Patents

Literature

35results about How to "With photocatalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollutant control device and control method for recycling of metal mine water resources

ActiveCN107892441AAchieve adsorptionAchieve filteringWaste water treatment from quariesWater treatment parameter controlConstructed wetlandFiltration

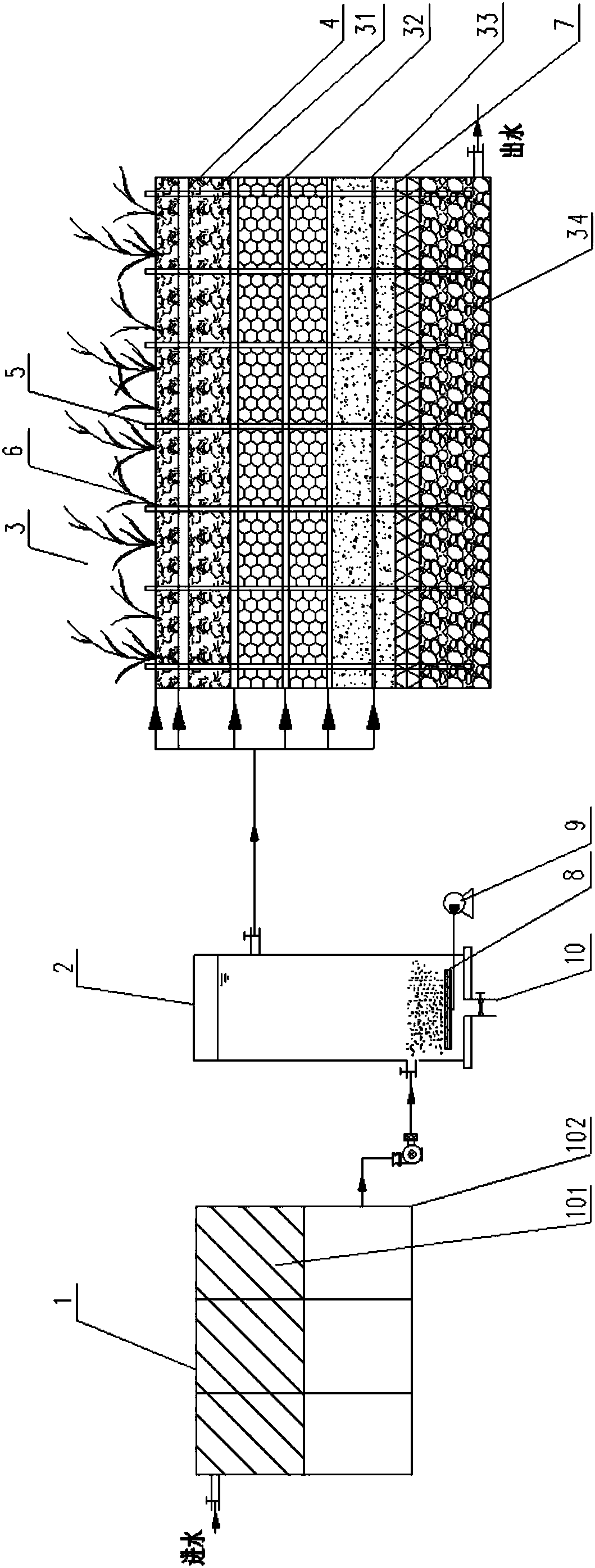

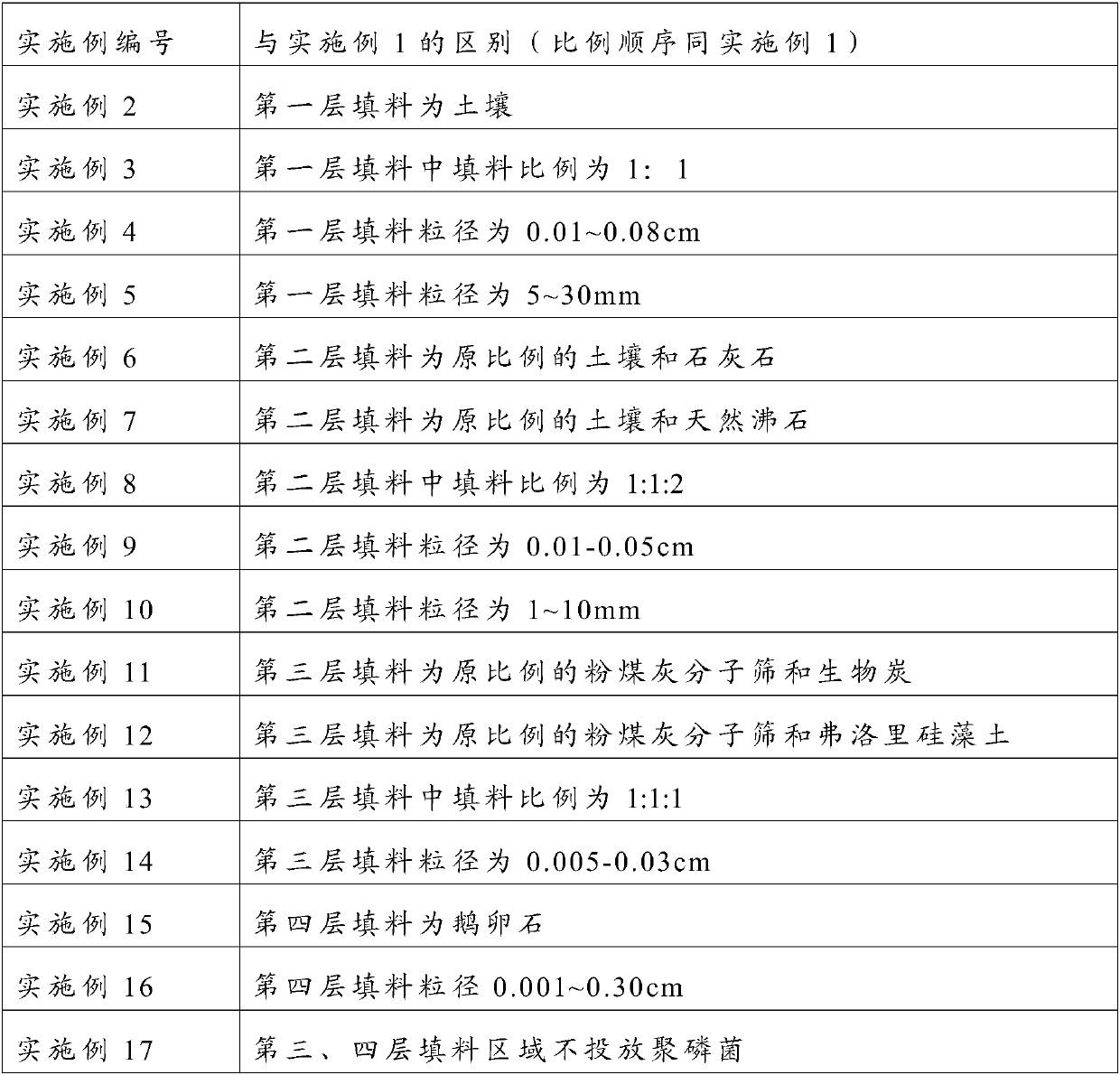

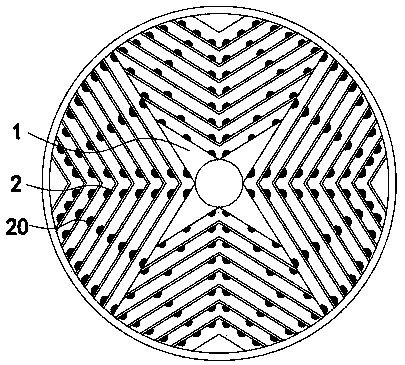

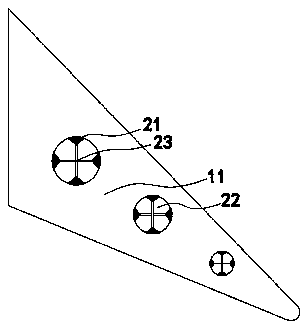

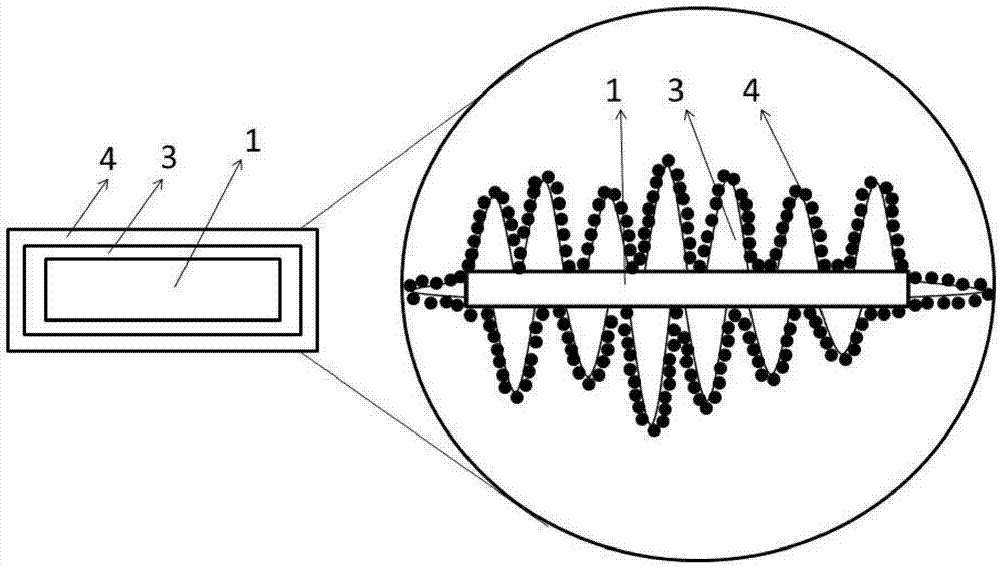

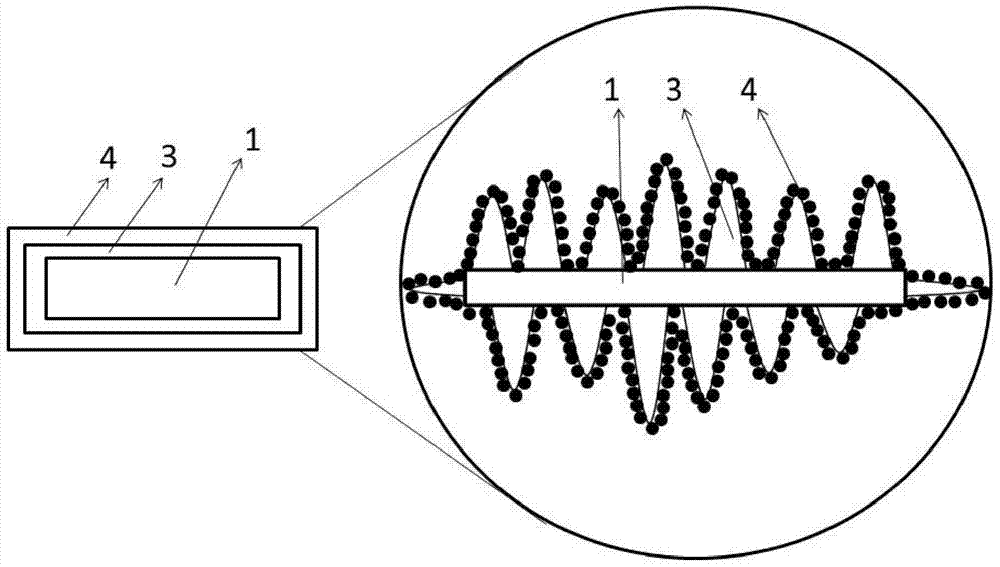

The invention discloses a pollutant control device and control method for the recycling of metal mine water resources. The device comprises a multi-stage water inlet constructed wetland (3), and one or more layers of fillers are spread in the multi-stage water inlet constructed wetland (3), water distribution pipes (4) are buried in the filler layers at different height levels for performing multi-stage