Patents

Literature

142 results about "Tungsten hexachloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten hexachloride is the chemical compound of tungsten and chlorine with the formula WCl₆. This dark violet blue species exists as a volatile solid under standard conditions. It is an important starting reagent in the preparation of tungsten compounds. Other examples of charge-neutral hexachlorides are ReCl₆ and MoCl₆. The highly volatile WF₆ is also known.

Preparation method of WO3 nano-sheet array

ActiveCN107117831AImprove photoelectrochemical performanceSimple and fast operationTungsten oxides/hydroxidesFibre treatmentSolventOxygen

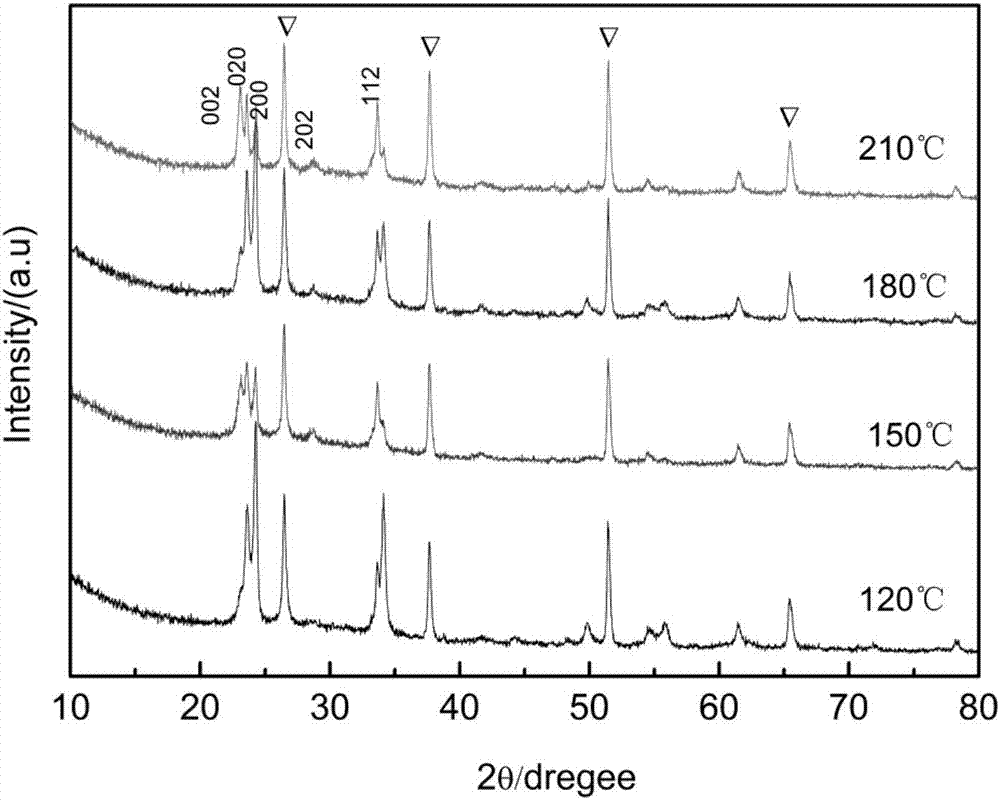

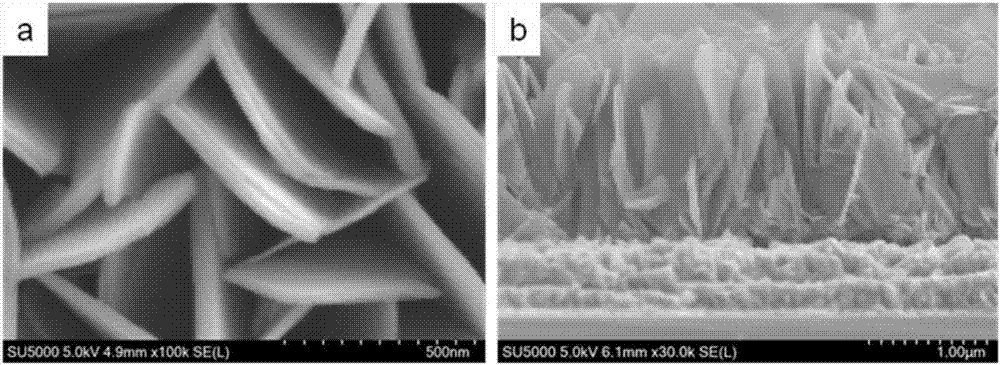

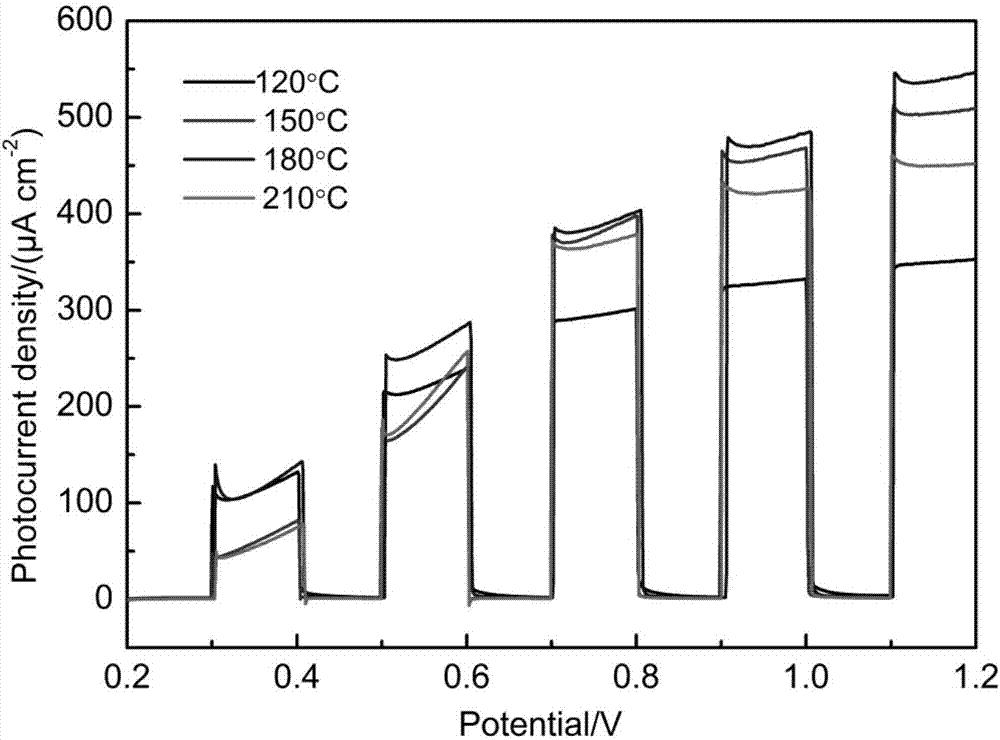

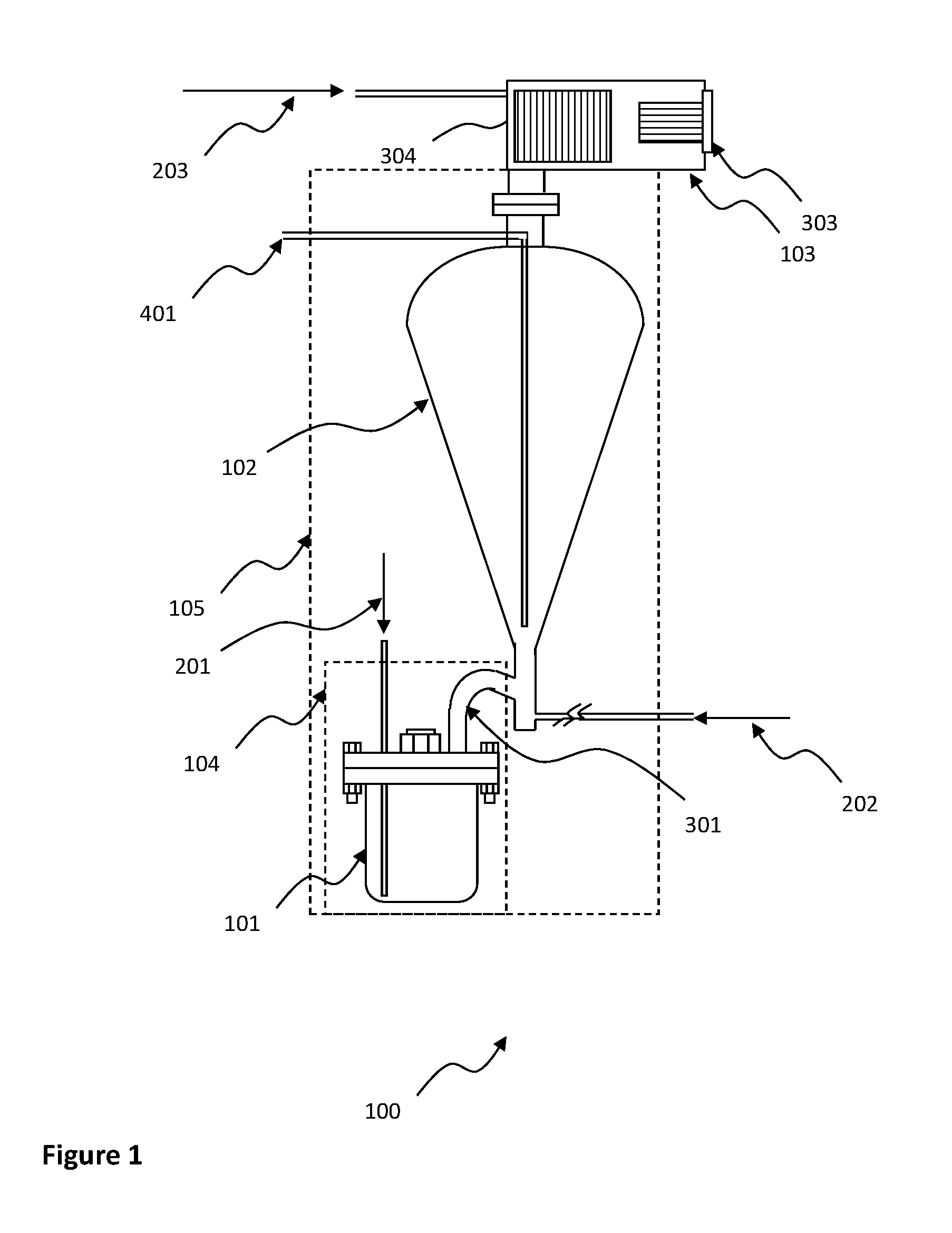

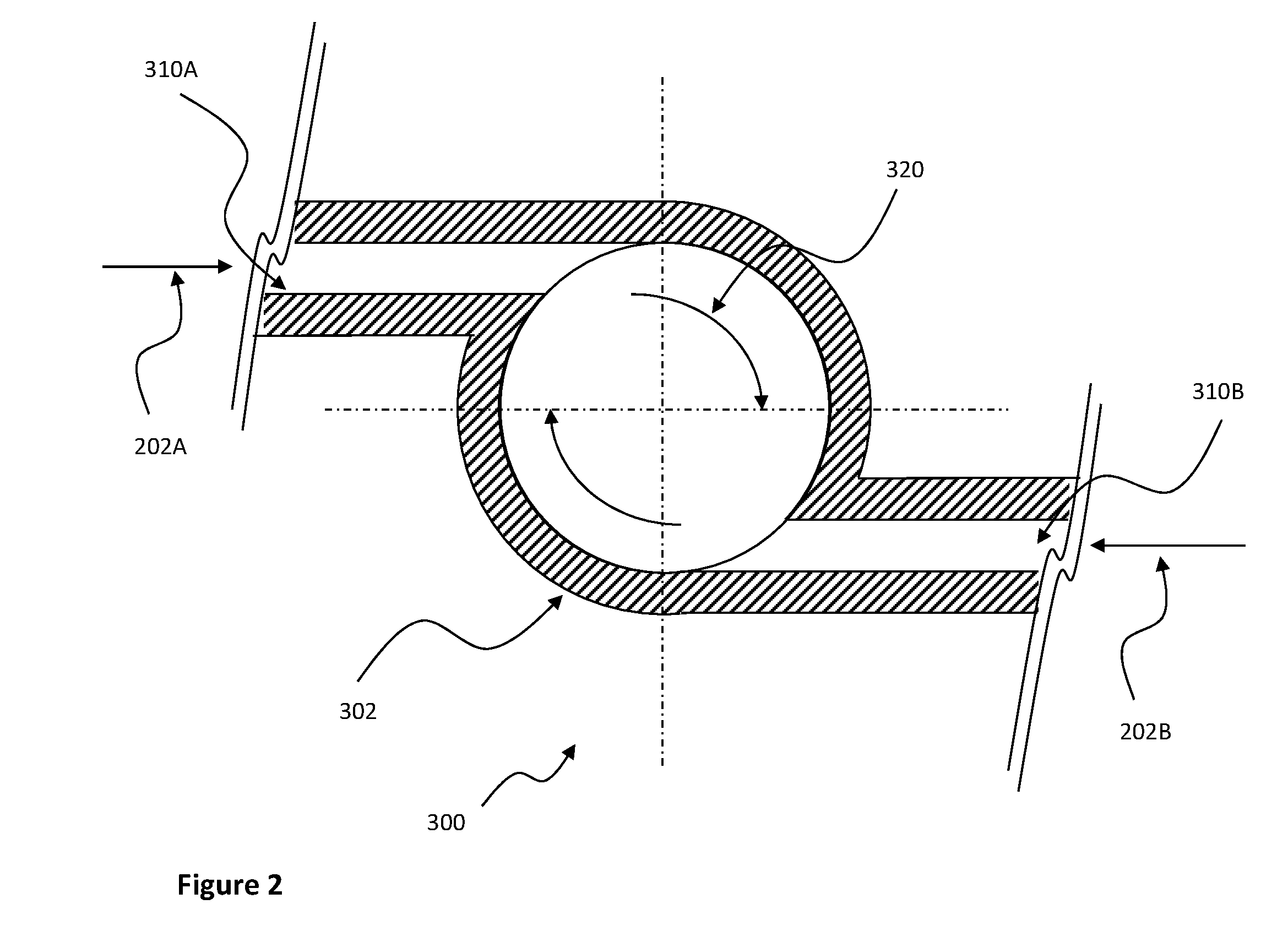

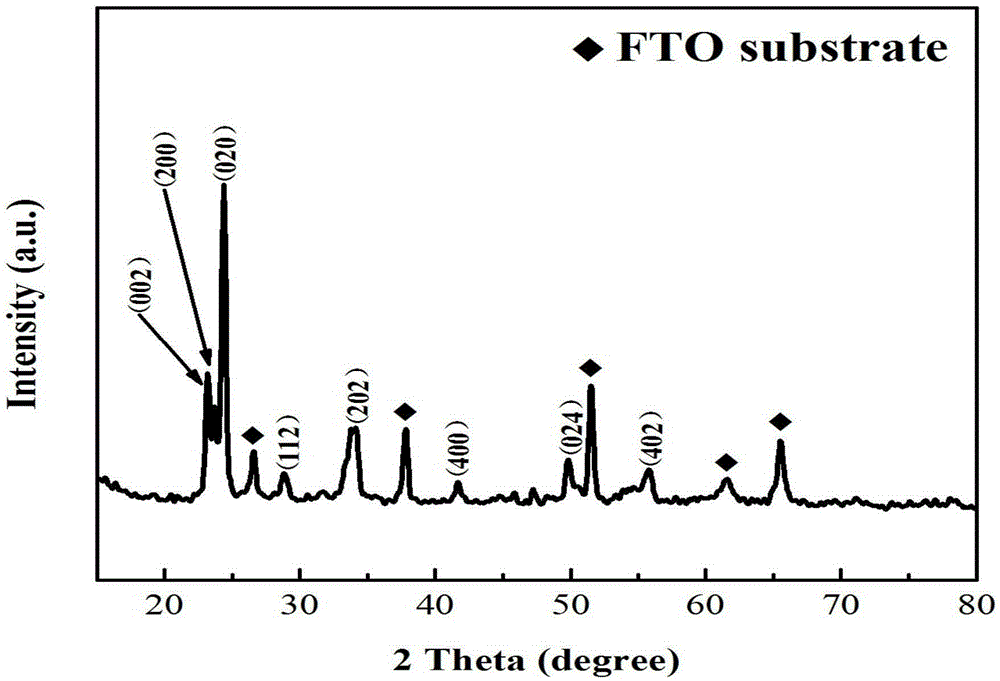

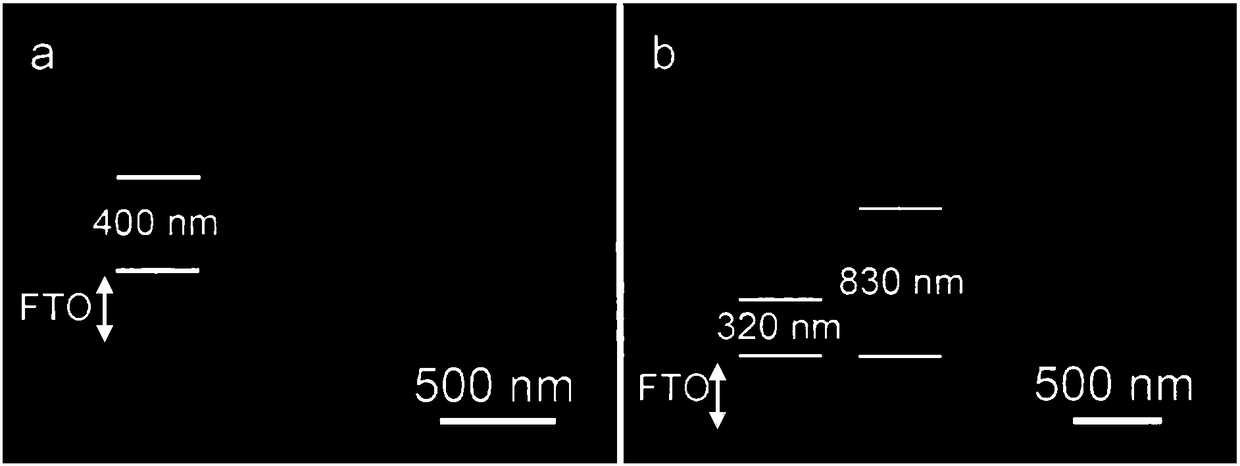

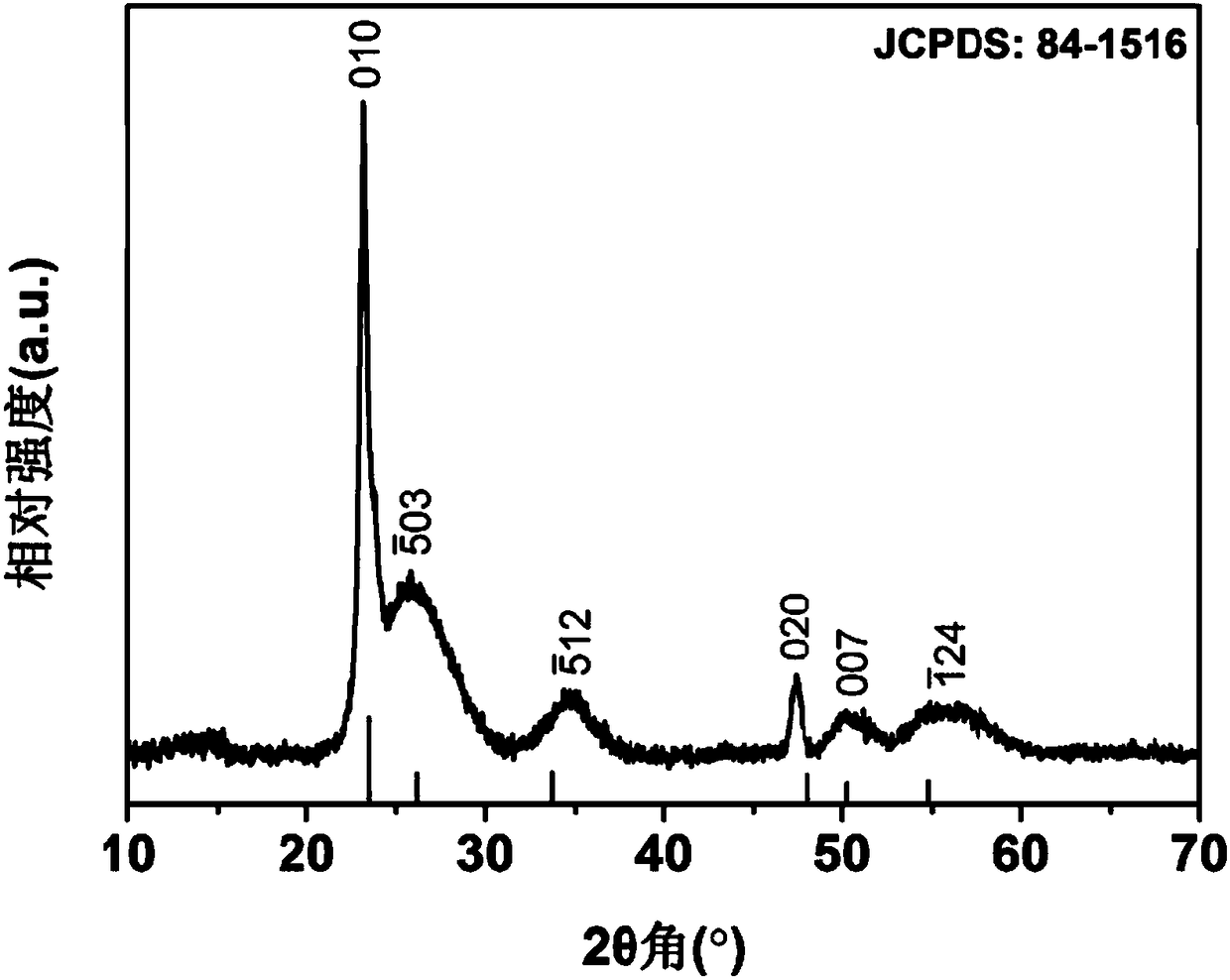

The invention discloses a preparation method of a WO3 nano-sheet array. The preparation method comprises the following steps: firstly, growing WO3-x.H2O nano-sheet array thin films with oxygen defects on surfaces of FTO (Fluorine-doped Tin Oxide), carbon cloth and a silicon wafer through an oxalic acid, ethanol and tungsten hexachloride solvent-thermal method; calcining in a muffle furnace at certain temperature to obtain the WO3 nano-sheet array with a relatively good crystallization property. WO3 prepared on a substrate represents a regular and vertically aligned nano-sheet array, so that the specific surface area of the WO3 nano-sheet array is greatly improved; the light current of a WO3 nano-sheet reaches 0.8mA / cm<2> in 0.5ml / L of Na2SO4 electrolyte under 0.7 sunlight light intensity and bias voltage of 1.2V. The method disclosed by the invention is simple and convenient to operate and easy to control; a WO3 nano-sheet array thin film prepared by the method has a large specific surface area and high photoelectric chemical activity and stability.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

