Polypropylene composition for preparing polypropylene microporous membrane and preparation method of polypropylene composition

A polypropylene composition and polypropylene microporous membrane technology, applied in the field of preparation of the polypropylene composition, can solve the problems of difficult control of pore size and porosity, low product quality, influence on the industrialization process of lithium-ion battery separators, and the like, Achieve excellent tensile strength and puncture resistance, improve molding performance, and be suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 90 parts of homopolypropylene A powder (weight average molecular weight 301,000, isotactic index 96.0%) and 10 parts homopolypropylene B powder (weight average molecular weight 52,000, isotactic index 97.9%)) , 5 parts of polypropylene wax, 0.1 part of N'N-dicyclohexyl terephthalamide, 0.5 part of nano-calcium carbonate, 0.05 part of antioxidant 1010 and 0.05 part of antioxidant 168 mixed with each other, adding Stir and mix in a high-speed mixer, the stirring speed is 400 rpm, and the stirring and mixing time is 15 minutes. After the mixing is completed, the material is discharged, and the premixed material is immediately added to a twin-screw extruder at a set temperature for melt mixing, extrusion and granulation to obtain a polypropylene composition. The set temperature of the twin-screw extruder is 180~250°C.

[0042] The prepared polypropylene composition is extruded through an extruder at 190-280°C to cast sheets, and stretched longitudinally and transversely in...

Embodiment 2

[0045] 60 parts of homopolypropylene A powder (weight average molecular weight 44.6, isotactic index 96.8%) and 40 parts of homopolypropylene B powder (weight average molecular weight 127,000, isotactic index 97.9%)), 0.5 parts of polypropylene wax, 0.5 parts of calcium suberate, 0.05 parts of antioxidant 1010 and 0.05 parts of antioxidant 168 are mixed together, then added to a high-speed mixer and stirred at a speed of 400 rpm , and the mixing time was 15 minutes. After the mixing is completed, the material is discharged, and the premixed material is immediately added to a twin-screw extruder at a set temperature for melt mixing, extrusion and granulation to obtain a polypropylene composition. The set temperature of the twin-screw extruder is 180~250°C.

[0046] The prepared polypropylene composition is extruded through an extruder at 190-280°C to cast sheets, and stretched longitudinally and transversely in sequence. The stretching temperature is 100-120°C, the stretching ...

Embodiment 3

[0049] 40 parts of homopolypropylene A powder (weight average molecular weight 650,000, isotactic index 97.5%) and 60 parts homopolypropylene B powder (weight average molecular weight 212,000, isotactic index 97.6%)) , 3 parts of polyethylene wax, 0.15 parts of zinc pimelate, 0.1 part of naphthalene dicyclohexylamide, 0.25 parts of nano-silica and 1 part of antioxidant 1010 are mixed with each other, then added to the high-speed mixer and stirred , the stirring speed is 400 rpm, and the mixing time is 15 minutes. After the mixing is completed, the material is discharged, and the premixed material is immediately added to a twin-screw extruder at a set temperature for melt mixing, extrusion and granulation to obtain a polypropylene composition. The set temperature of the twin-screw extruder is 180~250°C.

[0050] The prepared polypropylene composition is extruded through an extruder at 190-280°C to cast sheets, and stretched longitudinally and transversely in sequence. The stre...

PUM

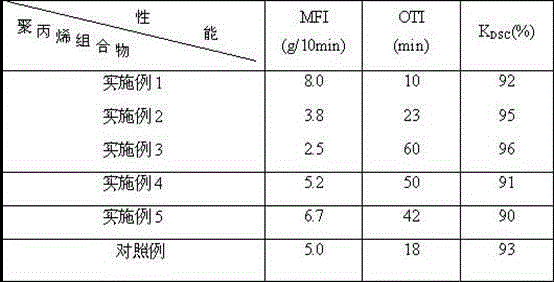

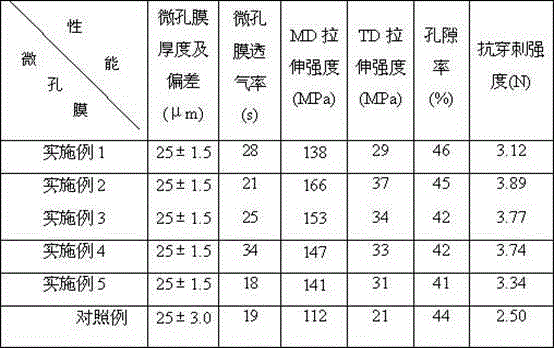

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com