water inflow, and pollutants are degraded or removed by making received basin water flow through each layer of the filler. In the multi-stage water inlet constructed wetland, the filler varieties, use amount ratio, particle sizes and filling heights in each layer of the filler are specially selected, so that the adsorption of heavy metals, the filtration of suspended matter, the degradationof organic matter, dephosphorization and denitrification in the multi-stage water inlet constructed wetland can be effectively realized, the accumulation of the heavy metals is effectively preventedfrom harming human health, the good conditions of farmland is maintained, and the sustainable and healthy development of agriculture is promoted.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

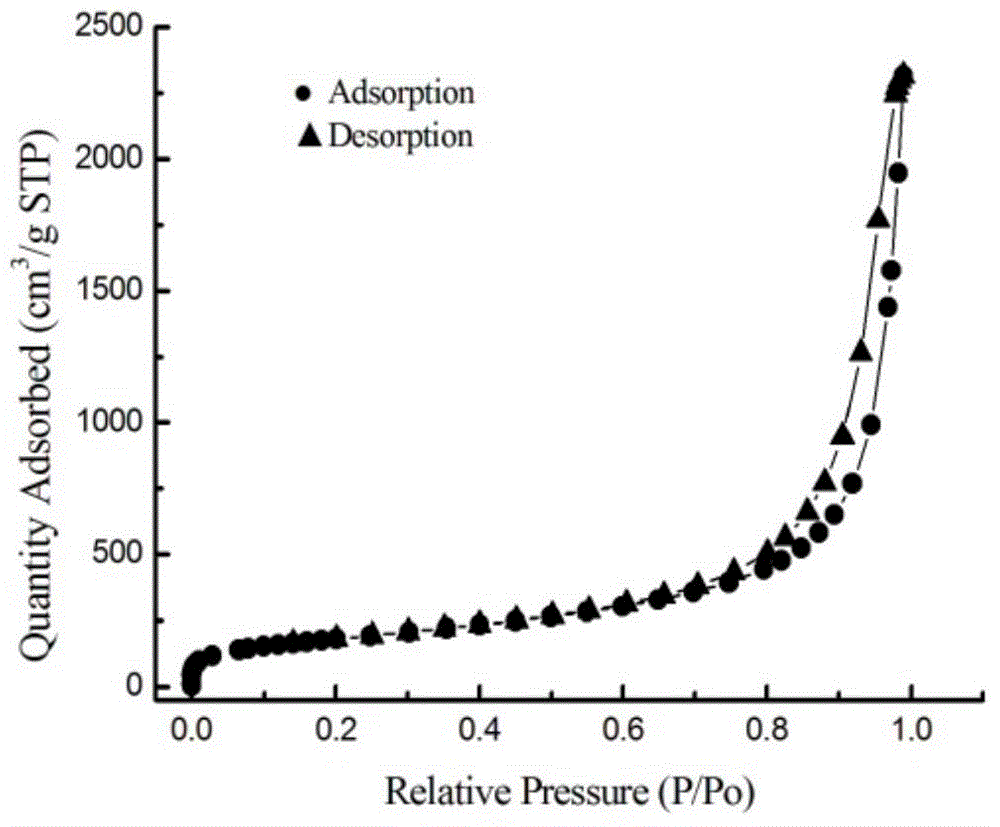

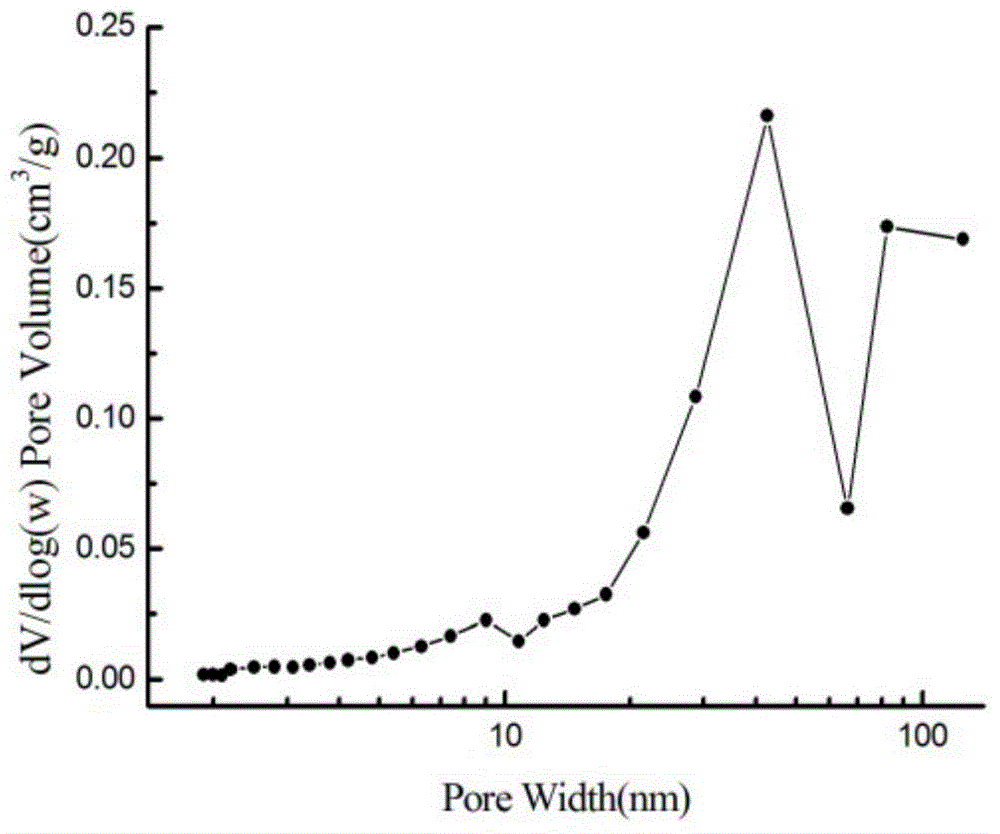

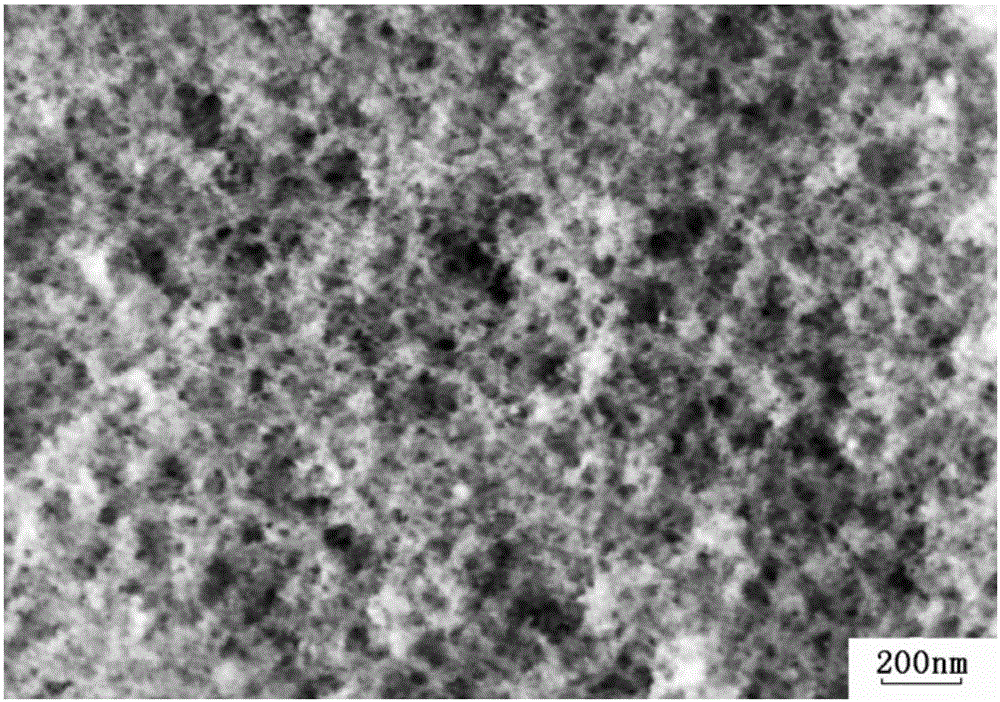

TiO2 nanotube/SiO2 aerogel composite photocatalytic material and preparing method thereof

