Patents

Literature

510 results about "Dialysis membranes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

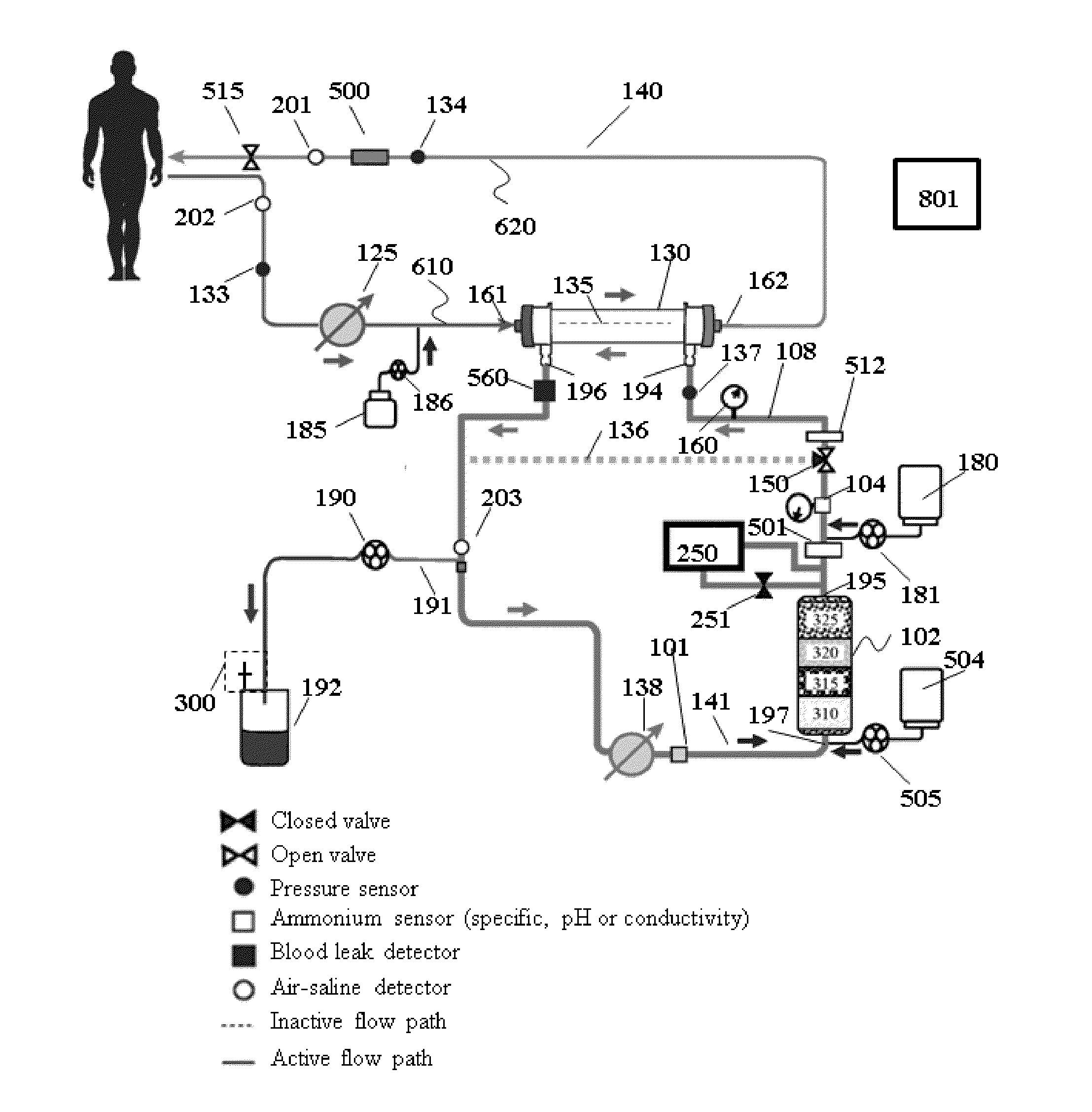

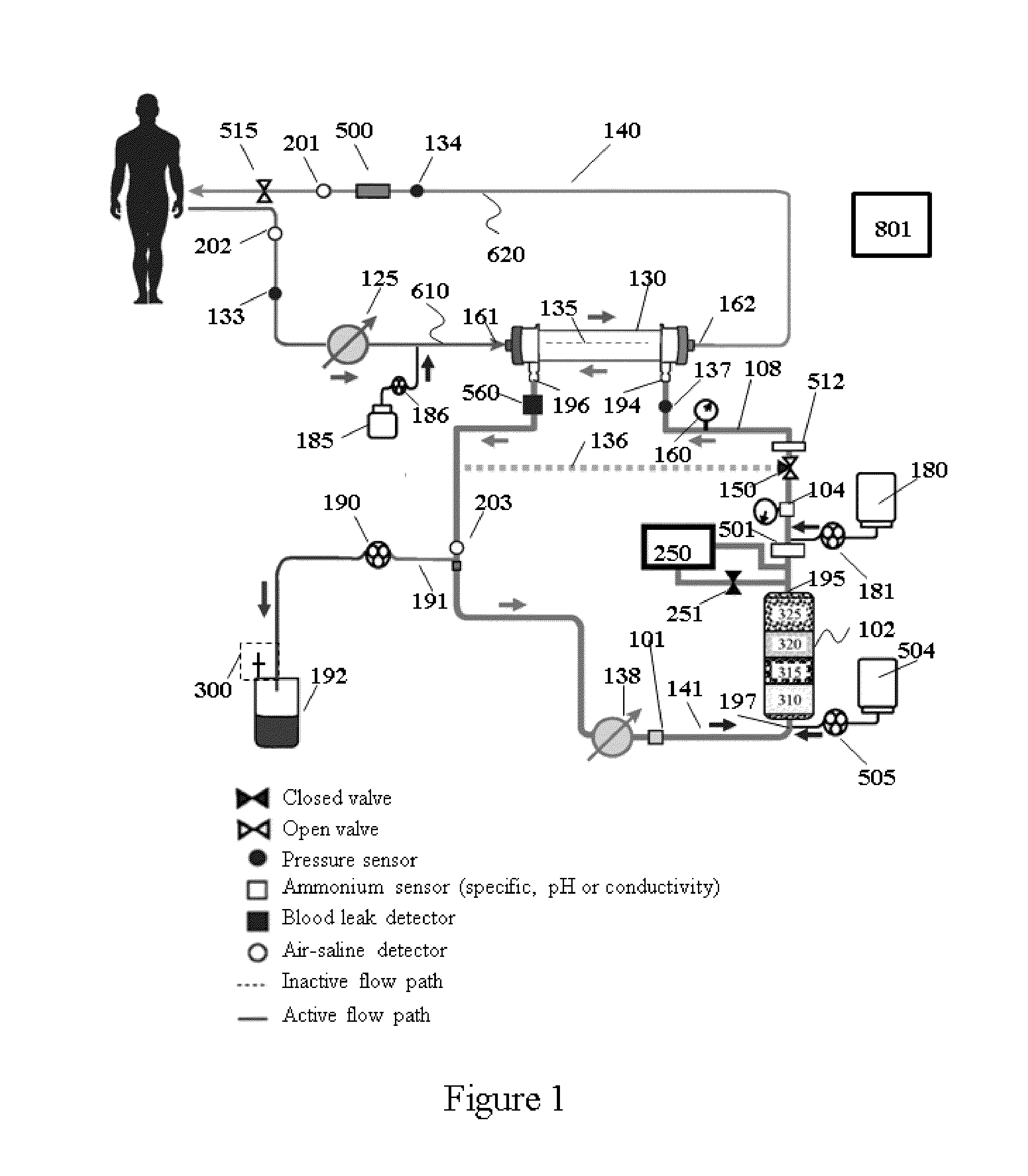

Hemodialysis system having a flow path with a controlled compliant volume

ActiveUS20130199998A1Enhanced convective clearanceReduce riskSemi-permeable membranesSolvent extractionDialysis membranesHaemodialysis machine

