Method for preparing polymer ultrathin coating by inhibiting Rayleigh instability

A polymer coating, polymer technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of cumbersome process, harsh preparation conditions and small scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 100ul of PDMS-NH 2 with 10ml CHCl 3 In the reagent bottle, use a vortex mixer to stir and mix for 5 minutes at a speed of 800 rpm, and the obtained solution is 1v / v% PDMS-NH 2 / CHCl 3 .

[0039] (2) Weigh 1g of CNC-OHSO 3 In a beaker with 100ml of deionized water, use a cell pulverizer to disperse evenly. The frequency of the cell pulverizer is 60%, and the working time is 10min to 20min. The obtained dispersion is 10mg / ml CNC-OHSO 3 / H 2 O.

[0040] (3) The pH of the dispersion obtained in step (2) was prepared by using 0.1 mol / L hydrochloric acid and 0.1 mol / L sodium hydroxide solution to be: 2.02, 3.18, 4.94, 7.38, 11.03 respectively.

[0041] (4) Measure the surface tension of the two phases by using the interfacial viscoelastic measuring instrument with the five different pH solutions prepared in step (1) and step (3).

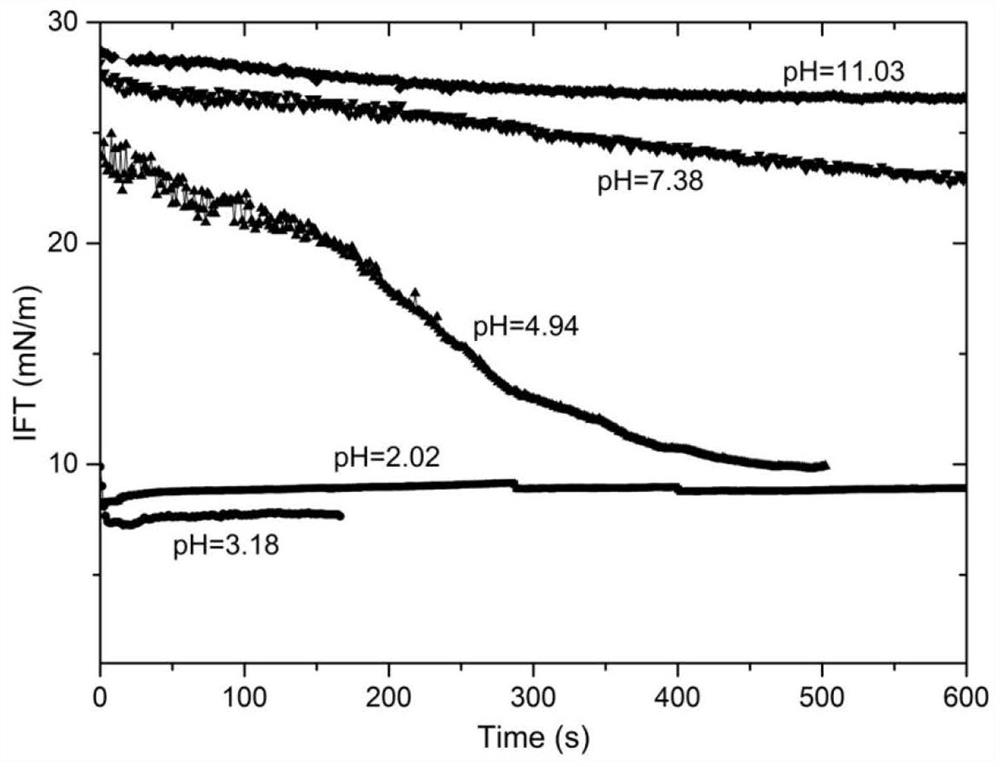

[0042] surface tension as figure 1 shown. CNC-OHSO at pH 2.02 and 3.18 3 / H 2 O with 1v / v% PDMS-NH 2 / CHCl 3 The interfacia...

Embodiment 2

[0044] (1) The 1v / v% PDMS-NH obtained in the above-mentioned Example 1 2 / CHCl 3 , add PMMA (Mw=350k), using a vortex mixer, under the condition of 800 rpm, stir and mix and dissolve for 30min, the obtained solution is 9wt%PMMA / 1v / v%PDMS-NH 2 / CHCl 3 .

[0045] (2) 9wt%PMMA / 1v / v%PDMS-NH in step (1) 2 / CHCl 3 10mg / mlCNC-OHSO of different pH in solution and above-mentioned example 1 step (3) 3 / H 2 The O dispersion liquid was put into two quartz tanks respectively, the stretched fiber first passed through the oil phase, and then passed through the water phase, and the morphology of the fiber in the water phase was observed by the interface viscoelasticity measuring instrument.

