High-strength beryllium-copper alloy bar and preparation process thereof

A beryllium-copper alloy and preparation process technology, which can be used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of insufficient strength of beryllium-copper alloy materials, inability to meet the needs of use, and reduced electrical conductivity, so as to inhibit the recrystallization process and reduce the fineness of the beryllium copper alloy. The effect of reducing recrystallized grains and suppressing phase transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

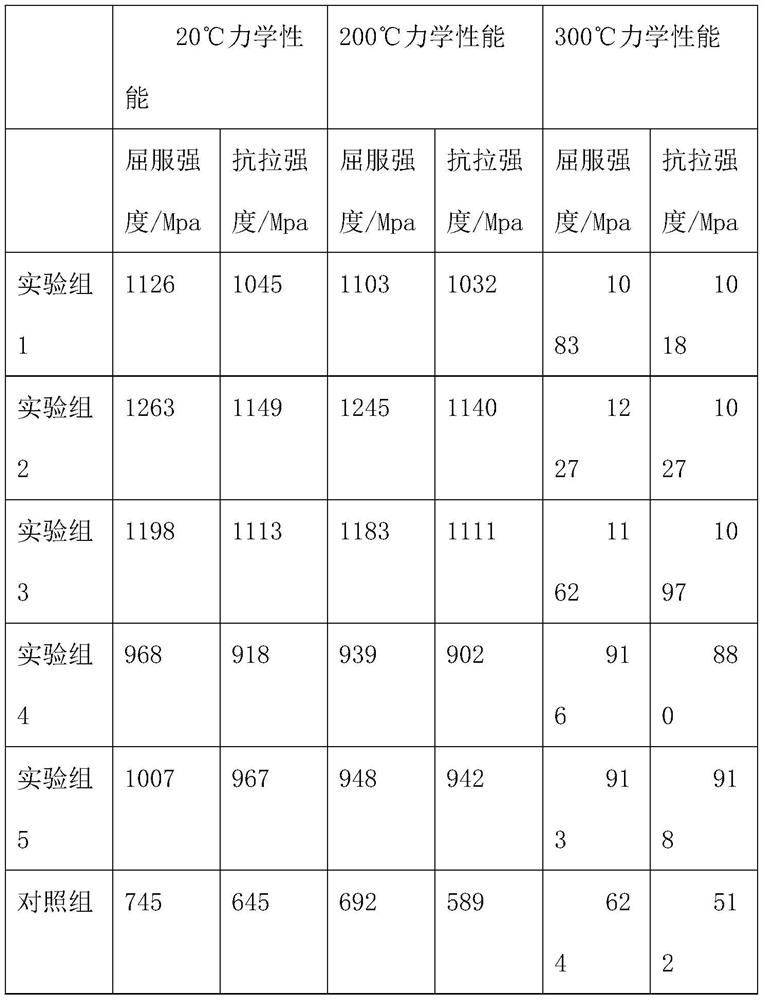

Embodiment 1

[0026] The invention provides a high-strength beryllium-copper alloy rod, including the following elements by weight percentage: Be: 1%, Si: 0.1%, Ni: 0.5%, Co: 0.1%, Zr: 0.05%, Ti: 0.005 %, V: 0.05%, rare earth elements: 0.05%, and the balance is Cu and unavoidable impurities.

[0027] In a preferred embodiment, the unavoidable impurity content is lower than 0.005%, the rare earth element is a mixture of lanthanum, samarium and cerium, and the mass ratio of lanthanum, samarium and cerium is 4:1.5:0.8 .

[0028] The present invention also provides a preparation process for a high-strength beryllium-copper alloy rod, the specific preparation steps are as follows:

[0029] Step 1: Melting, weigh the raw materials according to the above weight percentage, put the weighed raw materials into the vacuum melting furnace in turn, and melt in the vacuum melting furnace at 1250°C for 50 minutes, after the melting is completed, under the action of inert gas Import the smelting liquid i...

Embodiment 2

[0040] The difference from Example 1 is that the high-strength beryllium-copper alloy rod includes the following elements by weight percentage: Be: 1.3%, Si: 0.3%, Ni: 0.75%, Co: 0.3%, Zr: 0.1%, Ti: 0.025%, V: 0.1%, rare earth elements: 0.1%, and the balance is Cu and unavoidable impurities.

Embodiment 3

[0042] All different from Examples 1-2, the high-strength beryllium-copper alloy rod includes the following elements by weight percentage: Be: 1.6%, Si: 0.5%, Ni: 1%, Co: 0.5%, Zr: 0.15%, Ti: 0.045%, V: 0.15%, rare earth elements: 0.15%, and the balance is Cu and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com