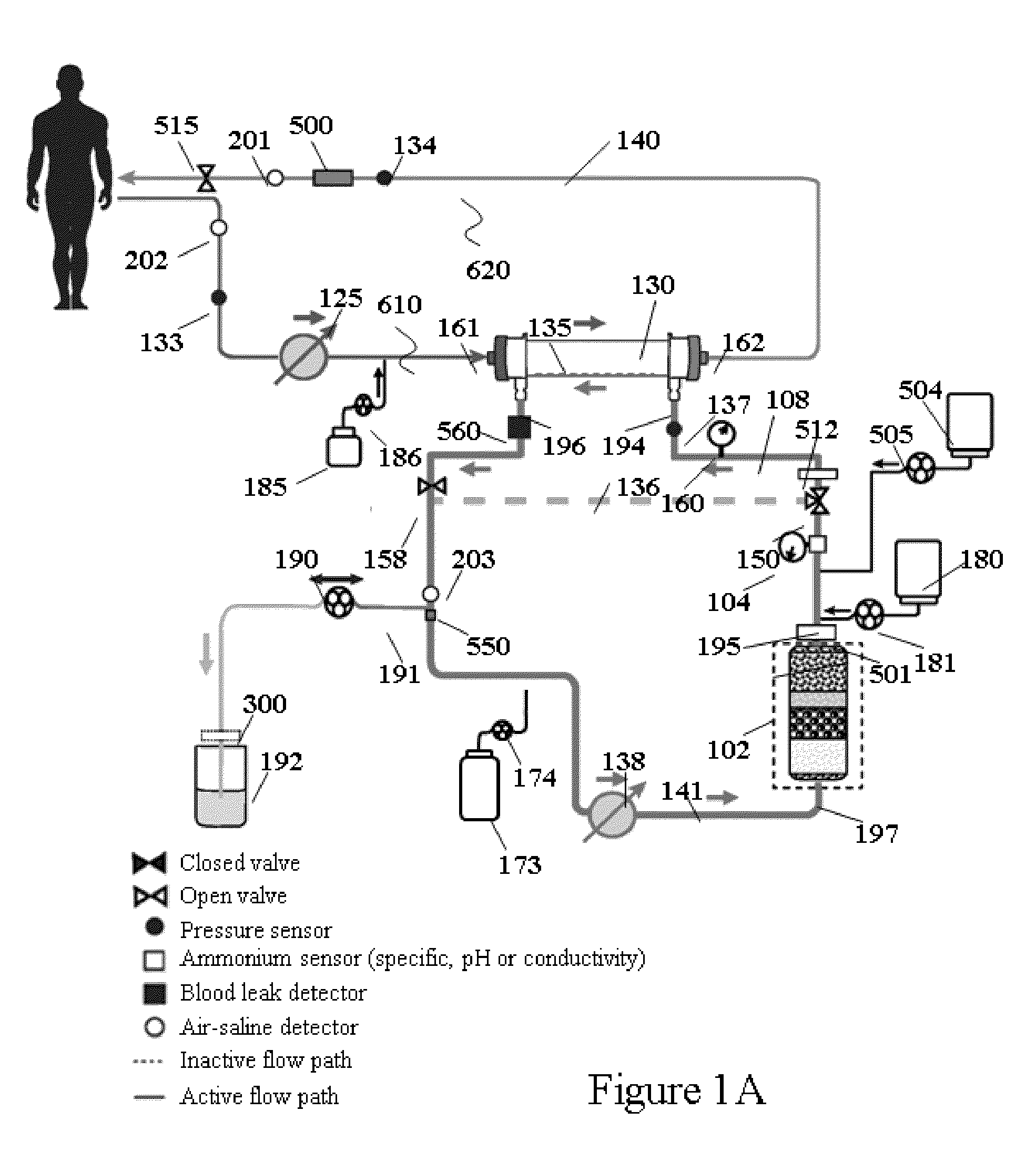

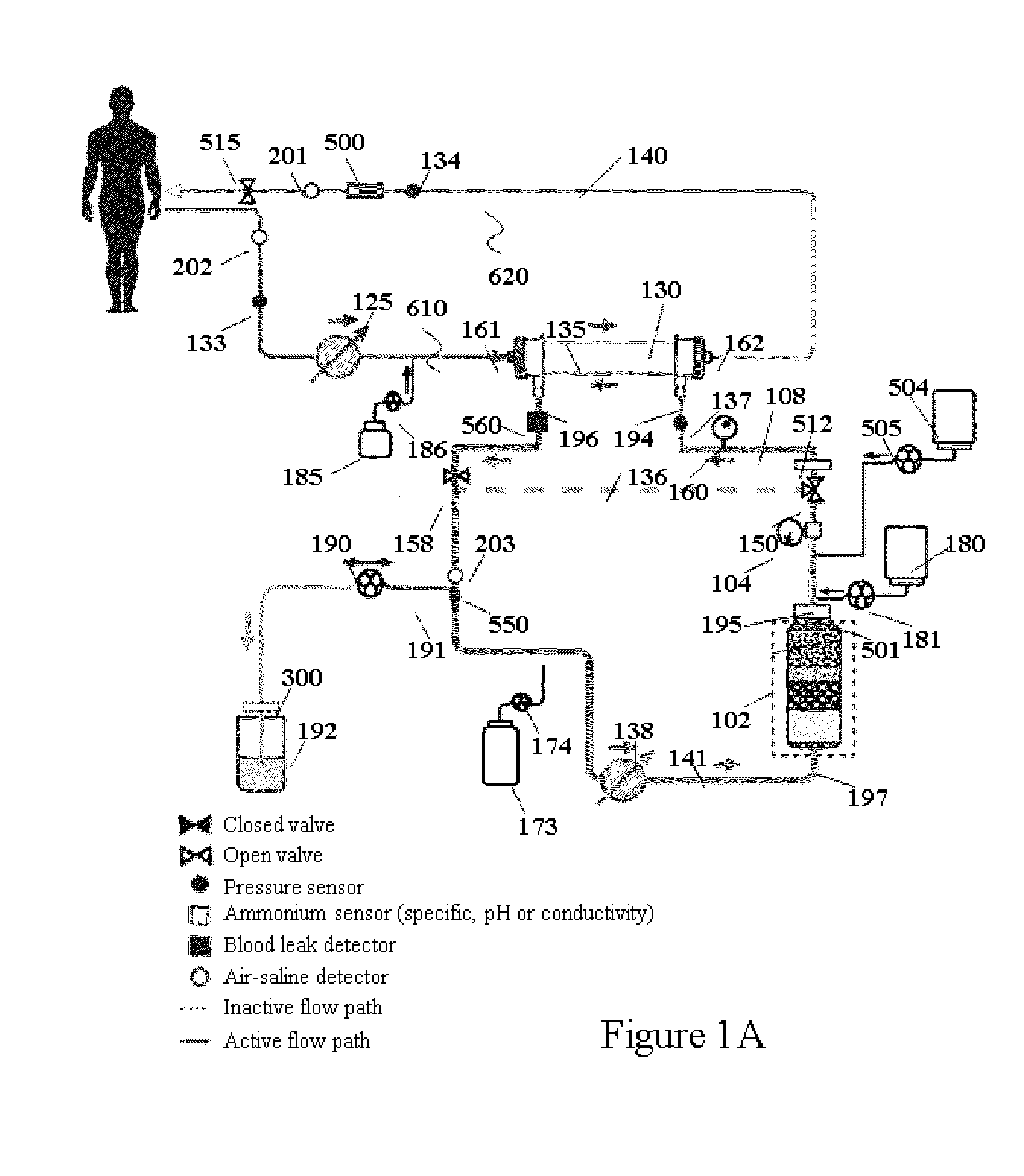

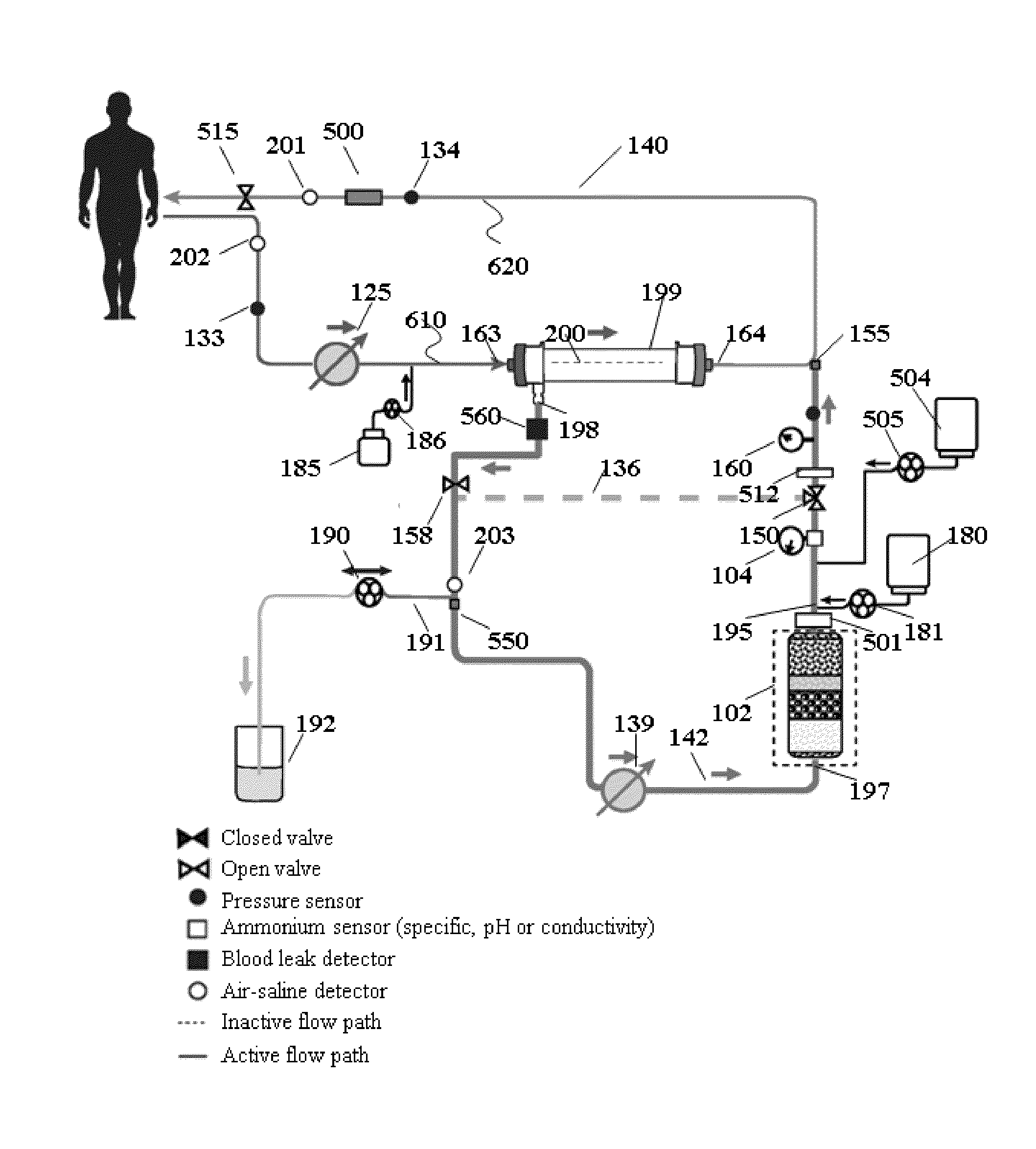

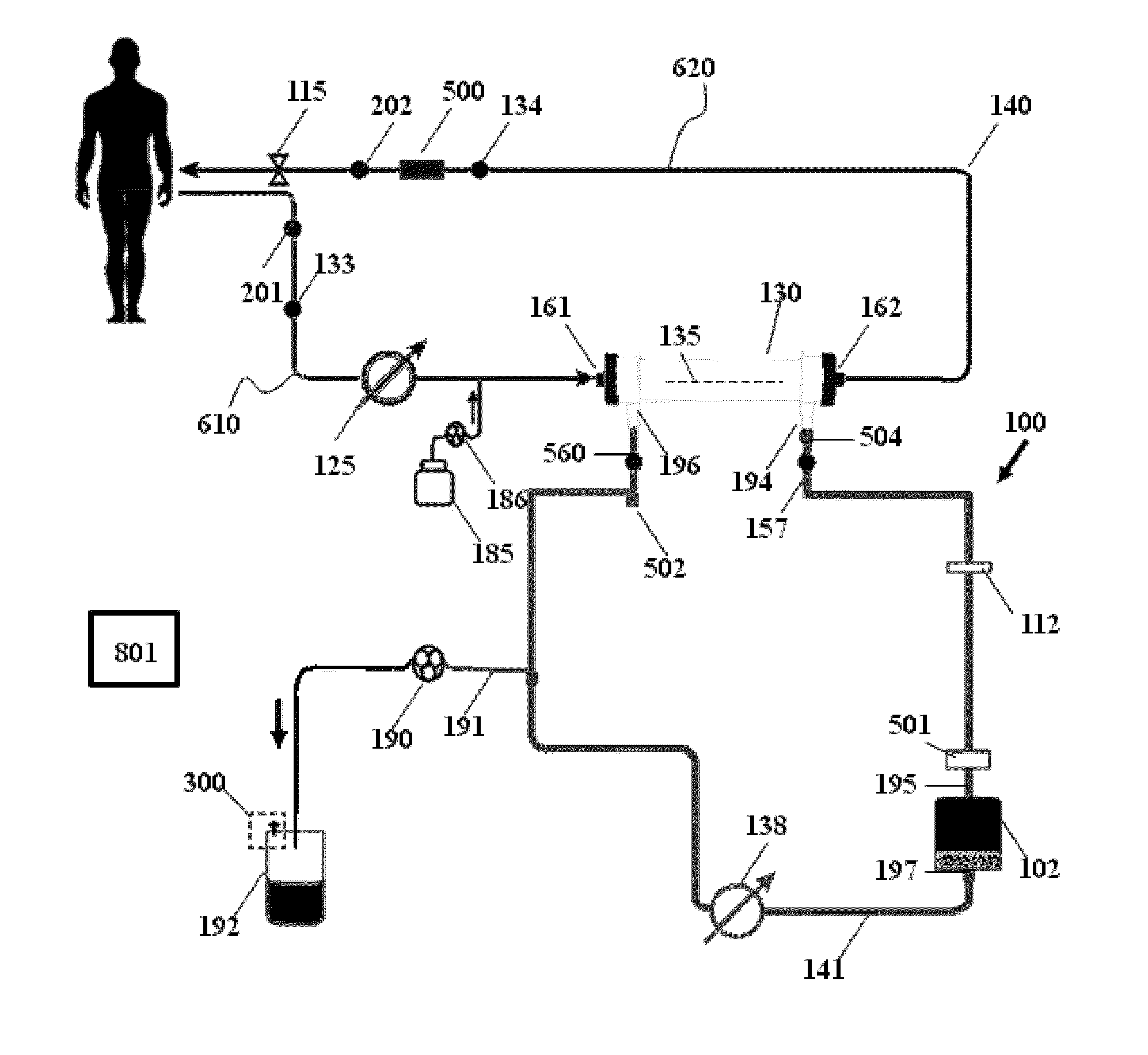

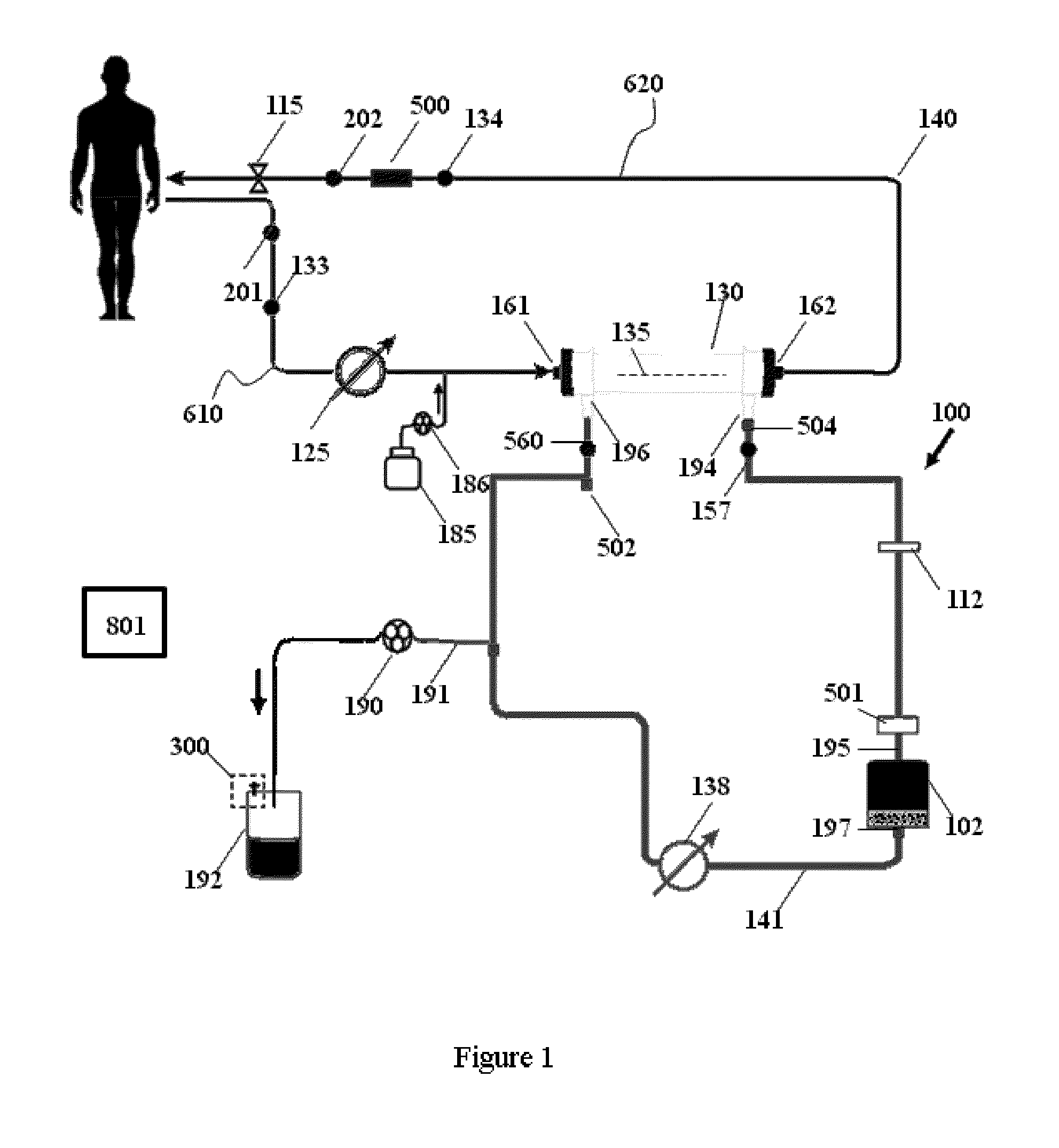

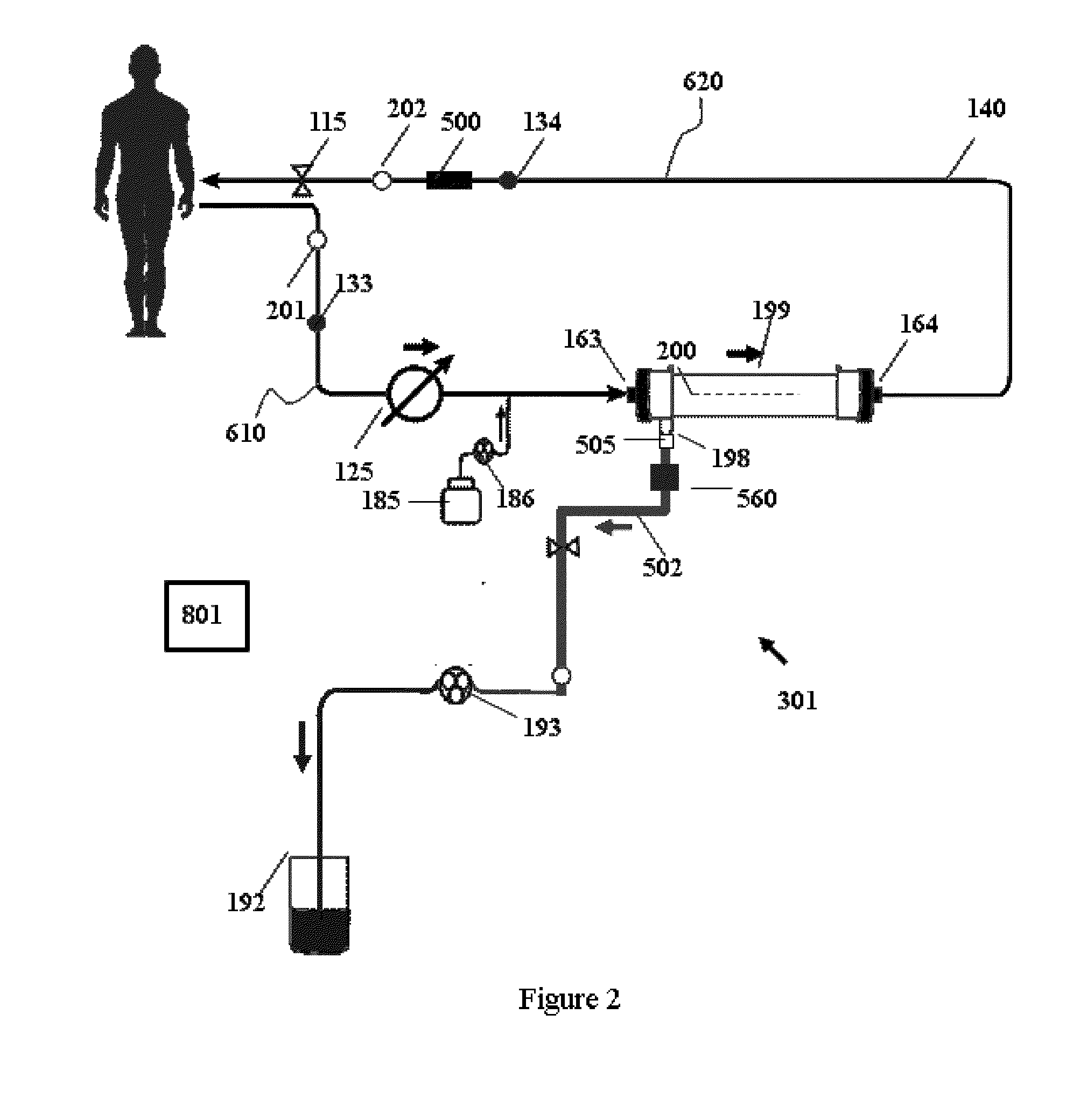

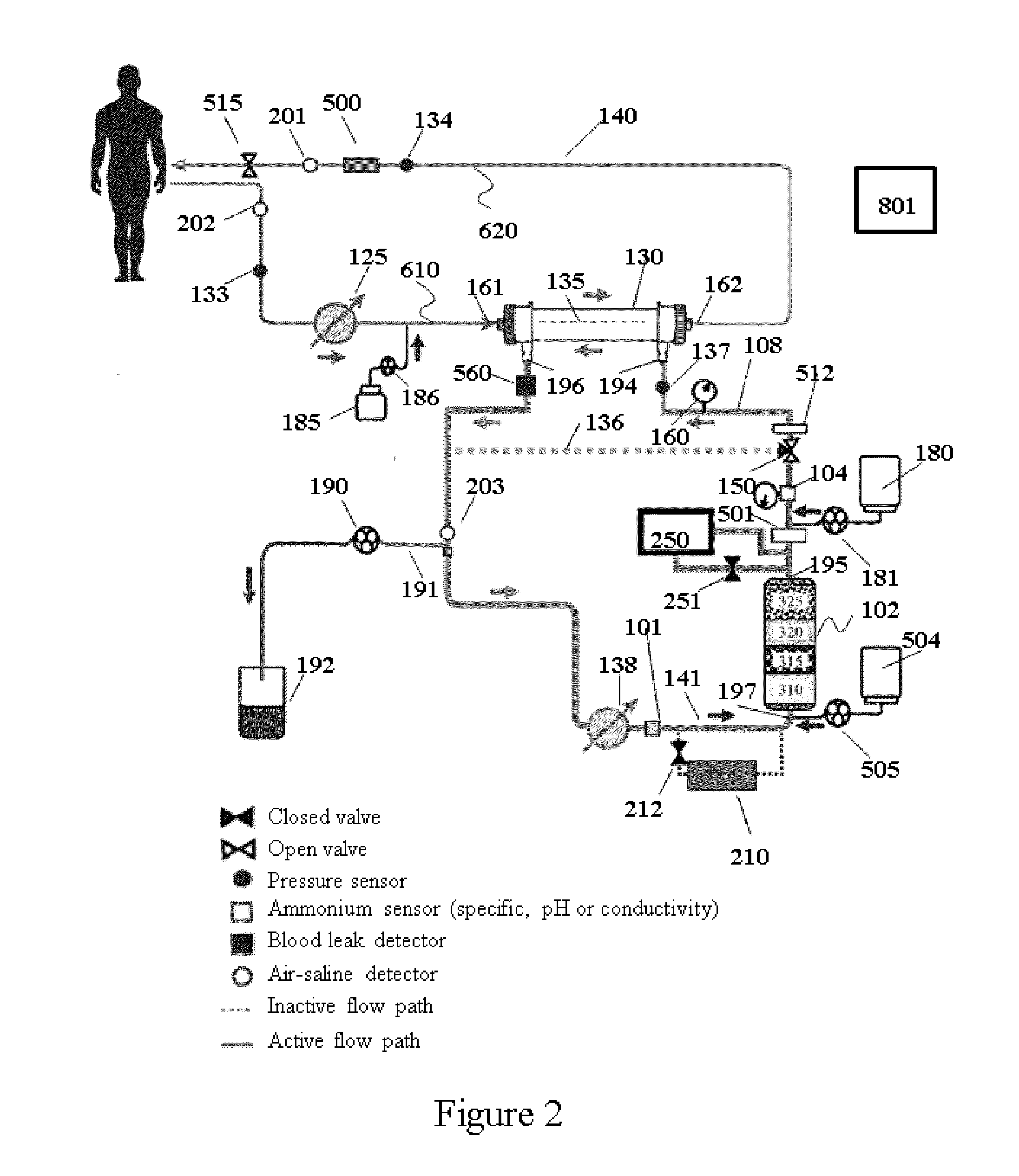

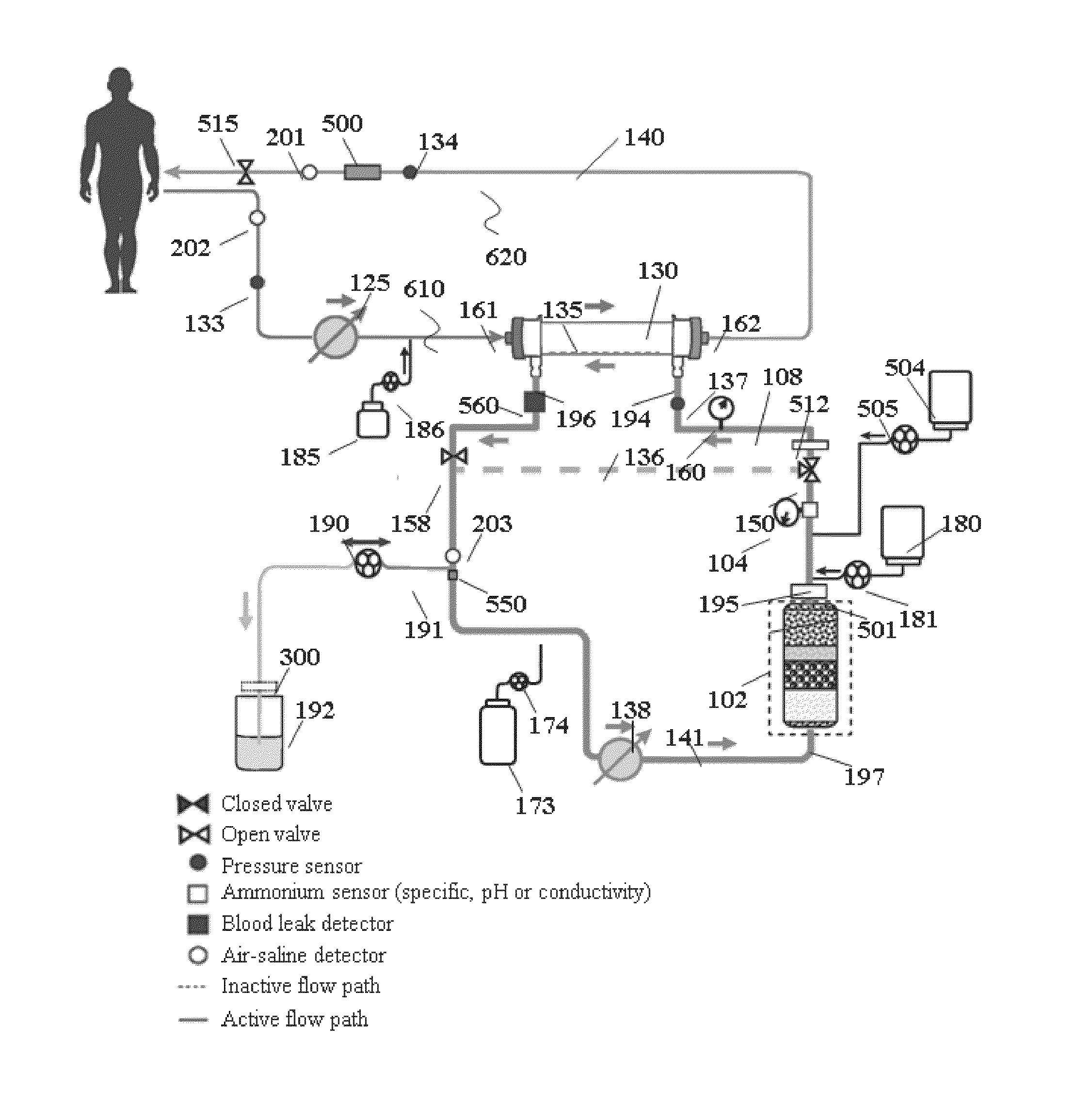

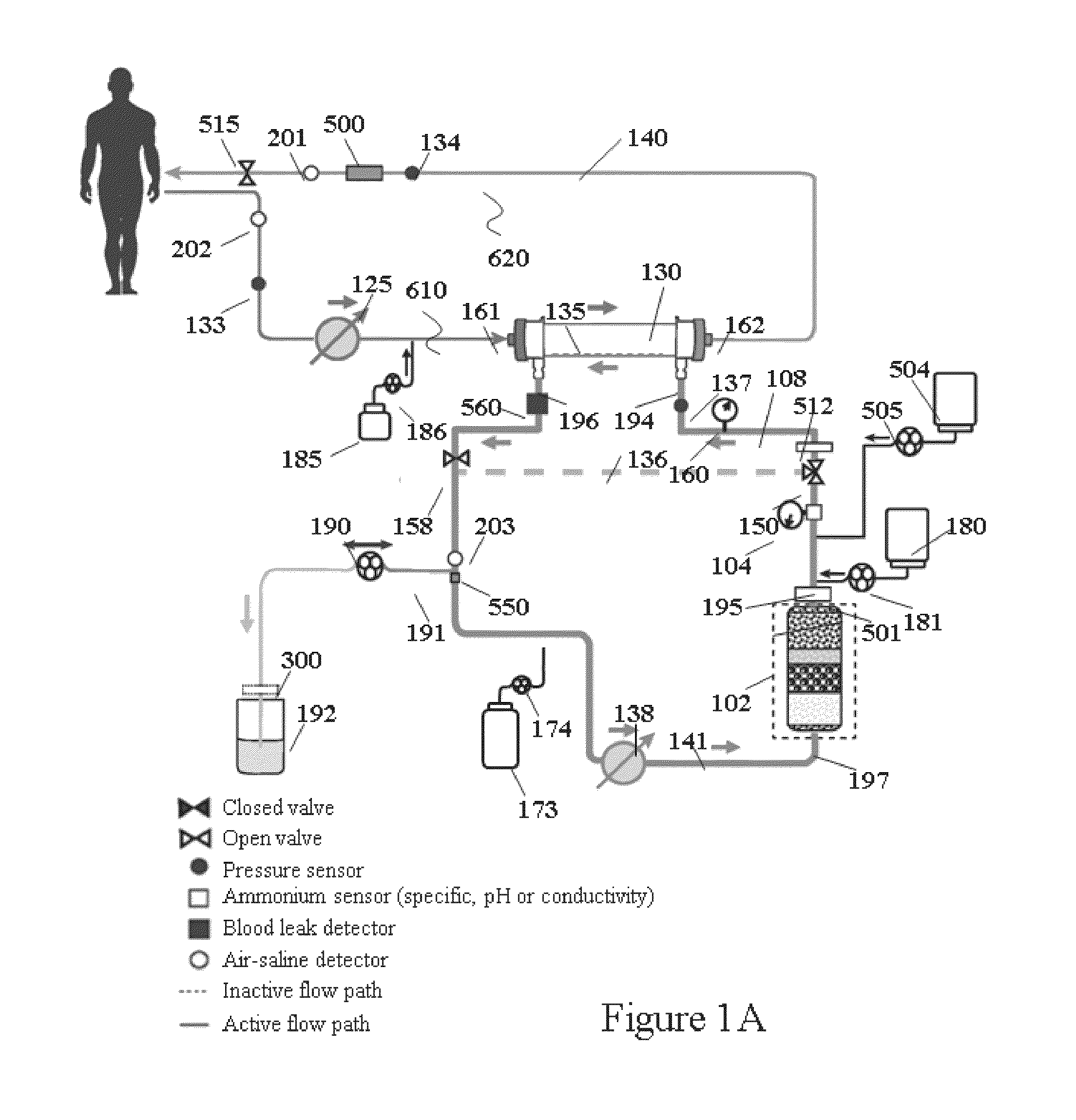

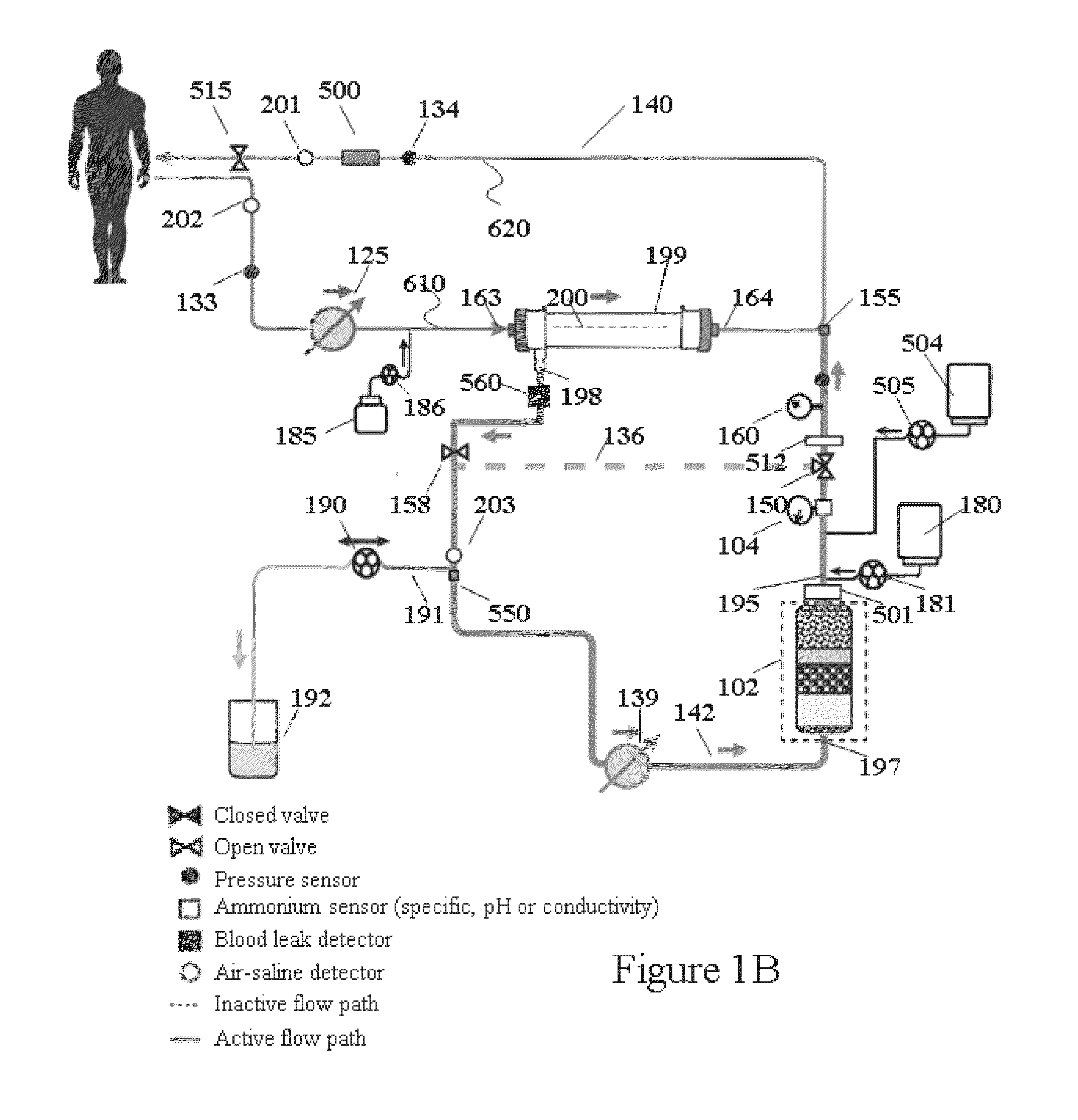

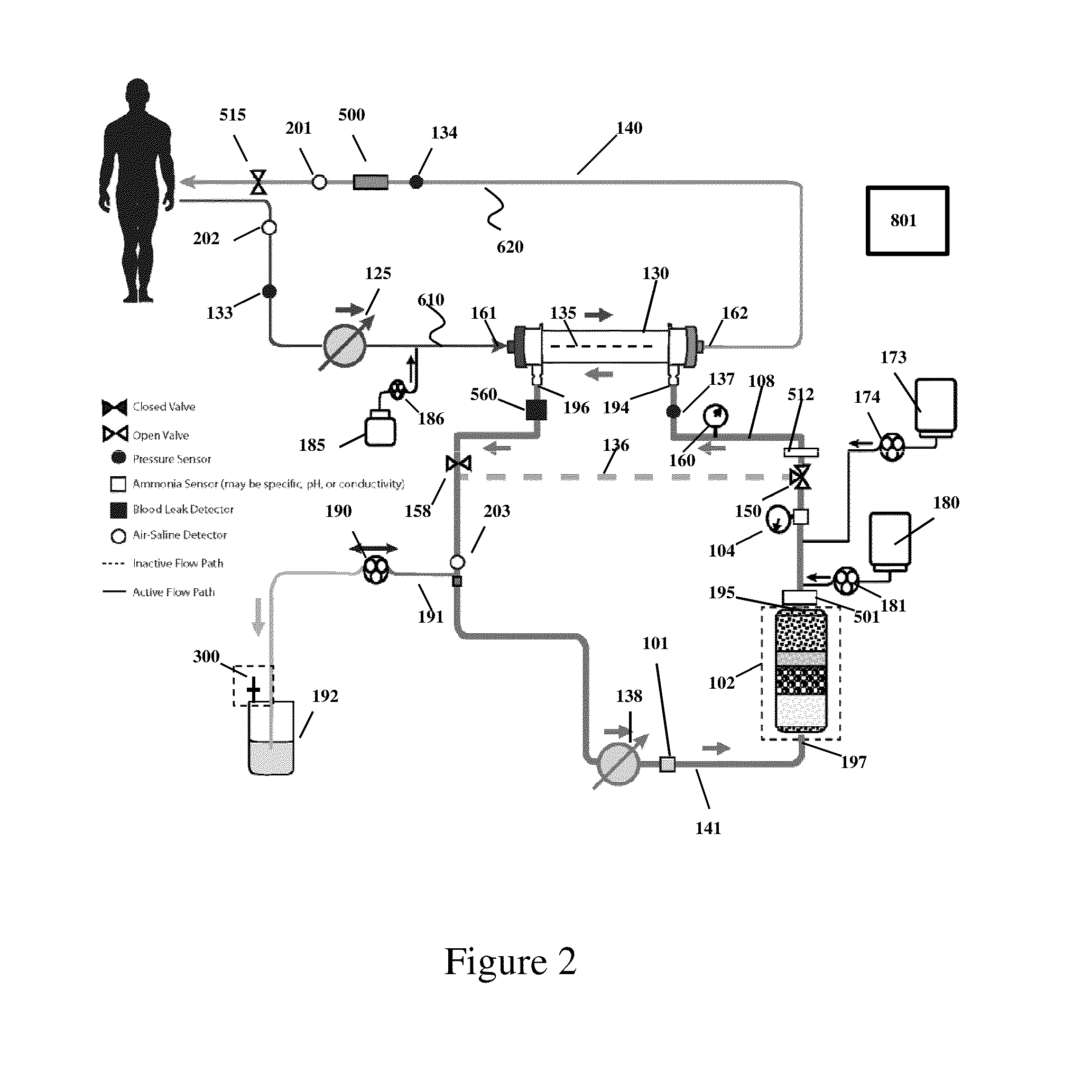

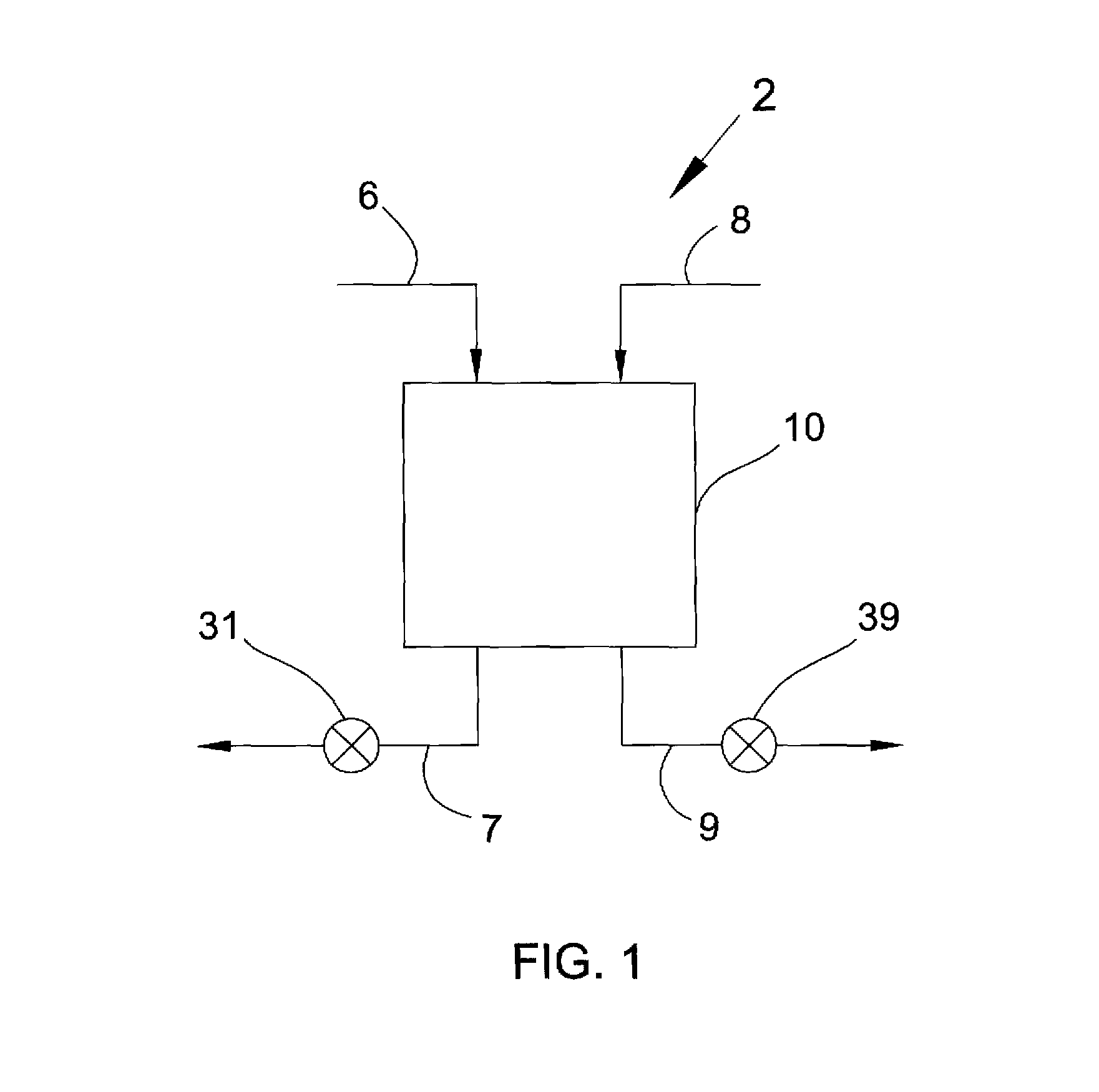

Systems and methods for the performance of kidney replacement therapy having or using a dialyzer, control components, sorbent cartridge and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment are disclosed. The system for performing kidney replacement therapy has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. The dialysis circuit and an extracorporeal circuit for circulating blood are in fluid communication through the dialysis membrane. The flux of fluid moving between the extracorporeal circuit and the dialysis circuit is modified by the rate at which the control pump is operating such that a rate of ultrafiltration and convective clearance can be controlled. The system provides for the monitoring of an inlet and outlet conductivity of the sorbent cartridge to provide a facility to quantify or monitor the removal of urea by the sorbent cartridge.

Owner:MOZARC MEDICAL US LLC

Modular hemodialysis system

ActiveUS20130213890A1Mechanical/radiation/invasive therapiesSolvent extractionDialysis membranesActivated carbon

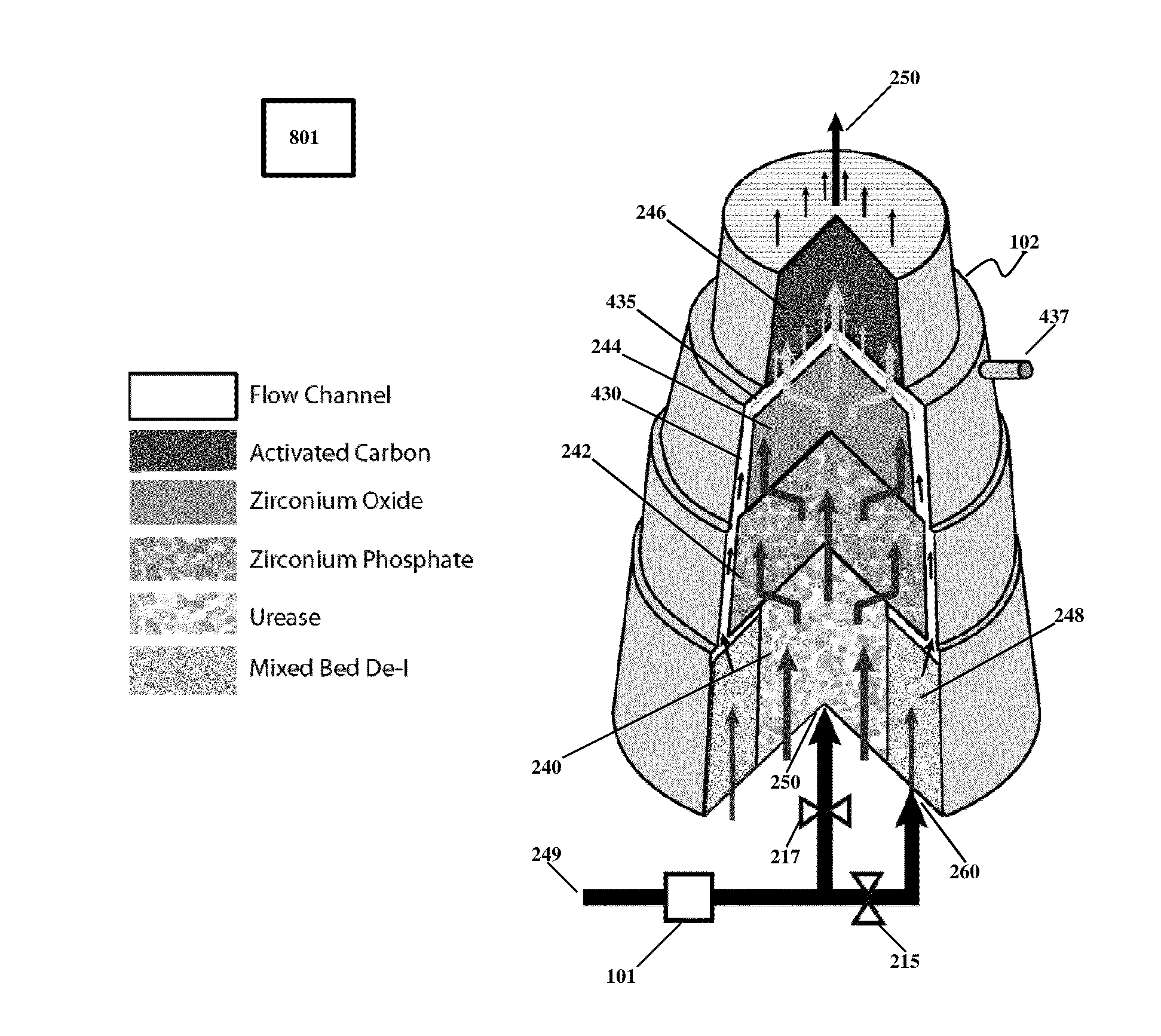

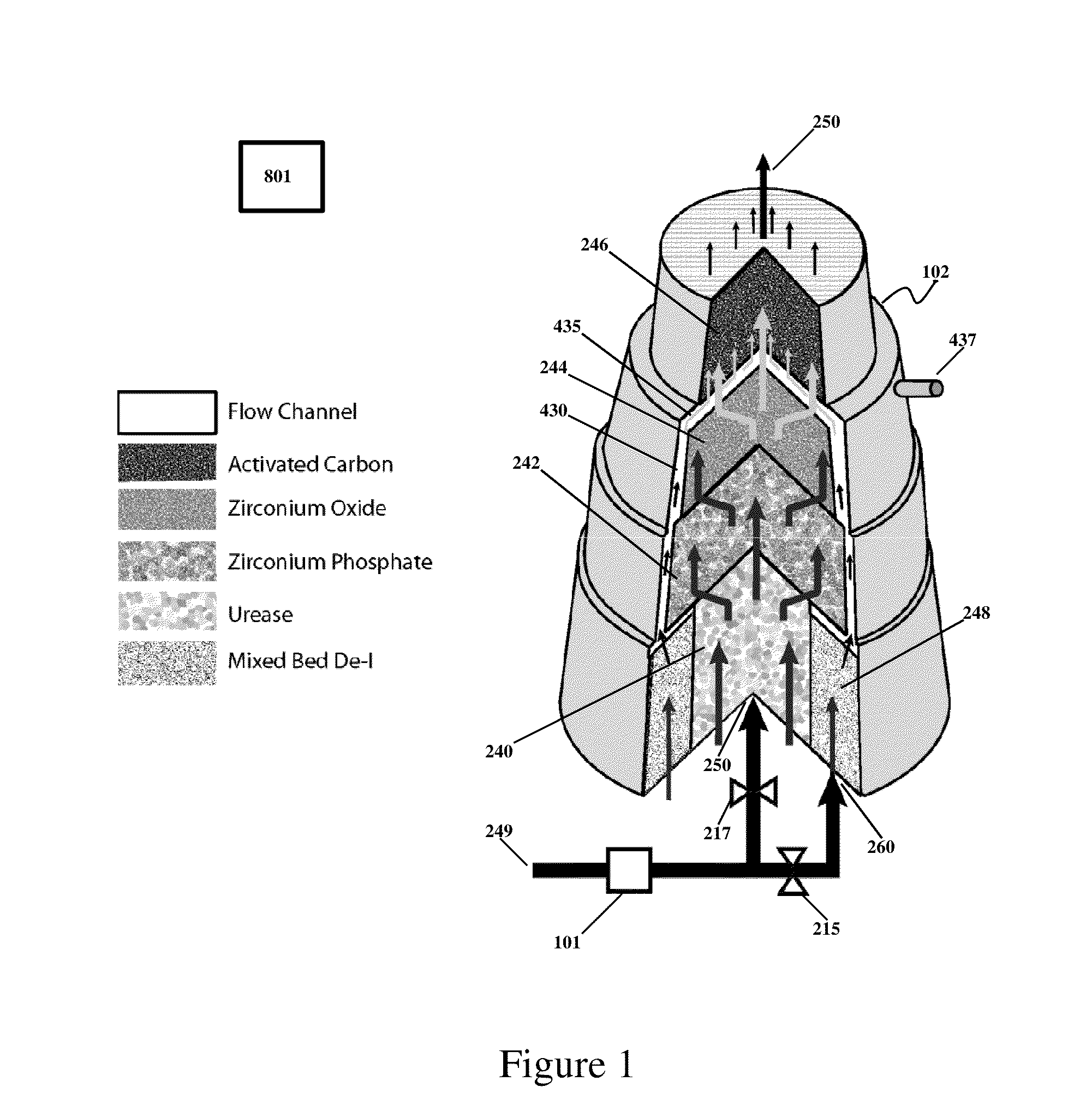

Apparatuses, systems, and methods for the performance of kidney replacement therapy having or using a dialyzer, control components, sorbent cartridge, and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment are disclosed. The system has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. A first sorbent cartridge is provided for use in a portable treatment module having activated carbon and zirconium oxide. The system also provides for the monitoring of an inlet and outlet conductivity of a sorbent cartridge containing urease to provide a facility to quantify or monitor the removal of urea by a detachable urea removal module.

