Patents

Literature

38results about How to "Potential for industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

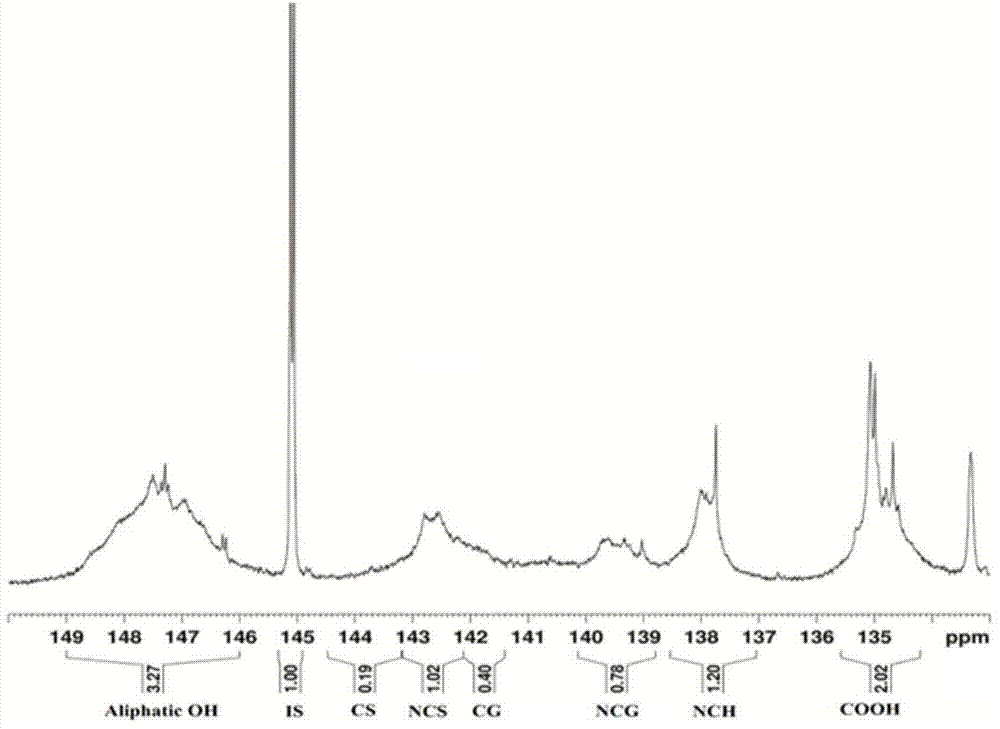

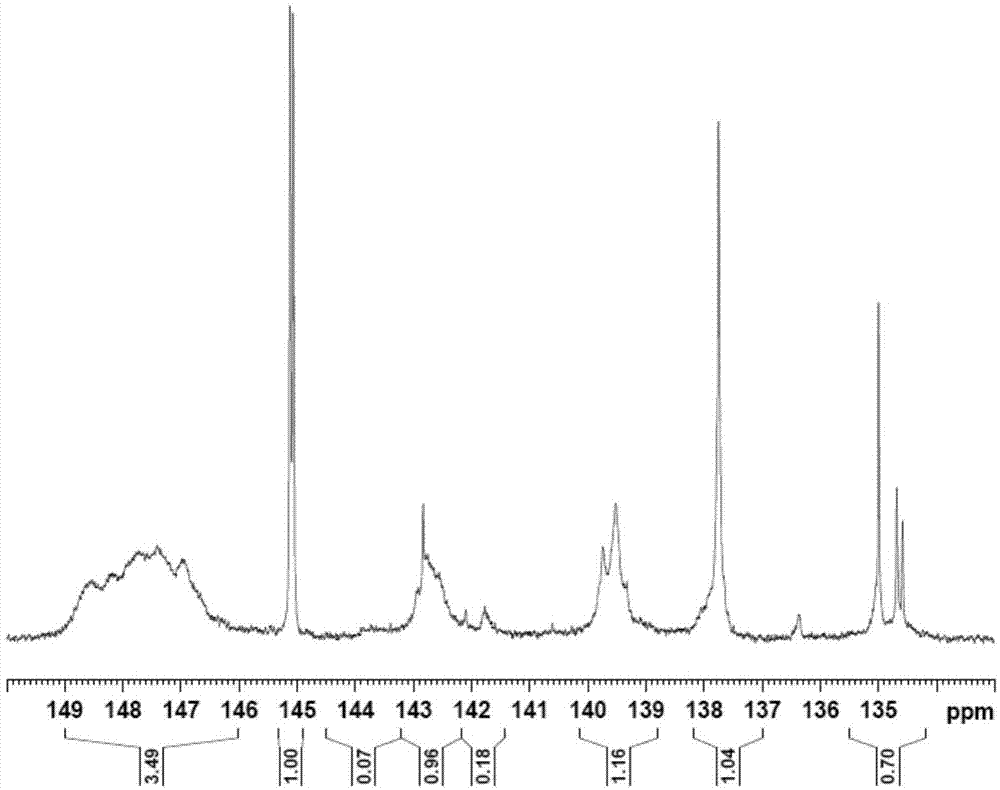

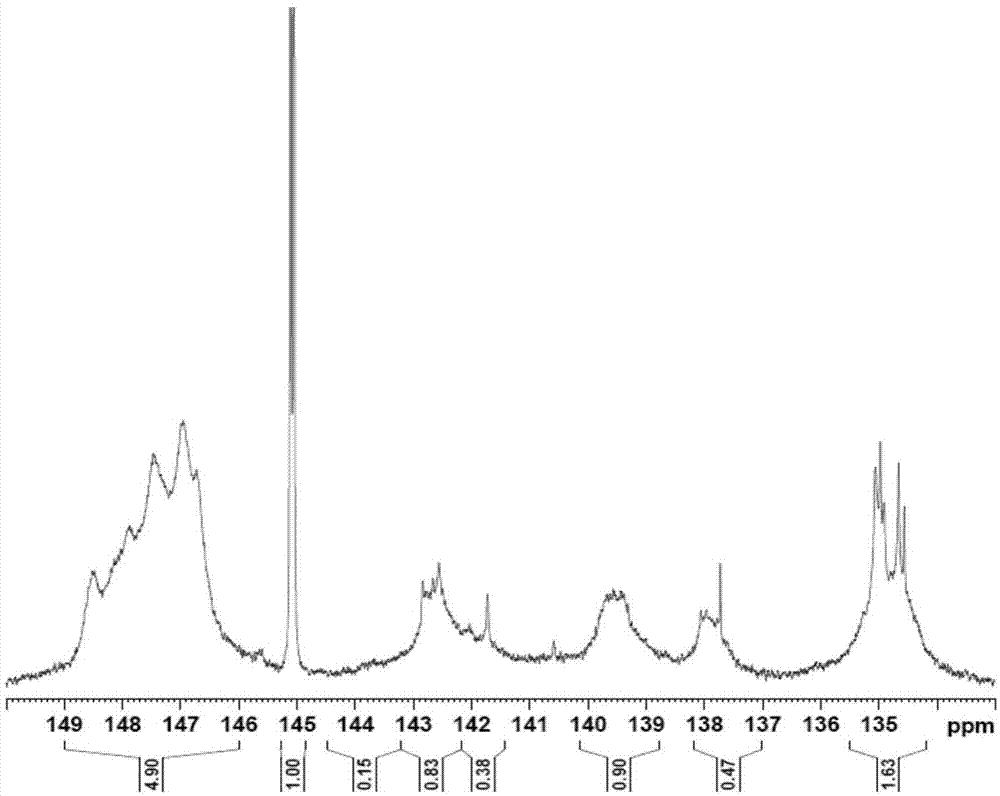

Method for preparing lignin-based environment-friendly phenolic resin adhesive

ActiveCN103804618AAvoid excessive releaseAdaptableAldehyde/ketone condensation polymer adhesivesAlcoholNMR - Nuclear magnetic resonance

The invention discloses a method for preparing a lignin-based environment-friendly phenolic resin adhesive. The method comprises the following steps: 1, carrying out quantitative analysis on hydroxyl of a lignin material by using a quantitative phosphorus spectrum of nuclear magnetic resonance technology, and obtaining the quantity of active site points in unit mass of lignin material when reacting with formaldehyde by calculating the quantity of phenolic hydroxyl groups and alcoholic hydroxyl groups; 2, mixing the lignin material with phenol to form a material mixture, wherein the mass ratio of the lignin material to the phenol is (1:9)-(8:2) in the mixing process; 3, calculating the gross of formaldehyde; 4, mixing the material mixture obtained in the step 2 with formaldehyde and aqueous alkali for reaction, so as to prepare the lignin-based environment-friendly phenolic resin adhesive. The biomass refined by-product lignin is utilized at high value on the basis that the problems of expensive product and formaldehyde pollution of the traditional lignin-based phenolic resin adhesive are solved, and the method has great economic significance and social significance.

Owner:HUNAN FORESTECH NEW MATERIALS CO LTD

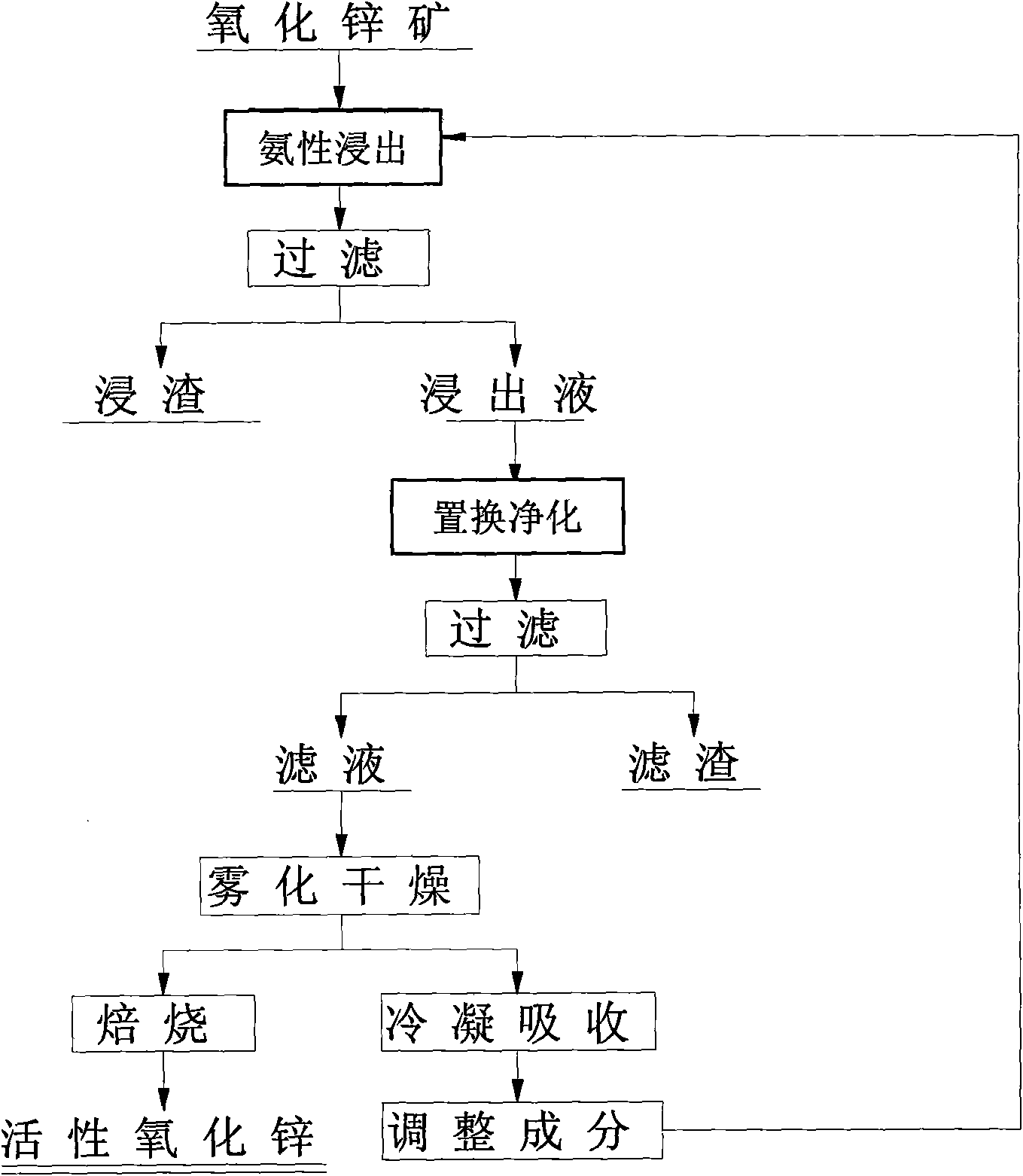

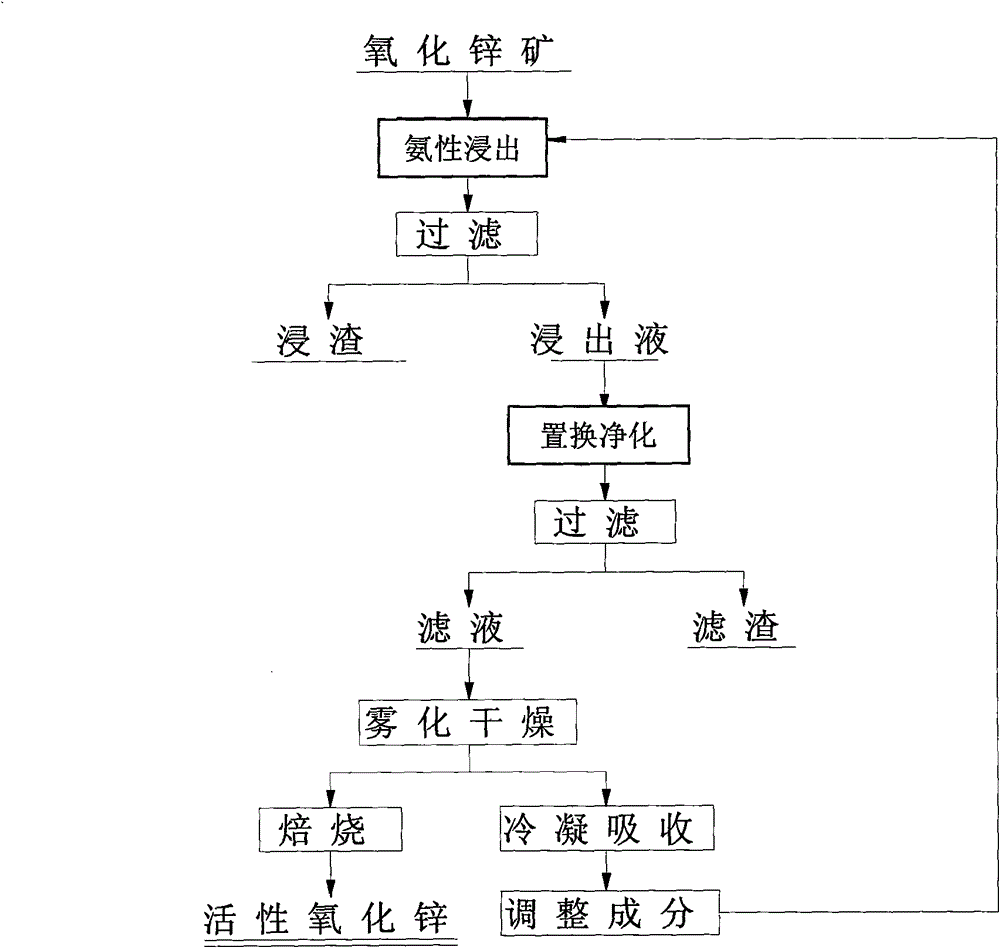

Method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide

The invention relates to a method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide. The method comprises the following steps: ammonium leaching: using zinc oxide ore containing 2-60% of zinc or complex zinc oxide secondary resource as raw material, extracting in an ammonium system coordinately, filtering to remove the residue, wherein the filtrate is applied to the next process; replacement and purification: replacing and purifying the extracted filtrate with zinc powder to eliminate impure elements, and then filtering and removing the residue, wherein the filtrate is applied to the next process; pulverization and drying: decomposing the purified filtrate through high-temperature pulverization to prepare powder A, condensing, spraying and absorbing the tail gas which is then returned to the leaching process to prepare the extracting agent; and toasting: toasting the powder A to obtain superfine active zinc oxide. The purified liquidcan be used for directly preparing even powder through efficient pulverization and drying. The technological process of the method has a circular loop so that a small amount of waste gas and waste water is discharged. The method has a rational tail gas heat exchanger. Ammonia gas is recycled in a condensing manner to prepare the leaching liquid. The rest of the ammonia gas is absorbed through spraying, thereby reducing the discharge pressure of three wastes, namely, waste gas, waste water and industrial residue.

Owner:JIANGXI UNIV OF SCI & TECH

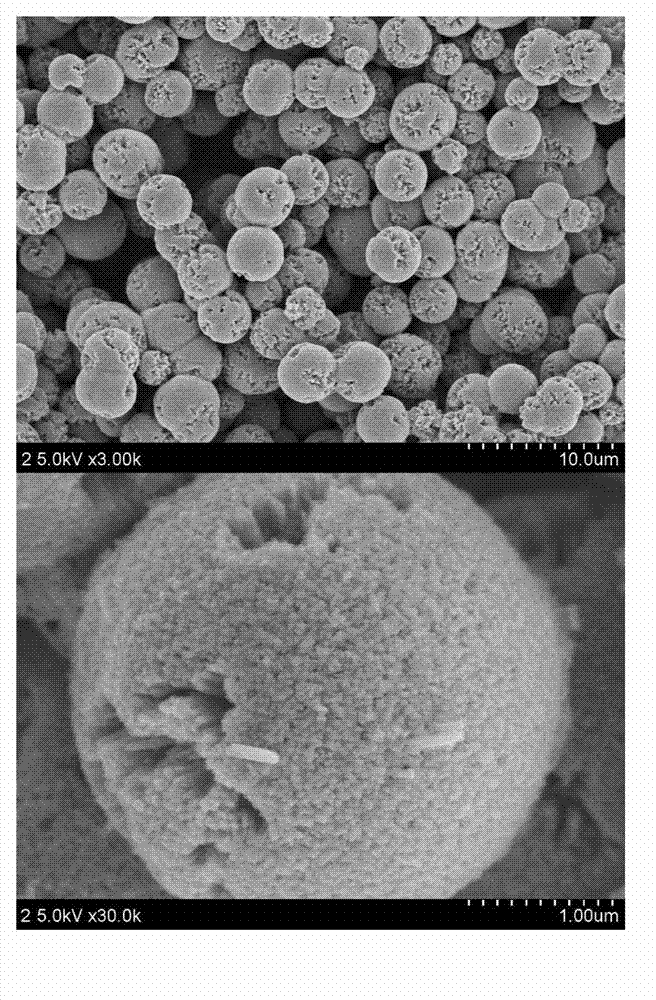

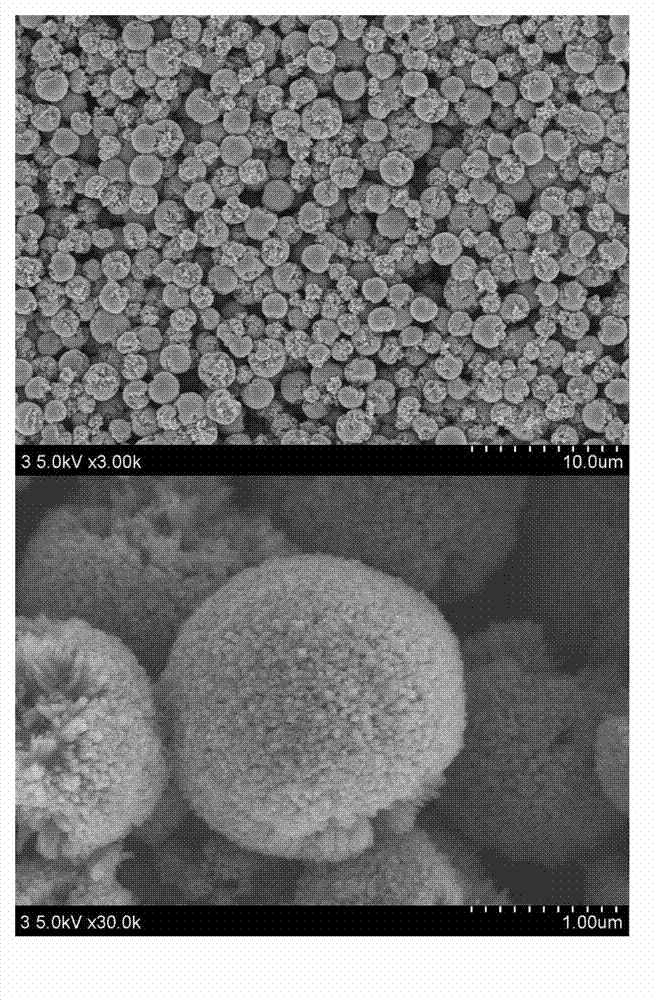

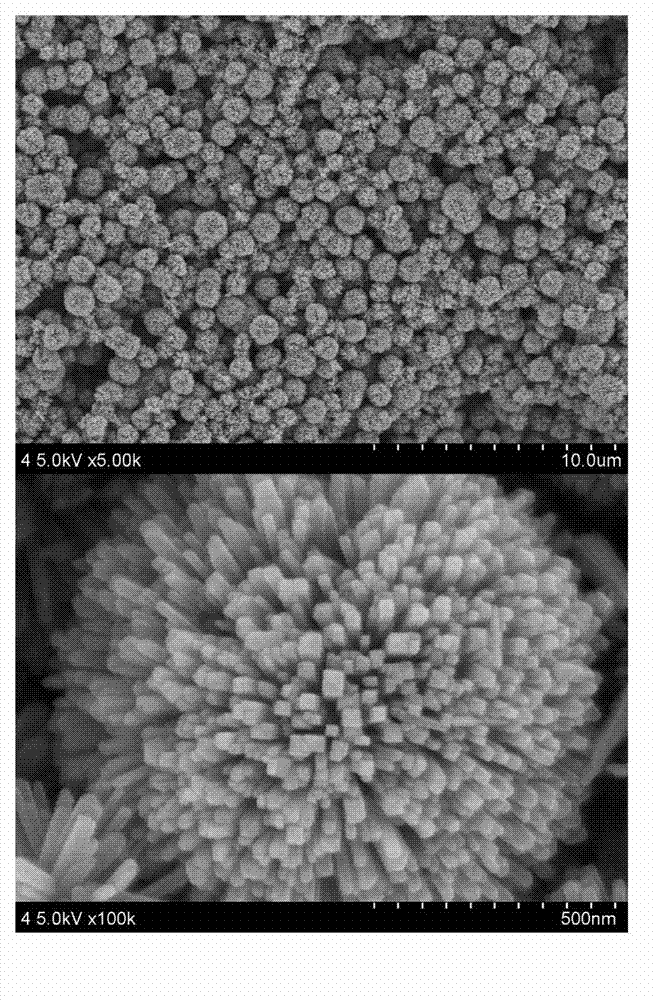

Method for preparing rutile type titanium dioxide nanorod microsphere

InactiveCN102786085AReduce energy consumptionShort cycleNanotechnologyTitanium dioxideNew energyMicrosphere

