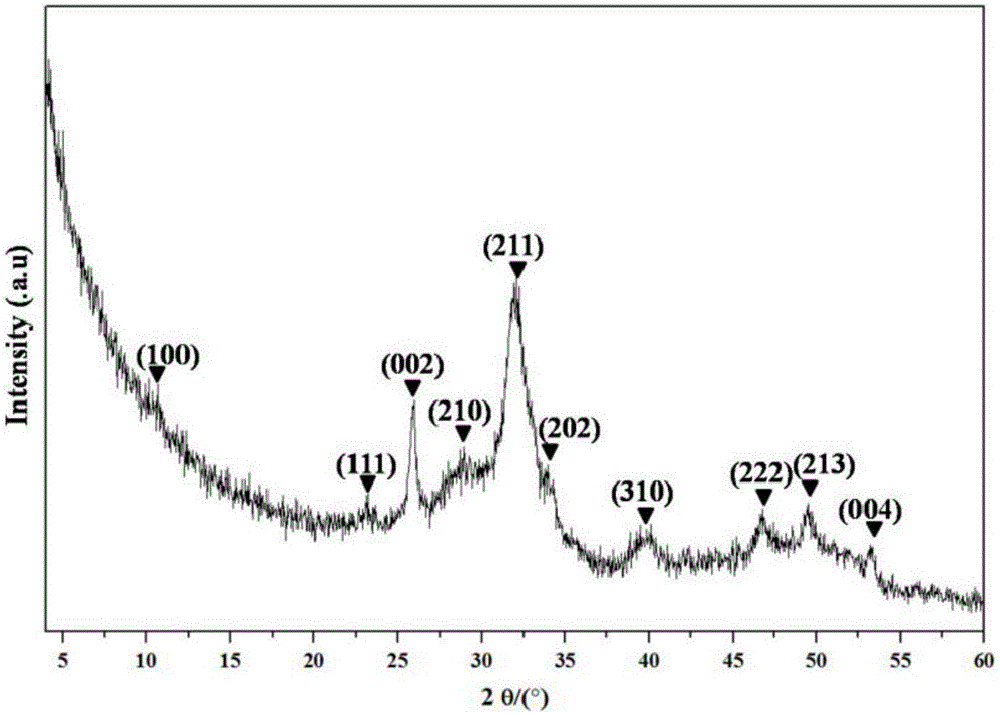

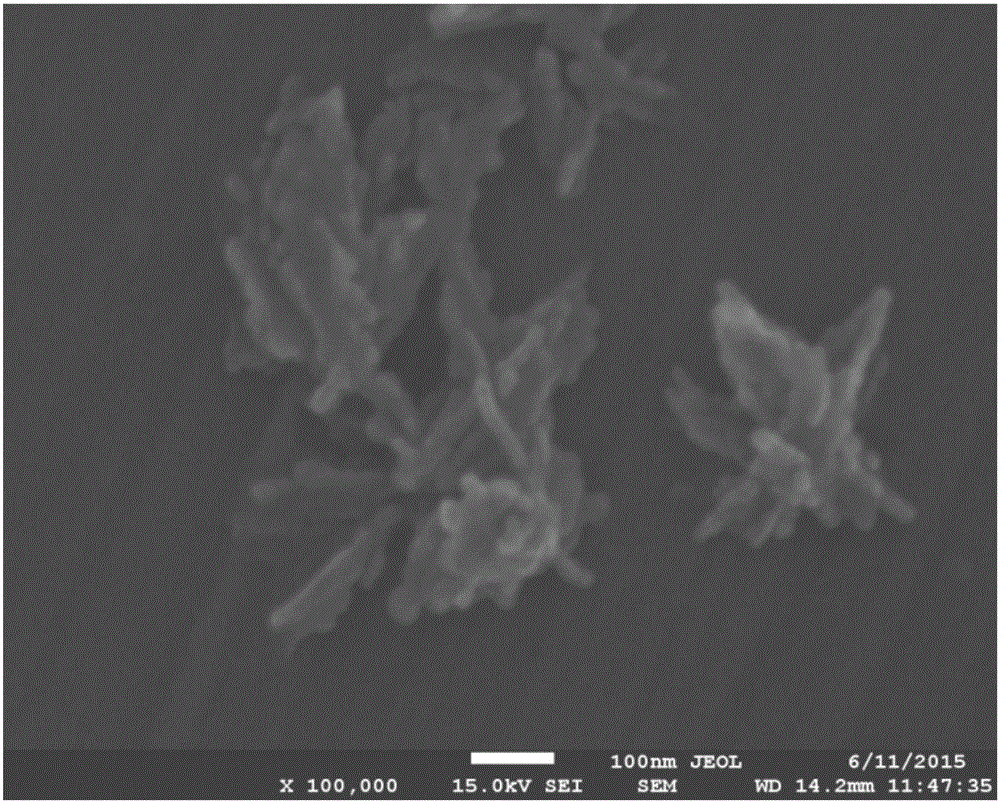

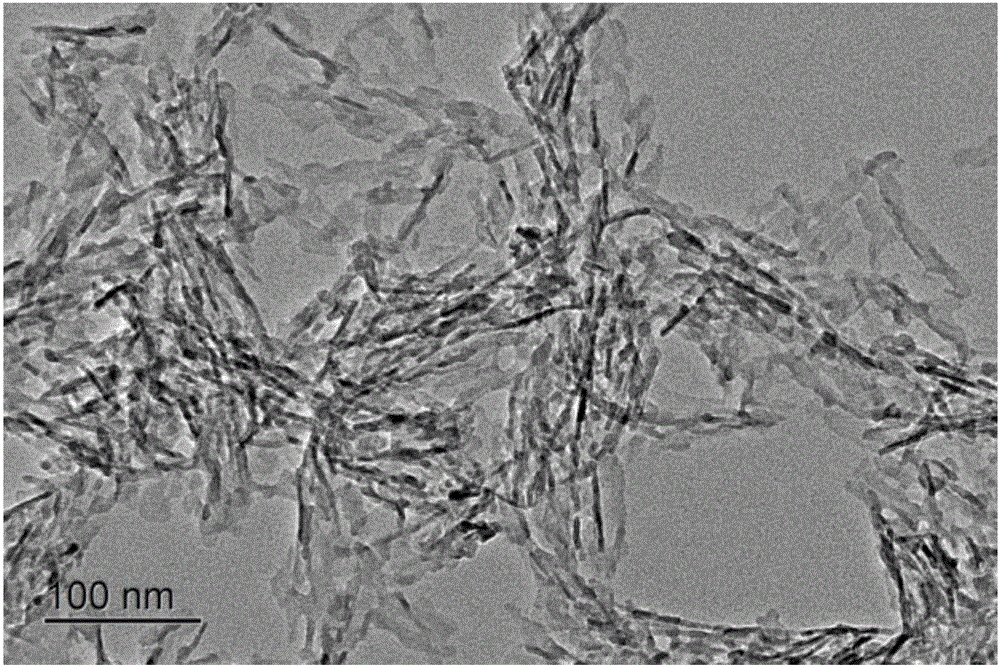

Simple and efficient preparation method of nano calcium phosphate

A nano-calcium phosphate, high-efficiency technology, applied in the field of biomedical materials, can solve the problems of difficult control of the nucleation and growth of calcium phosphate crystals, affect the yield of nano-calcium phosphate, and increase the production cost, so as to improve biocompatibility and benefit The effect of large-scale production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of simple and efficient preparation method of nanometer calcium phosphate, its steps are:

[0037] A. Preparation of calcium salt solution and phosphate solution:

[0038] Dissolve calcium nitrate tetrahydrate in deionized water to obtain calcium salt solution; ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) is dissolved in deionized water to obtain a phosphate solution;

[0039] B. Wet Synthesis of Nano Calcium Phosphate:

[0040] Under the action of magnetic stirring, add neridronate sodium into the calcium salt solution to dissolve neridronate sodium in the calcium salt solution; Reaction system, at the same time through the pH regulator - 0.1mol / L NH 4 OH solution, so that the pH value of the reaction system is 7.0; after the titration is completed, the mol ratio of calcium, neridronic acid sodium, and phosphorus in the reaction system is 0.5:0.01:1;

[0041] After the titration is completed, continue to stir for 30 minutes, and pass the pH regulator—0.1mo...

Embodiment 2

[0045] A kind of simple and efficient preparation method of nanometer calcium phosphate, its steps are:

[0046] A. Preparation of calcium salt solution and phosphate solution:

