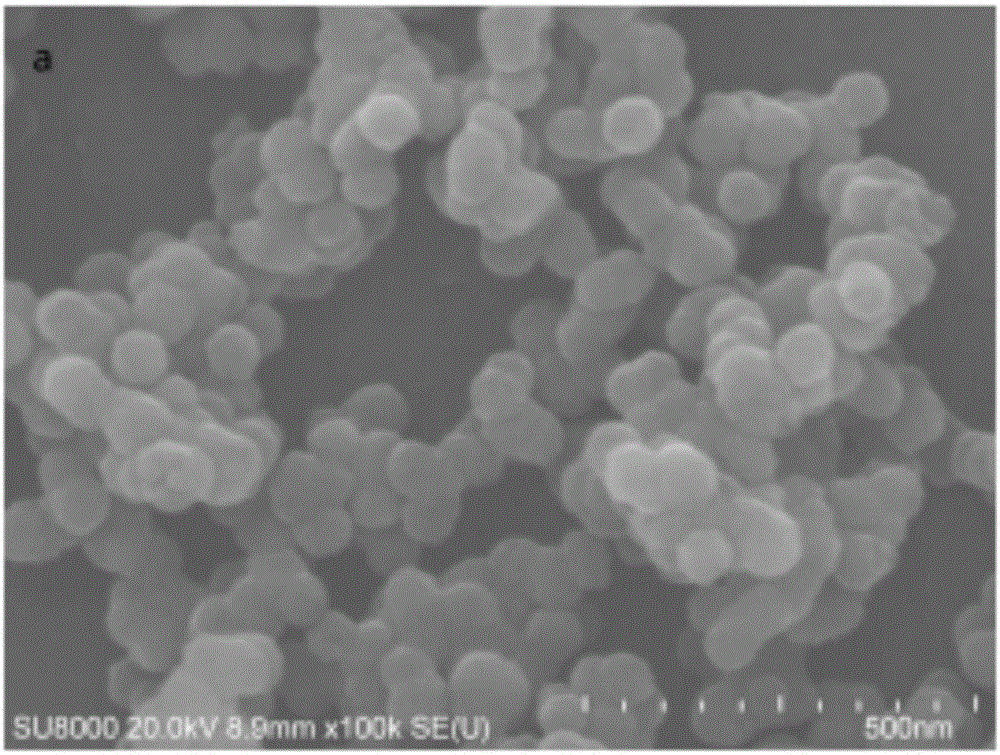

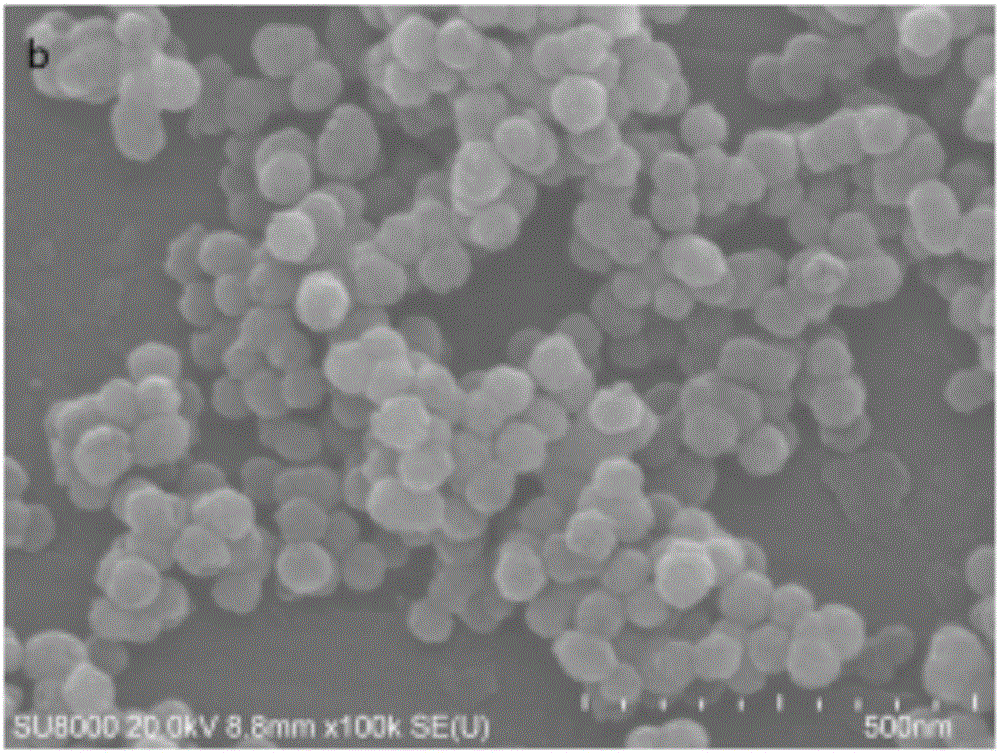

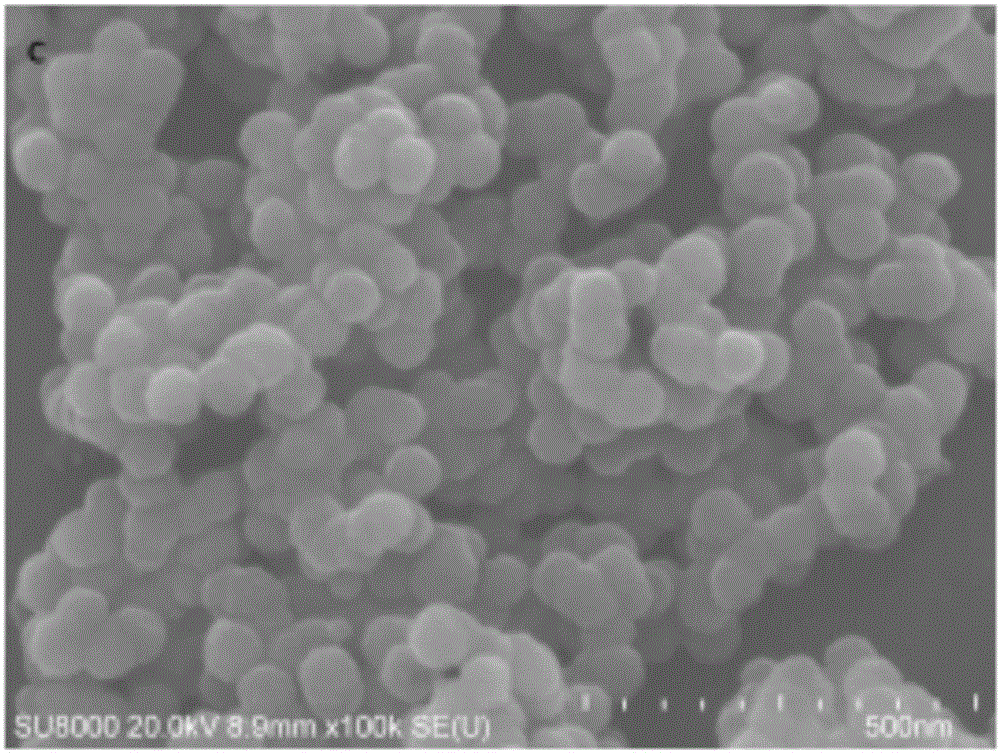

Method for preparing nano iron oxide red

InactiveCN1508192AQuick buildUniform dispersionPigmenting treatmentReaction temperatureBuffer solution

The invention relates to a nano iron oxide red preparing method, fully mixing crystal converting agent and lye under normal temperature and pressure, then stirring and adding the product obtained by oxidizing soluble trivalent or bivalent ferric salt solution at the same time to form gelatin, then adding in buffer solution, maintaining the pH value of the mixed liquid within 8-12, heating and maintaining the reaction temperature within 85-110 deg.C aging for 5-20minutes, centrifugating turbid liquid by centrifugal pump, washing for 3-5times, drying for 1.5-3hours under 25-50 deg.C, and grinding to obtain single disperse nano alpha-Fe2O3 particles. The particle size can be regulated and controlled within 10-100nm, the distribution even.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

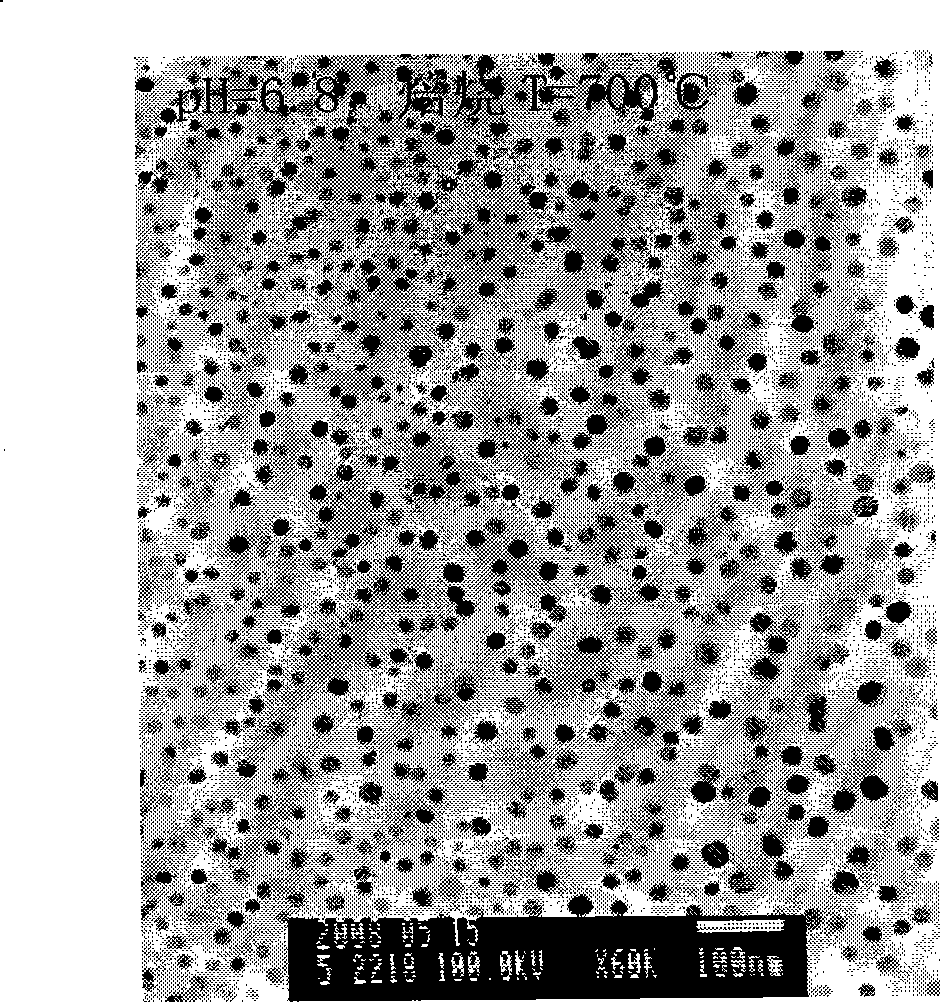

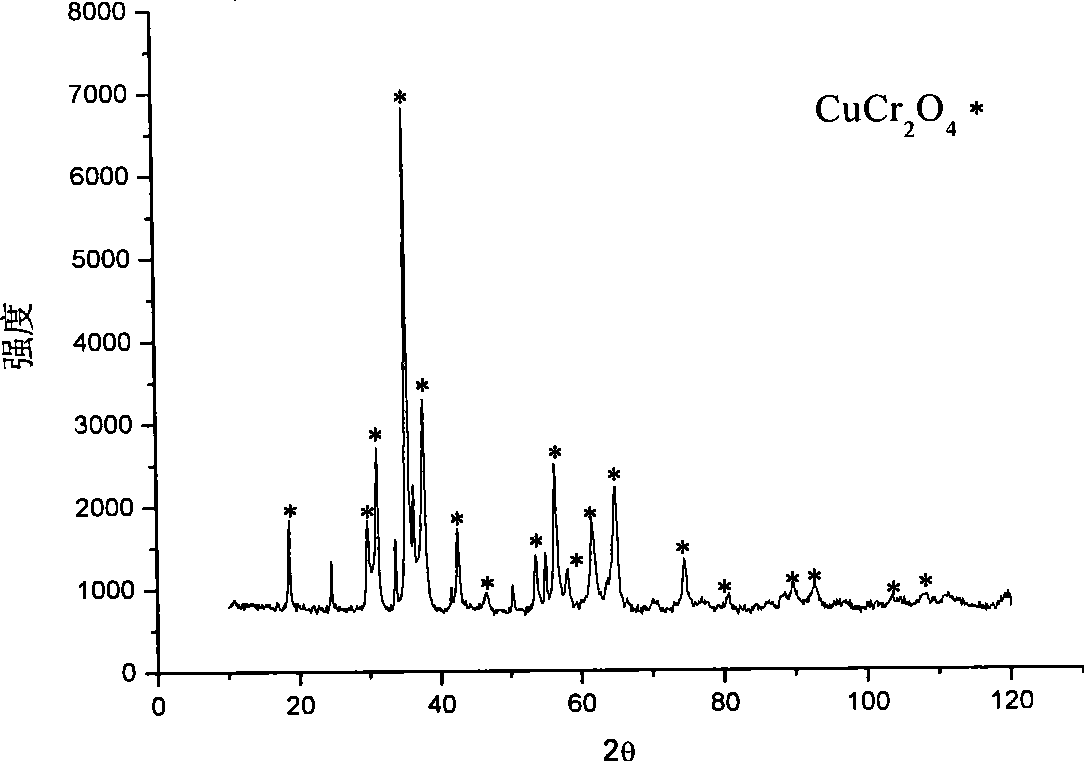

Method for preparing nano-catalyst copper chromite and copper ferrite

InactiveCN101367044AHigh puritySmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano catalyst

The invention discloses a method for preparing a nano-size catalyst of copper chromite and copper ferrite, and belongs to the technical field of nano-size catalyst preparation. The method of the invention comprises a sol-gel process and a vacuum freezing drying (VFD) process. Firstly, a mixed solution is prepared from a soluble copper salt and a soluble chromium salt or iron salt, added with a surface active agent, and mixed uniformly, and then the system is added with a precipitating agent to carry out precipitation reaction under the condition that the pH value is between 6.8 and 9.5, then is kept stand, aged, washed and melted in a water bath for 2 to 8 hours at a temperature of between 70 and 95 DEG C, thus sol is obtained; then the sol is subjected to freezing drying in a vacuum freezing dryer to obtain dried gel which is a precursor of the catalyst; finally, the dried gel is roasted to obtain the nano-size catalyst of copper chromite (CuCr2O4) or copper ferrite (CuFe2O4). The catalyst prepared by the method has the advantages of high purity, small grain diameter, good dispersivity, high catalytic activity, and the like.

Owner:TSINGHUA UNIV

Process for preparing alumina powder with high sinter activity

InactiveCN1369434AImprove sintering performanceLow costAluminium hydroxide preparationAluminium chlorideInorganic salts

A process for preparing alumine powder with high sinter activity includes reaction of Al-contained inorganic salt chosen from aluminium nitrate, aluminium chloride and aluminium ammonium sulfate on ammonium bicarbonate at 5-50 deg.C to generate NH4Al(OH)2CO3, depositing and ageing for 2-24 hrs, washing with deionized water, baking at 50-150 deg.C and sintering at 1100-1200 deg.C to obtain alpha-Al2O3 particles less than 400 nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of antimony-doped tin dioxide nano-slurry

ActiveCN102491408AGuaranteed Optical PerformanceAvoid hard clumpingMaterial nanotechnologyTin oxidesSal ammoniacChemistry

The invention discloses a preparation method of antimony-doped tin dioxide nano-slurry, belonging to the field of preparation of chemical raw materials. The method comprises the following steps of: preparing a saline solution of tin and antimony consisting of nitrate of tin, ethanol and nitrate of antimony, and an alkaline liquor consisting of sodium hydroxide or ammonia water; dropwise adding the alkaline liquor into a saline solution till the pH value of a system is adjusted to 0.8-2, adding hydrogen peroxide, oxidizing a part of Sb<3+> in the system into Sb<5+> to obtain a precipitated tin-antimony hydroxide, washing the tin-antimony hydroxide with water, filtering, adding a dispersing agent, and stirring and dispersing into water to obtain a tin-antimony hydroxide dispersed solution; and performing hydro-thermal treatment on the hydroxide dispersed solution in a high-pressure reaction kettle to obtain antimony-doped tin dioxide nano-slurry. The method has the advantages of simple process, low energy consumption, high dispersity of prepared slurry and stable performance.