The invention relates to a method for preparing a rutile type titanium dioxide nanorod microsphere. The method comprises the following steps of (1) mixing concentrated hydrochloric acid, deionized water and non-polar solvent, adding titanium alkoxide in the mixed solvent drop by drop under a magnetic stirring condition, after the titanium alkoxide is added, continuously stirring the mixture for 30-60 minutes, so that the titanium alkoxide can be fully hydrolyzed to form layered mixed solution; and (2) transferring the mixed solution to a high pressure reaction kettle to perform solvothermal reaction, after the reaction is finished, naturally cooling the high pressure kettle by placing the reaction kettle at a room temperature, and repeatedly washing and centrifugally separating the obtained precipitate to obtain the titanium dioxide nanorod microsphere. According to the method provided by the invention, the solvothermal reaction is carried out in the interface of polar / non-polar solution by adopting the titanium alkoxide, the process route is simple and convenient, no surfactant is required; the prepared titanium dioxide nanorod microsphere is good in dispersion, high in degree of crystallinity, large in specific area, and can be used in various fields of photochemical catalyst, paints, cosmetics, new energy and the like.

Owner:DONGHUA UNIV

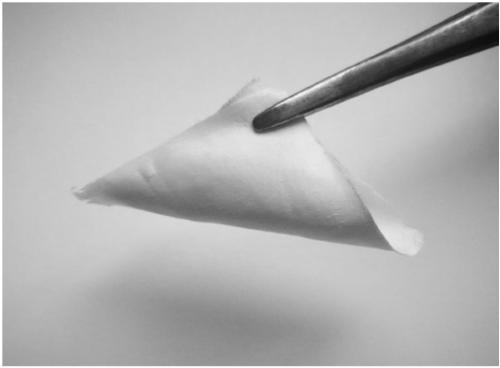

Method for preparing polyurethane-imide permeable vaporizing aromatic/alkane separating membrane

InactiveCN101121101AEasy to separateLow costSemi-permeable membranesHydrocarbon purification/separationAlkaneInfrared lamp

The invention relates to a preparation method of polyurethane imide pervaporation aromatic hydrocarbon / alkane separation membrane, which belongs to the technical field of pervaporation membrane separation. The existing polyurethane membranes have low separation factors, and most of them need to be tested for pervaporation separation performance at high temperature. The present invention includes 1) synthesis of polyurethane-imide prepolymer: under the conditions of nitrogen protection, mechanical stirring and condensing reflux, react polyethylene adipate diol with diisocyanate to obtain a blocked prepolymer , and then add pyromellitic dianhydride for chain extension to obtain a polyurethane-imide prepolymer solution; 2) Preparation of polyurethane-imide film: the solution is cast into a film and the solvent is volatilized under an infrared lamp, and then the Heat treatment at 150°C for 1.5-2 hours. The material synthesis and membrane-making process of the present invention are simple, and the prepared membrane has good thermal and chemical stability, and has a good separation effect on aromatic hydrocarbon / alkane mixed liquid under warm conditions, and has great practical value .

Owner:TSINGHUA UNIV

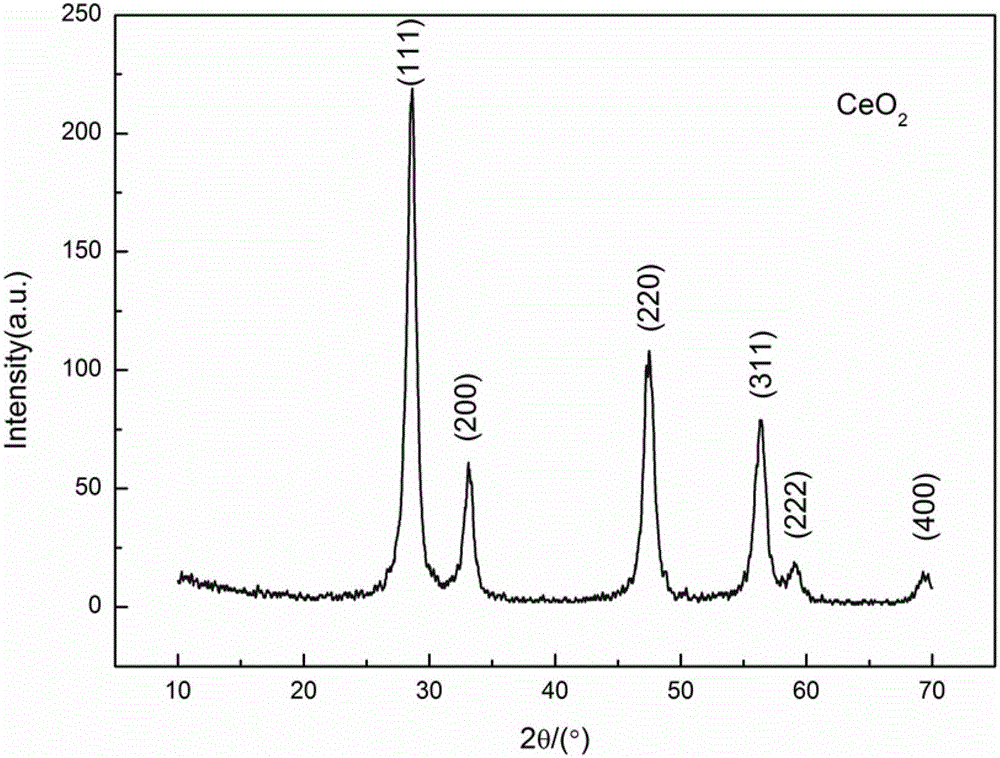

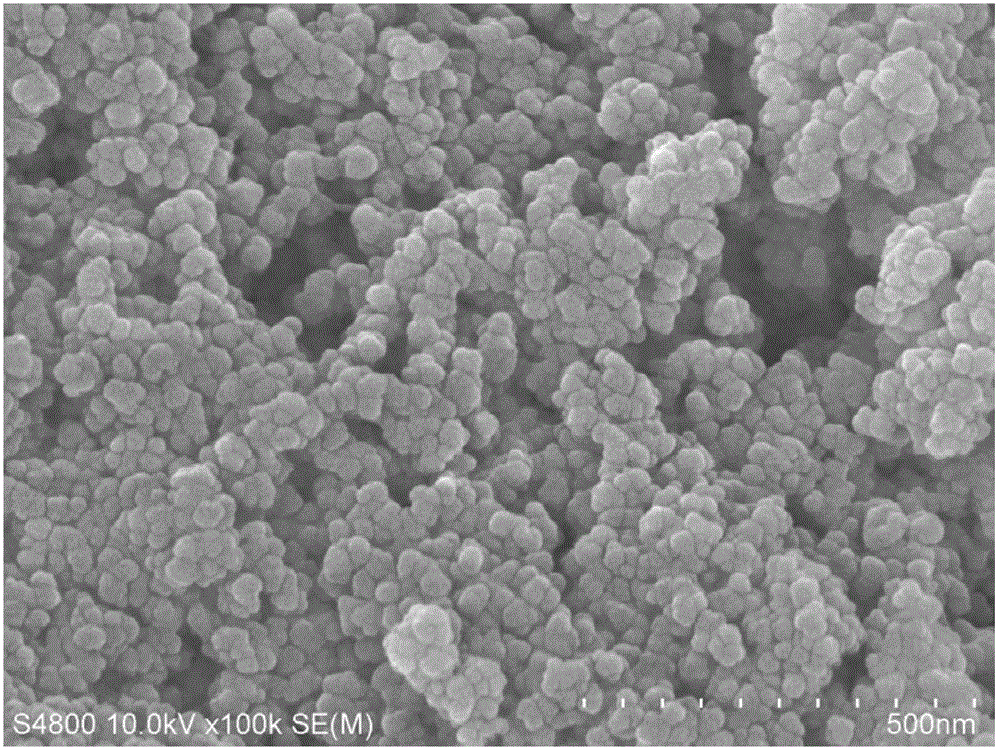

Method for preparing cerium dioxide nanometer powder

InactiveCN102942204ASave raw materialsEasy to operateMaterial nanotechnologyRare earth metal compoundsMicrowaveCerium

A method for preparing cerium dioxide nanometer powder includes: dissolving Ce(NO3)3-6H2O in deionized water to obtain Ce(NO3)3 solution; adding ethidene diamine and KBrO3 into the Ce(NO3)3 solution to continuously and evenly stir to obtain mixed solution; and transferring the mixed solution into a reaction kettle, placing the mixed solution into a microwave hydrothermal instrument to react for 0.5-1.5h at the temperature of 160-200 DEG C, performing centrifugal washing after the reaction, and drying at the temperature of 80 DEG C to obtain CeO2 nanometer powder. The method for preparing cerium dioxide nanometer powder is low in cost and easy to operate and control. The CeO2 powder prepared by the microwave hydrothermal method can be directly applied to preparation of mixed and compounded CeO2 nanometer powder, and a new application is provided for preparation of a CeO2-based new material. Compared with the traditional hydrothermal method, the microwave hydrothermal method has the advantages of being environment-friendly, energy-saving and efficient.

Owner:SHAANXI UNIV OF SCI & TECH

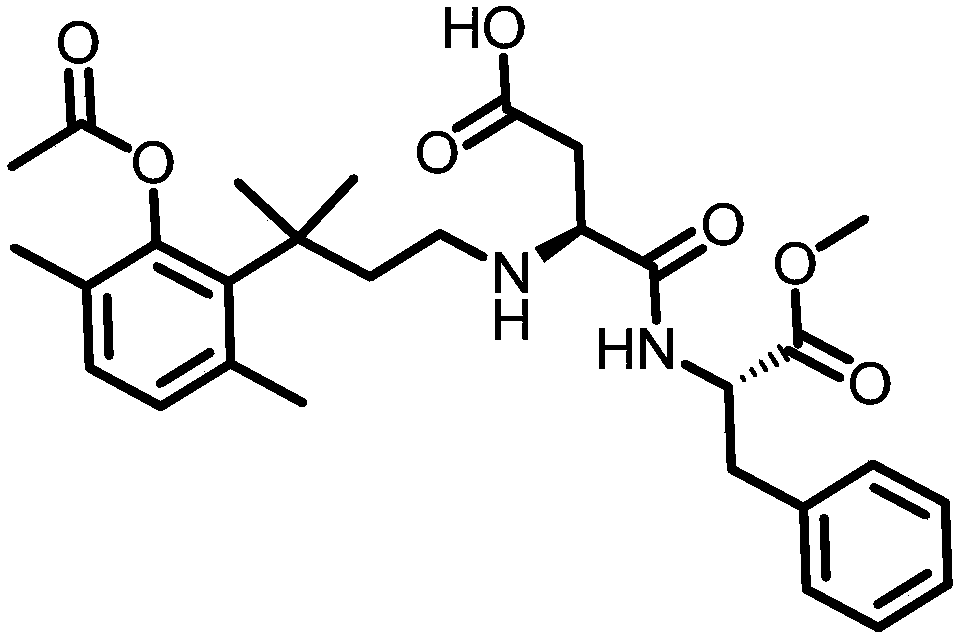

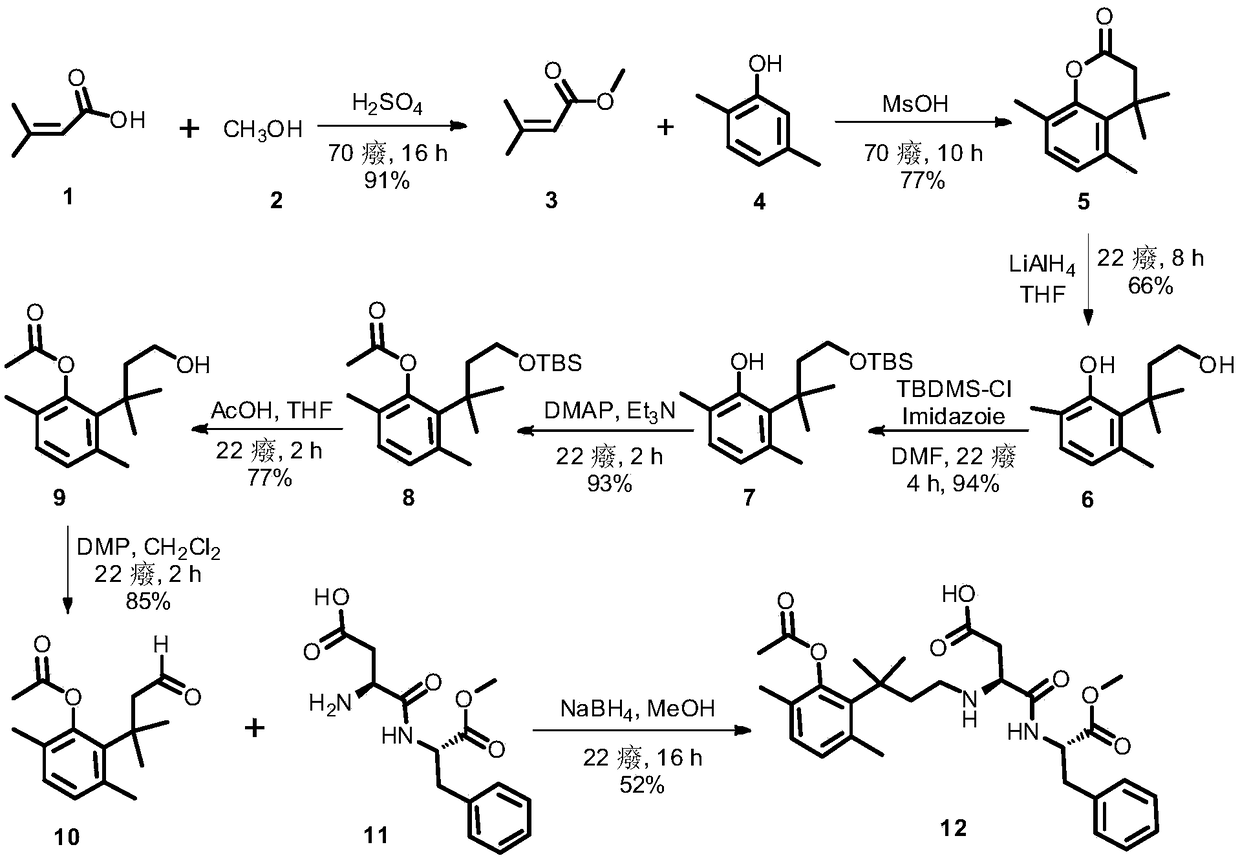

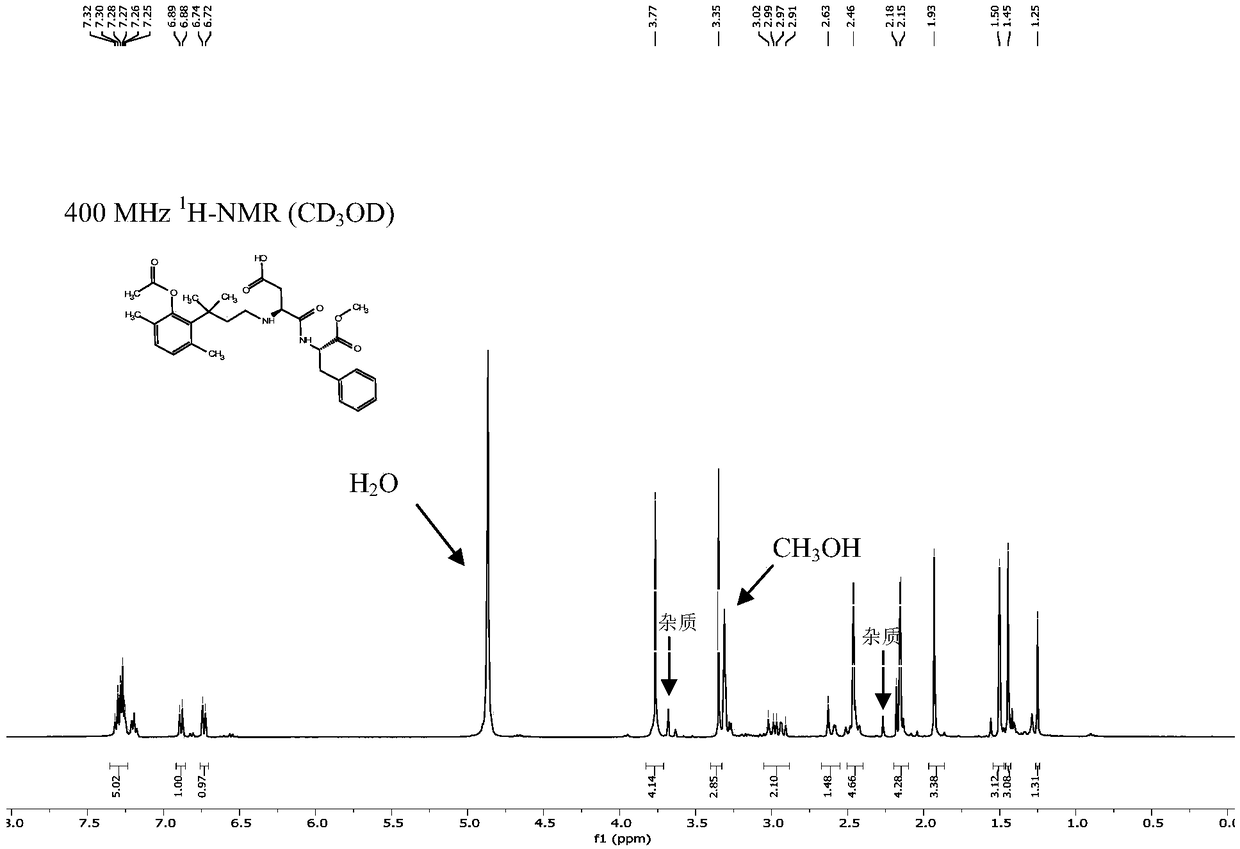

Dipeptide high sweetening agent and synthesis method thereof

InactiveCN108586573ASuperior sweetness performanceImprove performancePeptide preparation methodsFood ingredient as taste affecting agentDipeptideSucrose

The invention discloses a dipeptide high sweetening agent and a synthesis method thereof. The synthesis method comprises the steps of an esterification reaction, an alkylation reaction, a reduction reaction, protection and deprotection reactions, an oxidation reaction and a reductive amination reaction. According to the invention, methanol and 3,3-dimethyl acrylic acid are used as initial raw materials, and 4,4,5,8-tetramethyl-3,4-dihydrocoumarin is obtained by the esterification reaction and the alkylation reaction; LiAlH4 is used as a reducing agent, and 3-(2-hydroxyl-3,6-dimethylphenyl)-3-methylbutanol is obtained through reduction; the protection and deprotection reactions are carried out, and the intermediate 3-(2-acetyl-3,6-dimethylphenyl)-3-methylbutyraldehyde of a neotame analogueis obtained through the oxidization of the alcohol; and then a reaction with aspartame is carried out for synthesizing the dipeptide high sweetening agent with a sweetness of 70000 times of sucrose. The dipeptide high sweetening agent has excellent performance and good taste, and can meet the requirements of the current development of food industry. The synthesis method optimized by the inventionis simple in technical process and convenient in operation, the production process is green and environmentally friendly, the cost is relatively low, the method accords with the green development, andthe realization of industrialization is easy.