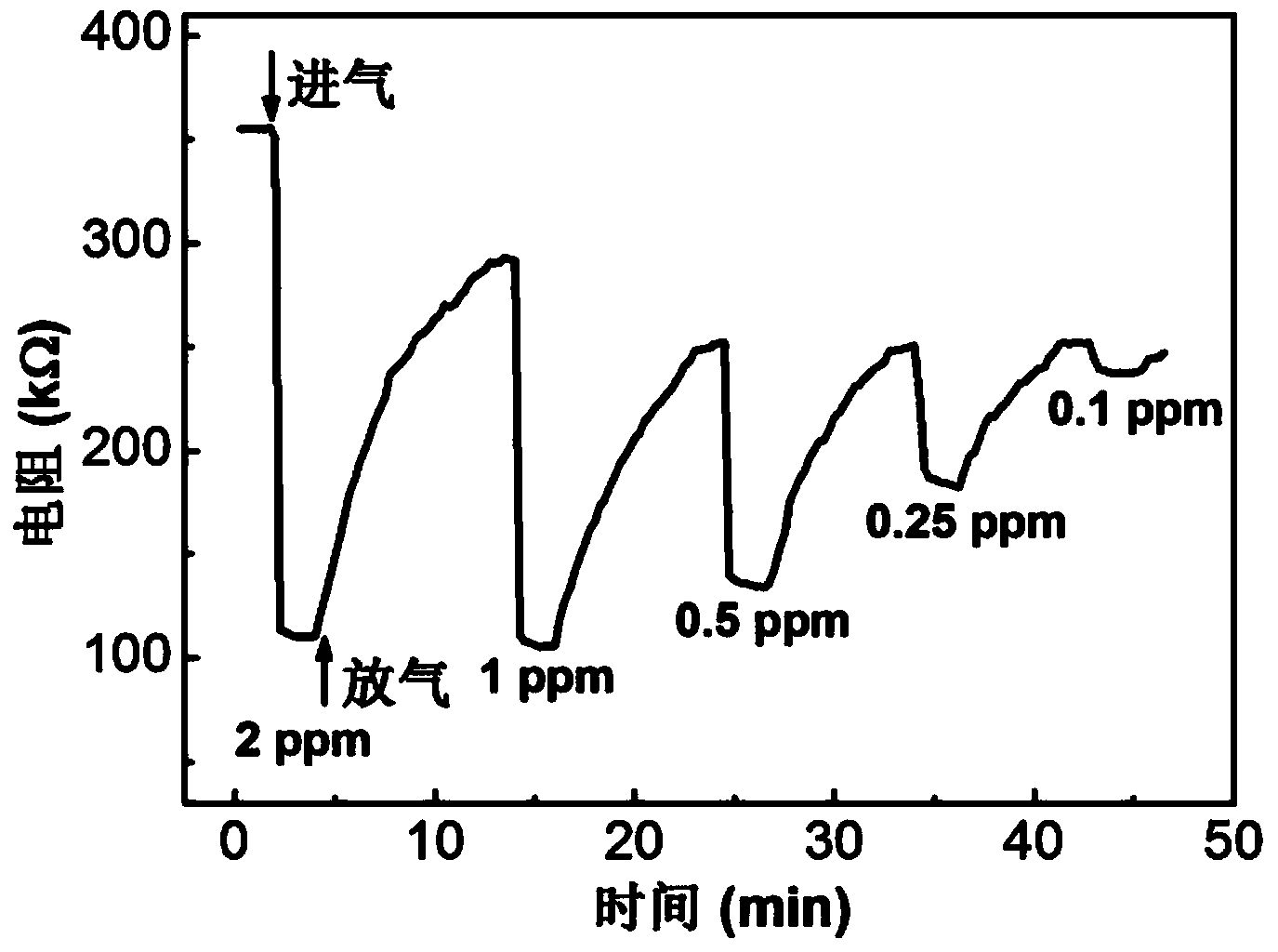

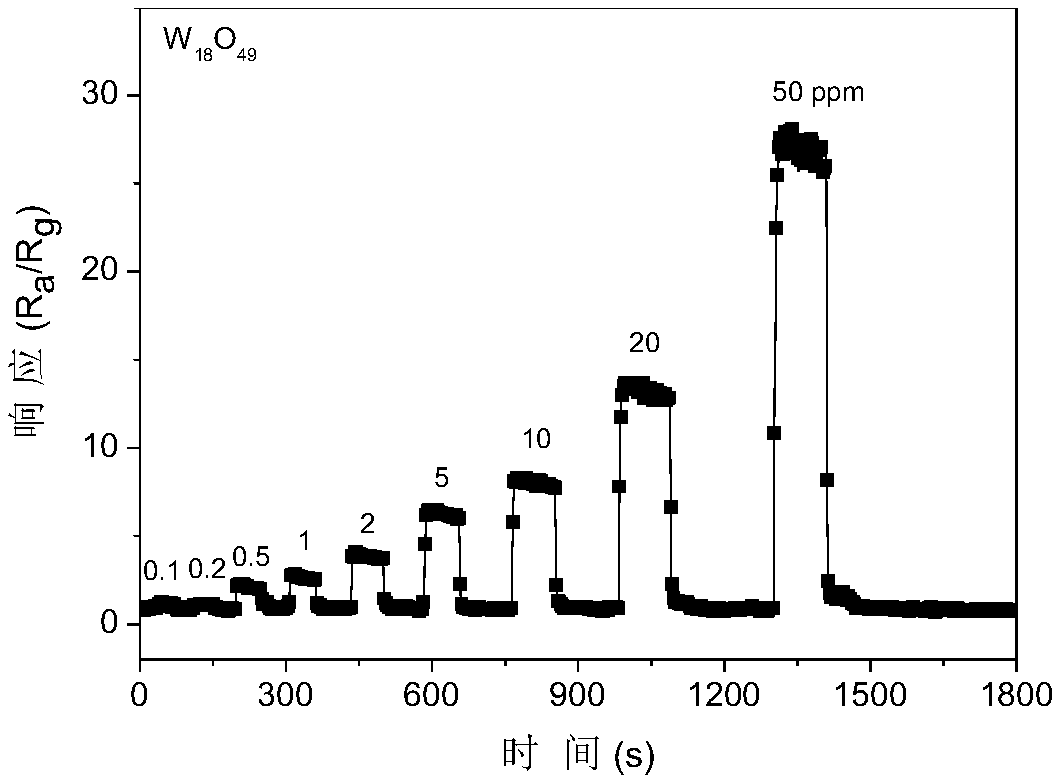

Preparation method of nitrogen oxide sensor component based on WO3 single-crystal particle

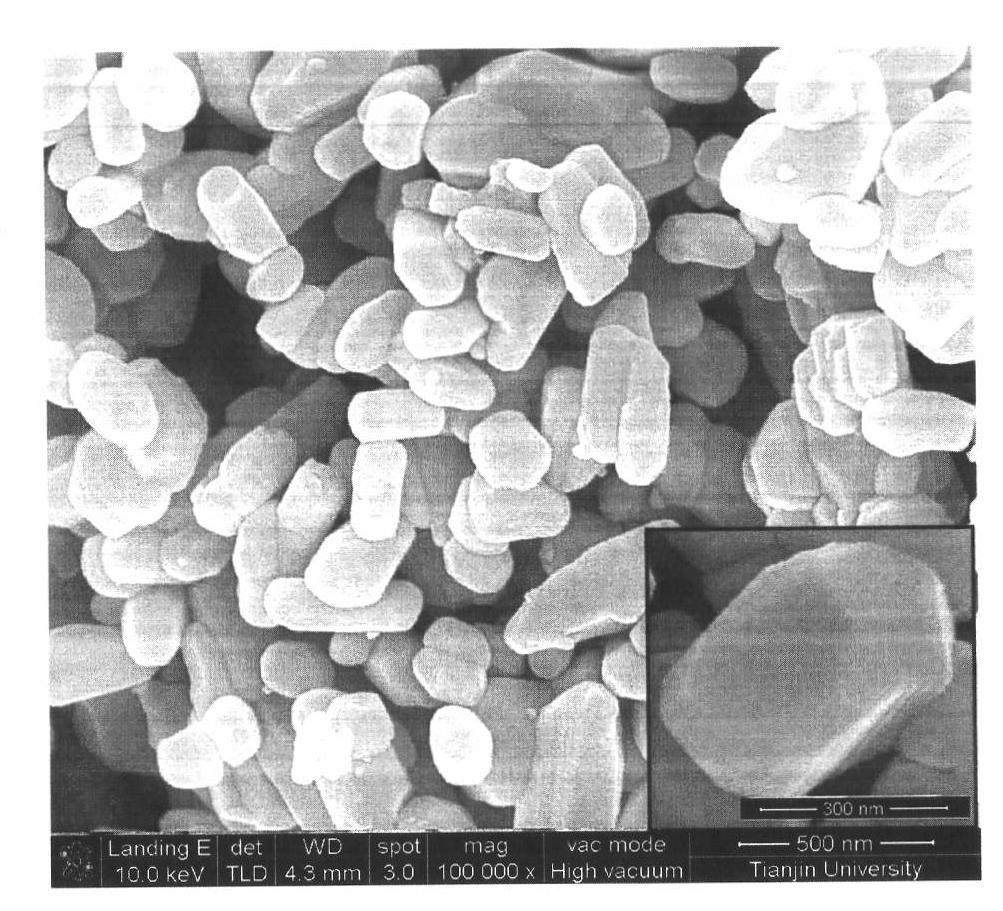

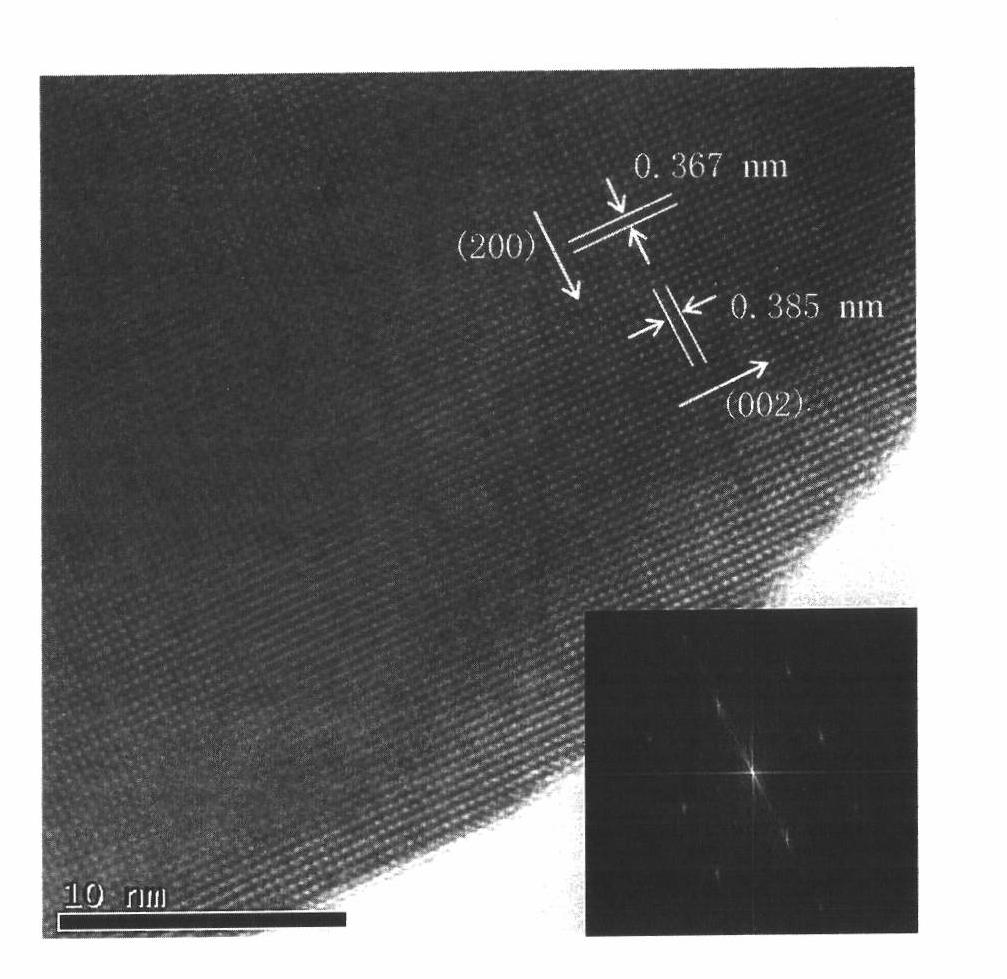

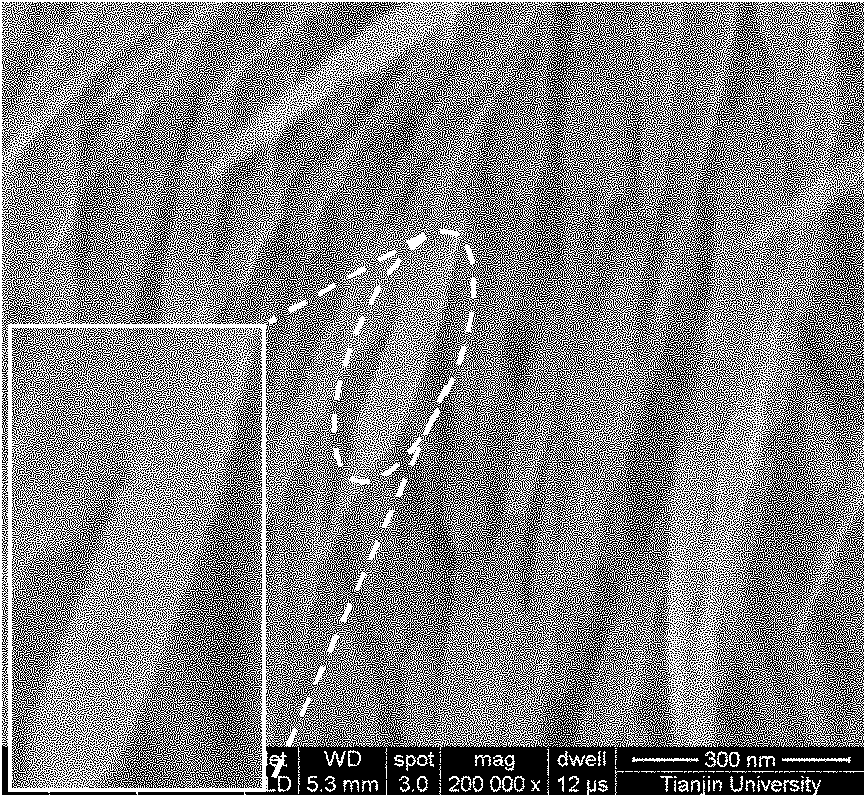

InactiveCN102495109AComplete structureHigh degree of crystallizationMaterial resistanceNanowireSingle crystal

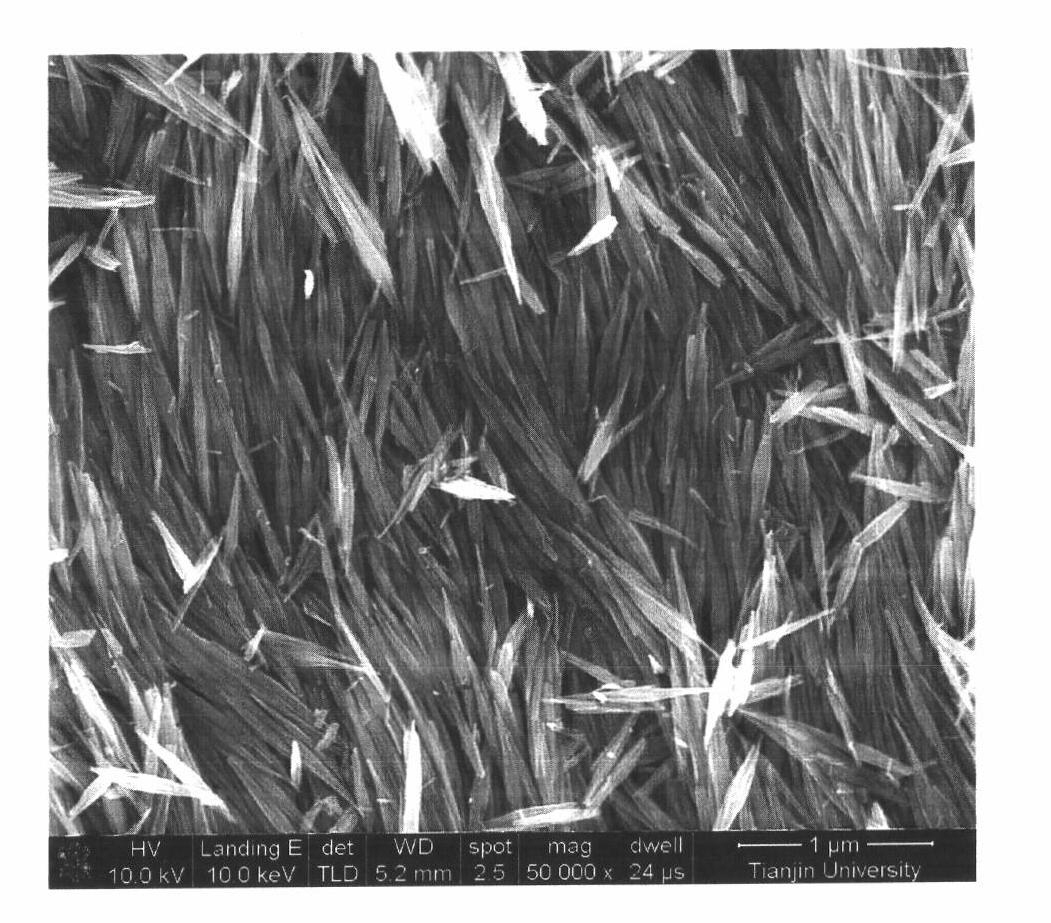

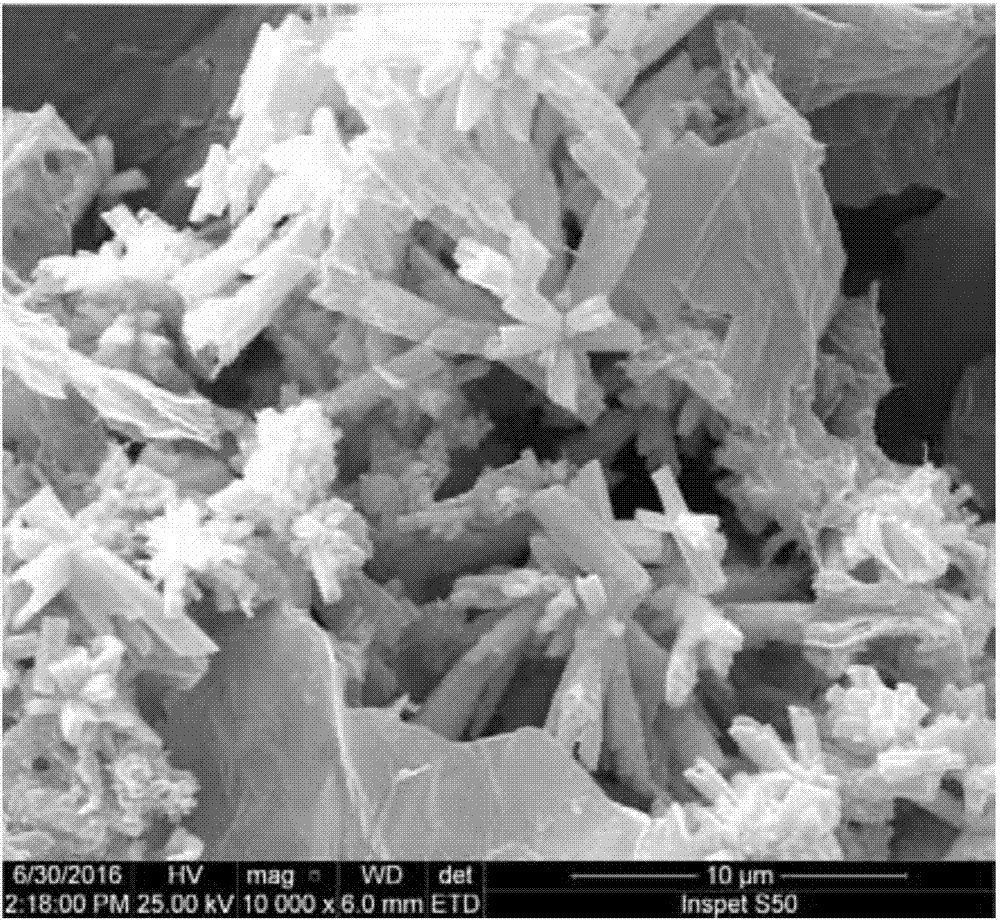

The invention discloses a preparation method of a nitrogen oxide sensor component based on WO3 single-crystal particles, which comprises: (1) preparing tungsten hexachloride solution; (2) adjusting the molar concentration of tungsten hexachloride to be 0.003-0.014M; (3) synthesizing quasi-oriented tungsten oxide nanowires; (4) preparing nanowire-based sensitive slurry; and (5) preparing the nitrogen oxide sensor component based on the WO3 single-crystal particles. The prepared WO3 single crystal has a pure single inclined-phase structure, and the single-crystal particles have a complete structure, a high degree of crystallization, a clear crystal face and regular morphology. By adopting the gas sensor based on the single-crystal tungsten trioxide material, high-sensitivity and high-selectivity rapid response can be realized for NO2 at the level of ppm to ppb.

Owner:TIANJIN UNIV

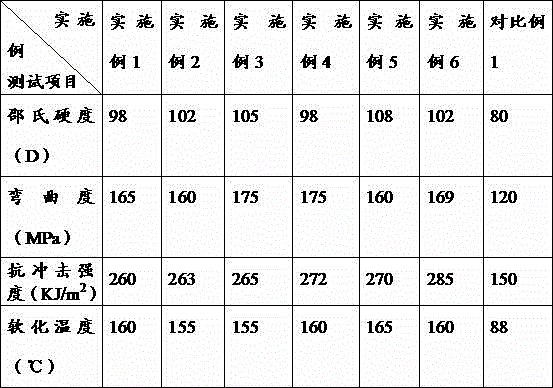

High-performance fiberglass reinforced plastic composite material and preparation method thereof

The invention provides a high-performance fiberglass reinforced plastic composite material and a preparation method thereof. The high-performance fiberglass reinforced plastic composite material consists of the following components in percentage by weight: 50 to 80 percent of dicyclopentadiene, 10 to 30 percent of hydrogen peroxide, 1 to 3 percent of potassium oxide, 0.1 to 0.5 percent of tungsten hexachloride, 1 to 5 percent of fire retardant, 2 to 4 percent of nano filler, 1 to 8 percent of glass fiber and 1 to 3 percent of metal filler. Hydrogen peroxide, fire retardant and potassium oxide are added into dicyclopentadiene, so that the softening temperature of the fiberglass reinforced plastic composite material can be increased and is more than 150 DGE C.