Owner:MOZARC MEDICAL US LLC

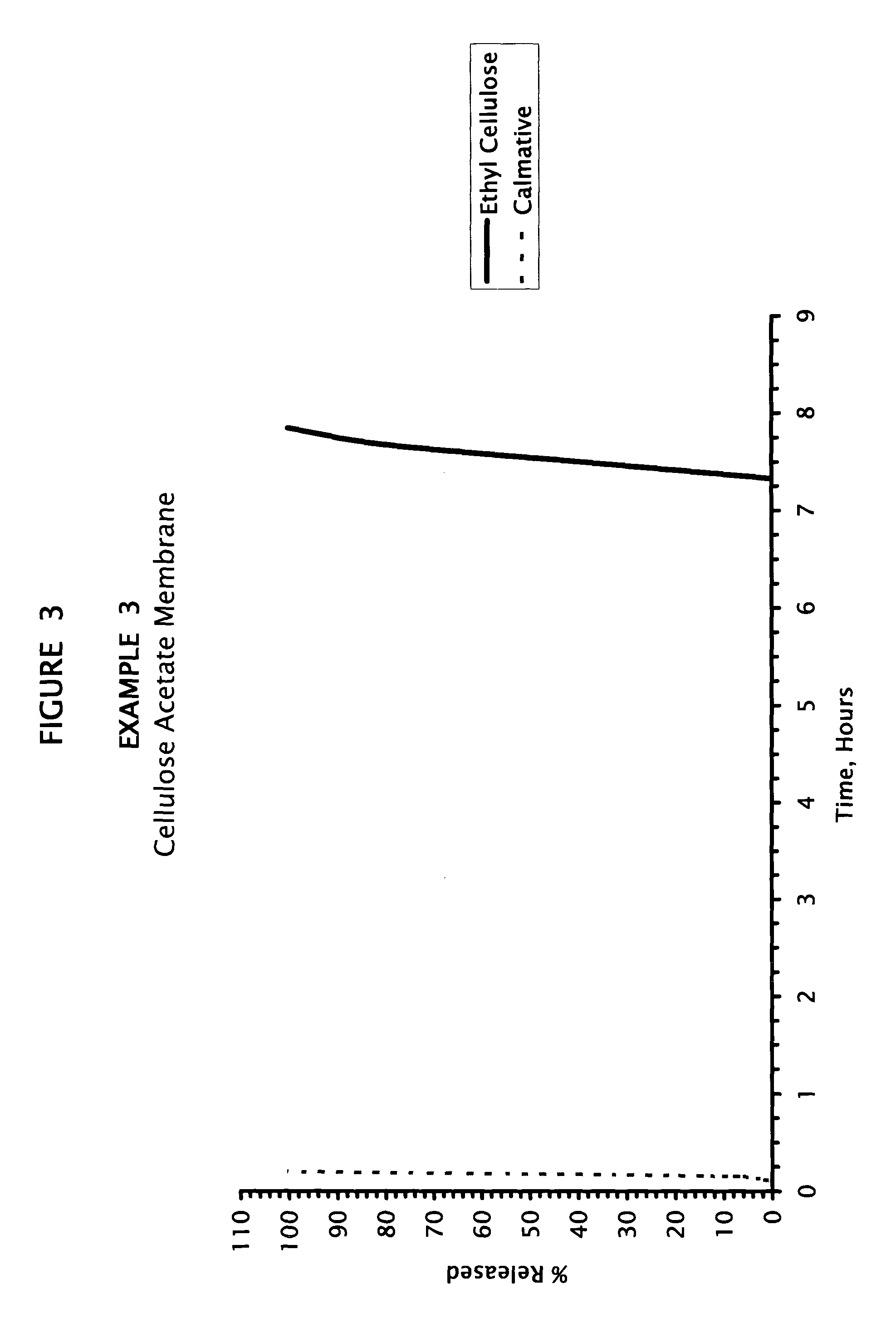

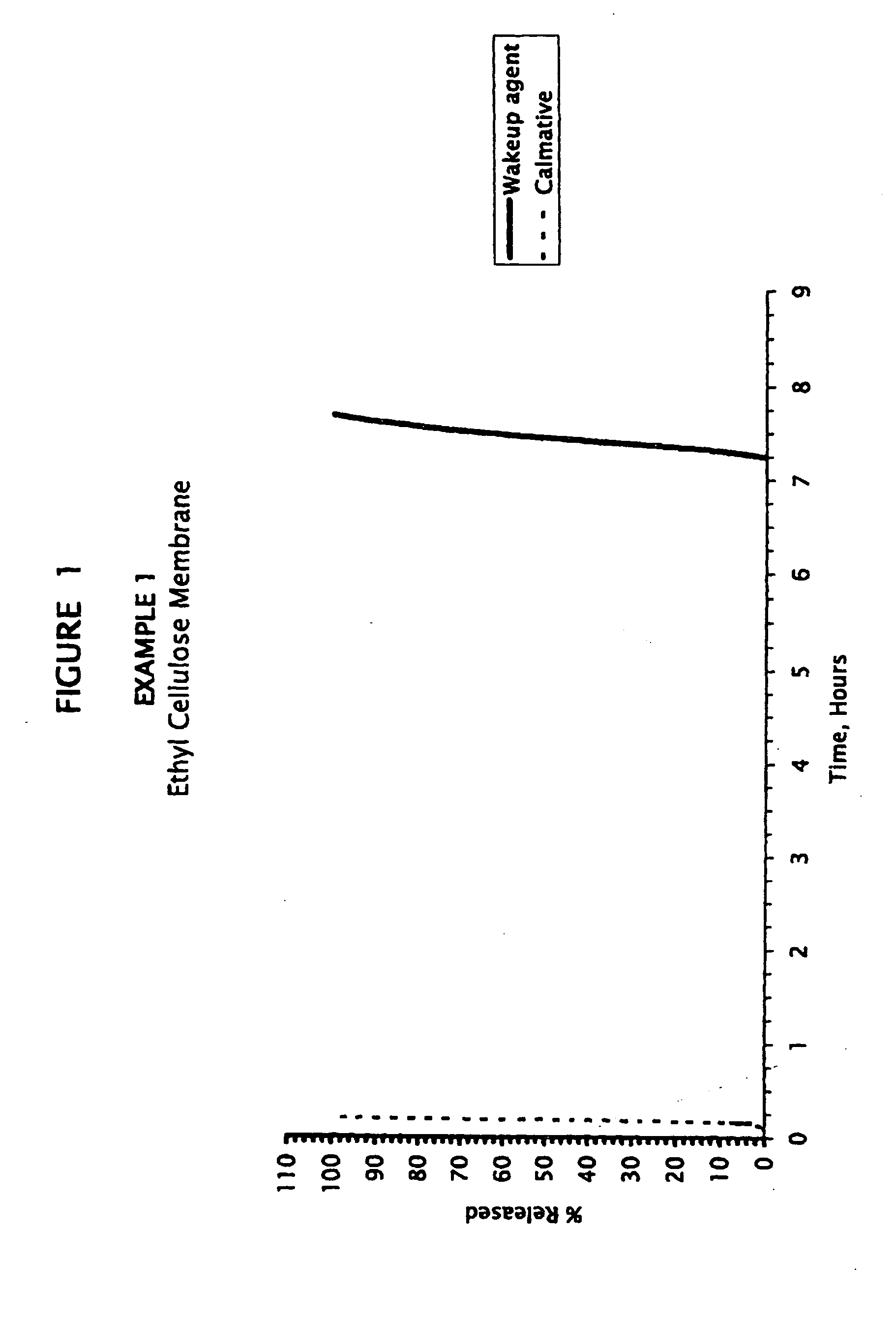

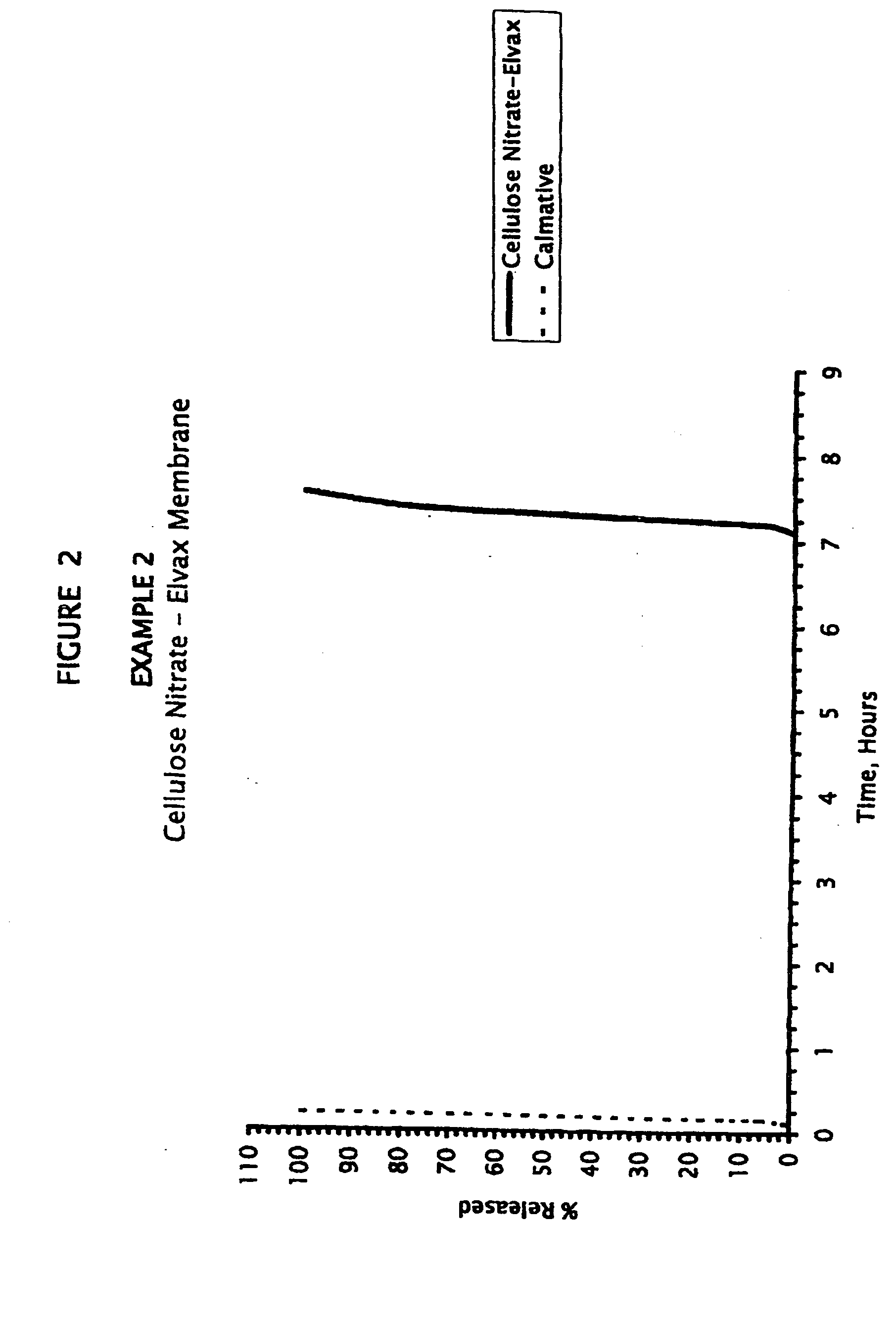

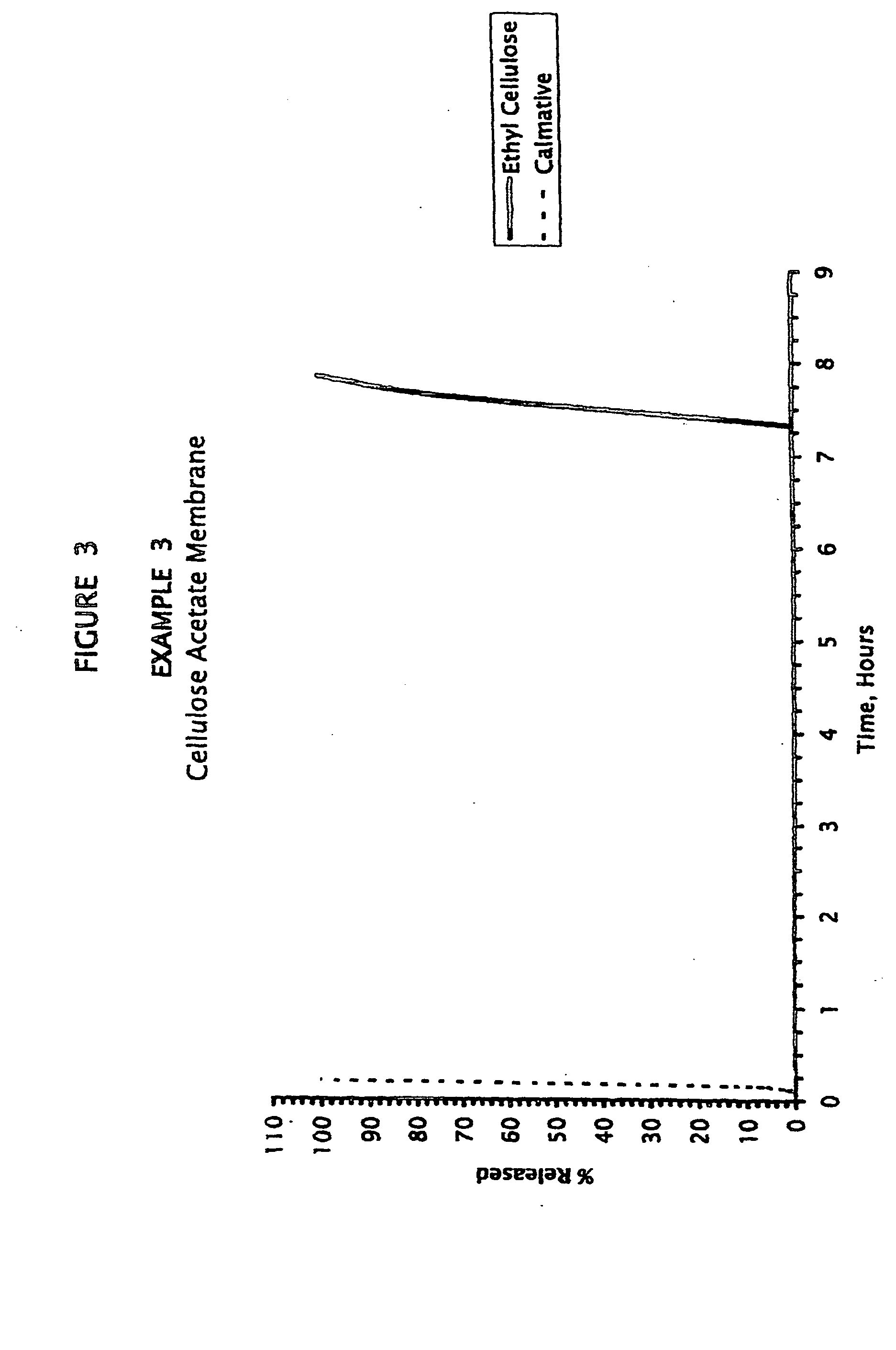

Positive wakeup pharmaceutical sleep system with compatible pre-bedtime administration

InactiveUS20050031688A1Fine stepsAvoid accidentsBiocideCarbohydrate active ingredientsDialysis membranesOral medication

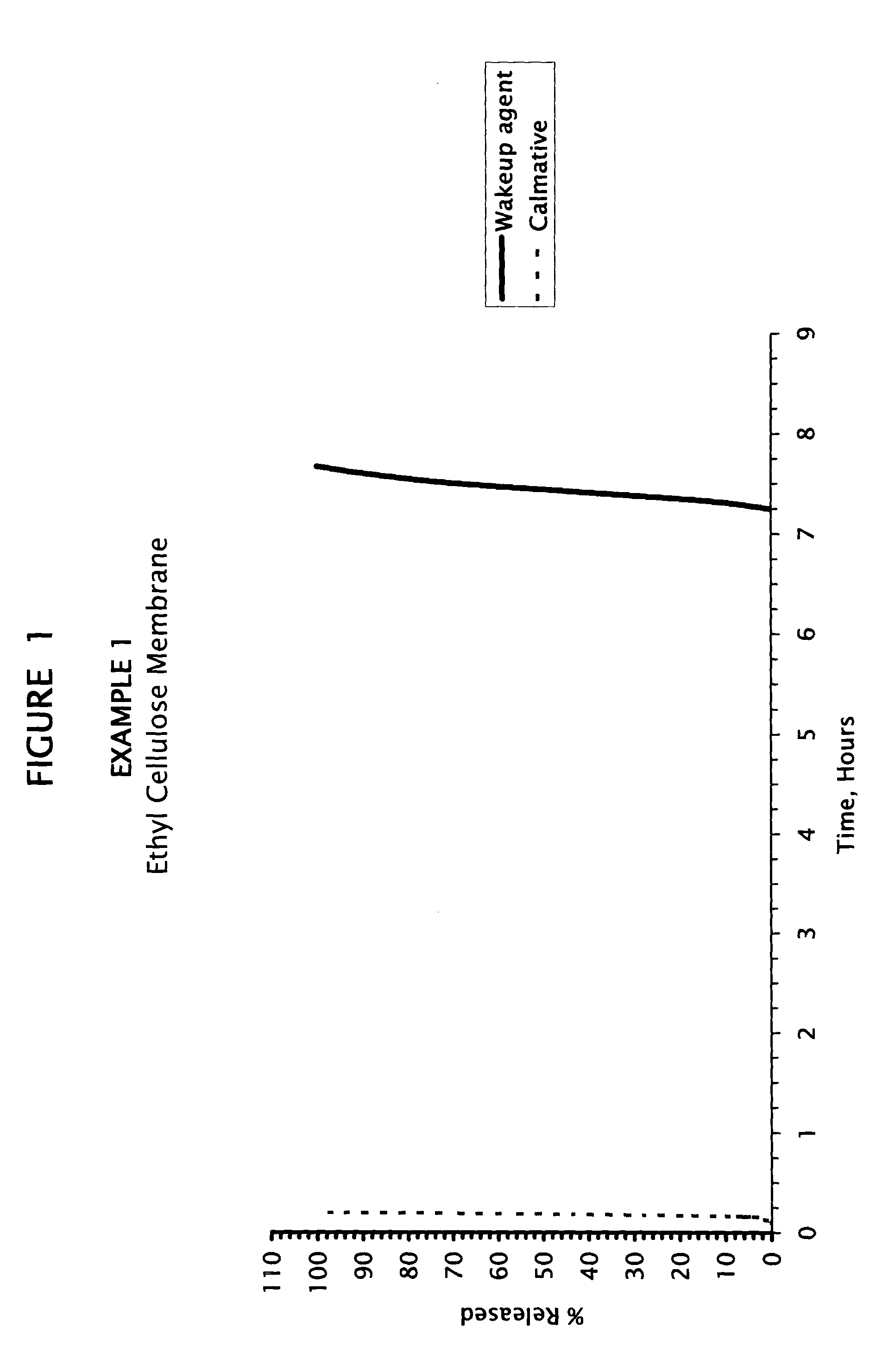

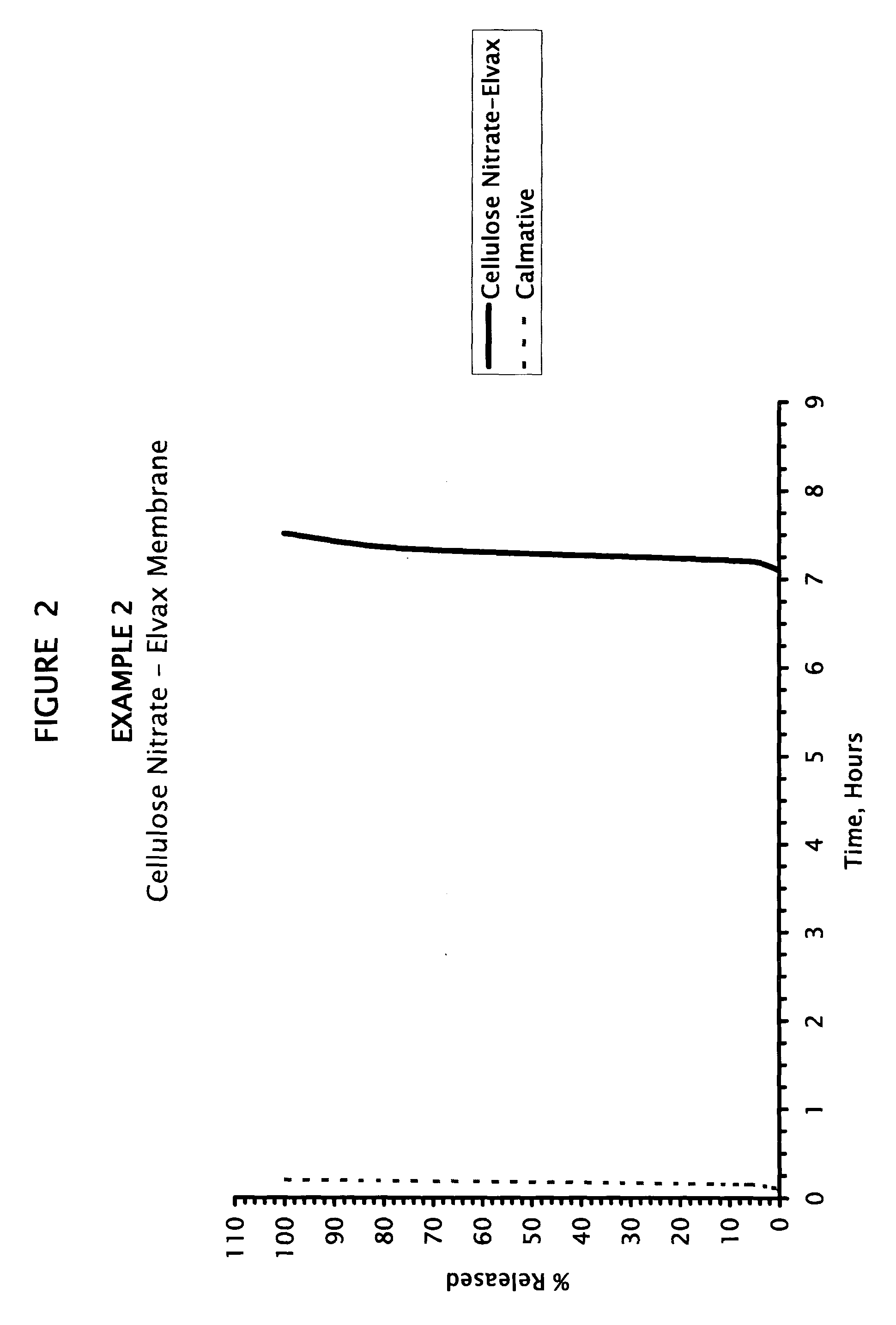

A novel sleep regulating pharmaceutical formulation is introduced, typically implementing two principal drugs having actions which are reversive to one another, yet incorporated into a unitary solid dosage, and prepared for oral administration before bedtime. Usually, structure is configured to initially release a calmative or other sleep-compatible substance by prompt dissolution. The initial release is followed by a specific period of delay, which in basic formulations entails no release of any drug, and which allows a nominal interval of sleep. At the terminus of the delay, a final agent is released to induce wakeup. Incorporation of agents of opposite action within a unitary dosage form renders utility which is uniquely appropriate to the invention. In a preferred embodiment, delay of release and final delivery of wakeup agent are arranged by a dialysis membrane which eventually bursts as a result of osmotic pressure generated by a hydrophilic core.