Owner:JINAN UNIVERSITY

Method for catalyzing and gasifying carbonized materials by utilizing wood vinegar as catalyst

InactiveCN101962573ALow priceOvercome the disadvantage of being expensiveGranular/pulverulent flues gasificationWater vaporReaction temperature

The invention discloses a method for catalyzing and gasifying carbonized materials (coal, petroleum coke and biomass coke) by utilizing wood vinegar as a catalyst. The invention is characterized in that the carbonized materials (the coal, the petroleum coke and the biomass coke) and the wood vinegar are evenly mixed by the solution immersion method; the moisture of the mixture is evaporated to dryness; and the mixture is dried at 110 DEG C to obtain an experimental sample. The mass of CH3COOK in the wood vinegar accounts for 5-15% of the mass of the carbonized materials. The catalytic and gasification reaction is carried out on the experimental sample and water vapour, wherein the reaction temperature is 750-850 DEG C, the water vapour differential pressure is 40-70% and the reaction time is 30-90min. In the invention, the carbonized materials added with the catalyst can have a conversion percent and a gasification rate both 3 times more than those when no catalyst is added; the wood vinegar, the adopted catalyst is the main by-product of the pyrolytic biomass, on one hand, the reactivity of the gasification of the carbonized materials is improved, and one the other hand, recycling of the by-product is realized.

Owner:EAST CHINA UNIV OF SCI & TECH

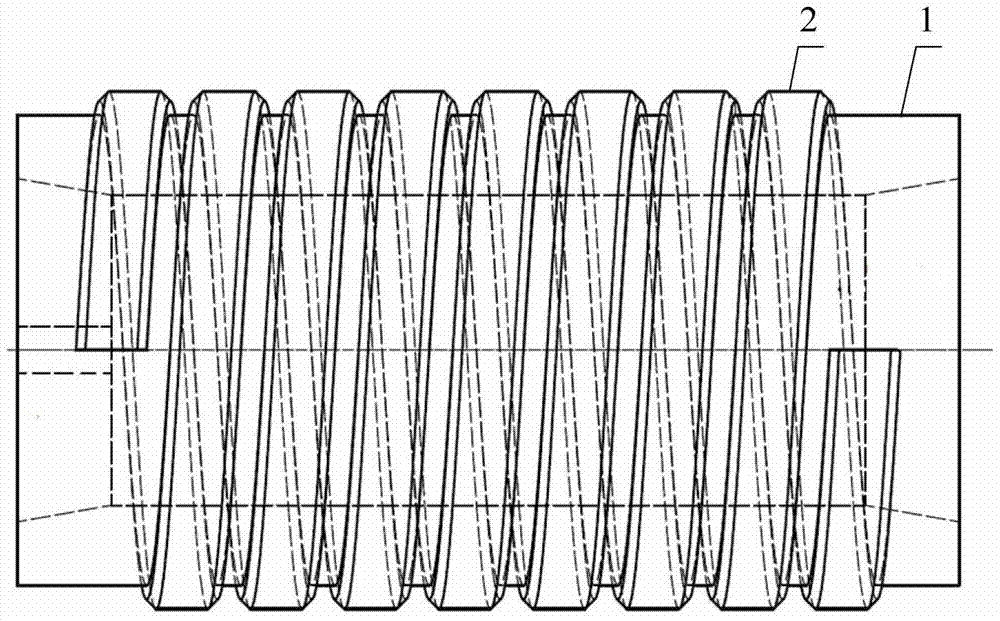

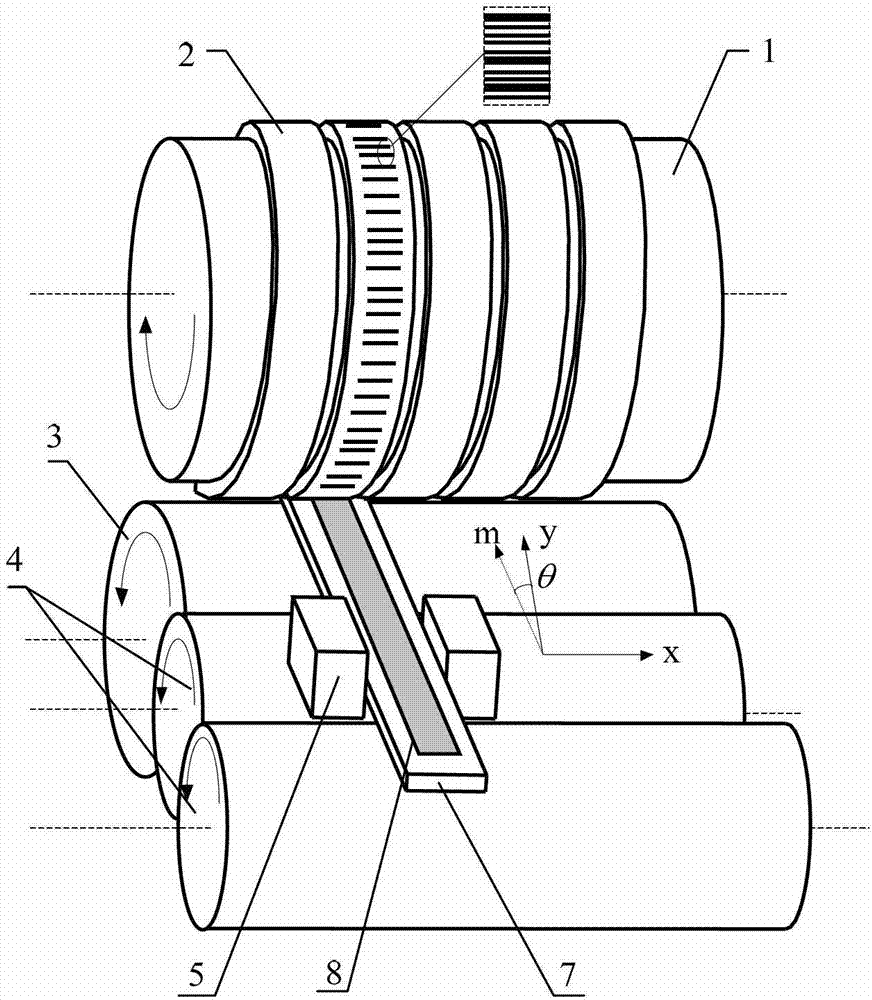

Roll-in printing manufacturing method of single-track absolute type grating ruler

InactiveCN102759857AWith bulkBatch fastPhotomechanical apparatusUsing optical meansBatch productionPhotolithography

The invention discloses a roll-in printing manufacturing method of a single-track absolute type grating ruler, which utilizes a spiral roll-in printing mould to carry out pressing replication on a metal material layer on the surface of a grating ruler blank by a roll-in printing process. The shape of the spiral roll-in printing mould is a spiral line belt with a lifting angle of theta; a single-track absolute type grating grid line is manufactured on the spiral line belt through rotary photoetching and wet-method etching; a grating ruler blank is horizontally placed between the roll-in printing mould and a supporting roller; and under the effect of a pressing force of the roll-in printing mould, the metal material layer on the grating ruler blank is subjected to plastic deformation and a grating grid line groove on the spiral line belt of the roll-in printing mould is filled, so that an single-track absolute type grating ruler grid line is formed on the grating ruler blank. According to the method disclosed by the invention, the spiral line belt is wound on a base body of a cylindrical roller mould by a plurality of circles and the single-track absolute type grating ruler with a customized length can be manufactured by a roll-in printing method; and compared with the traditional manufacturing manner of the absolute type grating ruler, the roll-in printing manufacturing method has the technical advantages of batch production, rapidness and low cost.

Owner:XI AN JIAOTONG UNIV +1

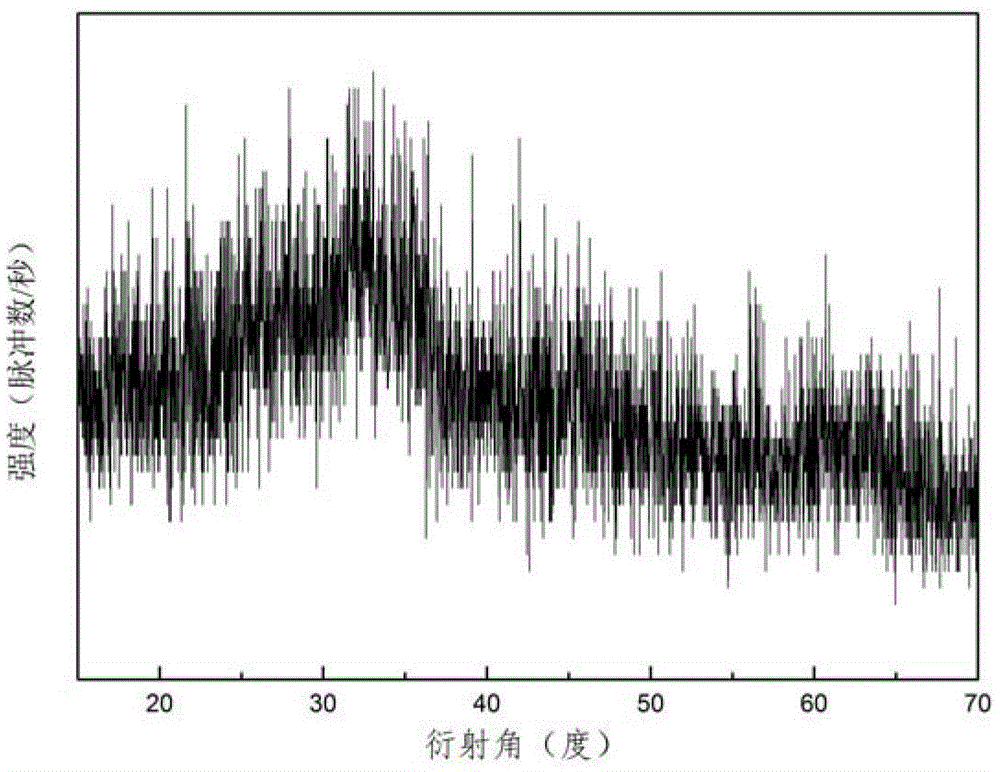

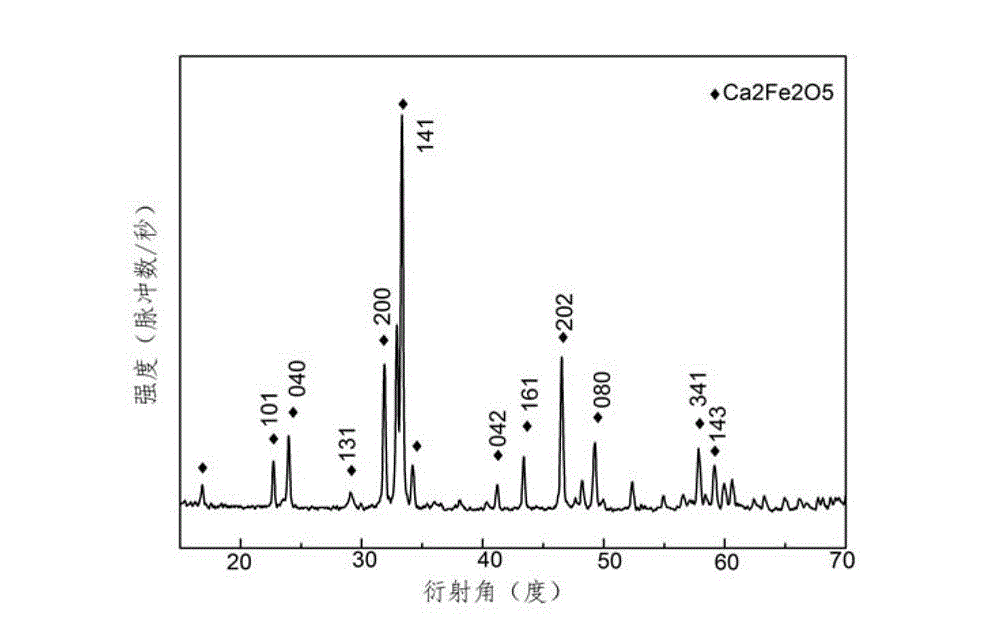

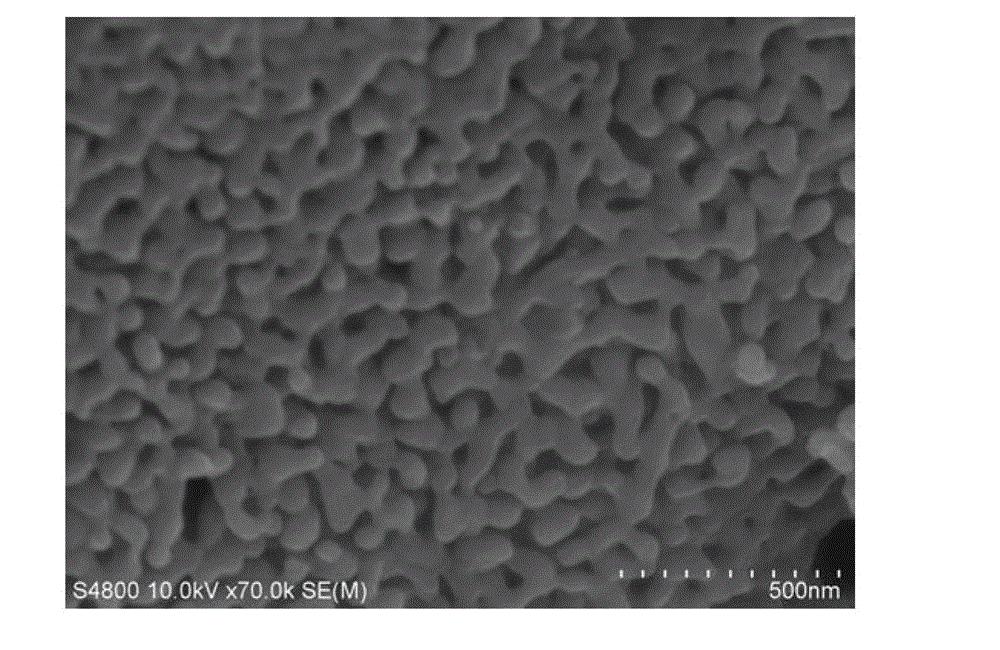

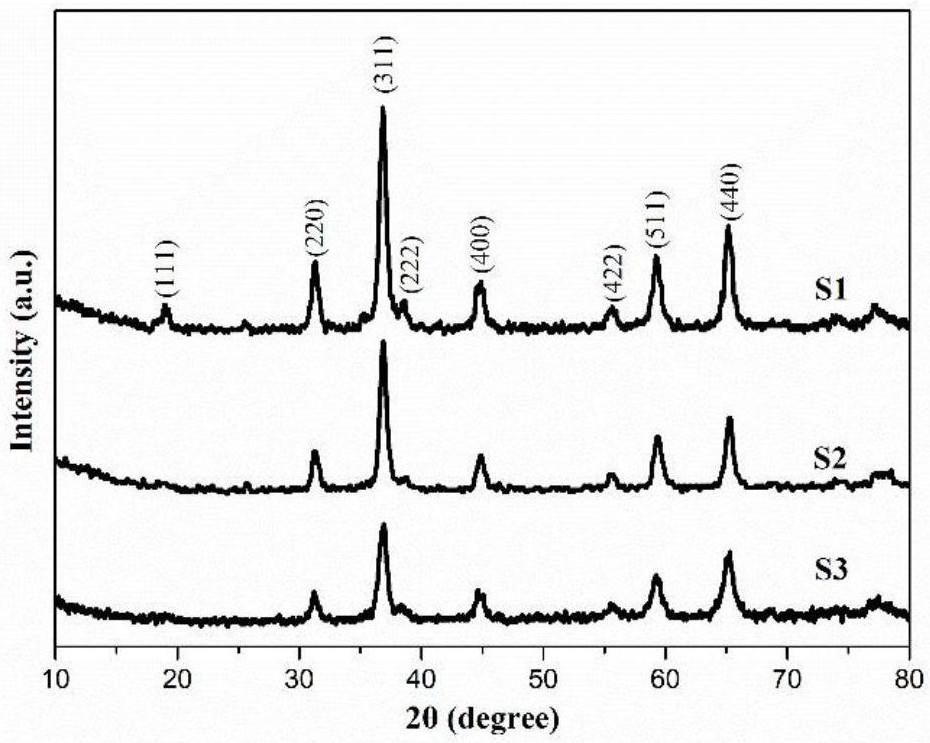

Method for preparing Ca2Fe2O5 nano powder

InactiveCN103145190ASmall granularityGood crystallization performanceMaterial nanotechnologyChemical industryMuffle furnaceChemistry

The invention provides a method for preparing Ca2Fe2O5 nano powder, which comprises the following steps: evenly mixing an iron nitrate solution and a calcium nitrate solution to obtain a mixed solution A; and adding glycine into the mixed solution A according to the propellant chemistry theory, sending into a muffle furnace, heating to 100-300 DEG C to carry out self-propagating reaction to obtain deep-brown fluffy primary powder, and roasting at 100-300 DEG C to obtain the Ca2Fe2O5 nano powder. The invention has the advantages of cheaper raw materials and simple technological operation; the roasting temperature is obviously lowered, thereby being beneficial to energy saving and environmental protection; and the glycine used as a combustion improver is non-toxic and harmless, thereby ensuring the health and safety of operating personnel. The Ca2Fe2O5 nano powder prepared by the method provided by the invention has the advantages of high purity, small and uniform particle size and favorable crystallinity, and can be used as a photocatalyst for degrading organic pollutants or as a cathode material for solid fuel cells.