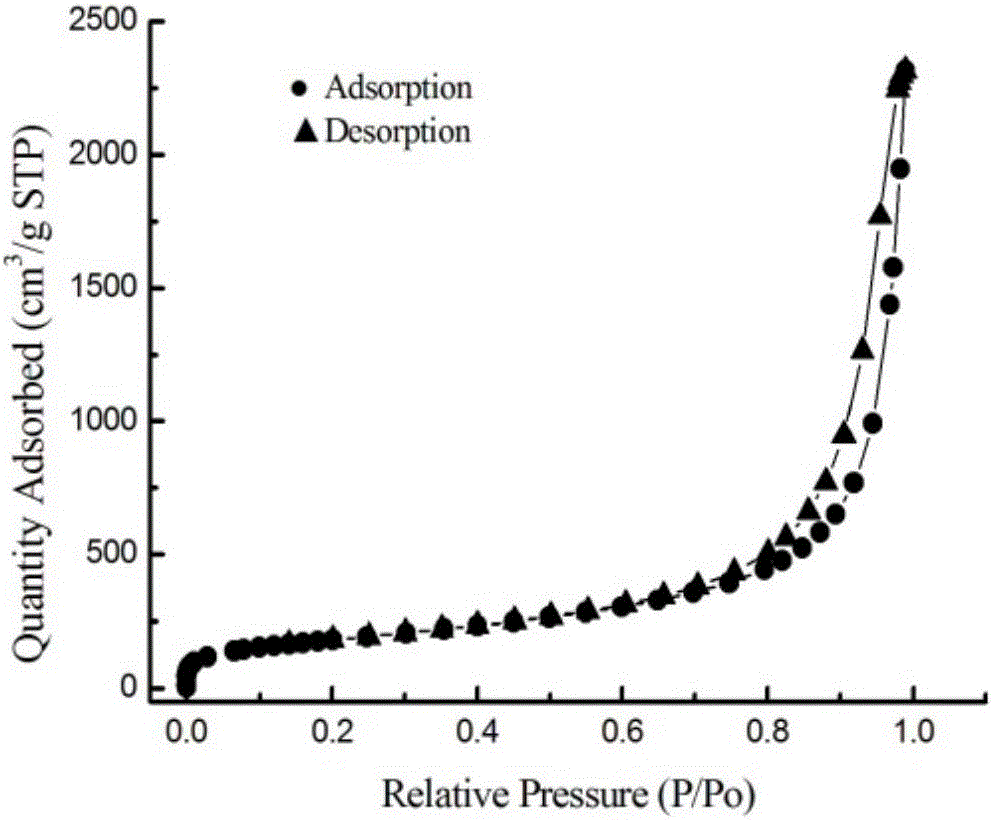

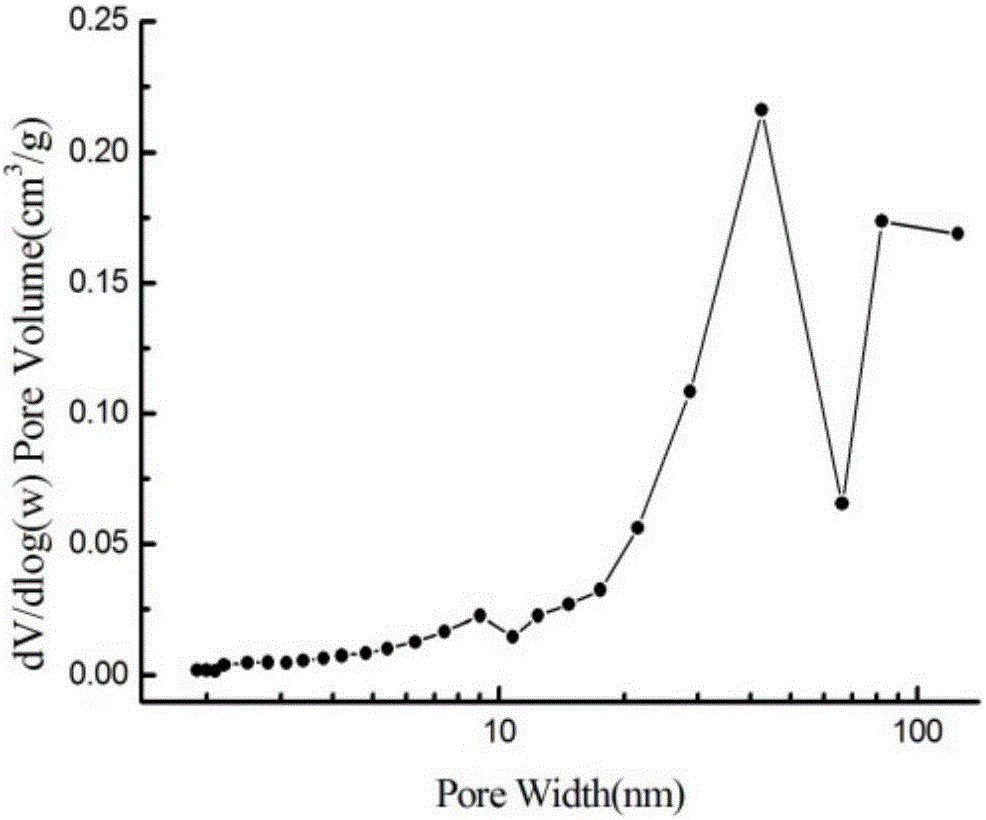

InactiveCN104874385ALarge specific surface areaHigh porosityPhysical/chemical process catalystsColloidal chemistry detailsNano catalystTio2 nanotube

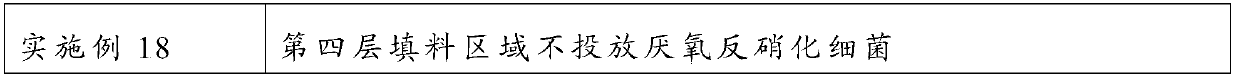

Disclosed are TiO2 nanotube / SiO2 aerogel composite photocatalytic material and a preparing method thereof. The preparing method includes: preparing TiO2 nanotubes by means of hydrothermal synthesis, preparing gel by means of a sol-gel method using the TiO2 nanotubes as a discrete phase base and SiO2 aerogel as a continuous phase base, and subjecting the gel to ageing and modifying to obtain the material. By the use of the hydrothermal method with the sol-gel method, the material prepared has the shape of the titanium nanotubes well retained; the equipment for use is simple and is safe to operate; the material is of a porous structure, and the excellent surface physical-chemical characteristics of the porous structure help partly improve the catalytic activity of the material; by using the SiO2 aerogel as a carrier, the loading problem of nano-catalyst is solved; the material is easy to recover, reusable, environment friendly and high in performance.

