Heparan polyurethane blended modified polyethersulfone hollow fiber membrane and preparation method and application thereof

A technology of blending modification and polyurethane, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problem that the anticoagulant function has not been significantly improved, and does not involve membrane anticoagulant performance and compatibility There are still some problems to be improved to achieve the effect of excellent anti-protein pollution ability, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

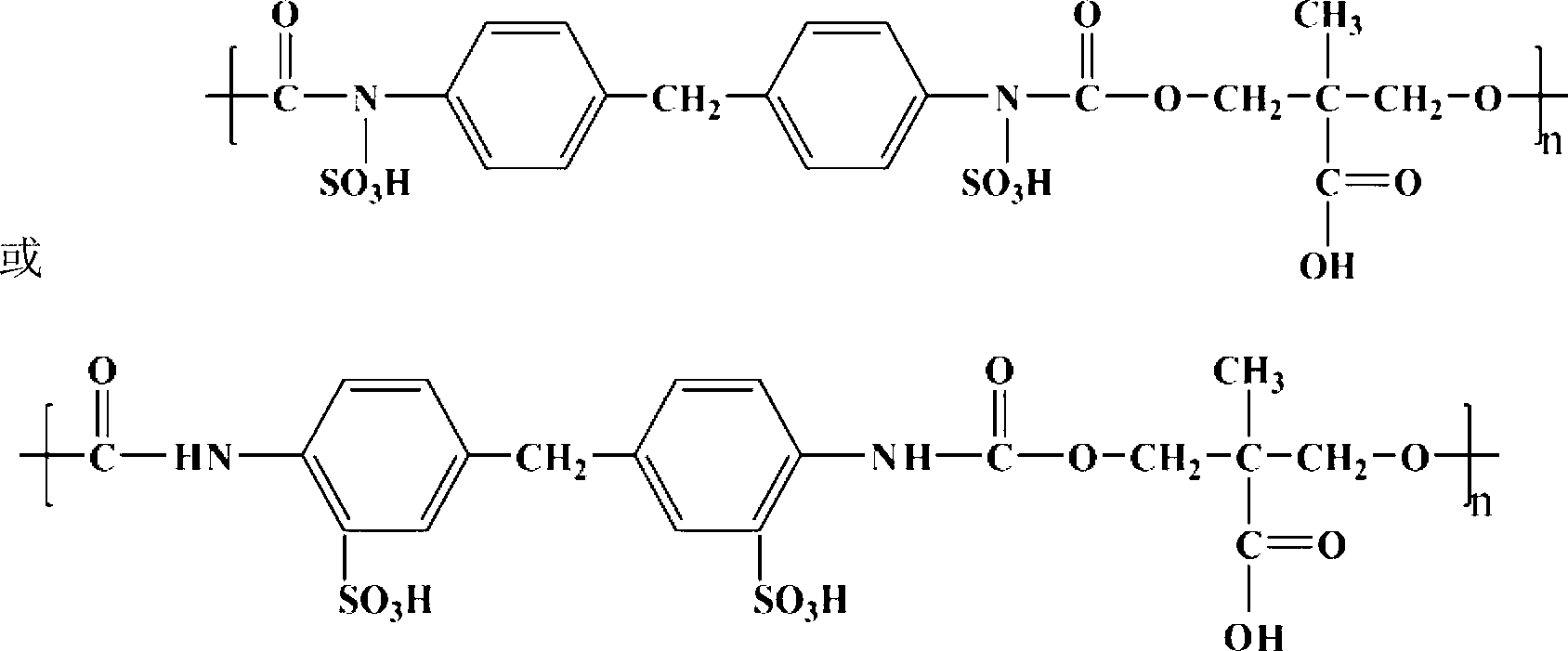

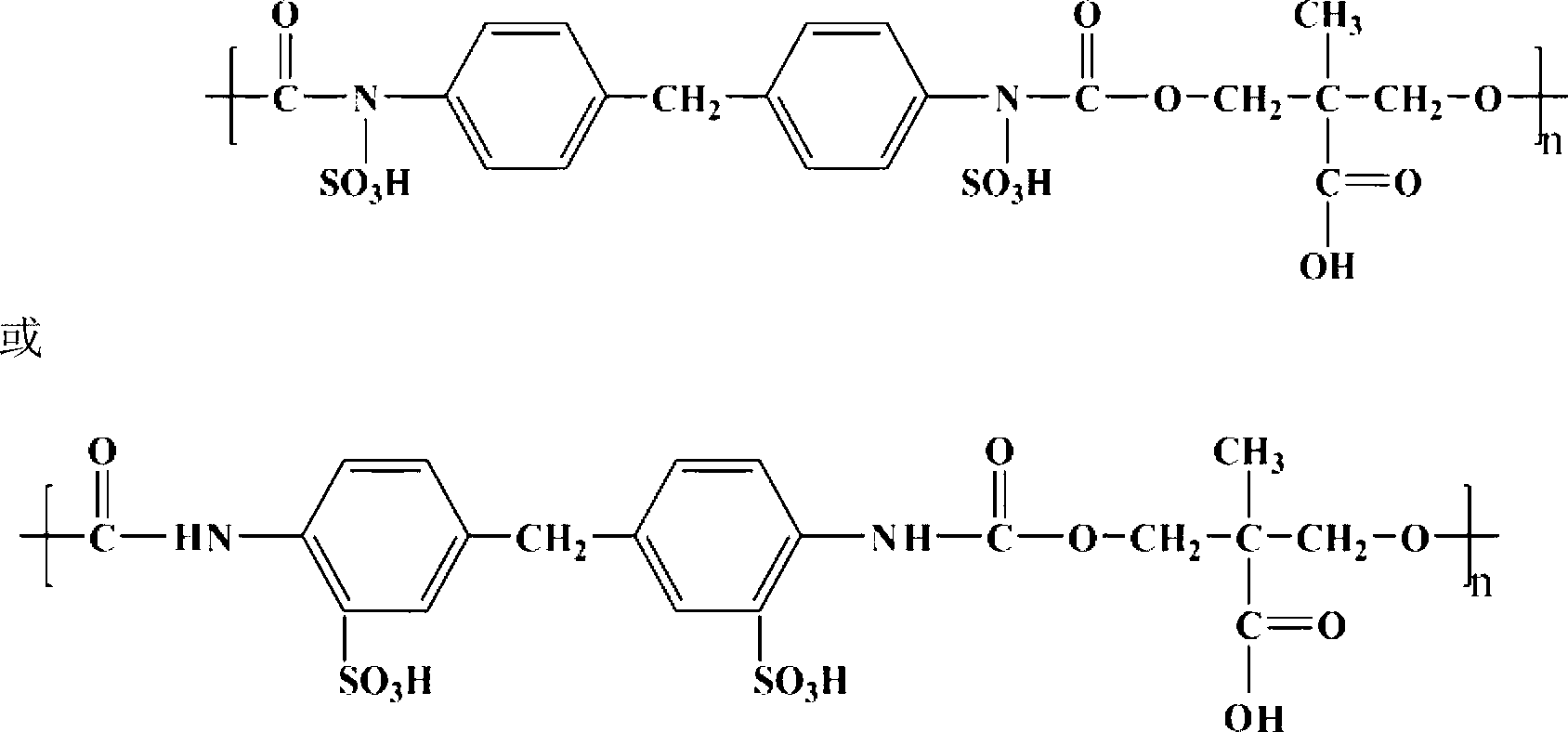

[0038] Add 10 parts of diphenylmethane diisocyanate, 5 parts of dimethylol propionic acid, and 85 parts of N-methylpyrrolidone into a dissolution tank equipped with a stirrer, temperature and reflux condenser, under stirring at a temperature of 85°C React for 6 hours, wash the product with methanol and distilled water, and dry to obtain carboxyl-containing polyurethane; add 100 parts of concentrated sulfuric acid to 10 parts of carboxyl-containing polyurethane for sulfonation, then wash with distilled water and dry to obtain carboxyl- and sulfonic acid-containing polyurethane; Put 10 parts of polyurethane containing carboxyl and sulfonic acid groups, 15 parts of polyethersulfone, and 75 parts of N-methylpyrrolidone into a dissolution kettle, and dissolve at 85°C for 24 hours under stirring to obtain a polyethersulfone solution; Degassing, placing and "curing" to obtain polyethersulfone spinning stock solution.

[0039]Filter the polyethersulfone spinning raw material by hydrau...

Embodiment 2