Owner:FIRST NEW MATERIAL TECH DEV

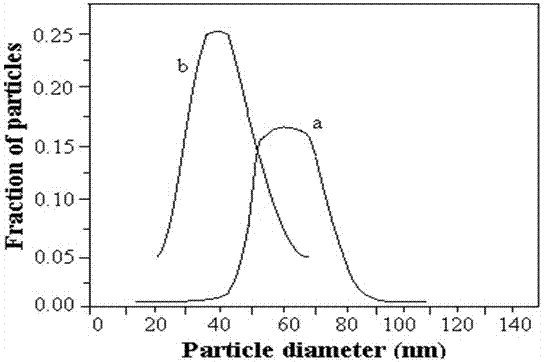

Tungsten-containing metal oxide nanoparticle dispersoid and preparation method thereof

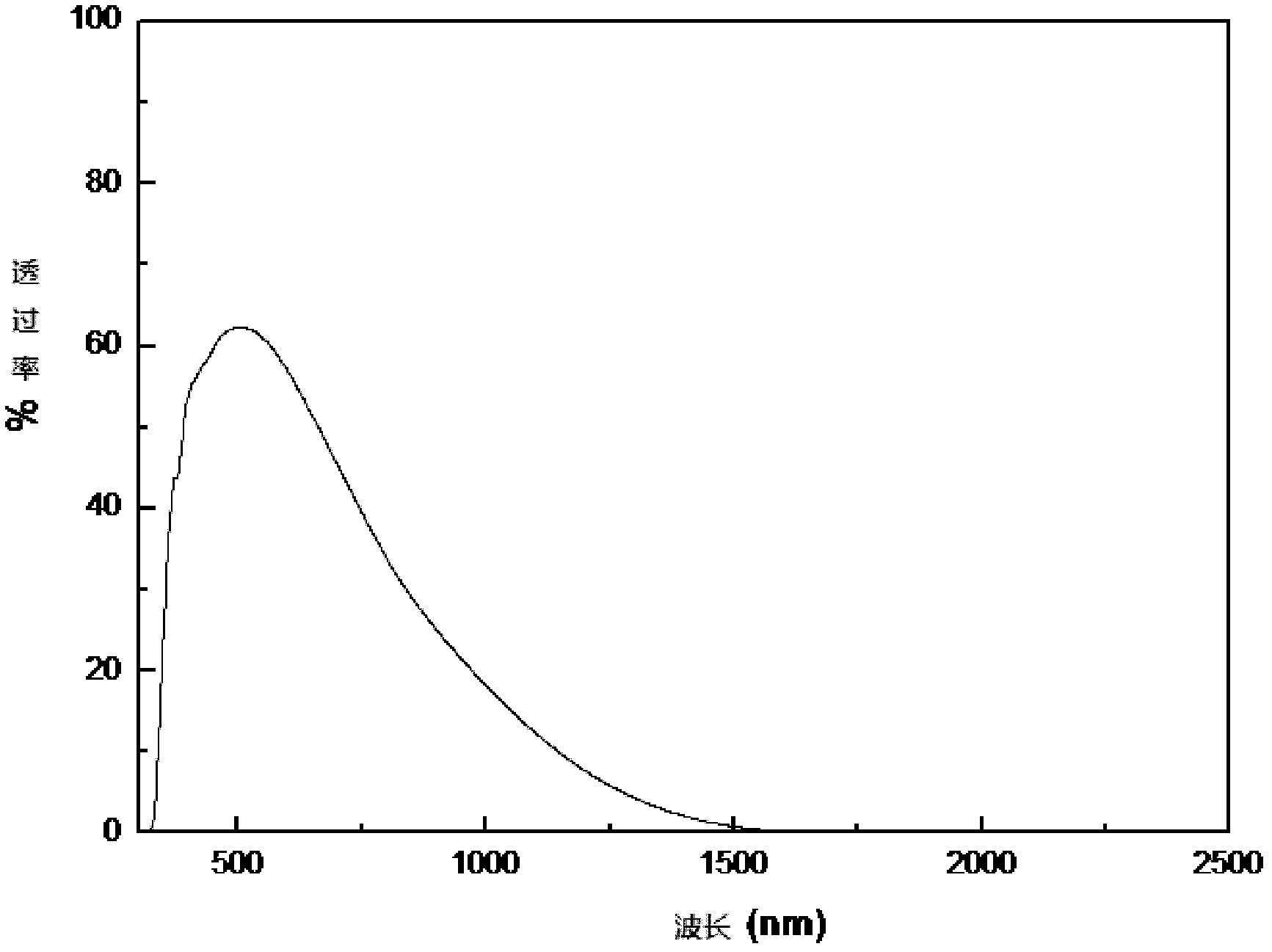

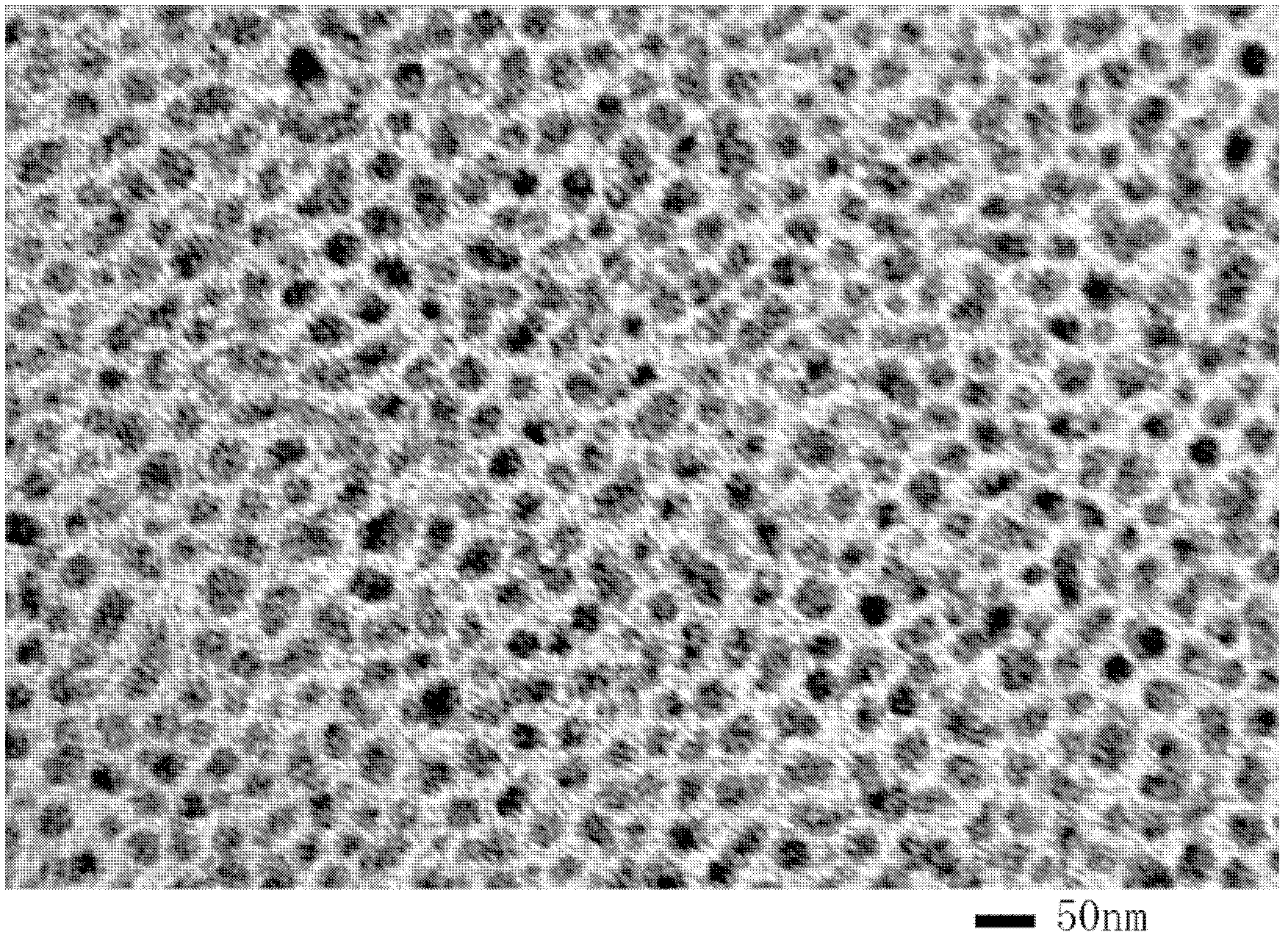

InactiveCN107083101AHigh solid contentGood dispersionCoatingsPigment treatment with organosilicon compoundsMetal oxide nanoparticlesSlurry

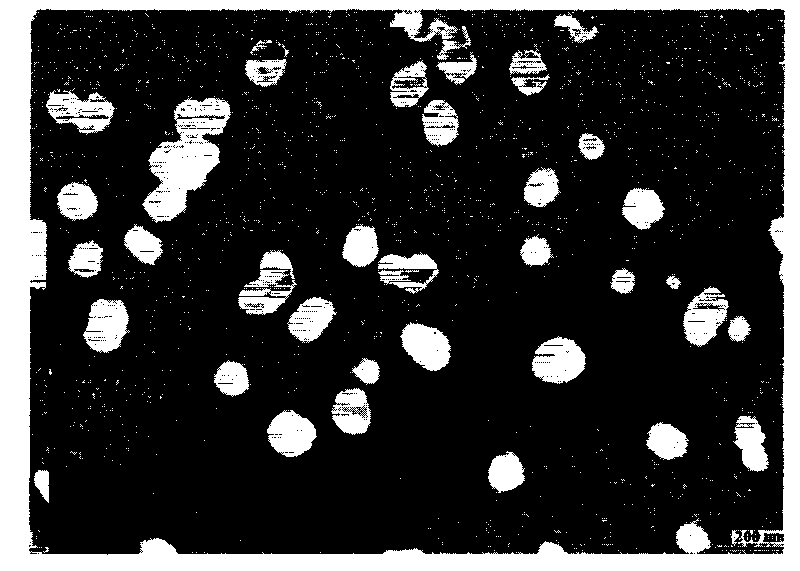

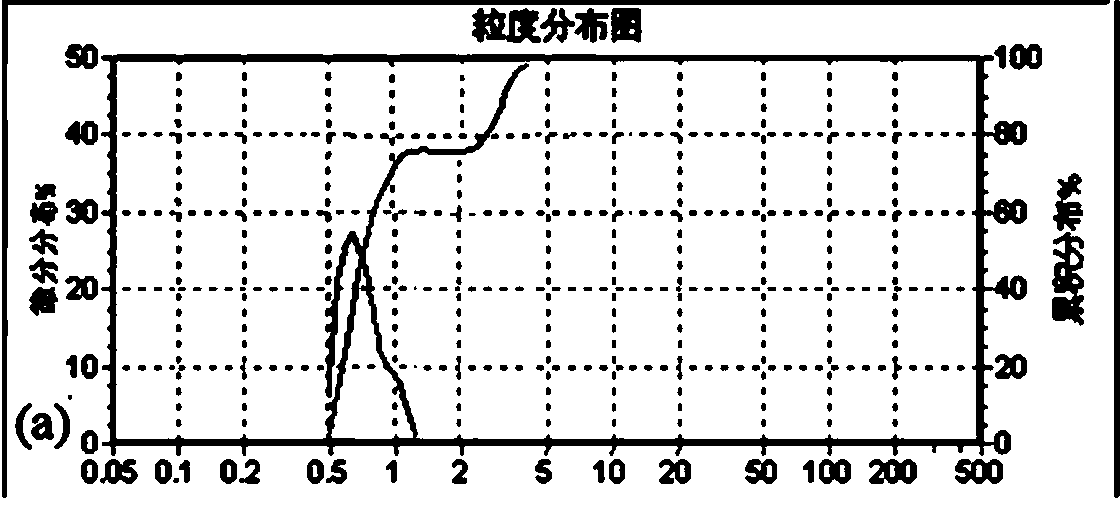

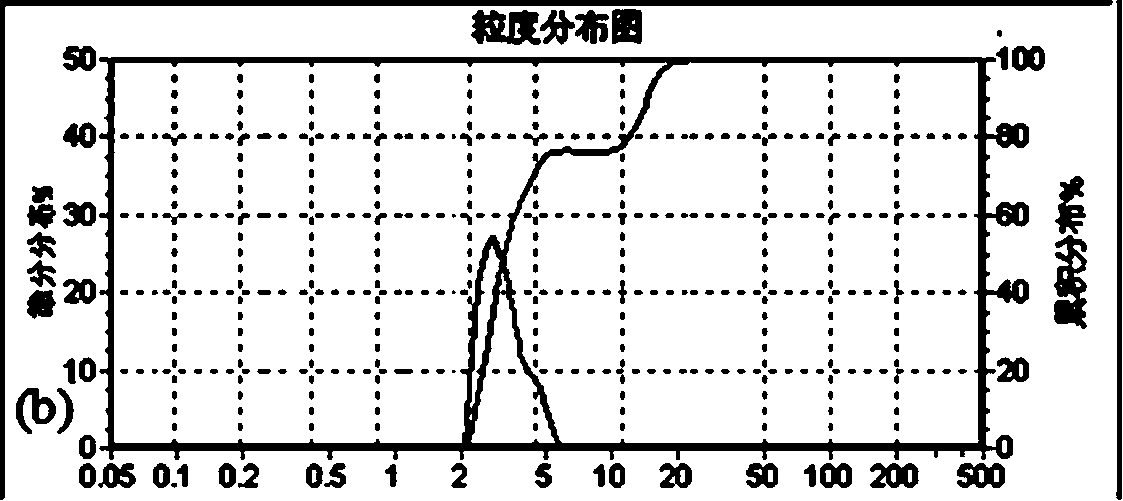

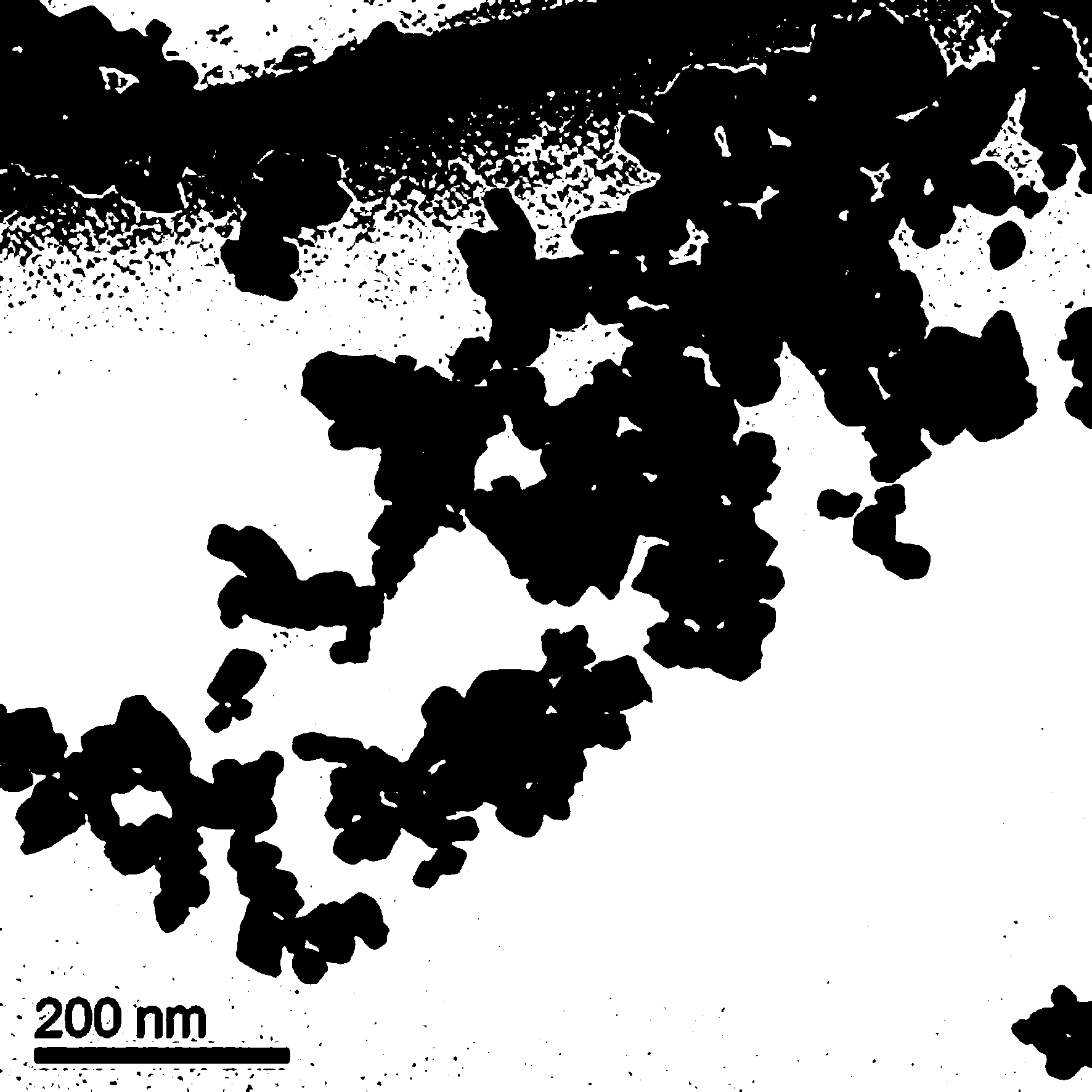

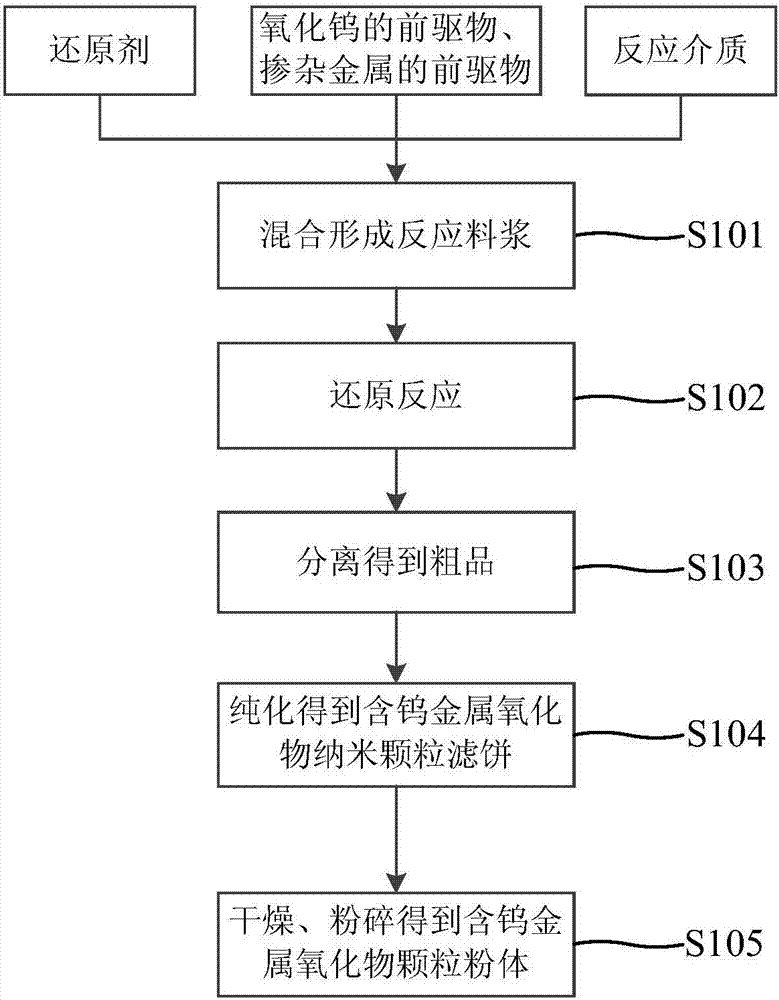

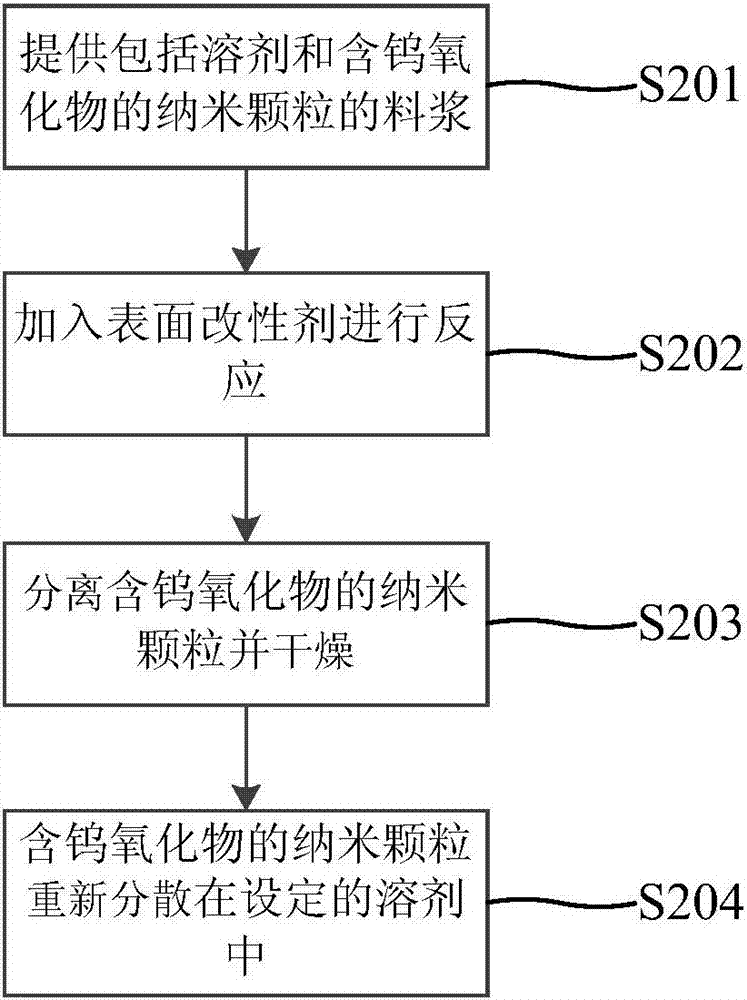

The invention provides a tungsten-containing metal oxide nanoparticle dispersoid and a preparation method thereof. The preparation method comprises providing slurry comprising a solvent and tungsten-containing metal oxide nanoparticles dispersed in the solvent, adding a surface modifier to the slurry, carrying out a reaction process until the reaction is finished, separating the tungsten-containing metal oxide nanoparticles subjected to surface treatment in the slurry, and re-dispersing the tungsten-containing metal oxide nanoparticles in the preset solvent so that the tungsten-containing metal oxide nanoparticle dispersoid is obtained. The method for forming the dispersoid through a wet surface treatment method is free of nanoparticle drying and can directly modify the particle surface in the liquid phase so that hard aggregation of the particles is avoided, is simple and easy in operation and can be easily industrialized. The dispersoid obtained by the preparation method has high solid content, a high degree of dispersion, narrow secondary particle size distribution and average secondary particle diameter of 30 to 100 nm.

