Settling method for long-acting washable natural antibacterial fabric

A natural antibacterial and fabric technology, applied in physical treatment, fiber treatment, textiles and papermaking, etc., can solve problems such as poor safety and chemical stability, increased manufacturing cost of antibacterial agents, unfavorable development of antibacterial finishing, etc., to improve tear strength And wash fastness, improve wash fastness, fabric antibacterial effect lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

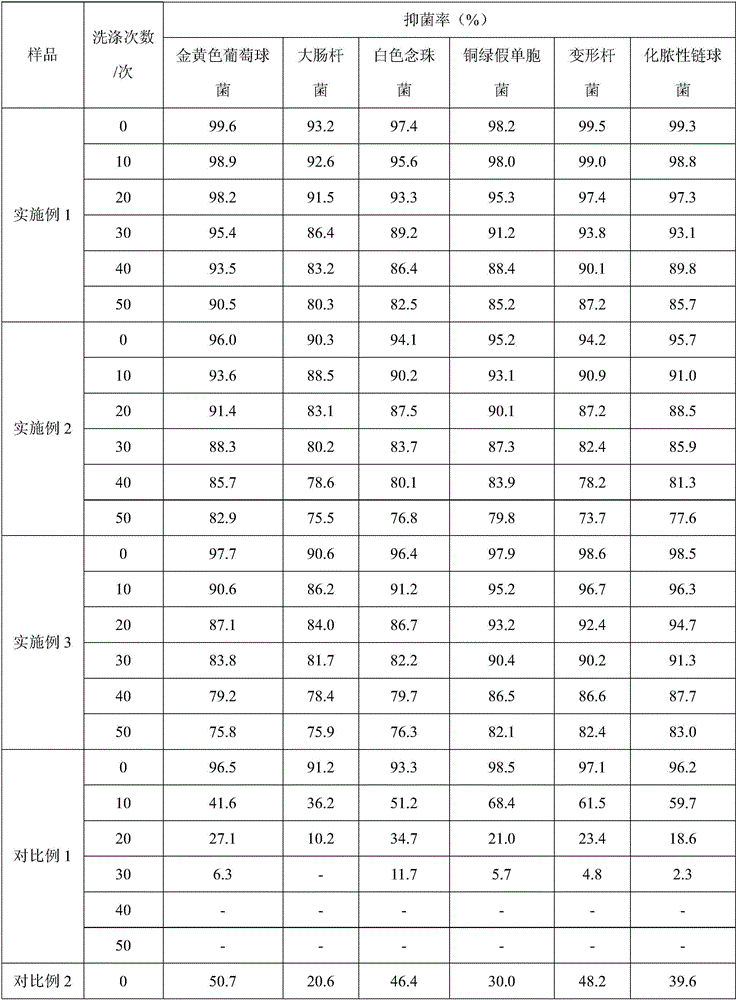

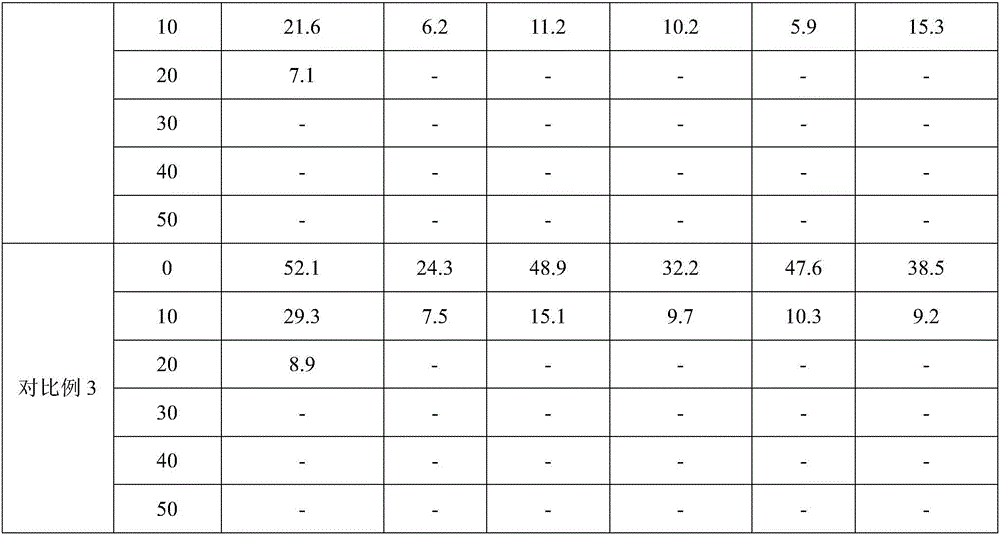

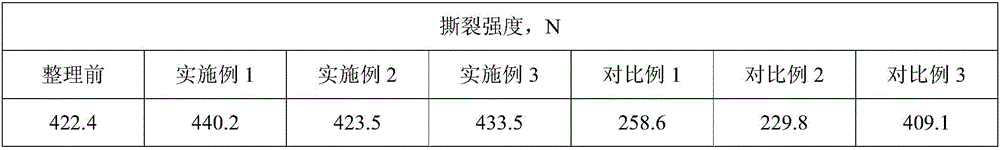

Examples

Embodiment 1

[0026] The present embodiment discloses the finishing method of natural antibacterial fabric, comprises the following steps:

[0027] (1) The fabric is dipped in a suspension containing 20g / L eucalyptus essential oil liposome in a bath ratio of 4:1, two dips and two rolls, the roll pressure is 0.2MPa, and the excess rate is 95%;

[0028] (2) Under the condition that the oxygen partial pressure is 0.75 atmospheric pressure, treat the fabric of step (1) with ultraviolet radiation; wherein, the ultraviolet wavelength range is 260nm, the irradiation time is 50s, and the ultraviolet irradiation intensity on the fabric surface is 90mW / cm 2 ;

[0029] (3) The fabric processed in step (2) is cross-linked with genipin, washed, and dried; wherein the concentration of genipin is 25g / L, the cross-linking reaction temperature is 90°C, and the reaction time is 1h; The washing temperature is 90°C, and the drying temperature is 120°C.

Embodiment 2

[0031] The present embodiment discloses the finishing method of natural antibacterial fabric, comprises the following steps:

