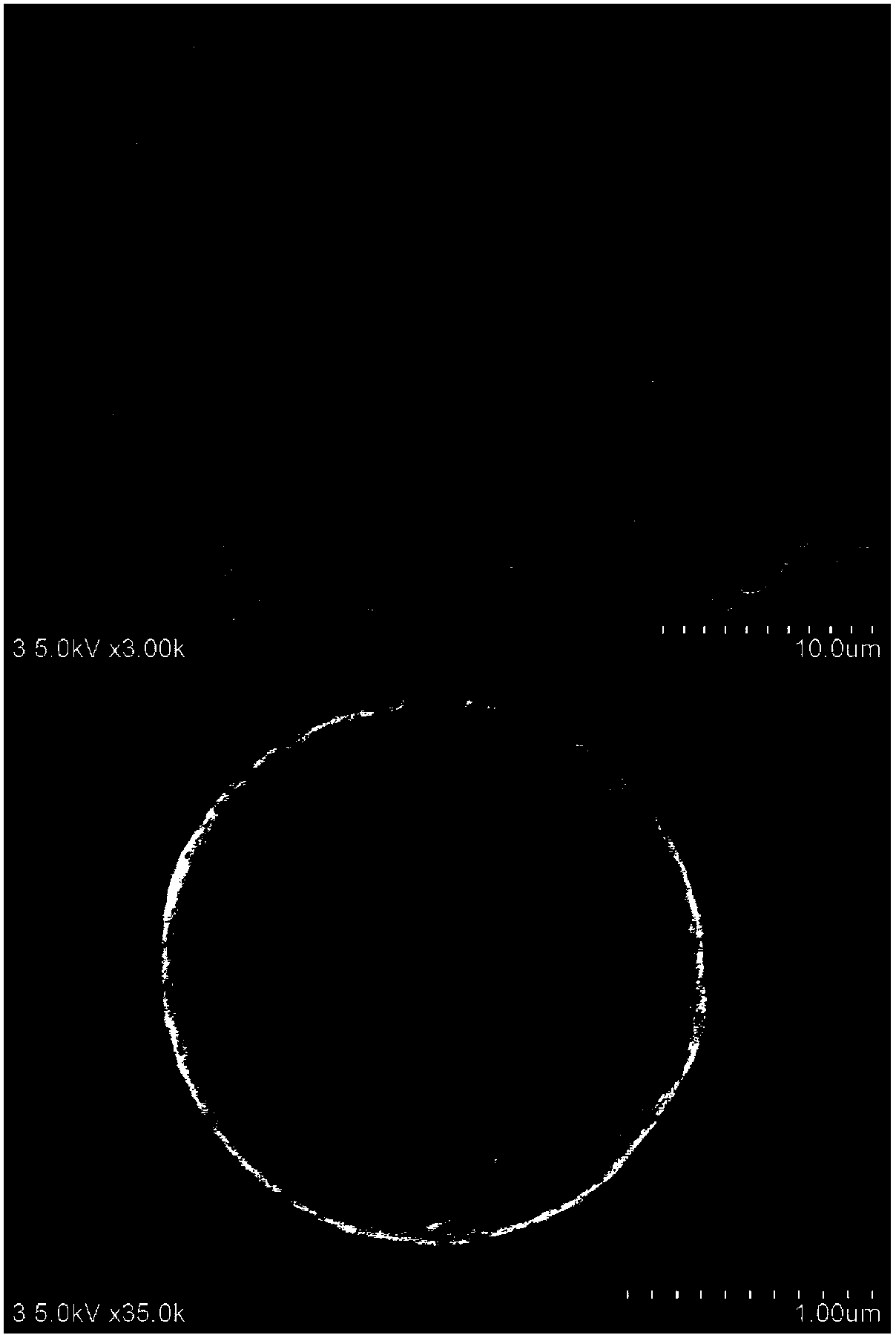

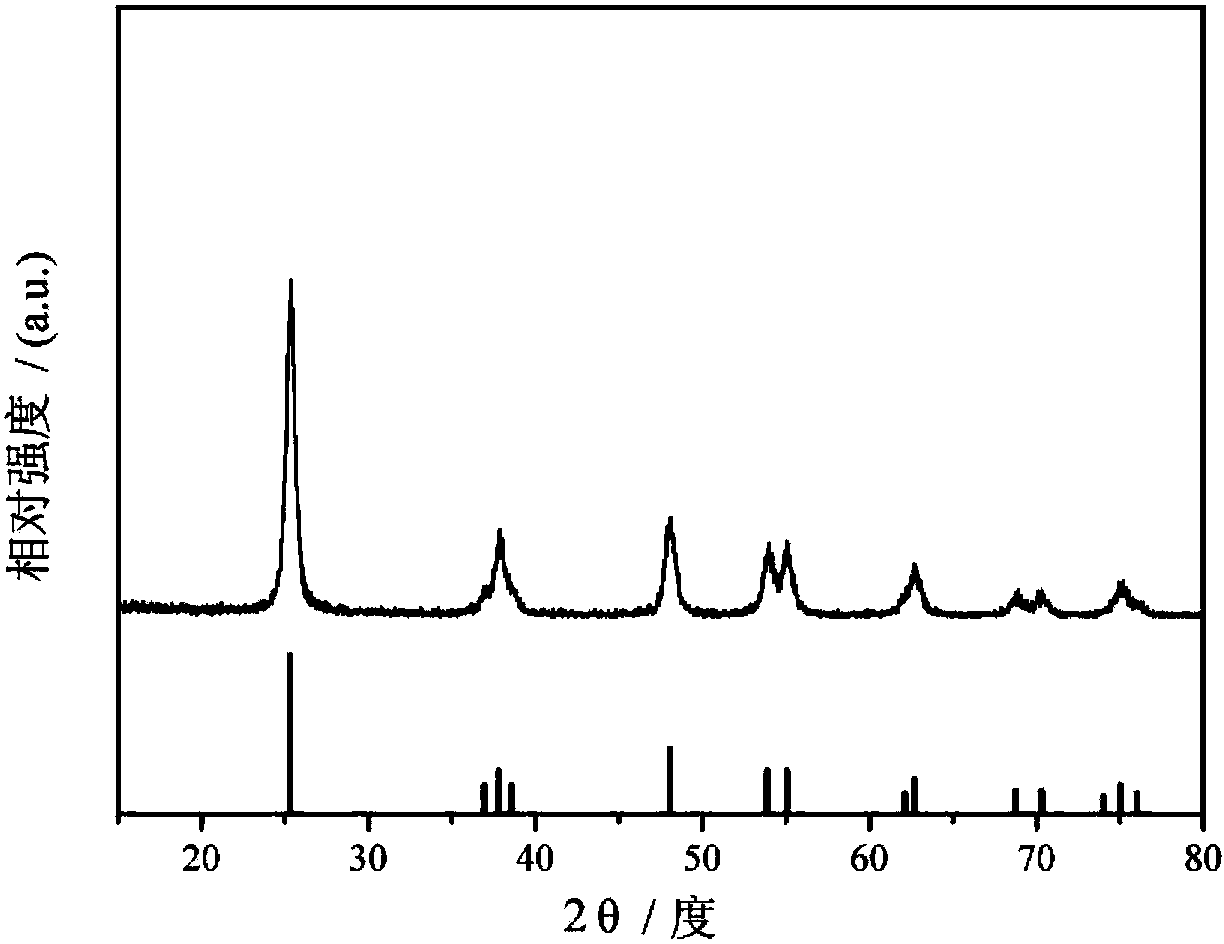

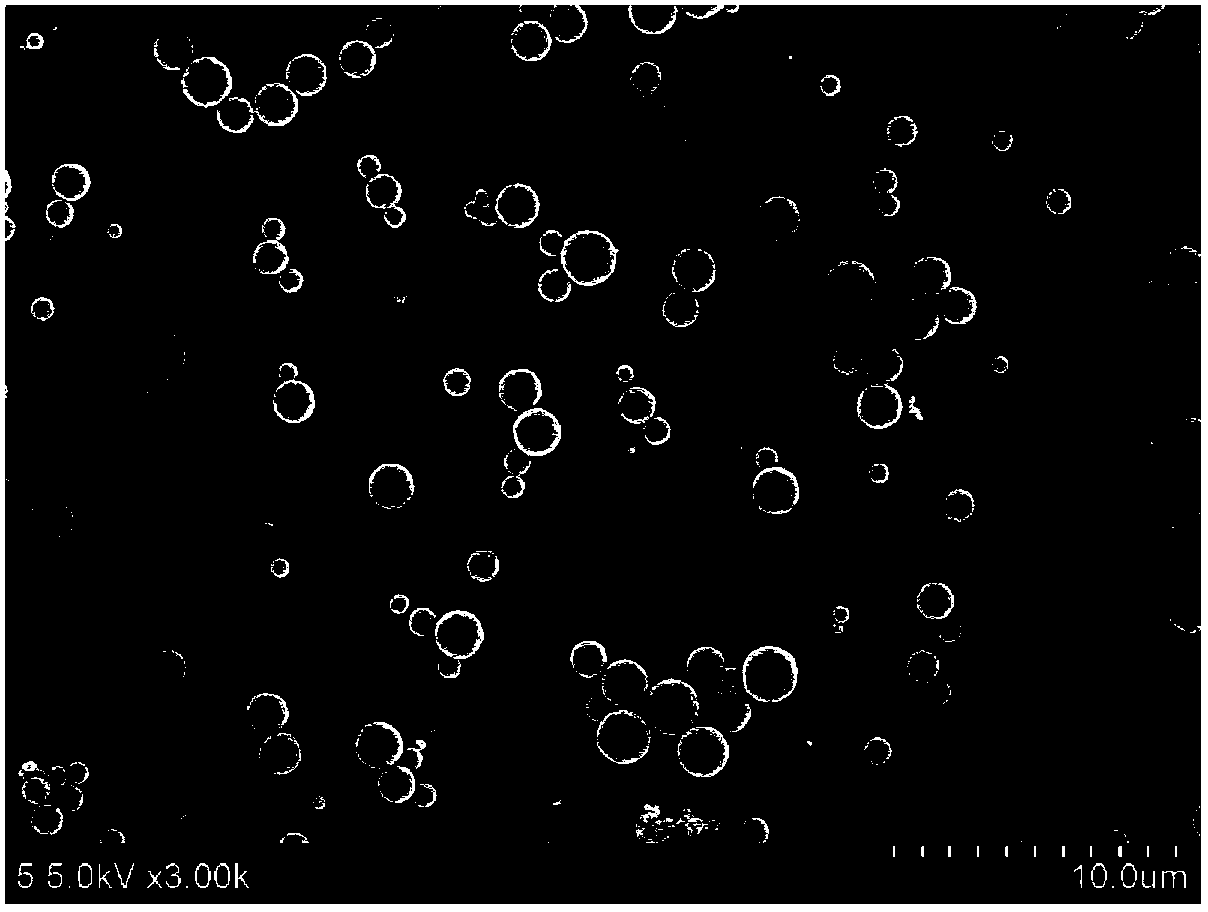

Preparation method of mesoporous titanium dioxide microballoons with controllable particle size

A mesoporous titanium dioxide, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of large specific surface energy of particles, limited application range, wide particle size distribution, etc., to achieve good dispersion, The effect of simple process route and narrow particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Under the condition of magnetic stirring, add titanium tetrachloride dropwise to the mixed solution of n-propanol and deionized water in an ice-water bath (volume ratio is 3:1), control the titanium tetrachloride The concentration is 0.1 mol / liter, and the precursor solution is obtained by continuous stirring at low temperature for 8 hours;

[0030] (2) Transfer the precursor solution in step (1) to a water (oil) bath and heat it to 70°C. White precipitates are formed. Continue to age for 30 minutes to completely hydrolyze the titanium tetrachloride precursor solution. The amount of precipitate no longer increase;