Owner:AYALA WILLIAM J

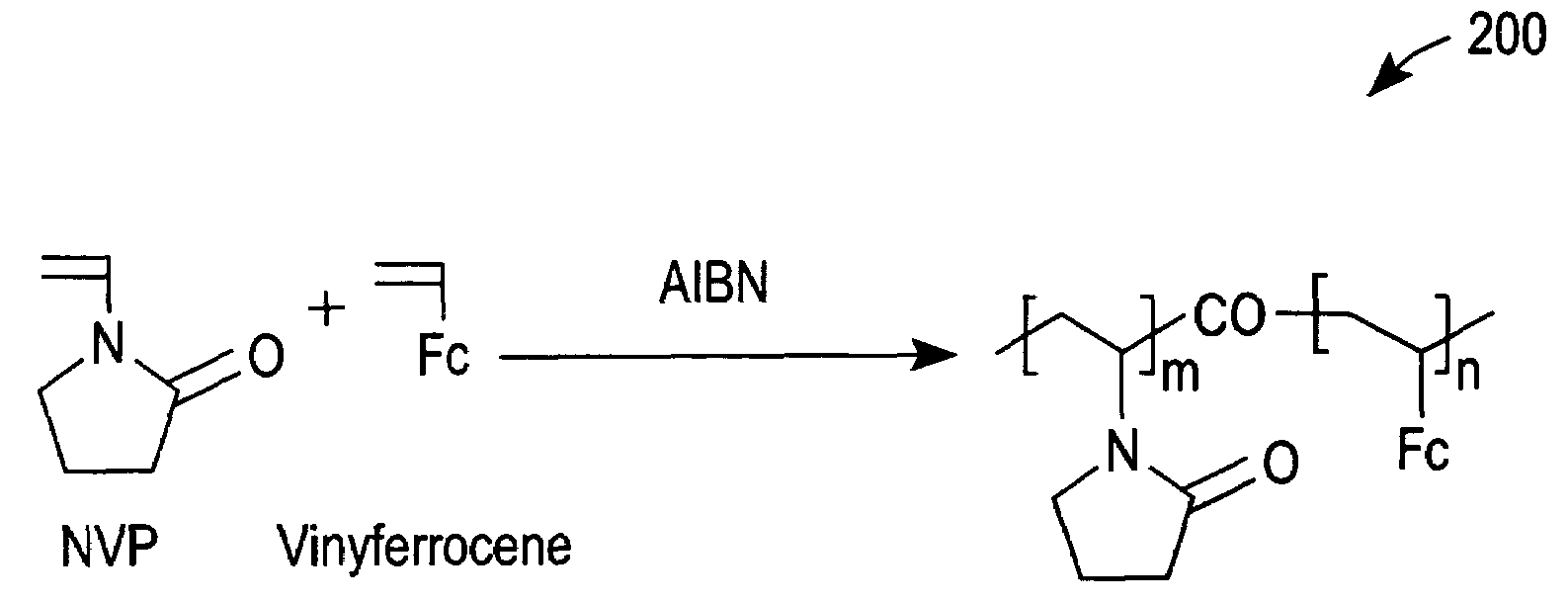

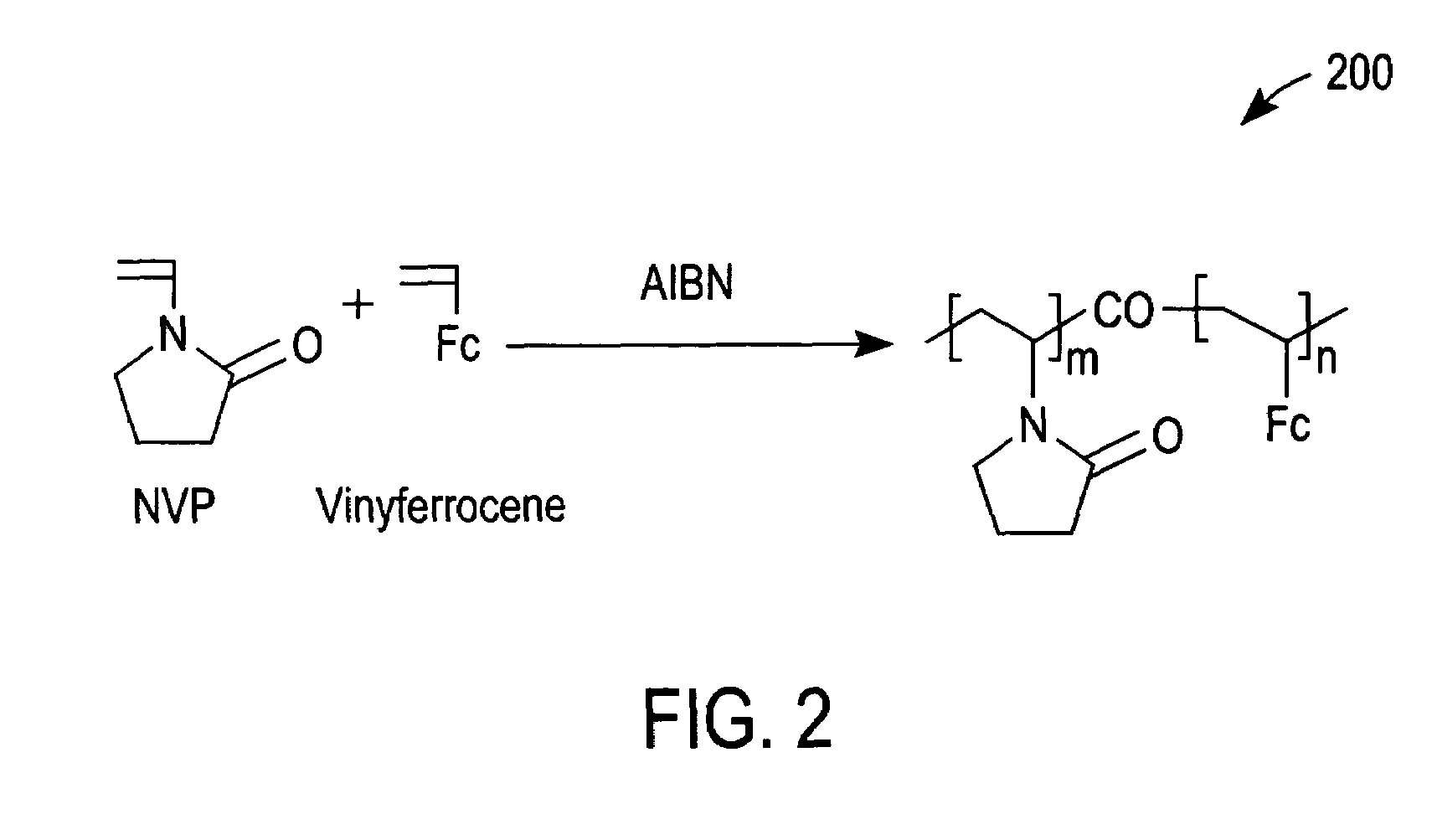

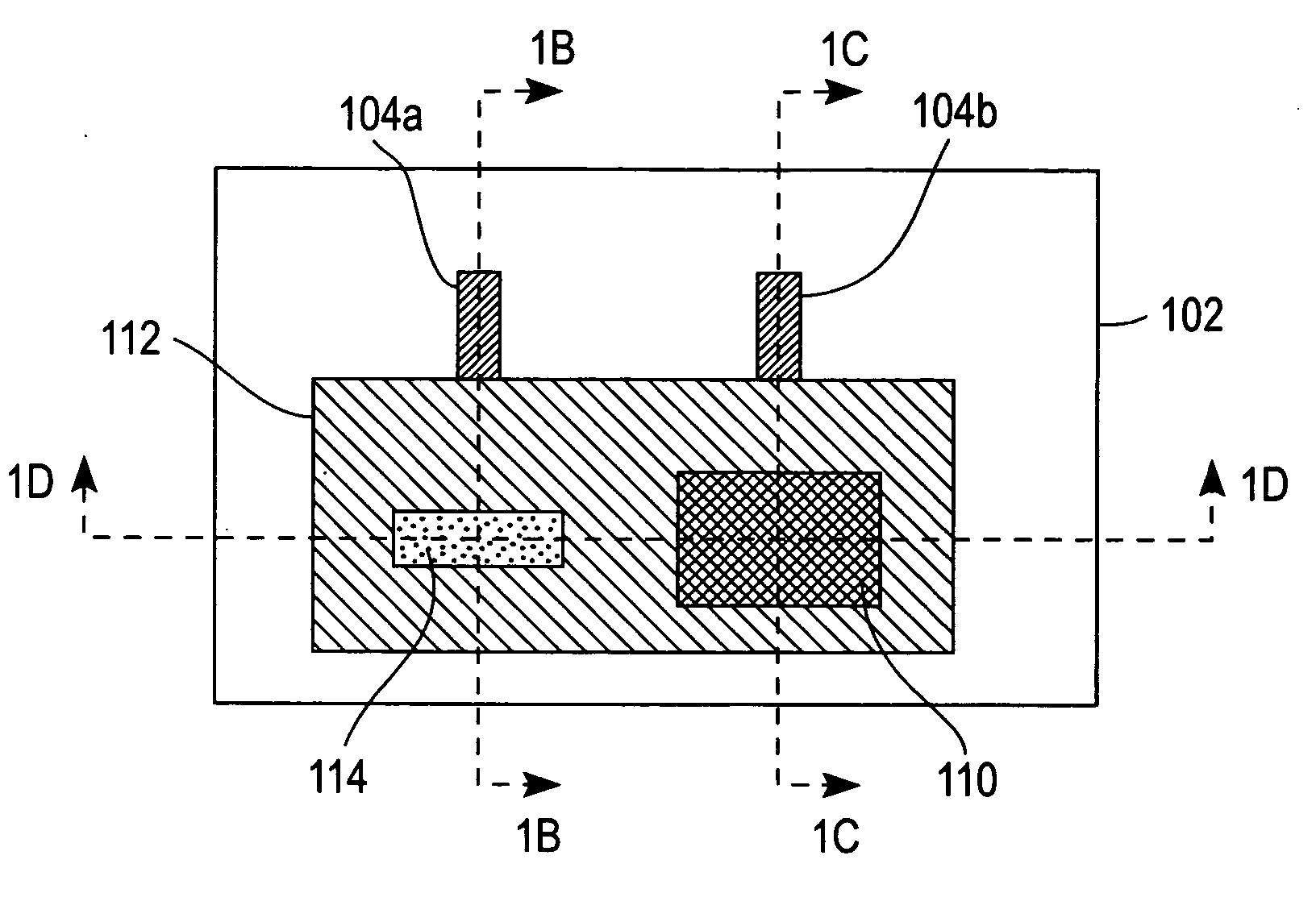

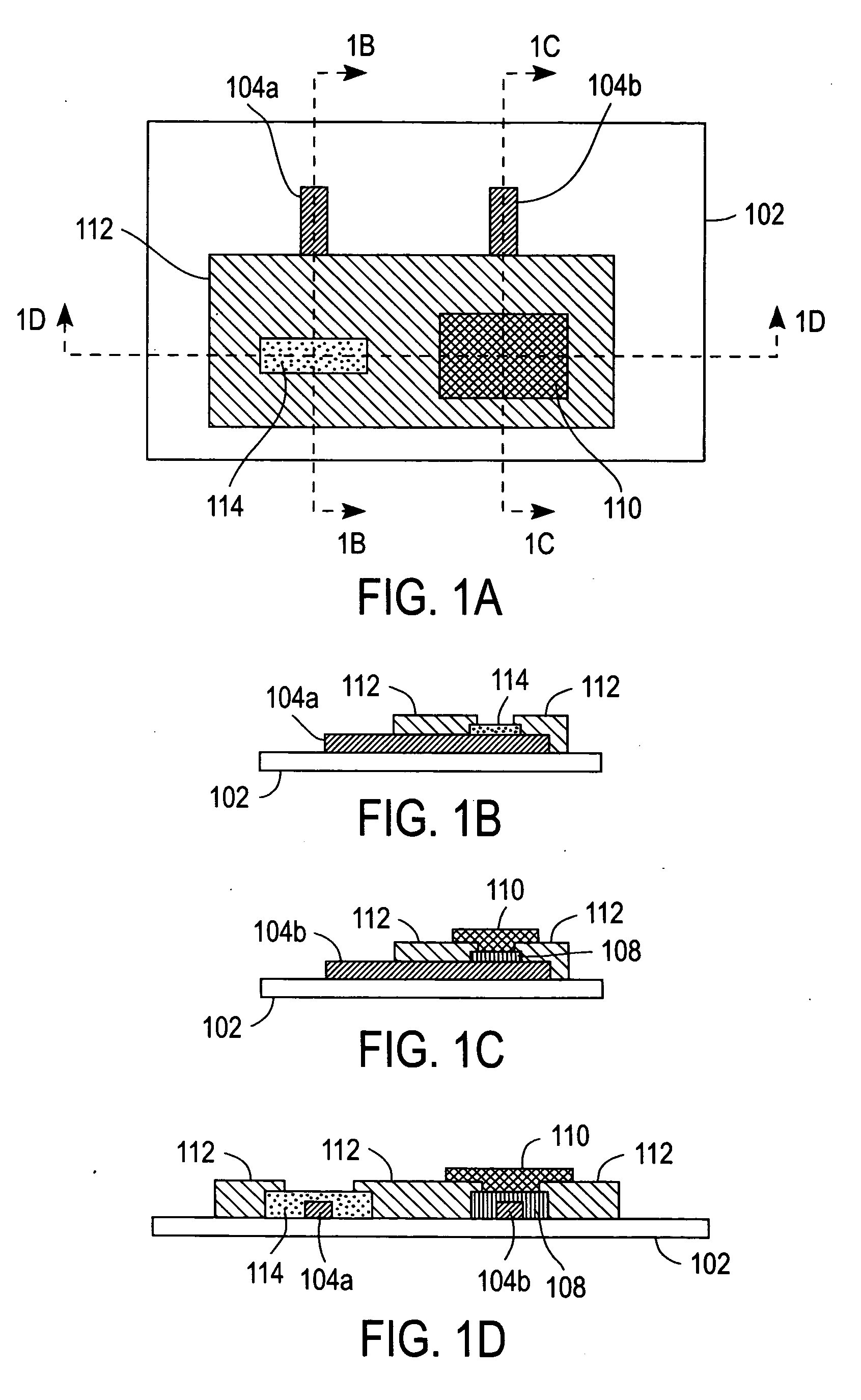

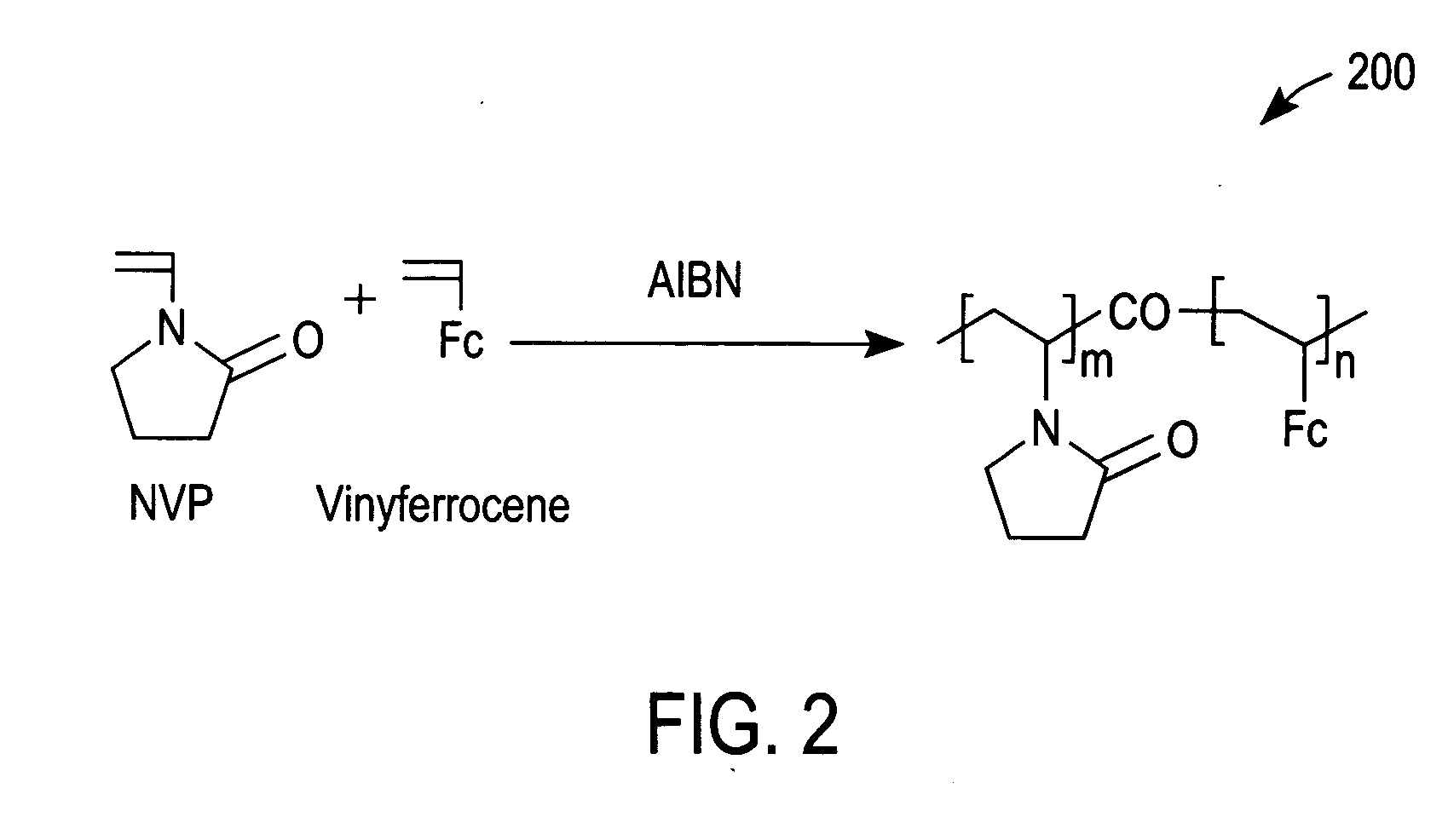

Electrochemical-based sensor with a redox polymer and redox enzyme entrapped by a dialysis membrane

ActiveUS7572356B2Rapid responseImmobilised enzymesBioreactor/fermenter combinationsRedox enzymesDialysis membranes

An electrochemical-based sensor includes an electrode with at least one electrode surface, a film disposed on the electrode surface, and a dialysis membrane disposed on the film. The film includes a redox enzyme and a hydrophilic redox polymer (i.e., a polymer with an attached redox mediator(s)). In addition, the dialysis membrane serves to entrap the redox polymer and redox enzyme in the vicinity of the electrode. Such entrapment is accomplished by employing a redox enzyme and a hydrophilic redox polymer of a sufficiently high molecular weight that they do not pass through the dialysis membrane.

Owner:CILAG GMBH INT +1

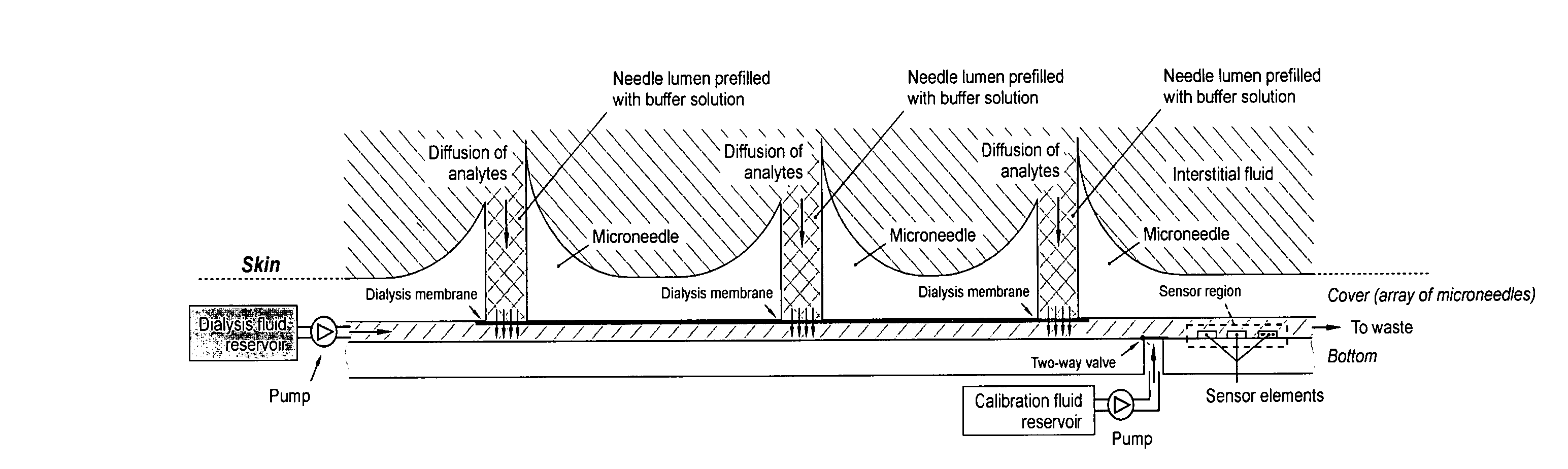

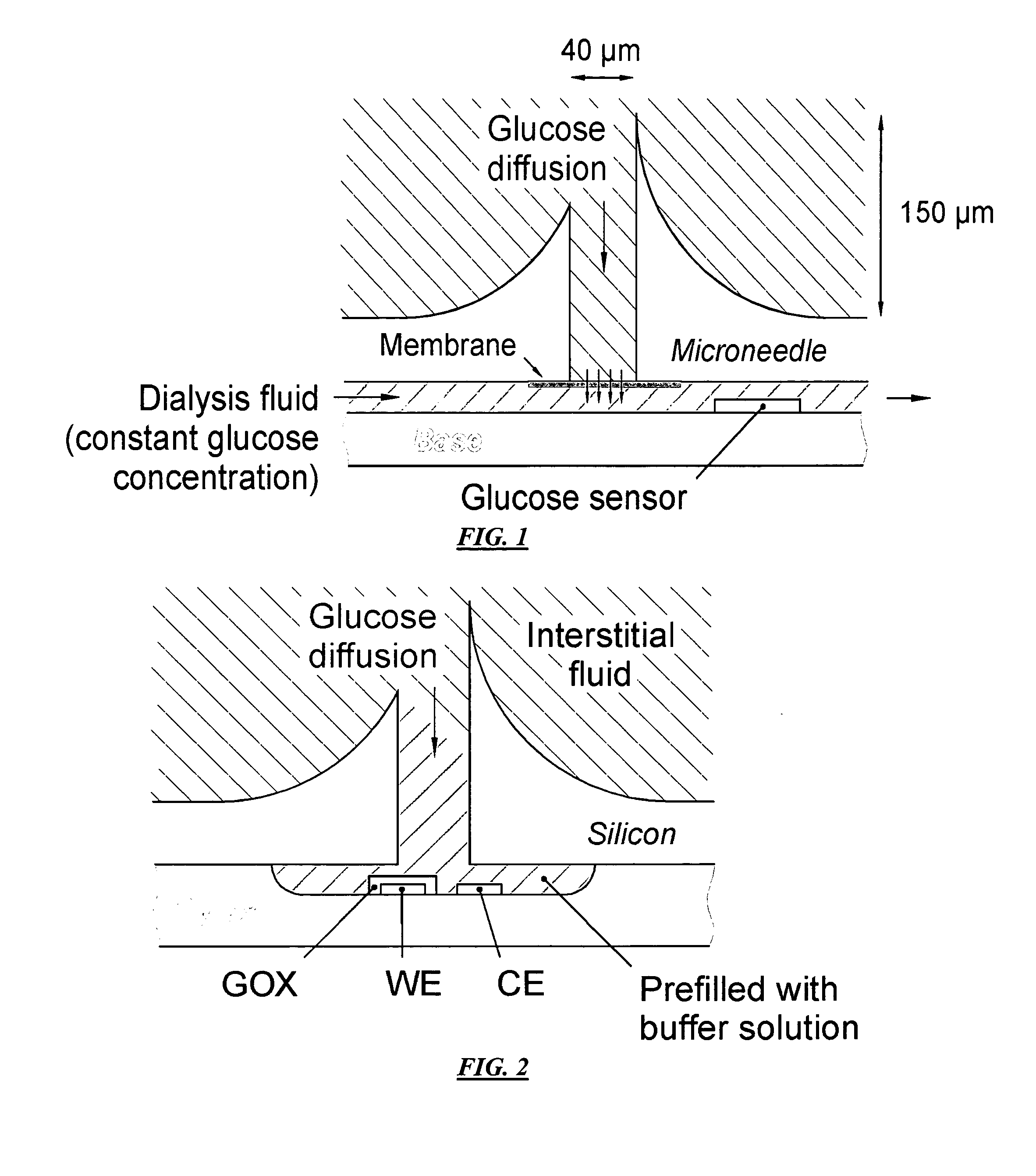

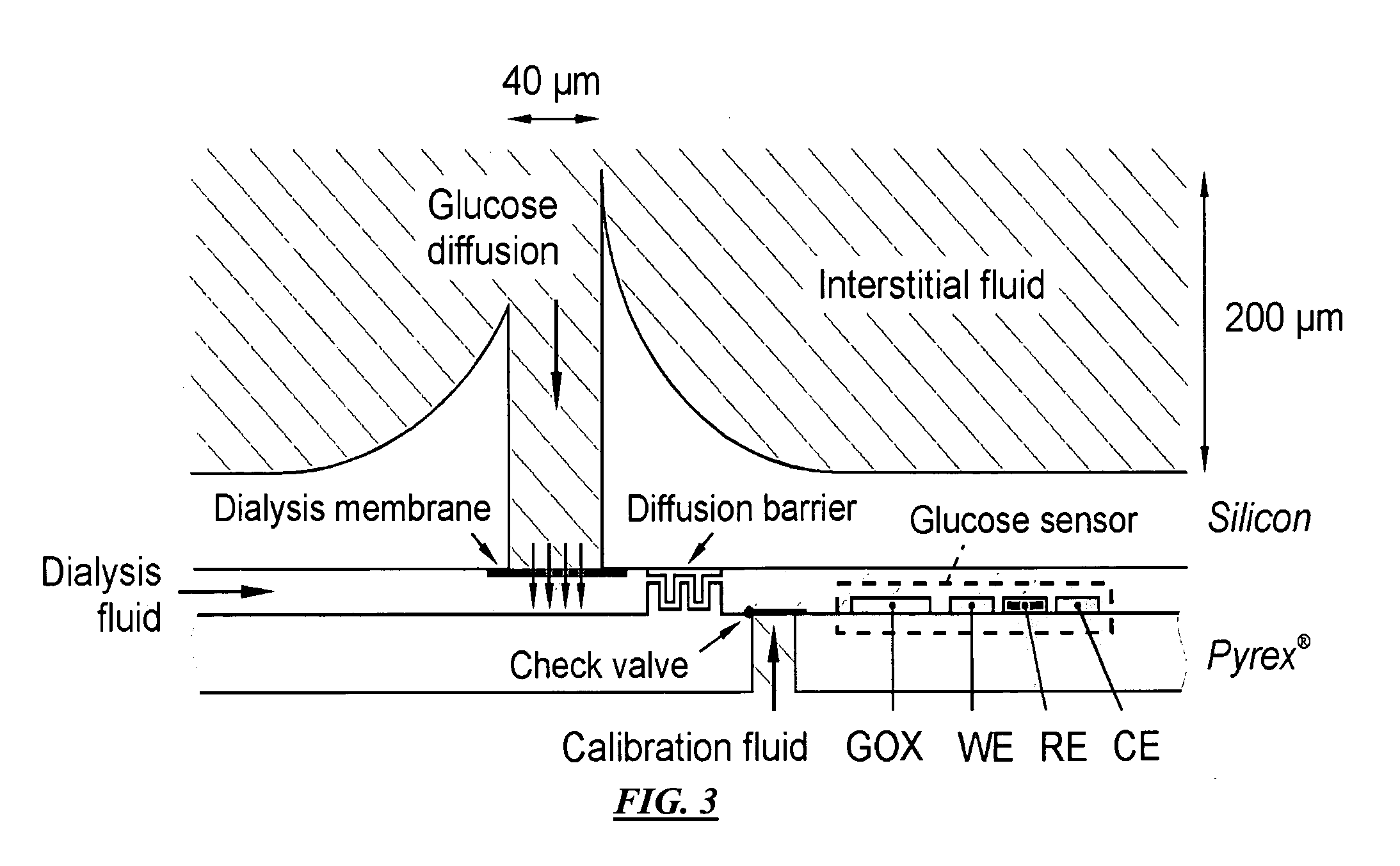

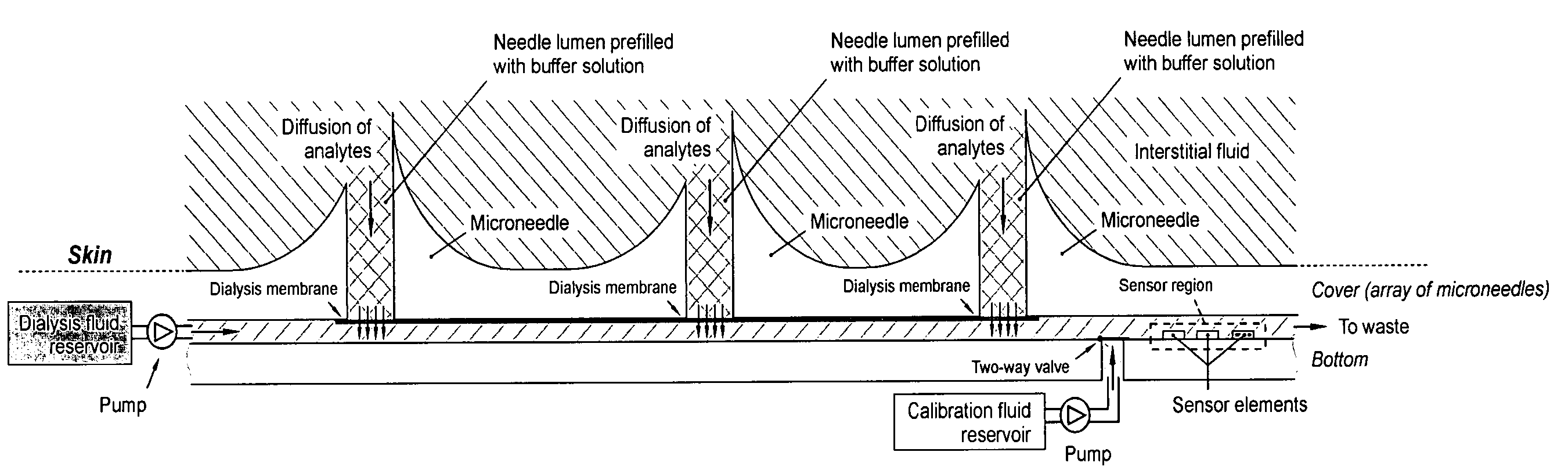

Monitoring method and/or apparatus

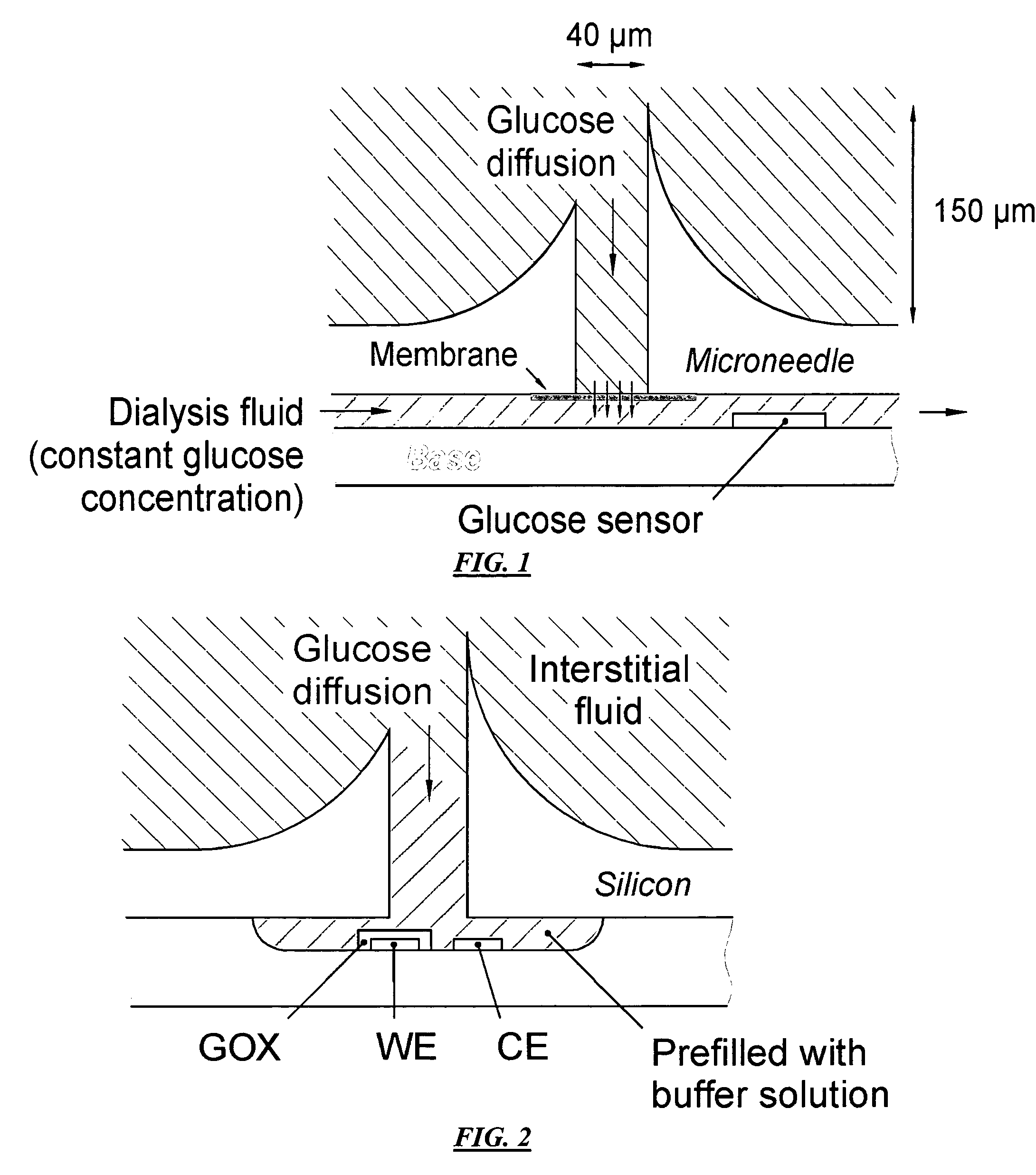

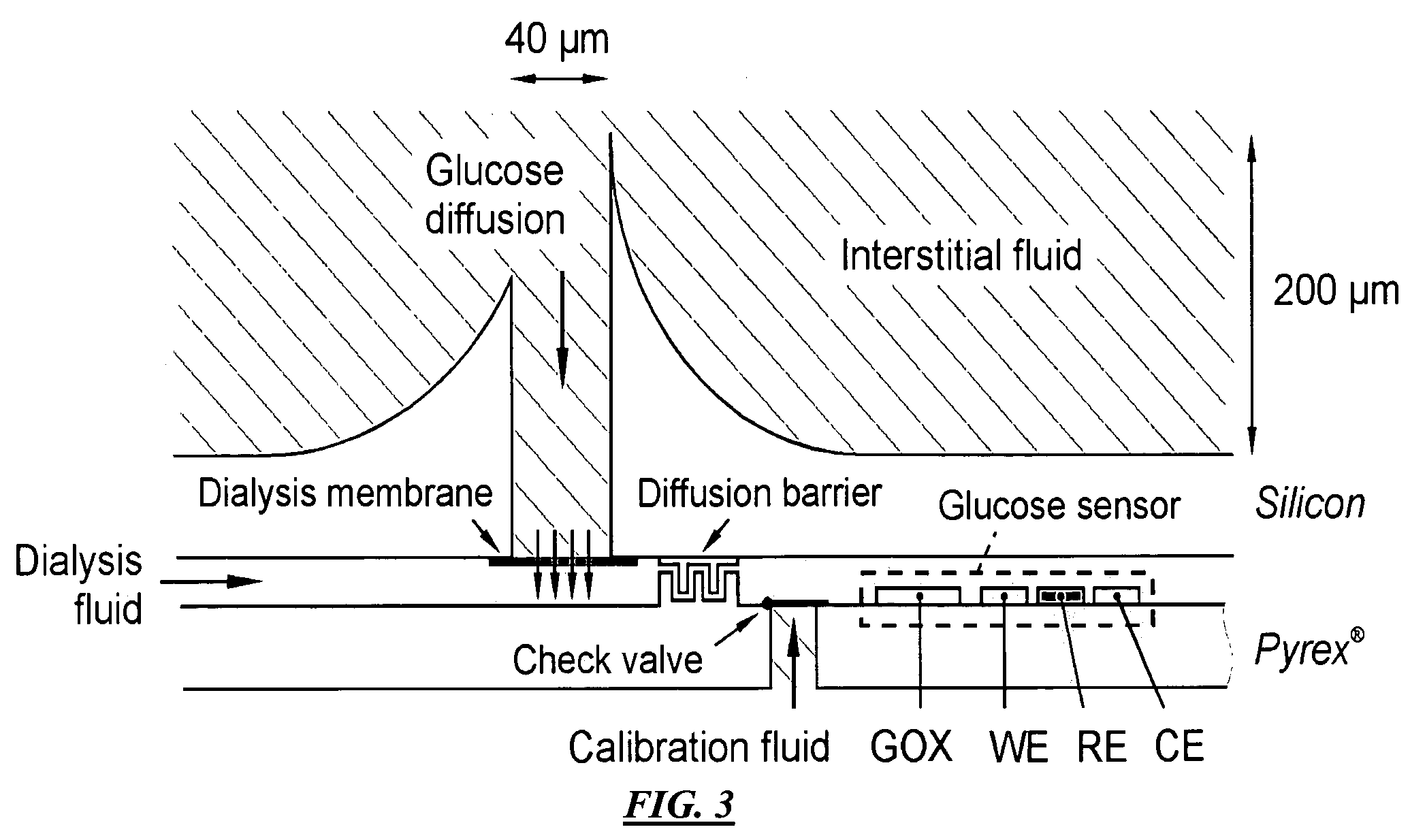

ActiveUS20060211933A1Easy recalibrationMinimally invasiveSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisDialysis membranesContinuous glucose monitoring

A method and apparatus for substance monitoring. One application is an easy to handle continuous glucose monitor using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer. The glucose of the interstitial fluid permeates a dialysis membrane and reaches a sensor. Using MEMS technology, for example, allows well-established batch fabrication at low cost.

