Antifouling and antibacterial coating paint and applications thereof

An antibacterial coating and coating technology, applied in the field of functional polymer materials, achieves the effect of lasting antifouling and antibacterial ability, considerable social and economic value, and good antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

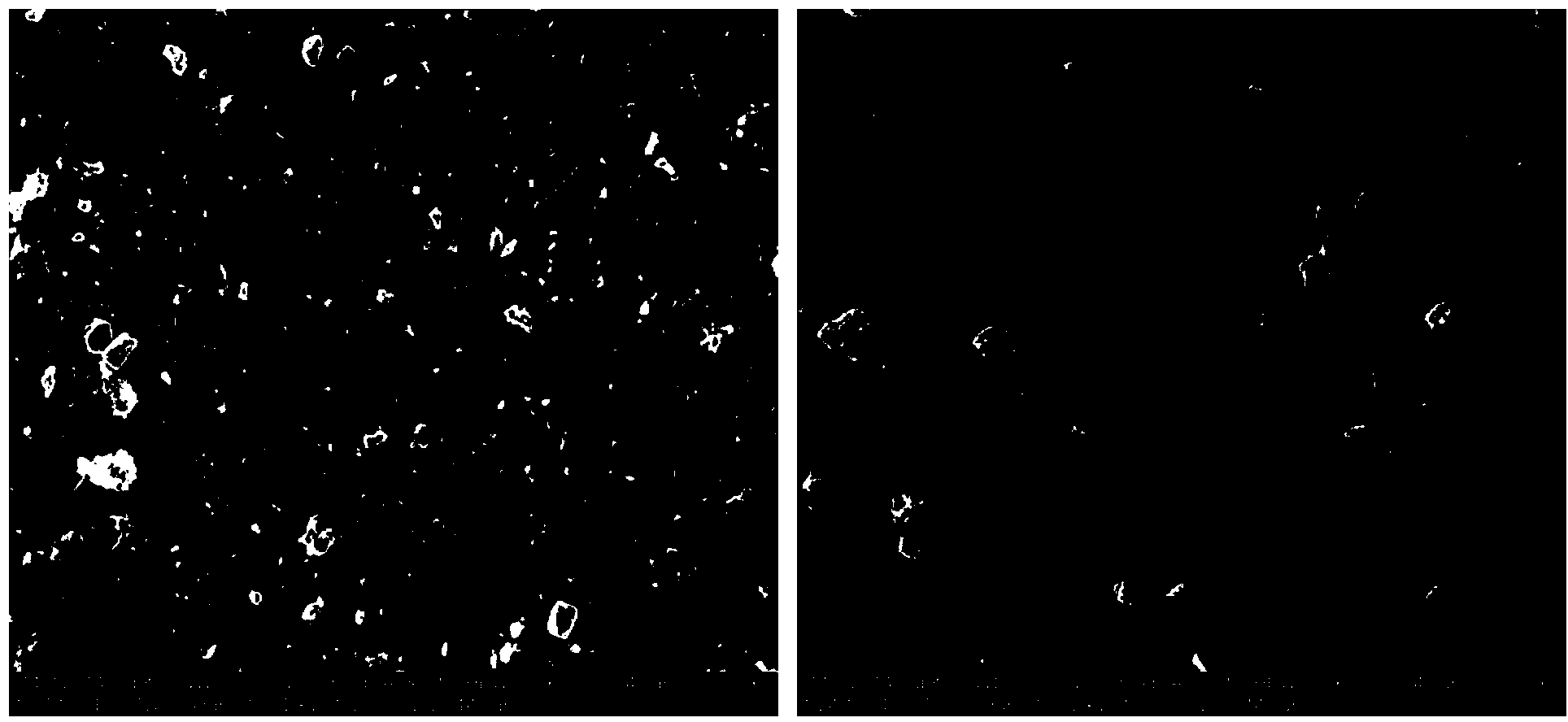

Image

Examples

Embodiment 1

[0022] 1) Take 1 g of methoxypolyethylene glycol-b-polyethyl methacrylate dimethylsulfopropyl betaine-b-polydimethylaminoethyl methacrylate and 0.5 ml of 3-chloropropyl tris Ethoxysilane, dissolved in 20mL of methanol, heated to reflux at 60°C for 48h under the protection of nitrogen, the obtained polymer solution is the antifouling and antibacterial coating.

[0023] 2) Application

[0024] The glass sheet was soaked in 30wt% hydrogen peroxide / 98wt% sulfuric acid mixture (v / v, 3:7) for 24 hours, washed with water and ethanol four times in sequence, and dried and activated at 100°C for 3 hours.

[0025] Immerse the activated glass piece in the polymer solution for 2 hours, take it out and let it dry naturally, that is to say, a polymer coating with antifouling and antibacterial properties is prepared.

Embodiment 2

[0027] 1) Take 0.8 g of methoxypolyethylene glycol-b-polyethyl methacrylate dimethylsulfopropyl betaine-b-polydimethylaminoethyl methacrylate and 0.5 ml of 3-chloropropyl tris Ethoxysilane, dissolved in 15mL of methanol, heated to reflux at 50°C for 36h under the protection of nitrogen, the obtained polymer solution is the antifouling and antibacterial coating.

[0028] 2) Application

[0029] The glass sheet was soaked in 30wt% hydrogen peroxide / 98wt% sulfuric acid mixture (v / v, 3:7) for 12 hours, rinsed with water and ethanol three times in sequence, and dried and activated at 100°C for 3 hours.

[0030] Immerse the activated glass piece in the polymer solution for 2 hours, take it out and let it dry naturally, that is to say, a polymer coating with antifouling and antibacterial properties is prepared.

Embodiment 3

[0032] 1) Take 0.8 g of methoxypolyethylene glycol-b-polyethyl methacrylate dimethylsulfopropyl betaine-b-polydimethylaminoethyl methacrylate and 0.5 ml of 3-chloropropyl tris Ethoxysilane, dissolved in 15mL of methanol, heated to reflux at 60°C for 36h under the protection of nitrogen, the obtained polymer solution is the antifouling and antibacterial coating.

[0033] 2) Application

[0034] Mix 30wt% hydrogen peroxide and 98wt% sulfuric acid in a volume ratio of 3:7 to prepare a mixed treatment solution;

[0035] Clean the surface with a mixed treatment solution according to the area to be coated; then rinse with water and ethanol for 3 times;

[0036] Dry and activate the washed glass sheet to be coated for 3 hours at a temperature of 80°C;

[0037] Brush the surface of the activated glass sheet and let it dry naturally to prepare a polymer coating with antifouling and antibacterial properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com