Owner:XIAMEN NANOTECH +1

Ceramic material powder used for denture preparation and preparation method of ceramic material powder

The invention relates to a material used for a denture, and in particular relates to a ceramic material powder used for denture preparation. The ceramic material powder comprises 90%-95% of stable tetragonal zirconia, and 2.5-3.49% of yttrium oxide used as a stabilizer, wherein a precursor is obtained by coprecipitation reaction of the ceramic material powder; the precursor is sequentially subjected to hydrothermal reaction and spray drying to obtain powder with bending strength greater than 600MPa. A method for preparing the powder comprises the following steps: a, forming 90%-95% of tetragonal zirconia, and 2.5-3.49% of yttrium oxide used as the stabilizer; b, carrying out hydrothermal reaction on the precursor produced in the step a, wherein the reaction temperature is 120-250 DEG C and the reaction time in a high-pressure reactor is 24-48 hours; c, adding a 2-5% polyvinyl alcohol solution into a product obtained in b as adhesive; d, carrying out centrifugal spray granulation on a product obtained in c at hot air temperature of 200-350 DEG C. Through the steps, high-quality ceramic powder with high bending strength greater than 600MPa, high fracture toughness, good chemical stability and good biocompatibility can be obtained.

Owner:厦门北大泰普医疗器械有限公司

Wet chemistry method for preparing lithium iron phosphate

InactiveCN1208241CEasy to controlEvenly distributedElectrode thermal treatmentLi-accumulatorsLithium iron phosphateLITHIUM PHOSPHATE

A wet chemical process for preparing iron lithium phosphate includes mixing the solution or suspensions of Li source compound, Fe source compound, P source compound, doping element compound or electric conducting agent, and precipitant, reaction at 5-120 deg.C for 0.5-24 hr while stirring, filtering, washing, baking to obtain nano precursor, quickly heating to 500-800 deg.C in non-air or non-oxidizing atmosphere, calcining for 5-48 hr, and cooling. Its advantages are easy control, high uniformity and electric conductivity.

Owner:郑绵平

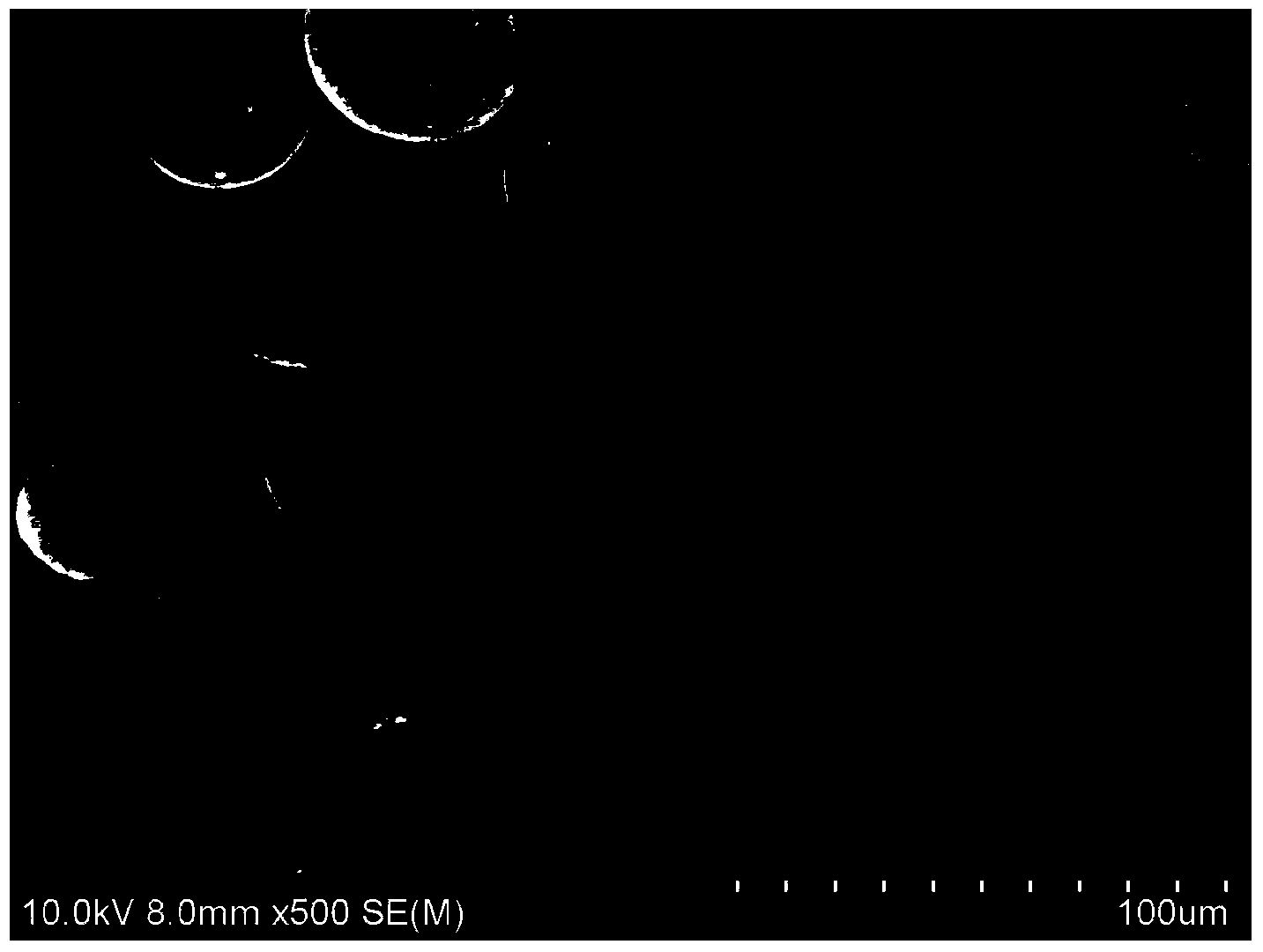

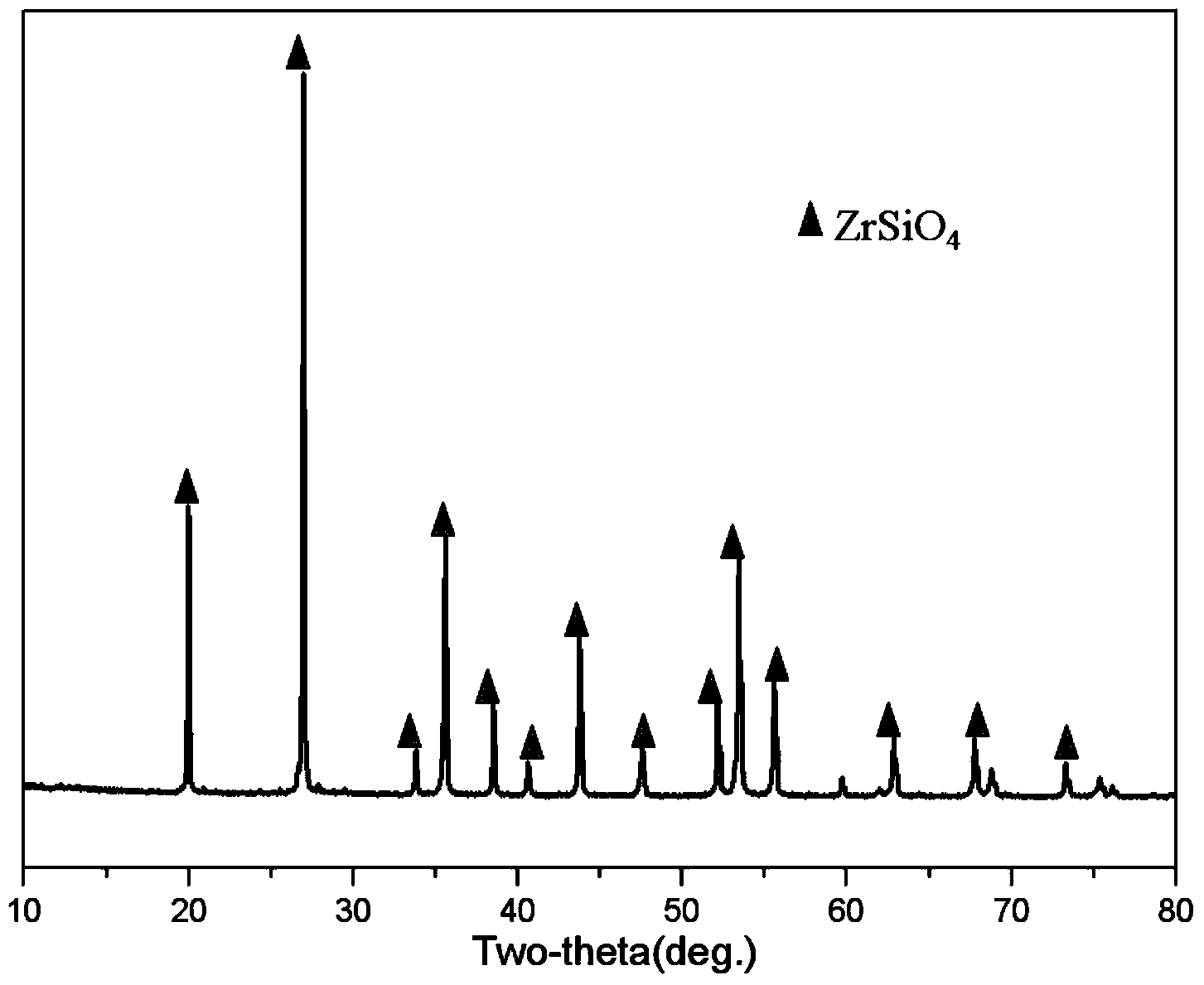

Preparation method of spherical zirconium silicate nano aggregate powder

InactiveCN103588211AReduce manufacturing costHigh purityMaterial nanotechnologySilicon compoundsSodium metasilicateAlcohol

The invention relates to a preparation method of spherical zirconium silicate nano aggregate powder, and belongs to the technical field of an inorganic material. The preparation method comprises the steps as follows: zirconium oxychloride and sodium metasilicate are mixed with water, precipitation is separated out, and washing and drying are performed to obtain a precursor; sodium fluoride and water are added into the precursor and reacts at the temperature of 180-380 DEG C for 4-10 hours to obtain zirconium silicate powder containing impurities; the zirconium silicate powder containing impurities is mixed with water and filtered and washed by an inorganic membrane separation device to obtain concentrated slurry, pie powder is obtained through pressure filtration, and zirconium silicate powder is obtained through drying; the zirconium silicate powder and absolute ethyl alcohol are mixed, and ground and emulsified in a colloid mill so as to obtain a mixed turbid liquid of the zirconium silicate nano powder and absolute ethyl alcohol; and the mixed turbid liquid is processed by a liquid powder feeder and inductive plasma spheroidization equipment, the zirconium silicate nano powder of the mixed turbid liquid is subjected to agglomeration, spheroidization and densification process to obtain the powder. The method is simple and low in cost, the spherical zirconium silicate nano aggregate powder can be directly prepared, and the purity quality is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

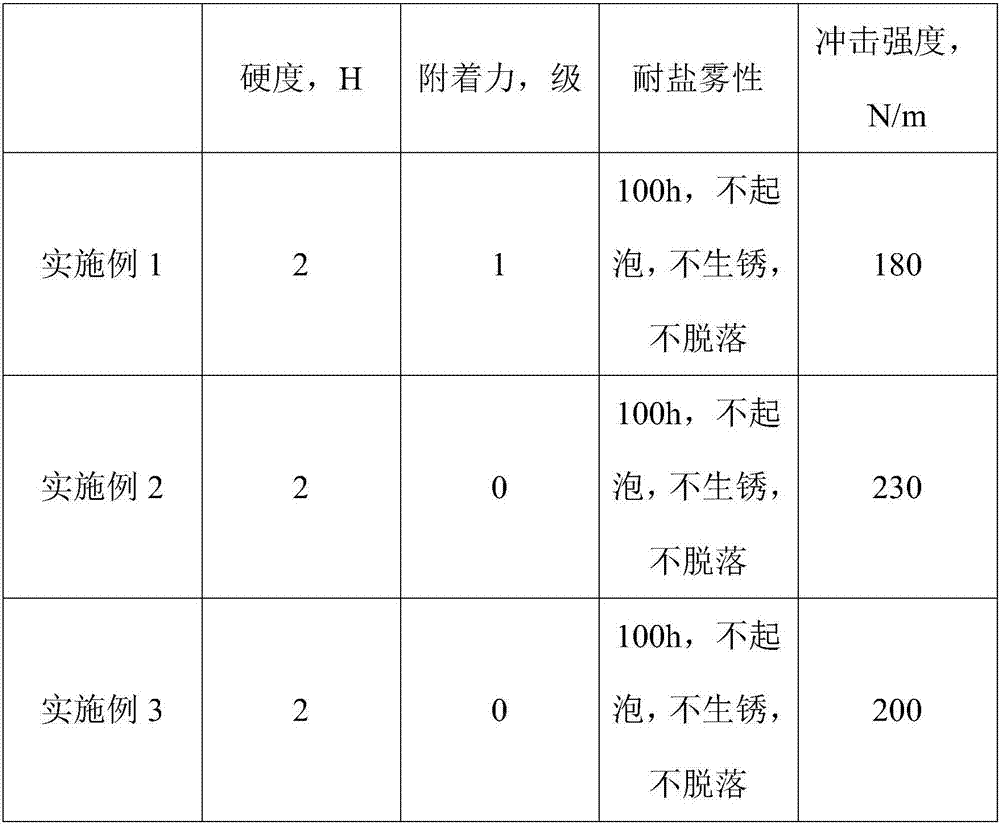

Preparation method of styrene-acrylic emulsion waterborne antirust paint based on composite modification of polydopamine/nano titanium oxide

ActiveCN107141951AAvoid hard clumpingImprove antibacterial and weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionSol-gel

Owner:SUZHOU ANTEK INDAL

Method for preparing hematite-type nano iron oxide red

The invention relates to a method for preparing hematite-type nano iron oxide red. The method comprises the following steps of: taking ferrous salts as raw materials, adding a dispersant and soluble alkaline matter and controlling pH value to obtain seed crystal; then, adding an oxidant and controlling the pH value by the soluble alkaline matter to carry out reaction at a certain temperature for 0.5 to 1 hour; obtaining solid after sedimentation and filtration of reaction products and carrying out low-temperature vacuum drying on the solid for 0.5 to 2 hours to obtain precursor; and mixing the precursor and a pore-expanding agent to carry out high-temperature ignition for 1 to 2 hours to obtain powder hematite-type nano iron oxide red after cooling and grinding. The preparation method has the characteristics of simple operation, easily obtained raw materials, less pollution, short production cycle, small grain diameter of products, excellent dispersive property, and the like.