[0031] (3) Add NH with an ammonia concentration of 0.5 mol / liter to the precipitation solution in step (2). 3 A mixed solution of ammonia water and n-propanol with a mass fraction of 27%, the solution is adjusted to neutrality, and the obtained precipitate is successively washed with deionized water and n-propanol by centrifugation;

[0032] (4) Disper...

Embodiment 2

[0036] (1) Under the condition of magnetic stirring, add titanium tetrachloride dropwise to the mixed solution of n-propanol and deionized water in an ice-water bath (volume ratio is 3:1), control the titanium tetrachloride The concentration is 0.1 mol / L, add 0.6 g / L hydroxypropyl cellulose, and continue stirring at low temperature for 6 hours to obtain a precursor solution;

[0037] (2) Transfer the precursor solution in step (1) to a water (oil) bath and heat it to 80°C. White precipitates of titanium dioxide are formed. Continue to age for 20 minutes to completely hydrolyze the titanium tetrachloride precursor solution. The precipitated no longer increase in volume;

[0038](3) Add NH with an ammonia concentration of 0.5 mol / liter to the precipitation solution in step (2). 3 A mixed solution of ammonia water and n-propanol with a mass fraction of 27%, the solution is adjusted to neutrality, and the obtained precipitate is successively washed with deionized water and n-prop...

Embodiment 3

[0043] (1) Under the condition of magnetic stirring, add titanium tetrachloride dropwise to the mixed solution of n-propanol and deionized water in an ice-water bath (volume ratio is 5:1), control the titanium tetrachloride The concentration is 0.05 mol / liter, add 0 g / liter of hydroxypropyl cellulose, and continue stirring at low temperature for 4 hours to obtain a precursor solution;

[0044] (2) Transfer the precursor solution in step (1) to a water (oil) bath and heat it to 60°C. White precipitates are formed. Continue to age for 10 minutes to completely hydrolyze the titanium tetrachloride precursor solution. The amount of precipitate no longer increase;

[0045] (3) Add NH with an ammonia concentration of 2.5 mol / liter to the precipitation solution in step (2). 3 A mixed solution of ammonia water and n-propanol with a mass fraction of 27%, the solution is adjusted to neutrality, and the obtained precipitate is successively washed with deionized water and n-propanol by ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com