Owner:RGT UNIV OF CALIFORNIA

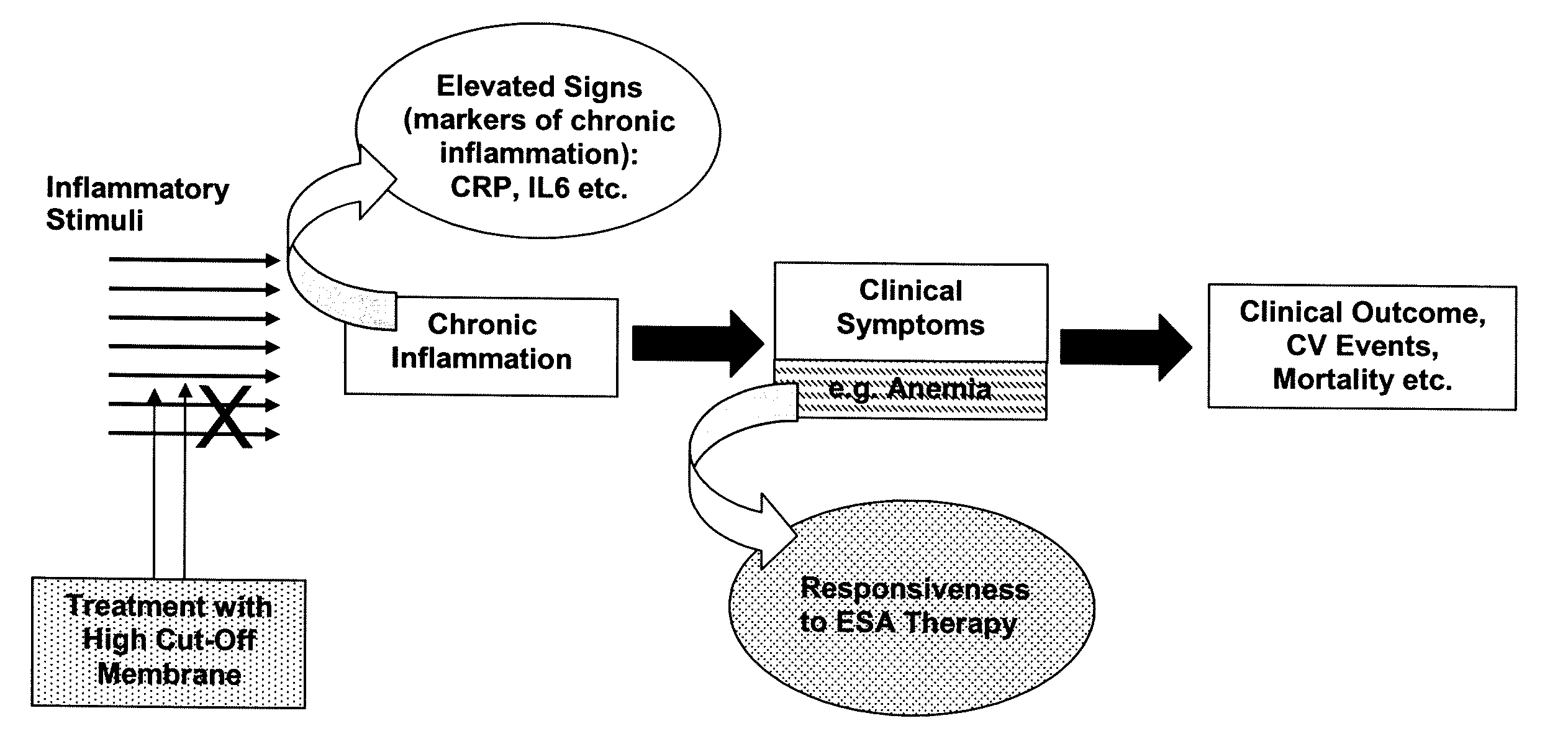

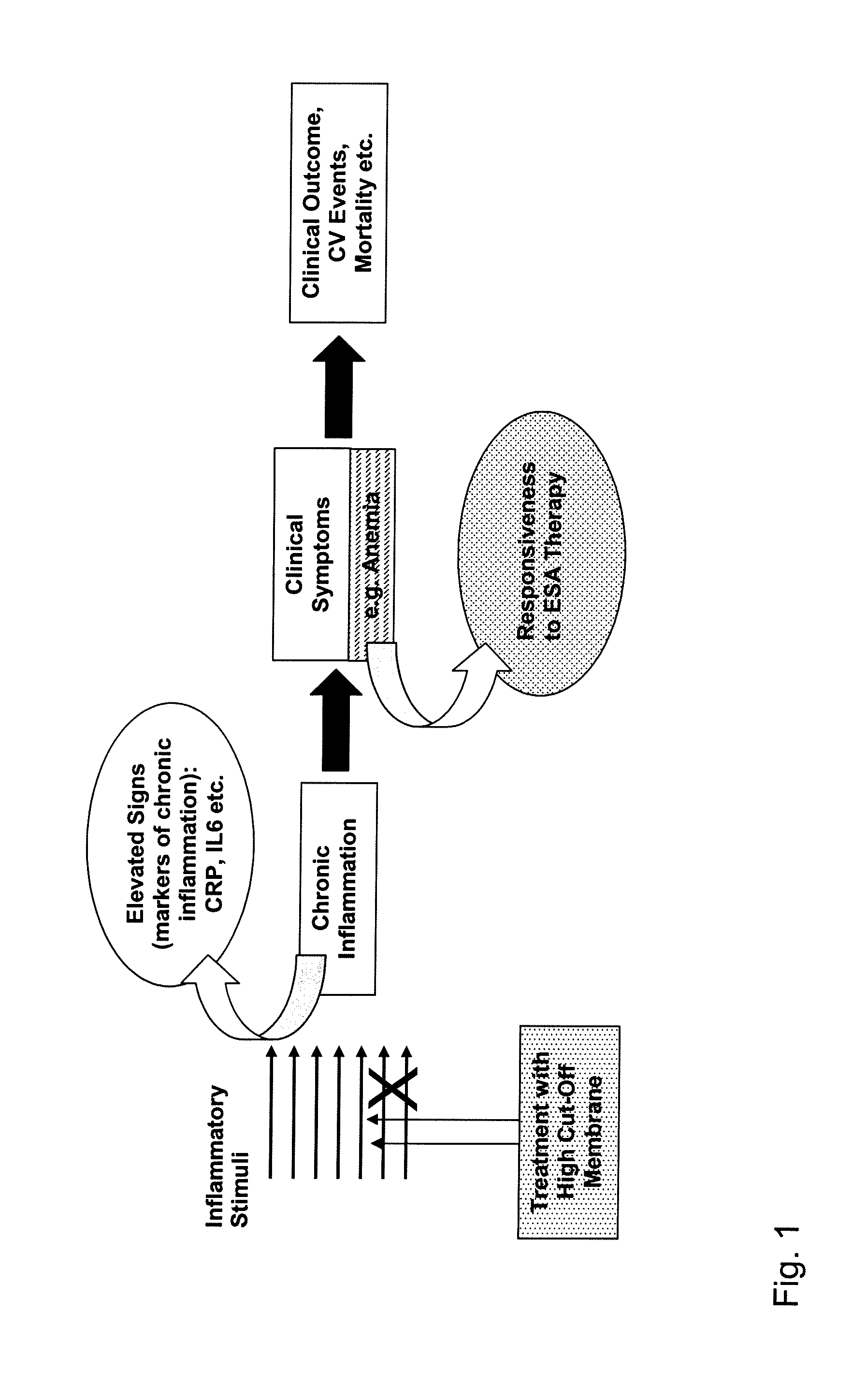

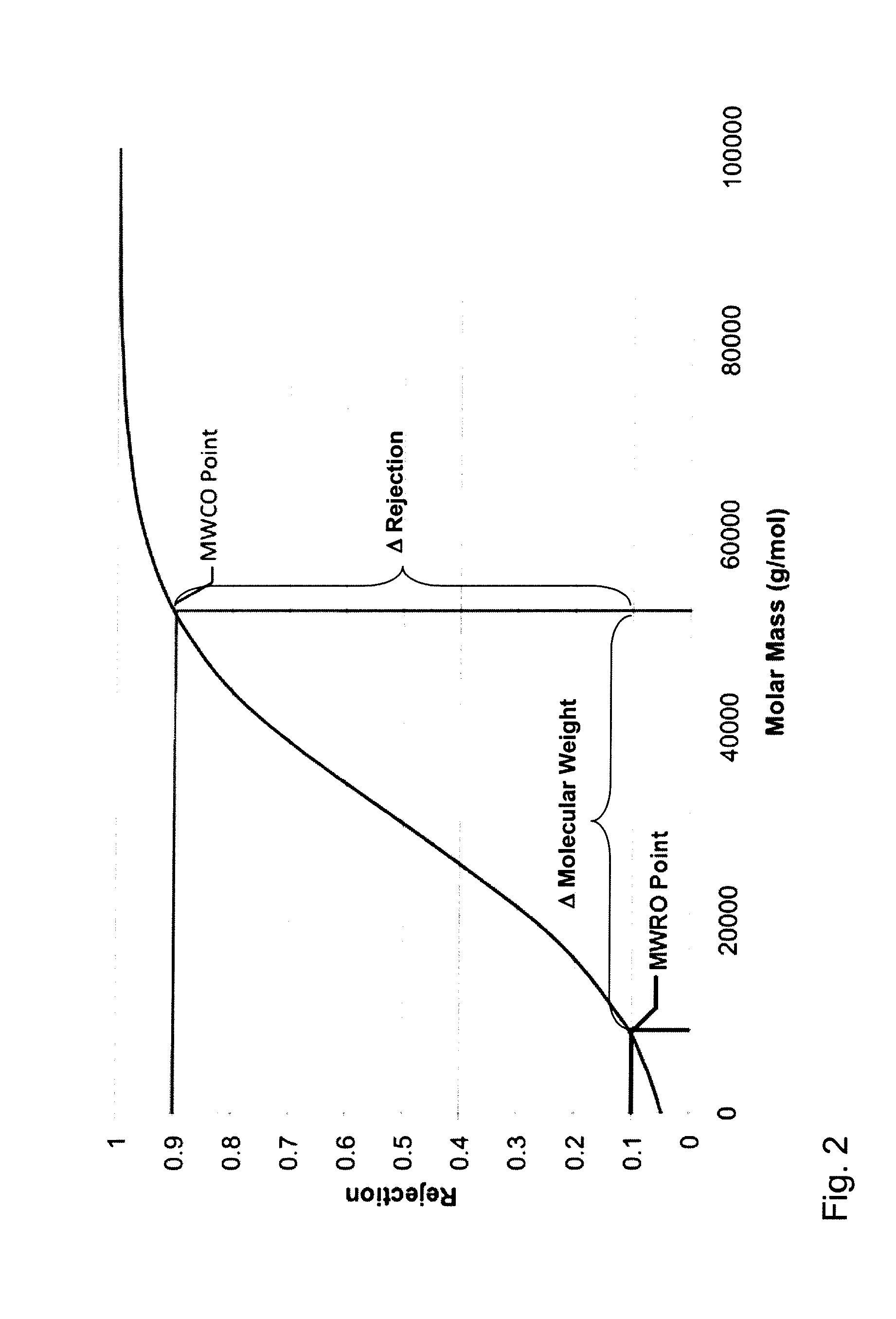

Method for Treating Anemia in Hemodialysis Patients

The present invention relates to a method of treating anemia especially in an EPO resistant hemodialysis patient, comprising hemodialysis with a high cut-off dialysis membrane, wherein the hemodialysis membrane is characterized in that it has a molecular weight cut-off in water, based on dextran sieving coefficients, of between 90 and 200 kD and a molecular weight retention onset in water, based on dextran sieving coefficients, of between 10 and 20 kD, and a ΔMW of between 90 and 170 kD. The invention further relates to a high cut-off hemodialysis membrane for the treatment of anemia in hemodialysis patients, especially EPO resistant hemodialysis patients.

Owner:GAMBRO LUNDIA AB

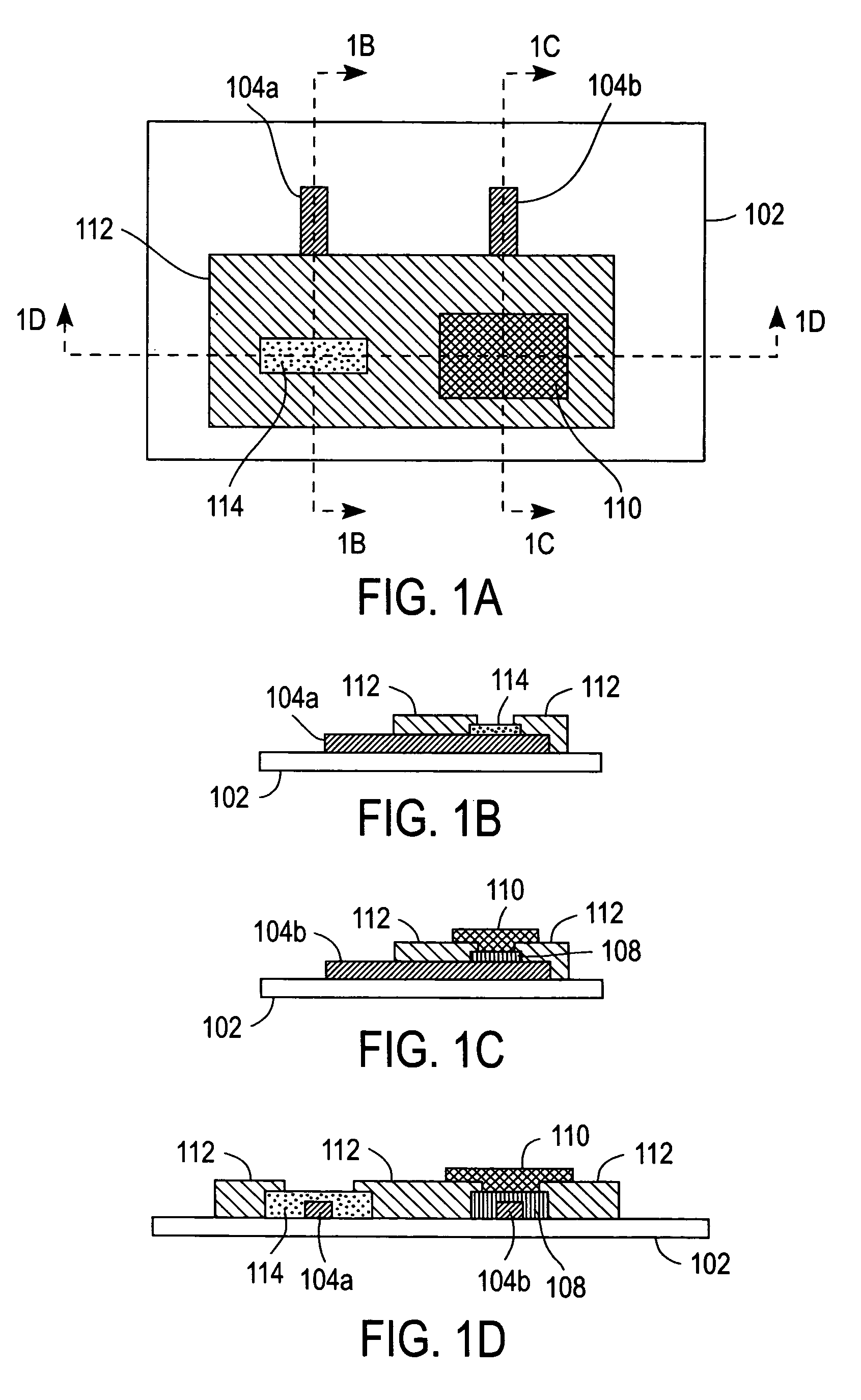

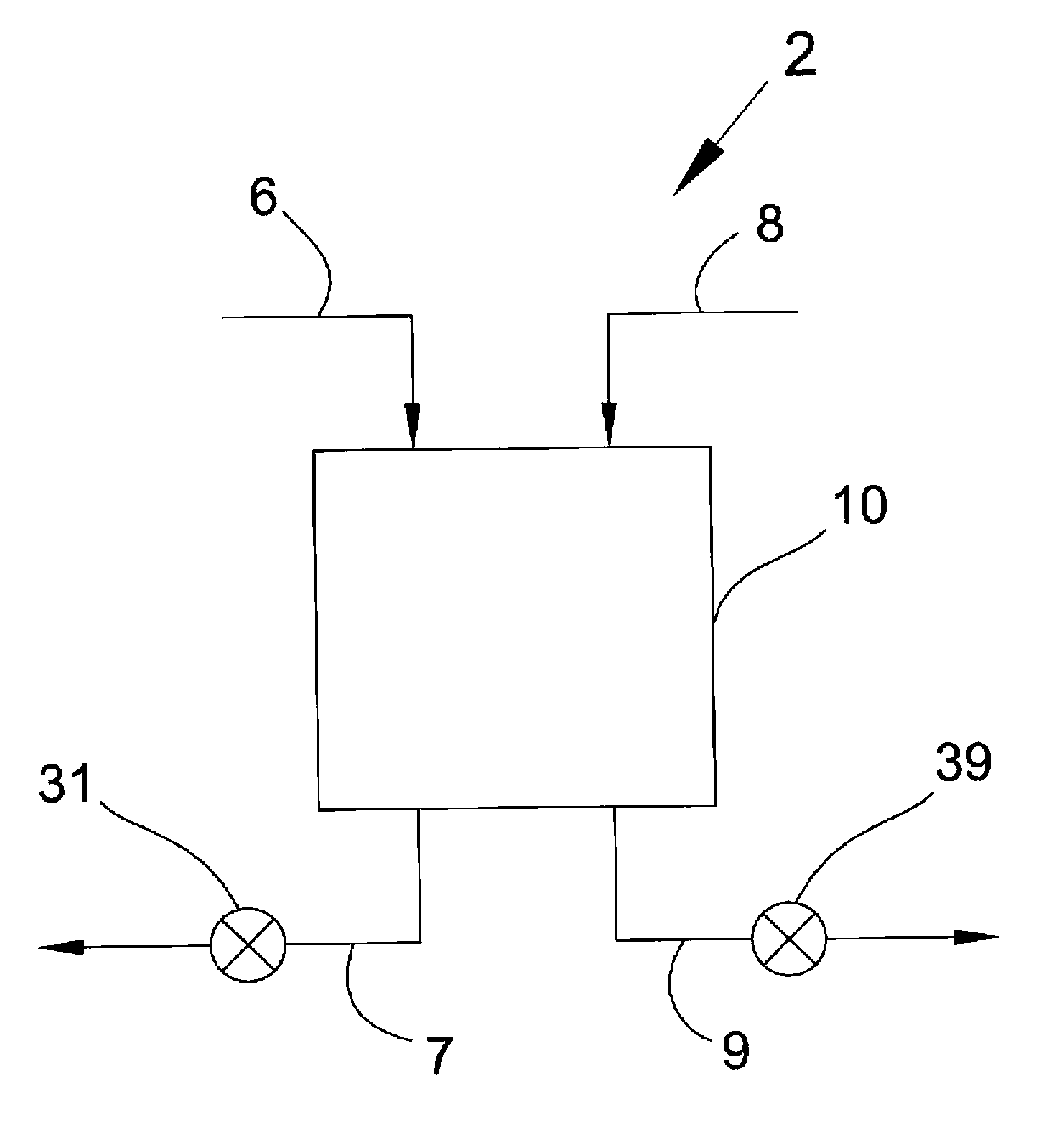

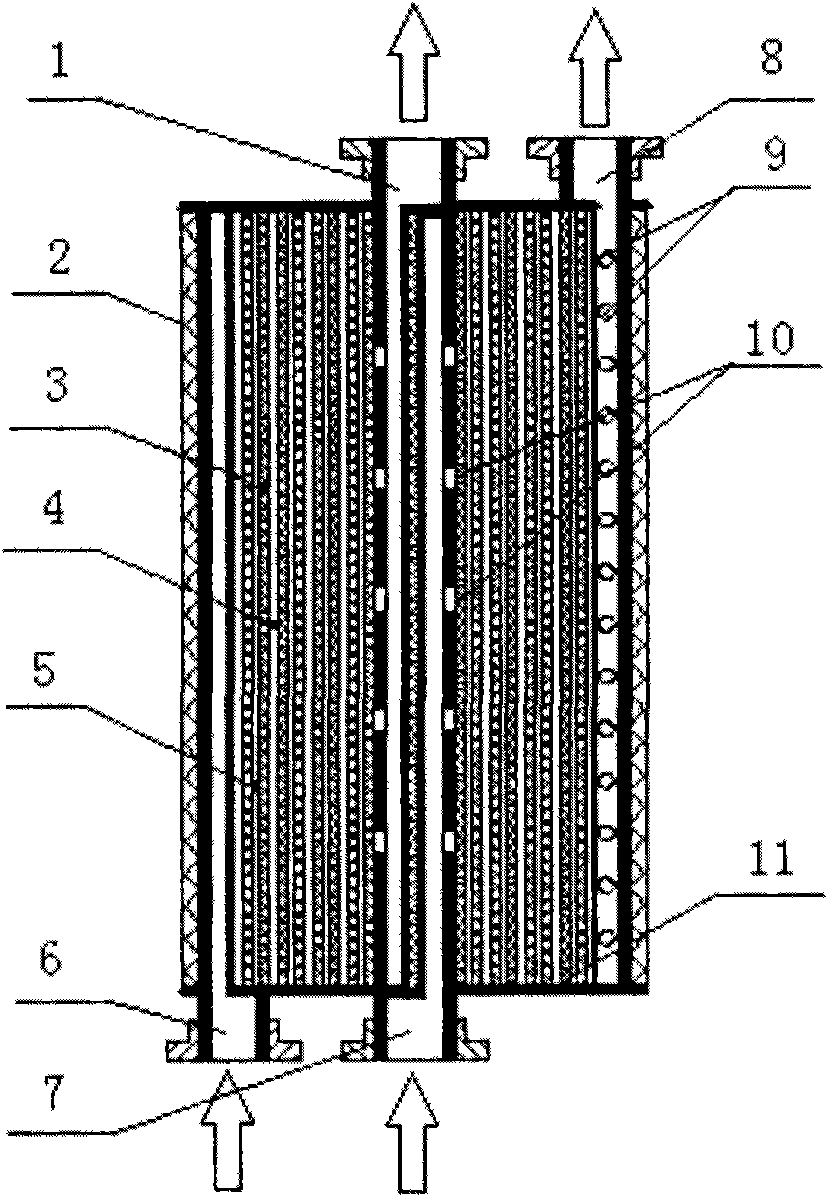

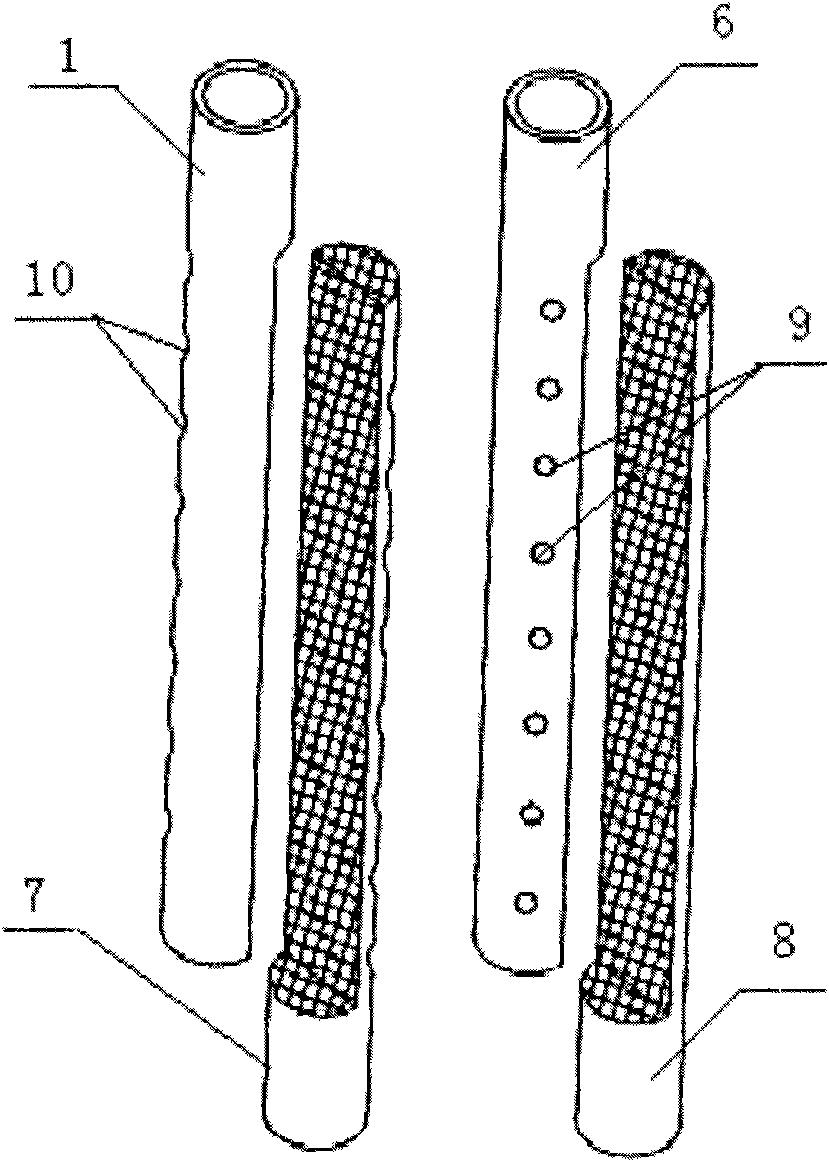

Mecs Diayzer

ActiveUS20080093298A1Enhanced mass transferImprove mass transfer efficiencyMembranesSolvent extractionDialysis membranesHaemodialysis machine