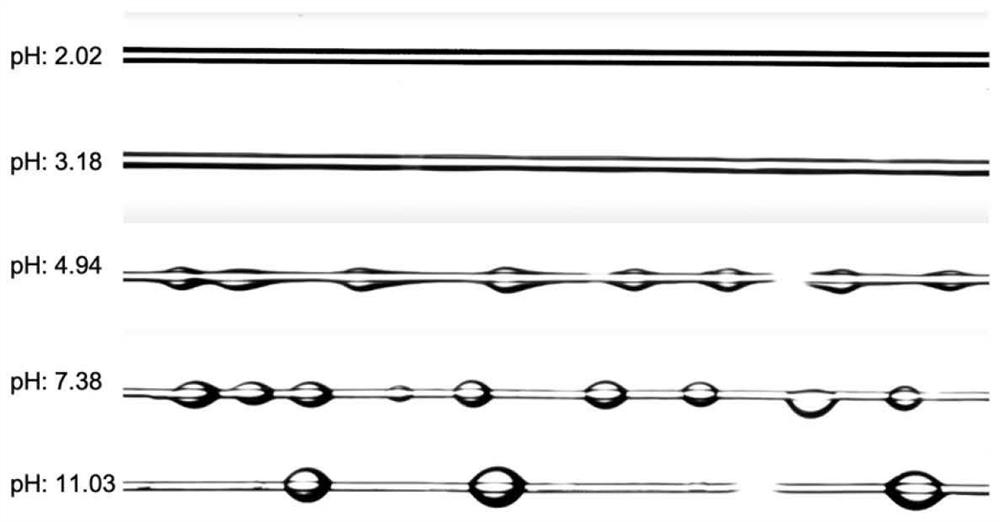

[0046] Such as figure 2 shown. When the pH is 2.02 and 3.18, the surface of the fiber is uniform without Rayleigh instability, but when the pH is 4.94, 7.38 and 11.03, the liquid film on the fiber surface presents a spindle structure, which is the performance of Rayleigh instability. It shows t...

Embodiment 3

[0048] (1) According to the above example 1, configure the CNC-OHSO with mass volume fractions of 2mg / ml, 3mg / ml, 5mg / ml and 10mg / ml respectively 3 / H 2 O, were adjusted to pH 2 with 0.1mol / L hydrochloric acid respectively.

[0049] (2) According to the same steps in the above-mentioned example 2, the drawn fiber is first passed through the oil phase (9wt%PMMA / 1v / v%PDMS-NH 2 / CHCl 3 ), and then through the aqueous phase (CNC-OHSO 3 / H 2 O), observe the morphology of fiber in aqueous phase by interfacial viscoelastic measuring instrument.

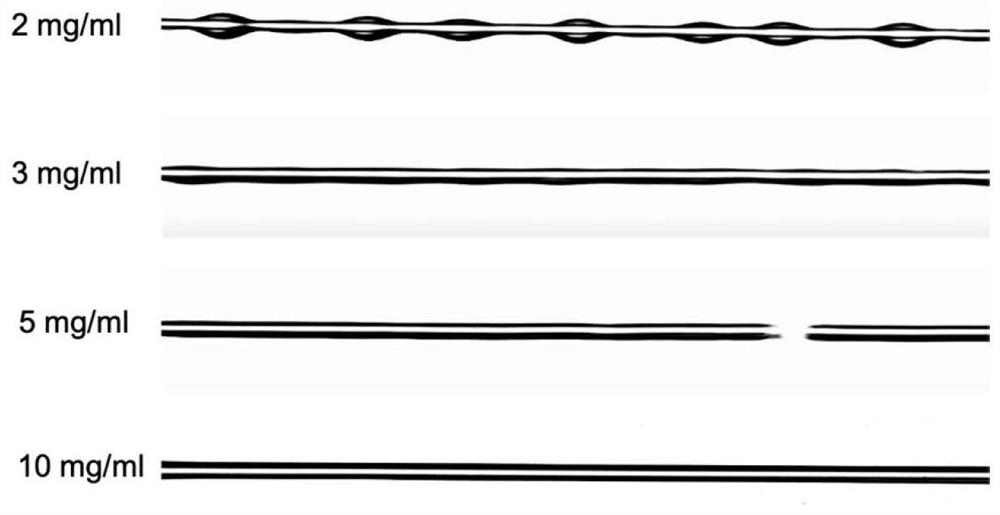

[0050] Such as image 3 shown. CNC-OHSO 3 / H 2 When O is 5mg / ml and 10mg / ml, the surface of the fiber is uniform without Rayleigh instability. Indicates higher concentration of CNC-OHSO 3 / H 2 The O two-phase interface assembles quickly, which can quickly suppress the Rayleigh instability of the liquid film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com