Owner:CHANGAN UNIV

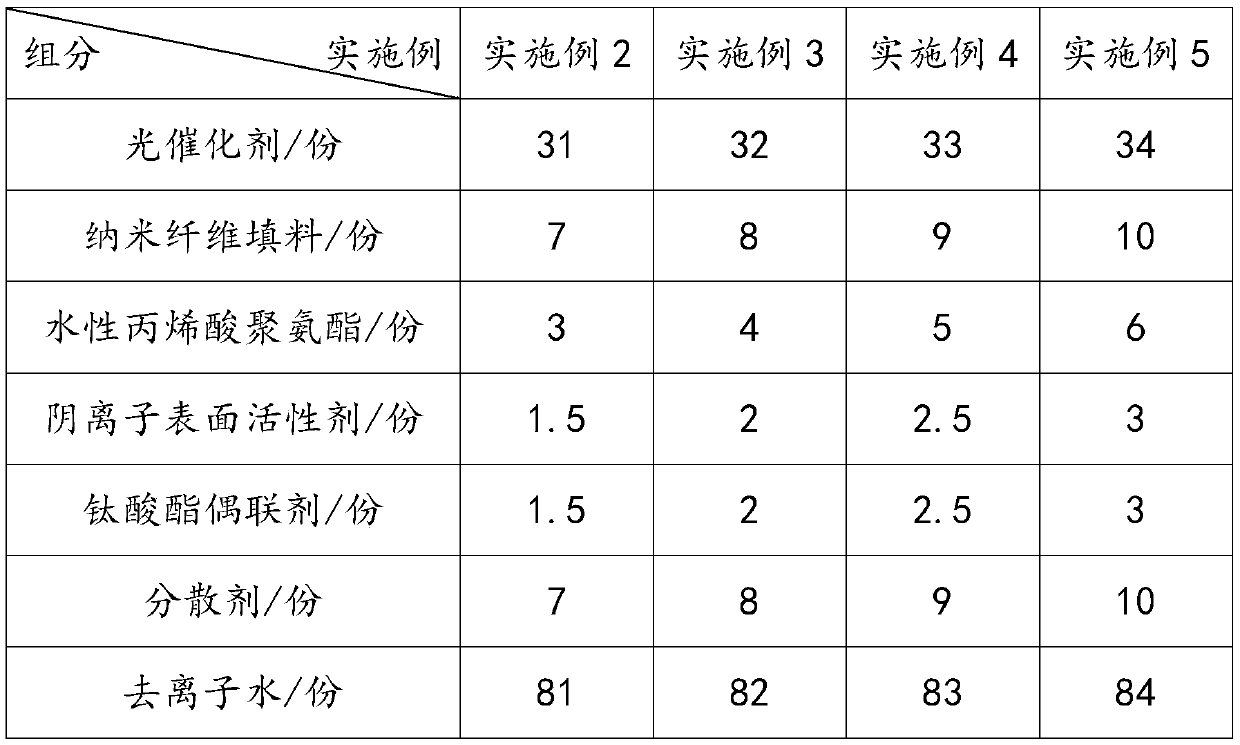

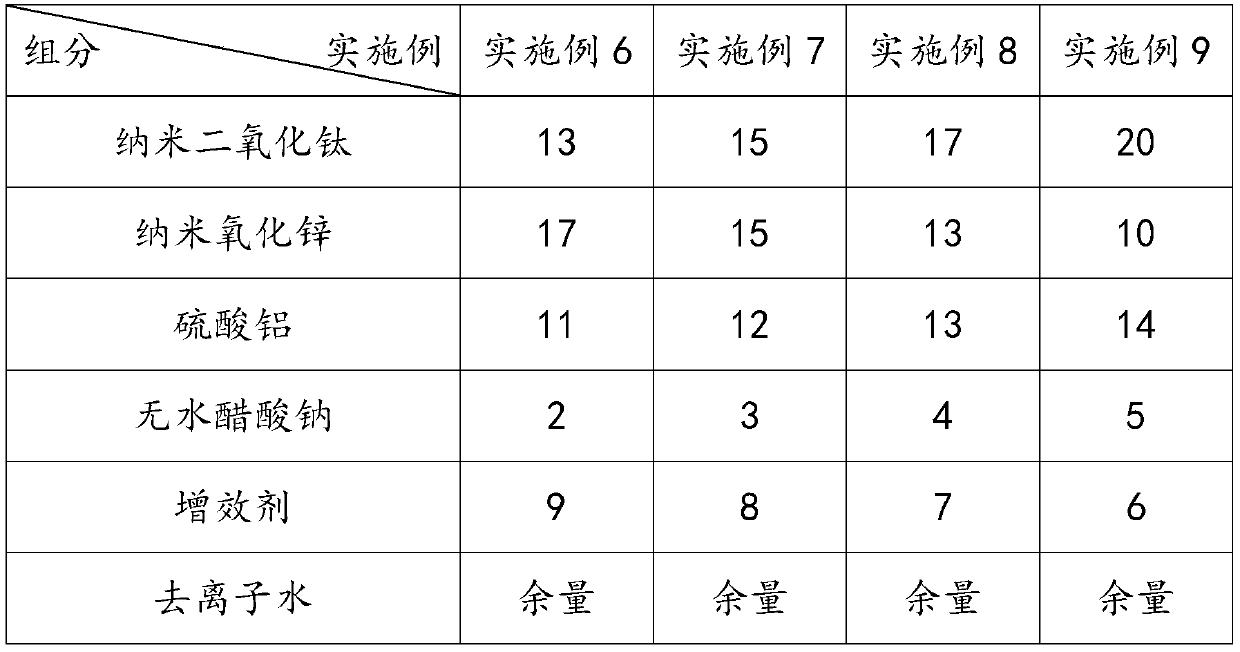

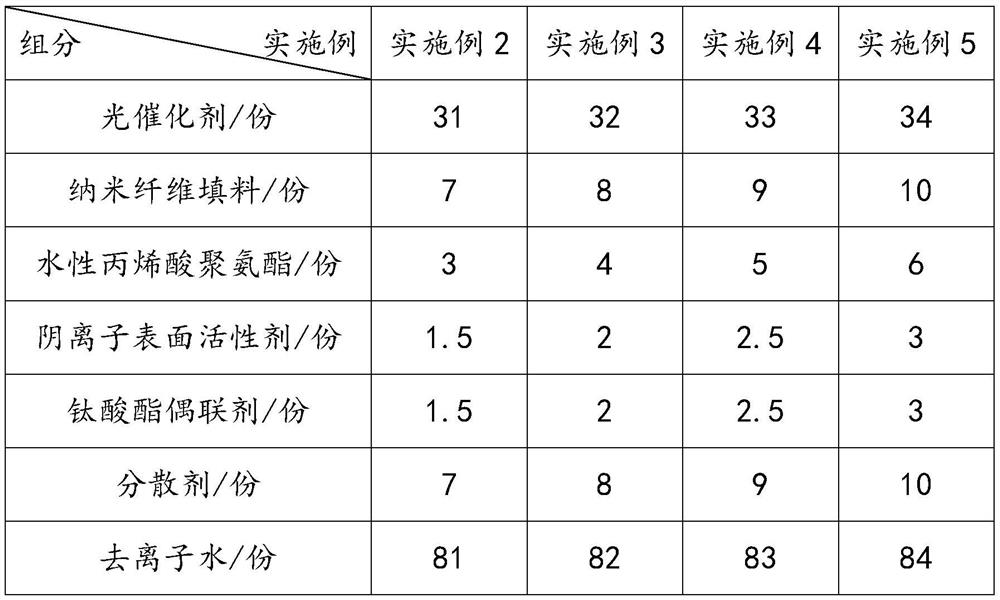

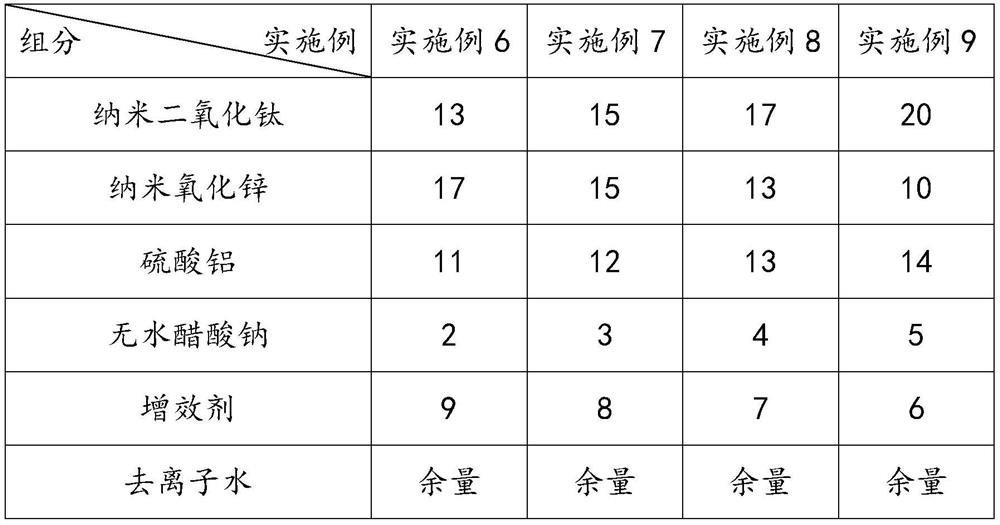

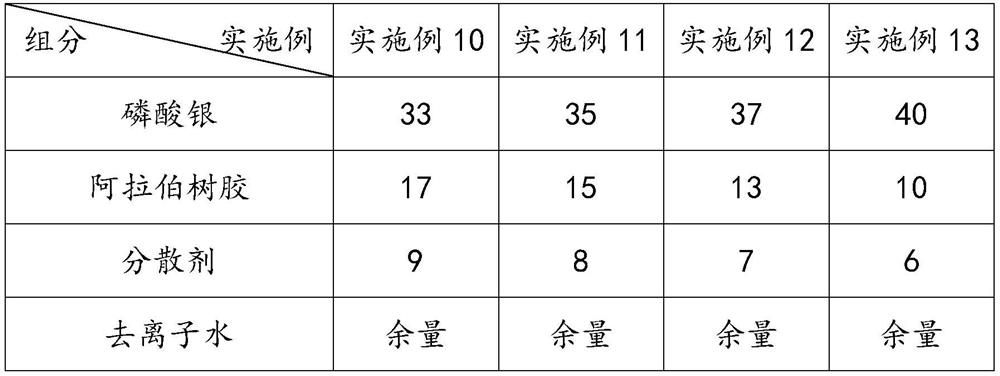

Formaldehyde removal liquid added with biological enzyme aid, and preparation method thereof

ActiveCN110743357AGood dispersionImprove purification efficiencyGas treatmentDispersed particle separationAluminium saltsActive agent

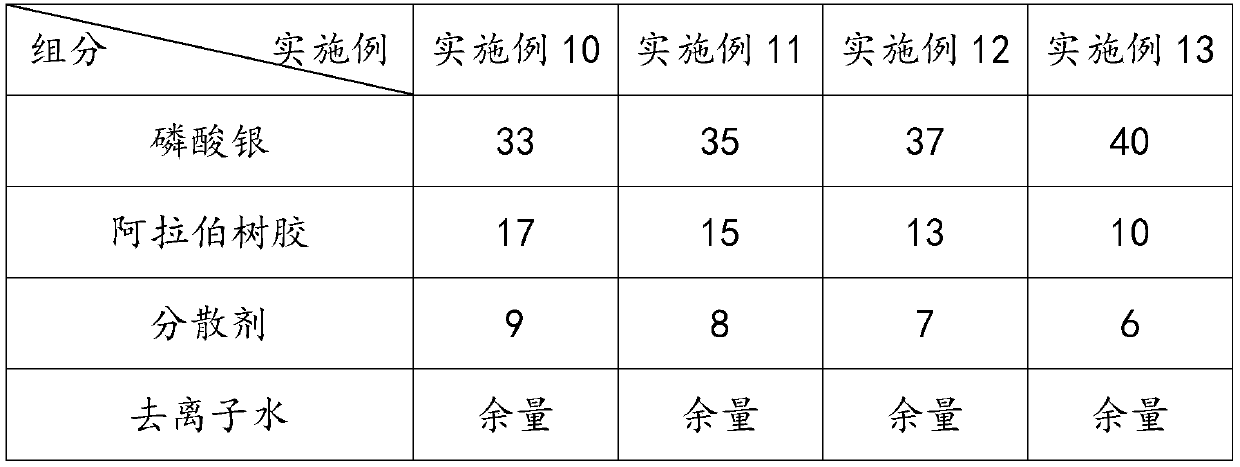

The invention relates to a formaldehyde removal liquid added with a biological enzyme aid, and a preparation method thereof, and relates to the technical field of air purification, wherein the formaldehyde removal liquid comprises a photocatalyst, the photocatalyst comprises the following raw materials by weight: 30-34 parts of a photocatalysis agent, 6-10 parts of a nanometer fiber filler, 2-6 parts of aqueous acrylic polyurethane, 1-3 parts of an anionic surfactant, 1-3 parts of a titanate coupling agent, 6-10 parts of a dispersing agent and 80-84 parts of deionized water, and the photocatalysis agent comprises the following raw materials by weight: 10-20% of nanometer titanium dioxide, 10-20% of nanometer zinc oxide, 10-14% of aluminum sulfate, 1-5% of anhydrous sodium acetate, 6-10% ofa synergist and the balance of deionized water. According to the invention, by modifying the nanometer titanium dioxide and the nanometer zinc oxide, the dispersity of the nanometer titanium dioxideand the nanometer zinc oxide is improved, so that the formaldehyde purification efficiency and the formaldehyde purification effect of the photocatalyst are improved.

Owner:浙江蓝民环保科技有限公司

Antibacterial protective environment-friendly composite polymer material and preparation method and application thereof

InactiveCN111286121AWith photocatalytic effectStrong antibacterial activityMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberMethyl carbonate

The invention discloses an antibacterial protective environment-friendly composite polymer material and a preparation method and application thereof, wherein the composite polymer material comprises the following components by weight: 20 parts to 30 parts of benzyl quaternary ammonium salt, 50 parts to 75 parts of a biocompatible high-molecular polymer, 15 parts to 30 parts of modified nano metaloxide, 10 parts to 20 parts of nano metal particles, 30 parts to 40 parts of modified fiber, 25 parts to 45 parts of trisilanol ethyl ester silsesquioxane, 5 parts to 10 parts of a silane coupling agent, 3 parts to 5 parts of ammonium persulfate, 3 parts to 5 parts of dimethyl carbonate, 8 parts to 15 parts of 3-mercaptopropyl trimethoxy silane, and 2 parts to 3 parts of allyl glycidyl ether. Thematerial is capable of blocking and self-cleaning apatter or air with viruses, bacteria or microorganisms, is antibacterial, capable of killing viruses, capable of being repeatedly used, good in shrinkage resistance, high in elastic property and easy to degrade, and can be used for manufacturing window cloth, air conditioners, air purifiers, screen windows, clothes, trousers and masks.