Owner:ZHEJIANG UNIV

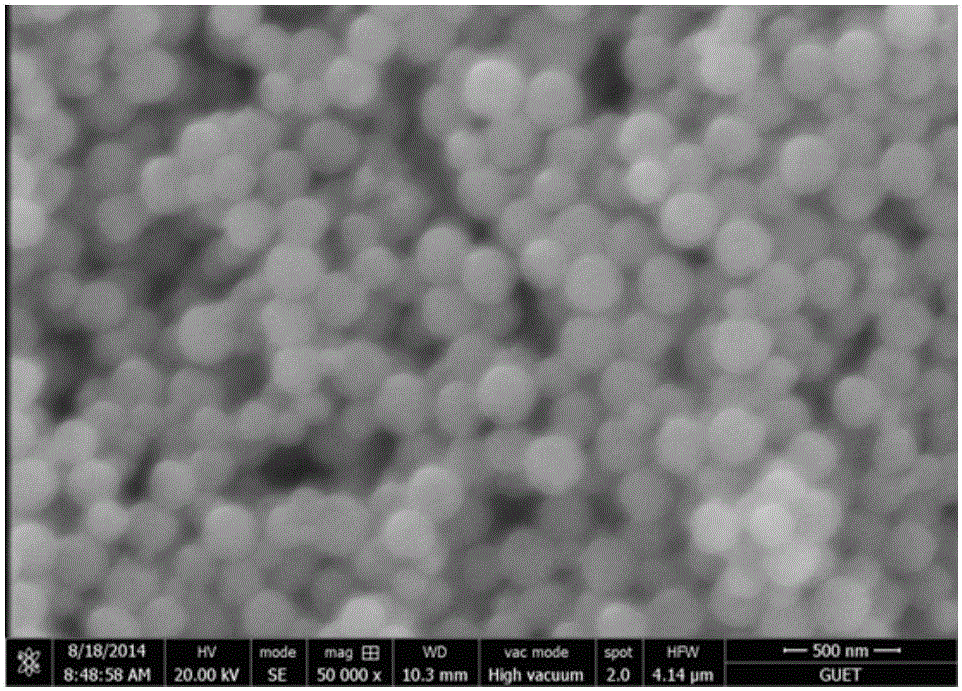

Preparation method of nanoscale spherical yttrium oxide powder

InactiveCN106044835AAvoid hard clumpingGood dispersionRare earth metal oxides/hydroxidesMaterial nanotechnologyAlcoholWastewater

The invention relates to a preparation method of yttrium oxide powder, in particular to a preparation method of nanoscale spherical yttrium oxide powder. According to the method, a precipitant solution with the concentration ranging from 0.5 mol.L<-1> to 0.1 mol.L<-1> is added to a yttrium salt aqueous solution with the concentration ranging from 0.05 mol.L<-1> to 0.1 mol.L<-1> and stirred to be dissolved, a mixed solution is obtained, surfactants accounting for 0.2%-2% of the mixed solution in mass are added, a yttrium oxide precursor precipitate is prepared, the precipitate is washed with water and small molecule alcohol after solid-liquid separation, a precipitate turbid liquid is dispersed by ultrasonic waves, and the yttrium oxide powder comprising nanoscale spherical particles is prepared through separation, drying and roasting, wherein the surfactants comprise a cationic surfactant and a non-cationic surfactant. With the method, the production efficiency of yttrium oxide can be significantly improved, the use quantity of precipitants is reduced, the production cost is low, the wastewater discharge volume is small, environmental protection is facilitated, and the method is simple and convenient to popularize and use.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

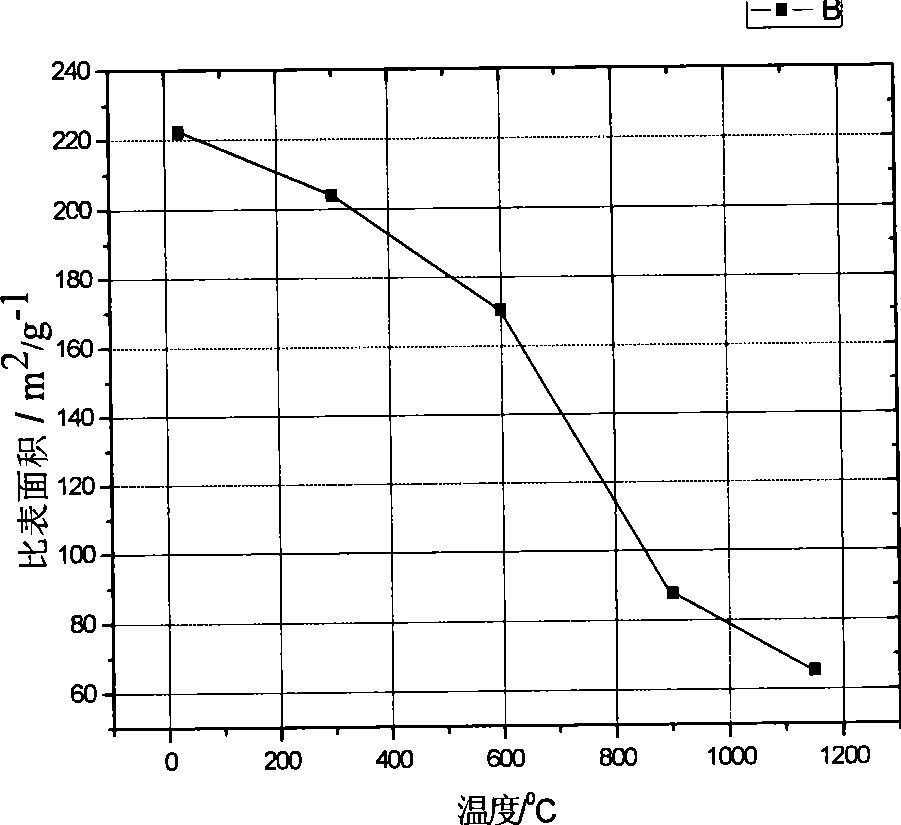

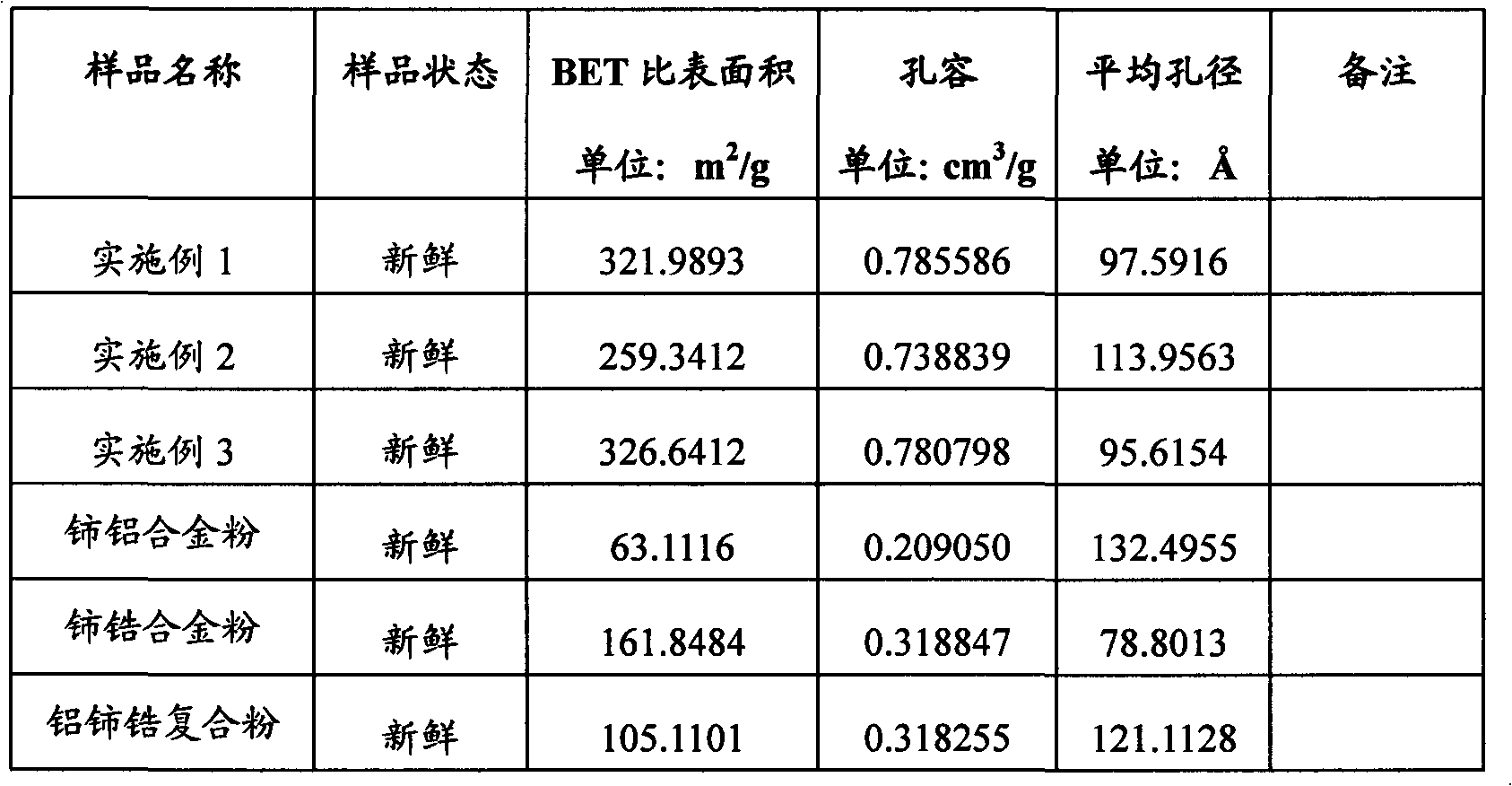

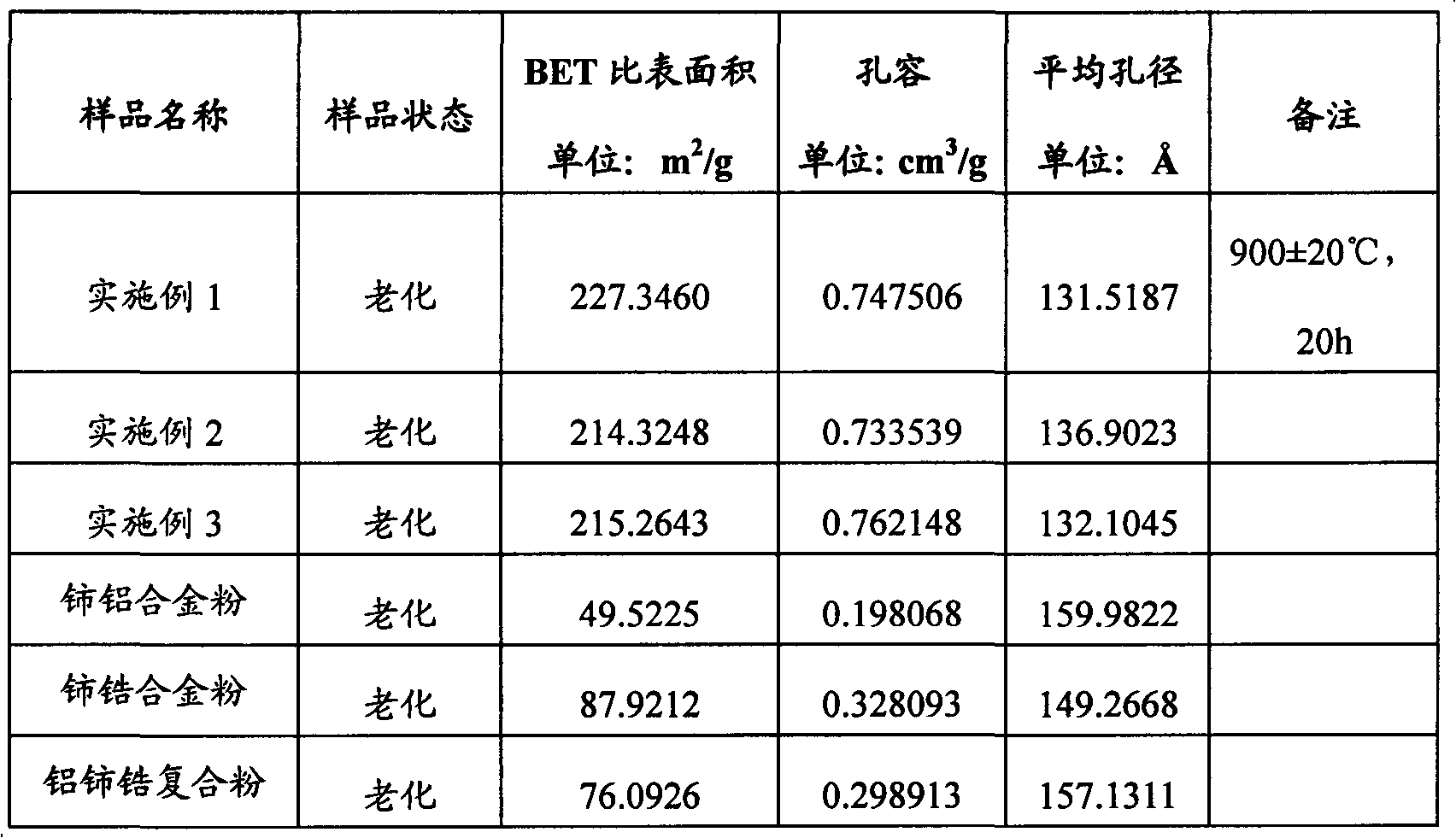

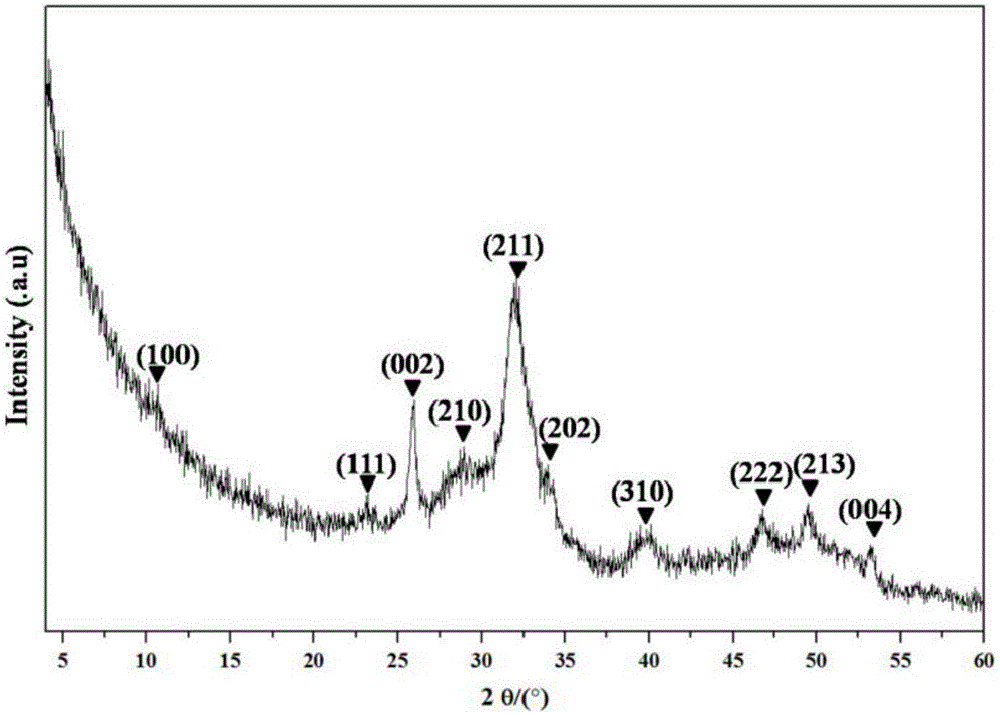

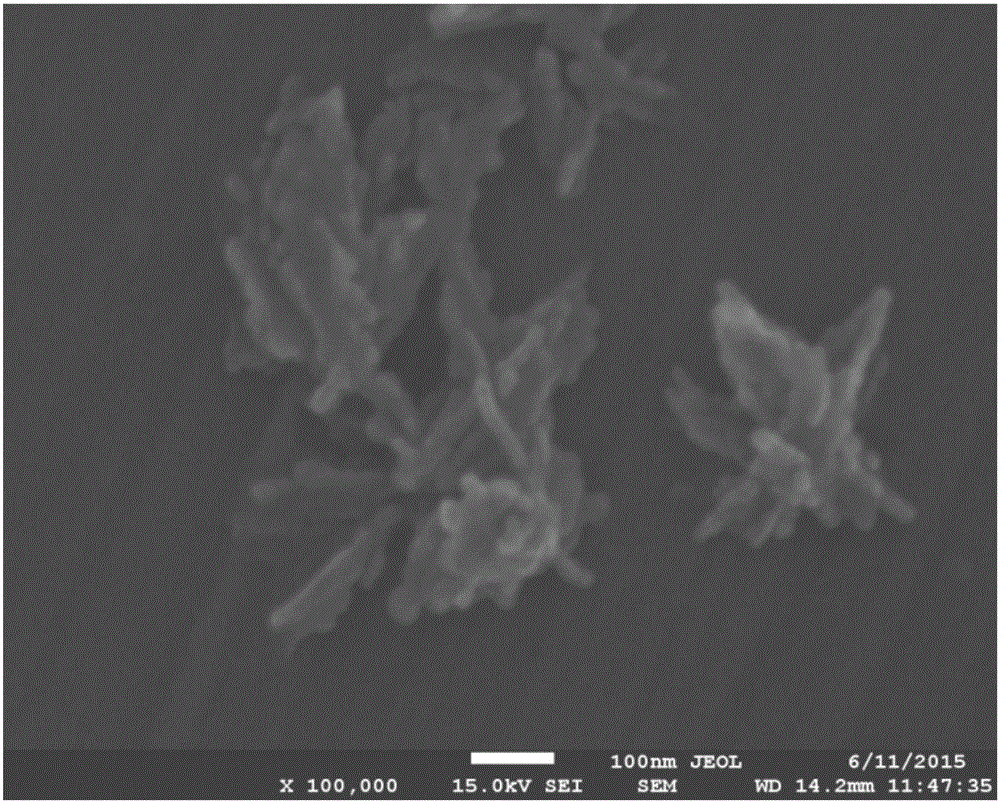

Cerium/aluminum-based composite oxide with high specific surface area and its preparation method

InactiveCN102847559AInhibit growthHigh specific surface areaCatalyst carriersDispersed particle separationRare-earth elementCerium

The invention provides a cerium / aluminum-based composite oxide with high specific surface area and its preparation method. The composite oxide has chemical formula of AlzCexRyO2, wherein R is rare earth element, x (10-50%), y (1-8%) and z (1-x-y) are molar ratios of Al, Ce and R. The composite oxide is used in three-way catalyst for exhaust gas purification of automobile, has large specific surface area, high thermal stability, and strong oxygen storage ability.

Owner:南京辉虎环保科技有限公司

Preparation method of anti-ultraviolet finishing agent for silk fabric

The invention discloses a preparation method of an anti-ultraviolet finishing agent for silk fabric. The preparation method comprises the following steps: filling 25-50mL of propylene glycol into a conical flask, dropwise adding 5-10mL of tetrabutyl titanate into the conical flask, introducing nitrogen gas with water at 60-80 DEG C and stirring for 30-60min; removing moisture in the conical flask by using a rotary evaporator at 80-100 DEG C, adding 5-10g of sodium stearate and 2-5g of hydroxyethyl cellulose into the conical flask, and carrying out water-bath ultrasonic treatment for 1-2h to obtain mixed paste; transferring the mixed paste in the conical flask into a high-speed dispersion machine, adding a wetting agent, a softening agent, a defoaming agent, a dispersing agent and a coupling agent, and stirring for 60-90min at 10000-15000r / min to obtain the anti-ultraviolet finishing agent for silk fabric. The anti-ultraviolet finishing agent for silk fabric has good heat resistance, is not easy to decompose when being heated, is non-toxic, is harmless to human body, has good biodegradability and facilitates environmental protection.

Owner:南通中宸印染有限公司

Nano titanium oxide modified transformer oil preparation method

The invention discloses a nano titanium oxide modified transformer oil preparation method. The method comprises the following steps: 1)uniformly mixing the transformer oil and tetrabutyl titanate, introducing aqueous nitrogen, and reacting for 1-3 hours under the temperature of 50-80 DEG C; 2)removing the residual moisture under the temperature of 60-100 DEG C; and 3)adding oleic acid, and performing ultrasonic treatment to obtain the nano titanium oxide modified transformer oil. According to the invention, hydrolysis of tetrabutyl titanate in the transformer oil is employed for acquiring the nano titanium oxide modified transformer oil, the transformer oil in the nano titanium oxide modified transformer oil is a disperse medium, nano titanium oxide particles are disperse phase, direct preparation of the inorganic nano particles in the disperse phase can save the storage and drying processes of the particles, so that hard agglomeration among particles can be avoided, titanium oxide in the transformer oil is dispersed to nano level, and can be dispersed in the transformer oil in a stable mode, and the nano titanium oxide modified transformer oil with good stability is obtained.