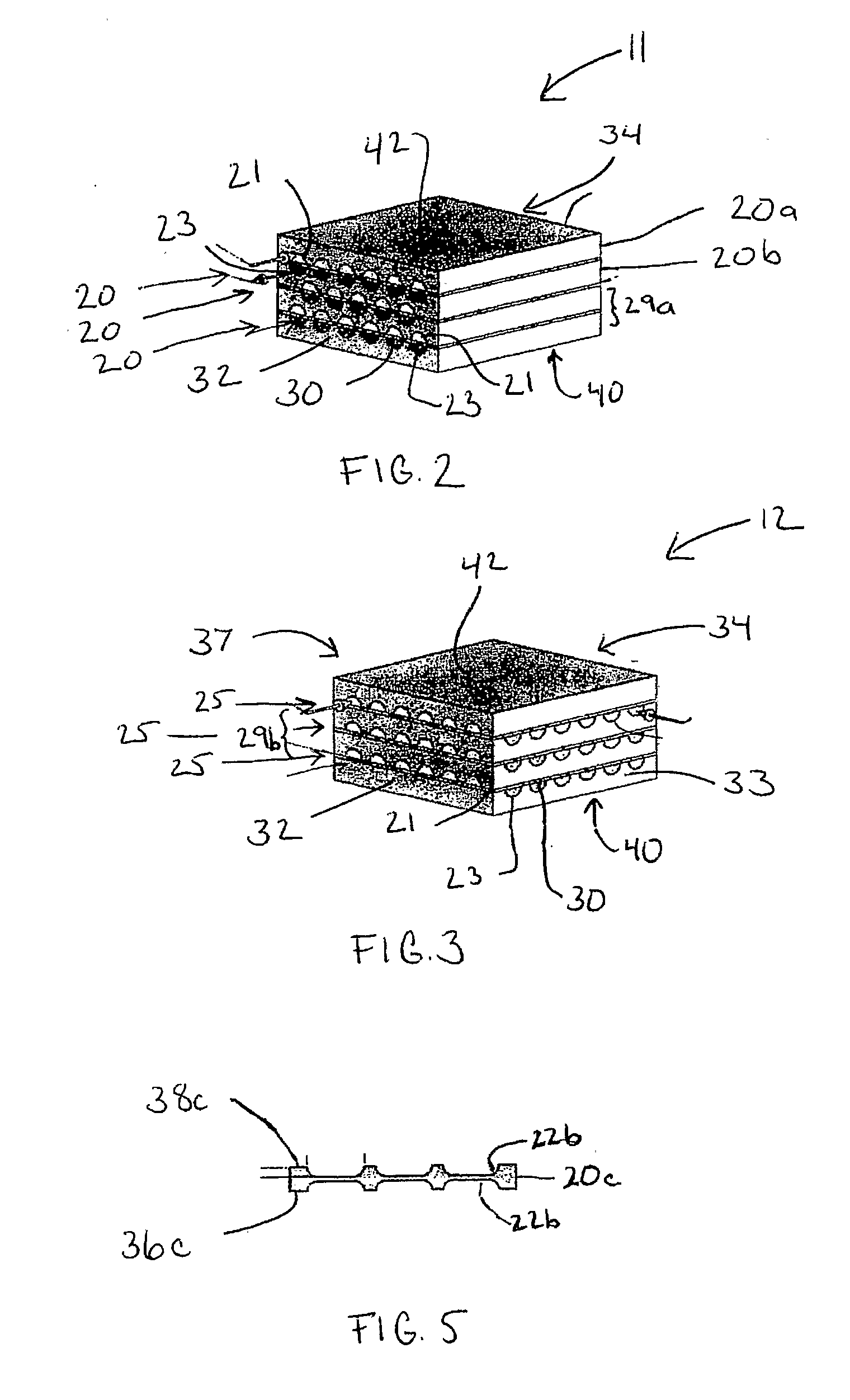

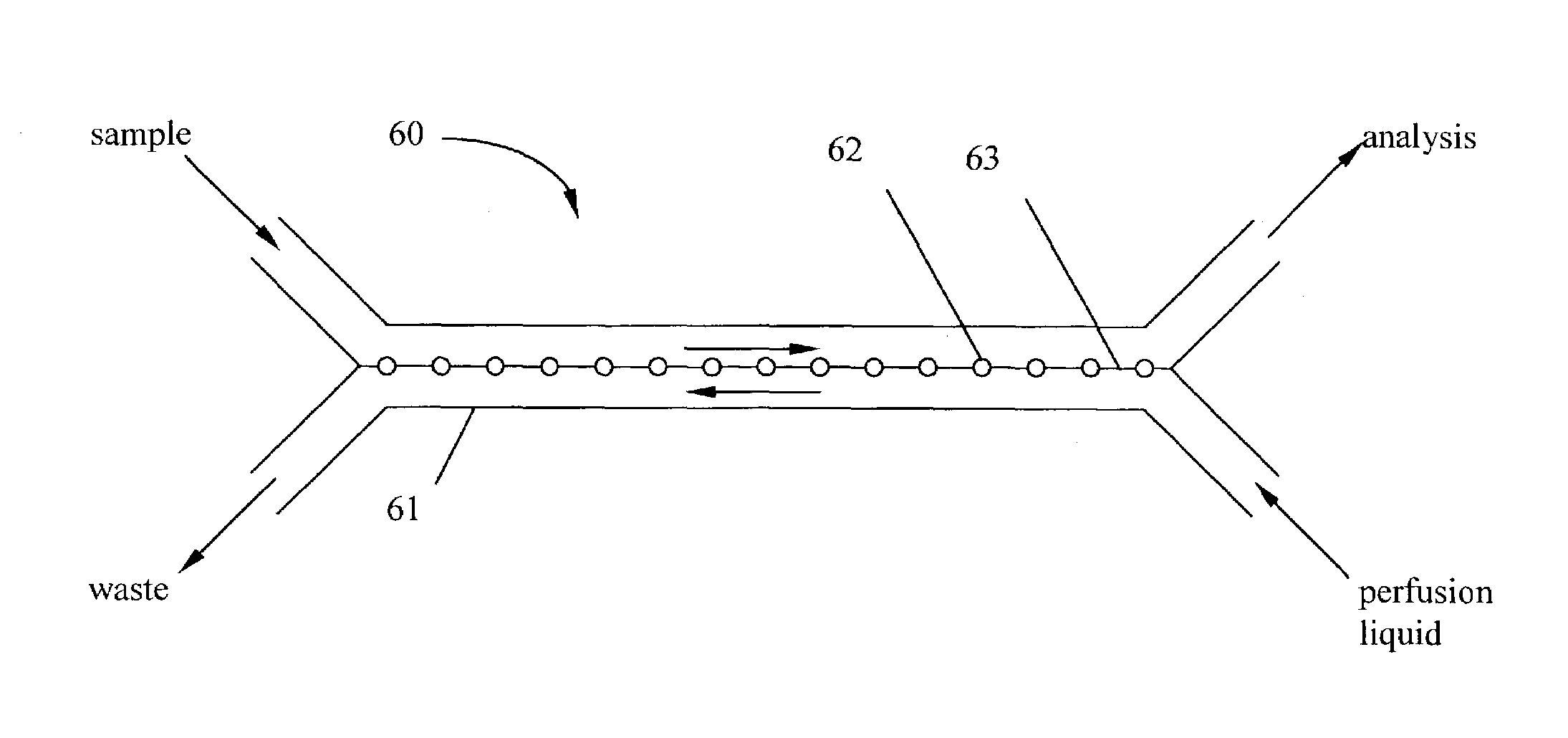

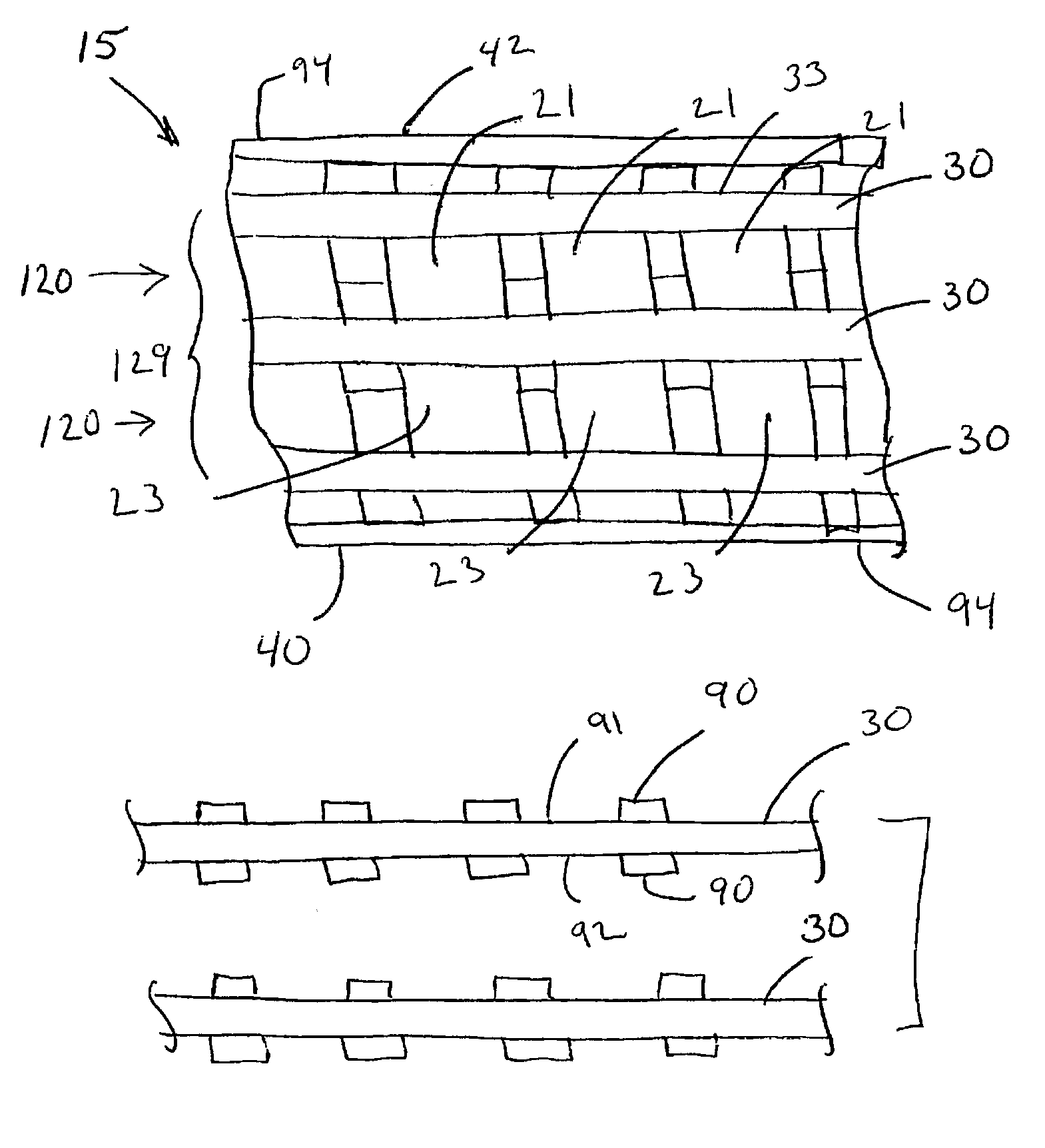

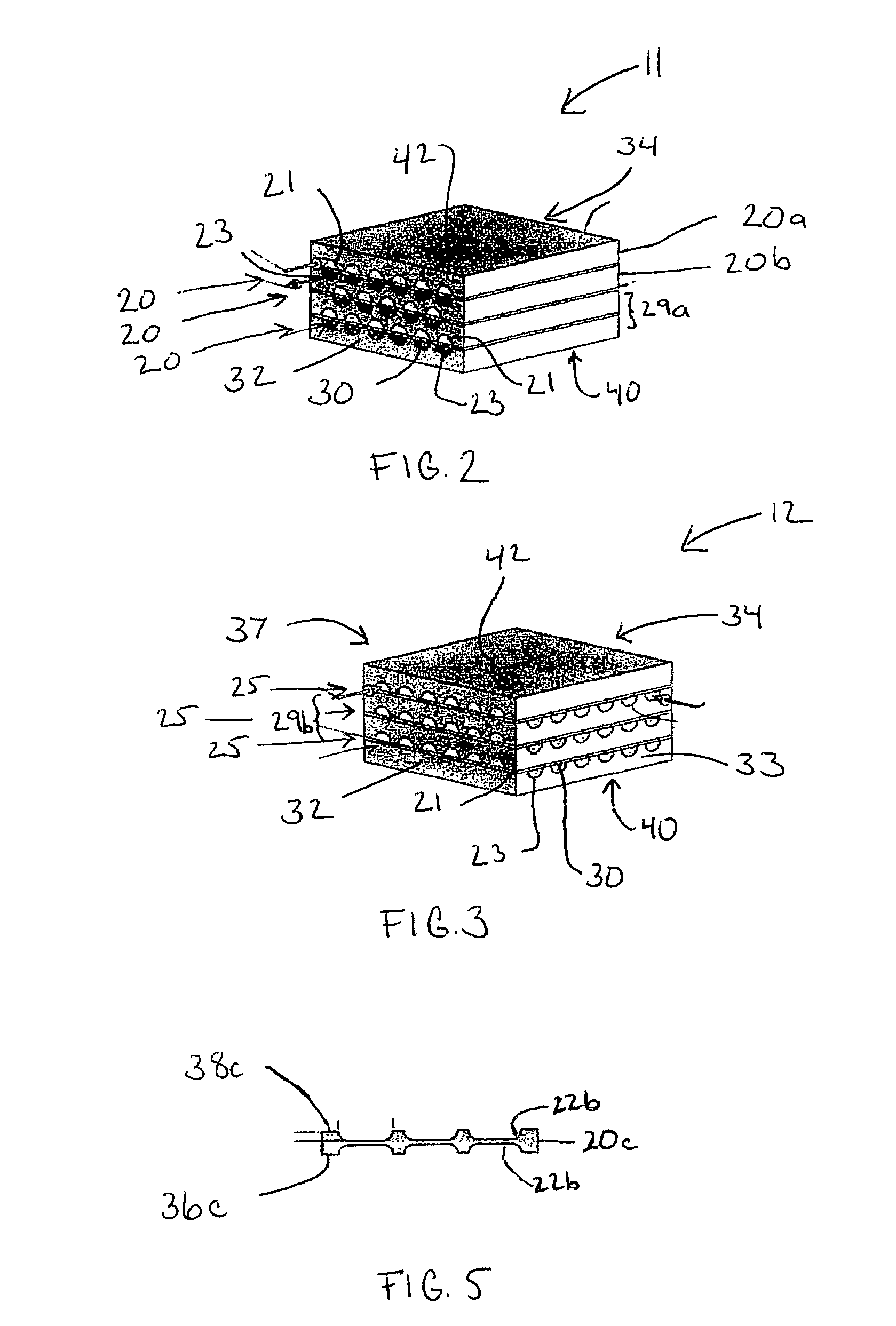

The present invention is related to hemodialysis, and more particularly, to a dialyser with improved efficiency of mass transfer across a dialysis membrane utilizing microchannel separation provided in accordance with embodiments of the present invention. In accordance with an embodiment, a dialyzer is provided comprising a plurality of semipermeable membrane sheets and a plurality of flow separators. The membrane sheets and flow are arranged in alternating configuration and coupled into a laminae stack defining a plurality of parallel microchannel layers. Each microchannel layer comprises a plurality of first microchannels and a plurality of second microchannels. The first and second microchannels of each microchannel layer are in fluid communication with each other via one of the plurality of membrane sheets therebetween. The MECS dialyzer is characterized as having a high surface to volume ratio and a high mass transfer coefficient.

Owner:OUTSET MEDICAL

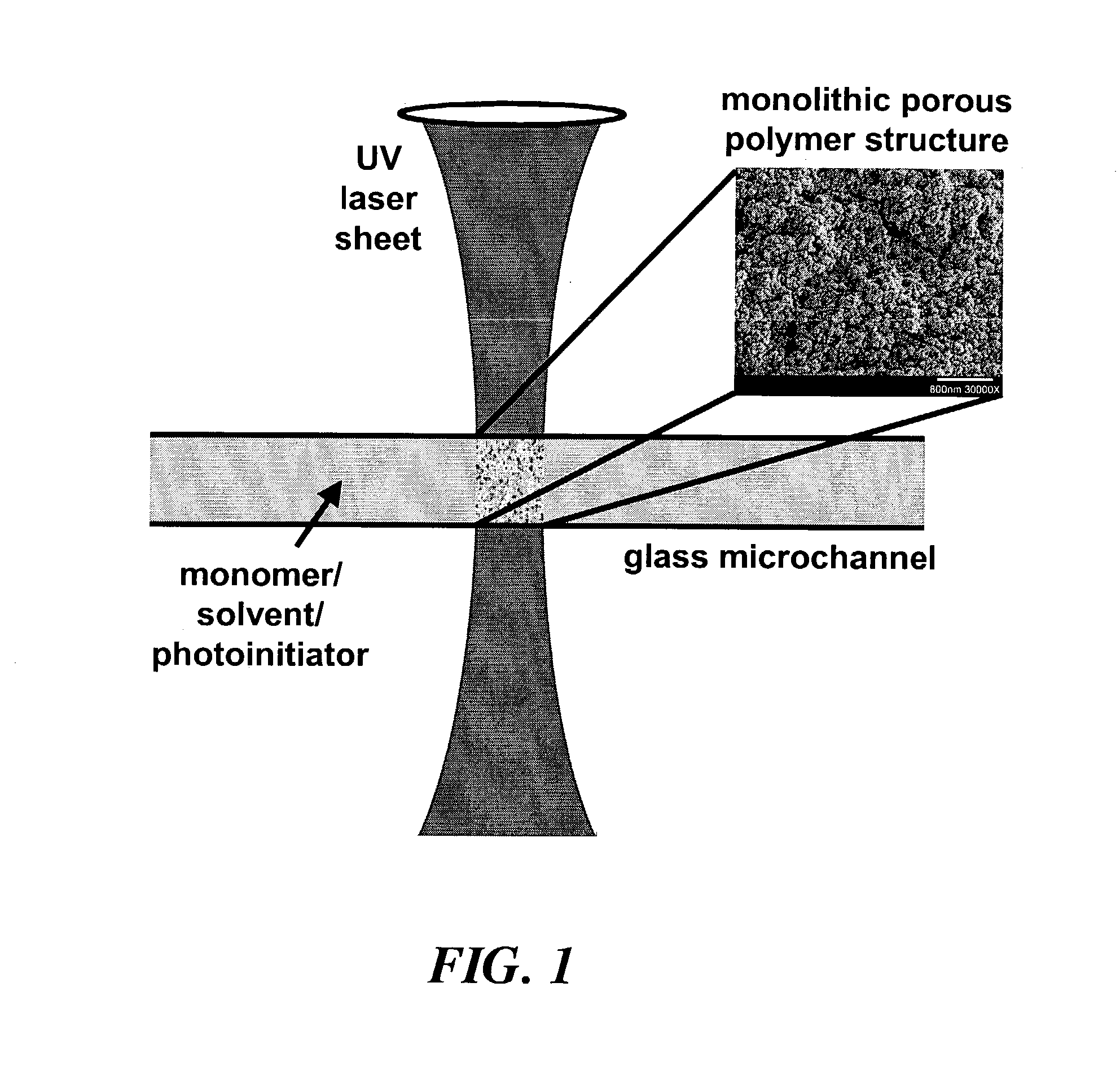

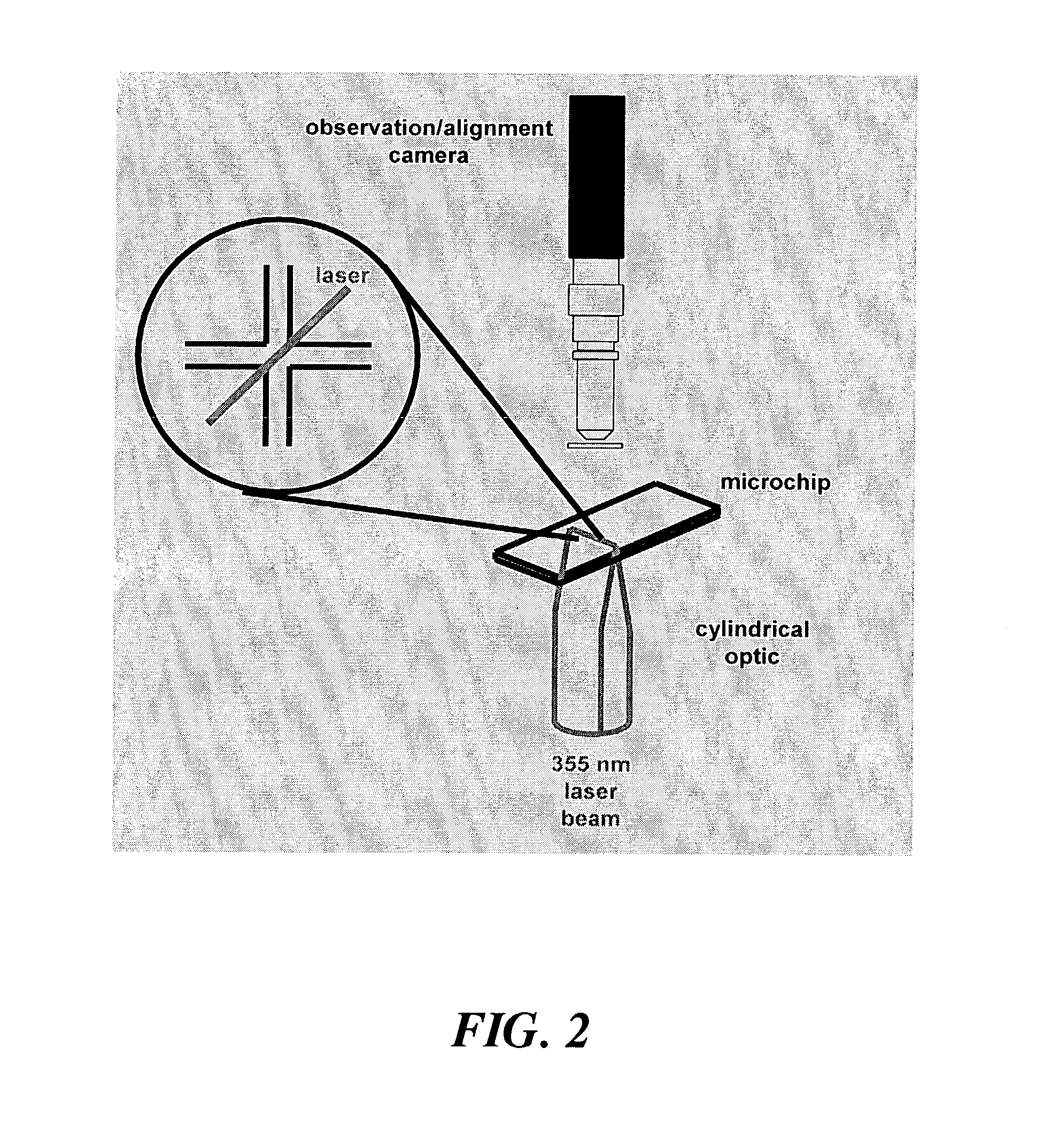

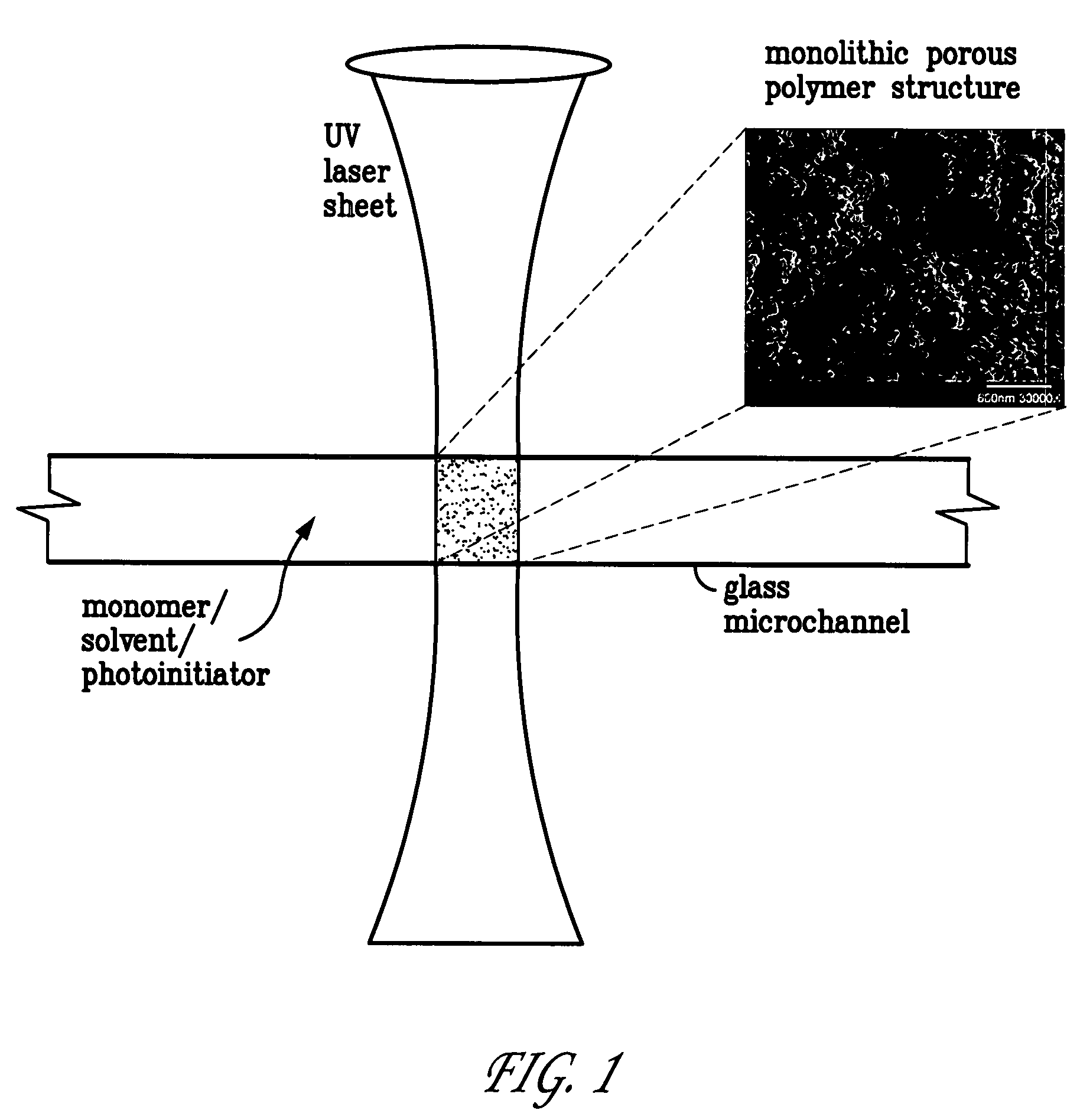

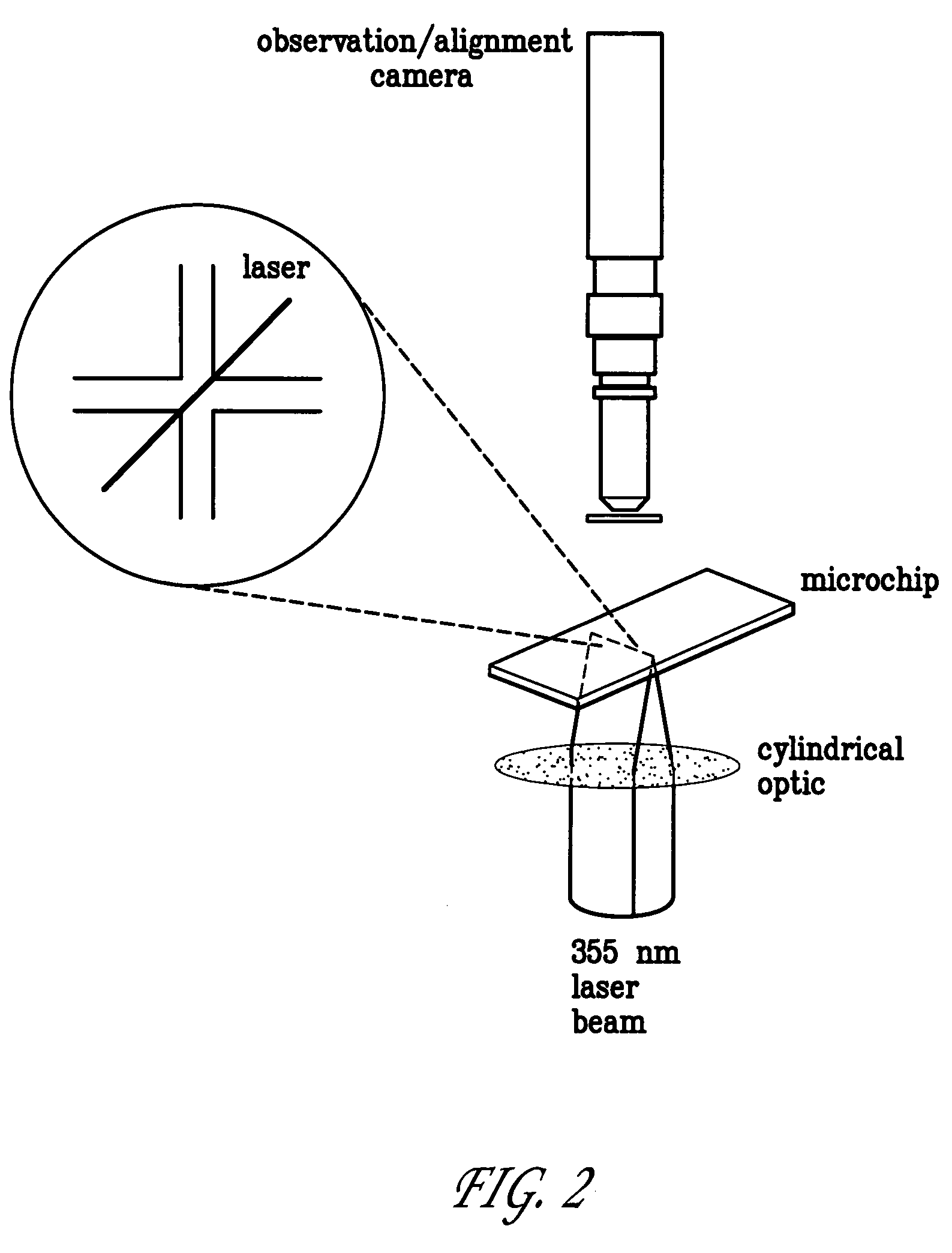

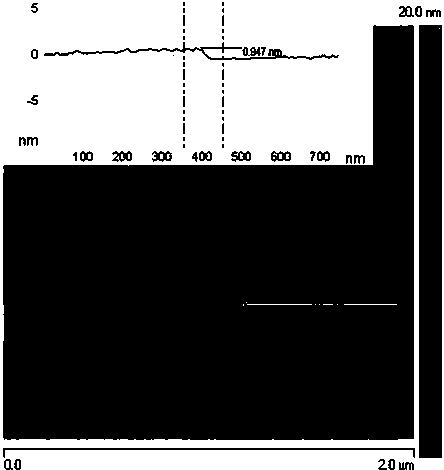

Dialysis on microchips using thin porous polymer membranes

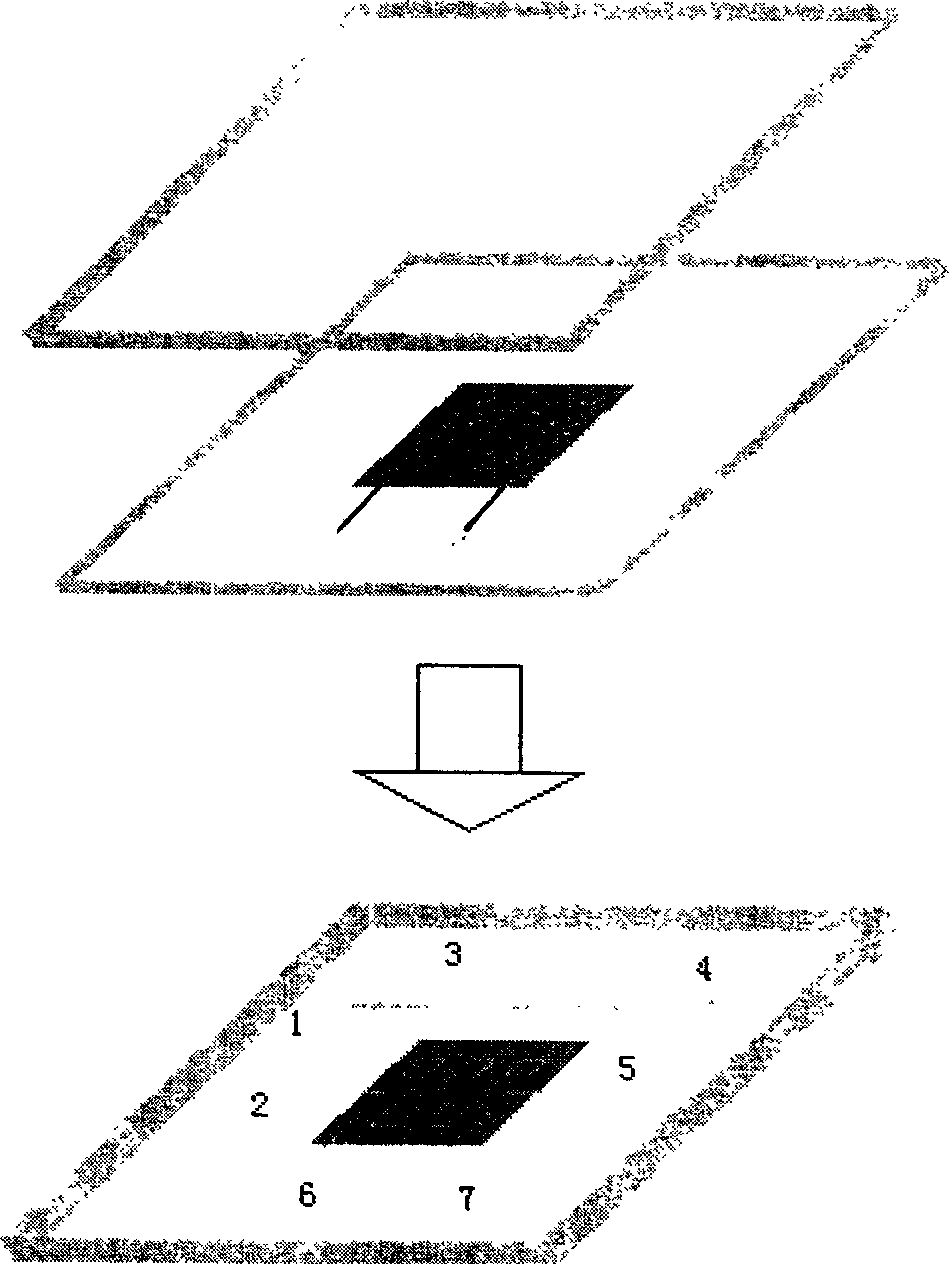

ActiveUS7264723B2Minimize handlingComplicated operationSolvent extractionTransportation and packagingDialysis membranesMeth-

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and form a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:SANDIA NAT LAB

