Method for nickel electroplating on surfaces of Sic fibers

A silicon carbide fiber and nickel electroplating technology, which is applied in the field of electroplating nickel on the surface of silicon carbide fiber, can solve the problems of SiC fiber that have not been reported yet, and achieve the effects of small porosity, controllable thickness, and reduced strength and weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with embodiment.

[0031] (1) Cut the continuous SiC fiber with a resistivity of 10Ω·cm according to the required length to obtain a fixed-length continuous SiC fiber (A);

[0032] (2) Place the continuous SiC fiber (A) in a porous graphite crucible, and then put the crucible into a tube furnace for heat treatment and degumming: heat up to 600°C at a rate of 5°C / min, and keep it at 600°C for 0.5h , and then cooled with the furnace to obtain degummed SiC fibers (B);

[0033] (3) Boil the degummed SiC fiber (B) in 1mol / L NaOH solution for 15min to remove the organic and inorganic attachments on the surface, and then rinse it with distilled water for more than 3 times to obtain the degreased SiC fiber (C);

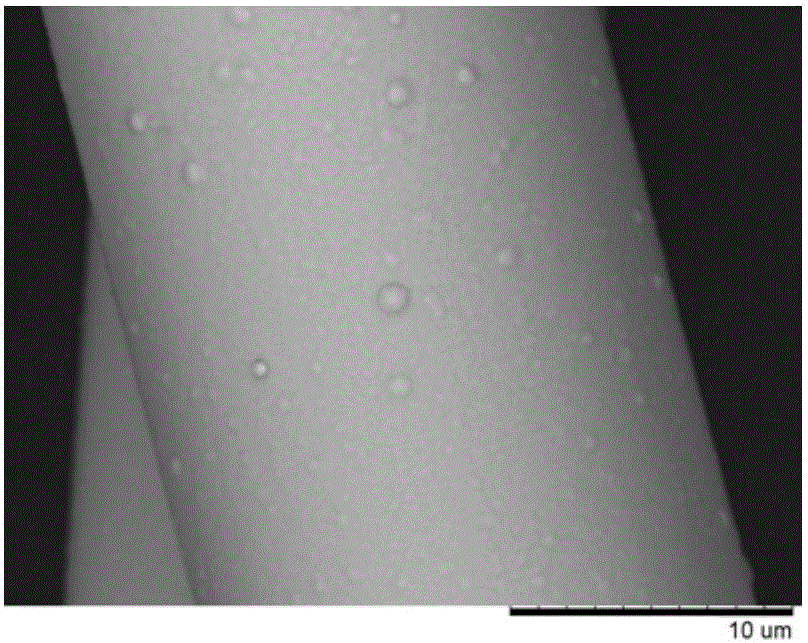

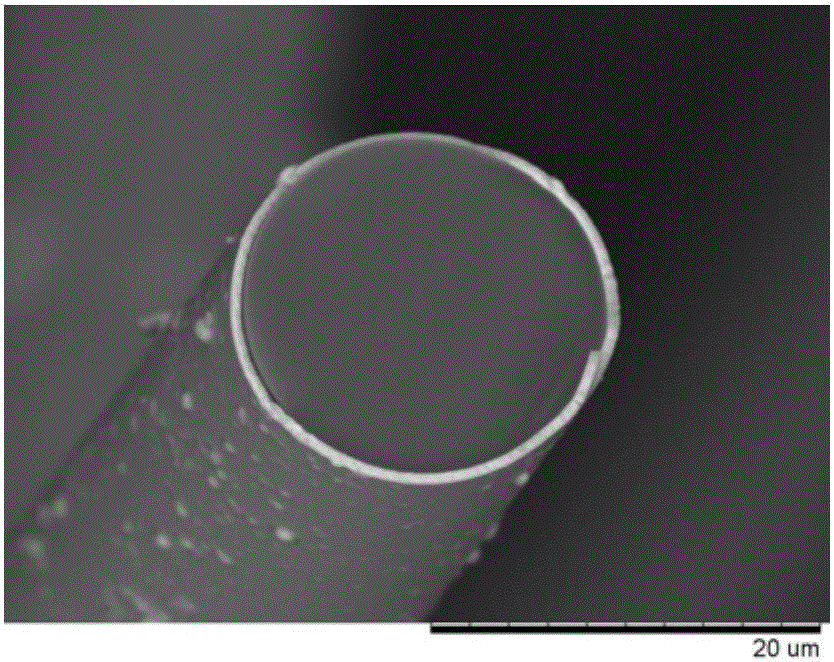

[0034] (4) Put the degreased SiC fiber (C) into an aqueous solution of nitric acid with a mass fraction of 65% for acid corrosion to roughen its surface to increase its surface energy and enhan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com