Owner:STATE GRID CORP OF CHINA +4

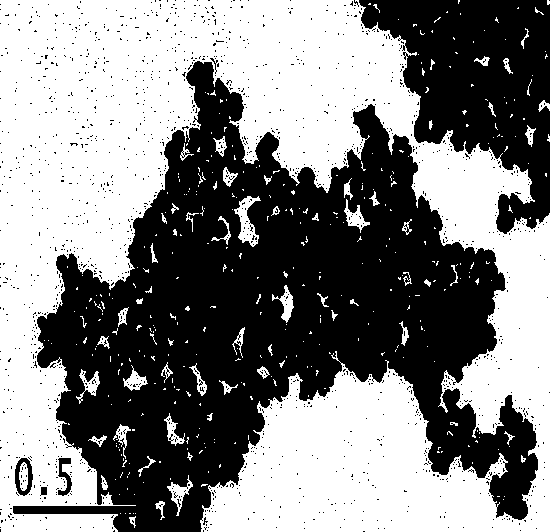

Method for simply and rapidly preparing nano WC-Co composite powder

ActiveCN104338935AWell mixedAvoid Microscopic InhomogeneityNanotechnologyMaterials scienceNanotechnology

The invention relates to a preparation technology of nano composite material, in particular to a method for simply and rapidly preparing nano WC-Co composite powder. The method comprises the following steps: firstly, preparing solution, secondly, preparing WC-Co composite powder precursor, and thirdly, preparing the nano WC-Co composite powder. The method has the advantages that molecular uniform mixing can be achieved, the prepared WC-Co composite powder has good dispersibility, production equipment and a process route are simplified, reducing gas or inert protective gas with potential hazards, such as H2, CH4, CO and the like, is not required to be used, and the cost is reduced.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

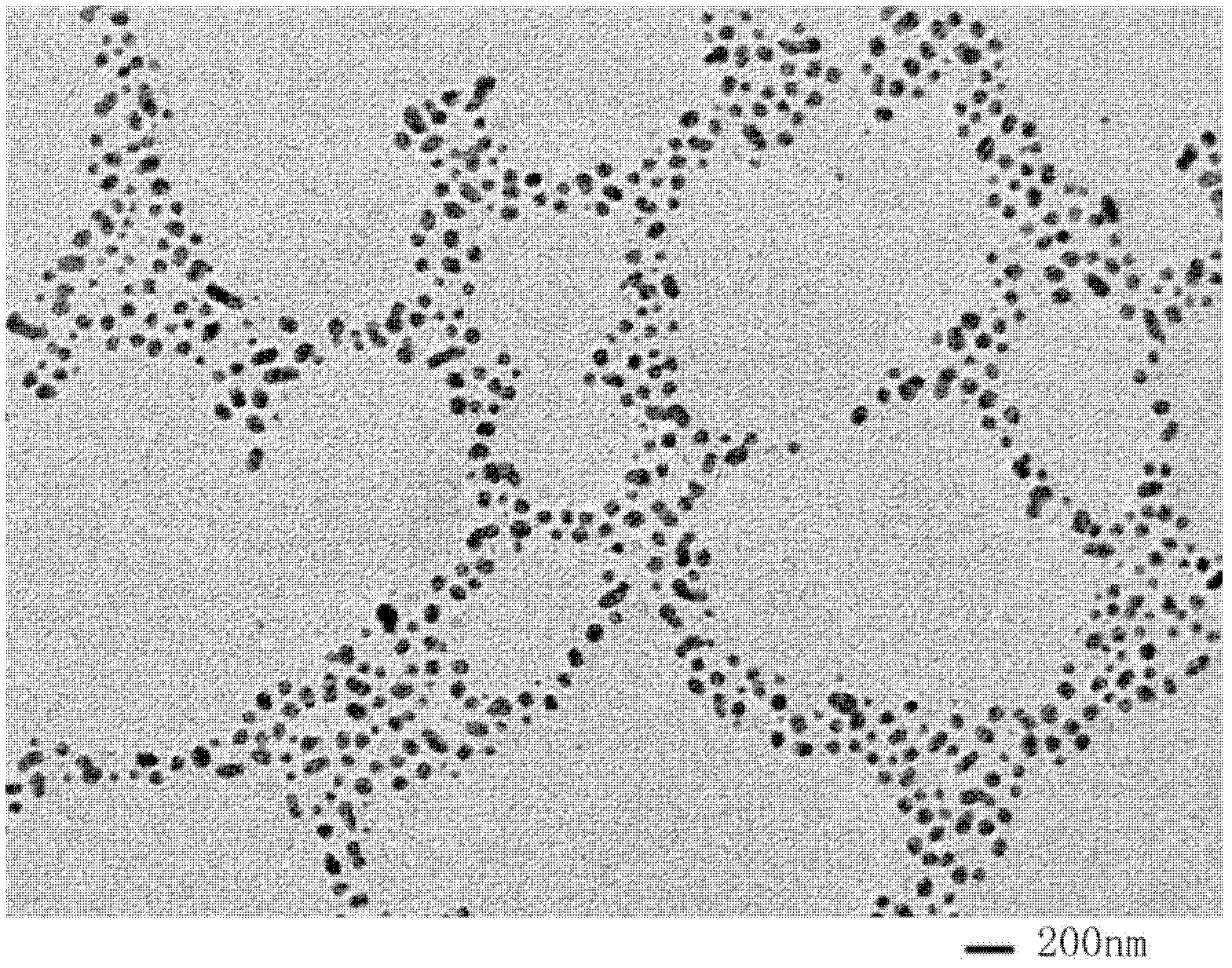

Simple and efficient preparation method of nano calcium phosphate

A simple and efficient preparation method of nano calcium phosphate comprises steps as follows: A, a calcium salt solution and a phosphate solution are prepared; B, diphosphonate is dissolved in the calcium salt solution, the phosphate solution is dropwise added to the calcium salt solution at the temperature of 37 DEG C, a reaction system is formed, and the pH value of the reaction system is adjusted to 7.0-11.0; the mole ratio of calcium to diphosphonate to phosphorus in the reaction system is (0.50-1.67): (0.01-0.02):1; after titration is completed, the reaction system is continuously stirred for 1-120 min, and the pH value of the reaction system is adjusted to 7.0-11.0; centrifugal washing and filtration are performed, precipitates are re-suspended in absolute ethyl alcohol, and a turbid liquid is obtained; C, a diphosphonate chemical is added to the turbid liquid, nano calcium phosphate slurry is obtained, and the mole ratio of diphosphonate to phosphorus in the nano calcium phosphate slurry is (0.01-0.02):1; the nano calcium phosphate slurry is subjected to ball milling treatment at the rotating speed of 300-600 r / min for 4-12 h and finally dried, and nano calcium phosphate powder is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

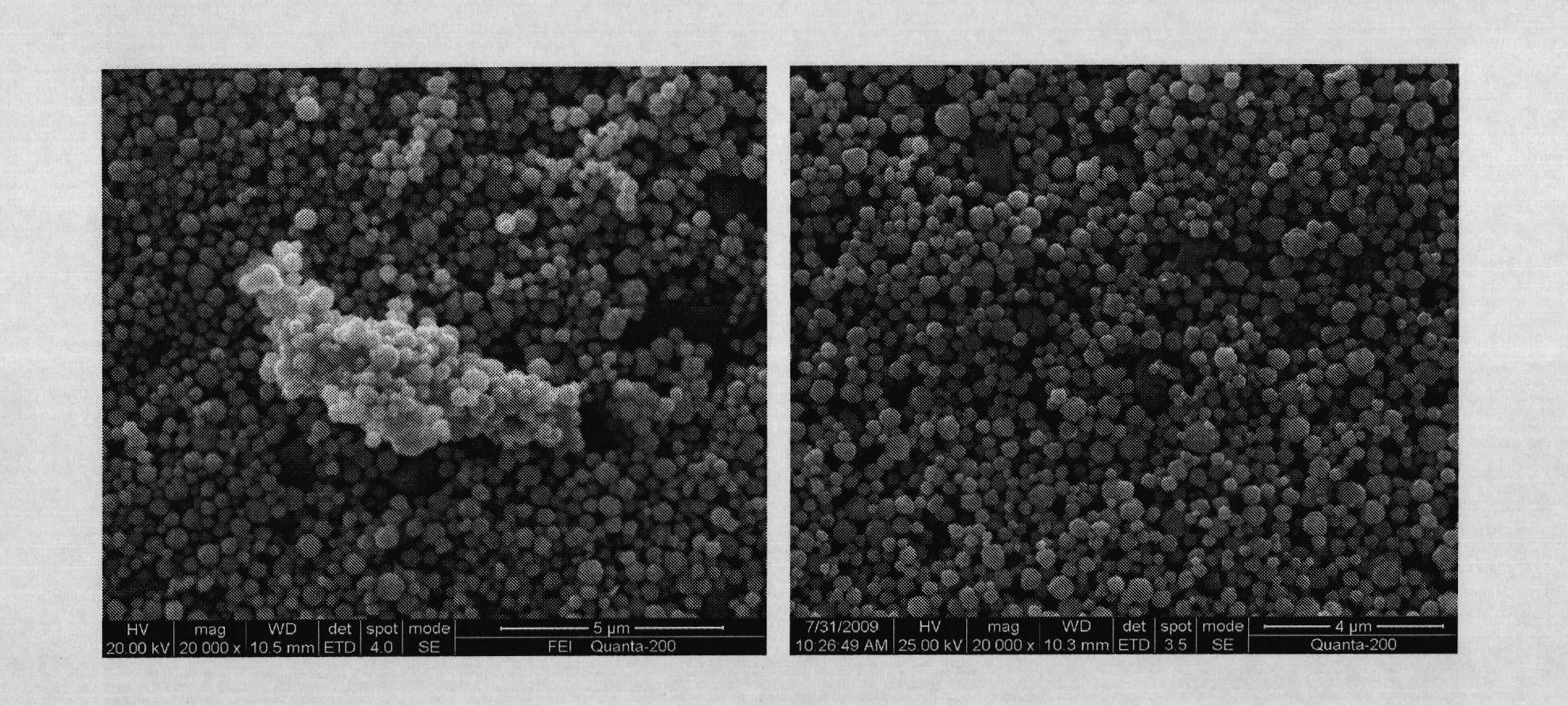

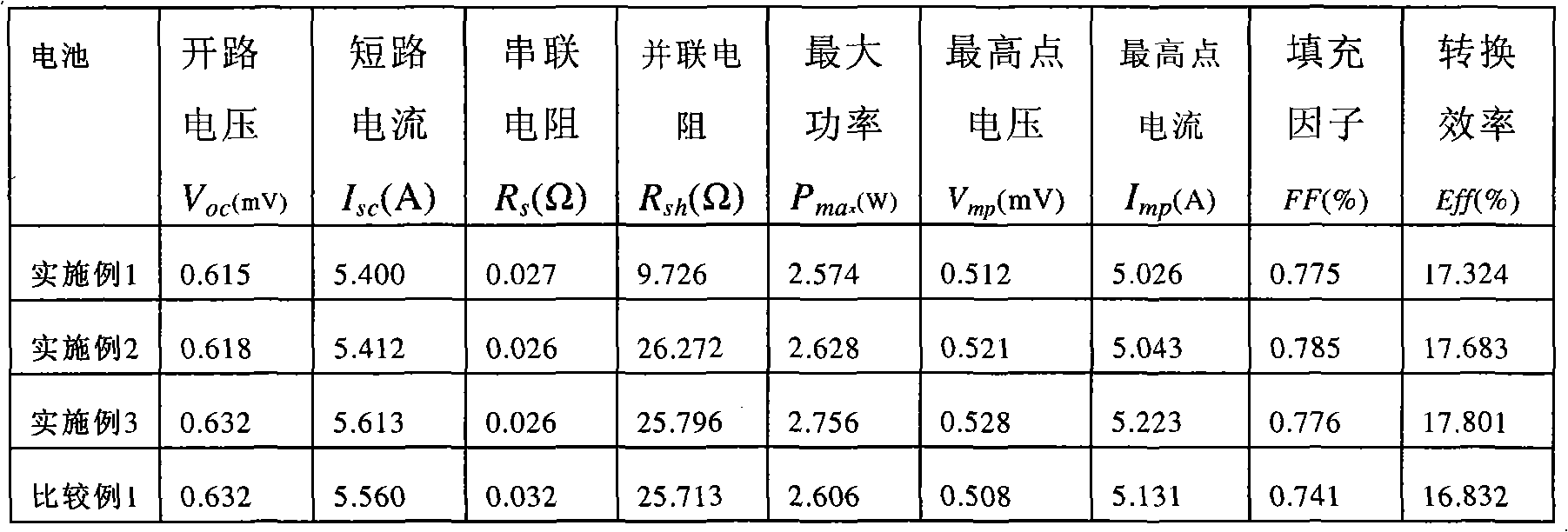

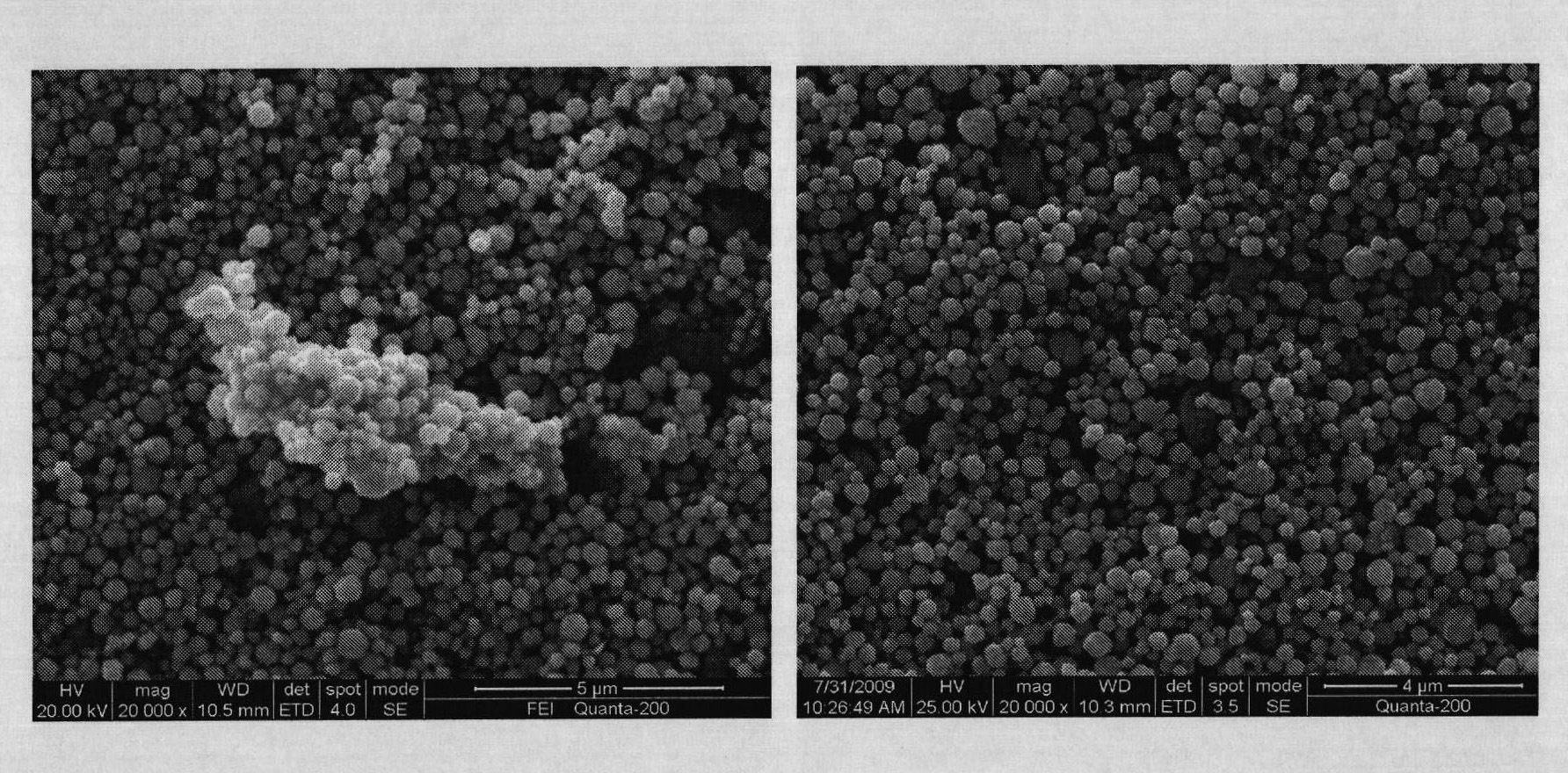

Silver paste used for positive electrodes of solar batteries and grid lines, preparation method thereof and solar battery containing same

InactiveCN102103895AInhibit easy agglomerationImprove dispersionFinal product manufactureNon-conductive material with dispersed conductive materialElectrical batteryHigh definition

The invention discloses a silver paste used for positive electrodes of solar batteries and grid lines, which comprises silver powder, glass powder, additive and an organic carrier. The silver paste is prepared by the following steps of: preparing a highly dispersed superfine silver grout used as the silver powder through a chemical liquid phase reduction method, then obtaining wet silver powder through solid-liquid separation, and preparing the agglomerate-free silver paste through direct mixing of the wet silver powder and the glass powder, the additive and the organic carrier according to the specified proportion without drying. The method for preparing the positive silver paste directly by using the wet silver powder comprises the steps of: preparation of the superfine silver powder through the chemical liquid phase reduction method, solid-liquid separation, washing, and direct preparation of the silver paste without a drying procedure in which the silver powder is easily agglomerated. The silver paste is characterized by high dispersity, no agglomeration and smaller fineness; and positive electrodes of solar batteries and grid lines, prepared through the screen printing and fast sintering process, have high definition, high evenness, high electrical conductivity and excellent photoelectric conversion efficiency.

