Tungsten-containing metal oxide nanoparticle dispersoid and preparation method thereof

A nanoparticle and oxide technology, applied in chemical instruments and methods, dyed organosilicon compound treatment, dyed low-molecular-weight organic compound treatment, etc. The problems of uneven secondary particle size and unstable dispersion quality can achieve the effect of narrow secondary particle size distribution, simple and easy operation method, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

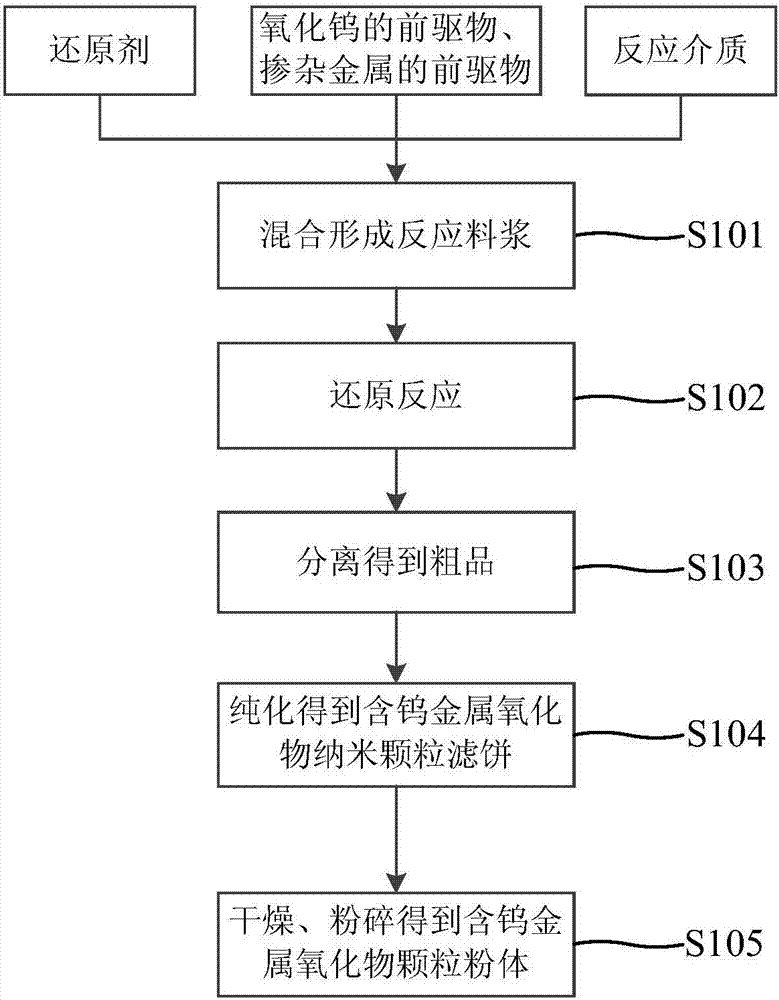

[0049] Please refer to figure 1 , the preparation method comprises the following steps:

[0050] Step S101: providing a precursor of tungsten oxide and a precursor of doped metal, wherein the doped metal is selected from one or more of group IA-VA metals and transition metals.

[0051] In one embodiment, the precursors of tungsten oxide include but are not limited to ammonium metatungstate, ammonium orthotungstate, ammonium paratungstate, tungstic acid, tungsten silicide, tungsten sulfide, tungsten oxychloride, tungsten hexachloride, tungsten tetrachloride , tungsten bromide, tungsten fluoride, tungsten carbide, tungsten oxycarbide, the aforementioned substances can also be used in combination, preferably ammonium metatungstate, ammonium orthotungstate, ammonium paratungstate, tungstic acid.

[0052] In one embodiment, doping metals include but are not limited to lithium, sodium, potassium, rubidium, cesium, aluminum, indium, gallium, tin, manganese, iron, cobalt, nickel, Co...

Embodiment 1

[0140] Add 200g of tungstic acid, 113g of cesium hydroxide, 833g of citric acid, and 50g of aspartic acid into a mixture of 1067mL of water and 267mL of ethanol to form a reaction slurry, which is reacted in a high-pressure reactor capable of raising and controlling temperature , under stirring, at a rate of 3°C / min, the temperature was gradually raised to 300°C, and kept at this temperature for 12 hours, and then forced to cool down to room temperature. Then take out the slurry, centrifuge the slurry to remove impurity ions in the slurry; disperse the obtained filter cake in 500mL water, and then centrifuge; redisperse the obtained filter cake in 500mL ethanol, then centrifuge and wash with ethanol The process is carried out twice, and the obtained filter cake can be directly dried and crushed to obtain a dry powder product.

[0141] Please refer to Figure 7 , using a scanning electron microscope (SEM) to observe the morphology and structure of the nanoparticle, it can be s...

Embodiment 2

[0149] 200g tungstic acid, 113g cesium hydroxide, 551g citric acid, 11.5g sodium borohydride (NaBH4 ), was added to a mixture of 1067mL water and 267mL ethanol, or 1334mL water to form a reaction slurry, which was reacted in a high-pressure reactor capable of raising temperature and controlling temperature, and was stirred at 3°C / min Gradually raise the temperature to 300°C, keep it at this temperature for 12 hours, and then forcefully cool it down to room temperature. Then take out the slurry, centrifuge the slurry to remove impurity ions in the slurry; disperse the obtained filter cake in 500mL water, and then centrifuge; redisperse the obtained filter cake in 500mL ethanol, then centrifuge and wash with ethanol The process is carried out twice, and the obtained filter cake can be directly dried and crushed to obtain a dry powder product.

[0150] The resulting nanoparticles are cesium-containing tungsten oxide crystals with the molecular formula Cs 0.3 WO 3 , the crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com