Owner:高金技术产业集团有限公司

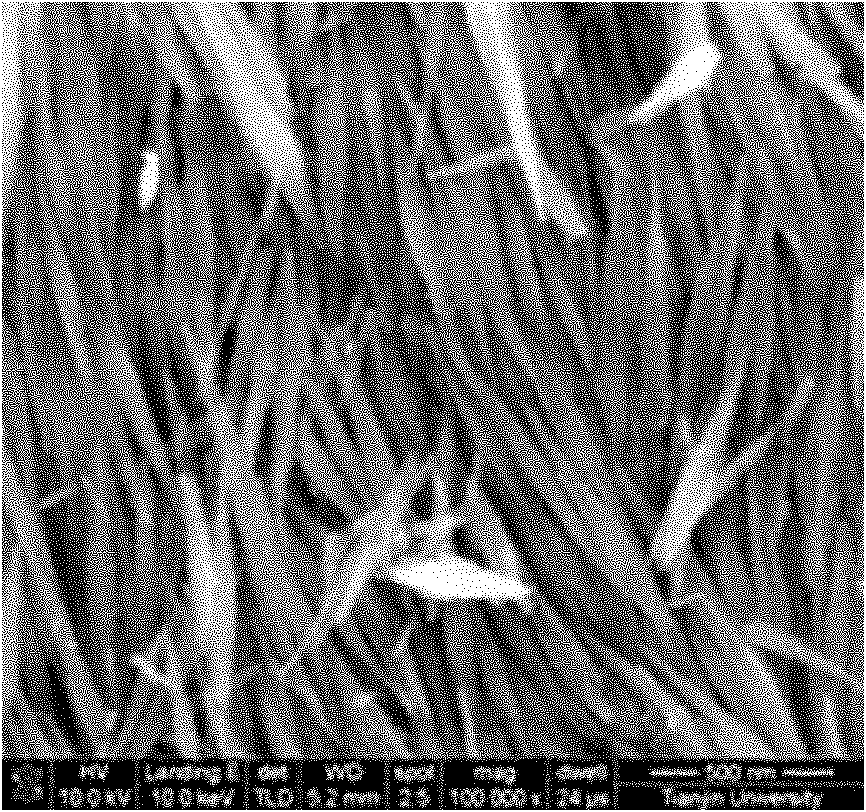

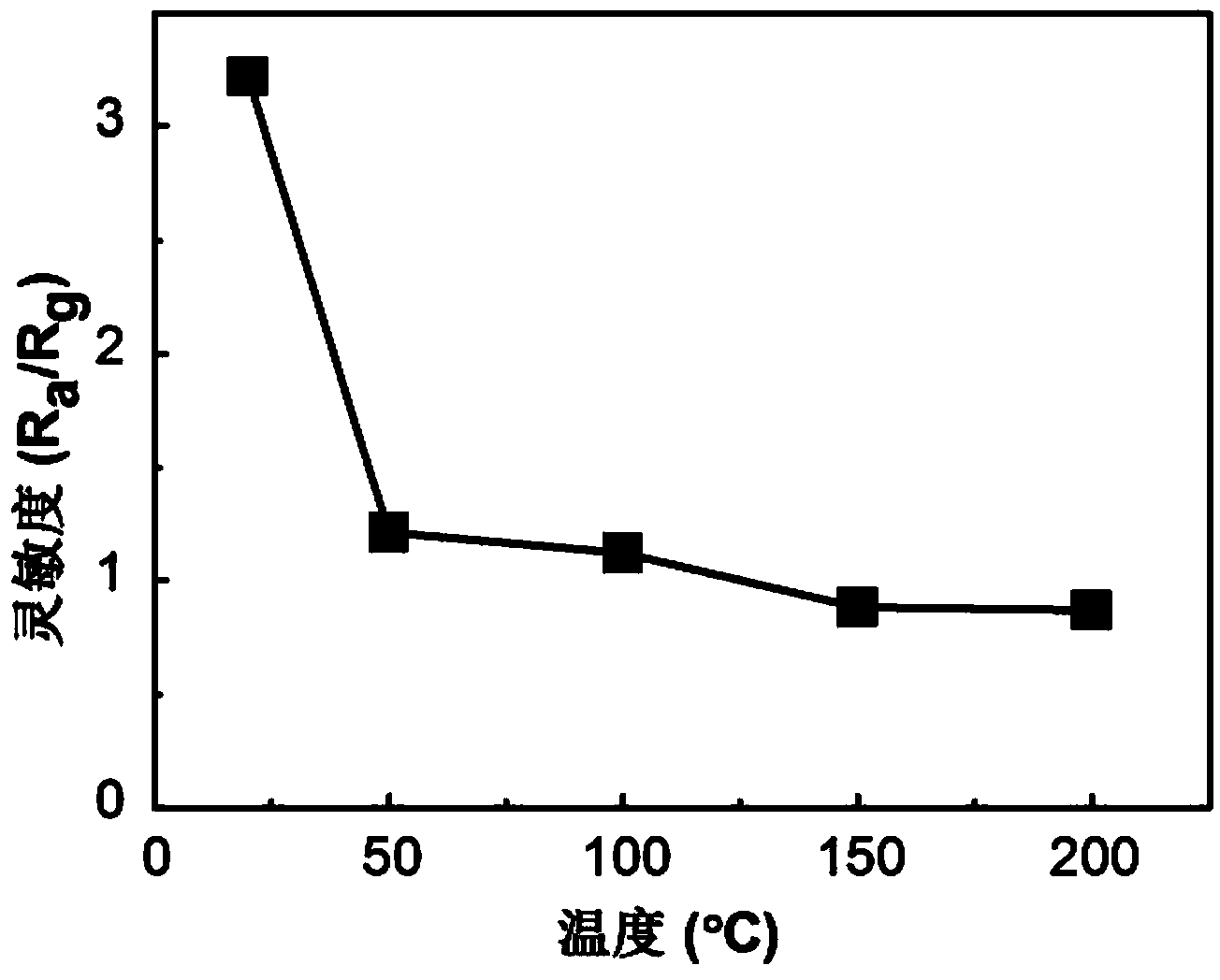

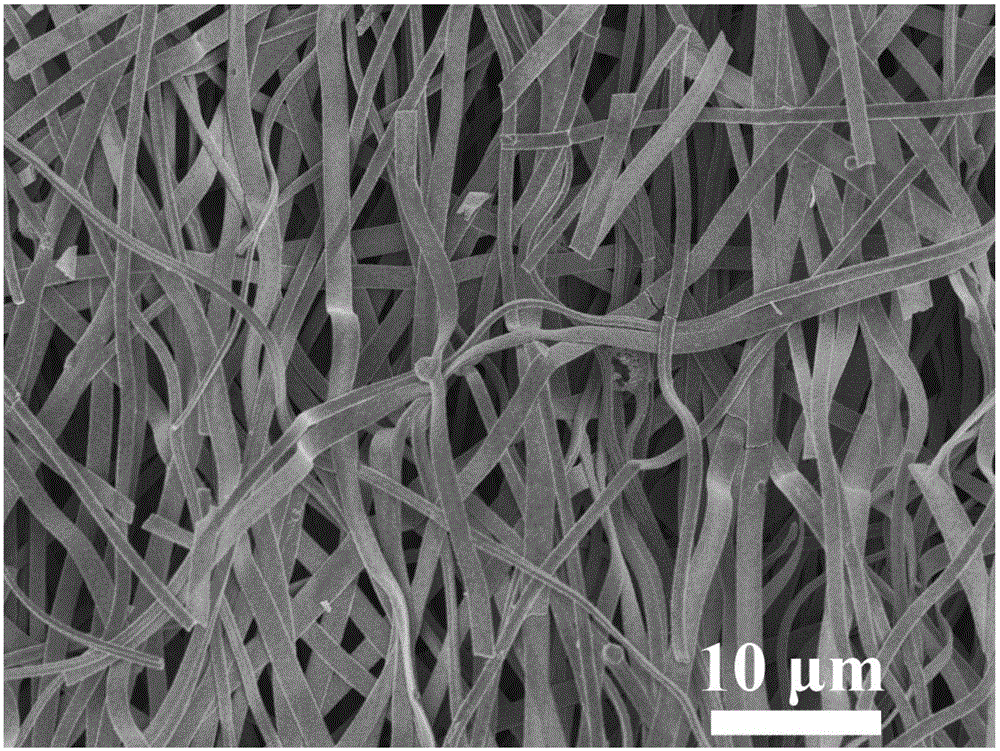

Preparation method of nitric oxide gas sensor element based on pseudodirected tungsten trioxide nano tape

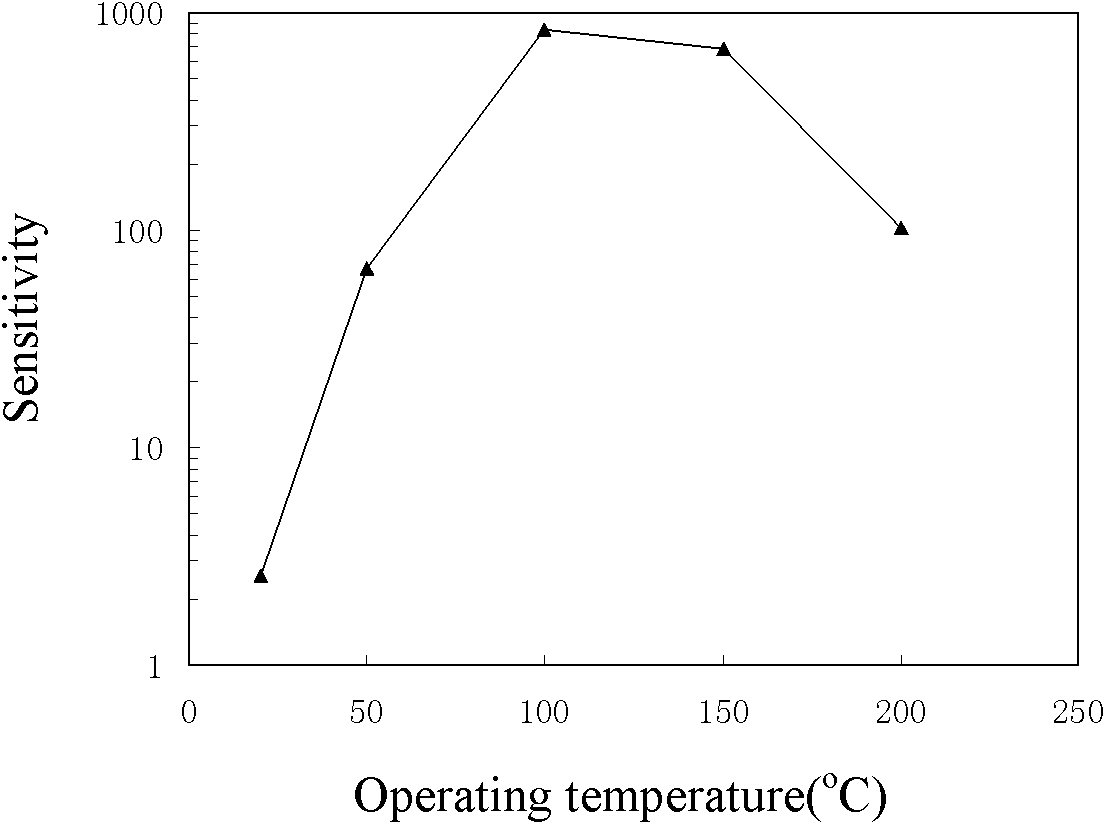

InactiveCN102012386ALower working temperatureReduce power consumptionMaterial resistanceNitrogen oxidesWorking temperature

The invention discloses a preparation method of a nitric oxide gas sensor element based on a pseudodirected tungsten trioxide nano tape, which comprises the steps of: 1, preparing a tungsten hexachloride solution; 2, regulating the mol concentration of tungsten hexachloride to be 0.003-0.012M; 3, synthesizing a pseudodirected tungsten oxide nano wire; 4, preparing a pseudodirected tungsten oxide nano wire; 5, preparing a sensitive material slurry; and 6, preparing the sensor element based on the pseudodirected tungsten trioxide nano tape. The sensor element based on the pseudodirected tungsten trioxide nano tape, prepared by using the method, has the advantages of high sensitivity, high selectivity, low working temperature and low power consumption for the low-concentration nitric oxide gas detection.

Owner:TIANJIN UNIV

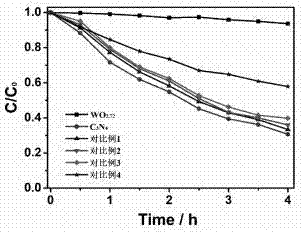

Oxygen-vacancy tungsten oxide/carbon nitride composite photocatalyst and preparation method and application thereof

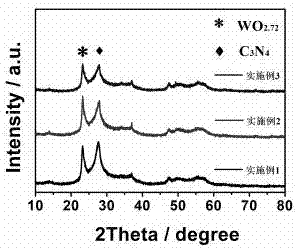

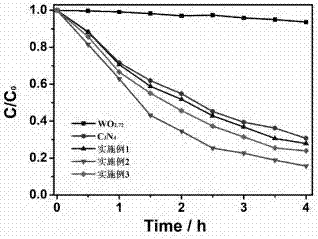

InactiveCN107999110AImprove photocatalytic activityWide band gapPhysical/chemical process catalystsWater/sewage treatment by irradiationProtonationPhotocatalytic reaction

The invention relates to an oxygen-vacancy tungsten oxide / carbon nitride composite photocatalyst and a preparation method and application thereof. The preparation method of the composite photocatalystcomprises the following steps of: S1, adding carbon nitride powder in a hydrochloric acid solution for protonation treatment, performing continuous stirring, and then conducting filtration, washing and drying; S2, dispersing the protonated carbon nitride powder in anhydrous ethanol or water for ultrasonic treatment, and then adding tungsten hexachloride for a hydrothermal reaction; and S3, collecting the product of the hydrothermal reaction, and performing washing, drying and grinding to obtain the oxygen-vacancy tungsten oxide / carbon nitride composite photocatalyst. According to the oxygen-vacancy tungsten oxide / carbon nitride composite photocatalyst and the preparation method and application thereof, doping treatment is performed on carbon dioxide by adopting oxygen-vacancy WO2.72 as adoping semiconductor, more active sites can be provided by the oxygen-vacancy structure of the tungsten oxide in a photocatalytic reaction, and meanwhile the oxygen-vacancy tungsten oxide / carbon nitride (WO2.72 / C3N4) composite material has a larger energy gap and a wider range of response to sunlight.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

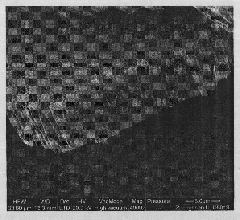

Method for preparing highly ordered tungsten trioxide nano-rod

The invention discloses a method for preparing a highly ordered tungsten trioxide nano-rod. The method comprises the following steps: mixing 0 to 50ml of deionized water and 0 to 50ml of 36.5-38 percent commercial concentrated hydrochloric acid to obtain mixed solution with total volume of 50ml; adding 0.2 to 4g of tungsten hexachloride into the mixed solution after the mixed solution is stirred for 5 minutes at normal temperature; moving the mixed solution to a 100ml high-temperature reaction kettle after the mixed solution is continuously stirred for 5 minutes; placing the conductive surface of clean conductive glass upwards in the high-temperature reaction kettle; placing the high-temperature reaction kettle in a thermostatic drying oven to perform a hydro-thermal reaction for 4 to 20 hours at constant temperature between 100 and 180 DEG C, naturally cooling the high-temperature reaction kettle; and taking the conductive glass out of the high-temperature reaction kettle, and drying the conductive glass in the drying oven after the conductive glass is washed by the deionized water. The method has the advantages of simple process and good repeatability, and the prepared tungsten trioxide nano-rod has the diameter between 80 and 100 nanometers and the length between 3 and 6 microns.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

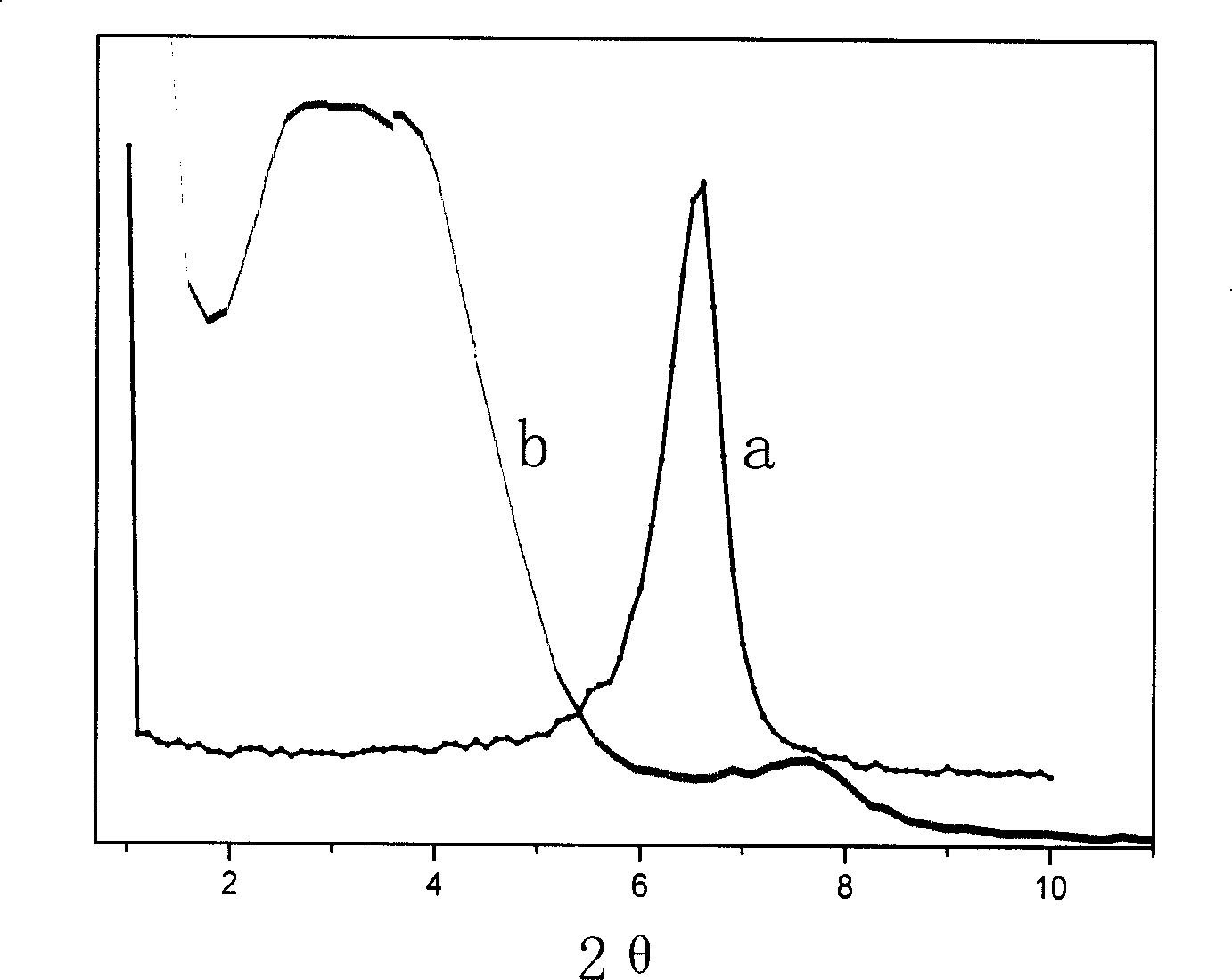

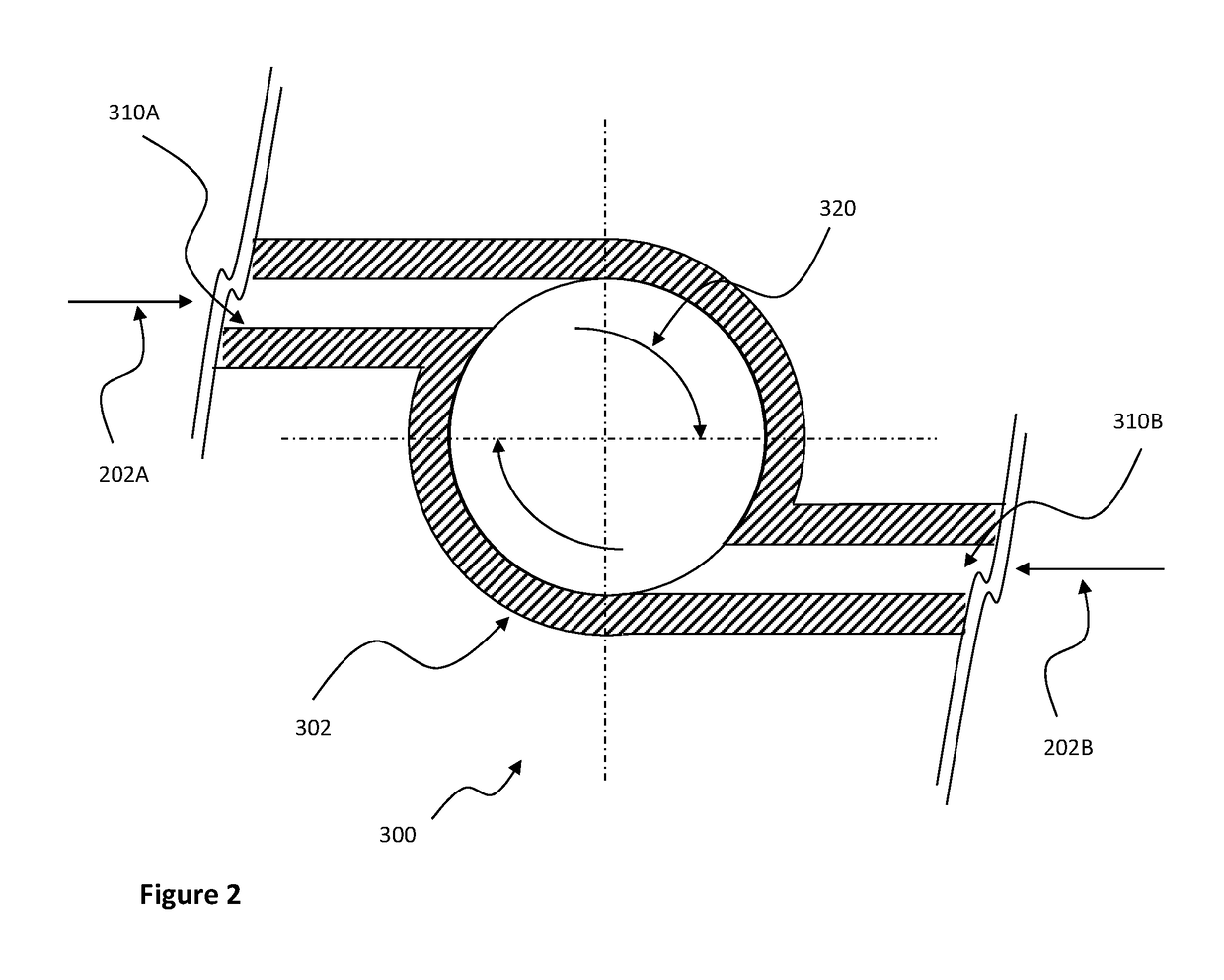

High purity tungsten hexachloride and method for making same

Condensable metal halide materials, such as but not limited to tungsten chloride (WCl6), can be used deposit films metal or metal containing films in a chemical vapor deposition (CVD) or atomic layer deposition process. Described herein are high purity compositions comprising condensable materials and methods to purify condensable materials. In one aspect, there is provided a composition comprising: tungsten hexachloride which is substantially free of at least one impurity and wherein the tungsten hexachloride comprises at least 90%, preferably 95% and more preferably 99% by weight or greater of a β-WCl6 and 5% by weight or less of the α-WCl6 as measured by X-ray diffraction.