Owner:湖南威能新材料科技有限公司

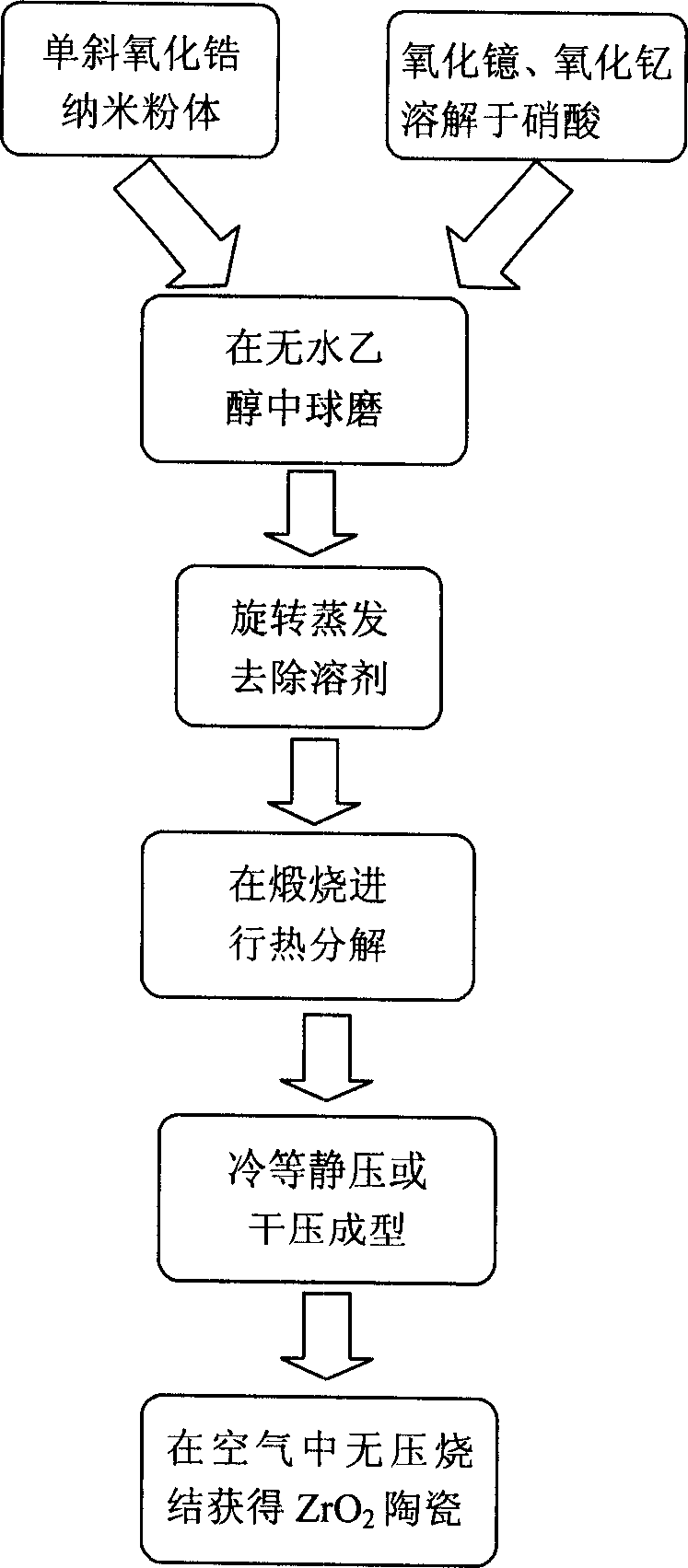

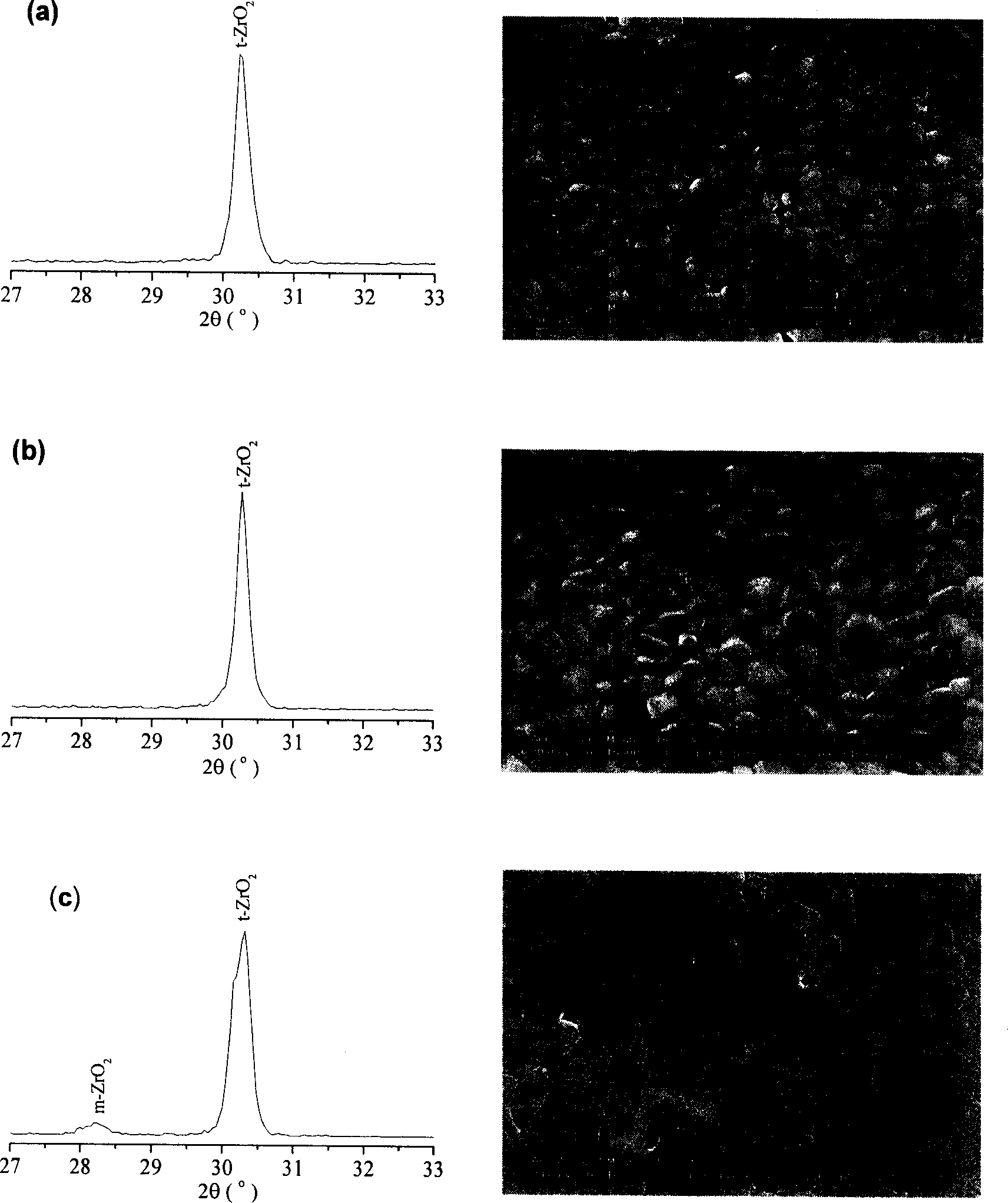

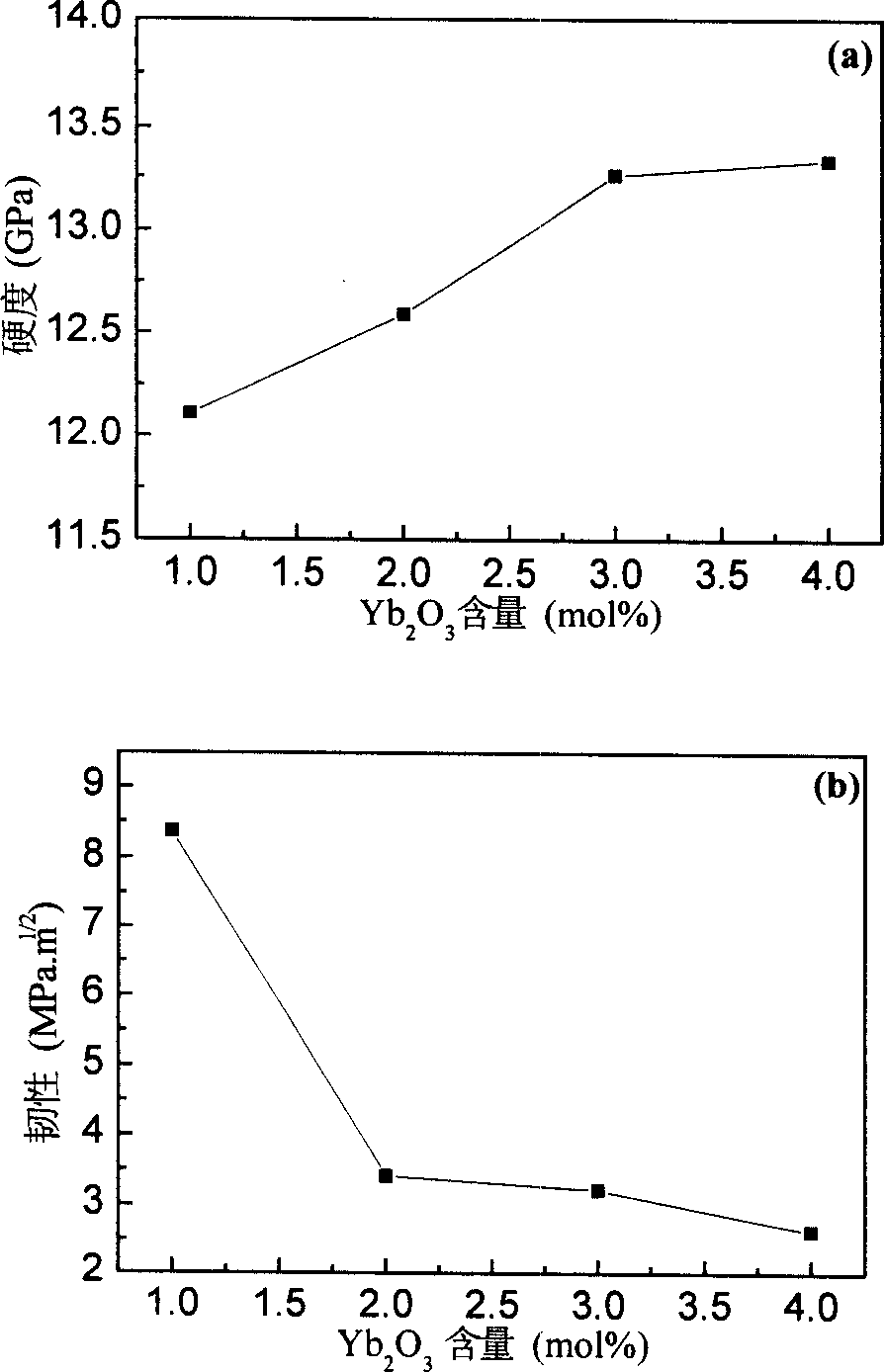

Ytterbium oxide and yttrium oxide co-stabilized zirconia ceramic material and its prepn process

The present invention features that two kinds of oxide, including ytterbium oxide and yttrium oxide, are used as the stabilizers simultaneously to coat nanometer zirconia powder and the obtained powder is sintered in the air and without pressure to obtain tetragonal zirconia polycrystal (TZP) and fully stabilized zirconia ceramic (FSZ) with low stabilizer content. The material includes Yb2O3, Y2O3 and monoclinic zirconia powder in purity over 99.9 wt%. The produced TZP ceramic contains Yb2O3 in 1.0-2.0 mol% and Y2O3 in 1.0-2.0 mol%, and the produced FSZ ceramic contains Yb2O3 in 3.0-4.0 mol% and Y2O3 in 1.0-2.0 mol%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

