Micro flow control chip with integrated dialysis function and preparing process thereof

A microfluidic chip and functional technology, which is applied in the preparation of test samples, analytical materials, instruments, etc., can solve the problems of solution flow range flow range mismatch, complex processing and operation technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

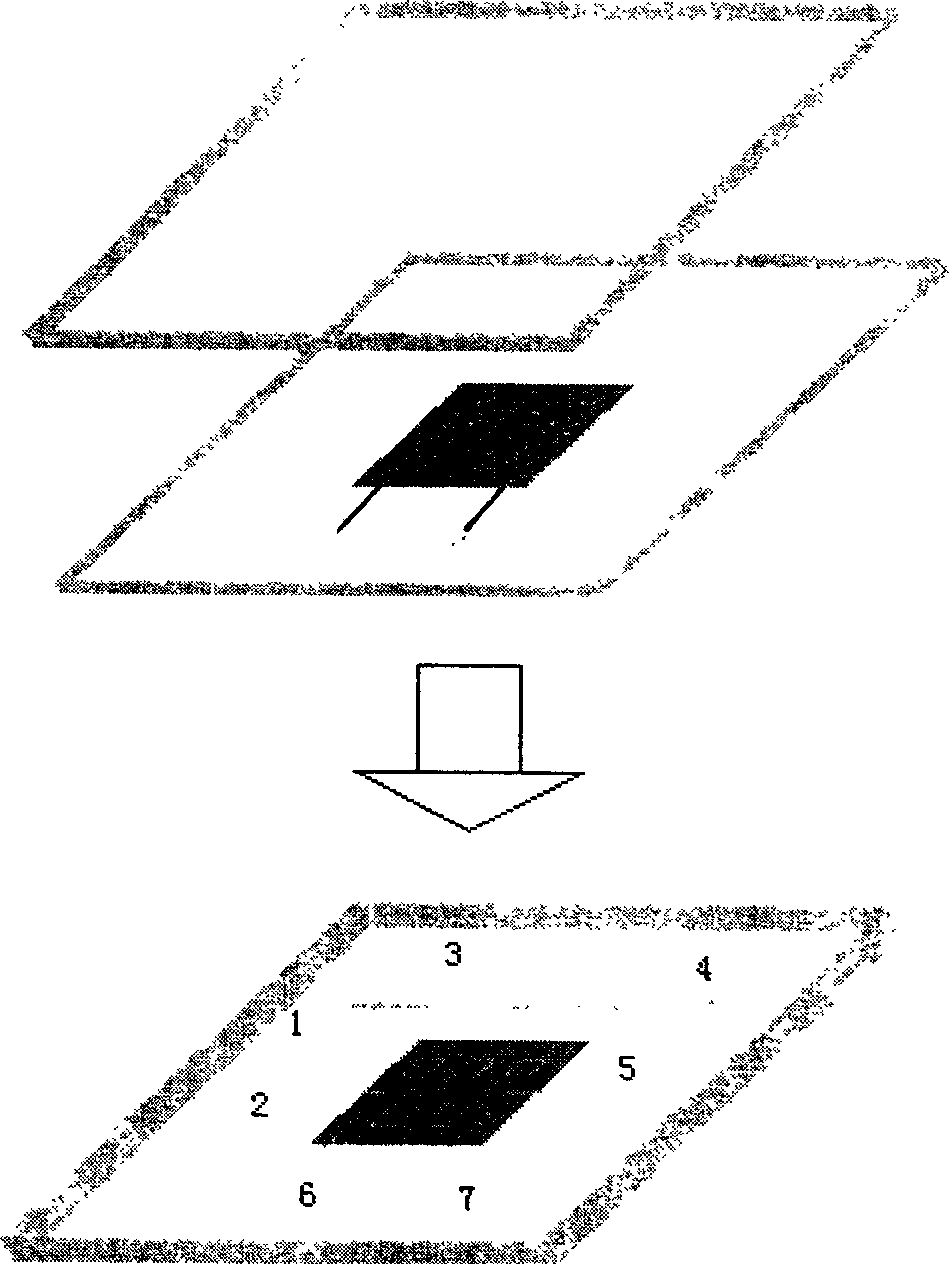

[0018] exist figure 1 In the chip design shown, two functional units of dialysis pretreatment and electrophoretic separation are integrated on the same chip. The main body of the chip is composed of upper and lower layers of PDMS, the solid line represents the lower channel, and the dotted line represents the upper channel; the shaded part is the dialysis membrane, which is sandwiched between the two layers of PDMS chips to separate the upper and lower channels. The specific processing process is as follows:

[0019] 1. Use SU-8 photoresist on the surface of the silicon wafer (or glass wafer) to make protrusions with upper and lower layer channel shapes respectively, as a template for pouring the upper and lower layer PDMS chips.

[0020] 2. Pour about 5mm thick PDMS (5:1) on the upper template, and pour about 2mm thick PDMS (20:1) on the lower template, and put both into an oven at 80°C for polymerization About 30 minutes.

[0021] 3. After peeling off from the template, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com