Owner:VERSUM MATERIALS US LLC

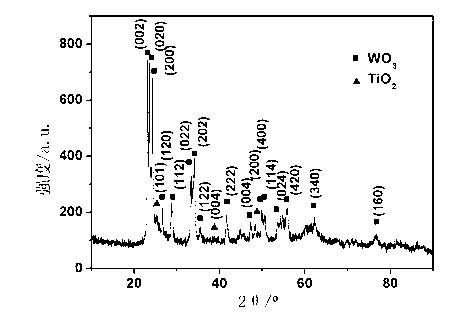

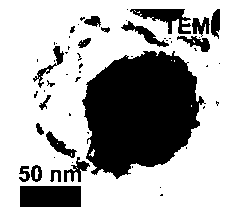

Method for preparing tungsten trioxide/titanium dioxide nanocomposite with core-shell structure

InactiveCN103191721AParticle size adjustmentControl photoelectricNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsDextrose waterMicrosphere

The invention discloses a method for preparing tungsten trioxide / titanium dioxide nanocomposite with a core-shell structure. The method comprises the following processes of: transferring a dextrose water solution to a sealed container, obtaining carbon microspheres by hydrothermal reaction, then dispersing and soaking the carbon microspheres into an ethanol mixed solution of titanium tetrachloride and tungsten hexachloride, separating, cleaning and drying to obtain the carbon microspheres of absorbing titanium ions and tungsten ions, and finally burning the carbon microspheres to obtain the tungsten trioxide / titanium dioxide nanocomposite with the core-shell structure. The method is simple in process, low in synthesis cost, free of poison, and easy for realization of industrial large-scale production; and the obtained tungsten trioxide / titanium dioxide nanocomposite with the core-shell structure is uniform in size and good in dispersibility, and has wide practical application value in the aspect of preparation of a photoelectric material or a photocatalytic material.

Owner:TIANJIN UNIV

Method for preparing tungsten trioxide film based room temperature gas sensor element

InactiveCN103512928AReduce duplicationLow repeatability and low power consumptionMaterial resistanceGas detectorMass ratio

The invention provides a method for preparing a tungsten trioxide film based room temperature gas sensor element, wherein a p-type monocrystalline silicon is taken as a substrate, platinum is taken as a target, and a platinum interdigital electrode is formed on a glazed surface of the silicon substrate through sputtering; then a sol-gel spin-coating method is used to deposit the tungsten trioxide film on the glazed surface of the silicon substrate with sputtered platinum interdigital electrode, wherein the precursor is a sol prepared from tungsten hexachloride and absolute ethyl alcohol at the mass ratio of (0.8-1):10; and then the product is put in a muffle furnace to be subjected to heat treatment. The invention provides the method for preparing the low-power-consumption and easy-in- silicon-substrate-integration tungsten trioxide film based gas sensor element, and the method can detect the low-concentration (0.1ppm) nitrogen dioxide gas at the room temperature and has the advantages of high sensitivity, rapid response / recovery, good selectivity and good repeatability.

Owner:TIANJIN UNIV

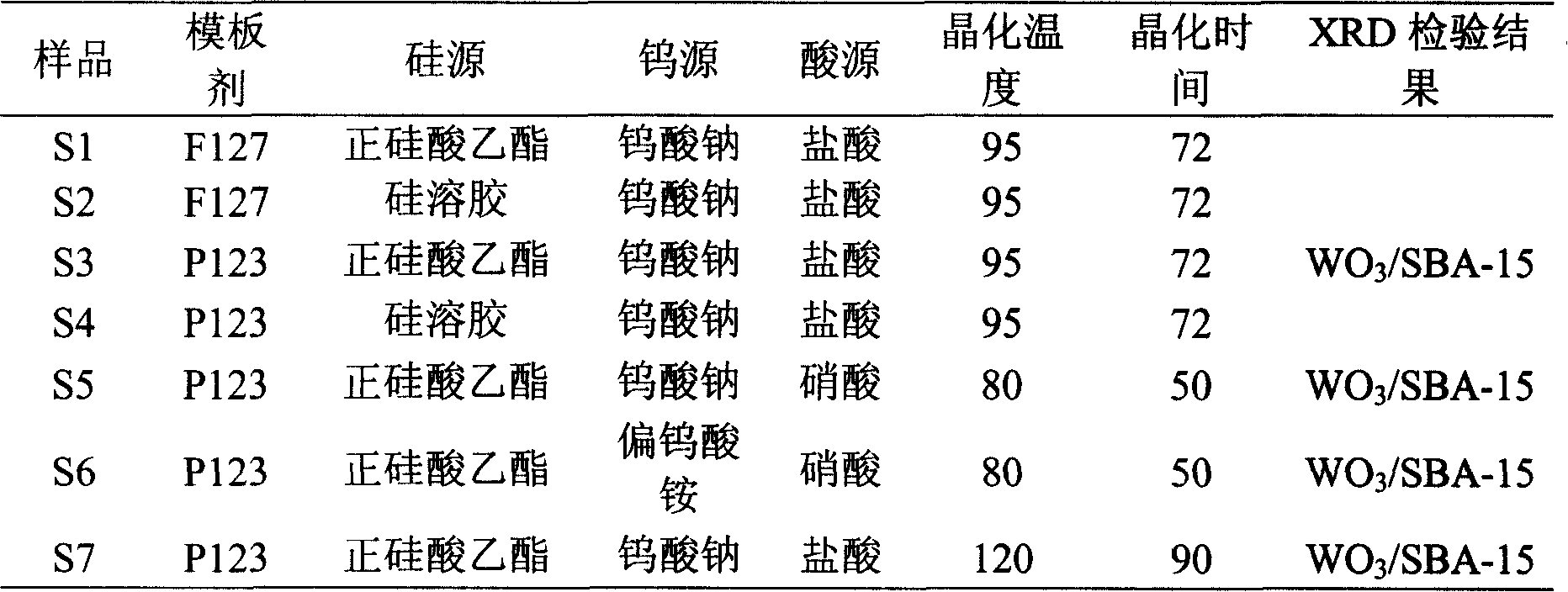

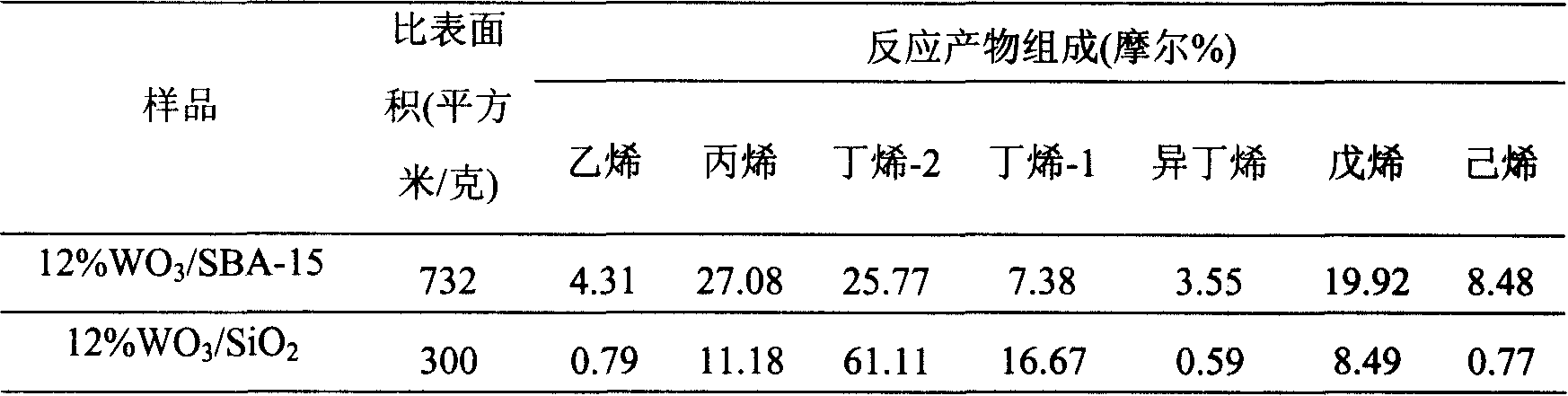

Method for preparing mesoporous WO3/SBA-15 molecular sieve

ActiveCN101172240AGood dispersionLarge specific surface areaMolecular sieve catalystsHydrocarbonsAmmonium paratungstateMesoporous silica

The invention relates to a preparation method of a meso-porous WO3SBA-15 molecular sieve, which mainly solves the problem of the former art that the synthetization of silica molecular sieve WO3SBA-15 including tungsten in the frame is not related. The invention adopts a three-block polymer of polyethylene-polypropylene glycol-polyethyleneglycol as template agent. Silica source selected from tetraethyl orthosilicate, silica sol, water glass or white carbon black is taken as a silica resource, ammonium metatungstate, ammonium paratungstate, sodium tungstate or tungsten hexachloride is taken as a tungsten source, the mole ratio of the raw materials is as follows: 1SiO2: 0.01 to 0.03M: 3 to 10H<+>:50 to 200H2O:0.03 to 0.25WO3, under the acidic condition, the crystallization temperature is 20 to 170 DEG C, and the WO3SBA-15 molecular sieve is obtained through hydrothermal crystallization for 6 to 120 hours. The invention can be used for the industrial production of olefin disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

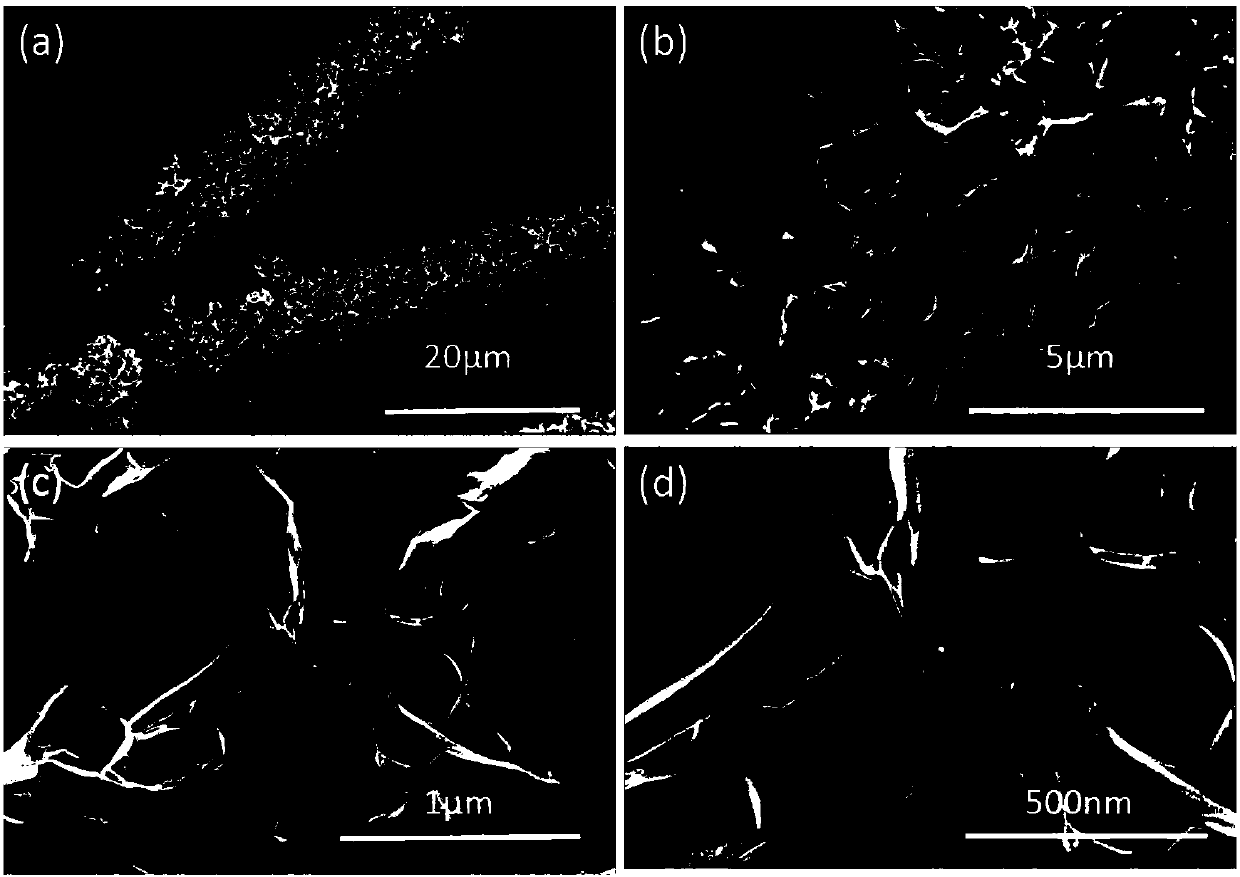

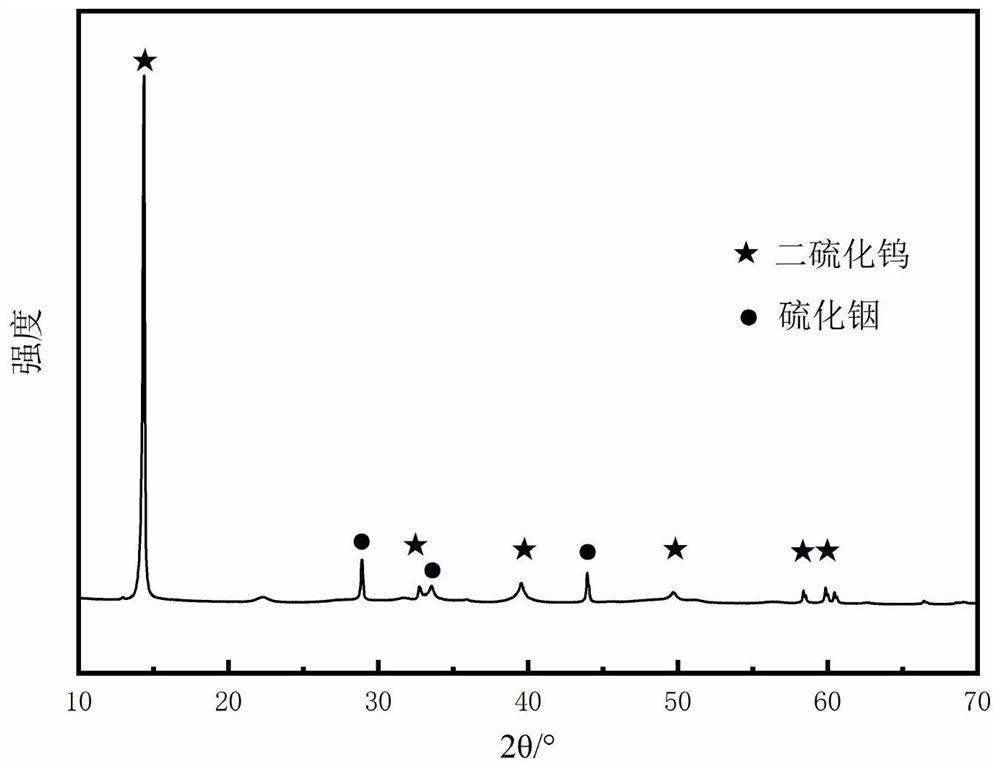

Preparation method of tungsten disulfide micron structure

InactiveCN102897841AUniform sizeReduce manufacturing costTungsten compoundsThioureaReaction temperature

The invention belongs to the manufacturing field of semiconductor micron materials and particularly relates to a preparation method of a tungsten disulfide micron structure. The preparation method is characterized in that the chemical vapor deposition (CVD) method is adopted, thiourea and tungsten hexachloride (WC16) are taken as reaction sources, and the structure is obtained in a vacuum state at 750-950 DEG C. According to the preparation method, the thiourea and WC16 are placed in a constant temperature area and a low temperature area respectively, the reaction temperature of the WC16 is maintained at 750-950 DEG C, the temperature difference between the WC16 and the thiourea is maintained at 50-150 DEG C, the saturated vapor pressure is reached simultaneously at a specific temperature by using the temperature difference, and steam is generated for reaction. The preparation method has the advantages of being simple and easy to implement, environment-friendly, non-toxic and even in product size; particularly the non-toxic thiourea is used as the S source, the production cost and toxicity of S sources such as H2S are reduced, and the preparation method is economical and environment-friendly.

Owner:ZHEJIANG ORIENT CRYSTAL OPTICS

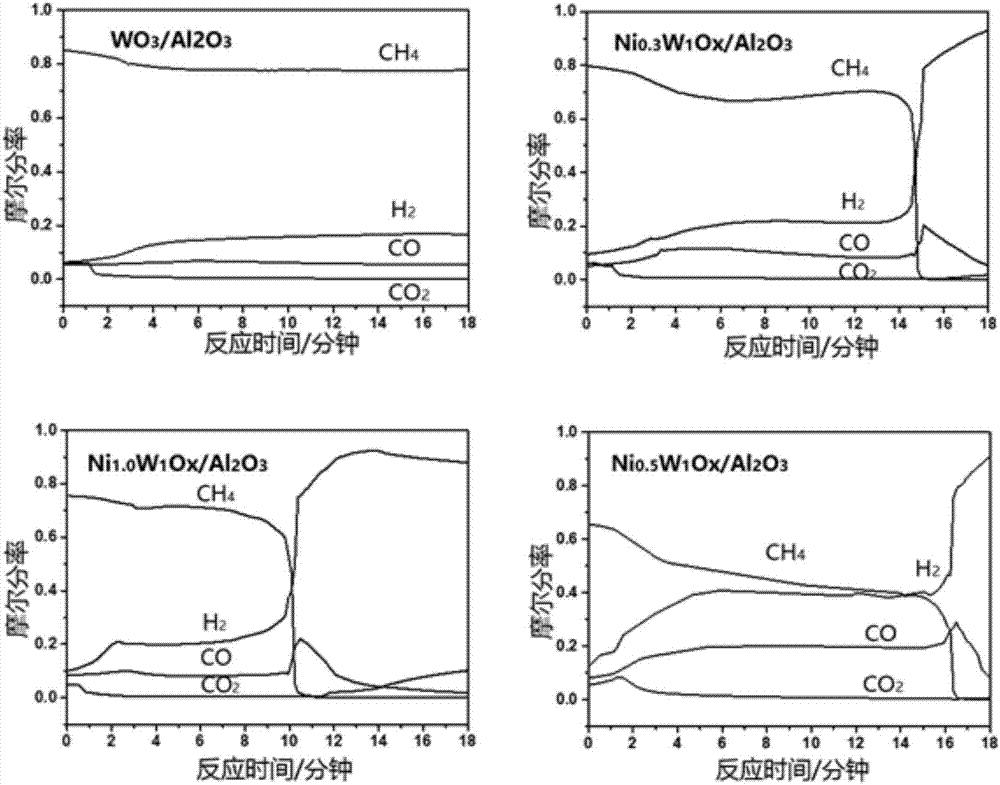

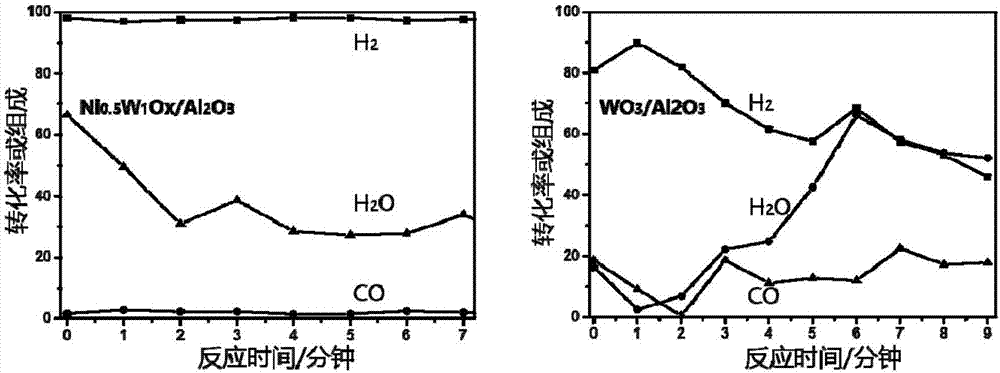

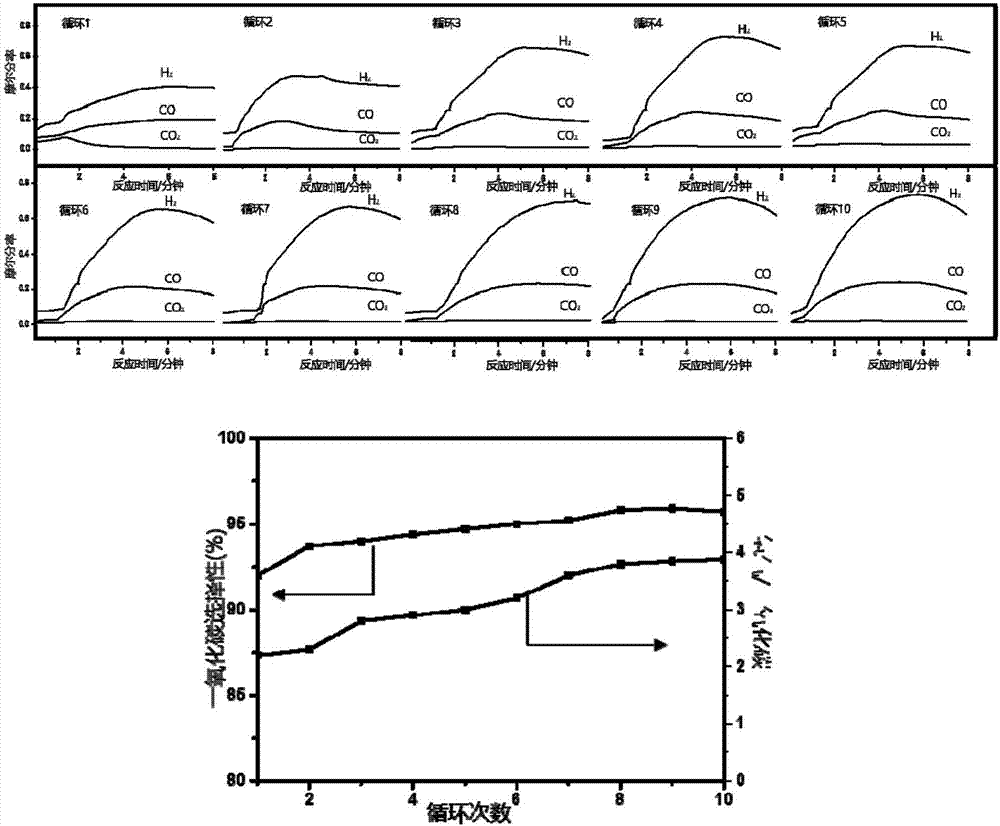

Supported nickel tungsten bimetallic composite oxide and preparation method and application thereof

The invention belongs to the technical field of chemical looping hydrogen, and discloses supported nickel tungsten bimetallic composite oxide and a preparation method and an application thereof. A molecular formula is NiyW1O3+y / Al2O3, y is 0.3-1; the preparation method comprises the following steps: completely mixing nickel nitrate hexahydrate, tungsten hexachloride and aluminum nitrate nonahydrate in ethanol according to proportion and then dissolving the materials; then dropping a NaOH aqueous solution and mixing with a mixture, after standing, performing centrifugal filtration on a flocculent precipitate and washing the material; and drying and roasting the material to obtain the product. The supported nickel tungsten bimetallic composite oxide can be used for tribed self-heating gasification with light alkane, and reforming and direct production of hydrogen and carbon dioxide. The advantages of chemical looping combustion, catalytic reforming and high purity hydrogen production by pyrolysis water, and self-heating reforming of a gas-solid counter current operation-type tribed reactor are combined, the coprecipitation preparation method having the advantages of simple operation and low cost is used, so that fuel can be directly converted to carbon dioxide and high purity hydrogen, and near-zero energy consumption in-situ separation of the product is realized.