[0041] Add 10 parts of diphenylmethane diisocyanate, 5 parts of dimethylol propionic acid, and 85 parts of N-methylpyrrolidone into a dissolution tank equipped with a stirrer, temperature and reflux condenser, under stirring at a temperature of 85°C After reacting for 6 hours, the product was washed with methanol and distilled water and dried to obtain carboxyl-containing polyurethane; 10 parts of carboxyl-containing polyurethane were added to 100 parts of concentrated sulfuric acid for sulfonation, then washed with distilled water and dried to obtain carboxyl- and sulfonic-acid-containing polyurethane; Carboxyl and sulfonic acid polyurethane; then put 5 parts of polyurethane containing carboxyl and sulfonic acid group, 10 parts of polyethersulfone and 85 parts of N-methylpyrrolidone into the dissolution kettle, and dissolve it at 75°C for 20 hours under stirring to obtain Polyethersulfone solution; after filtration, defoaming, and "aging", the polyethersulfone spinning stock s...

Embodiment 3

[0044] Add 15 parts of diphenylmethane diisocyanate, 8 parts of dimethylolpropionic acid, and 77 parts of dimethylacetamide into a dissolution tank with a stirrer, temperature and reflux condenser, and keep stirring at a temperature of 70°C After reacting for 12 hours, the product was washed with methanol and distilled water, dried to obtain carboxyl-containing polyurethane; 10 parts of carboxyl-containing polyurethane was added to 100 parts of concentrated sulfuric acid for sulfonation, and then washed with distilled water and dried. Obtain carboxyl group and sulfonic acid group-containing polyurethane; then put 10 parts of carboxyl group and sulfonic acid group-containing polyurethane, 15 parts of polyethersulfone and 75 parts of dimethylacetamide into the dissolving tank, and dissolve at 90°C for 8 hours under stirring. A polyethersulfone solution is obtained; after filtering, defoaming, and placing for "aging", a polyethersulfone spinning stock solution is obtained.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com