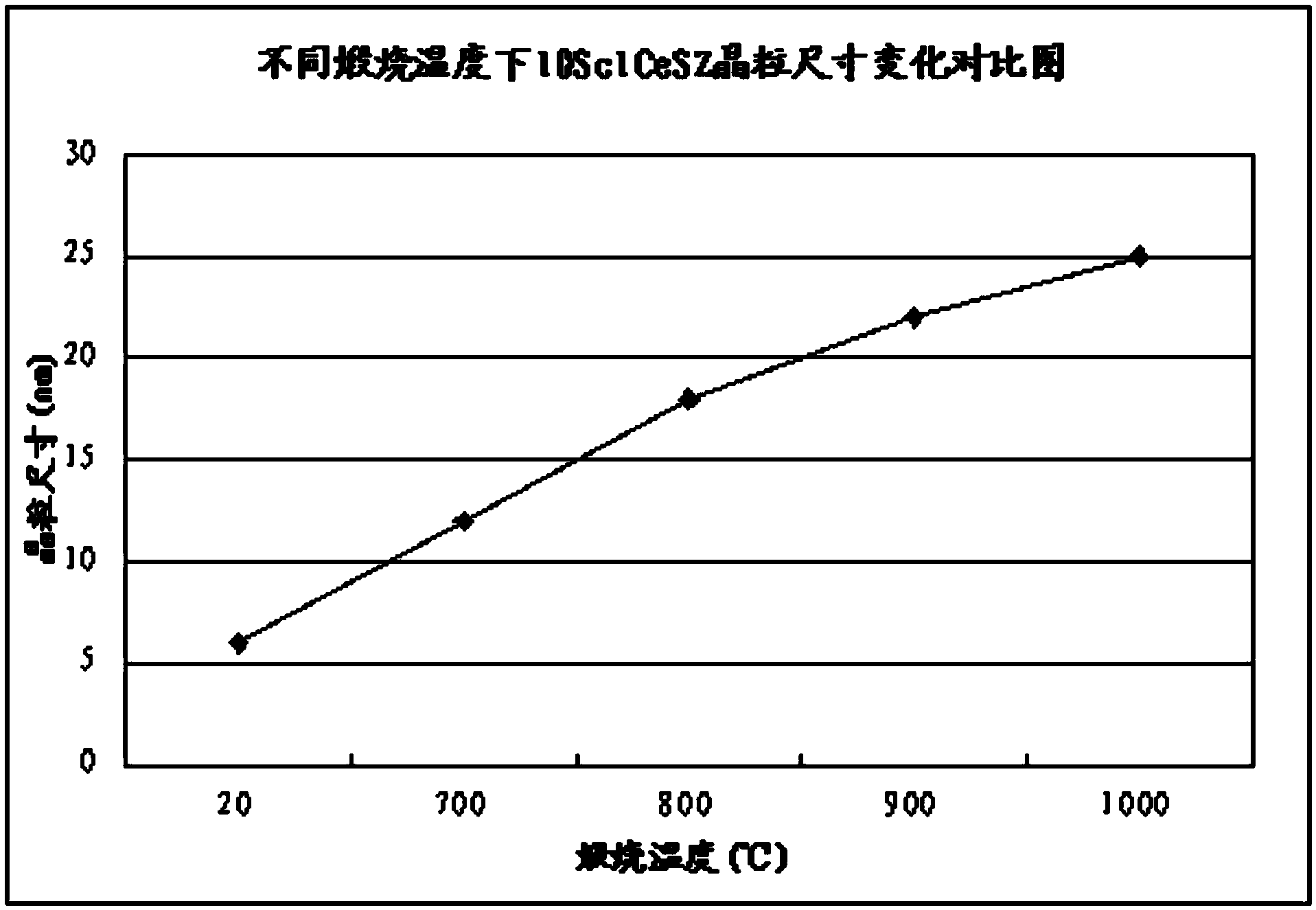

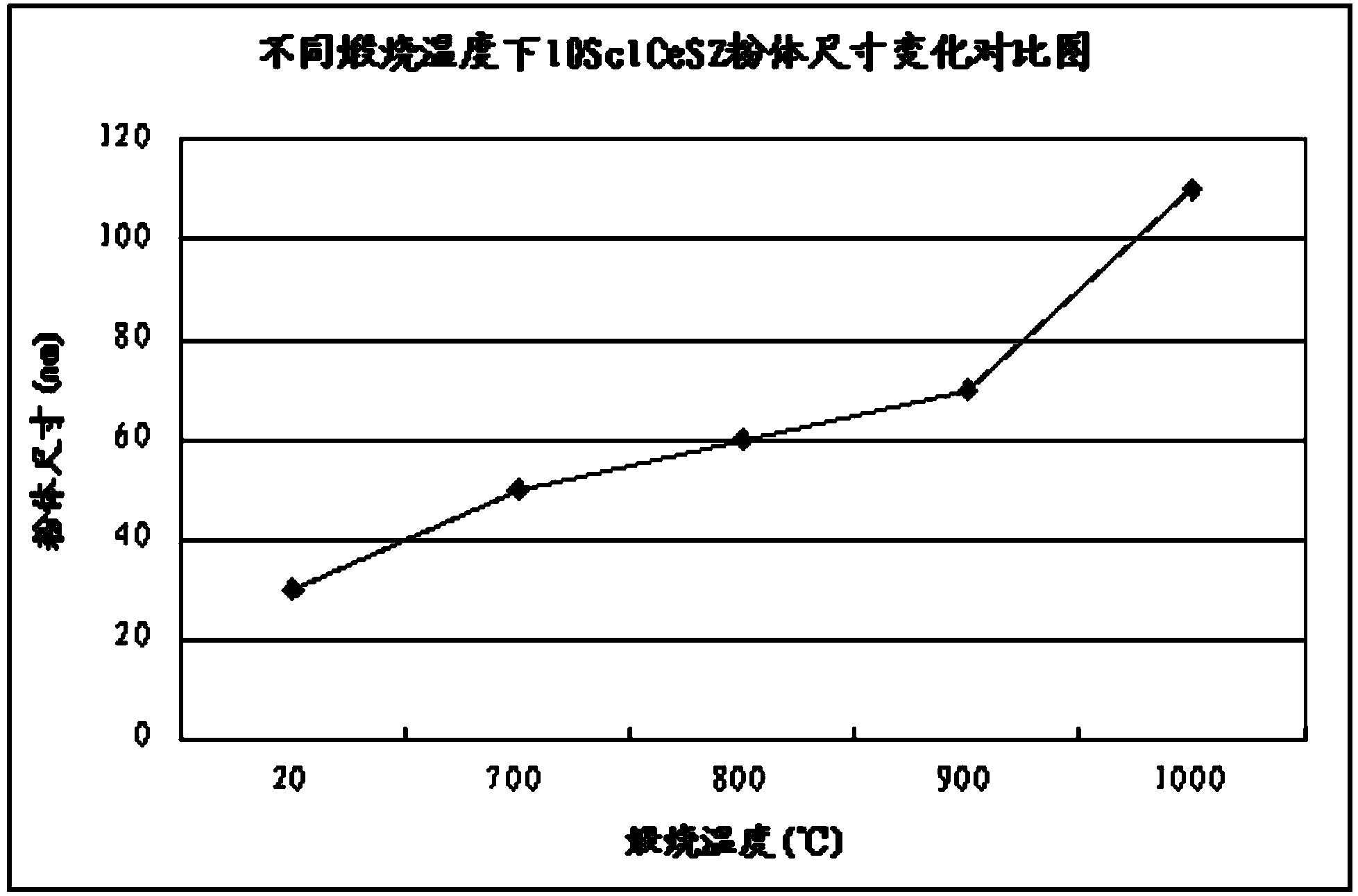

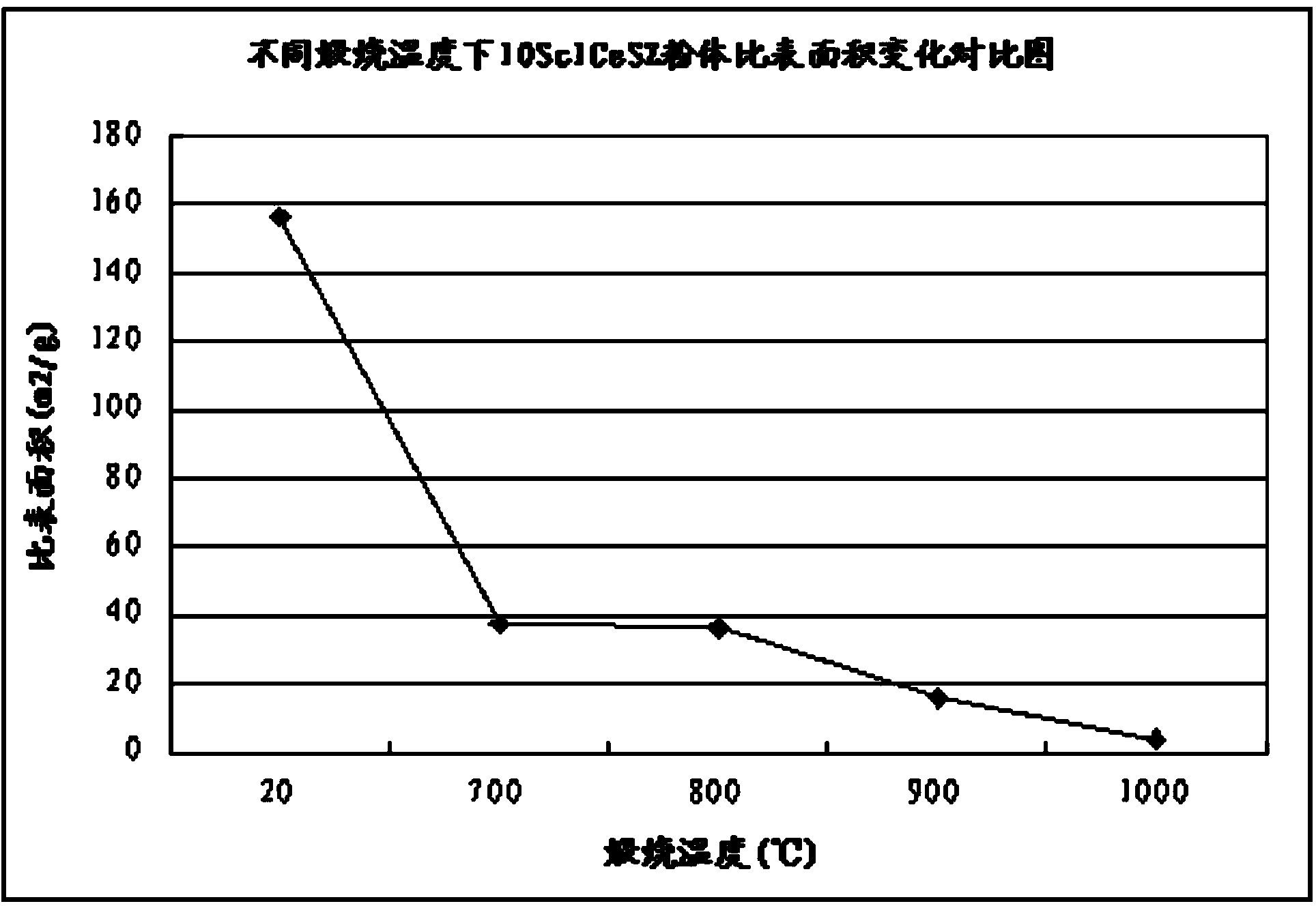

Scandium-cerium co-doped zirconium oxide powder and preparation method thereof

A disclosed preparation method for a scandium-cerium co-doped zirconium oxide powder comprises the following steps: A, preparing a mixed salt solution; B, preparing a precipitating-agent solution; C, generating a precursor precipitate; D, post-processing the precursor precipitate; and E, post-processing the scandium-cerium co-doped zirconium oxide powder. The scandium-cerium co-doped zirconium oxide powder prepared by using the preparation method has the advantages of relatively simple operation technology, uniform particle size distribution of the prepared powder, relatively good sintering activity, low cost and the like, and therefore the technology is suitable for large-scale production of the scandium-cerium co-doped zirconium oxide powder.

Owner:SUZHOU HUA TSING POWER SCI & TECH

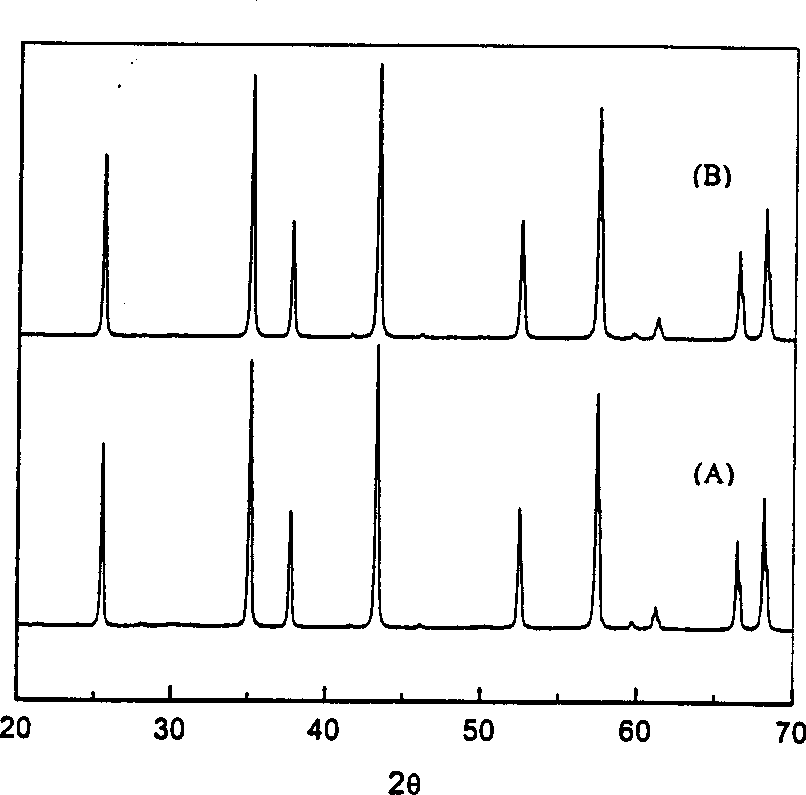

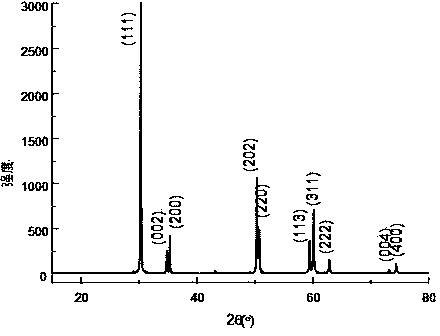

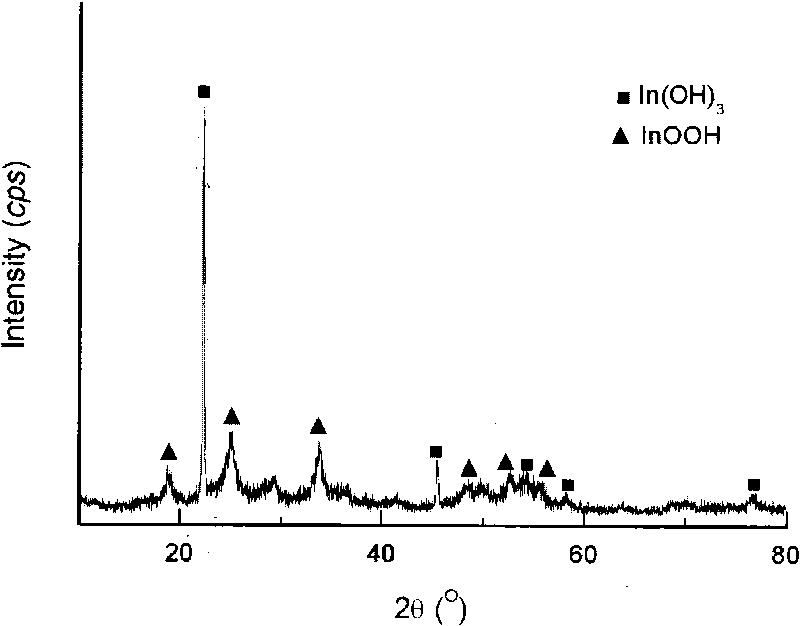

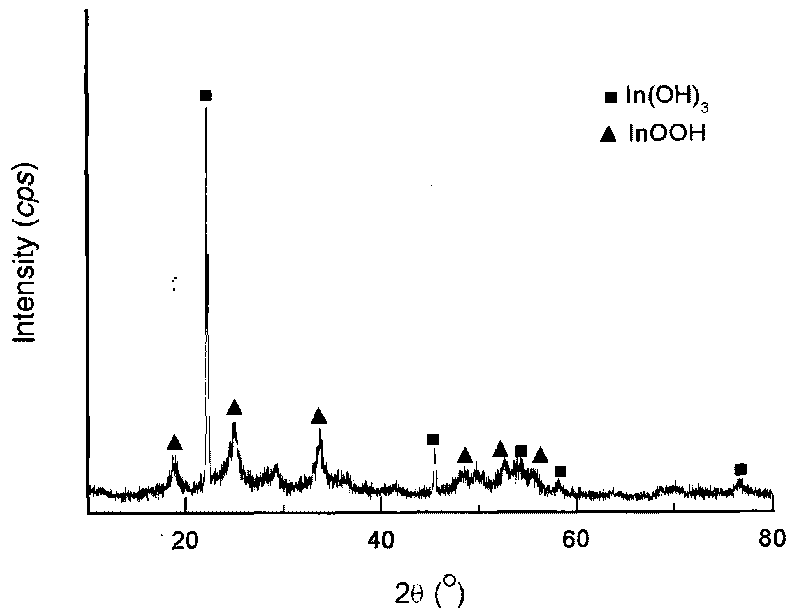

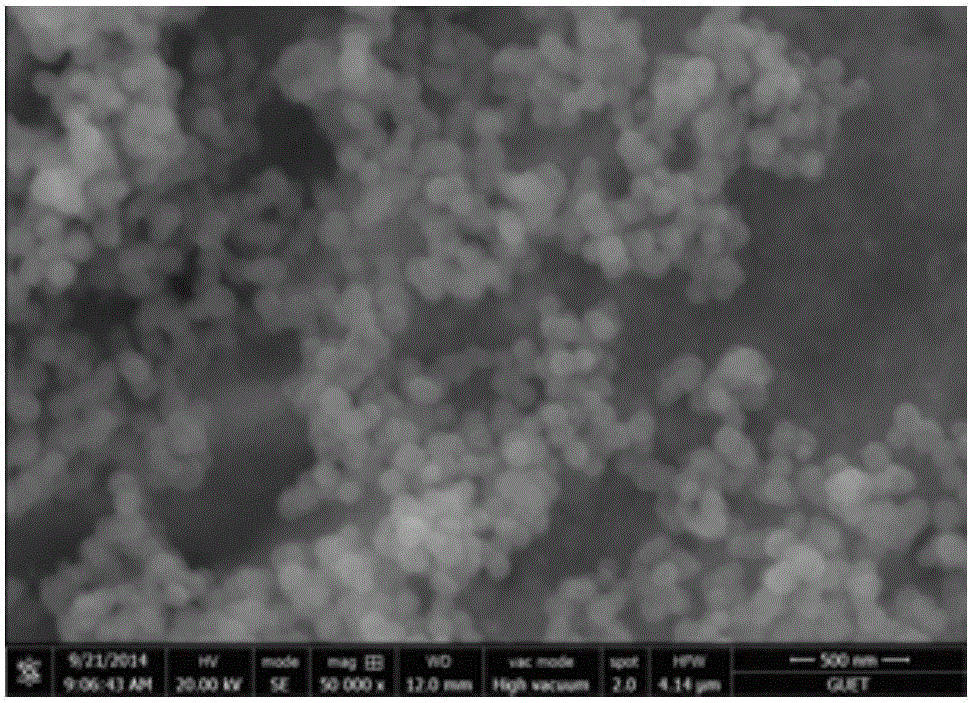

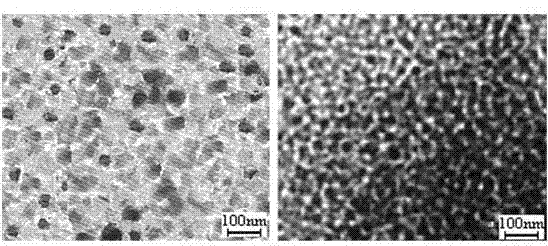

Preparation method of indium tin oxide nano-powder with controllable crystalline form

InactiveCN101704547AGood dispersionNo hard reunionGallium/indium/thallium compoundsTin oxidesIndiumIndium tin oxide

A preparation method of indium tin oxide nano-powder with controllable crystalline form is characterized in that the technological method comprises the following steps: (1) dissolving indium oxide and tin oxide in distilled water, using strong base aqueous solution as precipitant to prepare ITO precursor through two-step precipitation method; (2) washing the sedimentary precursor power with water, drying, grinding, screening to obtain indium tin oxide precursor power; and (3) calcining indium tin oxide precursor power under a certain atmosphere to prepare yellowgreen ITO nano-powder. The invention has the advantages that 1. no hard agglomeration exists among the ITO grains, the grain size is more uniform; 2. the calcining atmosphere can be selected to control the appearance of the ITO grains; 3. the preparation process of the precursor does not use any dispersant or surface complexing agent to inhibit the power agglomeration; and 4. the temperature and precipitation rate can be adjusted to change the grain size and length-diameter ratio of grains during the two-step precipitation process.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of spherical yttrium oxide powder

InactiveCN106082296AReduce energy consumptionIncrease productivityRare earth metal oxides/hydroxidesAlcoholWater volume

The invention relates to a preparation method of spherical yttrium oxide powder, and relate to a preparation method of yttrium oxide powder. The method comprises the following steps: adding a surfactant in an aqueous solution containing yttrium salt and a precipitating agent to prepare a reaction solution, wherein the yttrium salt concentration in the reaction solution is 0.05-0.1 mol.L<-1>, employing a homogeneous precipitation method to prepare a yttrium oxide precursor precipitate, after solid-liquid separating, respectively washing the precipitate by water and small molecular alcohol, processing precipitate suspending liquid by using ultrasonic dispersion, separating the suspending liquid, drying the material, and calcining the material to obtain the yttrium oxide powder composed by submicron spherical particles. The yttrium salt solution with concentration of 0.05-0.1 mol.L<-1> is taken as a reaction solution, production efficiency of yttrium oxide is obviously increased, precipitating agent amount is obviously reduced, production cost is reduced, waste water volume is reduced, and the method is in favor of the protection environment, has simple process, and is convenient for popularization and usage.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