Owner:TIANJIN UNIV

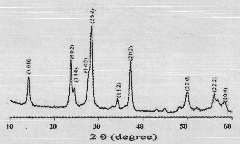

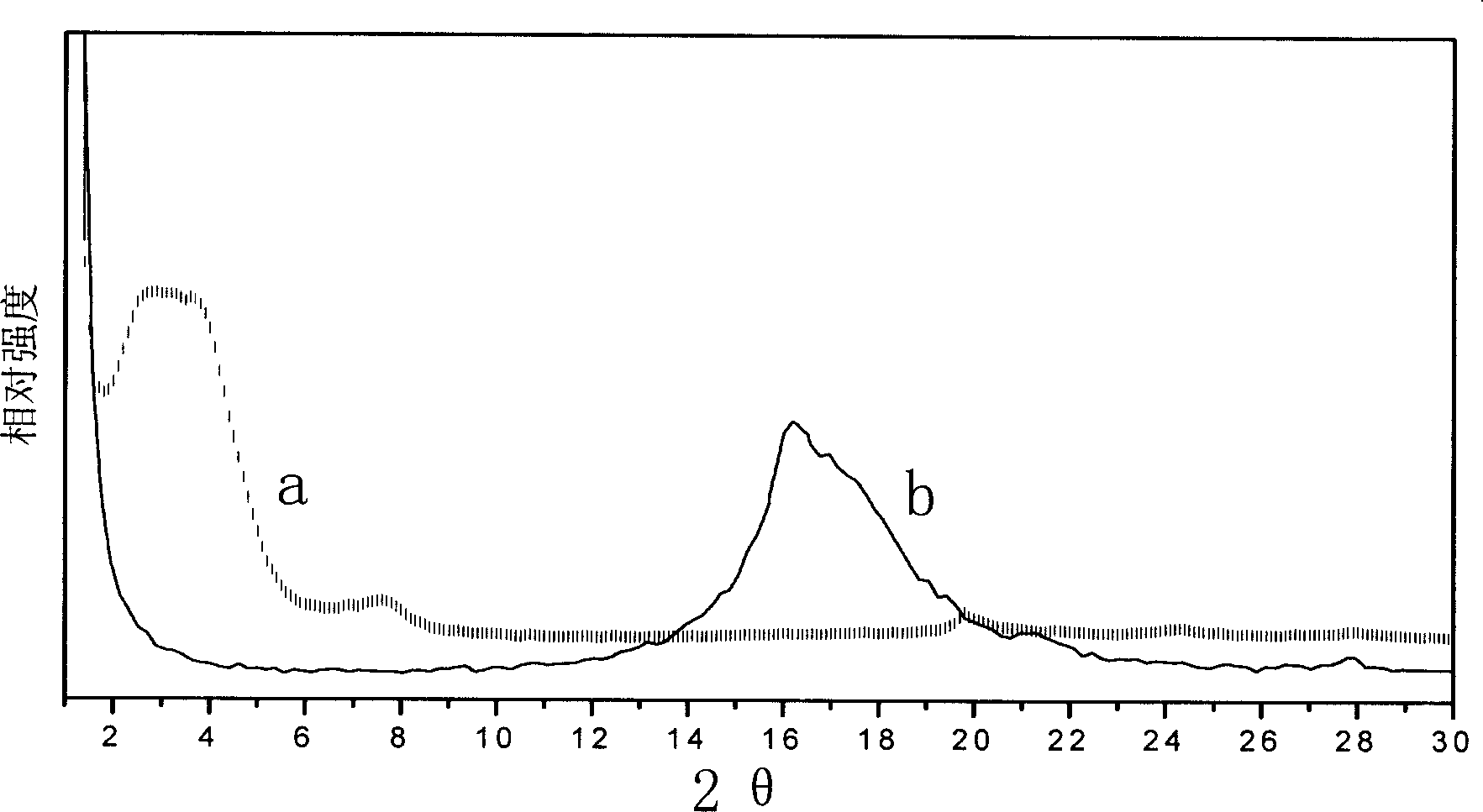

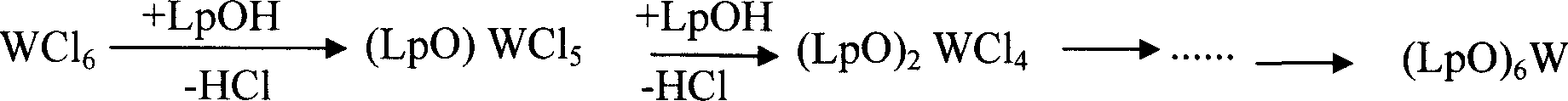

Preparation of polydicyclopentadiene/montmorillonite nano composite material

The invention discloses a preparation method of the poly-dicyclopentadiene / montmorillonite nanocomposites. The support catalysts is prepared through the complex compound compounded by the compound with hydroxide radical and the tungsten hexachloride attaching to the organic montmorillonite, and the complex compound comprises the paratert-butyl phenol, quadruple ((Beta-(3, 5-tert-butyl -4- hydroxy phenyl) monoprop) pentaerythritol ester or 2-hydroxy-4-n-octyloxybenzophenone, etc. The polymerization of the dicyclopentadiene is catalysed through the in situ polymerization model by the catalyst, the interlayer spacing is increased when the dicyclopentadiene monomer polymerizing in the interlayer of the montmorillonite, the interlayer of the montmorillonite is peeled by the heat produced in the reaction, the peeled interlayer of the montmorillonite is scattered in the poly-dicyclopentadiene, and the poly-dicyclopentadiene / montmorillonite Nanocomposites is produced, and then a model is prepared by the reaction injection molding method. The composites are showed with nanocomposites structure through the X-ray diffractogram.

Owner:HENAN UNIV OF SCI & TECH

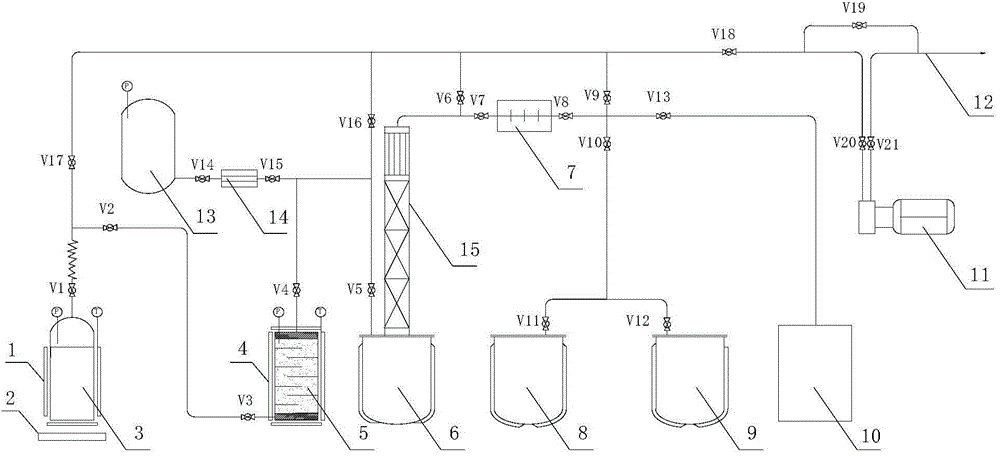

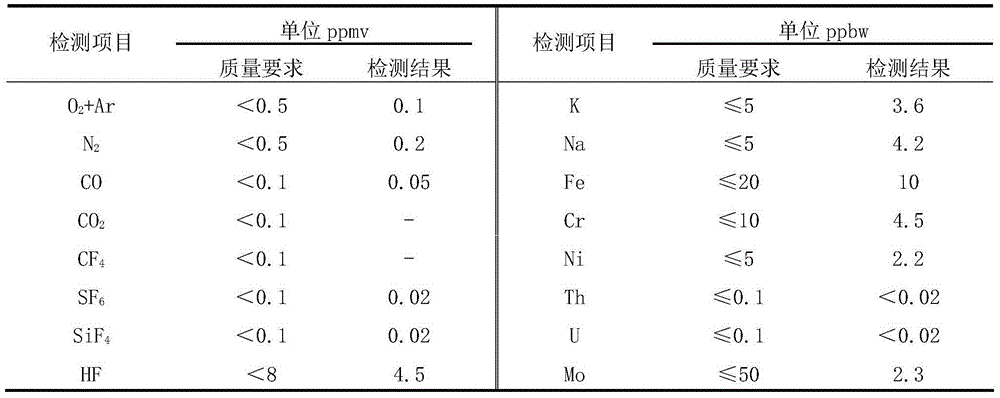

Purification method of tungsten hexafluoride gas

ActiveCN104973629AEfficient removalReduce gas contentTungsten halidesHydrogen fluoridePurification methods

A purification method of a tungsten hexafluoride gas relates to a fluoride of tungsten. The purification method comprises the following steps: removing oil by equipment, pressurizing with nitrogen, vacuumizing to the limit, turning on a nitrogen heater, introducing the heated nitrogen into a system, and vacuumizing to the limit; filling a hydrogen fluoride removal tower with nitrogen, putting tungsten hexachloride into the hydrogen fluoride removal tower, introducing high-purity tungsten hexafluoride into a finished product gathering tank, reacting with steam adhered to the wall of the tank to generate hydrogen fluoride, sucking-back impure tungsten hexafluoride in the finished product gathering tank into a rectifying still for low-temperature curing after displacement, detecting content of foreign gas, and stopping high-purity tungsten hexafluoride displacement after qualified; heating primary tungsten hexafluoride and carrying out low-temperature curing, vacuumizing the rectifying still, adsorbing tail gas by a basic spray tower, thawing by hot water, and detecting when pressure is stable and rectifying; carrying out reflux condensation on evaporated tungsten hexafluoride gas in the rectifying tower, removing impurities, rectifying primary tungsten hexafluoride gas and gathering, detecting, gathering by the finished product gathering tank, taking a liquid sample, and detecting metal impurities in tungsten hexafluoride.

Owner:XIAMEN TUNGSTEN

Preparation method of tungsten trioxide nano film

InactiveCN105274503ALower requirementLow costLiquid/solution decomposition chemical coatingElectrodesAnhydrous ethanolRoom temperature

The invention discloses a preparation method of a tungsten trioxide nano film. The method includes the steps that firstly, tungsten hexachloride is dissolved in anhydrous ethanol, and a precursor solution is obtained after uniform stirring; secondly, the surface of a substrate is dropwise coated with the precursor solution through a dropwise coating method and is blown dry, heat treatment is performed for 3-5 min under the condition that the temperature of the substrate is 80-150 DEG C, and a film layer is obtained on the surface of the substrate after the substrate is cooled to room temperature; thirdly, the second step is repeatedly executed till the film layer is obtained on the surface of the substrate; and fourthly, the film layer is heated to 400-550 DEG C, high-temperature calcination is performed for 2-6 h, and the tungsten trioxide nano film is obtained on the surface of the substrate after high-temperature calcination. The preparation method is low in requirement for experimental equipment, easy to operate, low in cost and high in safety performance, the prepared tungsten trioxide nano film serves a photo anode material to be applied to a photoelectric chemical decomposition seawater system, good photoelectric performance and high chemical stability are shown, and low-cost and high-efficiency application can be achieved.

Owner:XIAN UNIV OF SCI & TECH

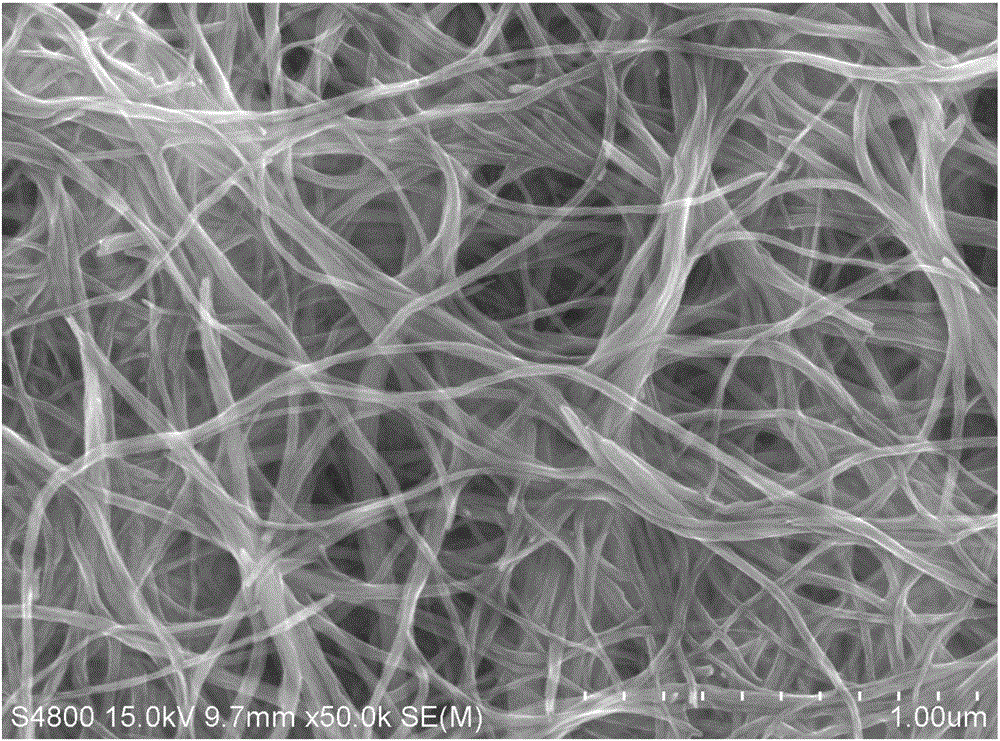

Synthetic method of tungsten oxide nano-wires for preparing gas sensitive sensors

InactiveCN106542580AHigh purityReductiveMaterial nanotechnologyTungsten oxides/hydroxidesAlcoholOrganic solvent

The invention belongs to the technical field of inorganic nano-materials, and relates to a synthetic method of tungsten oxide nano-wires for preparing gas sensitive sensors. The synthetic method includes the steps: (1) placing tungsten hexachloride into absolute ethyl alcohol; (2) uniformly stirring the tungsten hexachloride, transferring formed light-green tungsten hexachloride alcoholic solution into a stainless steel hydrothermal reaction kettle, performing reaction of predetermined time at the predetermined temperature, and enabling the tungsten hexachloride to convert into tungsten oxide; (3) centrifuging solution of the tungsten oxide obtained by reaction, and ultrasonically cleaning reactants by the aid of ethyl alcohol and water; (4) drying obtained tungsten oxide nano-wires in a vacuum drying oven for 1-2 hours at the temperature ranging from 40 DEG C to 60 DEG C to obtain the tungsten oxide nano-wires. The synthetic method has the advantages that other organic solvents and surface active agents are omitted, so that materials have good purity, subsequent purification is omitted, the tungsten oxide nano-wires have reducibility and the advantages of high safety, high in operability and easiness in popularization, and the obtained materials have high crystallizing degree.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

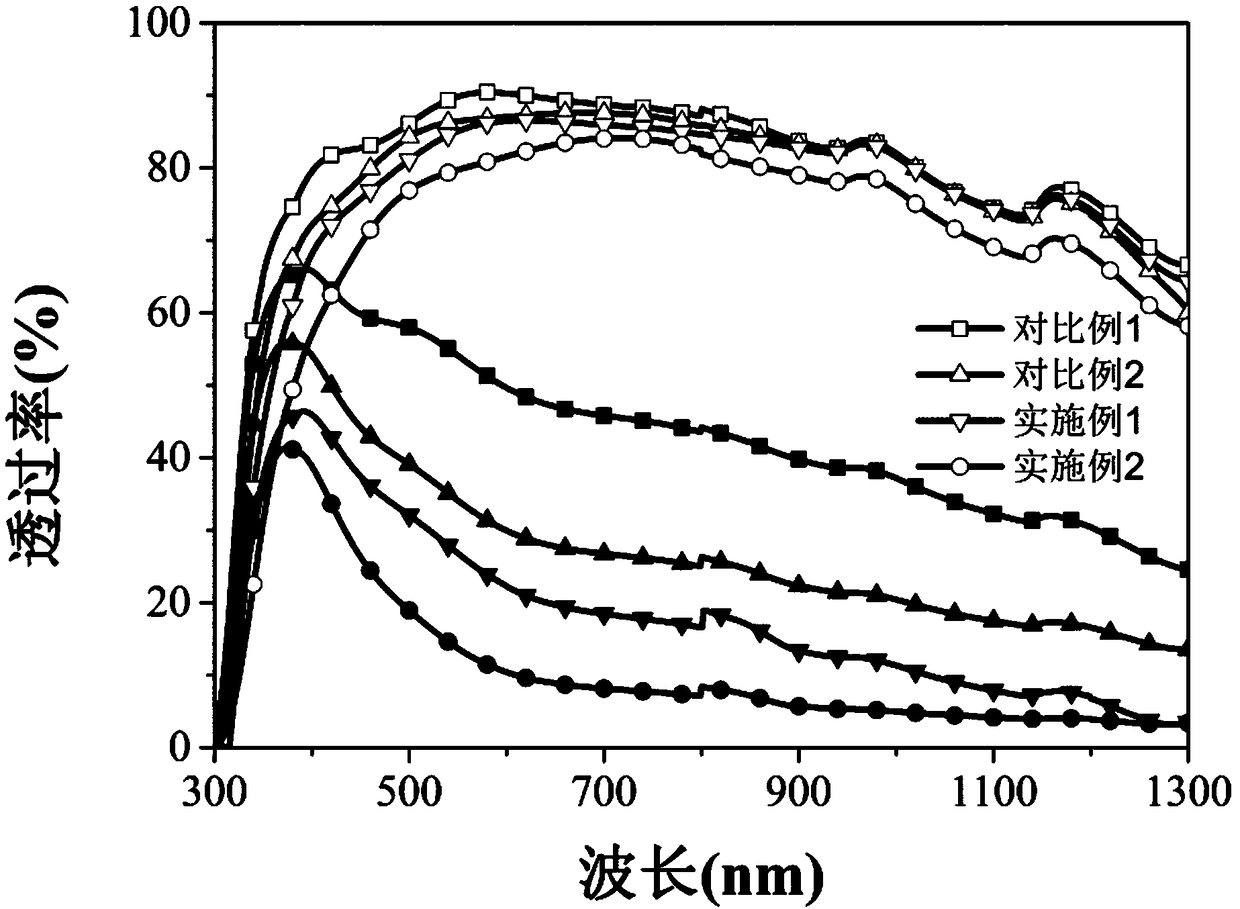

Tungsten oxide electrochromic film with high spectral adjustment range and preparation method thereof

The invention discloses a preparation method of a tungsten oxide electrochromic film with a high spectral adjustment range. The method includes: adopting tungsten hexachloride and oxalic acid as the raw materials to prepare a precursor solution, and then carrying out solvothermal reaction to obtain the product. In the precursor solution, the concentration of tungsten hexachloride is 1-15g / L. According to the preparation method of the tungsten oxide electrochromic film with a high spectral adjustment range provided by the invention, oxalic acid is introduced as a structural adjustment agent toincrease the adhesion amount of the tungsten oxide electrochromic film on a conductive substrate under a low W source concentration, thus effectively enhancing the spectral adjustment range and increasing the raw material utilization. The preparation method is simple, is low in cost, and is safe and reliable.