Owner:上海古太创意服务有限公司

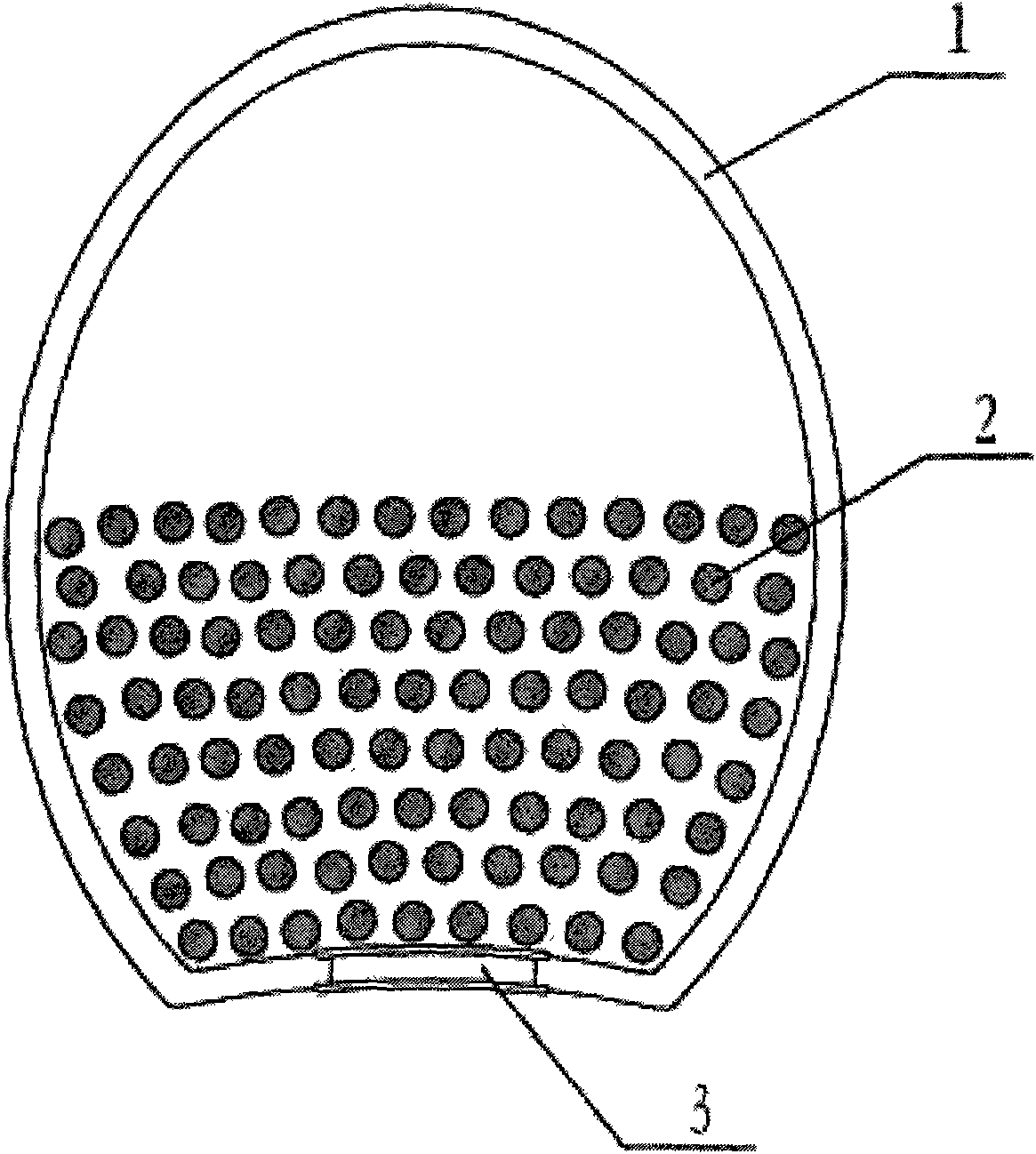

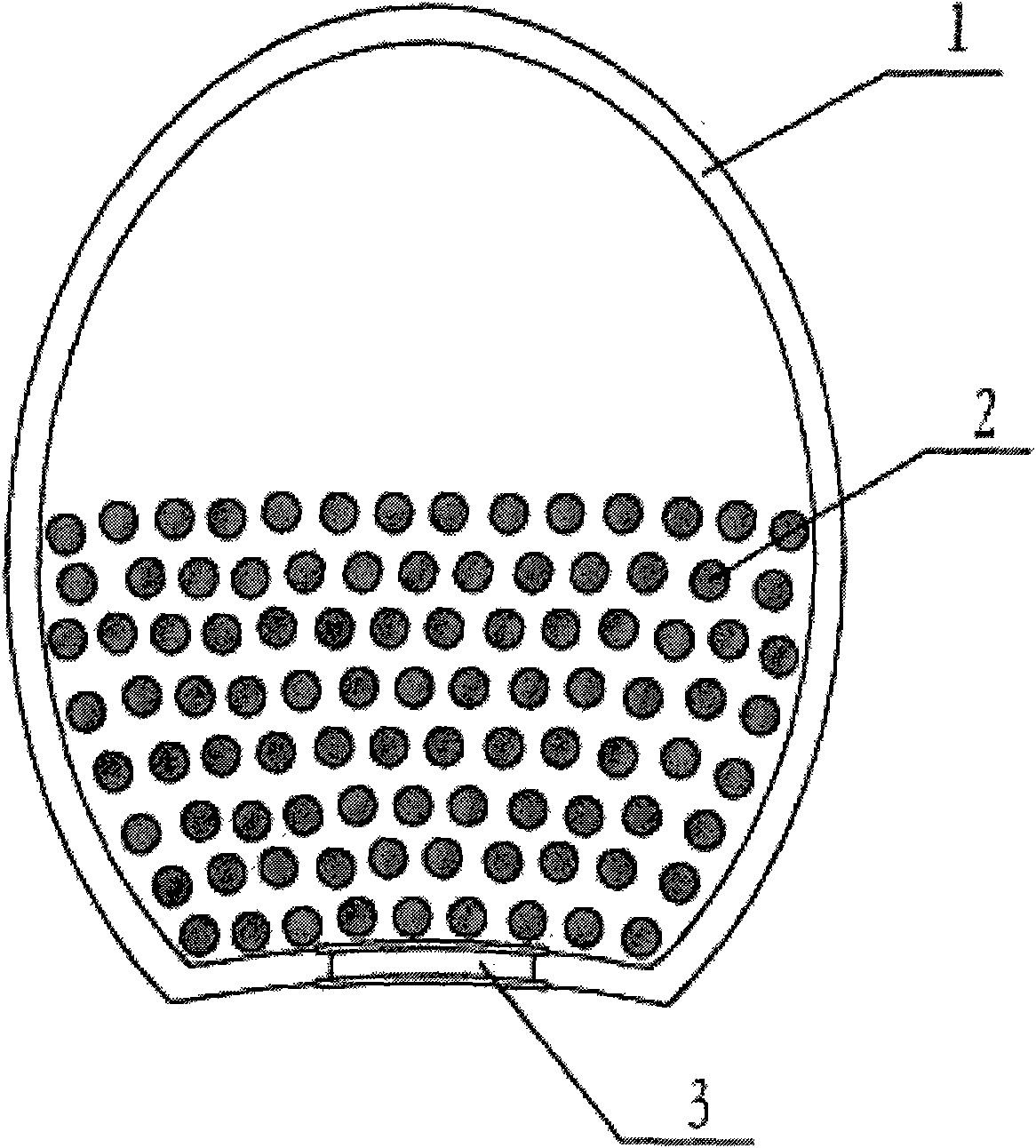

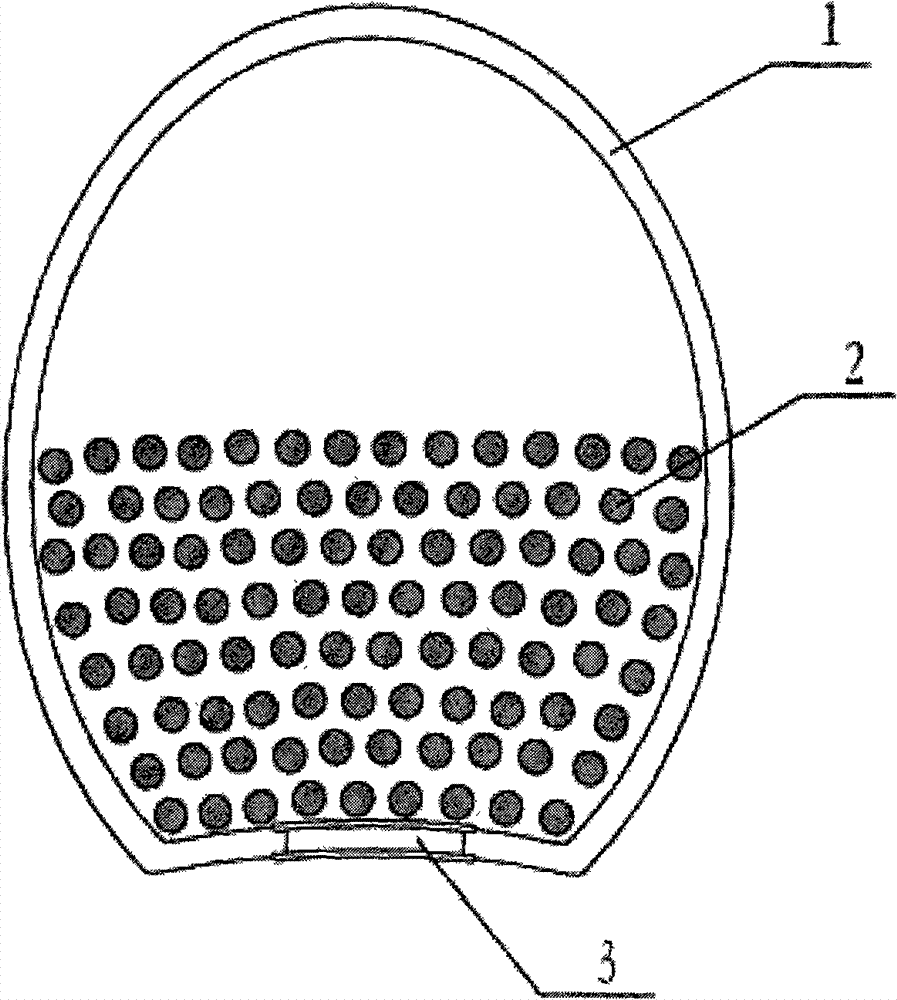

Wide waveband photocatalyst air cleaner

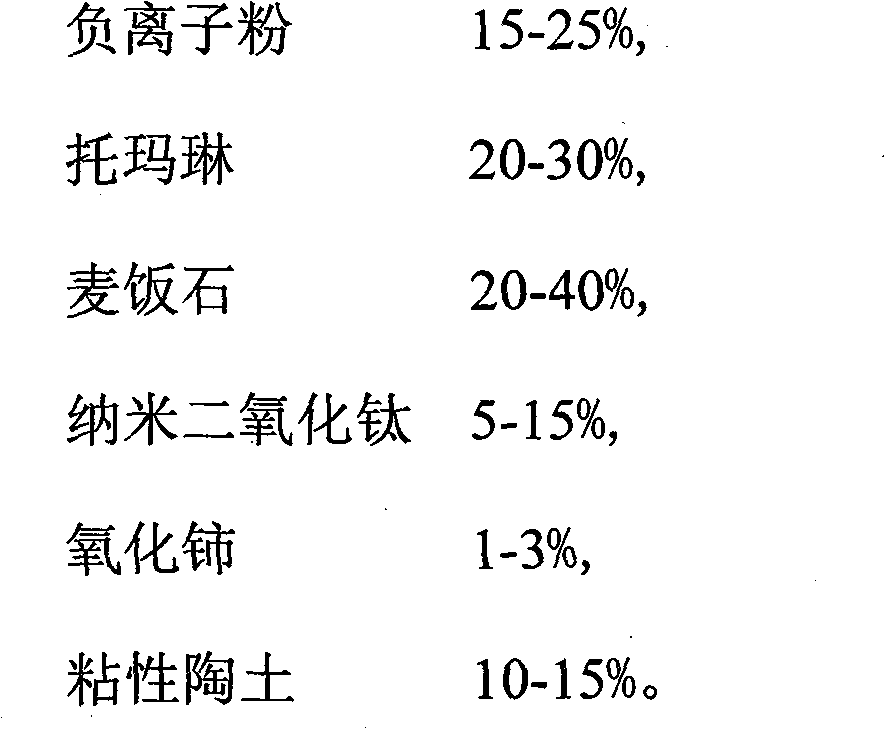

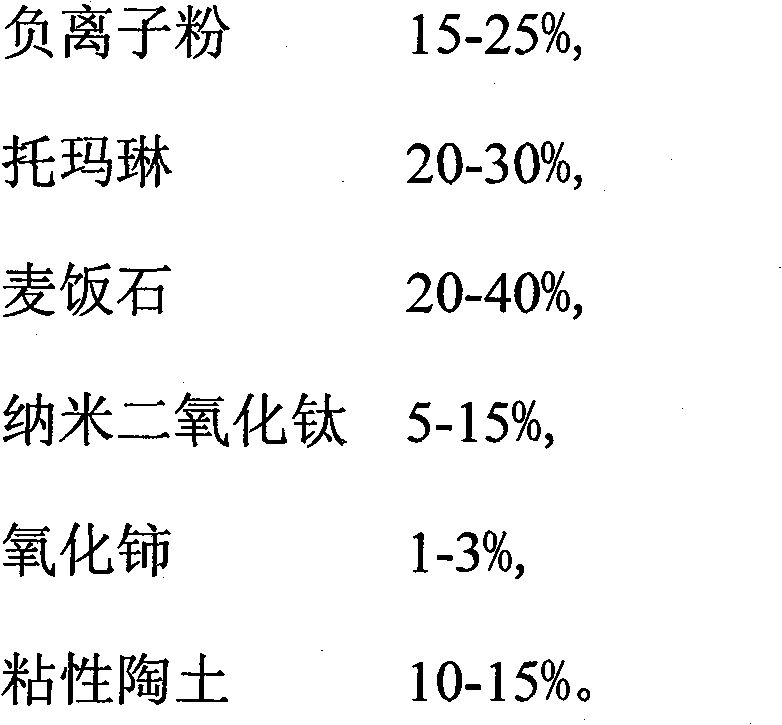

ActiveCN101862467AWith photocatalytic effectImprove photocatalytic efficiencyDispersed particle separationDeodrantsProduction rateDolomite

The invention discloses a wide waveband photocatalyst air cleaner, which comprises a container, wherein compound photocatalyst particles are arranged in the container. The container is prepared by sintering anion power, dolomite and pore-forming agent. The compound photocatalyst particles are prepared by sintering the anion power, tourmaline, maifanitum, nanometer titanium dioxide, cerous oxide and viscous pottery clay. The invention has the following great advantages: 1, the production rate of anions is high; and 2, no additional power supply is needed, and natural light can penetrate through a container wall and an air hole on the container wall to exchange with the surfaces of the compound photocatalyst particles so as to realize the purpose of purifying air, thereby bringing greatly convenience for use. The air cleaner in the invention can be arranged on desks, bedside tables and windows as well as in automobile and the like. The container can be made into various ornaments, such as egg-shaped, vase-shaped, animal-shaped, cartoon-shaped ornaments and the like, and has beautiful appearance and practical use.