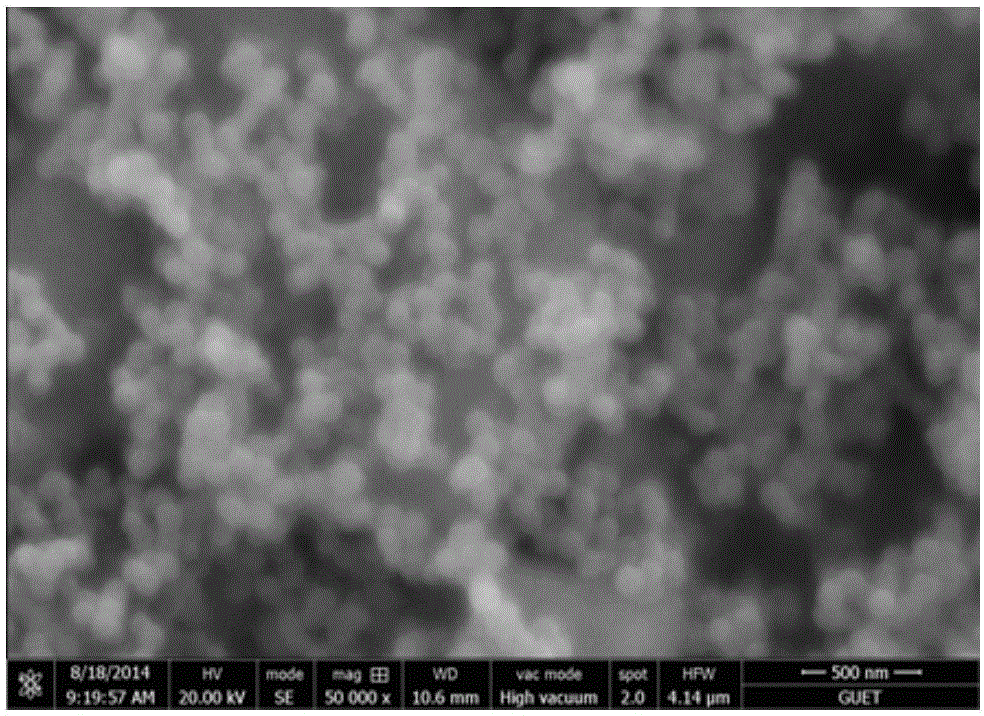

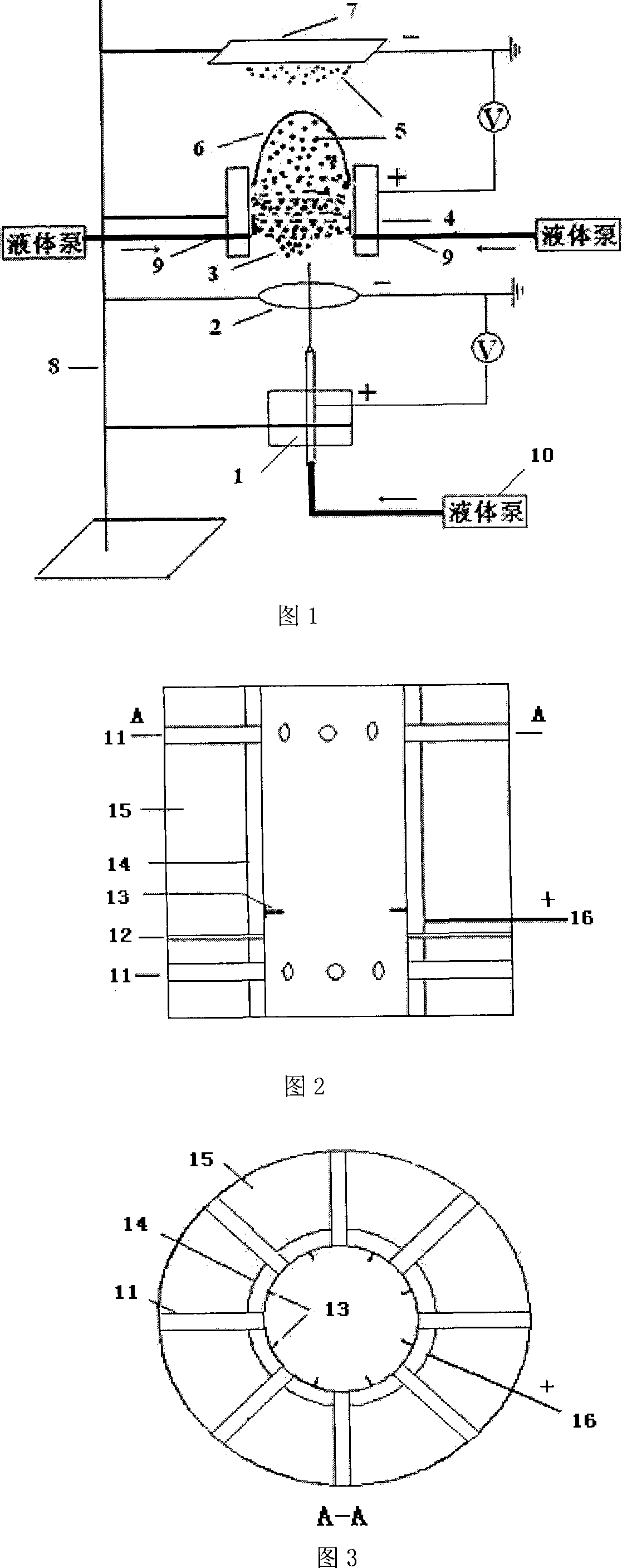

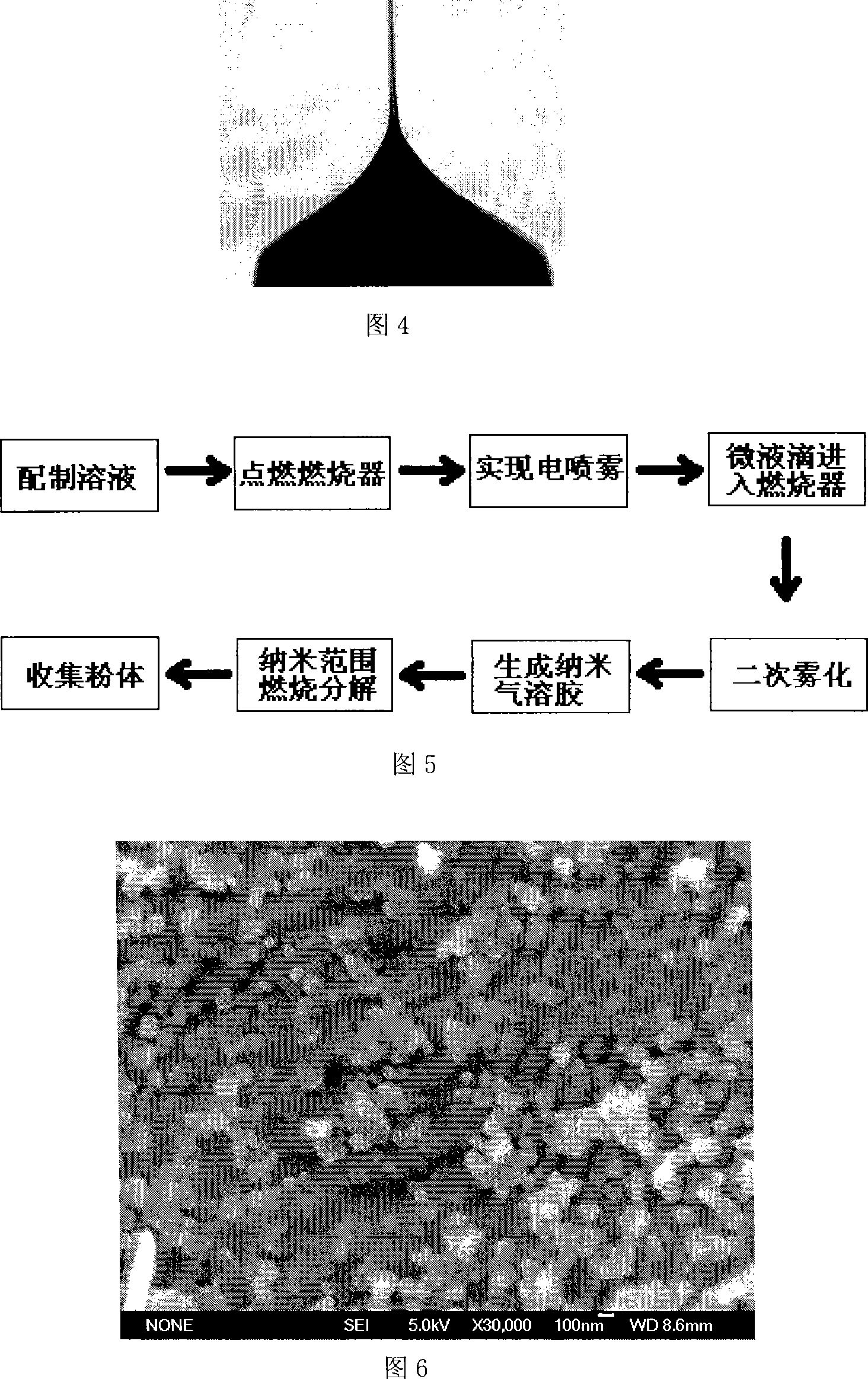

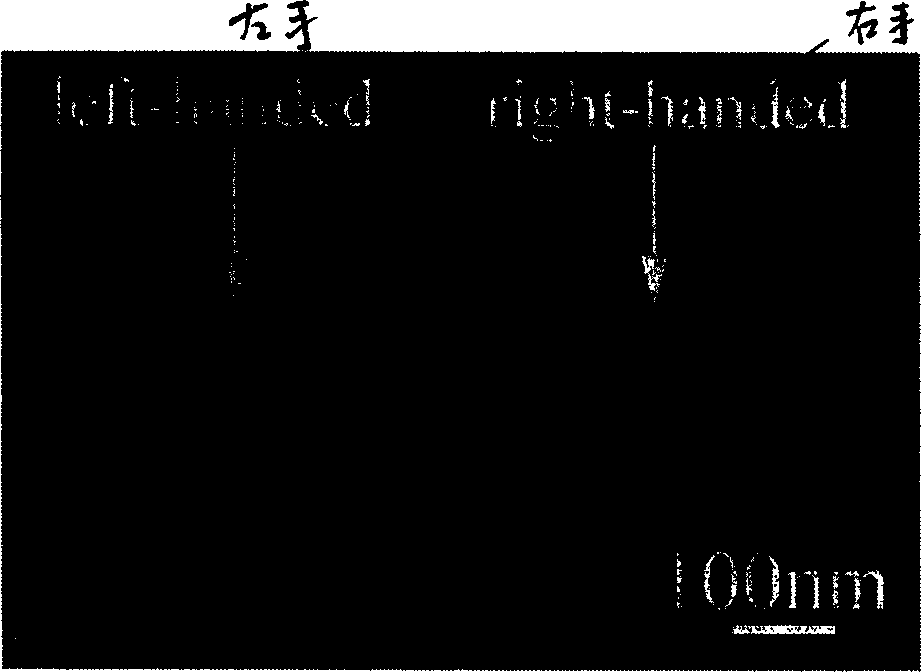

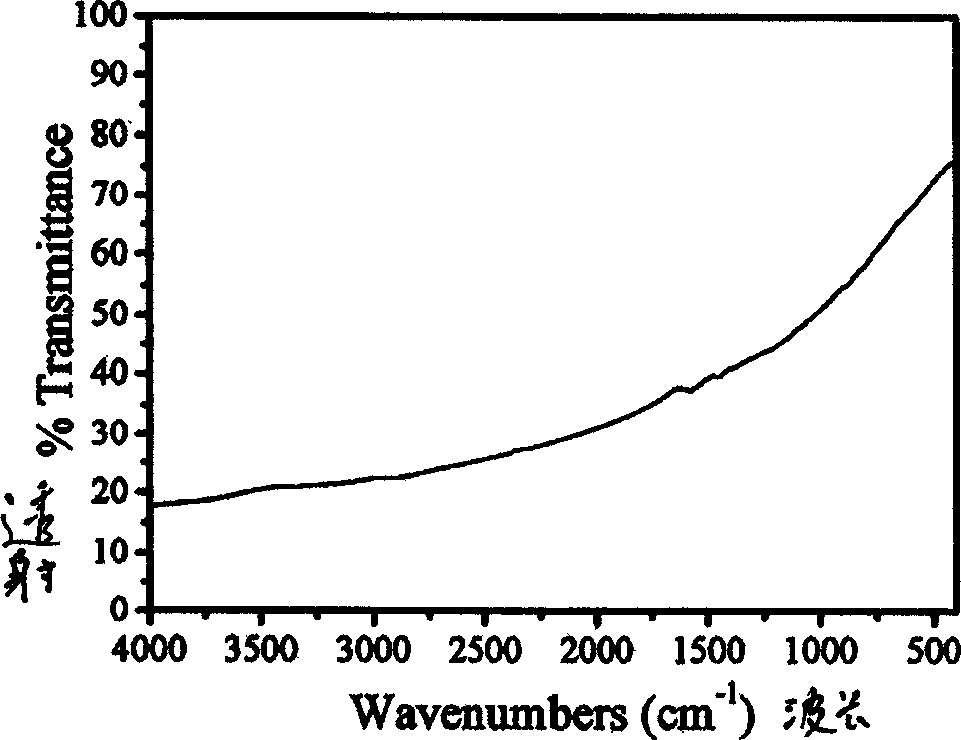

Method and device for manufacturing non-glomeration nano-oxide powder body

InactiveCN101219776AAvoid hard clumpingReasonable structureOxide/hydroxide preparationZinc oxides/hydroxidesCombustorNanoparticle

The invention relates to a method and a device for preparing nanometer oxide powders without agglomeration. The method combines an electron spraying and a combustion method, separates nanometer particles by charging the surfaces of aerosol particles which are generated during nanometer combustion with the same charge, and overcomes hard agglomeration existing in the combustion method. The preparation device comprises a combustor, a liquid pump, a bracket and a collecting board; an outlet of the liquid pump is connected with an electronic sprayer through a tube; a nozzle of the electronic sprayer aims at an inlet of the combustor, and an outlet of the combustor aims at the collecting board. The method and device of the invention can prepare and obtain the nanometer oxide powders without hard agglomeration.

Owner:SHANGHAI UNIV

UV proof, antimicrobial nano-function powder and method of producing the same

ActiveCN101402844AGood dispersionGood grain crystallizationBiocideOther chemical processesZinc hydroxideAntibiosis

The invention relates to a nanometer functional powder and the technical field of the preparation method thereof, in particular to a UV resistance and antibiosis nanometer functional powder and a preparation method thereof. The nanometer functional powder consists of the components according to parts by mass as follows: 50 to 70 percent of zinc oxide, 30 to 48 percent of titanium oxide and 0.45 to 2 percent of silver. The preparation method is as follows: zinc hydroxide sol, rutile phase high-pure titanium oxide of 10 to 30 nanometers and silver oxalate are added into a high pressure reaction kettle; the reaction concentration is regulated to be between 8 and 15 percent; the pH is regulated to be between 6.5 and 7.5; then the mixture is reacted for 4 hours under high temperature between 126 and 136 DEG C, filtered, washed and dried under lower temperature between 60 and 70 DEG C, thus obtaining the silver-loaded compound powder of nanometer zinc oxide and nanometer titanium oxide with the UV resistance and antibiosis functions; and the prepared powder has excellent functional cooperation effects and can avoid the fluctuation phenomenon of each function.

Owner:广东拓扑中润科技发展有限公司

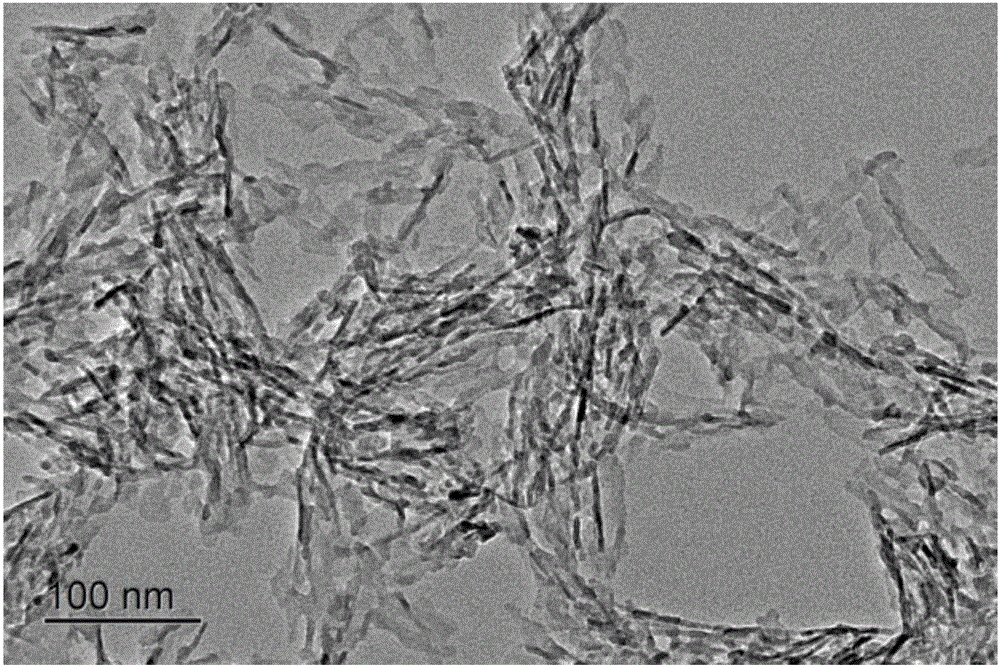

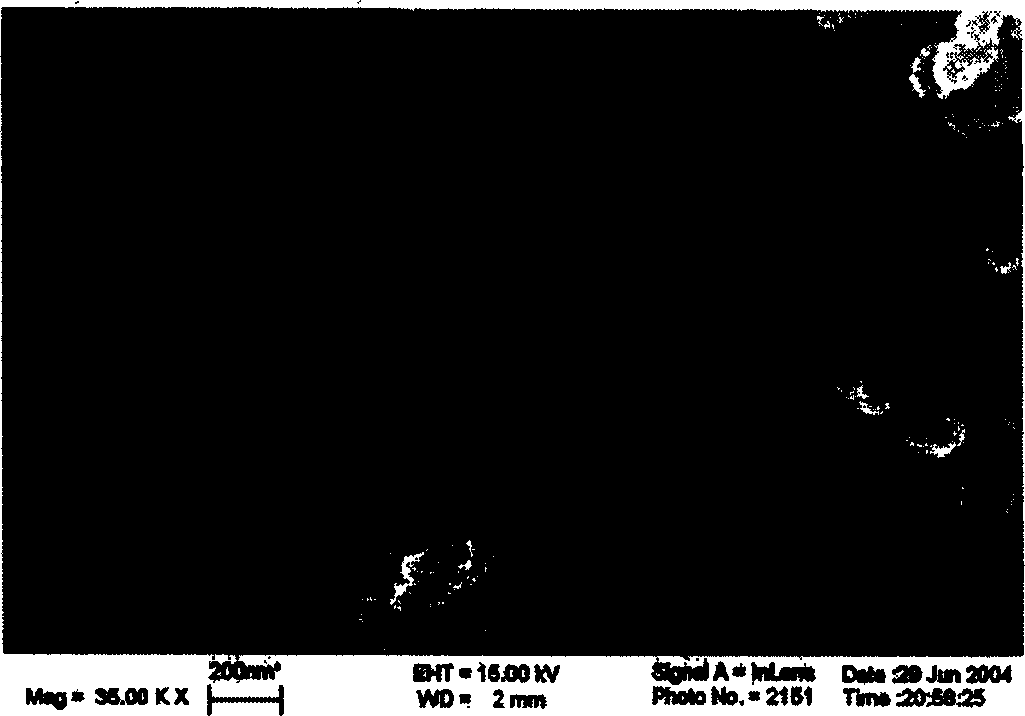

Preparation method of chiral helical carbon fiber

InactiveCN1603478AAvoid hard clumpingSmall particle sizeFibre chemical featuresTextile fiberCarbon fibers

The chiral spiral carbon fiber assumes take a hard nanometer pellet as the center highly symmetrically grows, carbon fiber particle size approximately for hard pellet diameter. Its preparation method is take the hard oxide compound as the catalyst forerunner, this oxide compound take the ferric chloride or the ferrous sulfate as the raw material, the citric acid is the complexing agent, the absolute ethyl alcohol forms the even non- hydrosol preparation method for the solvent, after the process complexing dryly forms in the air does the gelatin, in the air bakes in advance removes the organic matter to obtain. 450 deg c under returns to original state in the H2 atmosphere namely obtains a Fe nanometer beaded catalyst. The preparation craft simple, the process is easy to control, is suitable the large scale production. The carbon fiber particle size approximately for the hard nanometer pellet diameter, take iron catalyst becomes as the center of symmetry highly symmetrically grows. We law prepares the carbon fiber is highly symmetrical, on each catalyst granule grows two carbon fibers, is a left hand, is a right hand, also the textile fiber diameter, the curl diameter, the curl turn, the growth direction is all same.

Owner:NANJING UNIV

Method for synthesizing nanometer gama-Al2O3 by adopting solvent replacement/azeotropic distillation drying method and applications thereof

InactiveCN103395809ALarge specific surface areaSmall particle sizeWater/sewage treatment by flocculation/precipitationAluminium oxides/hydroxidesAluminium chlorideFurnace temperature

The invention discloses a method for synthesizing nanometer gama-Al2O3 by adopting a solvent replacement / azeotropic distillation drying method. The method is characterized in that the concentration of a AlCl3 solution is 0.7mol.L<-1>, the molar concentration ratio of Al<3+> to a dispersing agent is 250:1, adding a solvent is added and then agitating is carried out, the furnace temperature is 580DEG C, low-cost AlCl3 and n-butyl alcohol replace expensive alcohol aluminum as raw materials, the hydrolysis rate of Al<3+> and the particle size are controlled through adding a surfactant, the hard agglomerate of a precursor aluminium hydroxide gel can be effectively eliminated by adopting the solvent replacement / azeotropic distillation drying method, the prepared nanometer gama-Al2O3 is high in specific area and even in particle distribution, and the particle sizes range from 30nm to 70nm. The prepared nanometer gama-Al2O3 is added in polymeric aluminium chloride and fully mixed to prepare the nanometer modified polymeric aluminium chloride. The waste water coagulating sedimentation effect of the polymeric aluminium chloride can be effectively promoted.

Owner:NINGBO JIANGDONG CHENGCHUANG IND PROD DESIGN CO LTD +1

Ceramic powder for denture preparation and preparation method of ceramic powder

InactiveCN103767882ASmall particle sizeImprove flexural strengthImpression capsDentistry preparationsHigh fractureBioavailability

The invention relates to a material for denture, and in particular relates to a zirconium-containing ceramic powder for denture preparation and a preparation method of the ceramic powder. The ceramic powder for denture preparation comprises 90-95 percent by weight of stable tetragonal-zircania and 2.5-3.49 percent by weight of yttrium oxide serving as a stabilizer, wherein a precursor is prepared from the ceramic powder by a co-precipitation reaction; the precursor is sequentially subjected to vacuum lyophilisation, high-temperature calcination and ball mill to form powder with bending strength of more than 600MPa. According to the preparation method, high bending strength can be obtained, and the high-quality ceramic powder with bending strength of more than 600MPa, high fracture toughness, high chemical stability and good bioavailability can be obtained.

Owner:厦门北大泰普医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com