Owner:SHAANXI UNIV OF SCI & TECH

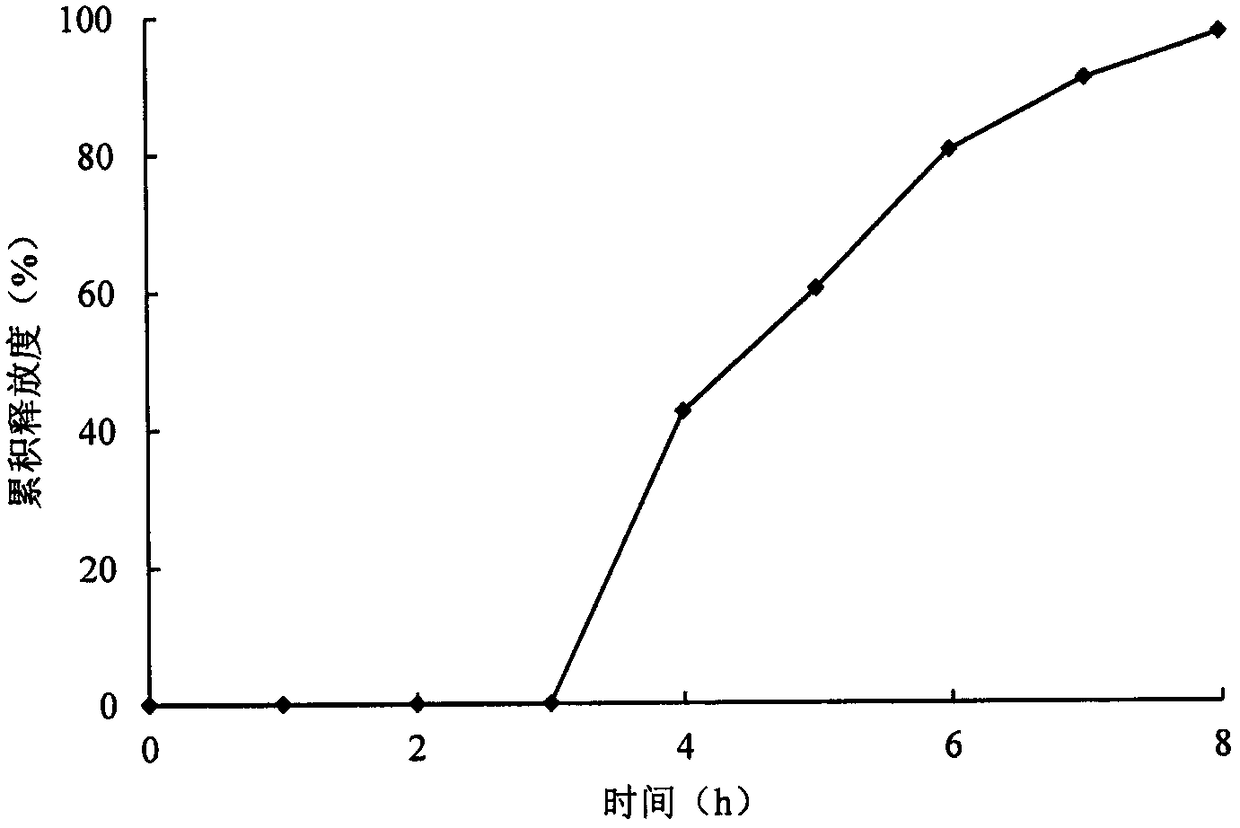

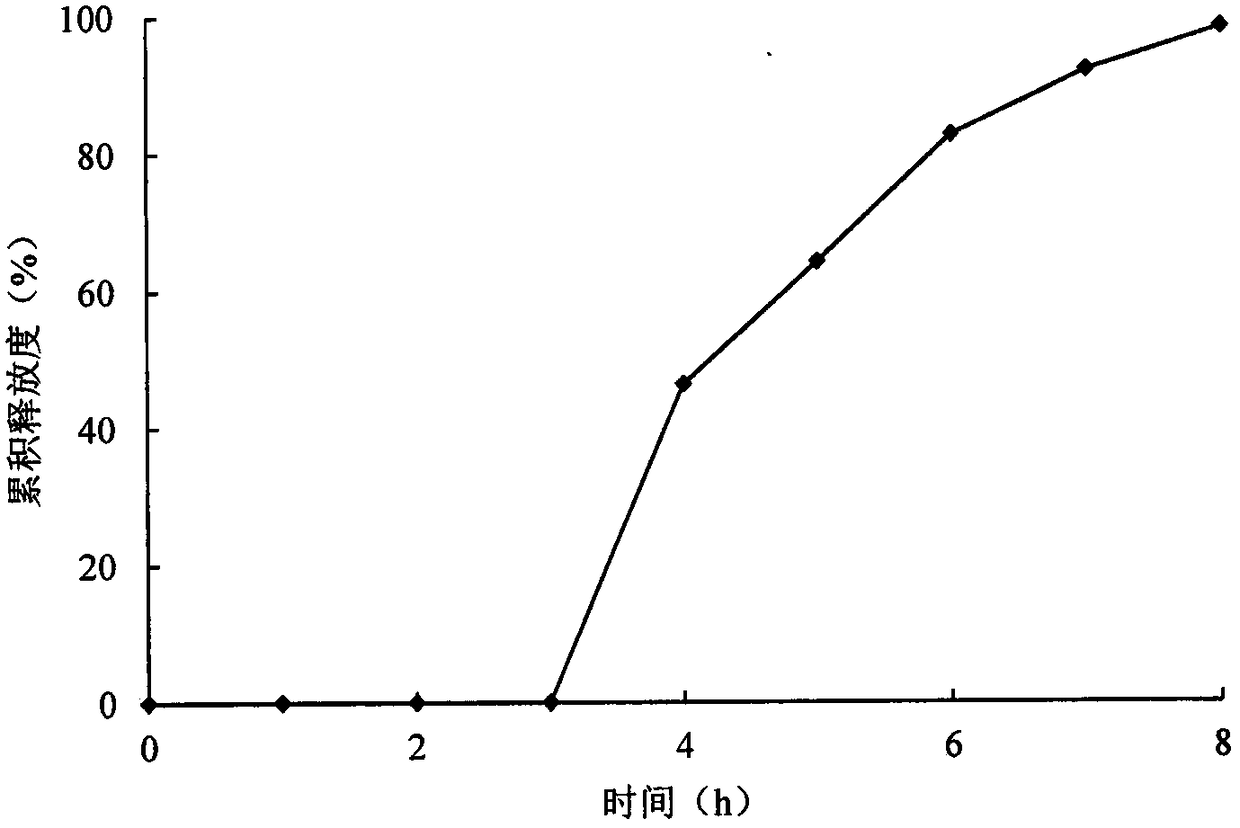

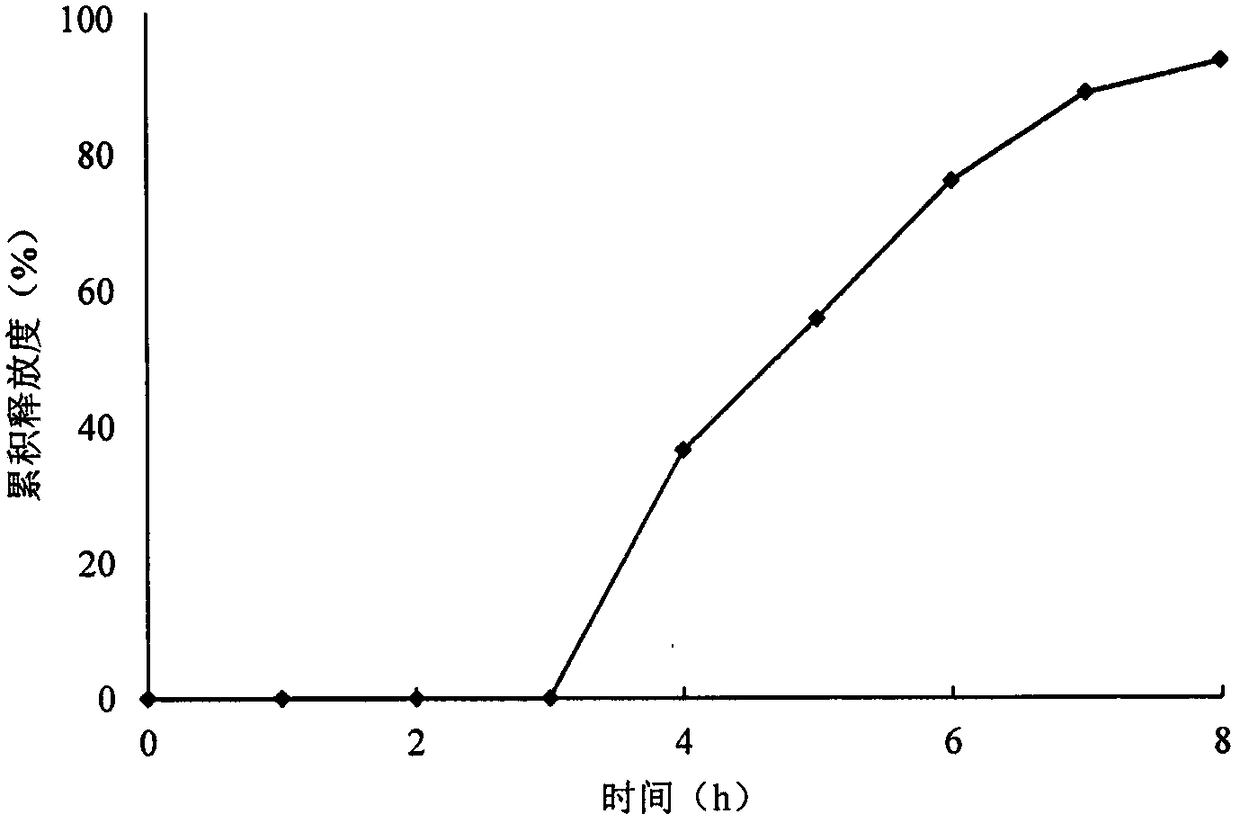

Melatonin delayed release tablet and preparation method thereof

InactiveCN109350605ASimple preparation processReduce manufacturing costOrganic active ingredientsNervous disorderControl releaseTime lag

The invention belongs to the field of pharmaceutic preparations, and relates to a melatonin delayed release tablet and a preparation method thereof. The delayed release tablet is composed of a double-layer tablet core and a compression coating which covers around the tablet core and plays a role of time lag. The double-layer tablet core comprises a medicated controlled release layer and a swellinglayer, wherein the swelling layer can be obviously swelled when wet so as to cooperate with the coating to regulate the drug-release starting point. After a patient orally takes the preparation, dueto the existence of the retardant coating, a drug is not released immediately, but after a certain time, the internal swelling layer is obviously swelled when wet to result in fracture of the coating,the medicated layer is exposed, and the controlled-release skeleton regulates release of the drug. The melatonin delayed release tablet has the advantages that the melatonin preparation has the functions of delayed release and controlled release, and the preparation method for the melatonin preparation is provided.

Owner:CHINA PHARM UNIV

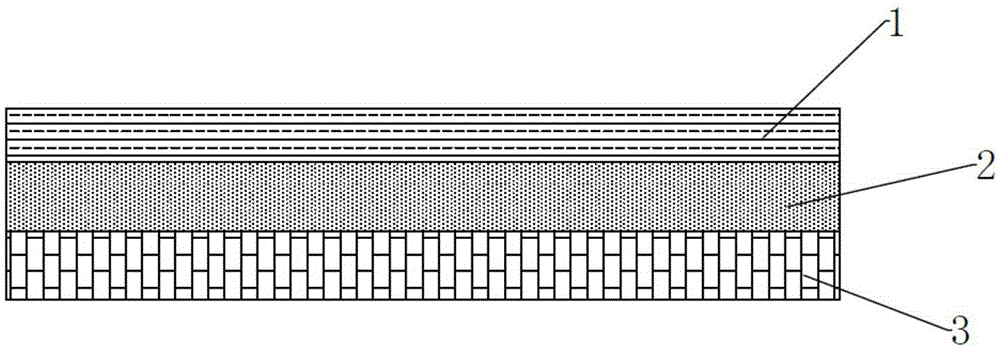

Shell material used for power generator

InactiveCN105415817AImprove noise reductionEffective noiseSynthetic resin layered productsMachines/enginesWhole bodyPolyvinyl chloride

The invention provides a shell material used for a power generator. The shell material comprises a wood layer, a PVC (Polyvinyl Chloride) layer and a rubber layer, wherein the wood layer is fitted on one side of the PVC layer; the rubber layer is fitted on the other side of the PVC layer; and the wood layer, the PVC layer and the rubber layer are fitted to form a whole body. By utilizing a combined design of the material, the material with a prominent noise reduction effect is obtained through structure optimization on the basis of respective characteristics of wood, PVC and rubber; and a power generator shell prepared from the material can be used for effectively isolating noises so that noise pollution in an application process is reduced. The prominent technical effect is obtained through a creative technical idea; and meanwhile, the shell material has relatively low cost, is easy to realize and extremely has industrialization potential.

Owner:TIANJIN PAUWAY POWER EQUIP CO LTD

Method for preparing polyurethane-imide permeable vaporizing aromatic/alkane separating membrane

InactiveCN101121101BEasy to separateLow costSemi-permeable membranesHydrocarbon purification/separationAlkanePolyurethane membrane

A preparation method of a polyurethane-imide infiltrated and vaporized aromatic hydrocarbon and alkane separation membrane belongs to the infiltrated and vaporized membrane separation technical field.The factors of the prior polyurethanes membrane separation is low, and a plurality of the prior polyurethanes membrane separations need a test of an infiltrated and vaporized separation performance at high temperature. The present invention includes firstly a prepolymer synthesis of polyurethane and imide is that under the conditions of a nitrogen protection, a mechanical mixing and a condensation circumfluence, a terminated prepolymer is obtained by a reaction of poly (ethylene adipate) glycol diol and diisocyanate, and pyromellitic dianhydride is added for a chain extension to obtain the polyurethane-imide prepolymer solution; secondly the preparation of a polyurethane-imide membrane is that the solution casts to form the membrane and an impregnant is volatilized under an infrared light, and the preparation of membrane can be finished after a heat treatment of 150 DEG C for 1.5 to 2 hours. The material synthesis and the membrane-preparation process of the present invention are simple, and the prepared membrane has a good thermal and chemical stability, and the prepared membrane can separate an aromatic hydrocarbon and alkane mixture under a proper temperature condition with a good separation effect as well as with a considerable practical value.

Owner:TSINGHUA UNIV

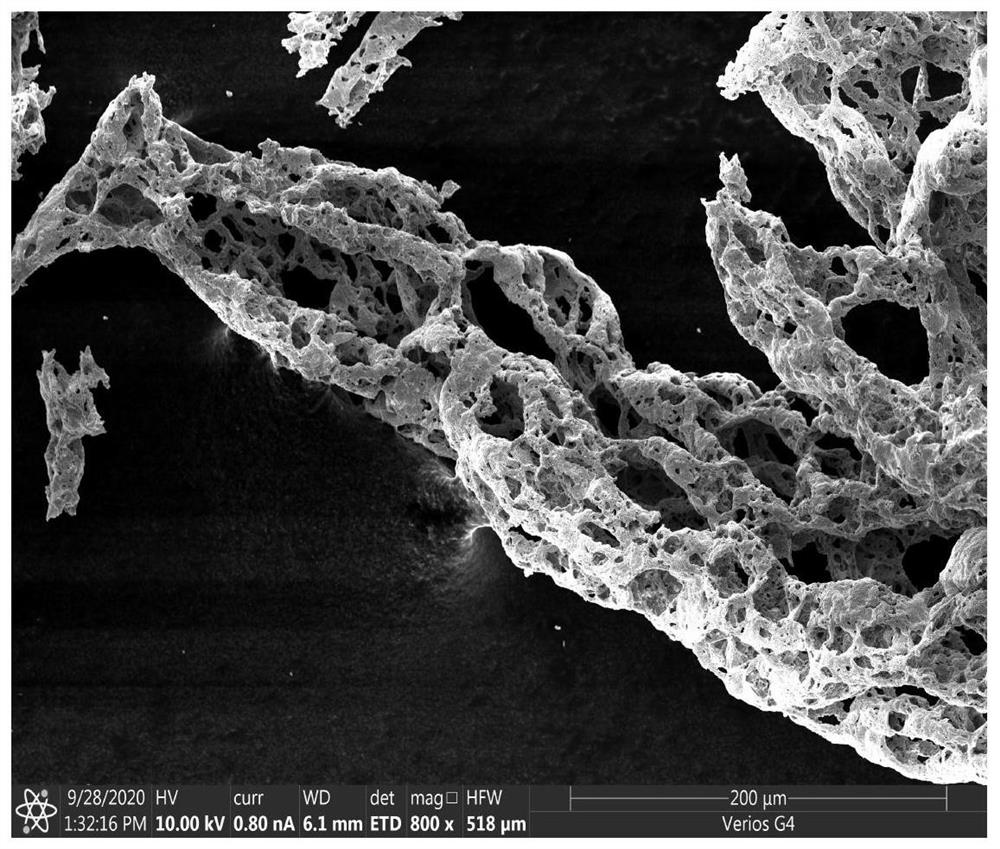

Nitrogen-doped carbon foam prepared by carbonizing polyester and preparation method thereof

ActiveCN112591749AIncrease profitPotential for industrializationCarbon preparation/purificationBulk chemical productionPolyesterPolymer science

The invention belongs to the technical field of nitrogen-doped carbon foam, and particularly relates to nitrogen-doped carbon foam prepared by carbonizing polyester and a preparation method of the nitrogen-doped carbon foam. The preparation method comprises the following steps: (1) uniformly mixing a polyester material, a cross-linking agent and molten salt to obtain a polyester and cross-linkingagent and molten salt mixture, wherein the cross-linking agent is a polyamino compound; and (2) heating the polyester and cross-linking agent and molten salt mixture to a carbonization temperature toobtain a carbonization product, and pickling the carbonization product to remove the molten salt, thereby obtaining the nitrogen-doped carbon foam. The introduction of the cross-linking agent promotesthe cross-linking reaction of polyester, the carbonization temperature is effectively reduced, the existence of the low-melting-point molten salt catalyst can eliminate part of weak chemical bonds inthe cross-linking structure to generate carbon dioxide, water vapor and other small molecular products, and the degradation products serve as the effect of an in-situ foaming agent, therefore, the utilization rate of polyester in the carbonization process is increased, and the method has great application potential in the aspect of recycling of waste polyester.

Owner:HUAZHONG UNIV OF SCI & TECH

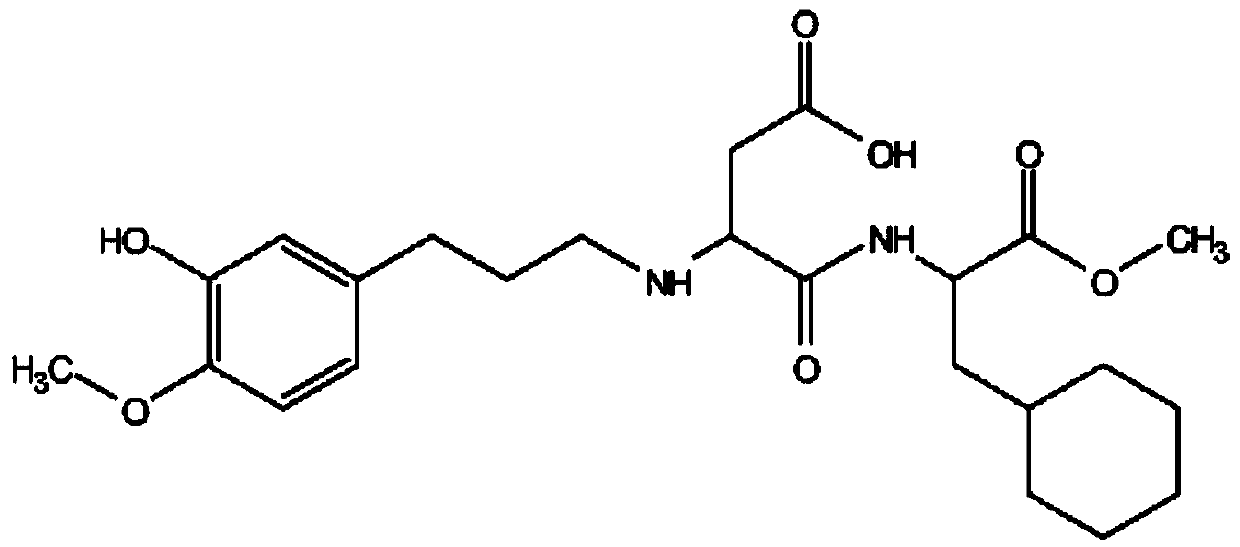

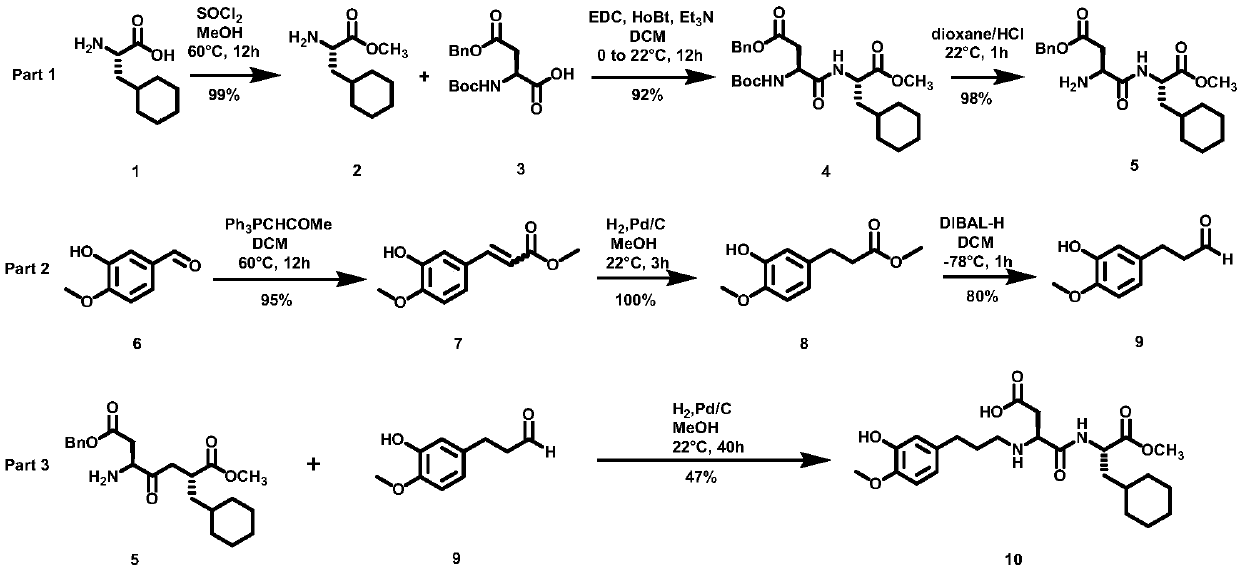

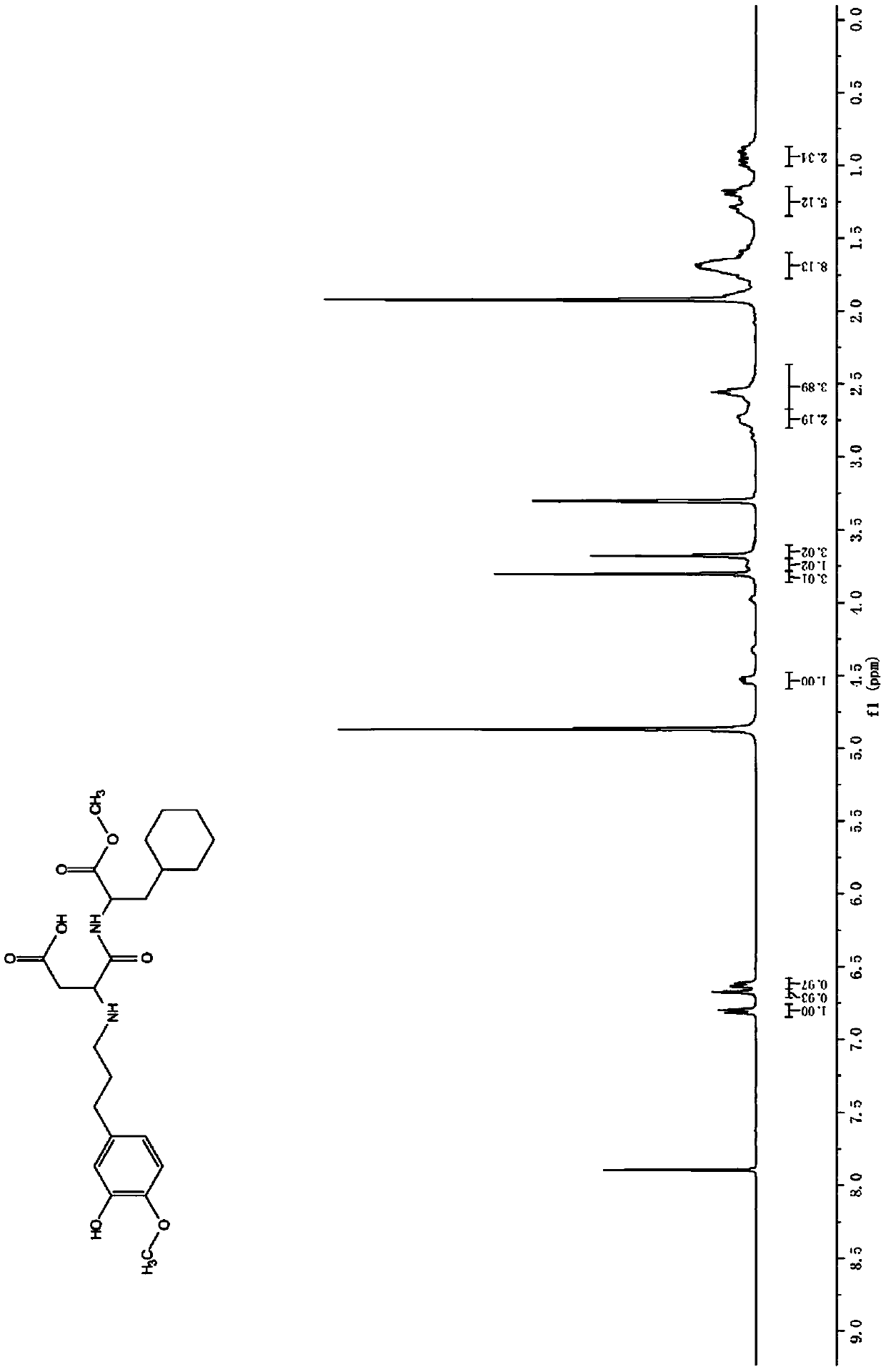

Compound, and synthesis method and application thereof

InactiveCN109535225ARaw materials are cheap and easy to getEasy routePeptide preparation methodsFood scienceSucroseAlanine