Owner:SHANGHAI ZHENAO BIOTECH +1

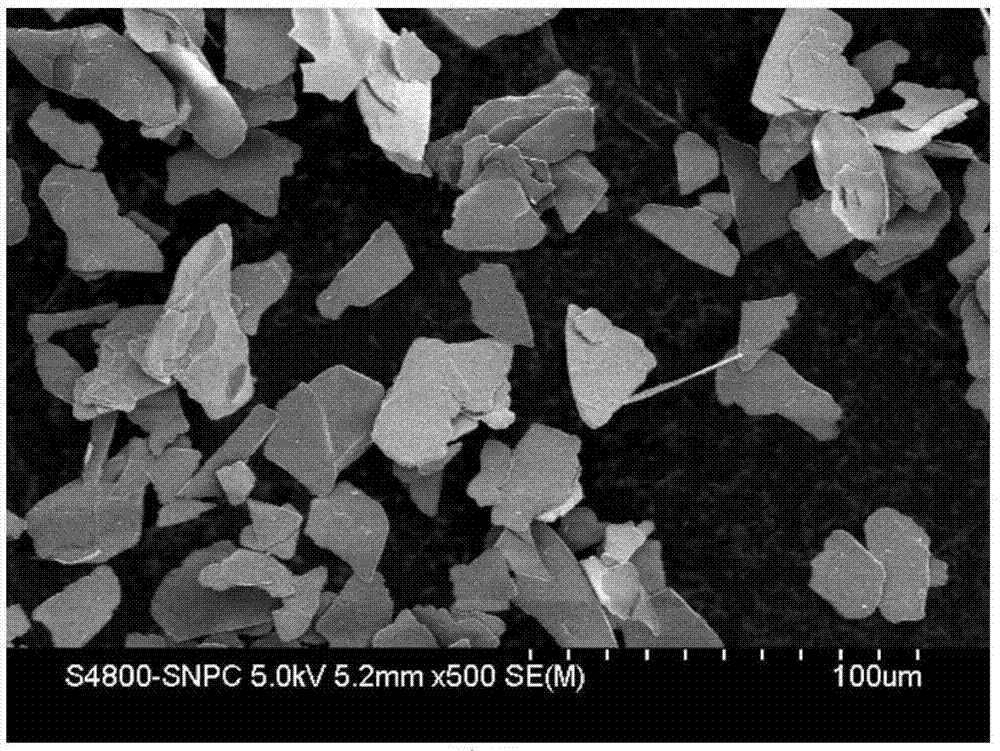

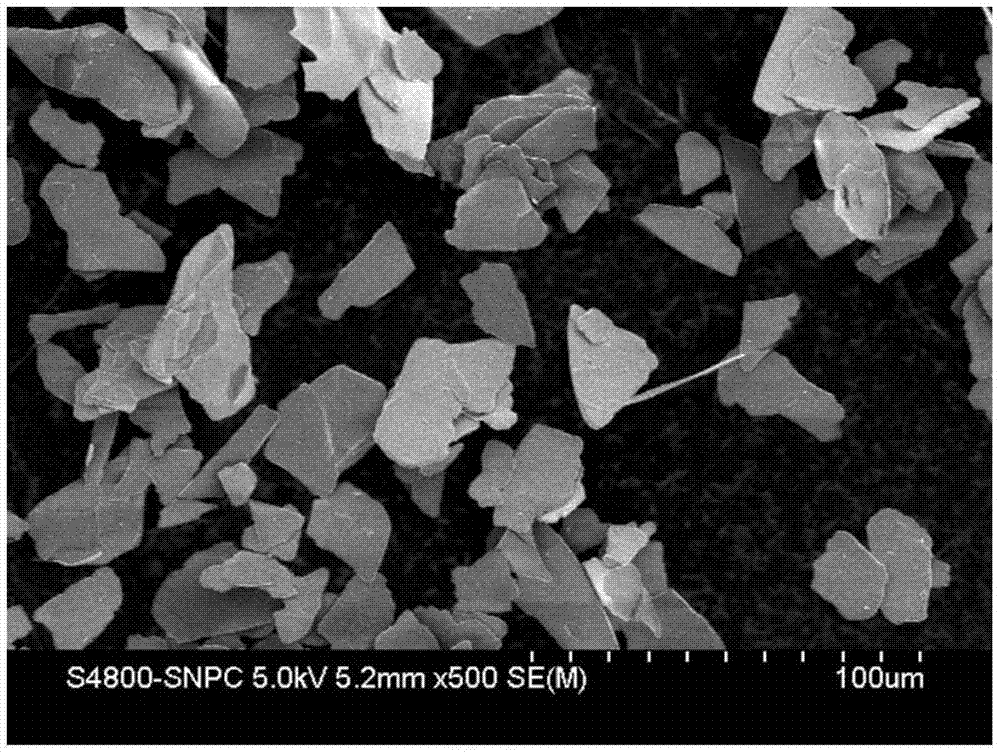

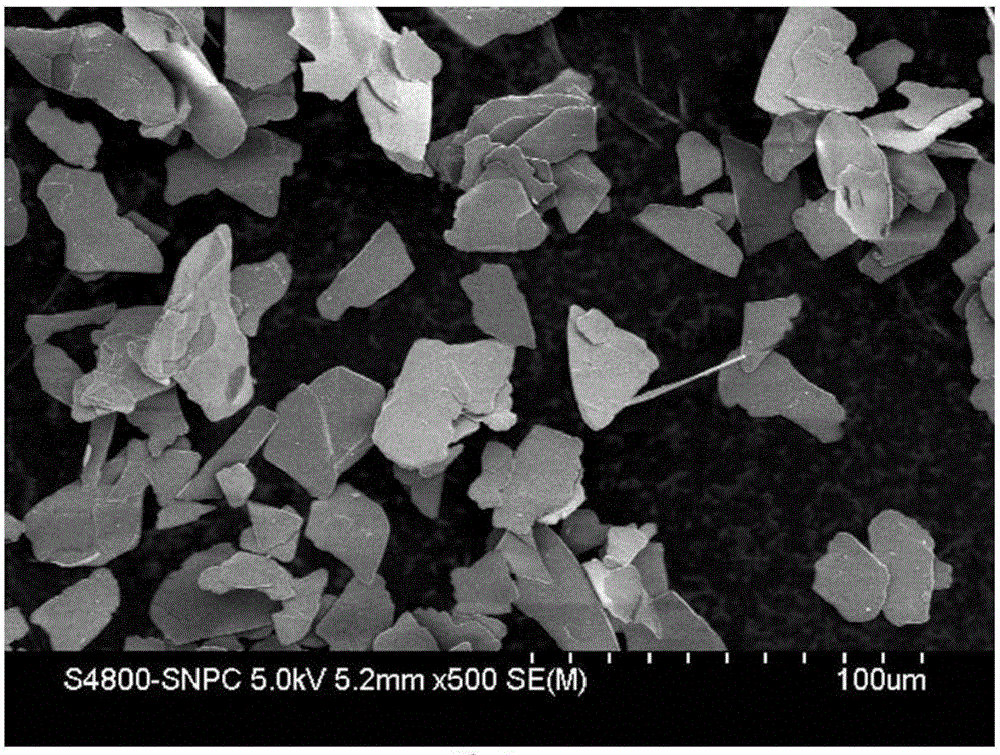

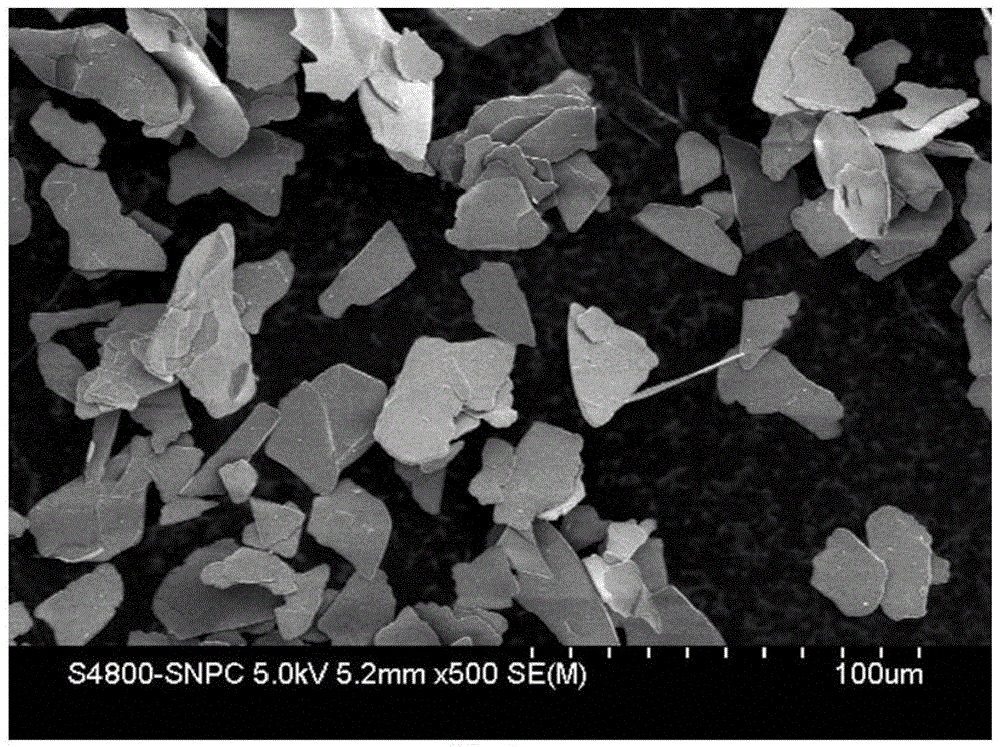

Metal coated pearlescent pigment

The invention discloses a metal coated pearlescent pigment. The pearlescent pigment is characterized by comprising a flaky substrate and a plurality of titanium dioxide nanorods which are arranged at intervals and are formed on the flaky substrate, so that a nano-structured surface with roughness can be formed by the titanium dioxide nanorods of the pearlescent pigment, and then, a plurality of metal particles are deposited on each titanium dioxide nanorod and the flaky substrate respectively.