Owner:ZHEJIANG UNIV

Preparation method and application of tubular tungsten oxide-graphene composite material

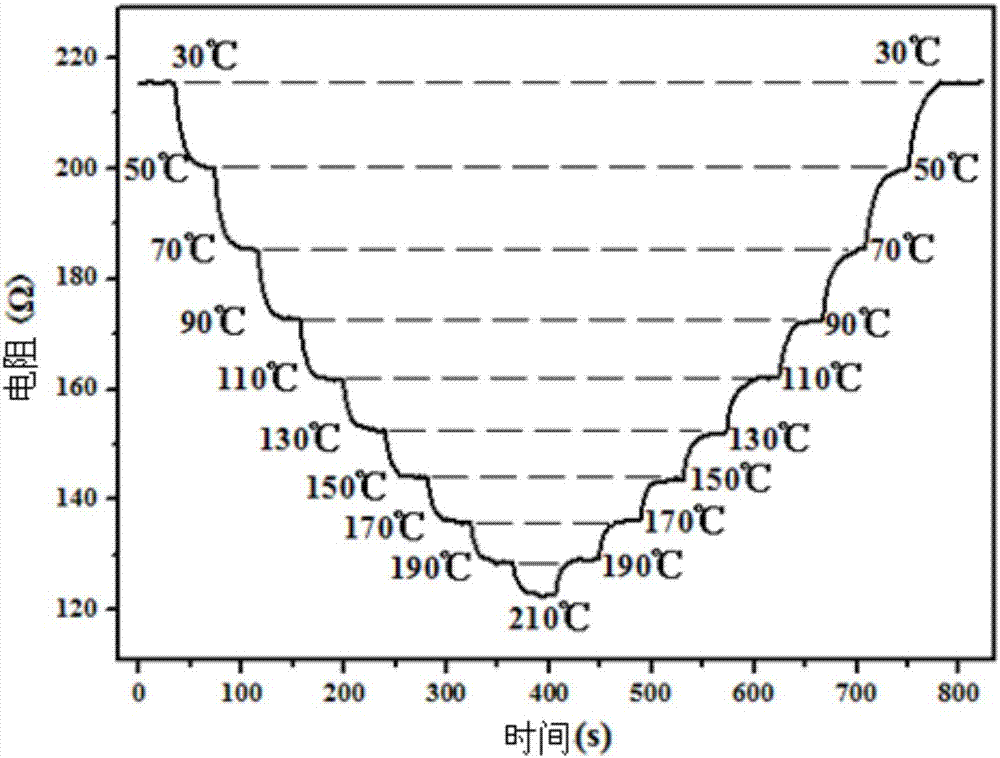

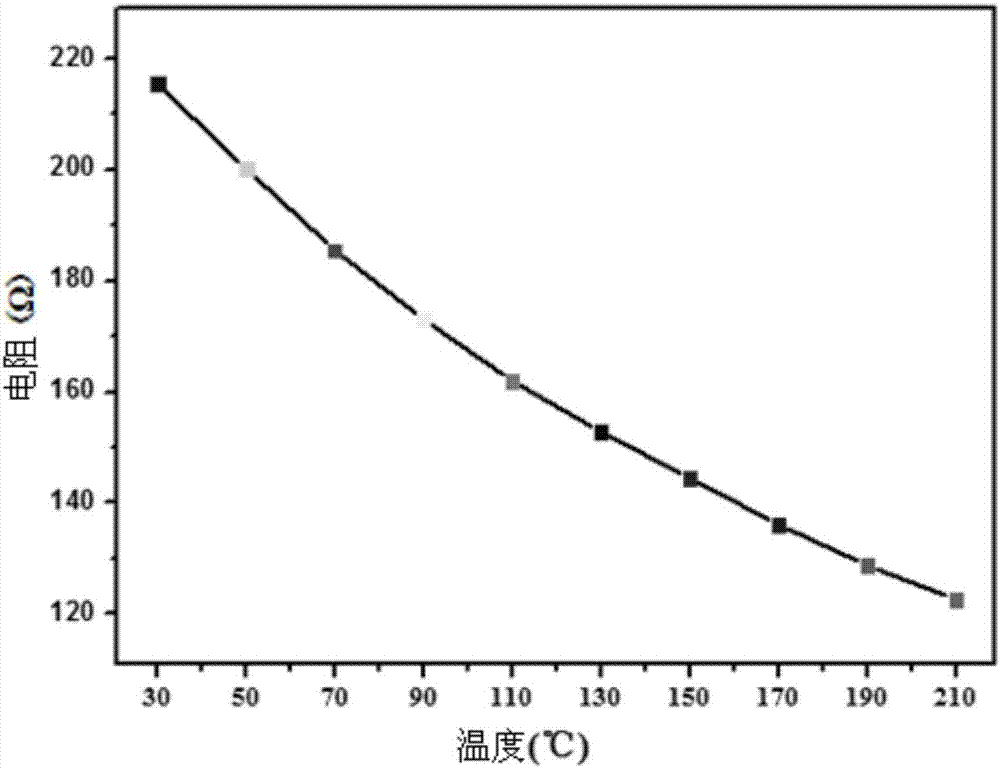

InactiveCN106872063AImproving the performance of temperature-sensitive materialsQuick responseThermometers using electric/magnetic elementsUsing electrical meansHydrazine compoundPhotocatalytic degradation

A preparation method and an application of a tubular tungsten oxide-graphene composite material are disclosed. The invention belongs to the technical field of advanced materials, and specifically relates to a preparation method and an application of a tubular tungsten oxide-graphene composite material. The invention aims to enhance the temperature sensitivity of a graphene material by preparing a tungsten oxide-graphene composite material. The method comprises the following steps: (1) oxidizing graphite into graphite oxide powder; (2) ultrasonically dispersing the graphite oxide powder in normal propyl alcohol, and adding tungsten hexachloride for hydrothermal reaction; and (3) adjusting the pH value to 9-10, adding 50% aqueous solution of hydrazine hydrate, conducting reaction in oil bath, and carrying out centrifugal cleaning and drying after reaction to get black powder, namely, the tubular tungsten oxide-graphene composite material. The material can be used as a temperature-sensitive material of temperature sensors, a sensitive material of gas sensors or a photocatalytic degradation material.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP +1

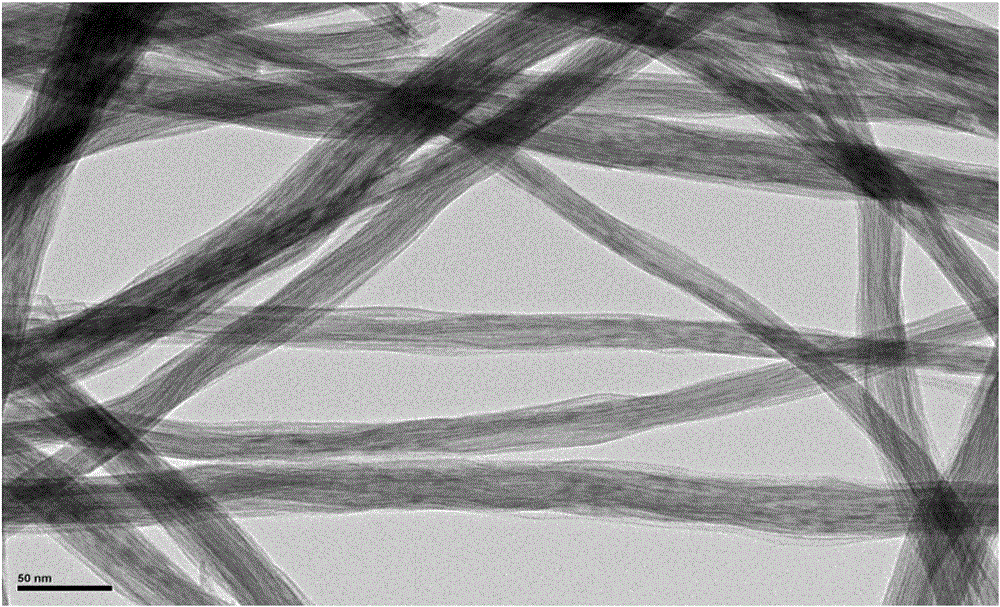

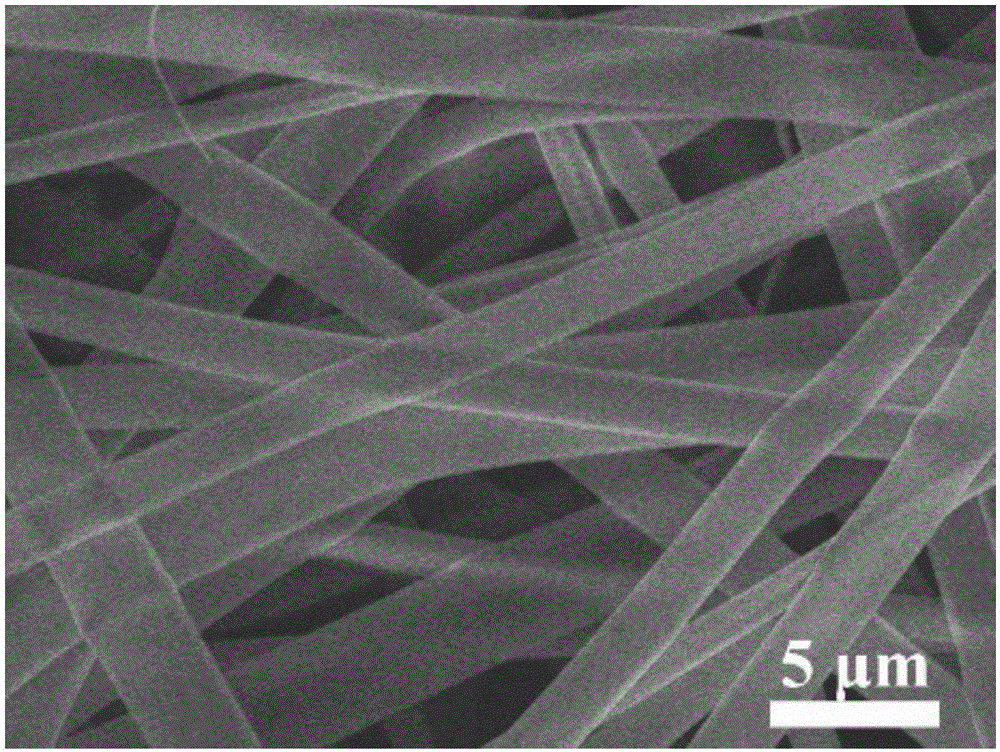

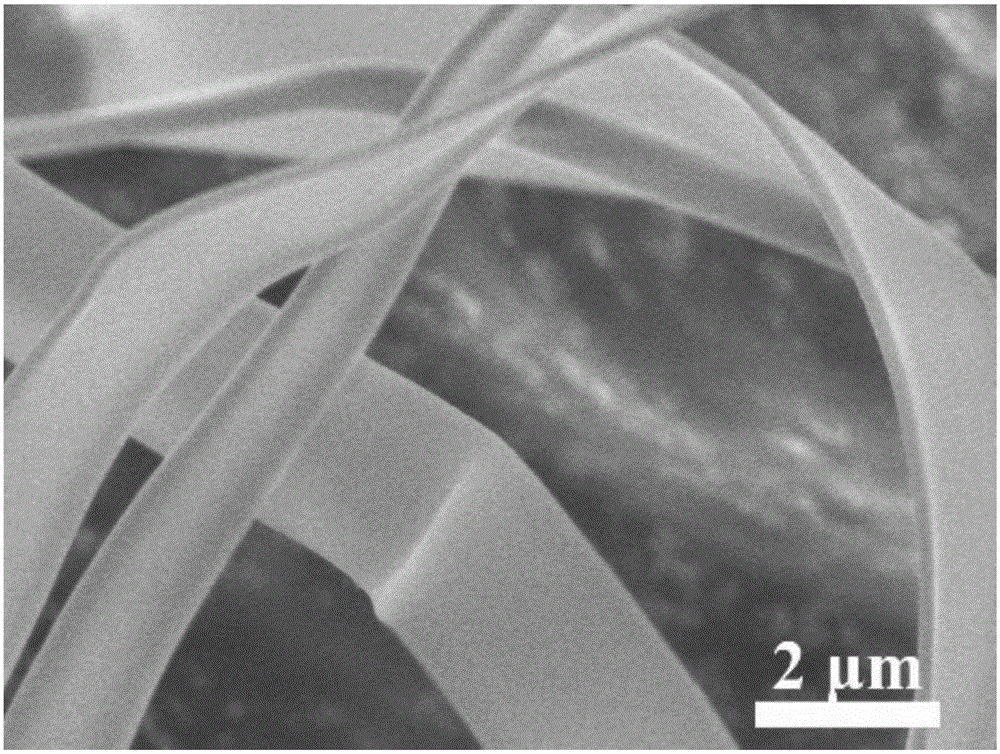

Preparation method of high purity WO<3> mesoporous nano-belt

ActiveCN105040161AHigh puritySimple processInorganic material artificial filamentsFilament/thread formingFiberFoaming agent

The invention relates to a preparation method of a high purity WO<3> mesoporous nano-belt and belongs to the technical field of nano-fibers. The preparation method comprises the steps of preparing a precursor spinning solution, wherein polyvinylpyrrolidone, tungsten hexachloride and tea saponin are dissolved into solvent in sequence, all constituents are mixed uniformly, and the precursor spinning solution is obtained; conducting the electrostatic spinning on the precursor spinning solution, and obtaining an organic precursor nano-belt; conducting high temperature calcination on the organic precursor nano-belt, and obtaining the high purity WO<3> mesoporous nano-belt. According to the preparation method of the high purity WO<3> mesoporous nano-belt, the process is simple, the repeatability is good, the controllable transformation of a WO<3> one-dimensional nano-structure from traditional cylindrical fibers to the mesoporous nano-belt can be achieved only by controlling the content of the forming agent, namely the tea saponin, and the controllable preparation of high purity WO<3> mesoporous nano-belts of different width-diameter ratios can be further achieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

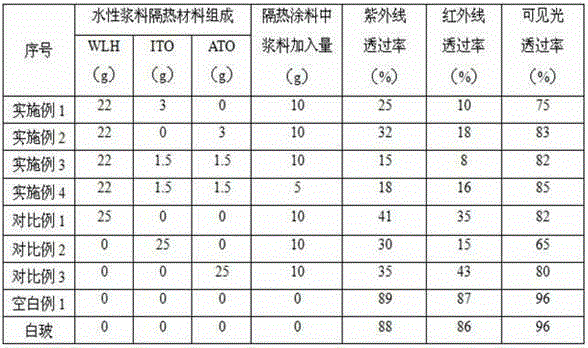

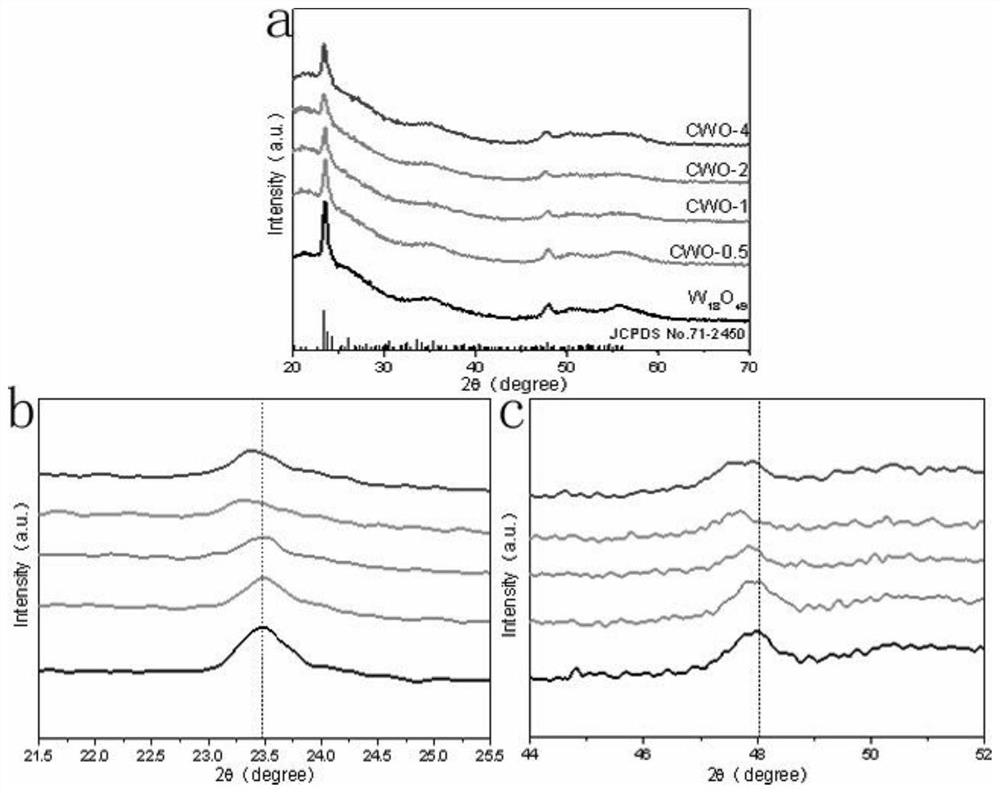

Transparent glass thermal insulation material and application thereof

ActiveCN104861762AEfficient barrier functionNon-macromolecular adhesive additivesFilm/foil adhesivesPolyvinyl butyralInfrared

The invention discloses a transparent glass thermal insulation material and application thereof. The transparent glass thermal insulation material is prepared from a tungsten complex and indium tin oxide and / or antimony tin oxide according to the mass ratio of 100:(0-30):(0-32), wherein indium tin oxide and antimony tin oxide cannot be zero at the same time; the tungsten complex is the complex generated by a reaction of tungsten hexachloride and tributyl phosphate; indium tin oxide and antimony tin oxide are both powder; the particle sizes of indium tin oxide and antimony tin oxide are less than or equal to 100 nm. The application is to apply the transparent glass thermal insulation material to prepare slurry of the transparent glass thermal insulation material, and further to apply the slurry to prepare a transparent glass waterborne thermal insulation coating and a transparent glass thermal insulation polyvinyl butyral photographic film. The thermal insulation glass which is coated with the transparent glass waterborne thermal insulation coating prepared by the transparent glass thermal insulation material disclosed by the invention or the thermal insulation sandwich glass formed by the transparent glass thermal insulation polyvinyl butyral photographic film prepared by the transparent glass thermal insulation material can achieve the higher infrared and ultraviolet rejection and the higher visible light transmittance.

Owner:湖南省华京粉体材料有限公司

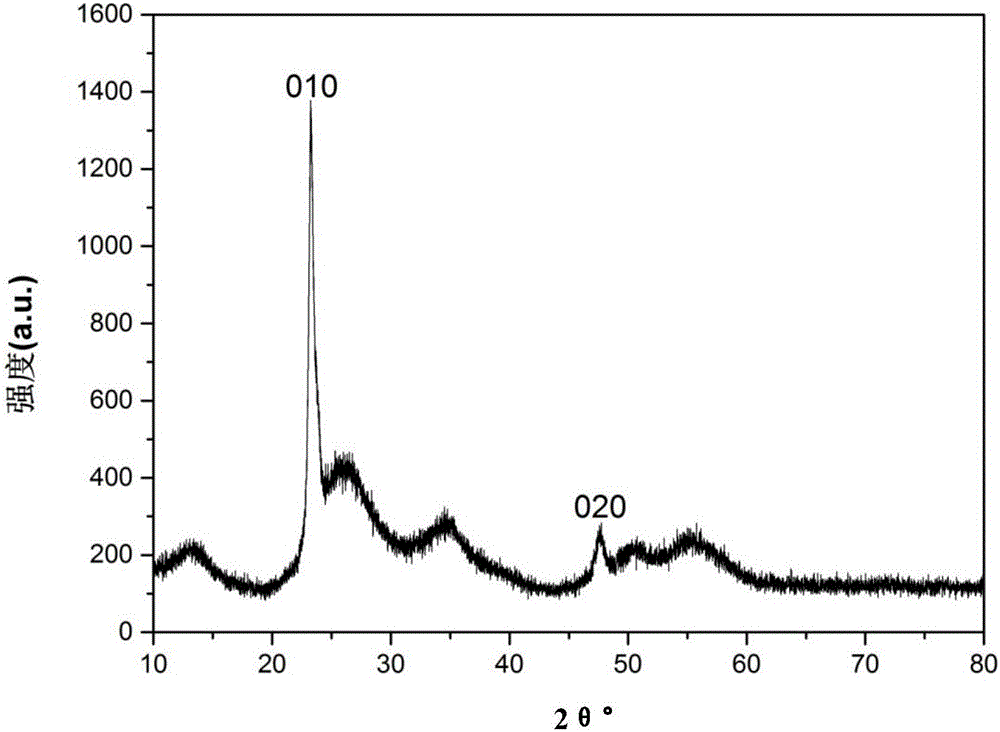

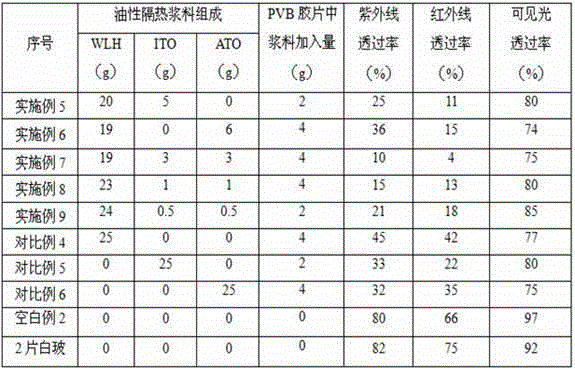

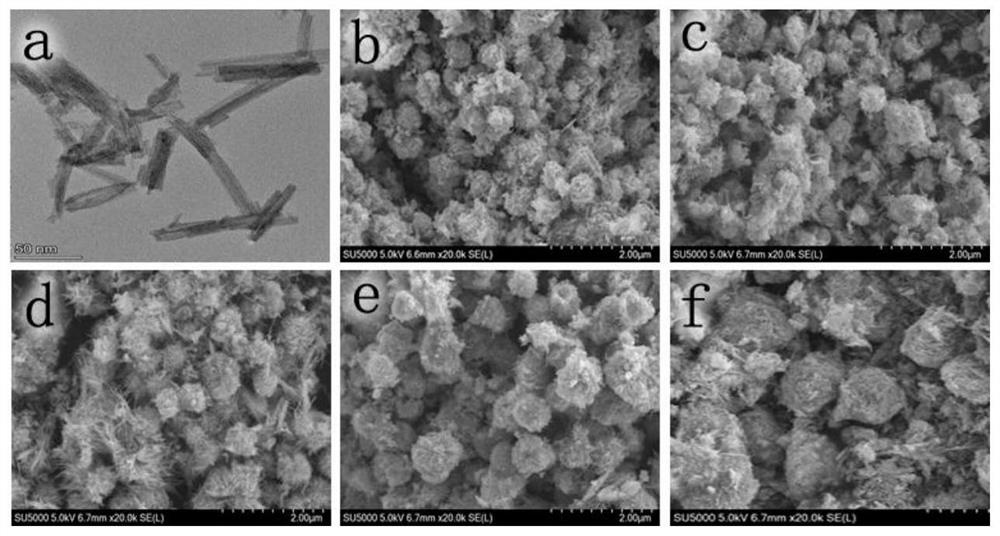

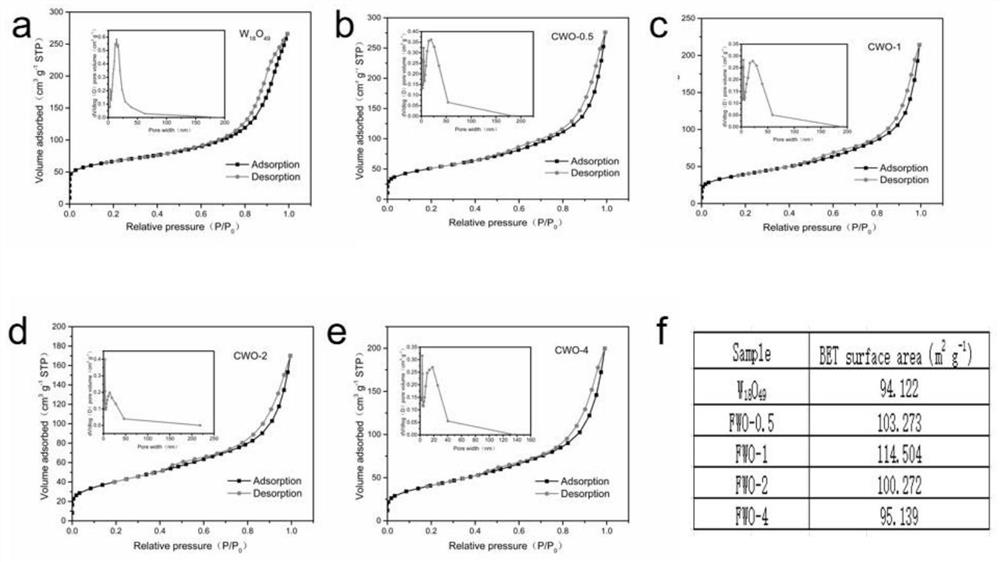

Ce-doped W18O49 nanowire photocatalyst and preparation method thereof

PendingCN113058589ALarge specific surface areaHigh activityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionPtru catalystPhysical chemistry