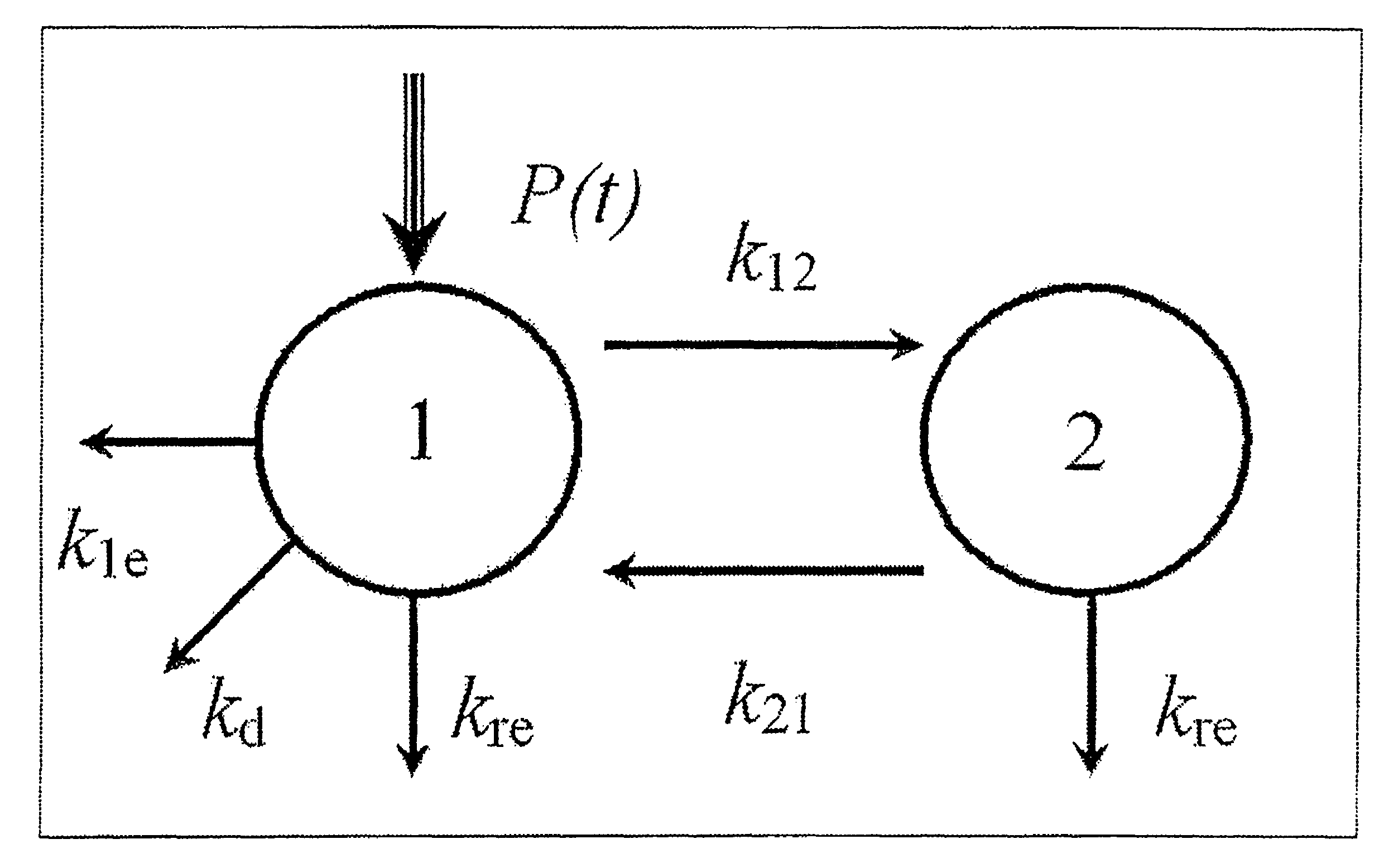

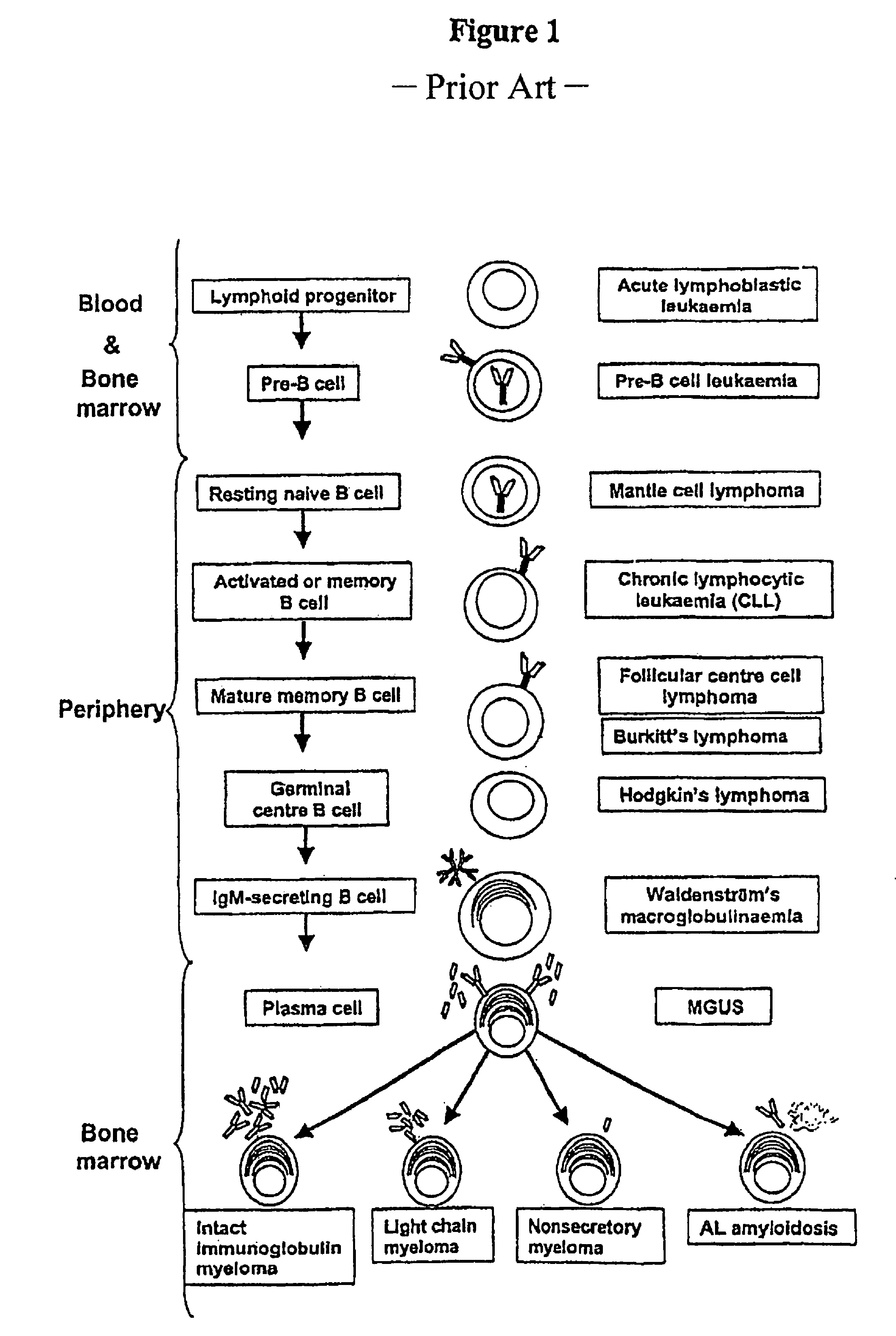

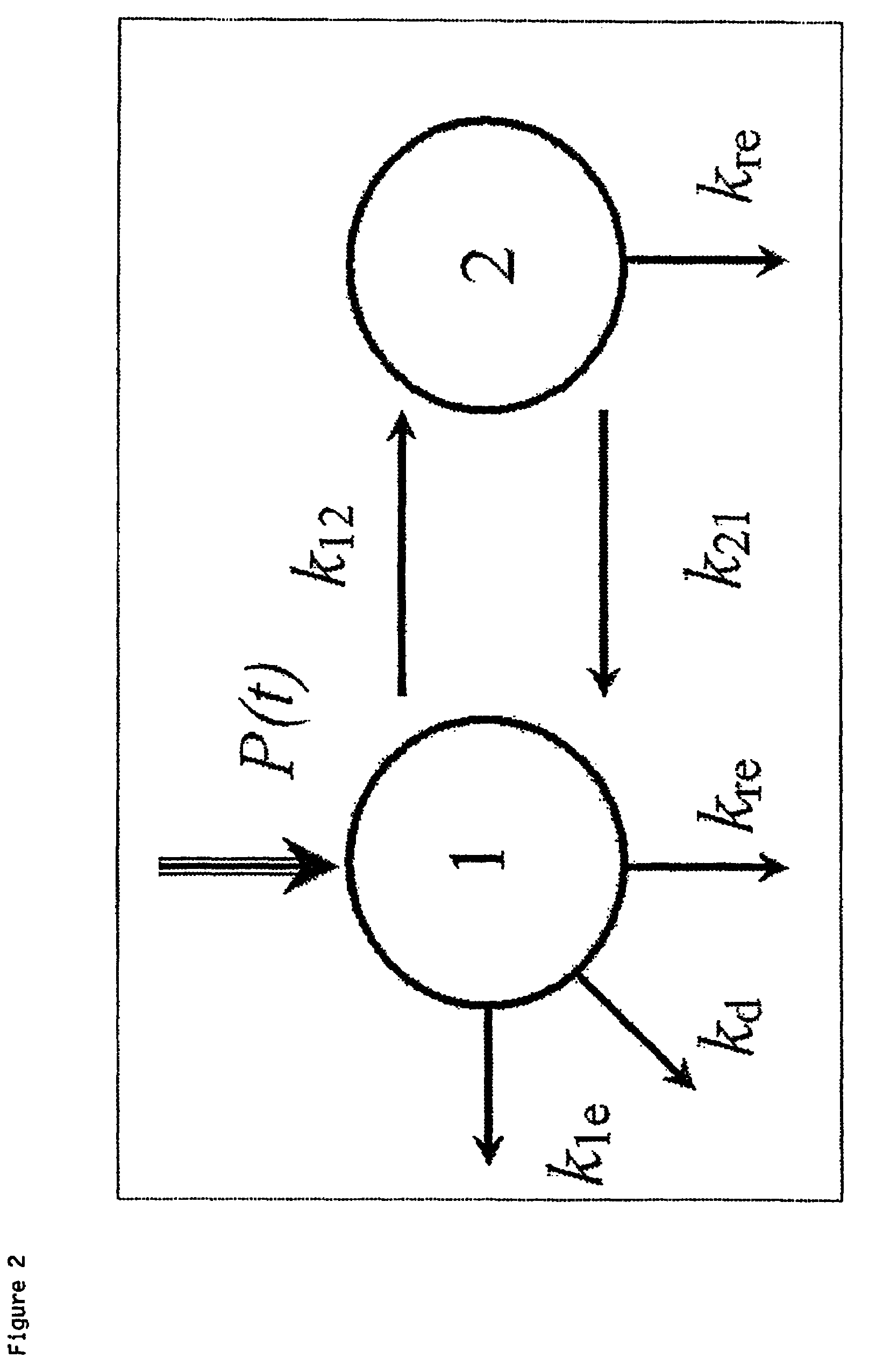

Method of removing antibody free light chains from blood

ActiveUS7875183B2Reducing renal failureReduce lightSemi-permeable membranesMembranesDialysis membranesFree Light Chain

Owner:GAMBRO LUNDIA AB +1

Monitoring method and/or apparatus

ActiveUS7415299B2Easy recalibrationMinimally invasiveSemi-permeable membranesMedical devicesDialysis membranesContinuous glucose monitoring

A method and apparatus for substance monitoring. One application is an easy to handle continuous glucose monitor using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer. The glucose of the interstitial fluid permeates a dialysis membrane and reaches a sensor. Using MEMS technology, for example, allows well-established batch fabrication at low cost.

Owner:RGT UNIV OF CALIFORNIA

Method of generating hydrogen in drinking water using an enerceutical product added to magnesium in a hydrogen permeable but solute impermeable container

InactiveUS20100008850A1Increased hydrogen productionImprove usabilityHydrogen productionHydrogen/synthetic gas productionDialysis membranesWater use

Consuming water with increased hydrogen content can provide clinical benefits to humans and animals through a non-mitochondria alternative cellular energy (ACE) pathway and also as an antioxidant. This application discloses that the hydrogen content of drinking water can be safely increased by placing into the water a hydrogen generating device, such as a mixture of metallic magnesium and EH-101 (HB-101) containing solution, whereby the device allows for the selective passage of the generated hydrogen but restricts the passage of magnesium and EH-101 (HB-101) components. This partitioning of hydrogen from EH-101 (HB-101) components is achieved by using either reverse osmosis membrane, low density plastic material such as polyvinylidene chloride (PVDC or Saran), or low molecular weight cutoff dialysis membrane to create a sealed container of the magnesium and magnesium chloride, that can be placed into drinkable water. The EH-101 (HB-101) can be initially placed into a breakable inner compartment within the hydrogen permeable container. This compartment can be easily broken by simple squeezing just prior to placing the device into the water that is intended to have its hydrogen content increased. The increased hydrogen content can be assessed by the capacity of the water to decolorize a potassium permanganate test sample.

Owner:MARTIN WILLIAM JOHN

Polystyrene sulfonate resin for use with a hemodialysis system having a controlled compliance dialysis circuit

InactiveUS20130256227A1Semi-permeable membranesOther blood circulation devicesDialysis membranesPolystyrene

Sorbent cartridges having a polystyrene sulfonate resin saturated with calcium ions for the performance of kidney replacement therapy are disclosed. Systems and methods having or using a sorbent cartridge, a dialyzer, control components, a cartridge having a polystyrene sulfonate resin, and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment are disclosed. A system for performing kidney replacement therapy has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. The system provides for the monitoring of an inlet and outlet conductivity of the sorbent cartridge to quantify or monitor the removal of urea by the sorbent cartridge.

Owner:MEDTRONIC INC

Hemodialysis system having a flow path with a controlled compliant volume

ActiveUS20160038666A1Improve clearanceReduce riskSemi-permeable membranesSolvent extractionDialysis membranesHematological test

Systems and methods for the performance of kidney replacement therapy having or using a dialyzer, control components, sorbent cartridge and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment are disclosed. The system for performing kidney replacement therapy has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. The dialysis circuit and an extracorporeal circuit for circulating blood are in fluid communication through the dialysis membrane. The flux of fluid moving between the extracorporeal circuit and the dialysis circuit is modified by the rate at which the control pump is operating such that a rate of ultrafiltration and convective clearance can be controlled. The system provides for the monitoring of an inlet and outlet conductivity of the sorbent cartridge to provide a facility to quantify or monitor the removal of urea by the sorbent cartridge.

Owner:MOZARC MEDICAL US LLC

Dual flow sorbent cartridge

Disclosed are systems and methods for the performance of kidney replacement therapy having or using a dialyzer, control components, a sorbent cartridge with at least two separate flow paths, and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment. The system for performing kidney replacement therapy has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. The dialysis circuit and an extracorporeal circuit for circulating blood are in fluid communication through the dialysis membrane. The flux of fluid moving between the extracorporeal circuit and the dialysis circuit is modified by the rate at which the control pump is operating such that a rate of ultrafiltration and convective clearance can be controlled. The system provides for the monitoring of an inlet and outlet conductivity of the sorbent cartridge to provide a facility to quantify or monitor the removal of urea by the sorbent cartridge.

Owner:MOZARC MEDICAL US LLC

Preparation method for zinc ion-doped yellow fluorescent carbon quantum dot

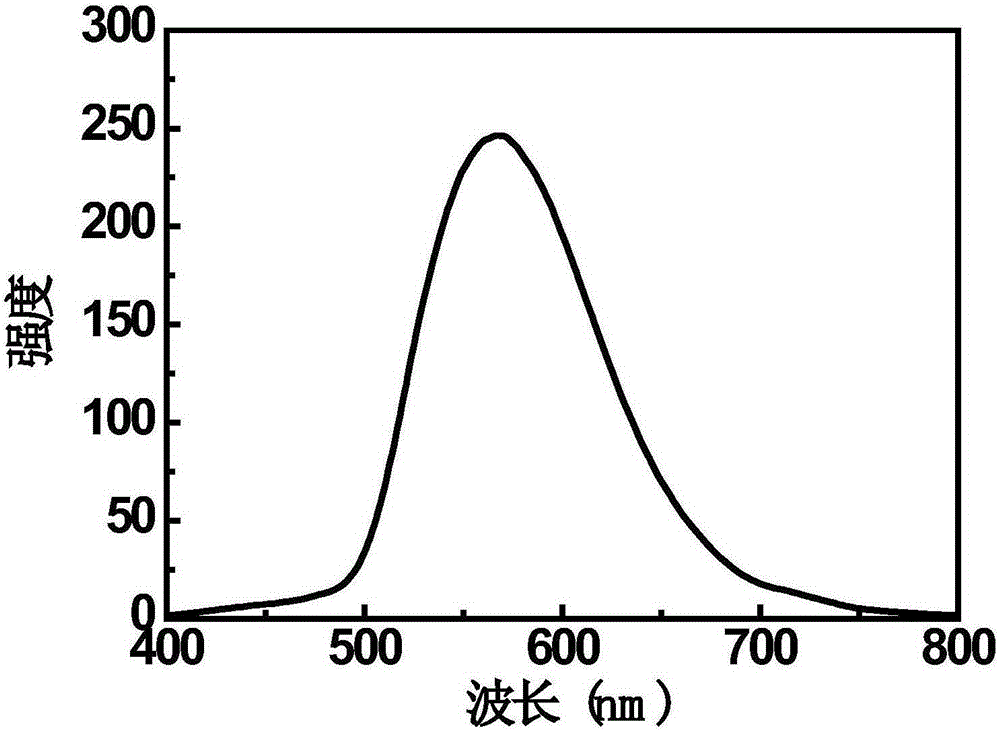

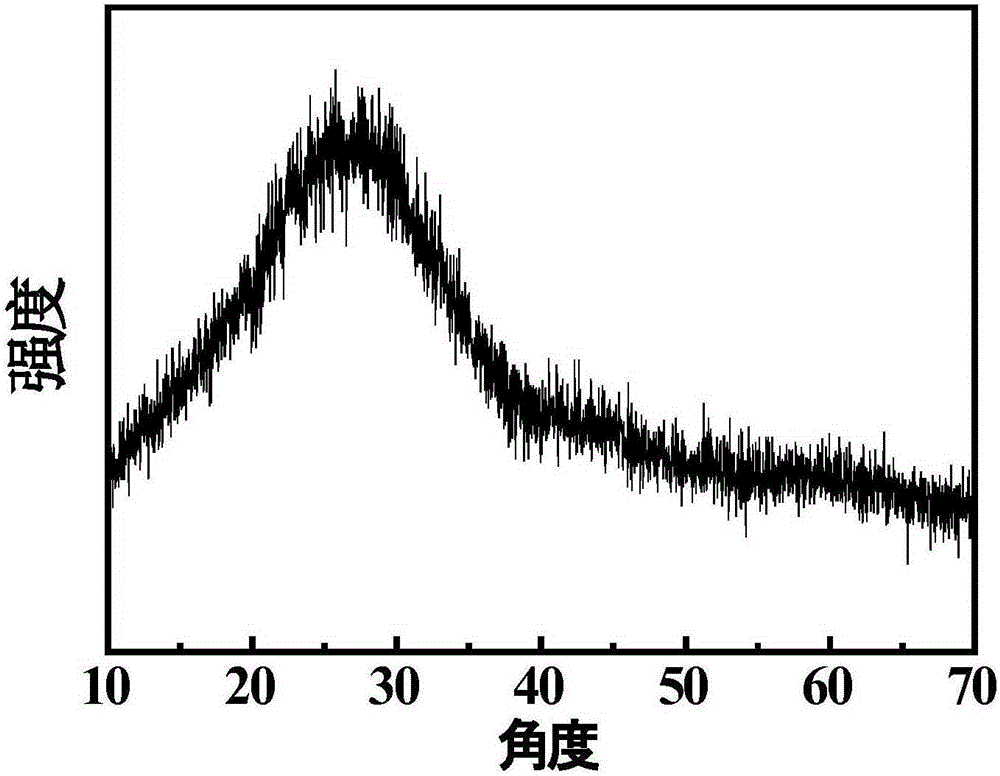

ActiveCN105219384AGuaranteed production and supplyMild reaction conditionsMaterial nanotechnologyInksQuantum yieldDialysis membranes

The invention relates to a preparation method for a zinc ion-doped yellow fluorescent carbon quantum dot. The preparation method comprises the following specific steps: placing a zinc source, a carbon source, a passivator and an organic solvent in a hydrothermal kettle, placing the hydrothermal kettle into a drying oven and heating for reaction; stopping heating after completion of reaction, cooling and taking out a solution in the hydrothermal kettle; centrifuging, taking supernatant, and carrying out rotary evaporation or drying so as to obtain solid powder, and after the solid powder is dissolved in water in an ultrasonic manner, dialyzing through a dialysis membrane so as to obtain a quantum dot aqueous solution. The characteristics that the reaction conditions are mild and the method is simple and easy to implement are realized. The prepared yellow fluorescent carbon quantum dot with high strength can stably emit yellow fluorescence and the quantum yield is high.

Owner:NANJING UNIV OF TECH

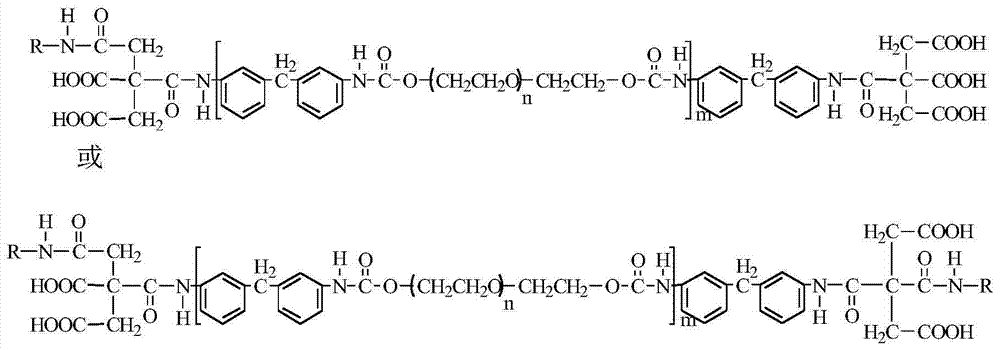

Preparation method of anticoagulation polylactic acid hemodialysis membrane

The invention discloses a preparation method of an anticoagulation polylactic acid hemodialysis membrane. Cellulose acetate membranes and polysulfone membranes are widely used in current clinical application. Poly lactic acid has a good membrane-forming property, but is inclined to hydrophobicity, and blood contacting materials are often required to have good hydrophilicity, can reduce the protein adsorption on material surfaces and reduce platelet aggregation. In the preparation method, firstly a polylactic acid hollow fiber membrane with epoxy groups is prepared by a one-step method, then diamine activation of the polylactic acid hollow fiber membrane is carried out, finally heparin is introduced into the activated polylactic acid hollow fiber membrane to obtain the anticoagulation polylactic acid hemodialysis membrane. In the preparation method, the polylactic acid is used as a dialysis membrane material, and the novel dialysis membrane is prepared through use of the wet / dry solution spinning method; and through in-situ polymerization of monomers having double bonds and the epoxy groups, groups of high reaction activity are introduced into a polylactic acid matrix, and reaction conditions of subsequent diamine grafting process and heparin fixing process are mild, so the method is a simple and convenient modification method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of polylactic-acid hollow fiber dialysis membrane

ActiveCN102961977AGood biocompatibilityLess protein adsorptionSemi-permeable membranesDialysis membranesBiocompatibility Testing

The invention relates to a preparation method of a polylactic-acid hollow fiber dialysis membrane, which aims to overcome the defects that the conventional dialysis membrane material is poor in biocompatibility and easy to cause environmental pollution. The preparation method comprises the following steps of: adding polylactic acid, a pore-forming agent, a toughening agent and an inorganic filler to a solvent, stirring the components at 40-120 DEG C for 8-12 hours to obtain a spinning solution, and then deforming the spinning solution; carrying out extrusion moulding on the defoamed spinning solution and core liquid which respectively pass through an external channel and an inner channel of a spinning nozzle, thus obtaining nascent fibers; curing the nascent fibers in coagulating bath after the nascent fibers pass through air gaps of 0 to 50cm, thus forming a nascent polylactic-acid hollow fiber membrane; collecting the nascent polylactic-acid hollow fiber membrane by a coiler at a speed of 1-30 m / min, thus obtaining the polylactic-acid hollow fiber membrane; and finally soaking the membrane in circulating deionized water at 20-45 DEG C for 6 to 48 hours, and taking out and drying the membrane. The preparation method has the advantages of little pollution and energy conservation; and the prepared dialysis membrane is good in biocompatibility and low in adsorption capacity of proteins, has a good elimination effect on urotoxy matters, and is biodegradable.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

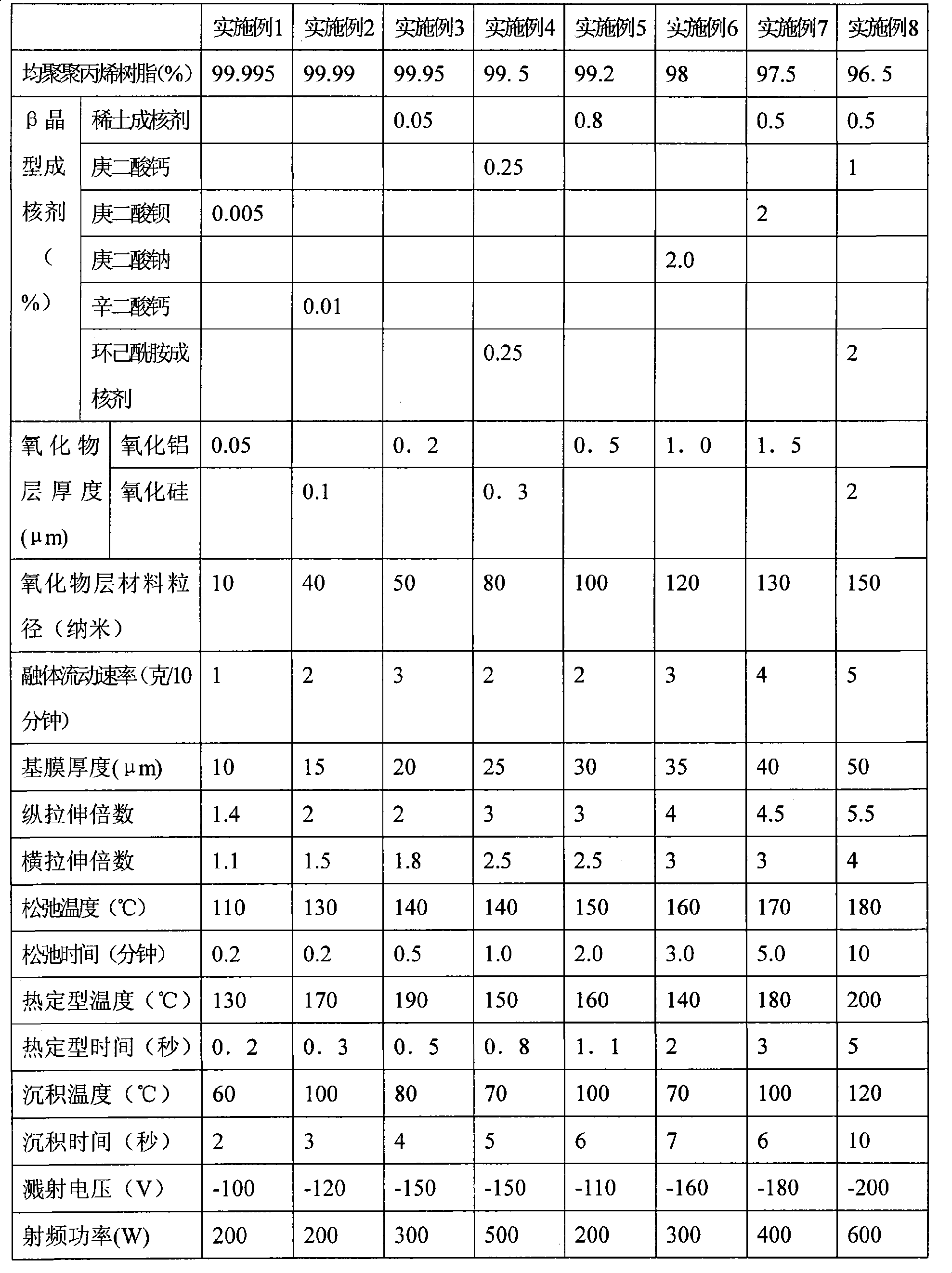

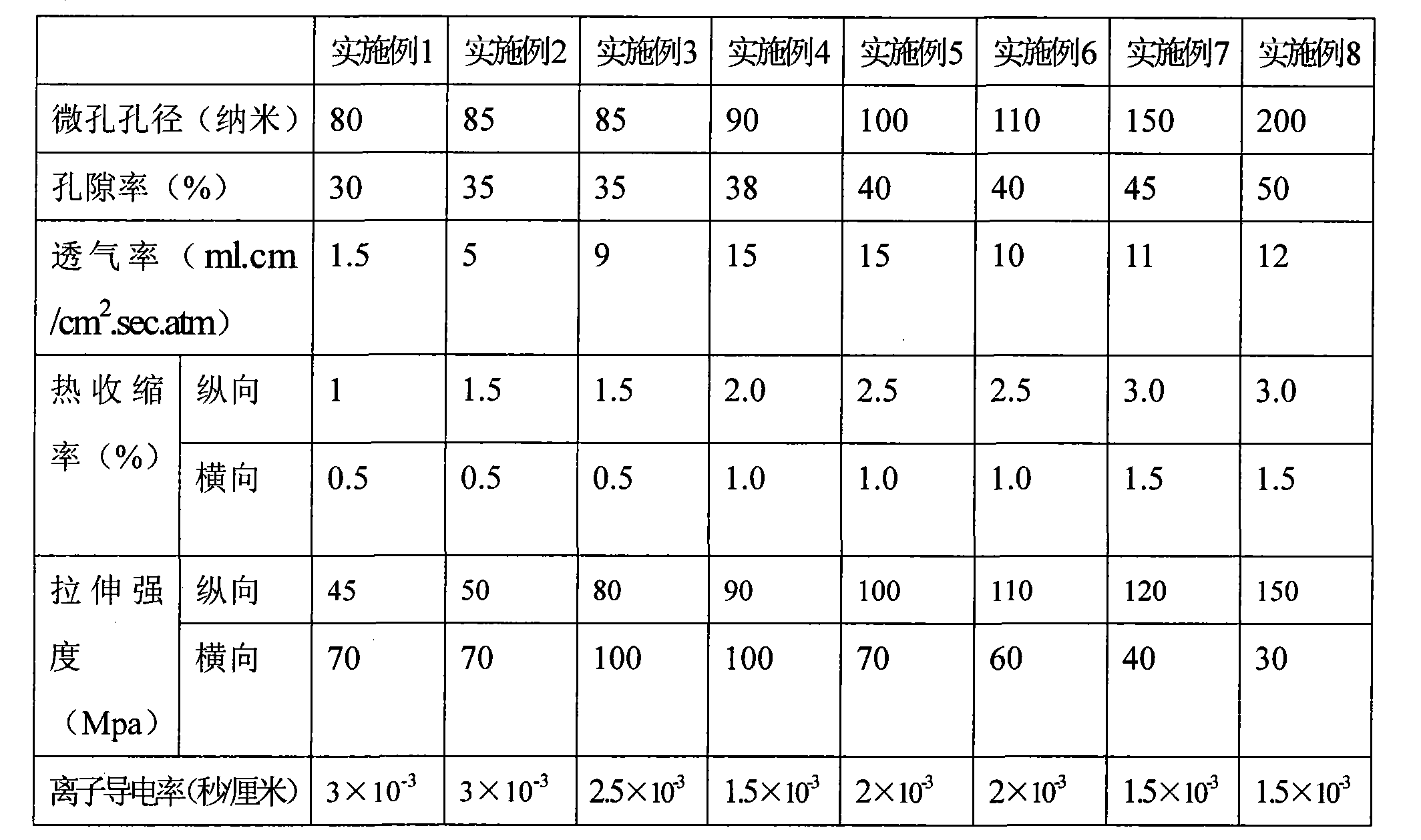

Polyolefin micropore barrier diaphragm and method for producing the same

InactiveCN101462381AImprove ionic conductivityImprove performanceSynthetic resin layered productsCell component detailsLithiumPorosity

The invention relates to a polyolefin microporous diaphragm and a manufacture method thereof, which belongs to the field of thin-film manufacture. The polyolefin microporous diaphragm consists of a polyolefin microporous basal membraneand oxide layer(s) on or / and under the polyolefin microporous basal membrane, wherein the polyolefin microporous basal membrane consists of 96.5 to 99.995 percent of homo-polypropylene resin and 0.005 to 3.5 percent of beta crystal form nucleating agent according to weight percentage; the polyolefin microporous basal membrane has the average pore size between 80 and 200 nanometers, the porosity between 30 and 50 percent and the air permeability between 1.5 and 15 ml / cm<2>.sec.atm; and the thickness of the oxide layer is between 0.05 and 2 microns. The polyolefin microporous diaphragm has the characteristics of uniform micropores, good air permeability, good thermal shrinkage properties and high ionic electrical conductivity, and can be widely applied to medical dialysis membranes, industrial water treatment membranes and lithium-ion secondary battery diaphragms.

Owner:韩伟嘉

MECS dialyzer

ActiveUS8128822B2Improve mass transfer efficiencyEnhanced mass transferMembranesSolvent extractionDialysis membranesHaemodialysis machine

The present invention is related to hemodialysis, and more particularly, to a dialyser with improved efficiency of mass transfer across a dialysis membrane utilizing microchannel separation provided in accordance with embodiments of the present invention. In accordance with an embodiment, a dialyzer is provided comprising a plurality of semipermeable membrane sheets and a plurality of flow separators. The membrane sheets and flow are arranged in alternating configuration and coupled into a laminae stack defining a plurality of parallel microchannel layers. Each microchannel layer comprises a plurality of first microchannels and a plurality of second microchannels. The first and second microchannels of each microchannel layer are in fluid communication with each other via one of the plurality of membrane sheets therebetween. The MECS dialyzer is characterized as having a high surface to volume ratio and a high mass transfer coefficient.

