Preparation method of anti-pollution aliphatic PVC anion exchange membrane

An anion-exchange membrane and aliphatic technology, applied in the field of separation membranes, can solve problems such as high water absorption and complex ion membrane preparation process, and achieve the effects of reduced adsorption, good anti-pollution ability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

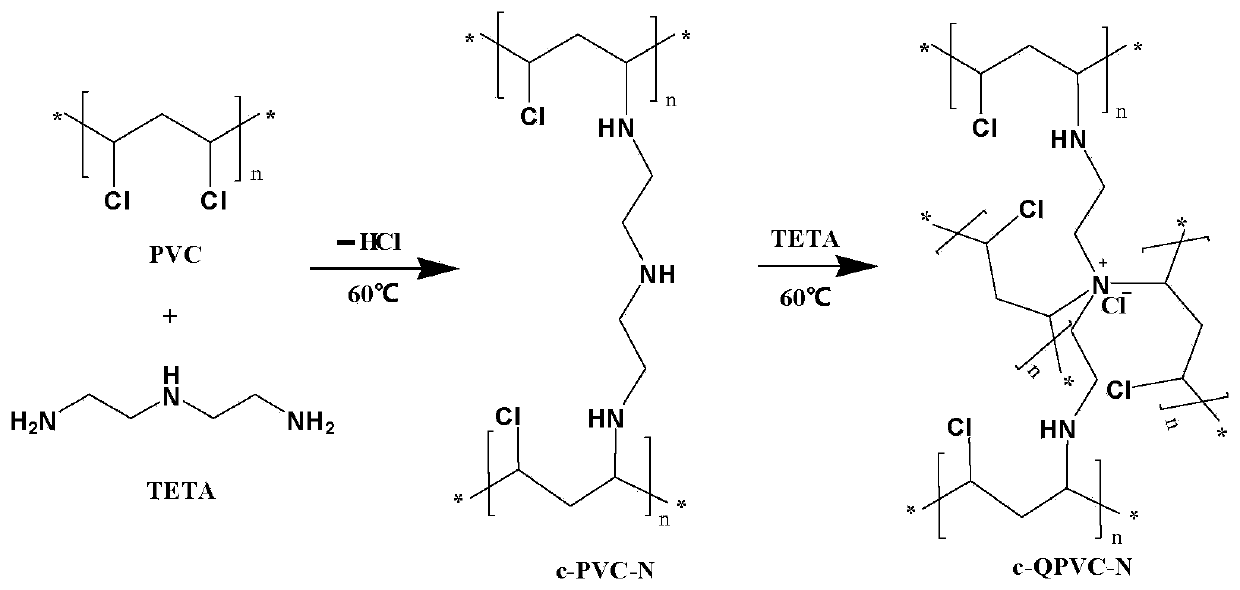

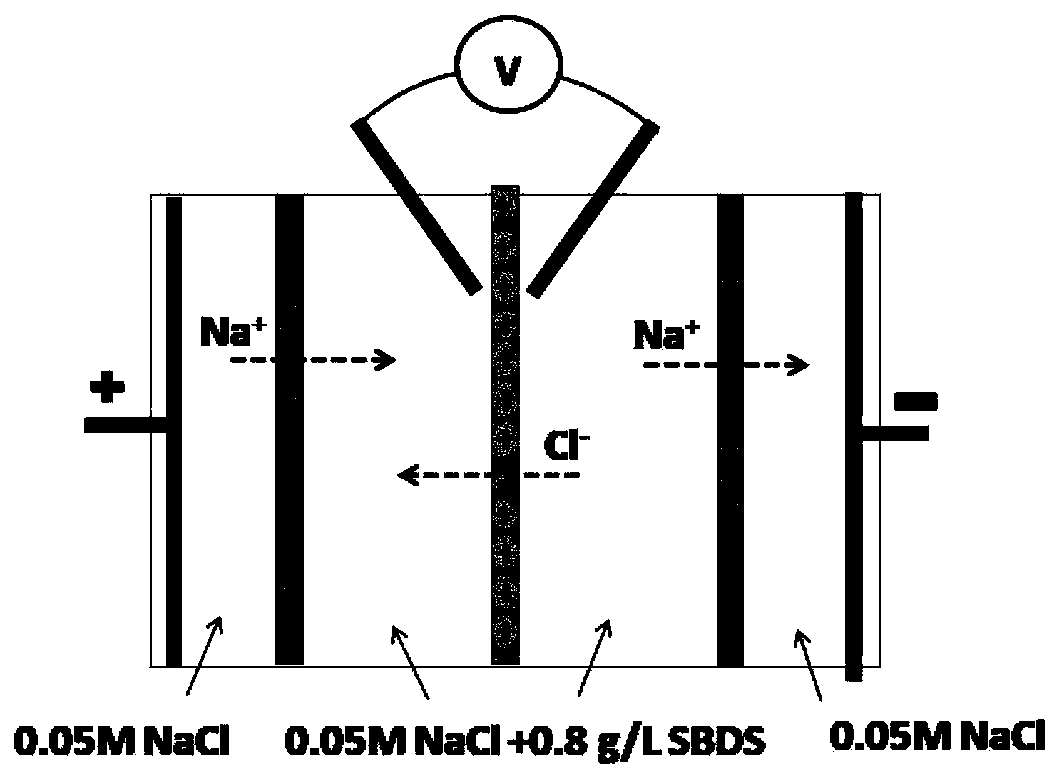

Method used

Image

Examples

Embodiment 1

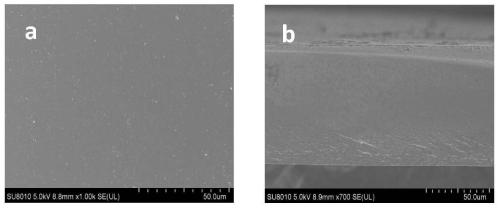

[0031] Add 10g of PVC powder to 90g of N,N-dimethylacetamide, heat to 60°C, dissolve to obtain a 10% solution, vacuum defoam the PVC solution, pour it on a glass plate, and scrape it with a scraper with a thickness of 100μm Apply it as a wet film, dry and evaporate the solvent on a flat heater at 60°C to obtain a PVC film. Take off the PVC membrane and soak it in 50mL of 70% triethylenetetramine aqueous solution at 60°C, take it out after reacting for h to obtain a quaternized and cross-linked QPVC-1 anion exchange membrane; take it out and rinse the surface with distilled water, soak it in 0.5M in NaCl solution for use. from figure 1 It can be seen from the SEM image that the surface and cross section of the QPVC film layer are dense and uniform, without holes and cracks.

Embodiment 2

[0033] Change the soaking time in the above example 1 to 8h, and keep other steps unchanged to obtain anion exchange membrane QPVC-2.

Embodiment 3

[0035] Change the soaking time in the above example 1 to 12h, and keep other steps unchanged to obtain anion exchange membrane QPVC-3.

[0036] Carry out ion exchange capacity (IEC) and membrane resistance (R to the QPVC ion-exchange membrane that embodiment prepares n ) investigation, such as Figure 4 As shown, with the prolongation of soaking time of PVC film in triethylenetetramine solution, IEC gradually increases, and R n Gradually decreases. This is because the longer the soaking time, the more quaternary ammonium salt functional groups grafted onto the PVC main chain, the more ion exchange flux, and the more ion transmission channels provided by the more hydrophilic quaternary ammonium salt, the mask resistance reduce.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com