The invention discloses a compound, and a synthesis method and application thereof. The synthesis method comprises an esterification reaction, an alkylation reaction and a reduction reaction. The method uses L-cyclohexylalanine and Boc-L-aspartic acid-benzyl ester as starting materials, and conducts the esterification reaction, alkylation reaction and reduction reaction to obtain a target productN-[3-(3-hydroxy-4-methoxyphenyl)]-alpha-L-aspartyl-3-cyclohexyl-L-alanine-1-methyl ester. The synthesized compound has a synthetic sweetness of about 25000 times that of sucrose, has superior performance and good taste, can satisfy demand for the development of the current food industry as a sweetener. The synthesis method optimized by the invention is simple in process, convenient in operation, green in production process, relatively low in cost, in line with green development, and easy to realize industrialization.

Owner:JINAN UNIVERSITY

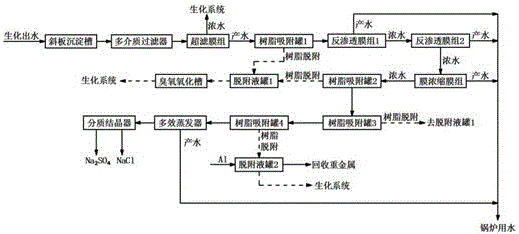

Zero-discharge treatment process for crushed coal pressurized gasification wastewater

InactiveCN106673290AAvoid pollutionSave waterSpecific water treatment objectivesTreatment involving filtrationUltrafiltrationFiltration

The invention provides a zero-discharge treatment process for crushed coal pressurized gasification wastewater. Most COD in bio-chemical effluent is removed with physical methods including inclined plate sedimentation, multi-medium filtration, ultrafiltration and resin adsorption, heavy metals and residual COD in concentrated water treated through two-level reverse osmosis and membrane concentration are removed through three-level resin adsorption, and finally, a crystalline salt product is obtained via an evaporative crystallization unit. Non-degradable COD in the bio-chemical effluent is removed with physical adsorption methods, the conditions of secondary pollution and increase of salt in water due to a chemical method are avoided, and the operation cost is greatly reduced. Besides, through three-level resin adsorption of the membrane concentrated water, COD and heavy metal salt ions in the concentrated water can be removed, and the crystalline salt product meets the reutilization requirement.

Owner:SEDIN ENG

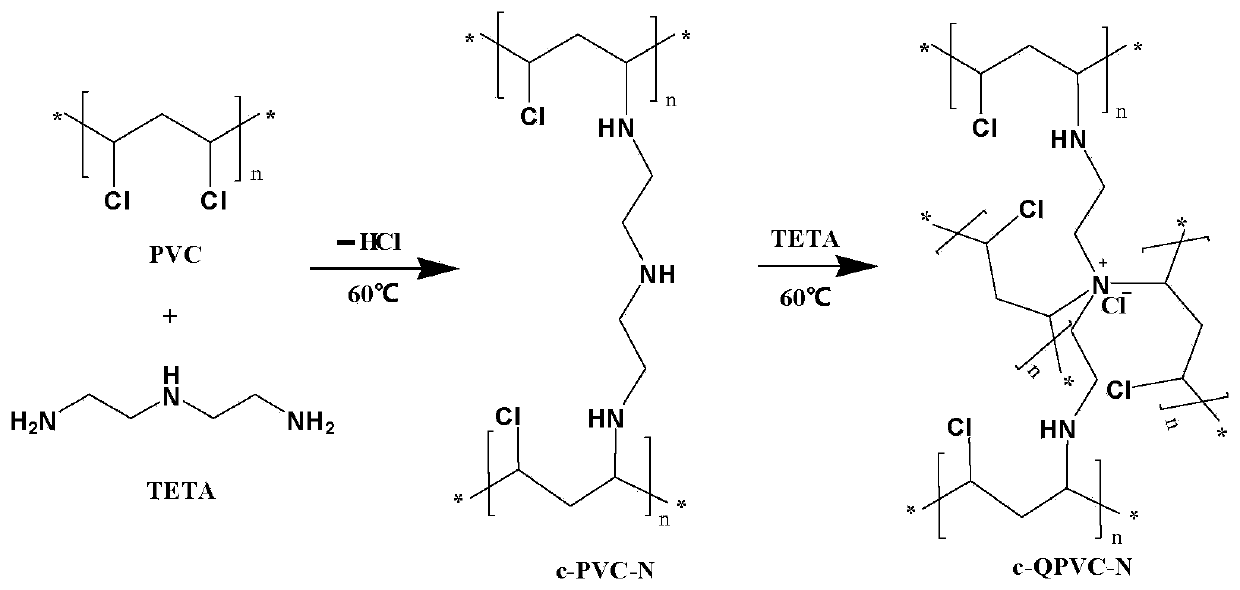

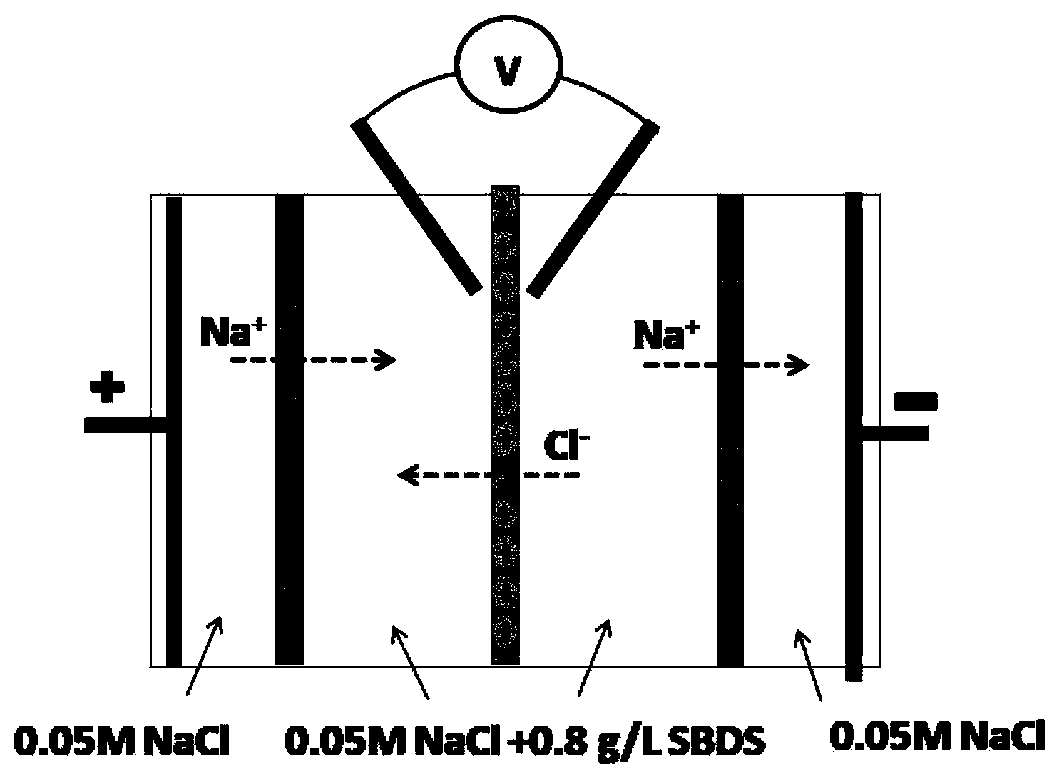

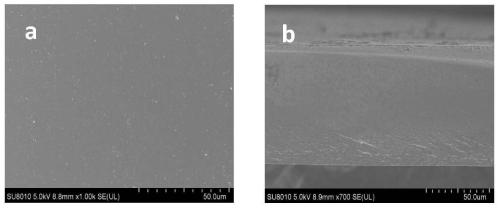

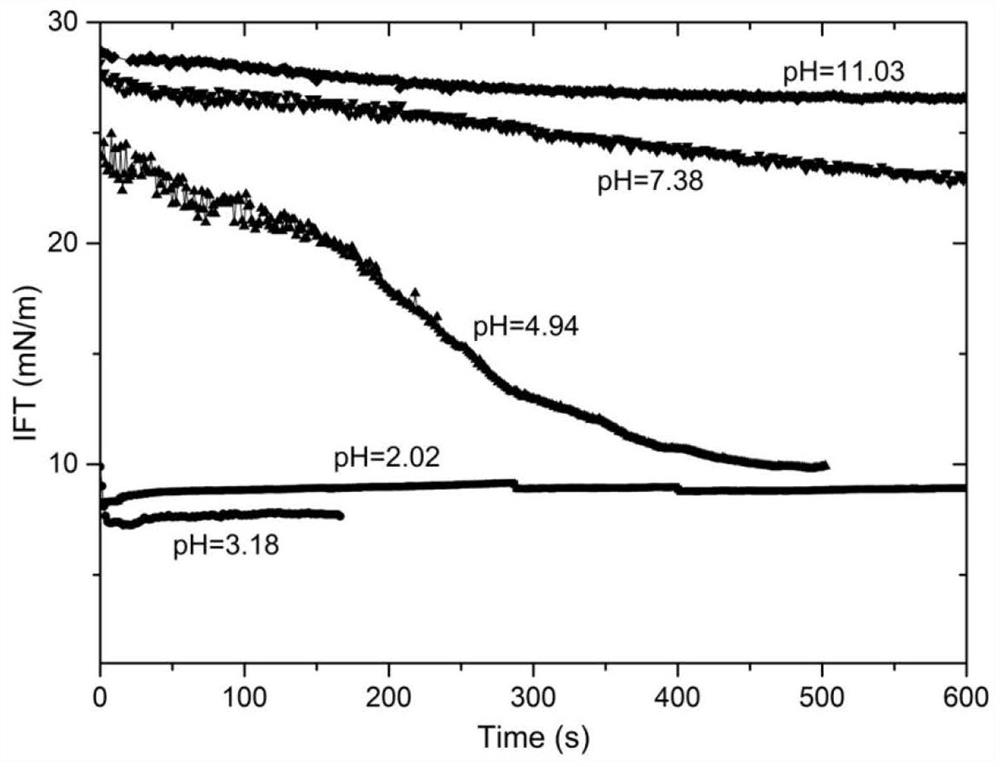

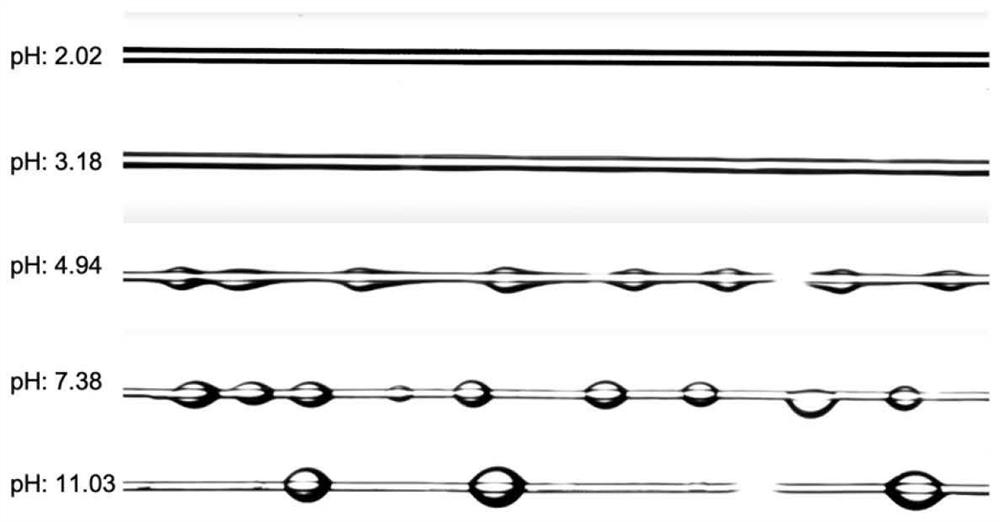

Preparation method of anti-pollution aliphatic PVC anion exchange membrane

PendingCN111135876AStrong anti-pollutionAvoid contactSeawater treatmentDispersed particle separationMembrane surfaceMembrane matrix

The invention discloses a preparation method of an anti-pollution aliphatic PVC anion exchange membrane. The preparation method comprises the following steps: 1) preparing a PVC base membrane; and 2)soaking the PVC base membrane prepared in the step 1) in a 50-70 wt% triethylene tetramine aqueous solution at 30-60 DEG C, reacting for 2-14 hours, and taking out to obtain the aliphatic PVC anion exchange membrane. According to the invention, quaternization and cross-linking of the PVC membrane are completed by adopting a one-step soaking method, the preparation process is simple, the conditionsare mild, and the obtained anion exchange membrane c-QPVC-N has a hydrophilic membrane surface and an aliphatic membrane matrix, so that the c-QPVC-N has good anti-pollution capability and has industrial potential.

Owner:ZHEJIANG UNIV OF TECH +1

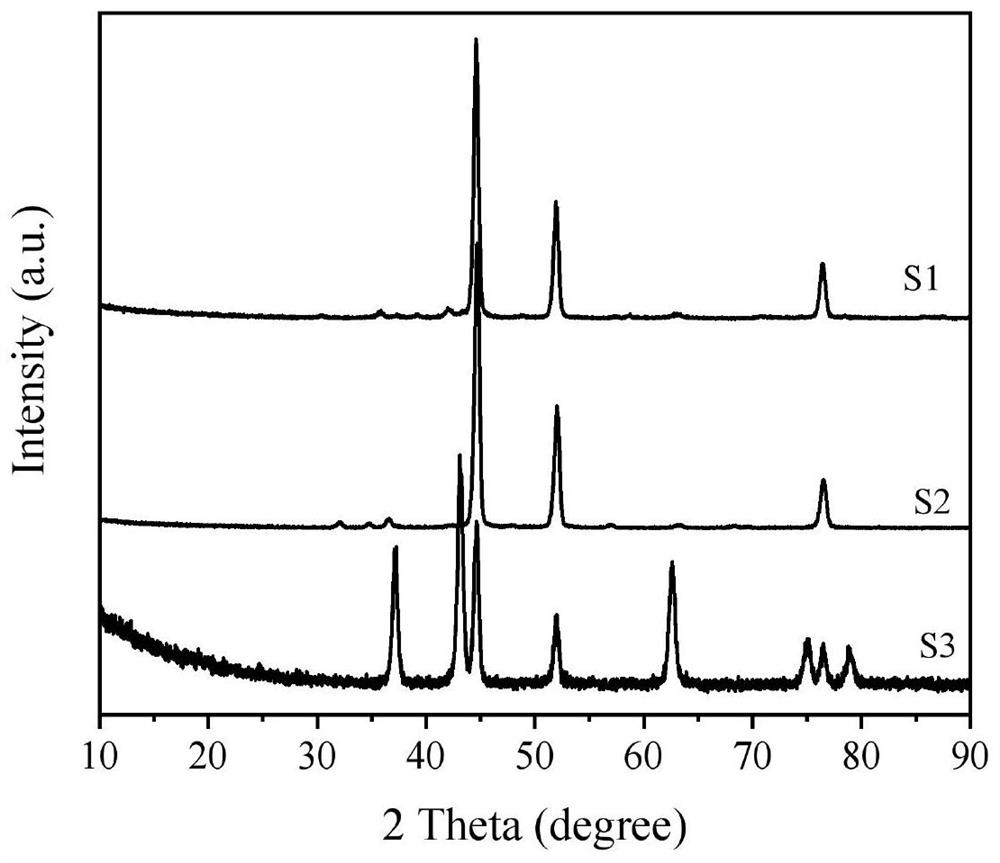

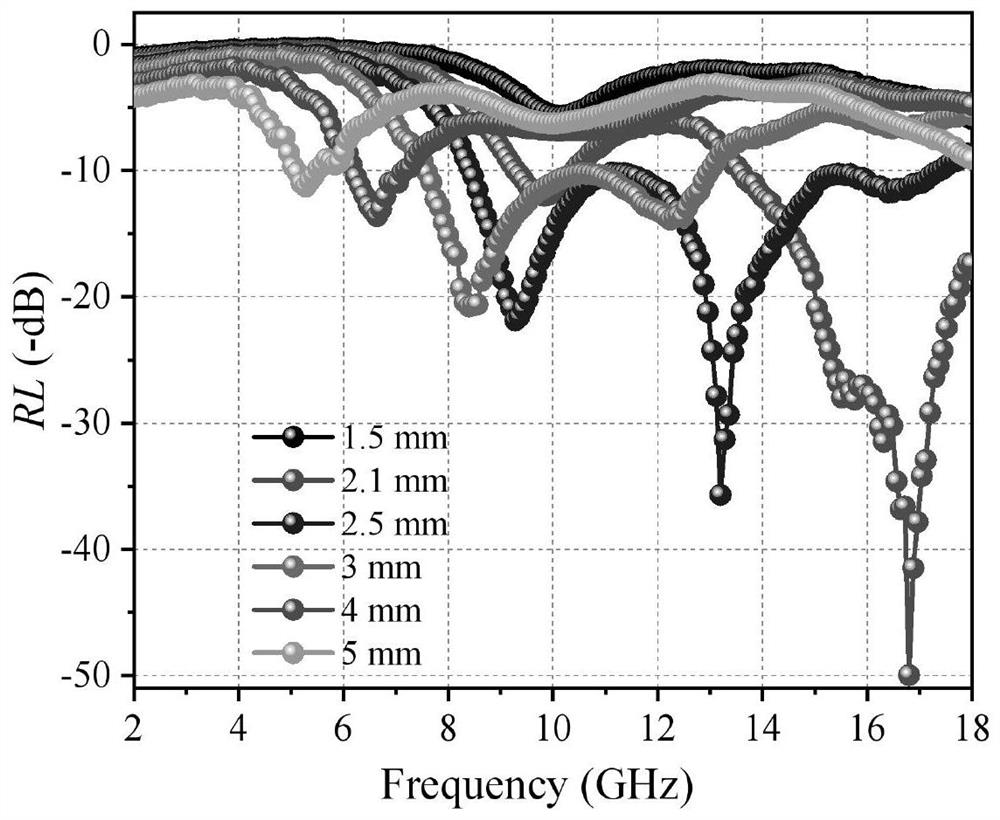

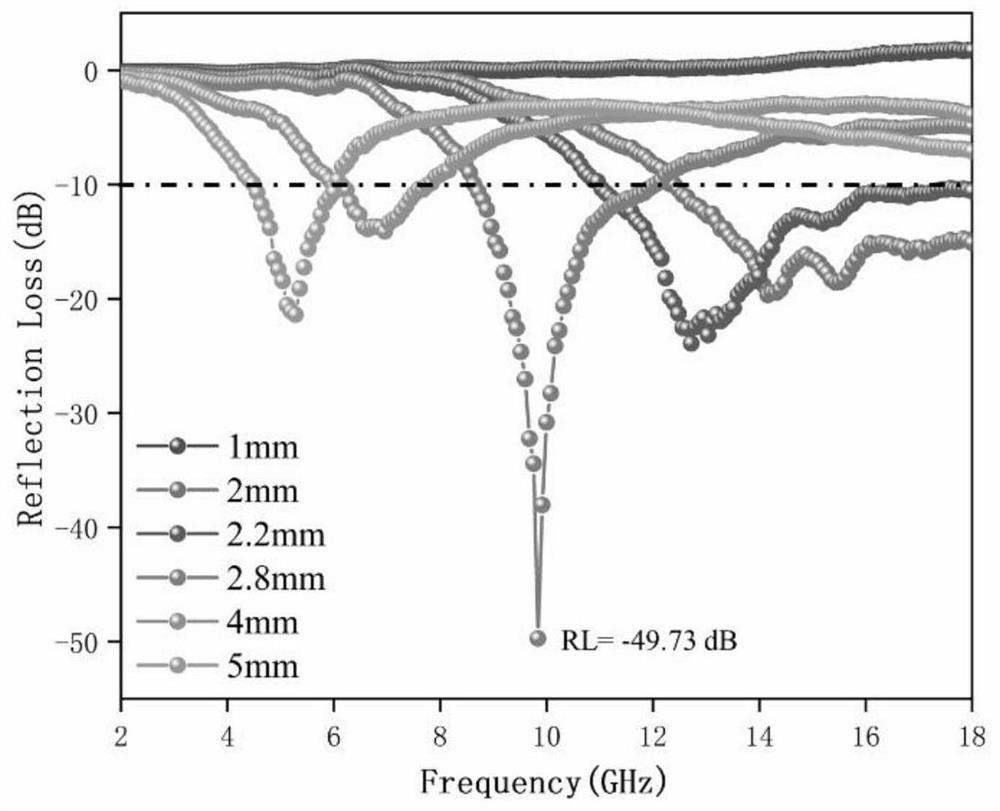

Preparation method of foamed nickel-based oxide composite wave-absorbing material