[0047] Dissolve calcium nitrate tetrahydrate in deionized water to obtain calcium salt solution; ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) is dissolved in deionized water to obtain a phosphate solution;

[0048] B. Wet Synthesis of Nano Calcium Phosphate:

[0049] Under the action of magnetic stirring, sodium opadronate is added to the calcium salt solution to dissolve sodium opadronate in the calcium salt solution; then, at a temperature of 37°C, the phosphate solution is dropped into the calcium salt solution to form Reaction system, at the same time through the pH regulator - 0.1mol / L NH 4 OH solution, so that the pH value of the reaction system is 8.0; after the titration is completed, the molar ratio of calcium, opadronate sodium, and phosphorus in the reaction system is 1:0.01:1;

[0...

Embodiment 3

[0054] A kind of simple and efficient preparation method of nanometer calcium phosphate, its steps are:

[0055] A. Preparation of calcium salt solution and phosphate solution:

[0056] Calcium nitrate tetrahydrate was dissolved in deionized water to obtain a calcium salt solution; disodium hydrogen phosphate (Na 2 HPO 4 ) is dissolved in deionized water to obtain a phosphate solution;

[0057] B. Wet Synthesis of Nano Calcium Phosphate:

[0058] Under the action of magnetic stirring, add alendronate sodium to the calcium salt solution to dissolve alendronate sodium in the calcium salt solution; then, at a temperature of 37°C, drop the phosphate solution into the calcium salt solution to form Reaction system, at the same time through the pH regulator - 1.0mol / L NH 4 OH solution, so that the pH value of the reaction system is 11.0; after the titration is completed, the molar ratio of calcium, sodium alendronate, and phosphorus in the reaction system is 1.67:0.02:1;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com