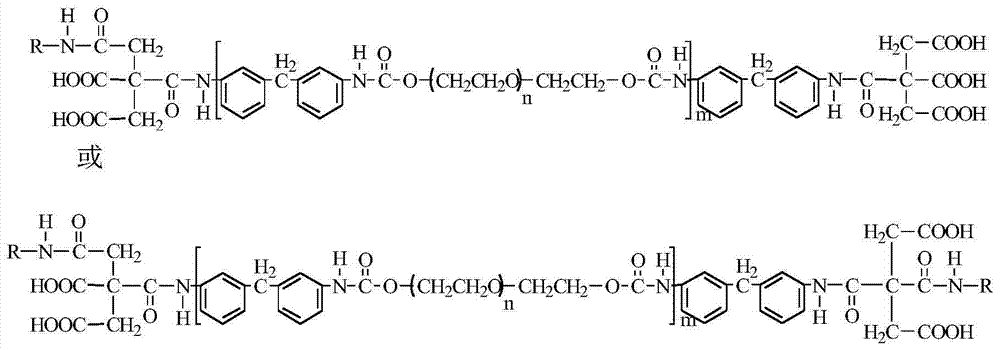

Citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and preparation method thereof

A chitosan modification, hemodialysis technology, applied in chemical instruments and methods, dialysis systems, peritoneal dialysis and other directions, can solve problems such as insufficient hemodialysis membrane, achieve excellent blood compatibility, good stability, and preparation method Simple and easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 16% of the above-mentioned anticoagulant modified polyurethane and 84% solvent (both are composed of mass percentage), add it to the raw material tank, heat and stir at 95°C for 2 hours, and after fully dissolving, let it stand for 8 hours at a temperature of 25°C Degassing to obtain a uniform membrane liquid; open the nitrogen valve to maintain the pressure of the raw material tank at about 0.06MPa, the membrane liquid is filtered and sent to the spinning head through a metering pump, the flow rate of the membrane liquid is 1.10mL / min, The core fluid is passed through, and the flow rate of the core fluid is 1.07mL / min. Under the traction of the wire winding machine, the nascent hollow fiber membrane enters the coagulation bath after passing through the 2cm air distance. The temperature of the coagulation bath is 30 ℃, and the cleaning bath is 30 ℃. On the silk machine, the winding speed is 50m / min. The prepared modified polyurethane hemodialysis membrane has an in...

Embodiment 2

[0026] Add 18% of the above-mentioned anticoagulant modified polyurethane and 82% solvent (both are composed of mass percentage), add it to the raw material tank, heat and stir at 90°C to dissolve for 2.5 hours, and after fully dissolving, let it stand at a temperature of 25°C for 8 hours Degassing to obtain a uniform membrane liquid; open the nitrogen valve to maintain the pressure of the raw material tank at about 0.08MPa, the membrane liquid is filtered and sent to the spinning head through a metering pump, the flow rate of the membrane liquid is 1.10mL / min, The core fluid was passed through, and the flow rate of the core fluid was 1.08mL / min. Under the traction of the wire winding machine, the nascent hollow fiber membrane enters the coagulation bath after passing through the 4cm air distance. The temperature of the coagulation bath is 26°C. On the silk machine, the winding speed is 45m / min. The prepared modified polyurethane hemodialysis membrane has an inner diameter of...

Embodiment 3

[0028] Add 24% of the above-mentioned anticoagulant modified polyurethane and 76% of solvent (both are composed of mass percentage), add it to the raw material tank, heat and stir at 85°C to dissolve for 3 hours, and after fully dissolving, let it stand at a temperature of 30°C for 10 hours Degassing to obtain a uniform membrane liquid; open the nitrogen valve to maintain the pressure of the raw material tank at about 0.10MPa, the membrane liquid is filtered and sent to the spinning head through a metering pump, the flow rate of the membrane liquid is 1.35mL / min, The core fluid is passed through, and the flow rate of the core fluid is 1.39mL / min. Under the traction of the winding machine, the nascent hollow fiber membrane enters the coagulation bath after passing through an air distance of 8cm. The temperature of the coagulation bath is 15°C. After the cleaning bath, the cleaning bath is 20°C. On the silk machine, the winding speed is 40m / min. The prepared modified polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com