ActiveCN112500832AEasy to manufactureAbsorbing frequency bandwidthOther chemical processesMagnetic/electric field screeningNickel saltOxide composite

The invention belongs to the field of inorganic wave-absorbing materials, and relates to a preparation method for forming a composite wave-absorbing material by in-situ growth of an oxide on a foamednickel substrate by adopting a solvent-free method, which comprises the following steps: S1, mixing a divalent nickel salt, a metal salt of an oxide to be generated and a low-melting-point polymer, uniformly performing grinding, and performing drying to obtain a precursor; and S2, calcining the precursor to obtain the foamed nickel-based oxide composite wave-absorbing material. The preparation method of the foamed nickel-based oxide composite wave-absorbing material provided by the invention is simple in process, short in preparation period, low in requirement on production equipment and easyfor industrial production; the prepared foamed nickel-based wave-absorbing material has the advantages of light weight, wide wave-absorbing frequency band and strong absorbing capacity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

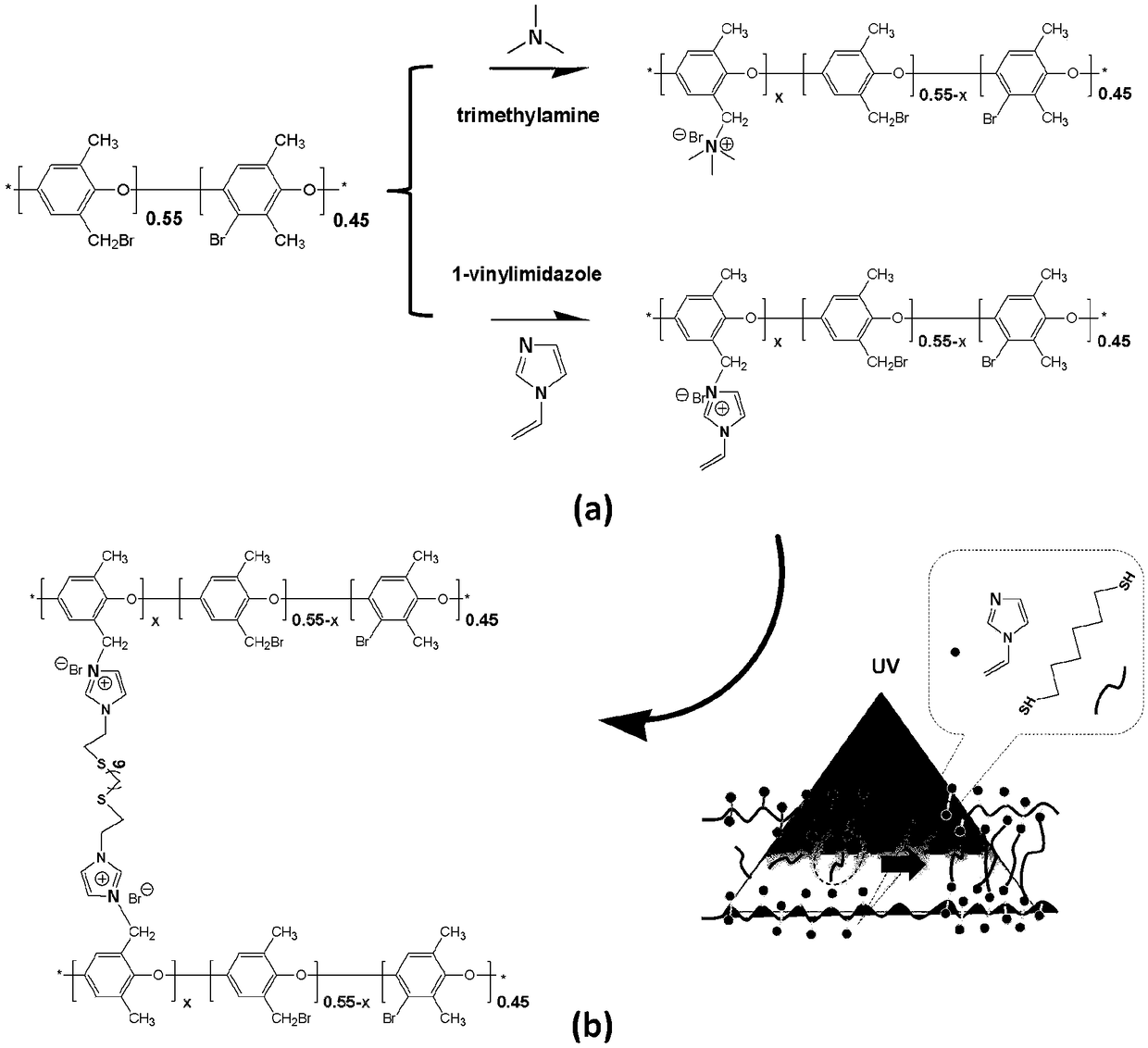

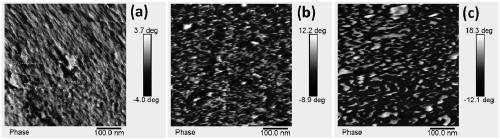

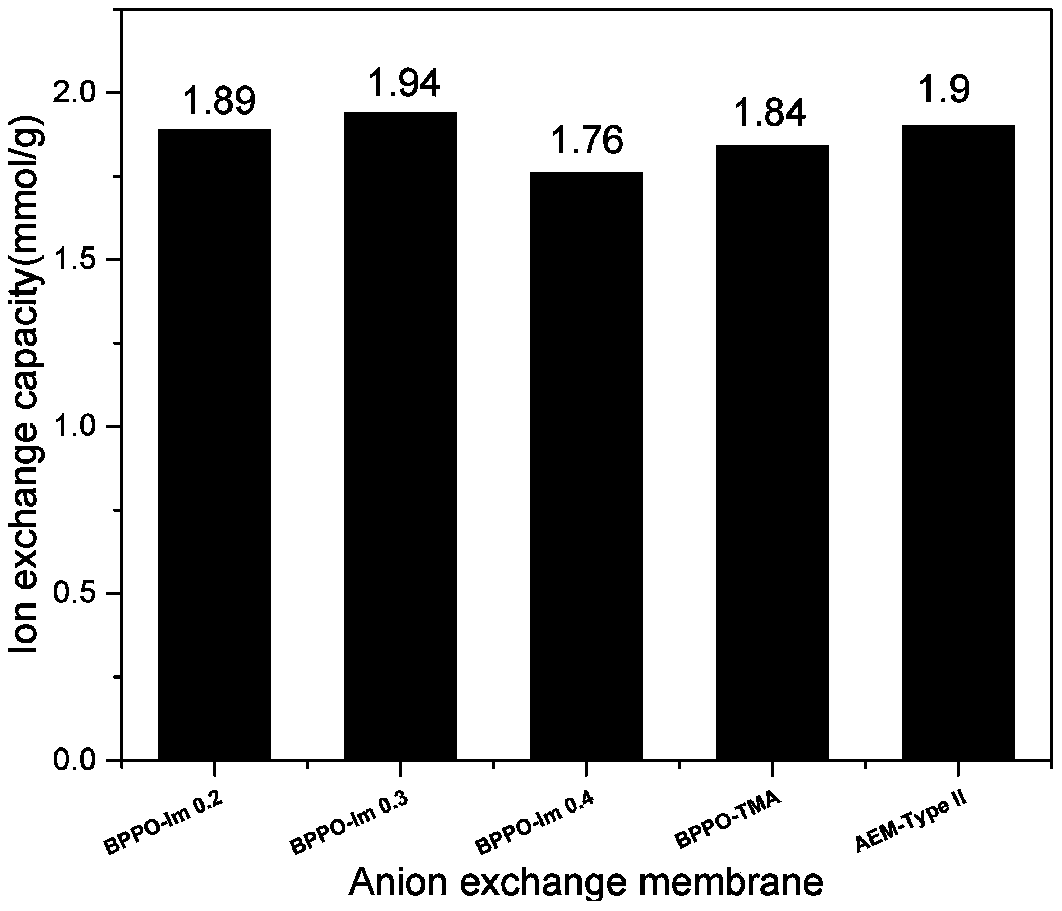

Preparation method of cross-linked anion exchange membrane with low water content

The invention relates to a preparation method of a cross-linked anion exchange membrane with low water content. The preparation method comprises: (1) adding a solvent 1-methyl-2-pyrrolidone to a bromomethylated polyphenylene oxide solid used as a base film material, mechanically stirring until completely dissolving, adding a quaternization reagent 1-vinyl imidazole to the completely dissolved solution, and mechanically stirring until completely reacting; (2) adding a cross-linking reagent 1,6-hexanedithiol and a photoinitiator to the solution obtained in the step (1), and stirring until forming a uniform solution; and (3) pouring the uniform solution obtained in the step (2) on a glass plate, forming a film on the glass plate in a scraping manner by using a scraping cutter, placing under an ultraviolet lamp, carrying out ultraviolet cross-linking, and heating the glass plate after completing the cross-linking until the solvent is completely volatilized so as to obtain the cross-linkedanion exchange membrane. According to the present invention, with the preparation method, the water content of the anion exchange membrane can be effectively reduced while the anion exchange membranehas the high ion exchange capacity so as to improve the anti-swelling property and the mechanical strength of the membrane.

Owner:ZHEJIANG UNIV OF TECH

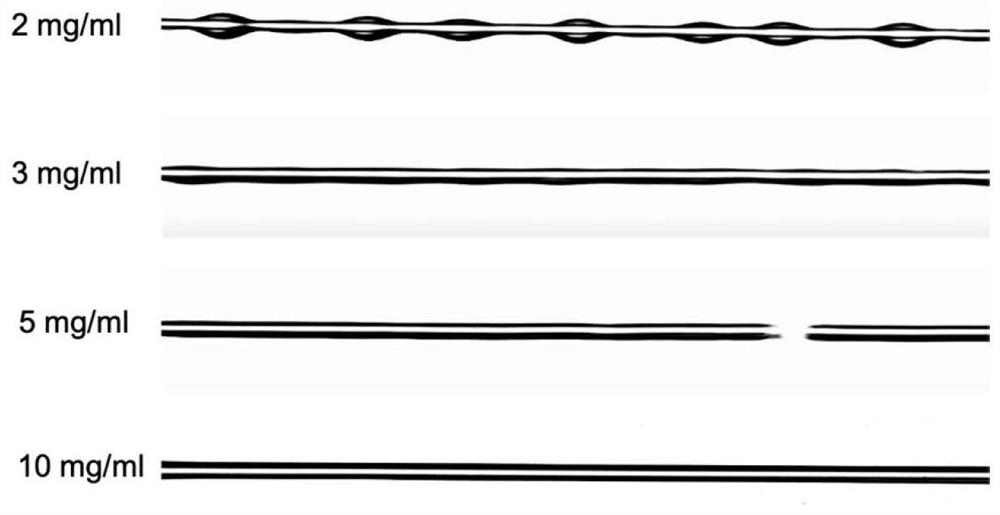

Method for preparing polymer ultrathin coating by inhibiting Rayleigh instability

ActiveCN113073475ASuppression of Rayleigh instabilityUniform and controllable thicknessFibre treatmentPolymeric surfacePolymer science

The invention relates to a method for preparing a polymer ultrathin coating by inhibiting Rayleigh instability, and belongs to the technical field of coating preparation. The preparation method comprises the following steps of (1) dissolving a polymer and a polymer surfactant in an oil phase, and dispersing terminated nanoparticles in a water phase, wherein the terminated nanoparticles and the polymer surfactant can generate electrostatic interaction; (2) immersing a base material into the oil phase to form a liquid film with the polymer and the polymer surfactant on the surface of the base material; and (3) immersing the base material into the water phase to form a uniform polymer coating on the surface of the base material. According to the method, the problems that a non-uniform coating is formed on the surface of the base material due to Rayleigh instability and subtractive manufacturing, limitation of small preparation scale, a complex method and harsh conditions exist in a solution processing process are effectively solved, the utilization efficiency of the material is greatly improved, and large-scale preparation can be achieved; and the method has a relatively wide application prospect in the technical field of coating preparation.

Owner:HUAZHONG UNIV OF SCI & TECH

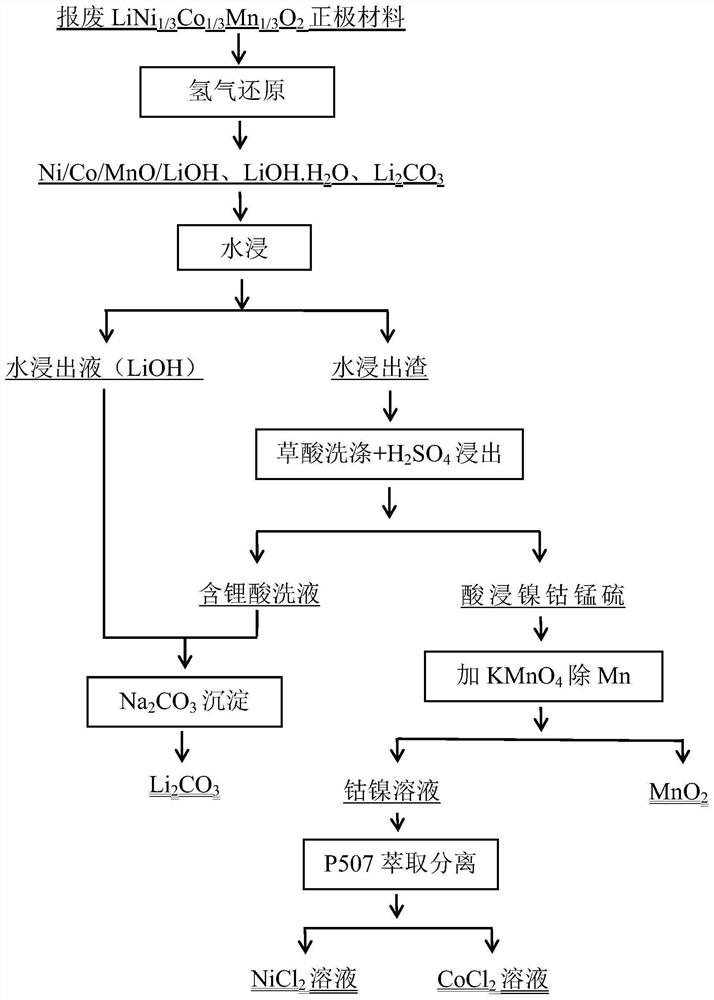

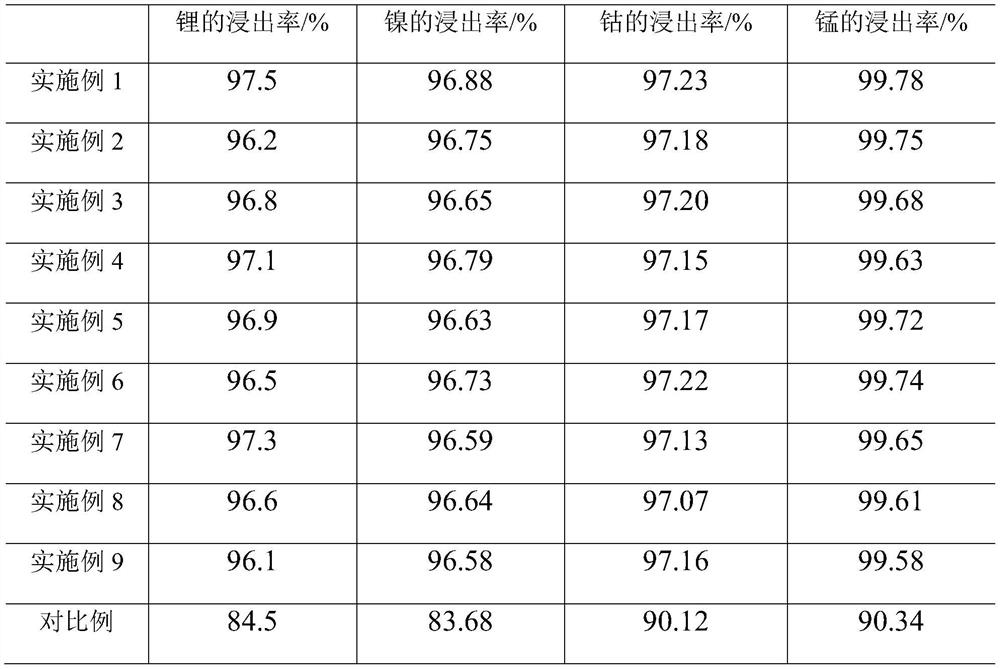

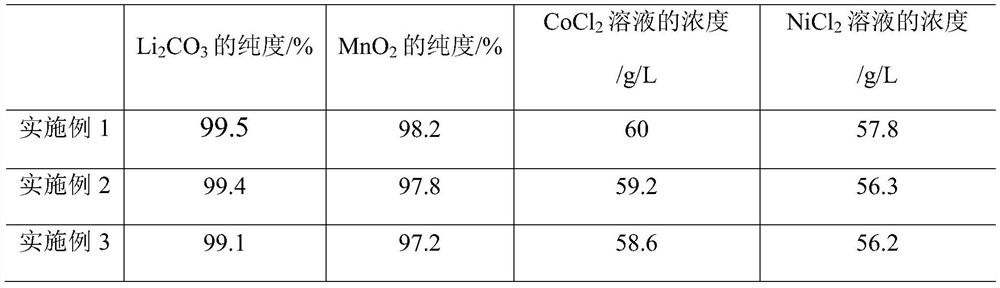

Method for recovering valuable metals from ternary positive electrode material of waste power battery

PendingCN112481493AHigh purityLess impuritiesWaste accumulators reclaimingProcess efficiency improvementPower batteryPregnant leach solution

The invention discloses a method for recovering valuable metals from a ternary positive electrode material of a waste power battery. The method comprises the following steps of 1) carrying out reduction treatment on the waste ternary positive electrode material; 2) putting the reduced ternary positive electrode material into water for water leaching to obtain a water leaching solution and water leaching residues; 3) sequentially carrying out acid pickling and sulfuric acid leaching on the leaching residues to obtain an acid pickling solution and an acid-leached nickel-cobalt-manganese sulfuricacid solution; 4) combining the water leaching solution with a pickling solution, and adding a precipitant for precipitation to obtain Li2CO3 precipitate; 5) adjusting the pH value of the acid-leached nickel-cobalt-manganese sulfuric acid solution by using sodium hydroxide, and adding KMnO4 into the adjusted system for precipitation reaction to obtain a cobalt-nickel solution and MnO2 precipitate; and 6) extracting the cobalt-nickel solution to obtain a nickel-containing salt solution and a cobalt-containing salt solution. Each valuable metal compound or metal salt solution recovered by the method provided by the invention has less impurities and high purity.