Owner:浙江瑞成新材料股份有限公司

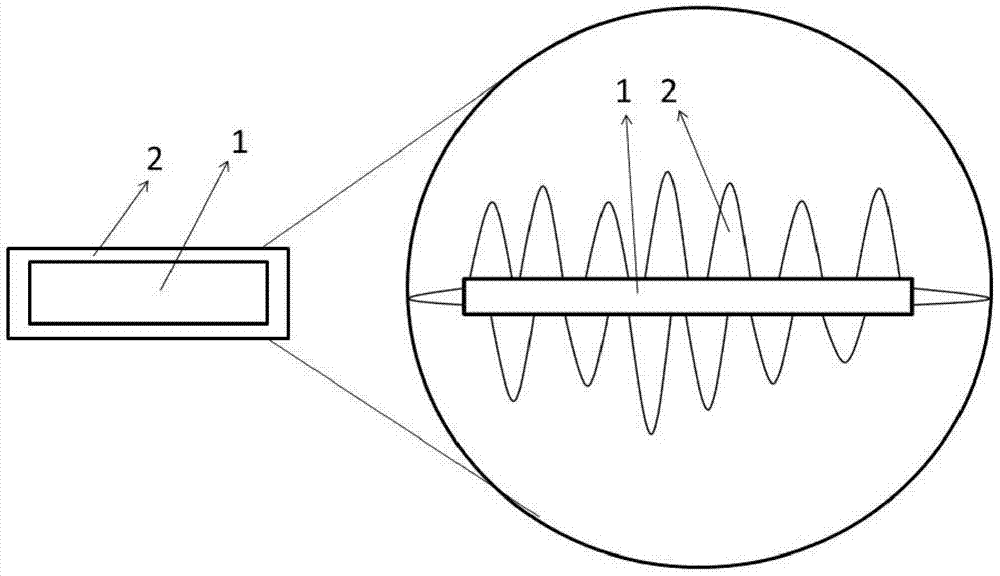

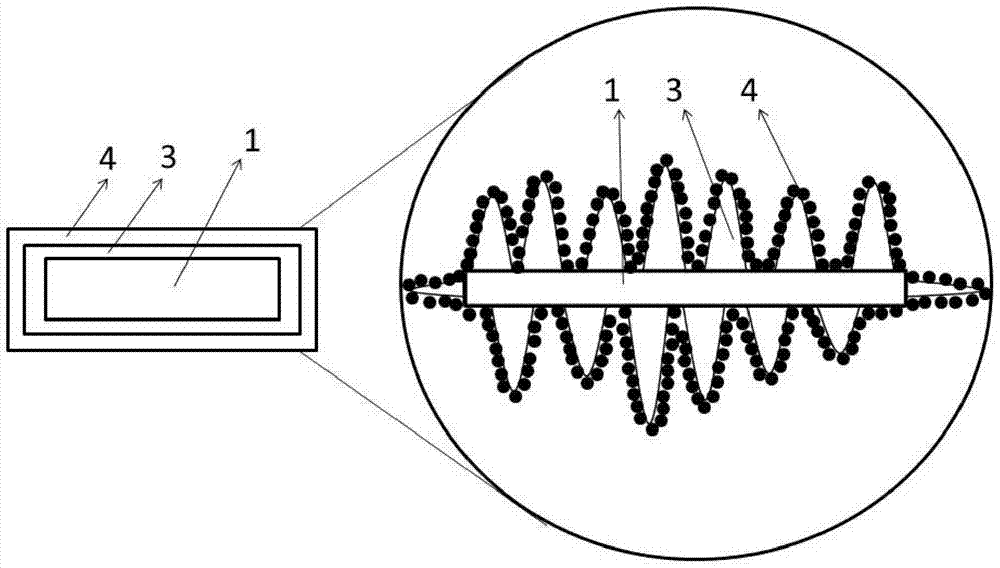

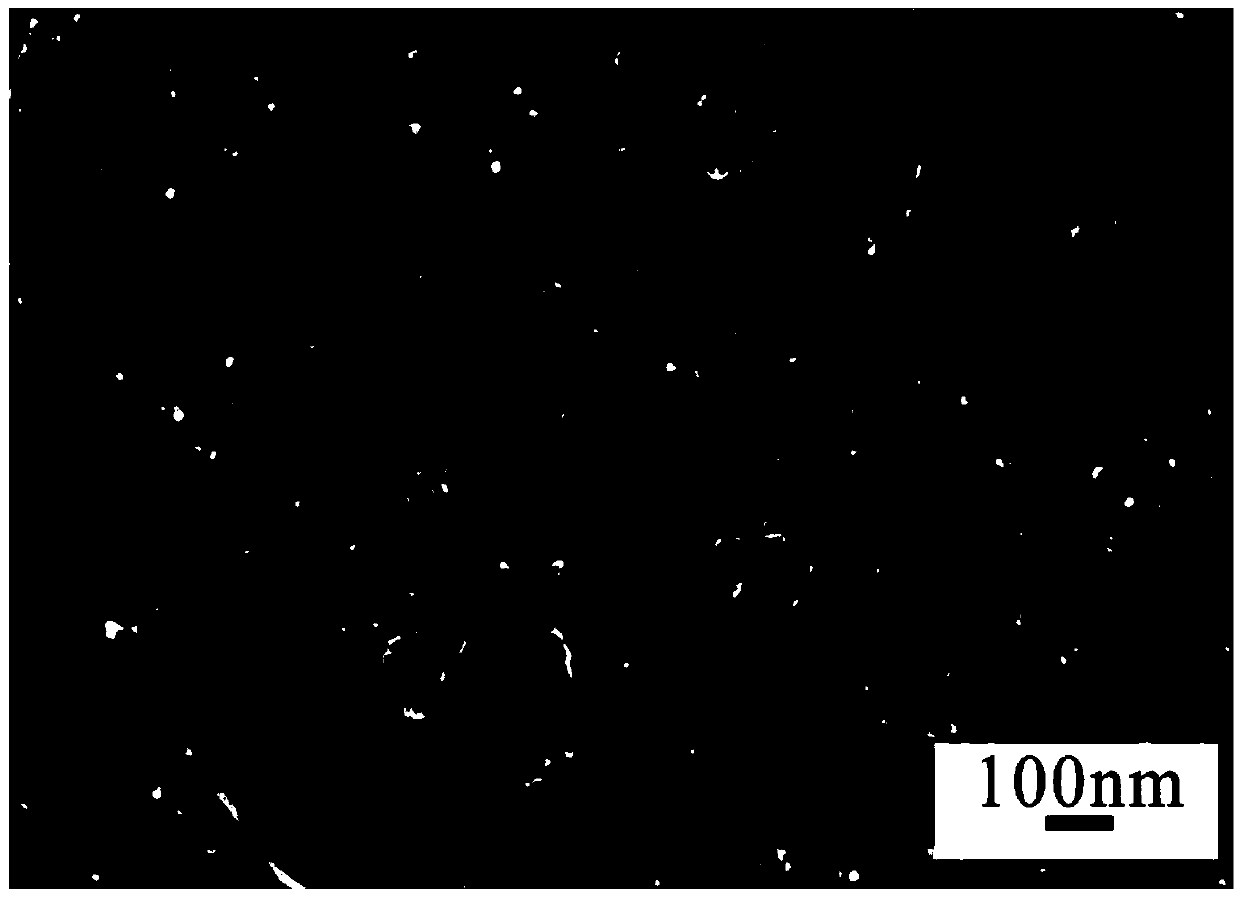

