Shell material used for power generator

A shell material, generator technology, applied in electronic equipment, engine components, machines/engines, etc., can solve the problem of high generator noise, and achieve the effects of noise isolation, low cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

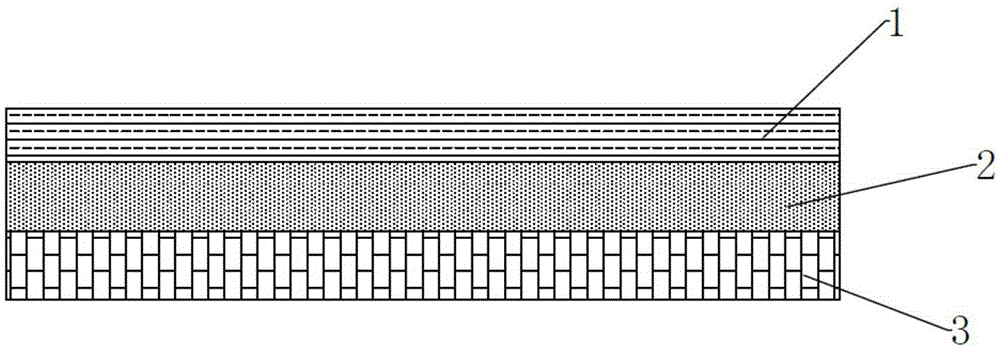

[0014] A casing material for a generator, characterized in that the casing material includes a wood layer 1, a PVC layer 2, and a rubber layer 3, wherein the wood layer 1 is attached to one side of the PVC layer 2, and the rubber layer 3 is attached to the PVC On the other side of the layer 2, the wood layer 1, the PVC layer 2, and the rubber layer 3 are laminated into one.

[0015] On the basis of the above technical solutions, the following conditions are met:

[0016] The thickness of the wood layer 1 is equal to the sum of the thicknesses of the PVC layer 2 and the rubber layer 3 .

[0017] The lamination is realized by means of gluing.

Embodiment 2

[0019] A casing material for a generator, characterized in that the casing material includes a wood layer 1, a PVC layer 2, and a rubber layer 3, wherein the wood layer 1 is attached to one side of the PVC layer 2, and the rubber layer 3 is attached to the PVC On the other side of the layer 2, the wood layer 1, the PVC layer 2, and the rubber layer 3 are laminated into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com