Owner:JINGMEN GEM NEW MATERIAL

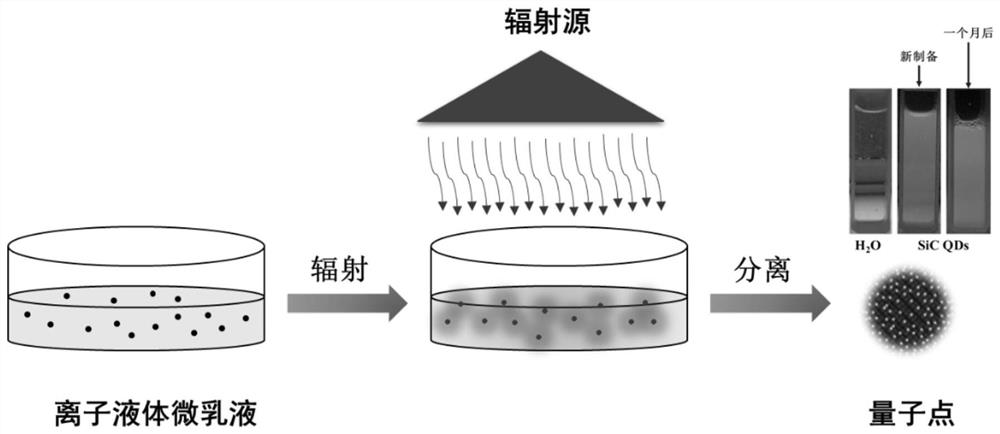

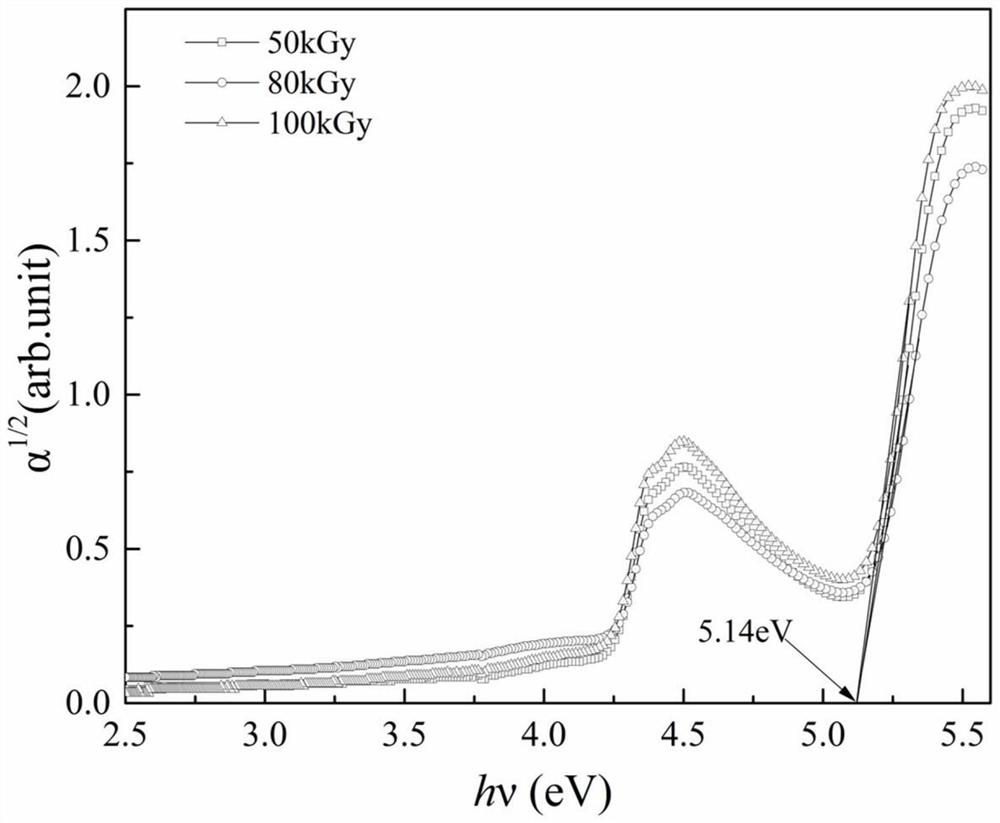

Radiation preparation method of silicon carbide quantum dots and product thereof

ActiveCN113135572ALow costReduce pollutionMaterial nanotechnologyCarbon compoundsActive agentSilanes

The invention belongs to the technical field of nano materials, and discloses a radiation preparation method of silicon carbide quantum dots and a product thereof, and the preparation method comprises the following steps: uniformly mixing a silane coupling agent and an ionic liquid to obtain a mixed solution, then preparing an ionic liquid-in-water type ionic liquid microemulsion, wherein the microemulsion comprises the following components in parts by weight: 70-80 parts of water, 20-30 parts of a surfactant and no more than 10 parts of ionic liquid, then, applying irradiation of 10 kGy to 200 kGy to the microemulsion by utilizing an ionizing radiation technology to obtain silicon carbide quantum dots through in-situ preparation; and finally, demulsifying, separating, washing and drying to obtain the silicon carbide quantum dots. According to the invention, the whole process design of the preparation method, the components of the key ionic liquid in water type ionic liquid microemulsion and the like are improved, so that the preparation method is simple in process, low in energy consumption, economical, environment-friendly and capable of realizing large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

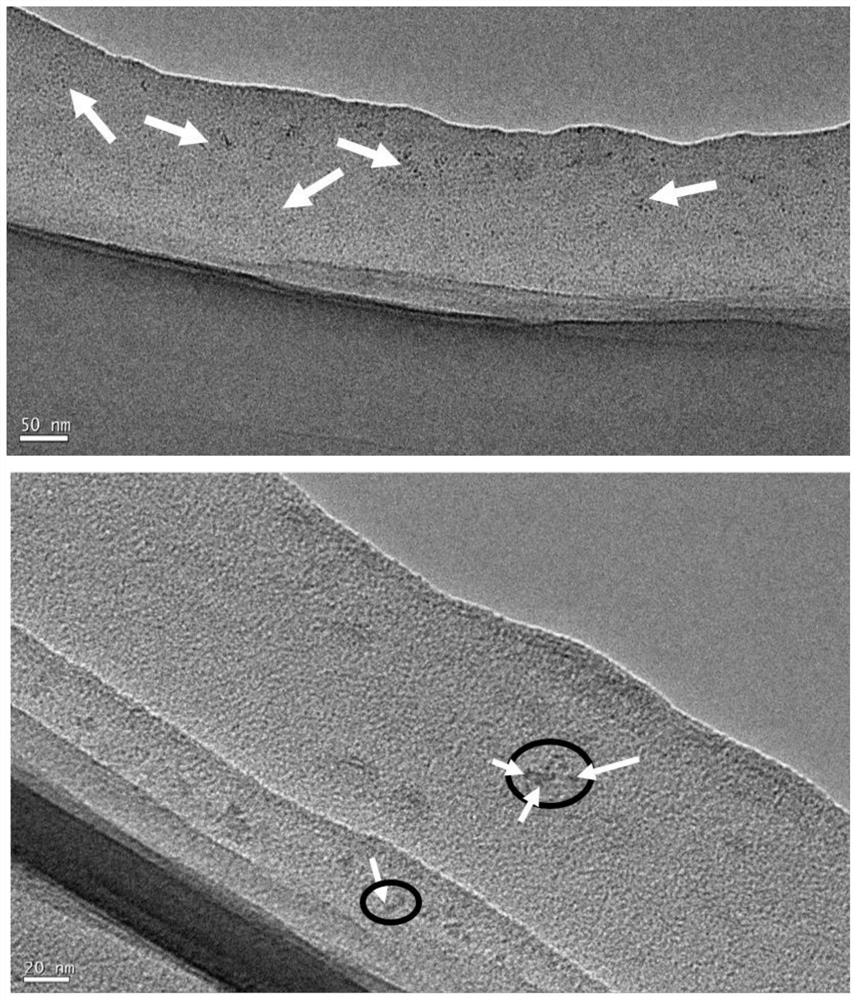

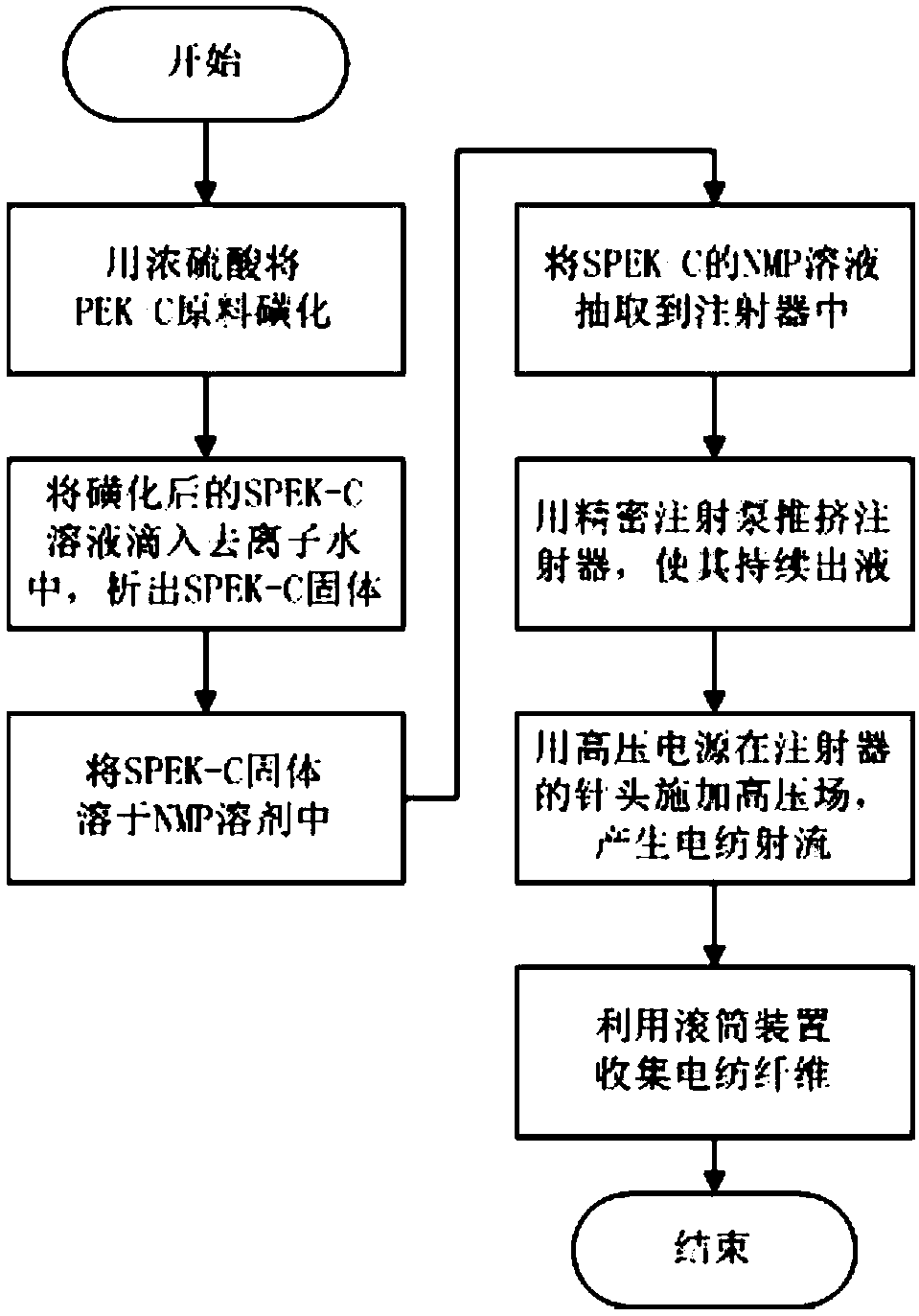

Sulfonated polyaryletherketone positive-electric particle adsorption membrane and electrospinning preparation method thereof

InactiveCN109385752ASolve Adsorption Removal ProblemsSolve just-needed problemsOther chemical processesWater contaminantsFiberSolvent

The invention relates to an electrospun fiber membrane and a preparation method thereof, in particular to a positive-electric particle adsorption membrane prepared by using a sulfonated polyaryletherketone (SPEK-C) material and an electrospinning preparation method thereof. The method comprises the basic steps that concentrated sulfuric acid is used for sulfonating a polyaryletherketone (PEK-C) material, deionized water is used for separating the sulfonated polyaryletherketone (SPEK-C) material, N-methylpyrrolidone (NMP) is taken as a solvent to dissolve the SPEK-C to prepare an electrospinning liquid, and finally the SPEK-C fiber membrane for adsorption is prepared by an electrospinning device with a roller. The degree of sulfonation of SPEK-C is deepened with the sulfonation time, and the adsorption capacity is also increased, that is to say that an adsorption active site can be controlled by adjusting a sulfonation parameter; the SPEK-C fiber membrane can be desorbed and regeneratedthrough a desorbent, and the electrospun fiber membrane can be recycled and used many times, is environmentally friendly, and greatly reduces the adsorption cost.

Owner:XIAMEN UNIV

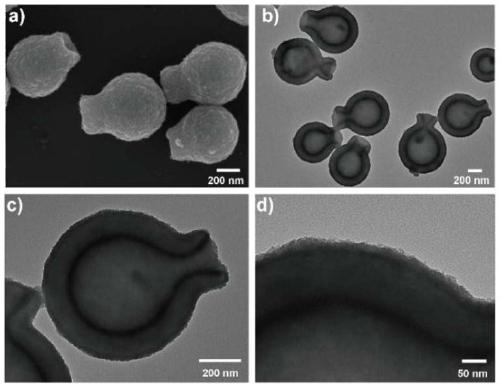

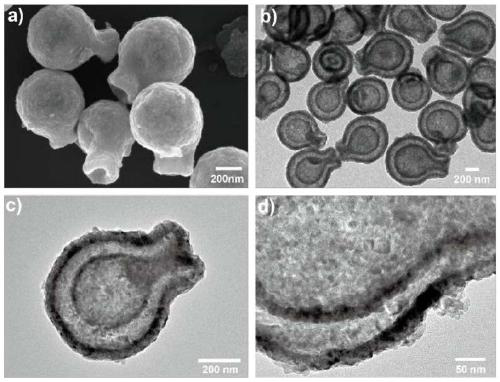

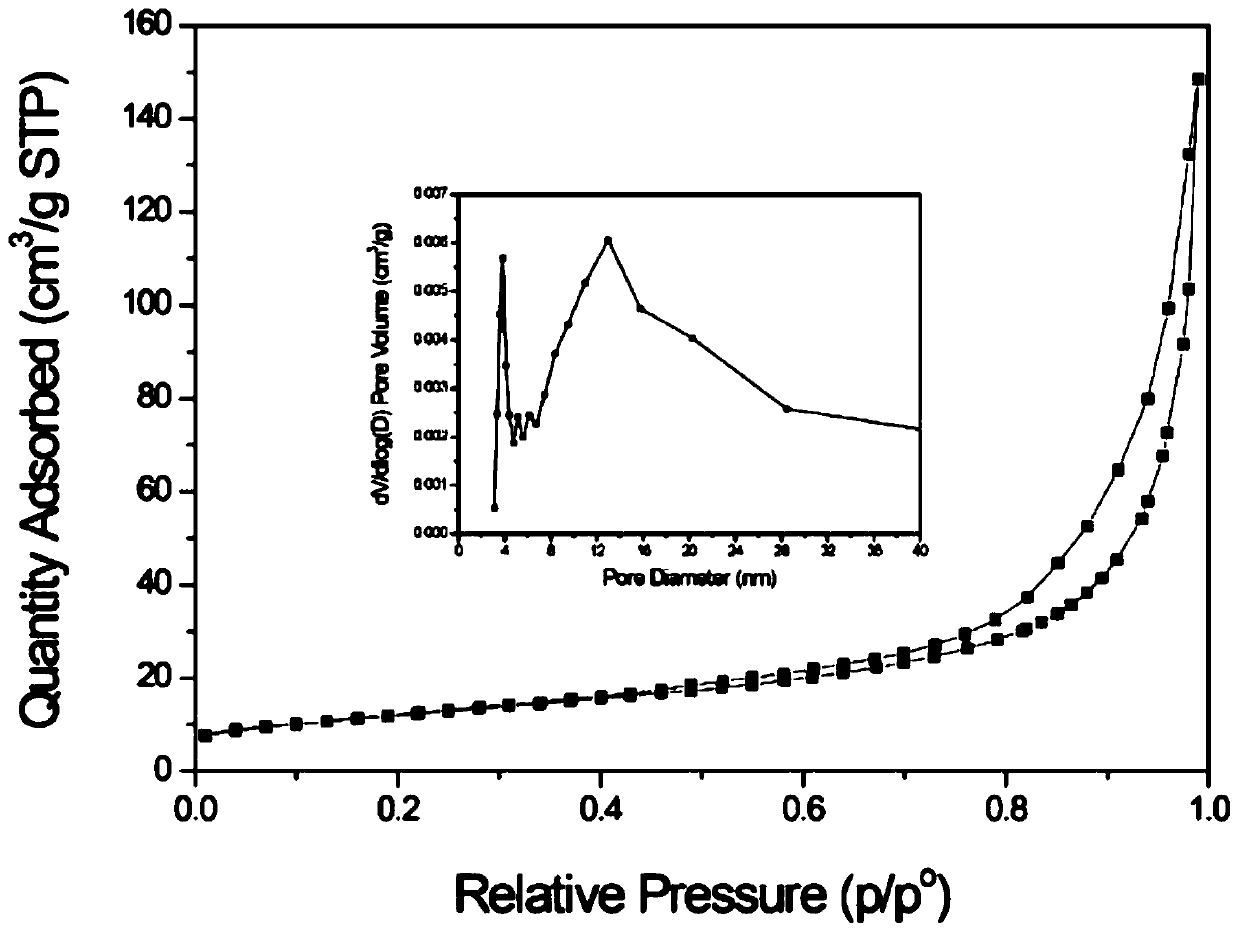

Double-shell asymmetric semiconductor material and super-assembly method thereof

PendingCN111302393ALarge specific surface areaWide range of pore size distributionMaterial nanotechnologyPhysical/chemical process catalystsSemiconductor materialsMicroemulsion

The invention provides a double-shell asymmetric semiconductor material and a super-assembly method thereof. The method comprises the following steps: 1, dissolving a template agent in water to form auniform microemulsion system, adding a carbon source, fully mixing and stirring, putting the obtained mixed solution into a reaction kettle, and reacting in an oven at 140-160 DEG C for 8-24 hours toobtain an asymmetric bottle-shaped open carbon polymer framework (VPFs), 2, by taking VPFs as a template and uniformly growing amorphous TiO2 layers on the outer surface and the inner surface of thetemplate to obtain an intermediate of a sandwich structure and 3, calcining the intermediate to remove a bottle-shaped open carbon polymer framework, thereby obtaining the double-shell asymmetric semiconductor material, wherein the step 2 comprises the following sub-steps: dispersing VPFs in ethanol, then adding ammonia water and tetrabutyl titanate, and putting the mixture into an oil bath pot at25-80 DEG C to react for 12-30 hours to obtain the intermediate.