The invention provides a Ce-doped W18O49 nanowire photocatalyst preparation method, which comprises: mixing and stirring a certain amount of ethanol and tungsten hexachloride, adding cerium salt, conducting stirring to obtain a mixed solution, transferring the mixed solution to a polytetrafluoroethylene reaction kettle, carrying out a solvothermal reaction at a temperature of 150-240 DEG C for 3-24 h, after the reaction is finished, conducting centrifuging, conducting washing with ethanol, and conducting drying in a drying oven to obtain the Ce-doped W18O49 nanowire material. The Ce-doped W18O49 nanowire photocatalyst prepared by the method disclosed by the invention has relatively high photocatalytic nitrogen fixation activity and stability.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

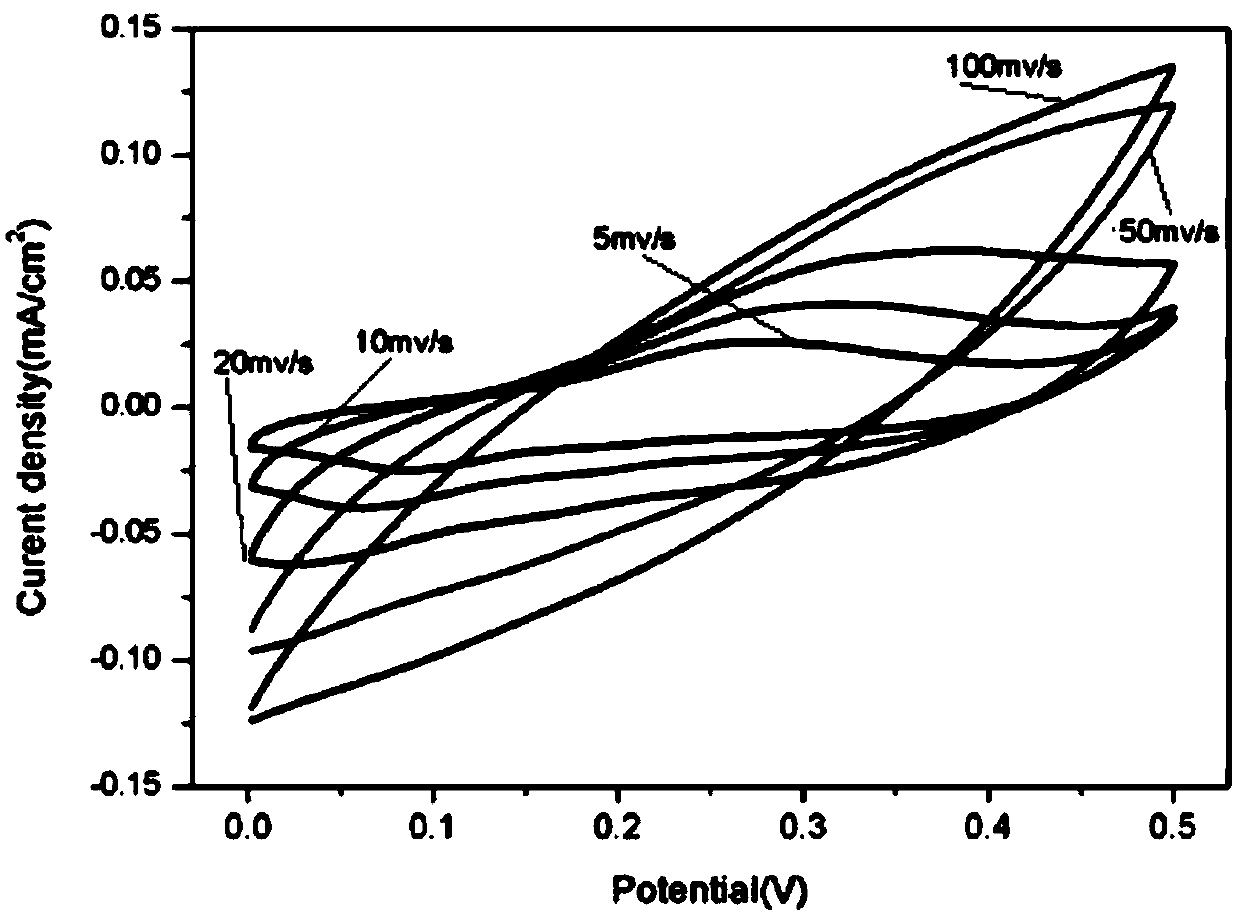

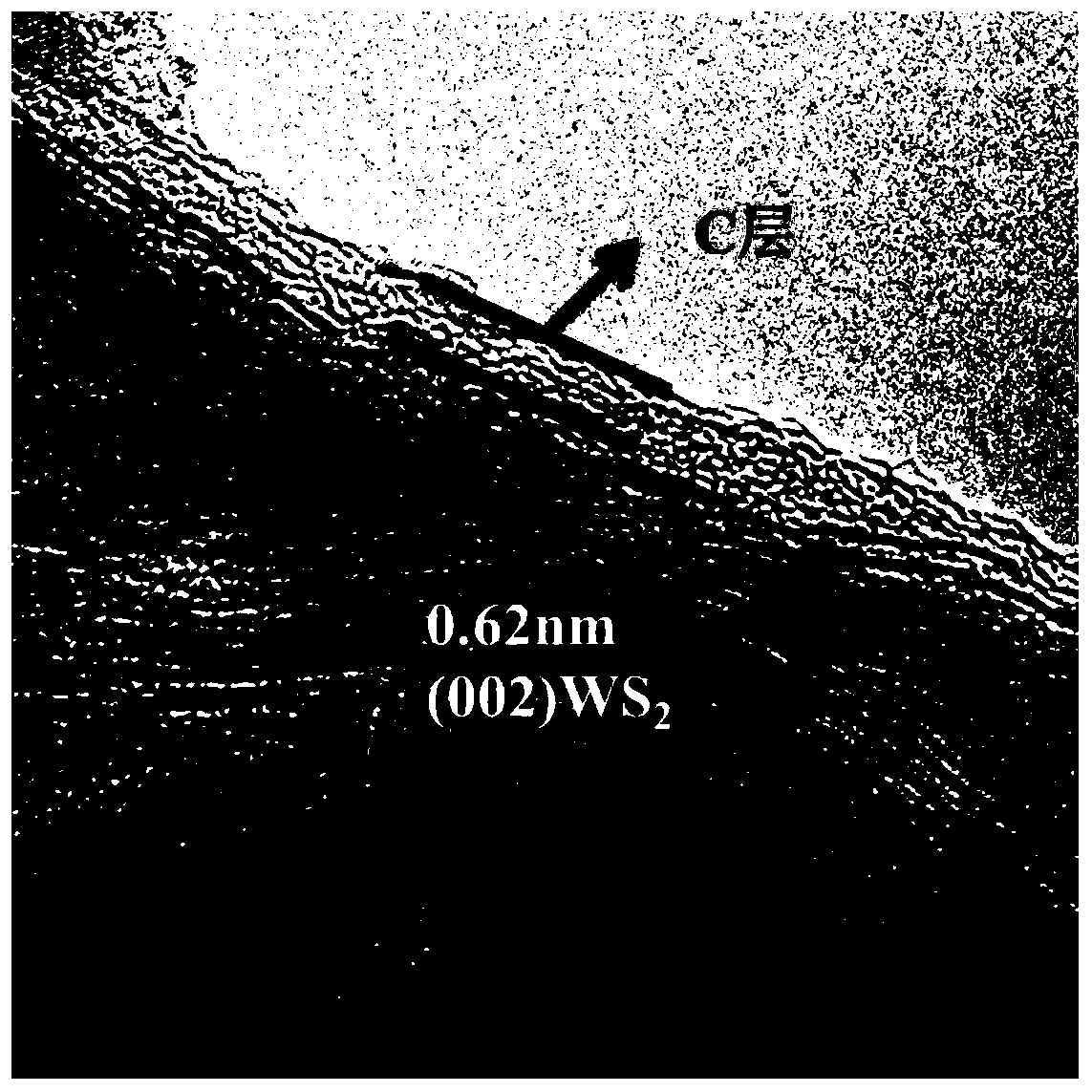

Preparation method of WS2 nano-material with macroporous network structure

InactiveCN108039289ALarge specific surface areaSimple manufacturing methodHybrid capacitor electrodesHybrid/EDL manufactureLithium-ion batteryVacuum drying

The invention provides a preparation method of a WS2 nano-material with a macroporous network structure. The preparation method comprises the steps that two kinds of powder of tungsten hexachloride (WCl6) and thioacetamide (CH3CSNH2) are weighed, are added into deionized water, and are stirred magnetically at room temperature for 1 hour, so that the powder raw materials are completely mixed; the powder is transfer into a 100ml water-heated kettle, is placed into 1*2cm carbon cloth, and is heat-preserved for 24 hours at different temperatures; after the reaction, the carbon cloth is washed 3 times with absolute ethyl alcohol and deionized water; vacuum drying is carried out at 60 DEG C; and heat preservation is carried out for 12 hours to acquire the WS2-carbon paper nano-material. According to the invention, the preparation method has the advantages of simple preparation process, controllable process, low cost, uniform distribution of WS2 with macroporous network structure, large specific surface area, good electrical conductivity, good photocatalysis performance, good biophile performance and the like, and is applicable to photocatalysis, wastewater treatment, lithium-ion batteries, biosensors and other fields.

Owner:SHAANXI UNIV OF SCI & TECH

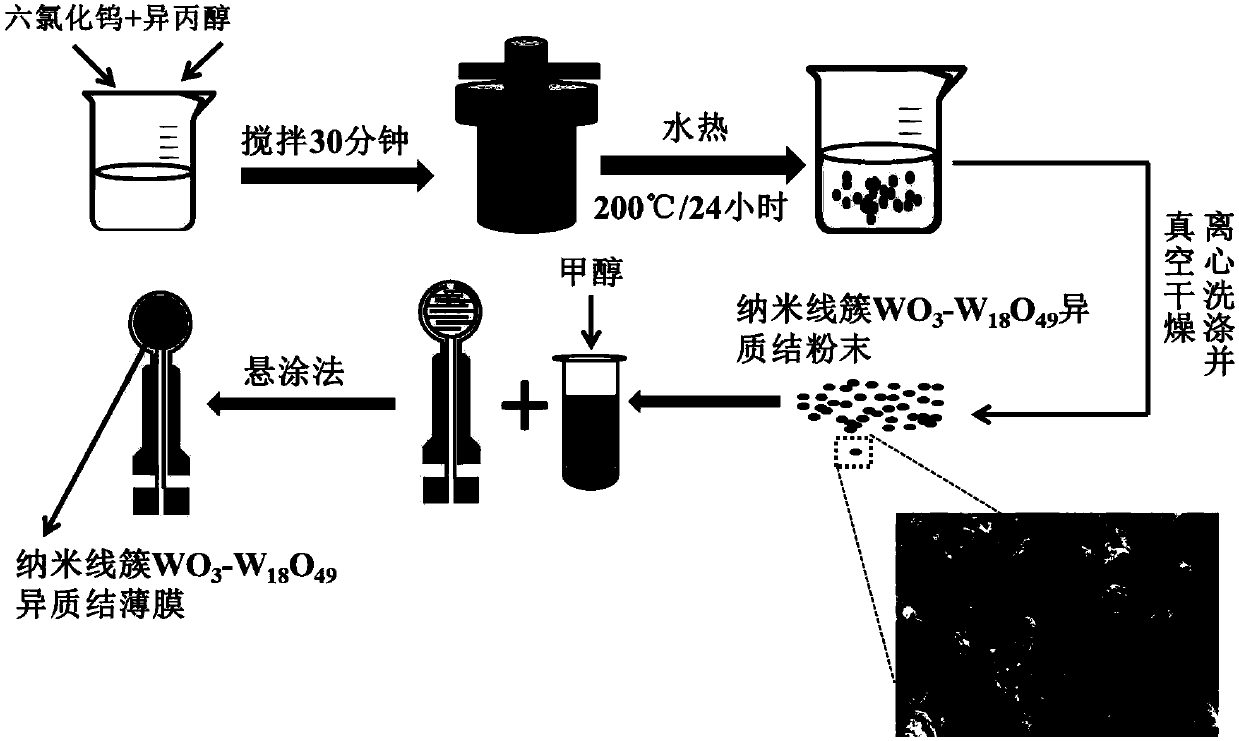

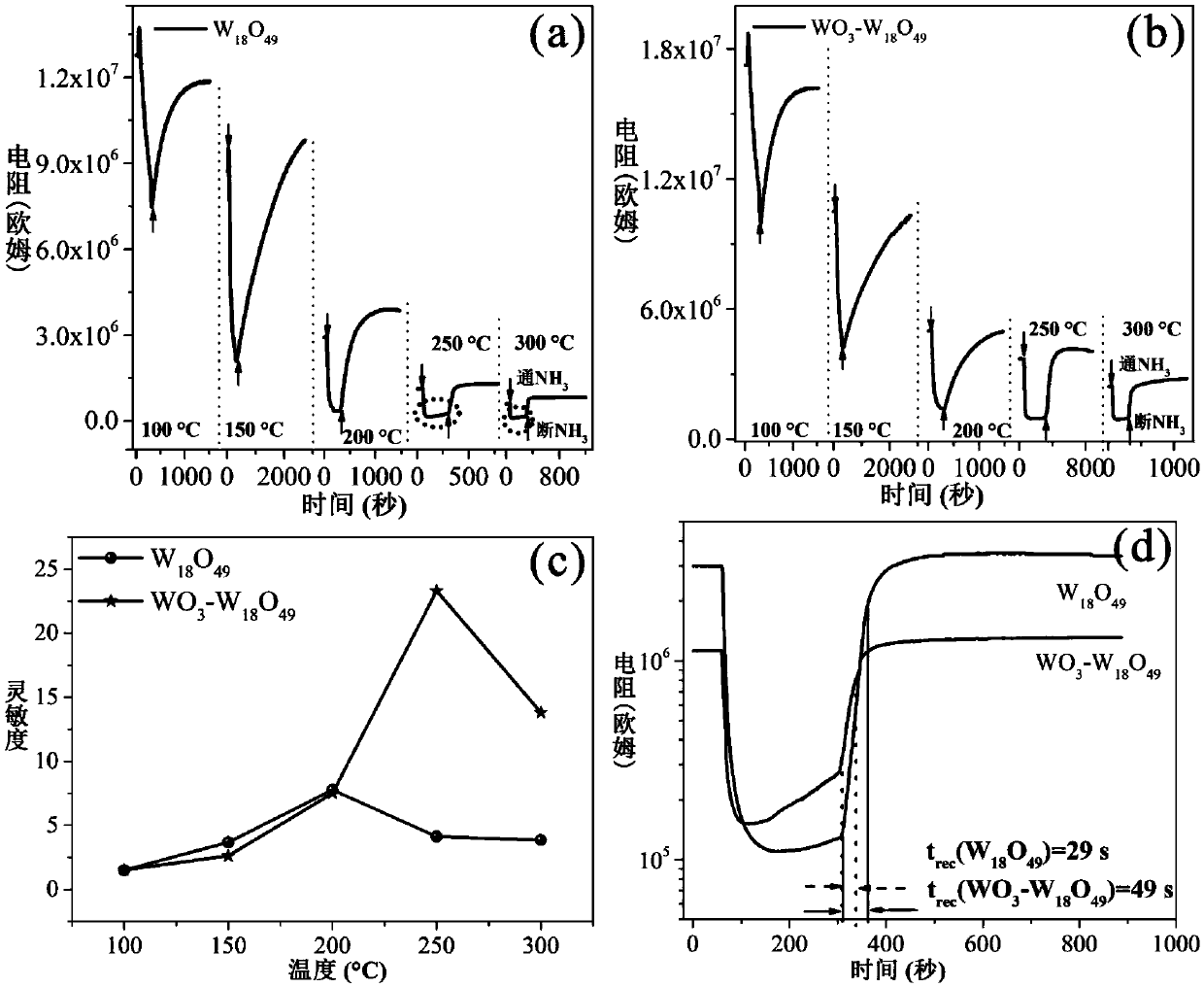

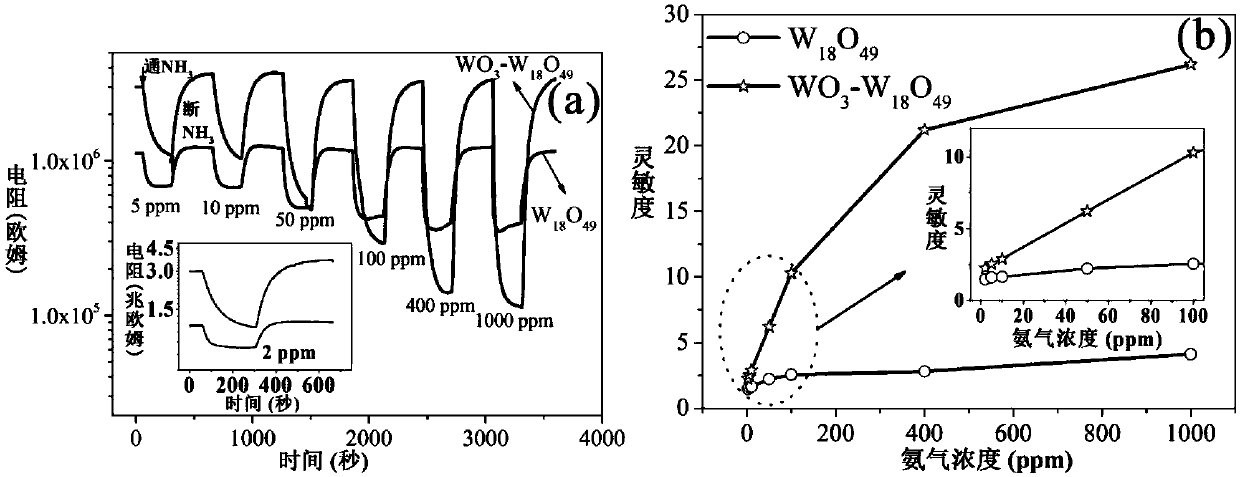

Nanowire cluster WO3-W18O49 heterojunction membrane sensitive to ammonia gas

InactiveCN107831194ALow costRealize highly sensitive detectionTungsten oxides/hydroxidesMaterial resistanceHeterojunctionNanowire

The invention provides a preparation method useful for detecting a nanowire cluster WO3-W18O49 heterojunction membrane of NH3, and belongs to the technical field of gas sensitive sensors. Tungsten hexachloride is mixed with isopropyl alcohol; nanowire cluster WO3-W18O49 heterojunction powder is prepared with a solvothermal method, is prepared into a membrane device through a suspension-coating method; and then a gas-sensitive test is performed. in a test temperature range (100 to 300 DEG C), a response value of a sample to 500ppm NH3 at the temperature of 250 DEG C is up to 23.3, and response / recovery time is 13s / 49s; moreover, the nanowire cluster WO3-W18O49 heterojunction membrane can be used for detecting NH3 (2 to 1000ppm) with a concentration in a large range, and has high selectivityand stability specific to NH3. The sensor membrane has the advantages of simple preparation method, low raw material cost, superior material membrane performance, high repeatability, and good application value and prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

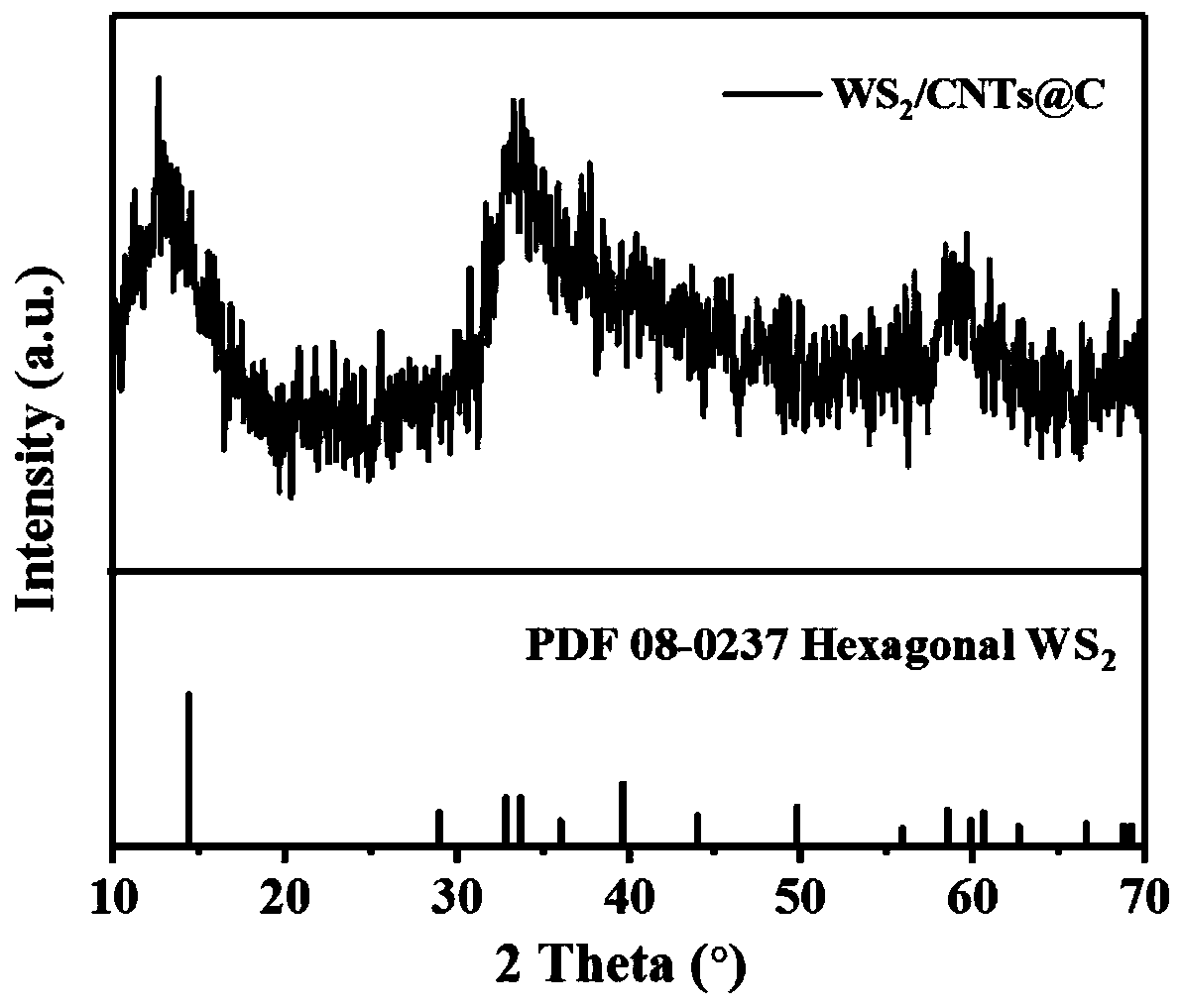

Tungsten sulfide/CNTs (carbon nanotubes)-C composite electrode material and preparation method thereof

InactiveCN110880597AImprove conductivityImprove mechanical propertiesSecondary cellsNegative electrodesArgon atmosphereFreeze-drying

The invention provides a tungsten sulfide / CNTs (at) C composite electrode material and a preparation method thereof. The preparation method comprises the following steps: adding CNTs into an ethanol solution, carrying out ultrasonic dispersion, adding tungsten hexachloride and thioacetamide, stirring, transferring into a microwave hydrothermal kettle, carrying out microwave hydrothermal reaction,and controlling the microwave hydrothermal temperature to be 200-220 DEG C, the pressure to be 0.5-5MPa and the reaction time to be 0.5-4h; washing and drying the reaction product to obtain a black WS2 / CNTs composite material; dissolving sucrose in water, adding the WS2 / CNTs composite material, stirring, freeze-drying to obtain a WS2 / CNTs (at) C precursor, and calcining at 400-650 DEG C for 1-3 hours under the protection of argon atmosphere to obtain the WS2 / CNTs (at) C composite material. The obtained composite electrode material has excellent cycling stability.

