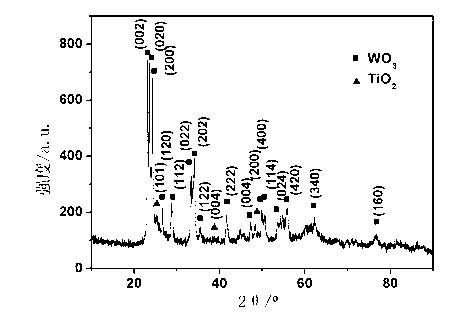

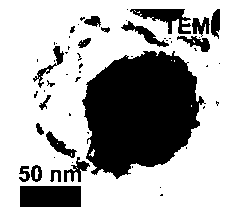

Method for preparing tungsten trioxide/titanium dioxide nanocomposite with core-shell structure

A nano-composite material, titanium dioxide technology, applied in the field of photocatalysis, can solve the problems of difficult to meet practical application requirements, harsh conditions, complex preparation methods, etc., and achieve the effects of broad practical application value, optimized performance, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Transfer 48 ml of glucose aqueous solution with a concentration of 0.1 mol / L to a closed container, hydrothermally react at a temperature of 200 °C for 20 h, filter and separate after cooling, wash the filtrate three times with ethanol and deionized water, and place in Dry at 60 °C for 6 h to obtain carbon microspheres.

[0016] 2) Disperse the carbon microspheres (100 mg) prepared in step 1) in 4 ml of ethanol mixed solution of titanium tetrachloride and tungsten hexachloride, wherein the concentration of titanium tetrachloride is 0.1 mol / L, hexachloride The concentration of tungsten chloride was 0.01 mol / L. After soaking for 36 h, the filtrate was separated by filtration, washed with ethanol three times, and then dried at 60 °C for 6 h to obtain carbon microspheres adsorbed with titanium ions and tungsten ions.

[0017] 3) Put the carbon microspheres adsorbed with titanium ions and tungsten ions prepared in step 2) into the calcination furnace, and heat up to 350 ℃...

Embodiment 2

[0020] 1) Transfer 48 ml of glucose aqueous solution with a concentration of 0.5 mol / L to a closed container, hydrothermally react at a temperature of 180 °C for 10 h, cool to room temperature and filter and separate, wash the filtrate three times with ethanol and deionized water respectively, and Dry at 60 °C for 6 h to obtain carbon microspheres.

[0021] 2) Disperse the carbon microspheres (400 mg) prepared in step 1) in 16 ml of ethanol mixed solution of titanium tetrachloride and tungsten hexachloride, wherein the concentration of titanium tetrachloride is 1.0 mol / L, hexachloride The concentration of tungsten chloride was 0.04 mol / L. After soaking for 24 h, the filtrate was separated by filtration, washed with ethanol three times, and then dried at 60 °C for 6 h to obtain carbon microspheres adsorbed with titanium ions and tungsten ions.

[0022] 3) Put the carbon microspheres adsorbed with titanium ions and tungsten ions prepared in step 2) into the calcination furnace, ...

Embodiment 3

[0024] 1) Transfer 48 ml of glucose aqueous solution with a concentration of 2.0 mol / L to a closed container, hydrothermally react at a temperature of 160 °C for 1 h, filter and separate after cooling, wash the filtrate three times with ethanol and deionized water, and place in Dry at 60 °C for 6 h to obtain carbon microspheres.

[0025] 2) Disperse the carbon microspheres (200 mg) prepared in step 1) in 6 ml of a mixed solution of titanium tetrachloride and tungsten hexachloride ethanol, in which the concentration of titanium tetrachloride is 2.0 mol / L, and the concentration of hexachloride The concentration of tungsten was 0.20 mol / L. After soaking for 3 h, the filtrate was separated by filtration, washed with ethanol three times, and then dried at 60 °C for 6 h to obtain carbon microspheres adsorbed with titanium ions and tungsten ions.

[0026] 3) Put the carbon microspheres adsorbed with titanium ions and tungsten ions prepared in step 2) into the calcination furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com