Owner:OUTSET MEDICAL

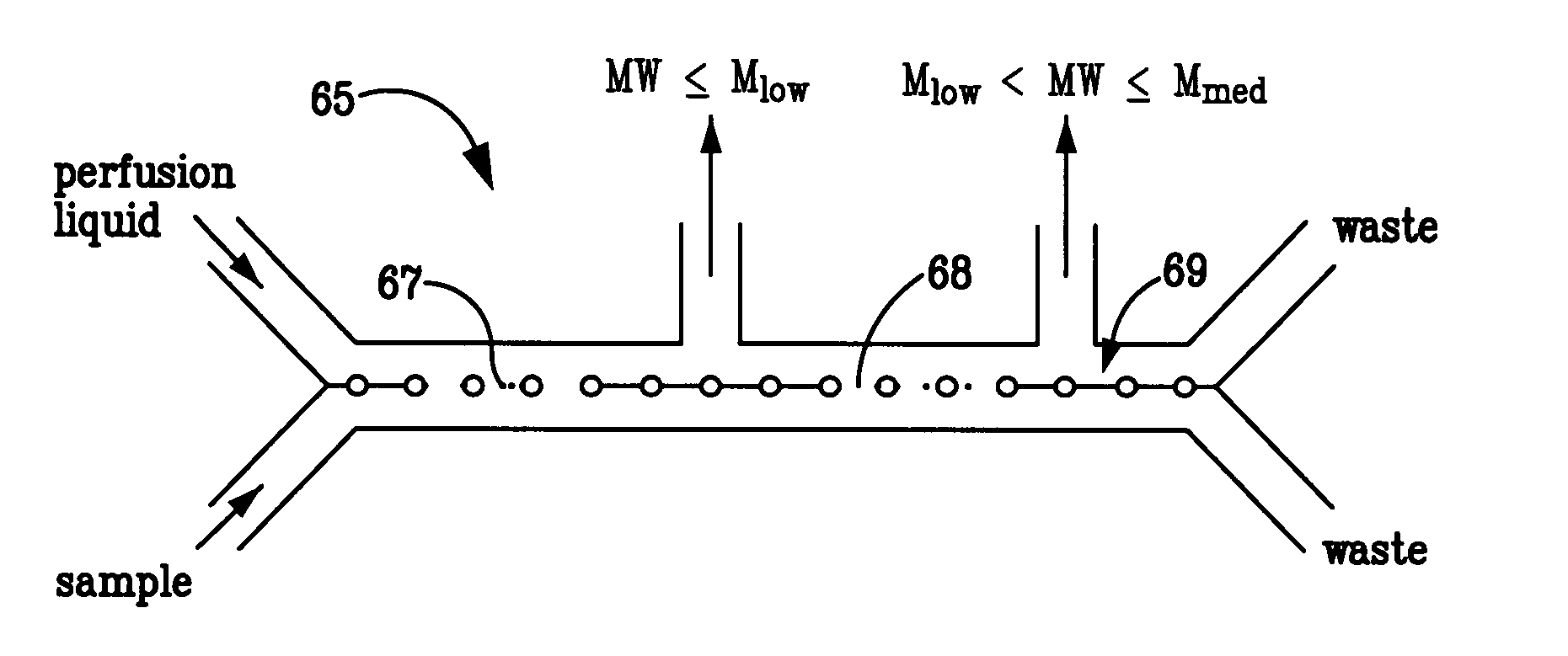

Micro flow control chip with integrated dialysis function and preparing process thereof

InactiveCN1629640APermanent sealEnough timePreparing sample for investigationDialysis membranesMicrofluidic channel

This invention provides a micro flow control chip formed by three sealed parts integrating the dialyzing functions. The top and bottom layers of the chip have channels for microfluid and the sandwich layer is a dialysis membrane. The preparation method includes three steps: first of all, casting the upper and lower PDMS layer to be aggregated in a bake oven for 20-60min to be stripped from the form board, a small hole on the top is opened for the fluid enter then the dialysis membrane is stuck at a suitable place of the bottom PDMS to be adhered closely with the top to align the two layers of channels accurately, finally, the total chip is aggregated for 1~3h in a bake oven, the chip is always sealed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for dialysis on microchips using thin porous polymer membrane

InactiveUS7534315B1Minimize handlingComplicated operationGlovesPretreated surfacesDialysis membranesMicrosphere

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and forms a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Positive wakeup pharmaceutical sleep system with compatible pre-bedtime administration

A novel sleep regulating pharmaceutical formulation is introduced, typically implementing two principal drugs having actions which are reversive to one another, yet incorporated into a unitary solid dosage, and prepared for oral administration before bedtime. Usually, structure is configured to initially release a calmative or other sleep-compatible substance by prompt dissolution. The initial release is followed by a specific period of delay, which in basic formulations entails no release of any drug, and which allows a nominal interval of sleep. At the terminus of the delay, a final agent is released to induce wakeup. Incorporation of agents of opposite action within a unitary dosage form renders utility which is uniquely appropriate to the invention. In a preferred embodiment, delay of release and final delivery of wakeup agent are arranged by a dialysis membrane which eventually bursts as a result of osmotic pressure generated by a hydrophilic core.

Owner:AYALA WILLIAM J

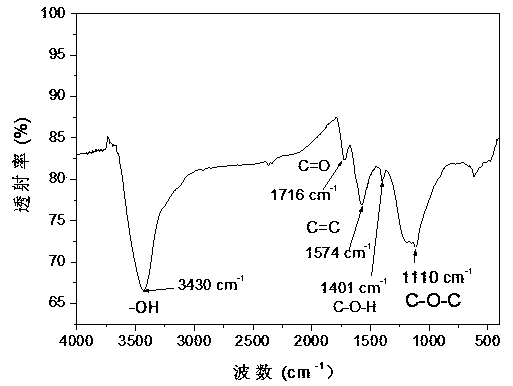

Method for adsorbing and separating low-concentration rare earth ions with oxidized graphene colloid

InactiveCN103418166AEasy to regenerate and recycleLarge specific surface areaIon-exchange process apparatusIon-exchanger regenerationDialysis membranesSorbent

A method for adsorbing and separating low-concentration rare earth ions with an oxidized graphene colloid is characterized in that through the use of the screening characteristics of a dialysis membrane and the strong rare earth ion adsorption performance of the oxidized graphene colloid, the oxidized graphene colloid is packaged in a dialysis bag, the dislysis bag filled with the oxidized graphene colloid is placed in a rare earth ion solution, and rare earth ions pass through the dialysis membrane quickly to be adsorbed efficiently, so that separation and enrichment of the rare earth ions can be realized; after oxidized graphene that adsorbs the ions is treated with an acidic solution, the rare earth ions can be adsorbed efficiently, and the oxidized graphene can be regenerated and recycled at the same time; since oxidized graphene in the dialysis bag can not pass through the dialysis bag and can not enter an adsorbed water solution, the secondary pollution of a sorbent can be avoided, and solid-liquid separation amount can be reduced greatly. The method is simple in implementation and high in adsorption speed, has high adsorption capacity in a large pH range, and has a good application prospect in separation and enrichment of low-concentration rare earth ions in waste water of rare earth mines and separation plants.

Owner:NANCHANG UNIV

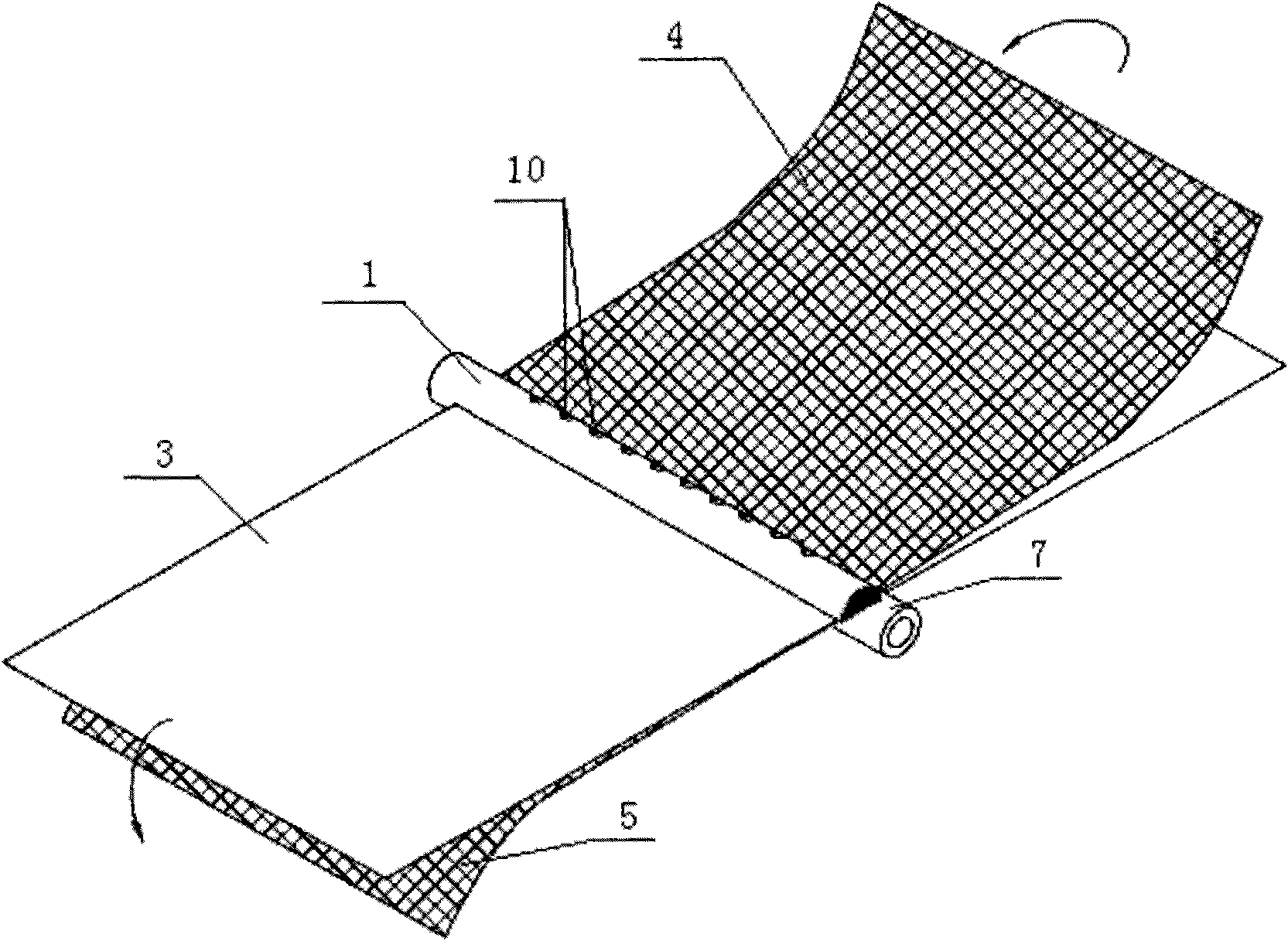

Spiral coil type diffusion dialysis membrane assembly and preparation method thereof

ActiveCN101983756AImprove performanceIncrease the average concentration differenceDialysisDialysis membranesCounter flow

The invention discloses a spiral coil type diffusion dialysis membrane assembly and a preparation method thereof. The spiral coil type diffusion dialysis membrane assembly is characterized in that an ion exchange membrane is clamped between two central tubes, runner screens on two sides mutually and tightly adhere for surrounding the central tubes to coil together according to same direction and are stuck on the axial edge to be sealed into a cylinder; the tail end of the ion exchange membrane forms two tangential runner openings which are radially symmetrical on the outer edge of the cylinder, and a side flow tube is sticked, sealed and fixed respectively by two openings; then the whole cylinder including the side flow tube is tightly wound and fixed by a plastic membrane to form a membrane core, the membrane core is put into a cylindrical shell, and two tips are cast and fixed by adhesive to form the spiral coil type diffusion dialysis membrane assembly with four inlet and outlet adapters. The equipment is compact, has big packing density, can be vertically assembled to occupy small space, can realize the radial spiral counter flow of diffusion liquid and dialysate flow, has big turbulence degree, high mass transfer efficiency and large feed liquid treatment capacity on unit membrane area and is easy to integrate with other reaction or separation equipment.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

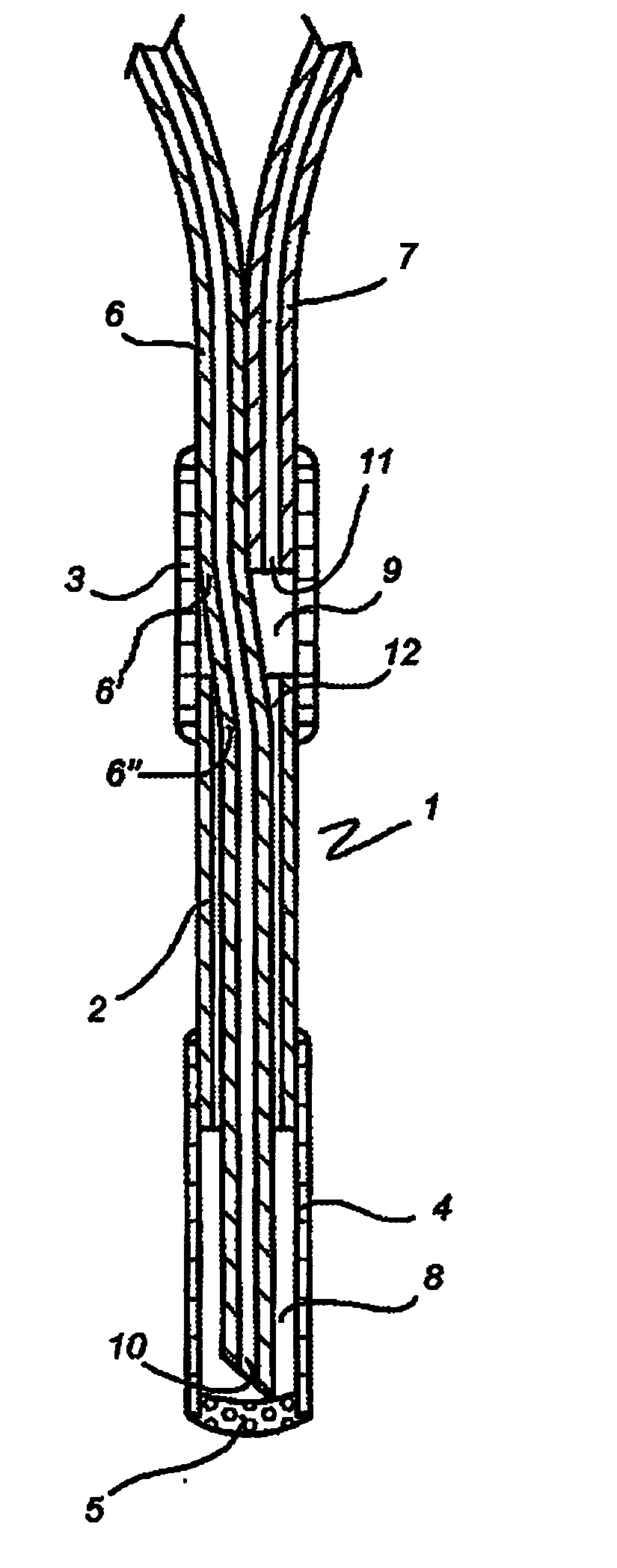

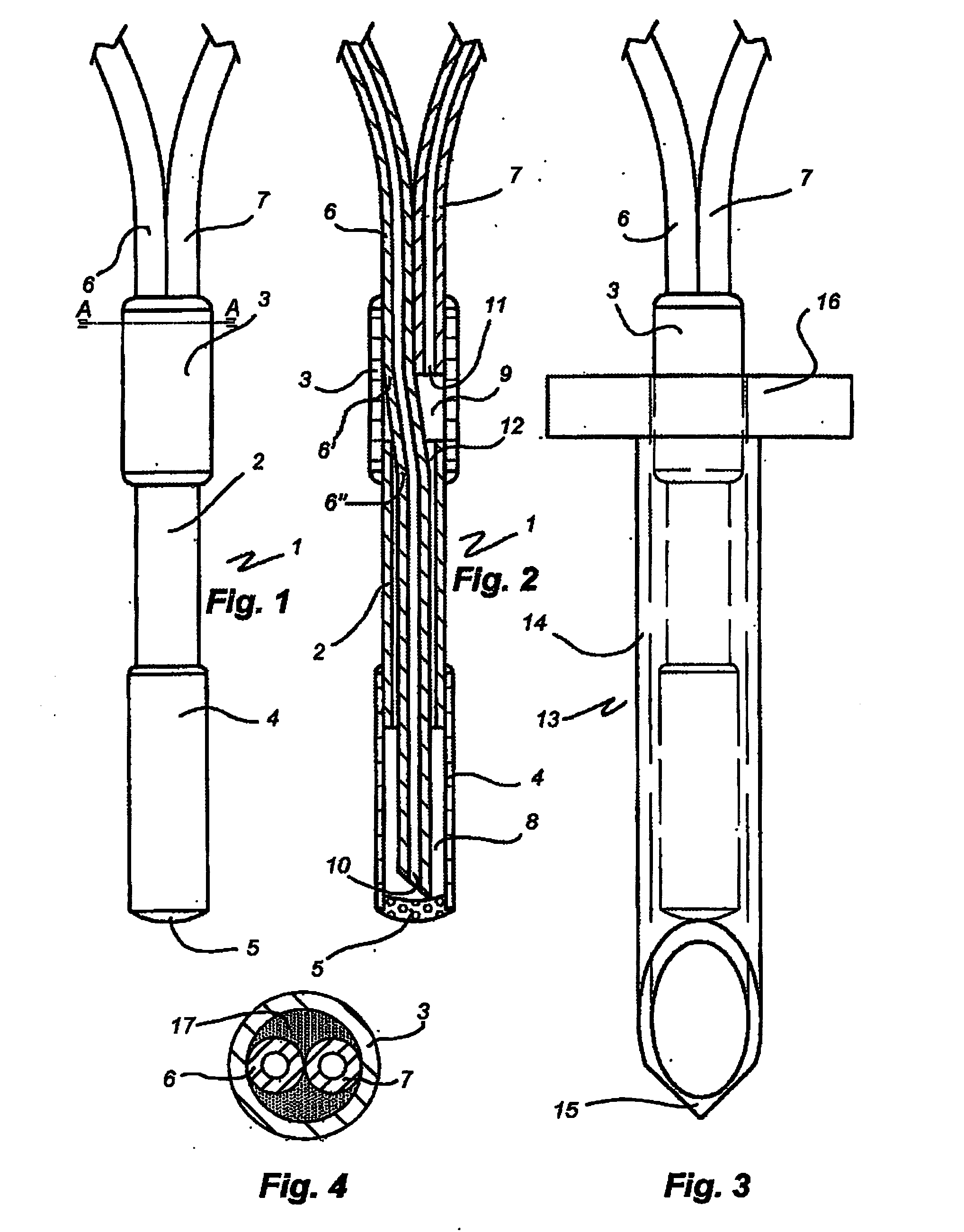

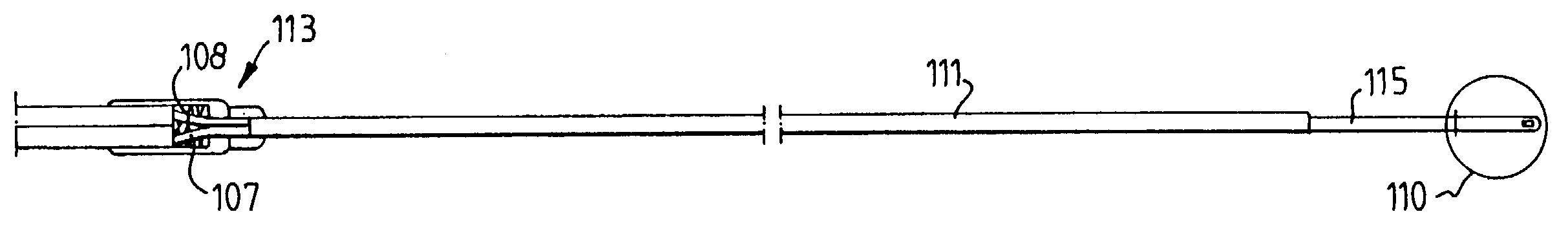

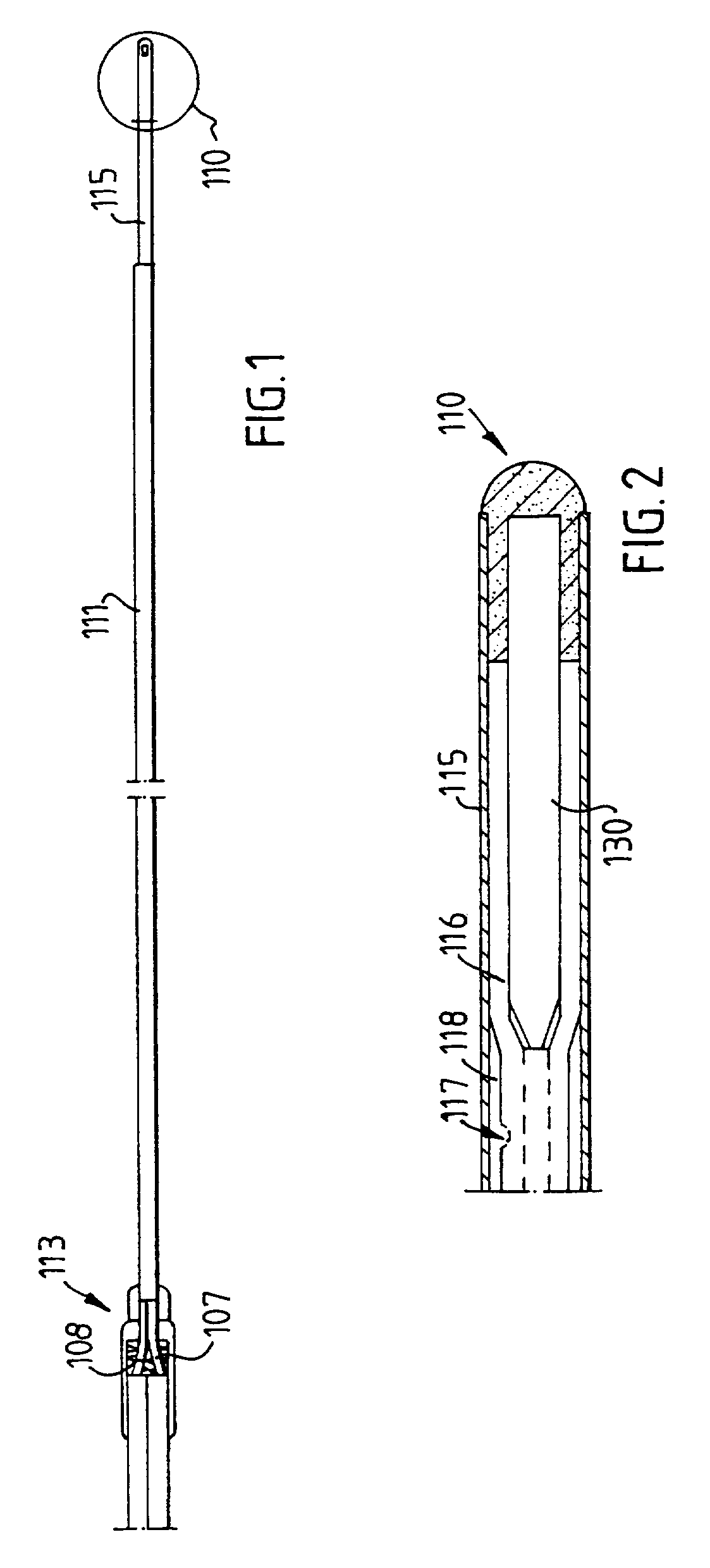

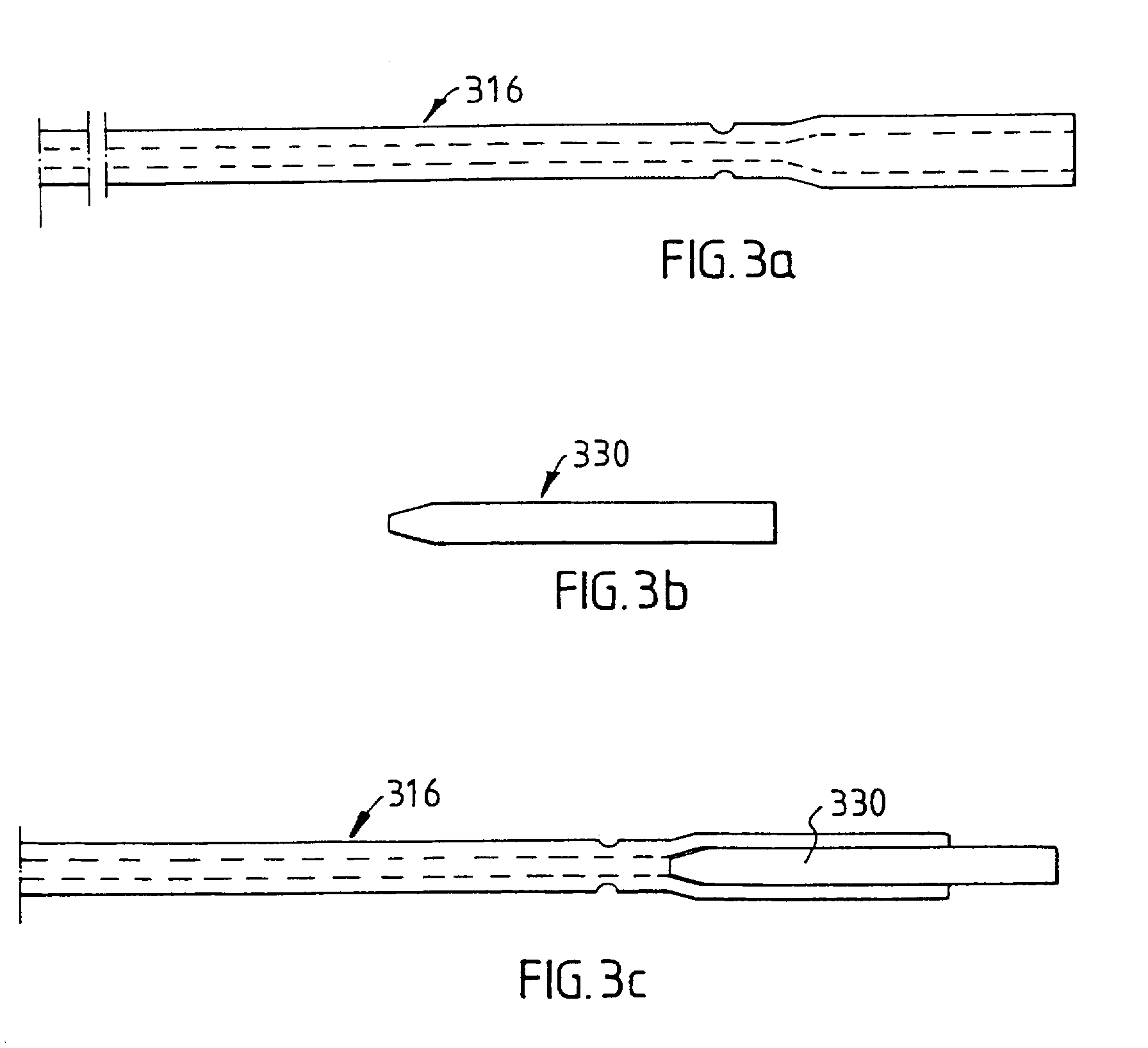

Microdialysis probe with inserting means and assembly

InactiveUS20050119588A1Easy to produceDialysis systemsAnimal teeth treatmentDialysis membranesCatheter

A microdialysis probe comprises a tubiform probe body, a tubiform dialysis membrane disposed distally of the probe body, and flexible conduits for adducing and abducing dialysis fluid, distal end portions of which are disposed in the probe body. Apart from the conduit portions disposed externally of the probe body the probe is substantially rotationally symmetrical. One of the conduits, preferably the abducing conduit, comprises an S-shaped portion inside of the probe, adjacent to the distal end of the other conduit. Also disclosed is an assembly of the probe and a cannula for inserting it into tissue; after insertion the cannula can be withdrawn in a proximal direction.

Owner:MICROBIOTECHSE

Method for preparing homogeneous-phase anion exchange film

InactiveCN1978038ASafe homogeneous performanceHomogeneous performance is stableSemi-permeable membranesAnion exchangersDialysis membranesFuel cells

The present invention relates to a preparation method of homogeneous anion-exchange membrane. Said method includes three processes of membrane-casting liquor preparation, membrane-forming and amination. Said invention also provides the concrete steps of above-mentioned every process. Said homogeneous anion-exchange membrane has extensive application field, it can be used for making concentration or desalination of dilute brine solution in electrodialysis method, can be used as electrolytic diaphragm in metallurgical industry, can be used as diffusive dialysis membrane for recovering acid and can be used as anionic selective electrode, etc.

Owner:UNIV OF SCI & TECH OF CHINA

Electrochemical-based sensor with a redox polymer and redox enzyme entrapped by a dialysis membrane

ActiveUS20060042944A1Rapid responseImmobilised enzymesBioreactor/fermenter combinationsRedox enzymesDialysis membranes

An electrochemical-based sensor includes an electrode with at least one electrode surface, a film disposed on the electrode surface, and a dialysis membrane disposed on the film. The film includes a redox enzyme and a hydrophilic redox polymer (i.e., a polymer with an attached redox mediator(s)). In addition, the dialysis membrane serves to entrap the redox polymer and redox enzyme in the vicinity of the electrode. Such entrapment is accomplished by employing a redox enzyme and a hydrophilic redox polymer of a sufficiently high molecular weight that they do not pass through the dialysis membrane.

Owner:CILAG GMBH INT +1

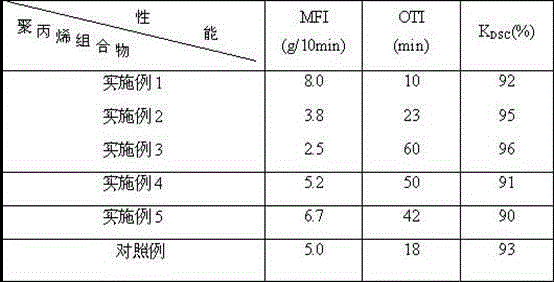

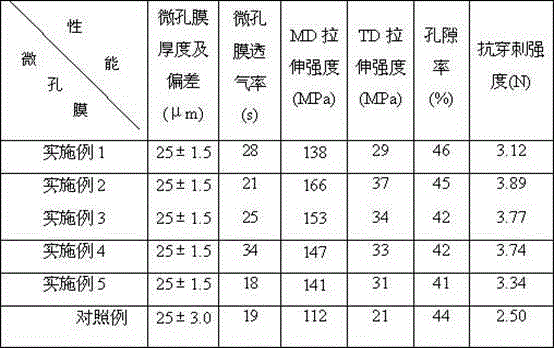

Polypropylene composition for preparing polypropylene microporous membrane and preparation method of polypropylene composition

The invention relates to a polypropylene composition for preparing a polypropylene microporous membrane. The melt flow rate of the polypropylene composition is 2.5-8.0g / 10min; the oxidation induction time is not lower than 10min; beta-crystal content (KDSC Kimmage Development Studies Centre) is not lower than 90%. The invention further relates to a preparation method for the polypropylene composition. The polypropylene composition provided by the invention improves the moulding processability of the microporous membrane effectively and particularly is suitable for the polypropylene microporous membrane formed by a dry-process dual-elongation technology. The microporous membrane obtained from the polypropylene composition provided by the invention has excellent air permeability, smaller thickness volatility, more excellent tensile strength and puncture resistance. The polypropylene composition can be applied to a lithium-ion battery separator and fields of an artificial kidney dialysis membrane, an artificial lung membrane, aseptic filtration and an aseptic packaging membrane, an air purification membrane, a gas separation membrane, a food preservation membrane, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and preparation method thereof

InactiveCN104841285AGood blood compatibilityImprove antibacterial propertiesSemi-permeable membranesPeritoneal dialysisESCHERICHIA COLI ANTIGENDialysis membranes

The invention discloses a citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and a preparation method thereof. The membrane is of a hollow fibrous structure, and the inner surface and outer surface are dense cortical layers, and the middle is a porous supporting layer, so that the blood dialysis membrane is high in permeability and separating property and antibacterial property; the inner diameter is 160 to 250mu m; the membrane thickness is 30 to 50 mu m, and the ultrafiltration coefficient is 7.0 to 60 ml / m<2>.h.mmHg; citric acid-chitosan-modified anticoagulation polyurethane is taken as membrane materials, and in membrane solution, the percentage mass content of the modified anticoagulation polyurethane is 15 to 30%, and the percentage mass content of a solvent is 70 to 85%, and the blood dialysis membrane is prepared by using a nonsolvent induced phase separation method. The preparation process of the dialysis membrane is simple and easy to control, and the prepared membrane has good anticoagulant activity, biocompatibility and antibacterial property, and the clearance rates of urea, beta2-microglobulin and albumin are respectively 55 to 80%, 48 to 60%, and 2.5 to 9%, and the rate of resisting pathogenic escherichia coli is 99%.

Owner:CENT SOUTH UNIV

Microdialysis probe

InactiveUS6929618B1Easy to installSemi-permeable membranesMulti-lumen catheterDialysis membranesNon invasive

A microdialysis probe includes a dialysis membrane located and supported between a closed distal end of the probe and a proximal end of the same, the membrane essentially surrounding a space for passage of perfusion liquid. The probe has an inlet and outlet for perfusion liquid, where a position indicating object at the distal part of the probe allows non-invasive examination of the location of the distal part of the microdialysis probe.

Owner:CMAMICRODIALYSIS HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com