Owner:SHAANXI UNIV OF SCI & TECH

Formula of high-temperature resistant glass reinforced plastic

The invention relates to a formula of high-temperature resistant glass reinforced plastic, belonging to the technical field of glass reinforced plastic. The formula is characterized by comprising thefollowing components in percentage by weight: 30-40 parts of an unsaturated polyester resin, 10-30 parts of hydrogen peroxide, 1-3 parts of potassium oxide, 1-3 parts of phenol modified tungsten hexachloride, 1-5 parts of a flame retardant, 2-4 parts of a nano filler, 10-20 parts of glass fiber, 1-3 parts of a metal filler and 2-8 parts of an ultraviolet absorbent. The formula has the beneficial effects that the unsaturated polyester resin and other auxiliary materials are adopted as a curing system, glass fiber yarns are adopted as a reinforcing material, a high-performance composite linear material is produced, and due to a reasonable formula system, the strength of the product is improved; and due to adoption of the ultraviolet absorbent, the stability of the material is remarkably improved.

Owner:成都双瑞暖通设备有限公司

High purity tungsten hexachloride and method for making same

Condensable metal halide materials, such as but not limited to tungsten chloride (WCl6), can be used to deposit metal films or metal containing films in a chemical vapor deposition (CVD) or atomic layer deposition process. Described herein are high purity compositions comprising condensable materials and methods to purify condensable materials. In one aspect, there is provided a composition comprising: tungsten hexachloride which is substantially free of at least one impurity and wherein the tungsten hexachloride comprises at least 90%, preferably 95% and more preferably 99% by weight or greater of a β-WCl6 and 5% by weight or less of the α-WCl6 as measured by X-ray diffraction.

Owner:VERSUM MATERIALS US LLC

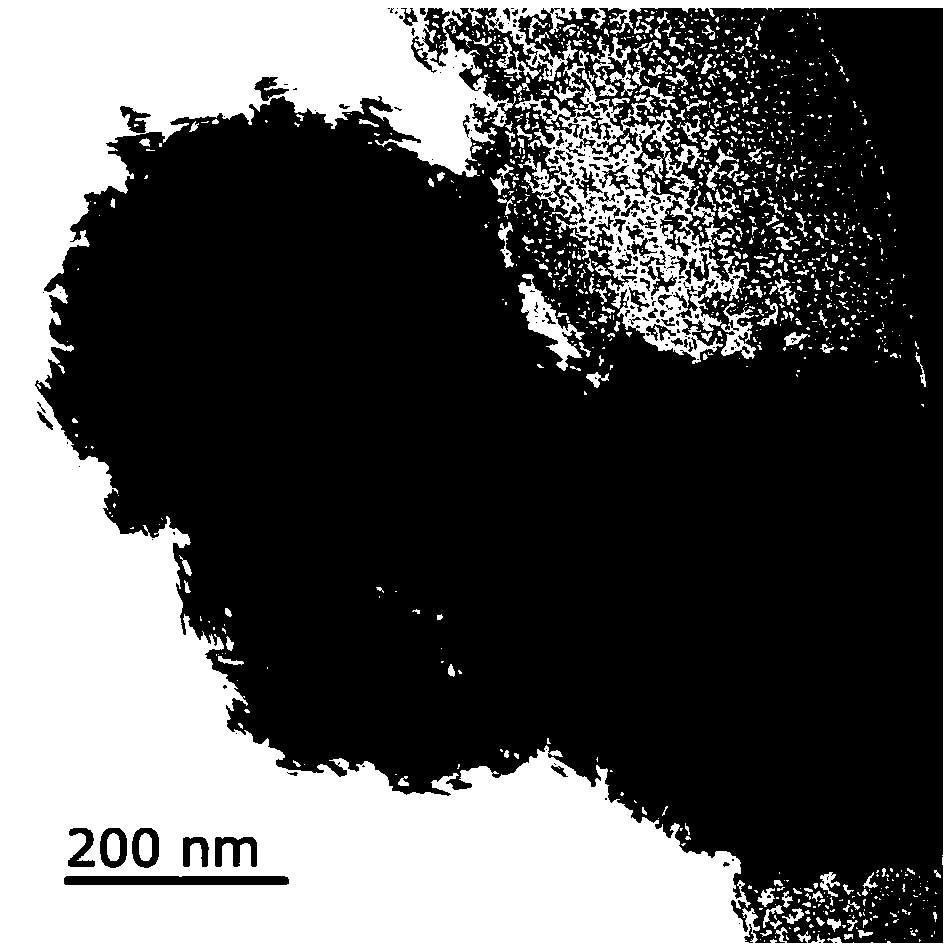

Preparation method of composite hollow microspheres with improved triethylamine detection performance

ActiveCN109621854AFacilitated DiffusionFacilitate transmissionMaterial resistanceMicroballoon preparationMicrosphereSolvent

The invention belongs to the technical field of semiconductor metal oxide gas sensors, and relates to a preparation method of composite hollow microspheres with improved triethylamine detection performance. The preparation method comprises: preparing a W18O49 hollow microsphere structure by using tungsten hexachloride and acetic acid as reaction raw materials and using ethanol as a solvent througha hydrothermal synthesis technology, placing the W18O49 hollow microspheres in a Co(NO3)2 ethanol solution, stirring until the solvent is completely evaporated, collecting the powdery material, and calcining to obtain the W18O49 / Co3O4 composite hollow microspheres. According to the present invention, the prepared W18O49 / Co3O4 composite hollow microspheres have the porous layered sphere shell, andhave the large specific surface area so as to provide more active sites for surface gas sensing reactions and increase the diffusion and transport of gas molecules inside the material; the surface ofthe obtained W18O49 / Co3O4 composite hollow microspheres contains a large amount of Co3O4 nanoparticles to construct a large number of p-n heterogeneous interfaces, such that the enhancement of the gas-sensitive response of triethylamine is promoted; and the obtained W18O49 / Co3O4 composite hollow microspheres have advantages of low cost, small size, flexibility and portable property, and are suitable for the actual detection of triethylamine.

Owner:QINGDAO UNIV

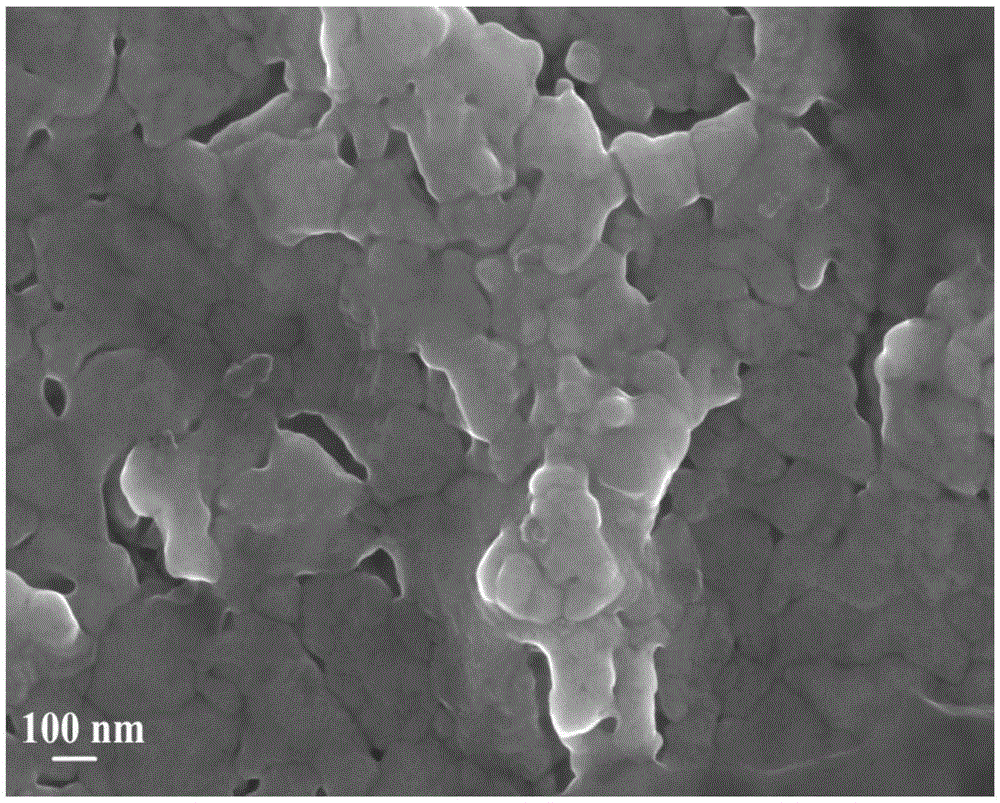

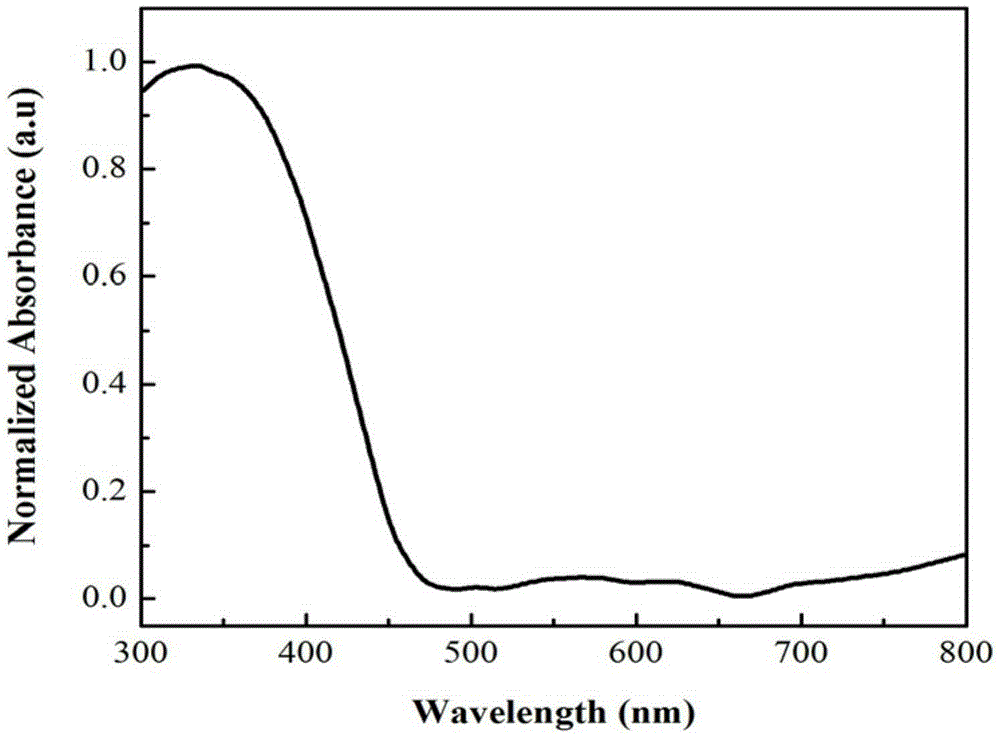

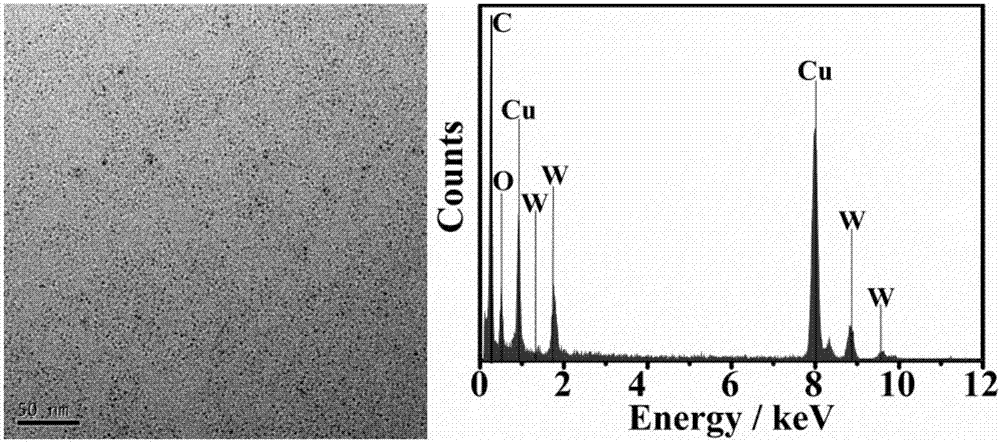

Super-small defect tungsten oxide nano-particle, method for preparing same and application of super-small defect tungsten oxide nano-particle

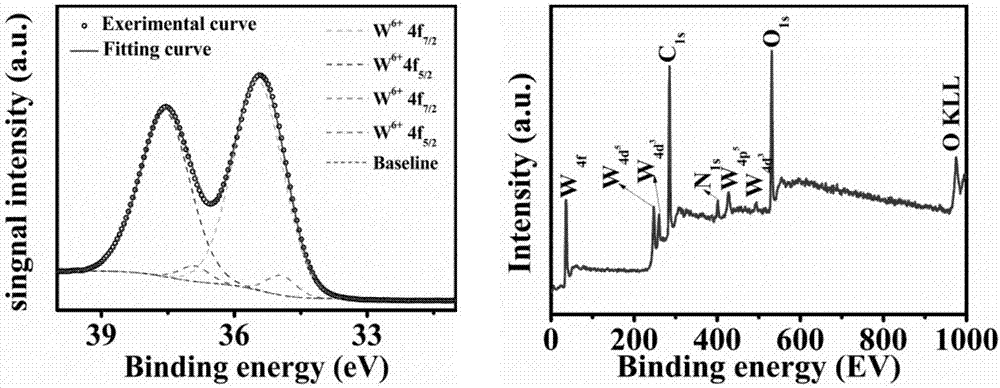

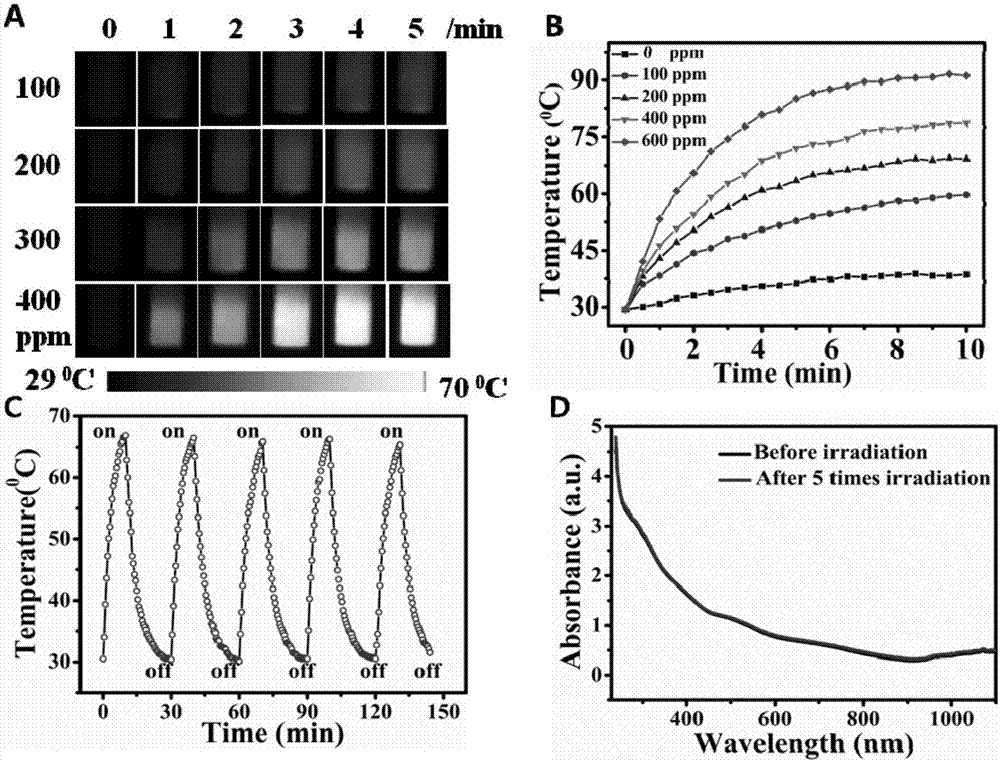

InactiveCN107032404ASmall particle sizeObvious photothermal effectTungsten oxides/hydroxidesPhotodynamic therapyOxygenTungsten hexachloride

The invention discloses a super-small defect tungsten oxide nano-particle, a method for preparing the same and application of the super-small defect tungsten oxide nano-particle. The method includes uniformly stirring dopamine hydrochloride and tungsten hexachloride in organic solvents and then synthesizing super-small WO<3-x> quantum dots by the aid of hydrothermal processes. The dopamine hydrochloride is used as a reducing agent and a stabilizer, and the tungsten hexachloride is used as a precursor. The super-small defect tungsten oxide nano-particle, the method and the application have the advantages that heat and singlet-state oxygen can be generated by the quantum dots under 808 nm laser radiation conditions, and accordingly photo-thermal therapy and photodynamic therapy can be carried out.

Owner:CENT SOUTH UNIV

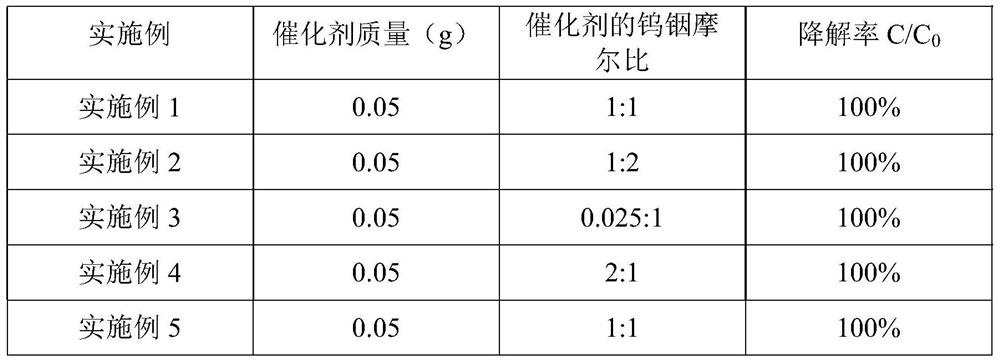

Preparation method of tungsten disulfide/indium sulfide composite nano material

ActiveCN111822004AInhibit synthesisImprove transfer abilityPhysical/chemical process catalystsWater/sewage treatment by irradiationThio-Solvothermal reaction

The invention discloses a preparation method of a tungsten disulfide / indium sulfide composite nano material. The method comprises the following steps of: (1) dissolving tungsten hexachloride in an organic solvent until the solid is completely dissolved to form a solution A; (2) dissolving indium nitrate in an organic solvent to form a solution B; and (3) dropwise adding the solution B into the solution A, performing stirring, adding thioacetamide and ammonium diallyl methyl dodecyl bromide, and carrying out solvothermal reaction at 120-200DEG C to obtain the tungsten disulfide / indium sulfide composite nano material. The preparation steps are simple, the cost is low, the advantages of tungsten disulfide and indium sulfide are organically combined, the tungsten disulfide and indium sulfide generate a photoelectric synergistic effect, and the photocatalytic activity is enhanced.

Owner:NANTONG VOCATIONAL COLLEGE

Glass fiber reinforced plastic with antibacterial function

The invention relates to a glass fiber reinforced plastic with antibacterial function, which belongs to the technical field of glass fiber reinforced plastic, and is characterized in that it is composed of the following components in weight percent: 30-40 parts of unsaturated polyester resin, 10-30 parts of hydrogen peroxide, and 10-30 parts of potassium oxide. ‑3 parts, 1‑3 parts of phenol-modified tungsten hexachloride, 1‑5 parts of flame retardant, 2‑4 parts of nano filler, 10‑20 parts of glass fiber, 1‑3 parts of metal filler, non-elutable nano 1‑3 parts of silver antibacterial agent. The beneficial effect of the present invention is: use unsaturated polyester resin and other auxiliary materials as the curing system, use glass fiber yarn as the reinforcing material, produce high-performance composite linear materials, improve the strength of the product through a reasonable formula system; non-dissolution Type nano-silver antibacterial agent has long-lasting antibacterial and bactericidal effects.

Owner:成都双瑞暖通设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com