Owner:FUDAN UNIV

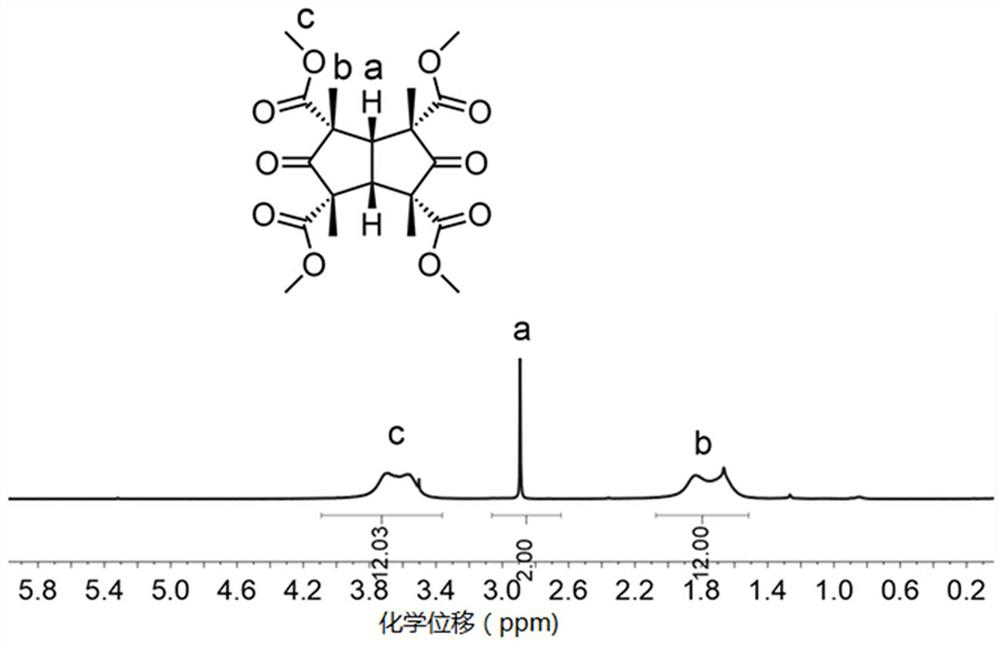

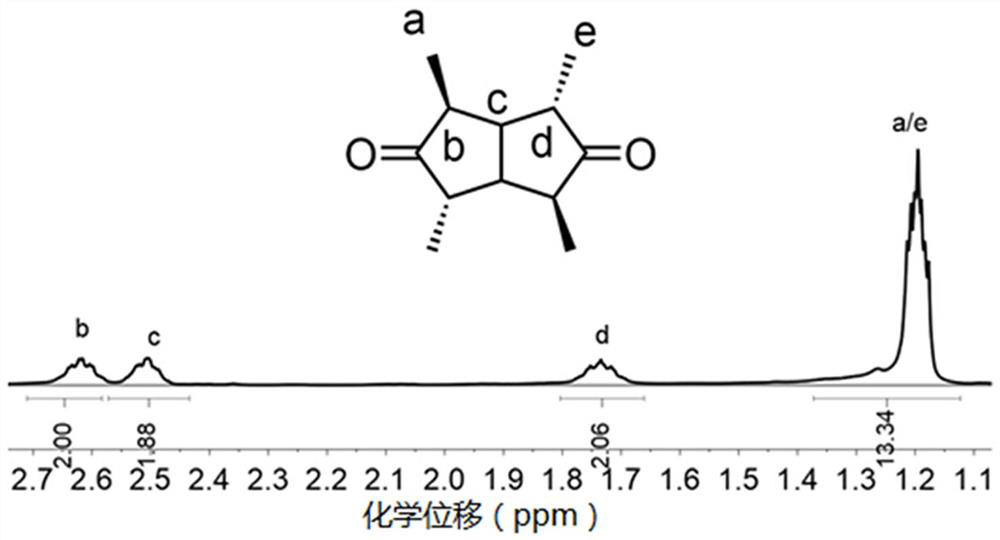

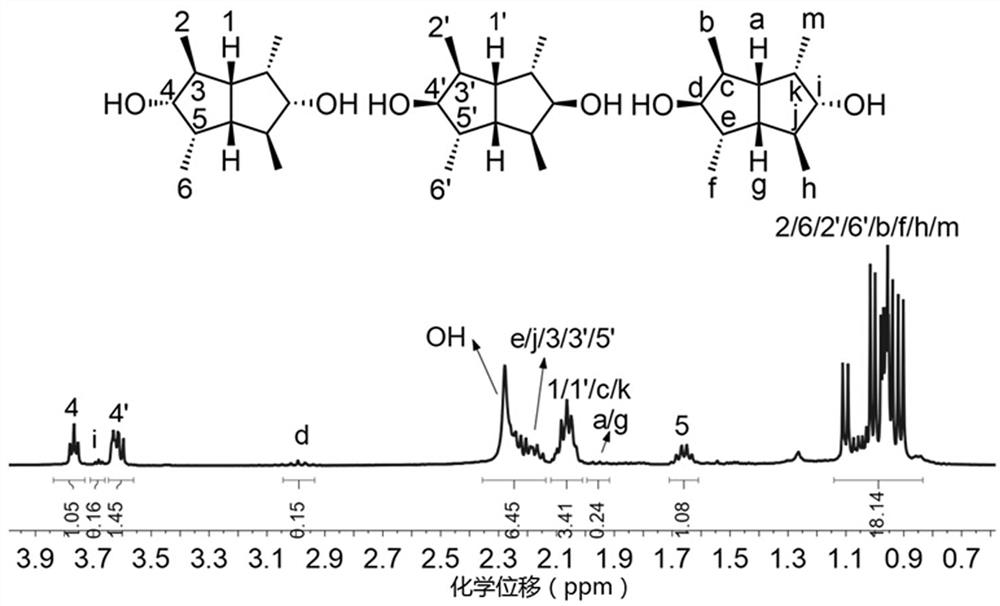

A kind of polycarbonate and its synthesis method, rigid monomer and its preparation method

ActiveCN112979937BGood weather resistanceNot easy to yellowOrganic compound preparationCarboxylic acid esters preparationPolymer scienceCarbonate ester

The invention discloses a polycarbonate and its synthesis method, rigid monomer and its preparation method. The polycarbonate contains the structural unit shown in the following formula (i): (i); The structure shown: the synthesis of the polycarbonate not only makes the synthesized polycarbonate overcome the defects of the existing polycarbonate BPA-PC, but also is biodegradable, easy to realize the diversification of structure and function, good weather resistance, and industrialized Potential, meet environmental protection requirements; especially the rigid monomer of the present invention can be prepared by using bio-based materials such as citric acid, the source of raw materials is wide, low in price, renewable, can reduce dependence on petroleum resources from the source, and is conducive to industrial applications .

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

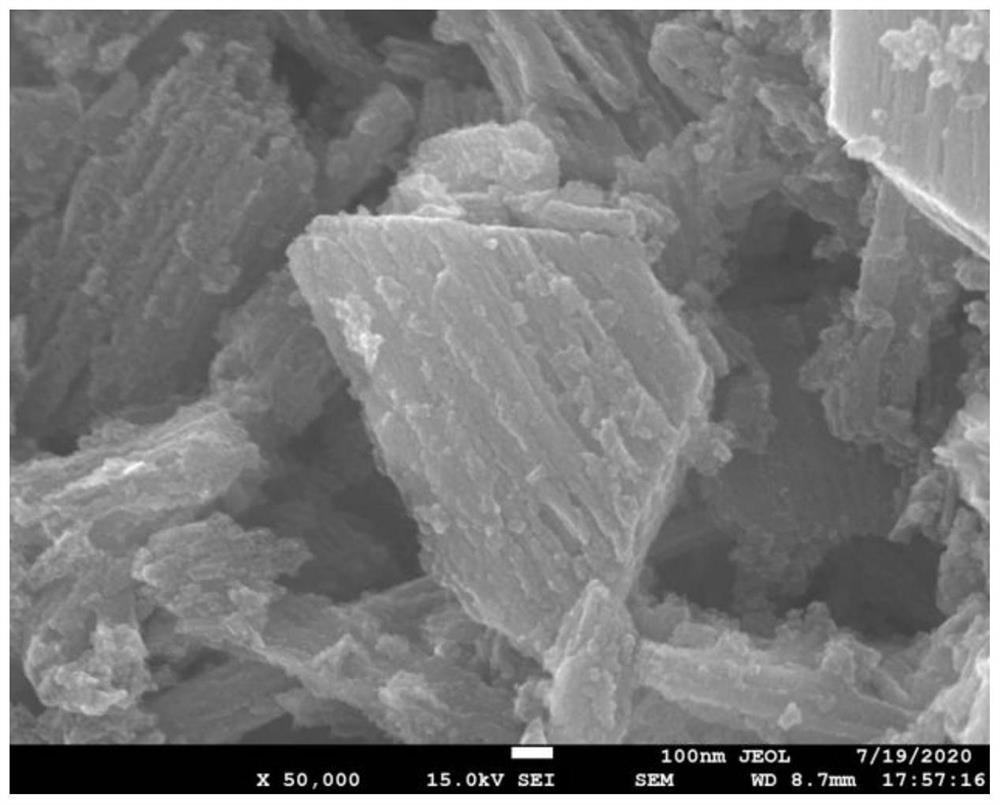

Accordion-shaped NiCo2O4 wave-absorbing material and preparation method thereof

The invention belongs to the technical field of inorganic wave-absorbing materials, and discloses a novel accordion-shaped NiCo2O4 wave-absorbing material and a preparation method thereof, and the wave-absorbing material has a special accordion shape and regular morphology. The specific preparation method comprises the following steps: S1, dissolving divalent nickel ion metal salt, divalent cobaltion metal salt and a complexing agent in water to obtain a nickel-cobalt ion complexing solution; S2, adding a template agent and a precipitant into the nickel-cobalt ion complexing solution, performing hydrothermal reaction, cooling, and sequentially filtering, washing and drying to obtain a precursor; and S3, calcining the precursor to obtain the wave-absorbing material. The prepared accordion-shaped NiCo2O4 wave-absorbing material has excellent wave-absorbing performance and has a good application prospect in the field of wave-absorbing materials; the preparation process is simple, raw materials are cheap and easy to obtain, requirements on production equipment are low, and industrial production is easy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing rutile type titanium dioxide nanorod microsphere

InactiveCN102786085BReduce energy consumptionShort cycleNanotechnologyTitanium dioxideNew energyMicrosphere

The invention relates to a method for preparing a rutile type titanium dioxide nanorod microsphere. The method comprises the following steps of (1) mixing concentrated hydrochloric acid, deionized water and non-polar solvent, adding titanium alkoxide in the mixed solvent drop by drop under a magnetic stirring condition, after the titanium alkoxide is added, continuously stirring the mixture for 30-60 minutes, so that the titanium alkoxide can be fully hydrolyzed to form layered mixed solution; and (2) transferring the mixed solution to a high pressure reaction kettle to perform solvothermal reaction, after the reaction is finished, naturally cooling the high pressure kettle by placing the reaction kettle at a room temperature, and repeatedly washing and centrifugally separating the obtained precipitate to obtain the titanium dioxide nanorod microsphere. According to the method provided by the invention, the solvothermal reaction is carried out in the interface of polar / non-polar solution by adopting the titanium alkoxide, the process route is simple and convenient, no surfactant is required; the prepared titanium dioxide nanorod microsphere is good in dispersion, high in degree of crystallinity, large in specific area, and can be used in various fields of photochemical catalyst, paints, cosmetics, new energy and the like.

Owner:DONGHUA UNIV

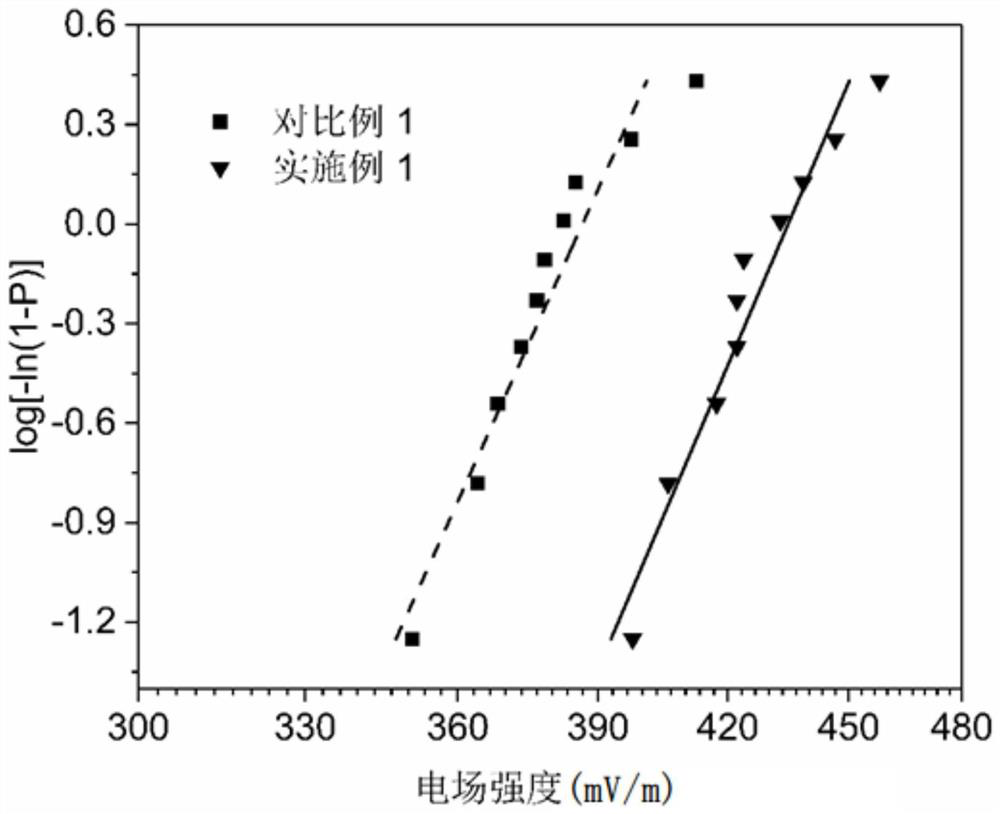

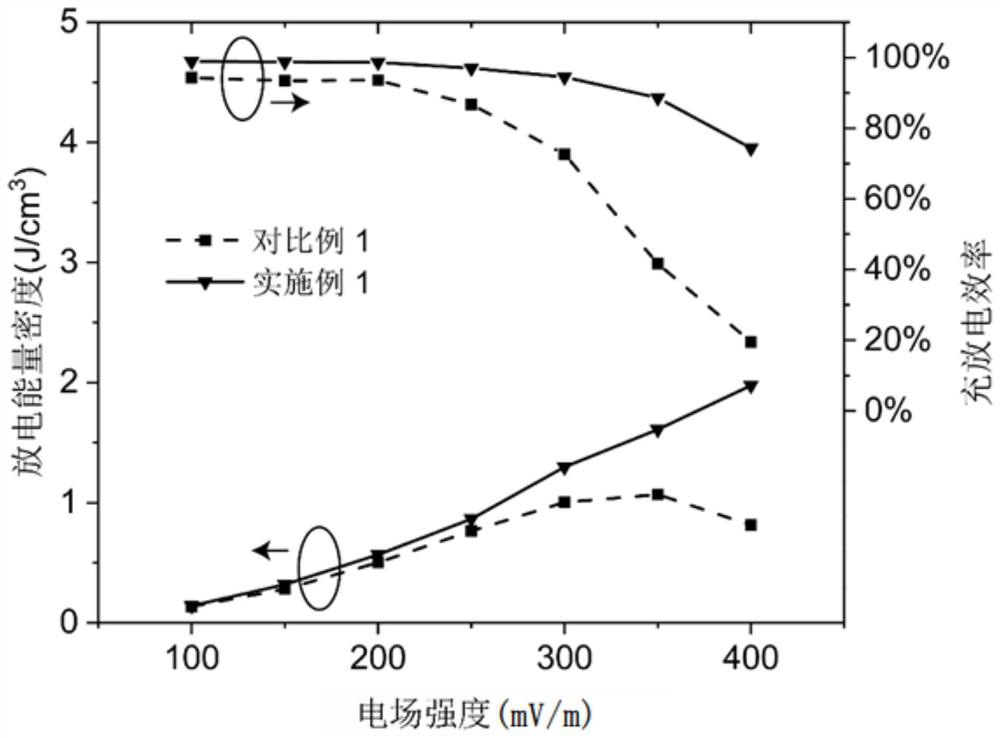

Energy storage polymer dielectric and preparation method and application thereof

InactiveCN113496820AHigh purityPromote densificationFixed capacitor dielectricSputteringPolymer dielectrics

The invention discloses an energy storage polymer dielectric as well as a preparation method and application thereof. The energy storage polymer dielectric comprises a polymer dielectric base film and a metal oxide thin film. The preparation method comprises the following steps of cleaning the dielectric medium film in advance, and depositing the metal oxide film on the clean polymer dielectric base film in a mixed atmosphere of Ar and O2 by taking a metal oxide as a target material and adopting magnetron sputtering. The method for preparing the energy storage polymer dielectric and improving the charging and discharging efficiency has the following advantages that the deposition rate is high, the temperature rise is small, and damage to the polymer dielectric base film is small; the bonding property of the sputtered film and the polymer dielectric medium is good; the sputtered metal oxide is high in purity, compact in film formation and good in uniformity; and compared with an original base film, the composite energy storage dielectric prepared after sputtering has the advantages that the charging and discharging efficiency is greatly improved, and the breakdown strength is also improved. The technology has good repeatability, film preparation parameters are easy to adjust, and the technology has the potential of achieving industrialization.

Owner:TSINGHUA UNIV +1

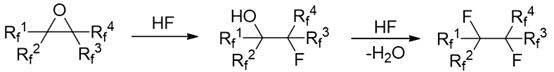

Method for preparing fluoroalkane compound from fluorinated epoxide

PendingCN114507115AEasy to operateRaw materials are safe and controllableOrganic compound preparationHydroxy compound preparationSide productEpoxide

The invention discloses a method for preparing a fluoroalkane compound from fluorinated epoxide, which comprises the following specific operation steps: putting fluorinated epoxide, hydrogen fluoride salt of amine and an aprotic solvent or an organic amine solvent into a reaction kettle together, heating the reaction kettle to 50-200 DEG C, stirring to react for 24 hours, cooling to normal temperature, and filtering to obtain the fluoroalkane compound. And taking out the product, and carrying out alkali washing, water washing, liquid separation and rectification purification to obtain the corresponding fluoroalkane compound. The method has the advantages of simple operation, safe and controllable raw materials, reaction yield of more than 90%, few by-products and environmental friendliness, has obvious advantages compared with an electric fluorination process and a fluorine gas fluorination process for preparing the fluoroalkane compound, and has industrial potential.

Owner:浙江诺亚氟化工有限公司

Method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide

The invention relates to a method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide. The method comprises the following steps: ammonium leaching: using zinc oxide ore containing 2-60% of zinc or complex zinc oxide secondary resource as raw material, extracting in an ammonium system coordinately, filtering to remove the residue, wherein the filtrate is applied to the next process; replacement and purification: replacing and purifying the extracted filtrate with zinc powder to eliminate impure elements, and then filtering and removing the residue, wherein the filtrate is applied to the next process; pulverization and drying: decomposing the purified filtrate through high-temperature pulverization to prepare powder A, condensing, spraying and absorbing the tail gas which is then returned to the leaching process to prepare the extracting agent; and toasting: toasting the powder A to obtain superfine active zinc oxide. The purified liquidcan be used for directly preparing even powder through efficient pulverization and drying. The technological process of the method has a circular loop so that a small amount of waste gas and waste water is discharged. The method has a rational tail gas heat exchanger. Ammonia gas is recycled in a condensing manner to prepare the leaching liquid. The rest of the ammonia gas is absorbed through spraying, thereby reducing the discharge pressure of three wastes, namely, waste gas, waste water and industrial residue.

Owner:JIANGXI UNIV OF SCI & TECH

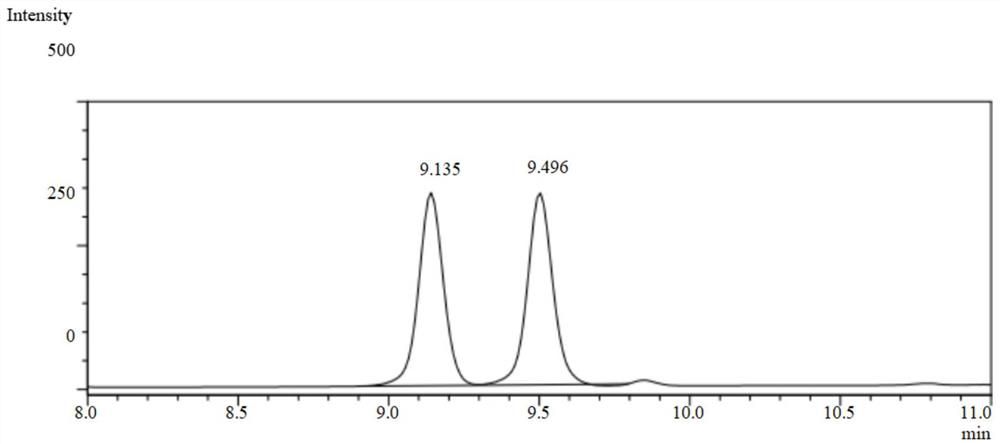

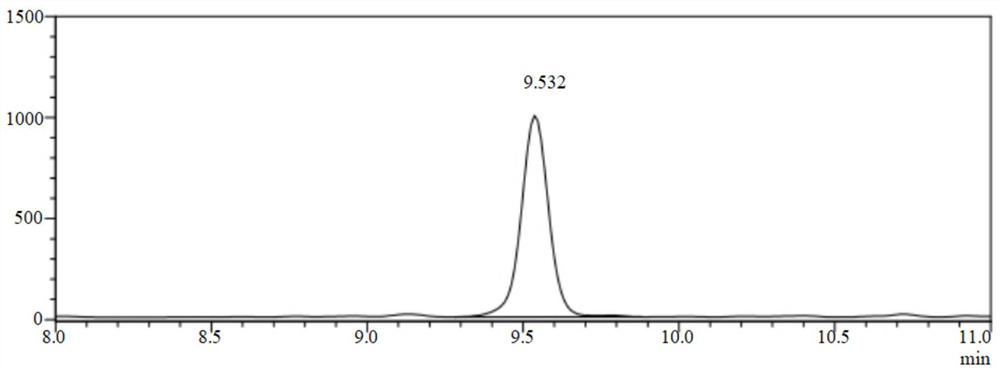

Method for preparing (S)-3-butyne-2-propynylamine through biological catalysis

The invention discloses a method for preparing (S)-3-butyne-2-propynylamine through biological catalysis, which is characterized in that in a liquid-phase reaction system, 3-alkynyl-2-butanone is used as a substrate, and in the presence of coenzyme, carbonyl of the 3-alkynyl-2-butanone is reduced into chiral amino under the catalysis of imine reductase to prepare the (S)-3-butyne-2-propynylamine. The method has the advantages of simple operation, mild and easily-controlled reaction conditions, short reaction time, high substrate conversion rate, and high chiral purity of the obtained product.

Owner:SHANGHAI STA PHARMA R&D CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com