High-performance fiberglass reinforced plastic composite material and preparation method thereof

A technology of composite materials and glass fiber reinforced plastics, which is applied in the field of high-performance polyester glass composite materials and its preparation, can solve the problems of low bending strength, difficult to meet the requirements of use, and low softening point, and achieve the effect of increasing the softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

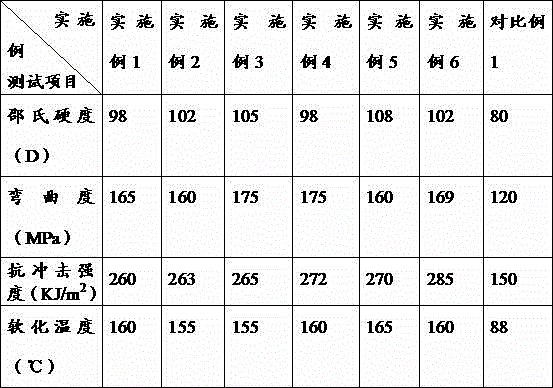

Examples

Embodiment 1

[0038] Preparation of polyester resin sheet: Add 50kg of dicyclopentadiene, 18kg of hydrogen peroxide, 0.3kg of phenol-modified tungsten hexachloride and 2.7kg of glass fiber into the reaction kettle at a temperature of 30°C and stir Mix all the above materials evenly, then increase the temperature of the reactor to about 160°C, and add 4kg of brominated polystyrene, whose brand is PBS-64HW, 3kg of nano-silica, and 2kg of potassium oxide, while continuing to stir. Continue to stir and react for about 6 hours to obtain a high temperature resistant dicyclopentadiene unsaturated polyester resin. Then process the dicyclopentadiene unsaturated resin into 2mm unsaturated polyester resin sheets for subsequent use.

[0039] Pre-impregnated glass fiber cloth: take 3 kg of iron powder and copper powder mixture with a fineness of 500 mesh, then mix the above mixture with 15 kg of dicyclopentadiene unsaturated resin, and then add 2 kg of glass fiber cloth woven from glass fiber pre-impre...

Embodiment 2

[0042] Preparation of polyester resin sheet: Add 35kg of dicyclopentadiene, 30kg of hydrogen peroxide, 0.5kg of phenol-modified tungsten hexachloride and 4kg of glass fiber into the reaction kettle at a temperature of 40°C, and stir to make Mix all the above-mentioned materials evenly, then increase the temperature of the reaction kettle to about 200°C, and add 5kg of brominated polystyrene, whose brand is PBS-64HW, 4kg of nano-silicon dioxide, and 1.5kg of potassium oxide, under the premise of continuing to stir. , continue to stir and react for about 6 hours, and high temperature resistant dicyclopentadiene unsaturated polyester resin can be obtained. Then process the dicyclopentadiene unsaturated resin into 3mm unsaturated polyester resin sheets for subsequent use.

[0043] Pre-impregnated glass fiber cloth: take 1 kg of iron powder and copper powder mixture with a fineness of 500 mesh, then mix the above mixture with 17 kg of dicyclopentadiene unsaturated resin, and then a...

Embodiment 3

[0046] Preparation of polyester resin sheet: Add 50kg of dicyclopentadiene, 10kg of hydrogen peroxide, 0.3kg of phenol-modified tungsten hexachloride and 2kg of glass fiber into the reaction kettle at a temperature of 60°C, and stir to make Mix all the above-mentioned materials evenly, then increase the temperature of the reaction kettle to about 250°C, and add 2kg of brominated polystyrene, whose brand is PBS-64HW, 1.7kg of nano-calcium carbonate, and 1kg of silicon dioxide, under the premise of continuing to stir. , 1 kg of potassium oxide, and continue to stir and react for about 6 hours to obtain high temperature resistant dicyclopentadiene unsaturated polyester resin. Then this dicyclopentadiene unsaturated resin is processed into 1 mm unsaturated polyester resin sheet for subsequent use.

[0047] Pre-impregnated glass fiber cloth: take 1 kg of iron powder with a fineness of 350 mesh, then mix the above mixture with 30 kg of dicyclopentadiene unsaturated resin, then add 1 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com