[0032] (1) the fabric is 3:1 pad-rolled in the suspension containing 10g / L tea tree essential oil liposome by bath ratio, two dips and two rolls, the roll pressure is 0.1MPa, and the pass rate is 80%;

[0033] (2) Under the condition that the oxygen partial pressure is 0.5 atmospheric pressure, treat the fabric of step (1) with ultraviolet radiation; wherein, the ultraviolet wavelength range is 200nm, the irradiation time is 30s, and the ultraviolet irradiation intensity on the fabric surface is 80mW / cm 2 ;

[0034] (3) The fabric treated in step (2) is cross-linked with catechin, washed with water, and dried; wherein the concentration of catechin is 15g / L, the cross-linking reaction temperature is 80°C, and the reaction time is 0.5h ; The washing temperature is 80°C, and the drying temperature is 100°C.

Embodiment 3

[0036] The present embodiment discloses the finishing method of natural antibacterial fabric, comprises the following steps:

[0037] (1) Padding the fabric in a suspension containing 30g / L eucalyptus essential oil liposomes in a bath ratio of 5:1, two dipping and two rolling, the roll pressure is 0.25MPa, and the excess rate is 100%;

[0038] (2) Under the condition that the oxygen partial pressure is 0.8 atmospheric pressure, treat the fabric of step (1) with ultraviolet radiation; wherein, the ultraviolet wavelength range is 400nm, the irradiation time is 60s, and the ultraviolet irradiation intensity on the fabric surface is 100mW / cm 2 ;

[0039] (3) The fabric treated in step (2) is cross-linked with oleuropein, washed with water, and dried; wherein the concentration of oleuropein is 30 g / L, the cross-linking reaction temperature is 85° C., and the reaction time is 1 h; The washing temperature is 95°C, and the drying temperature is 110°C.

[0040] The invention disclose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com