Polyolefin micropore barrier diaphragm and method for producing the same

A microporous diaphragm and polyolefin technology, which is applied in the field of film manufacturing, can solve the problems of easy tearing of the film, difficulty in controlling the pore size, and micropores penetrated by the film, so as to improve thermal shrinkage performance, improve performance, and reduce internal resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

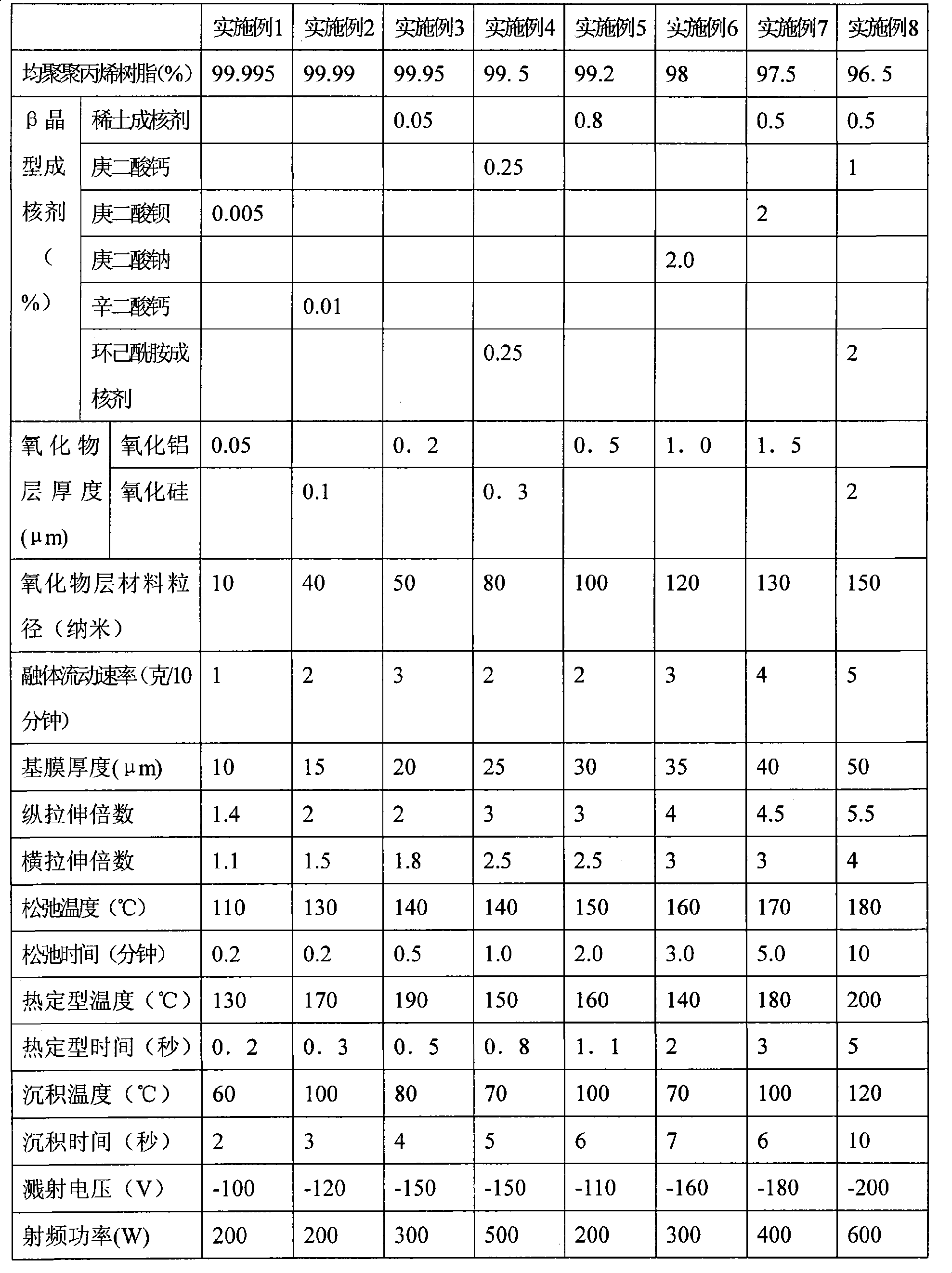

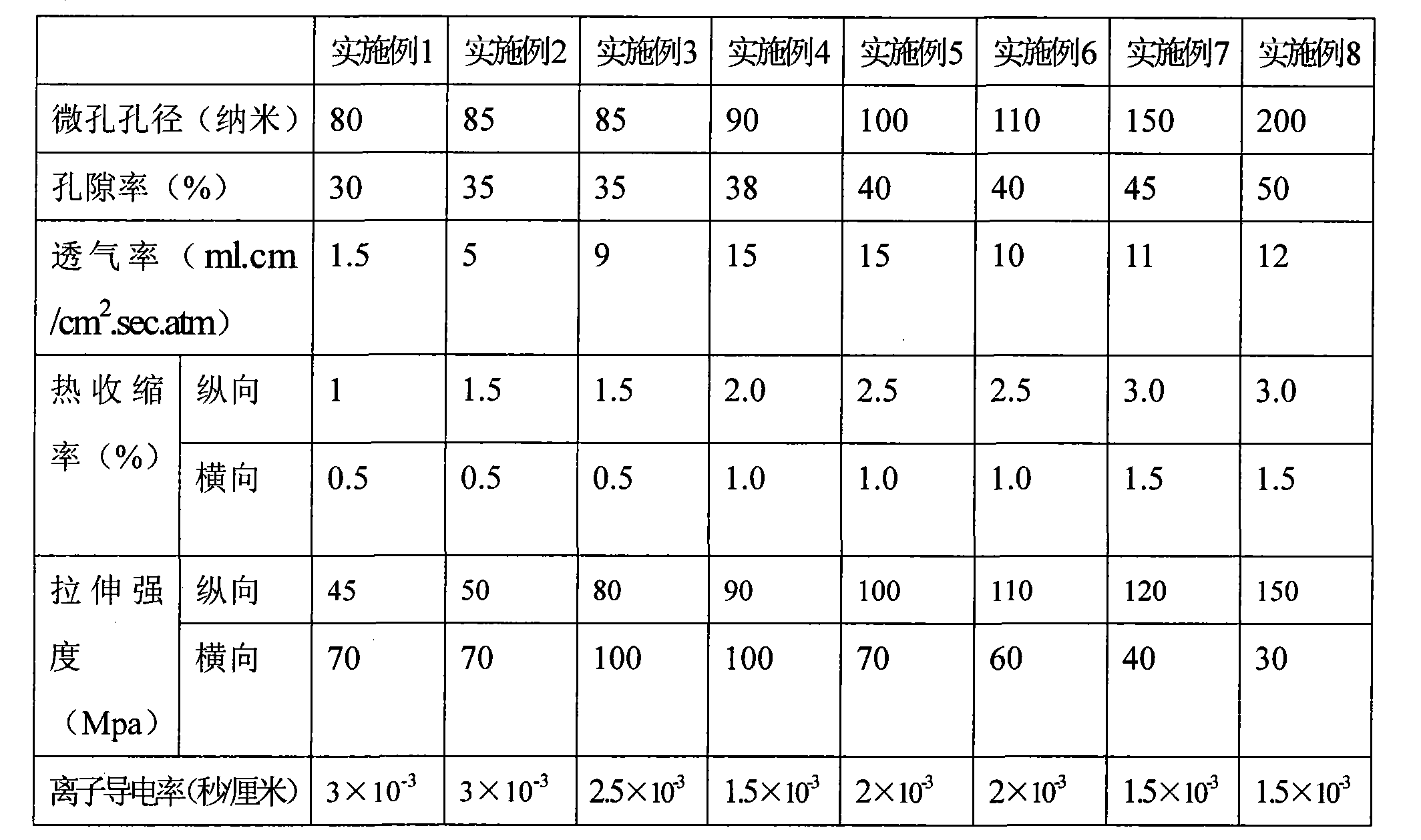

[0014] The polyolefin microporous diaphragm of the present invention is composed of a polyolefin microporous base film and an oxide layer plated on or / and under the polyolefin microporous base film. The polyolefin microporous base film is composed of 96.5%-99.995% homopolypropylene resin and 0.005%-3.5% beta crystal nucleating agent by weight percentage, and the melt flow rate of the homopolypropylene resin is 1 —5 g / 10 minutes, the average pore size of the polyolefin microporous base film is 80-200 nanometers, the porosity is 30%-50%, and the air permeability is 1.5-15ml.cm / cm 2 .sec.atm, and the thickness of the oxide layer is 0.05-2 microns, the oxide layer of the present invention is a nanoscale aluminum oxide layer or silicon oxide layer, and the material particle diameter of aluminum oxide or silicon oxide is at 10-150 nanometers , and the β crystal nucleating agent is one or two or three kinds of mixtures of rare earth nucleating agents, dicarboxylic acid salt nucleatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com