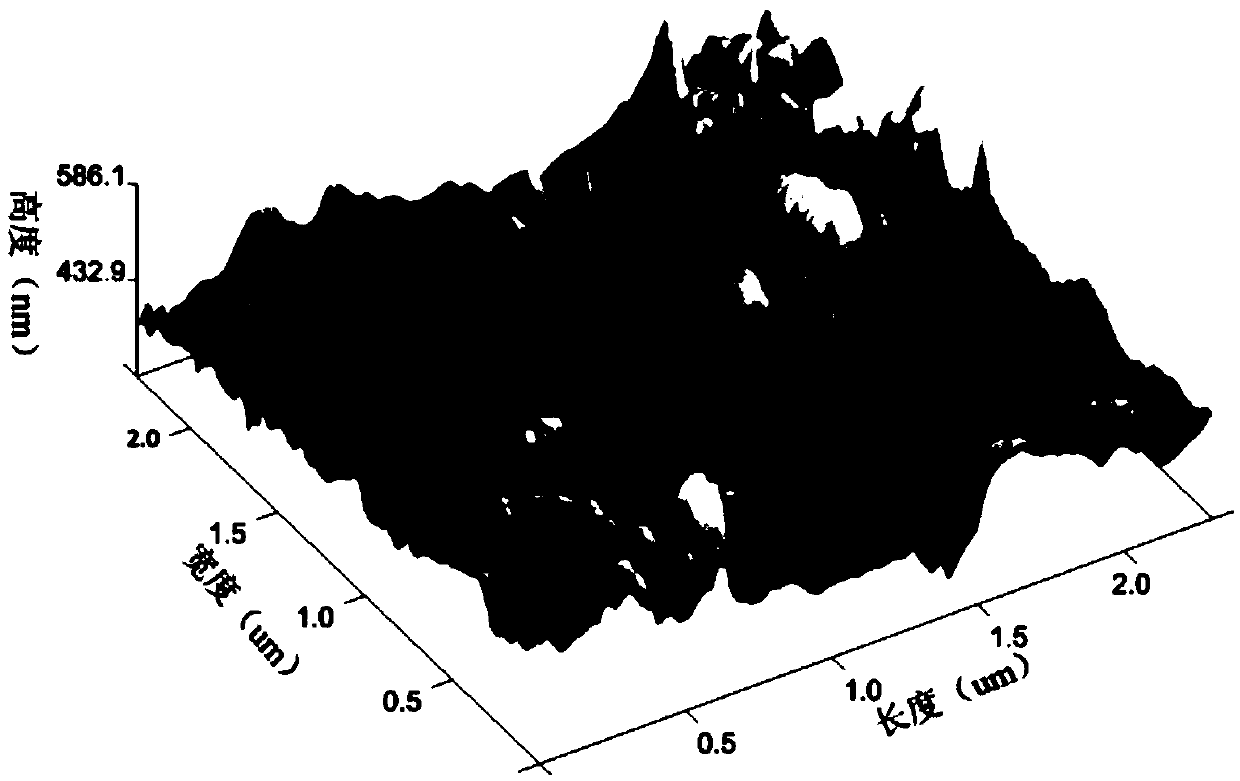

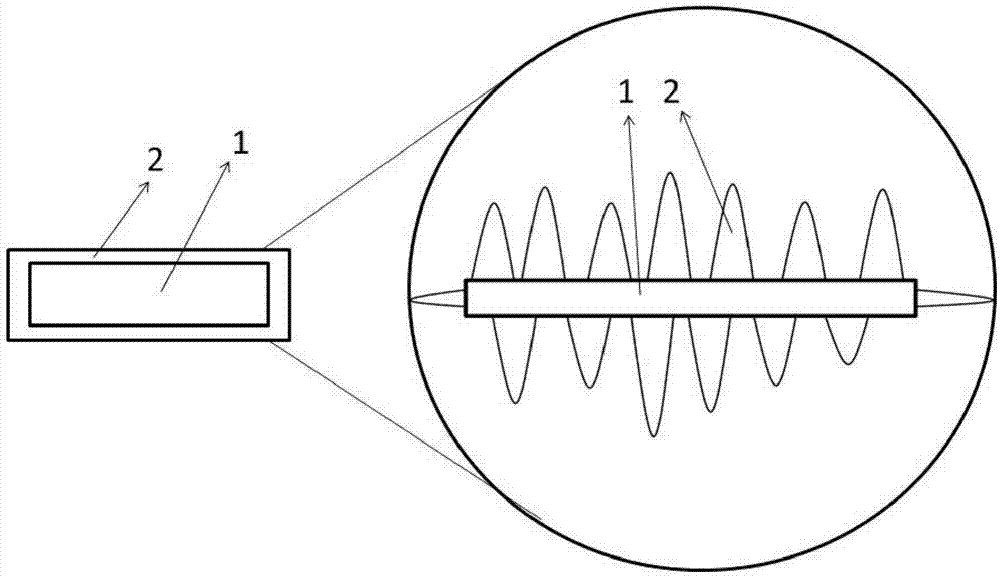

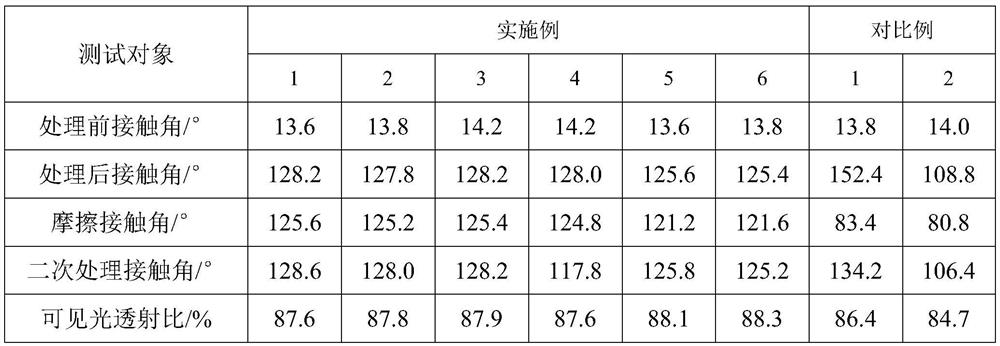

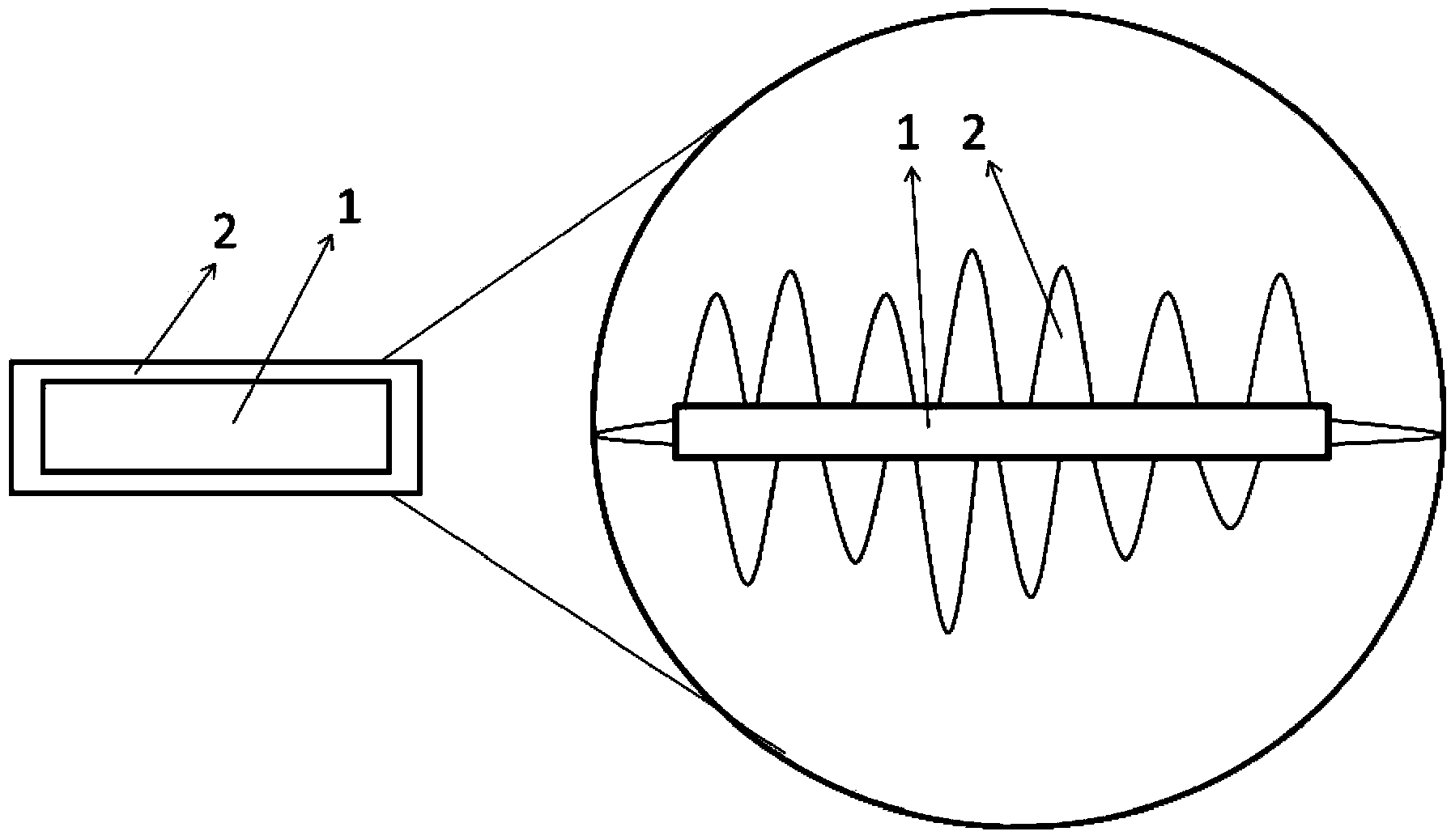

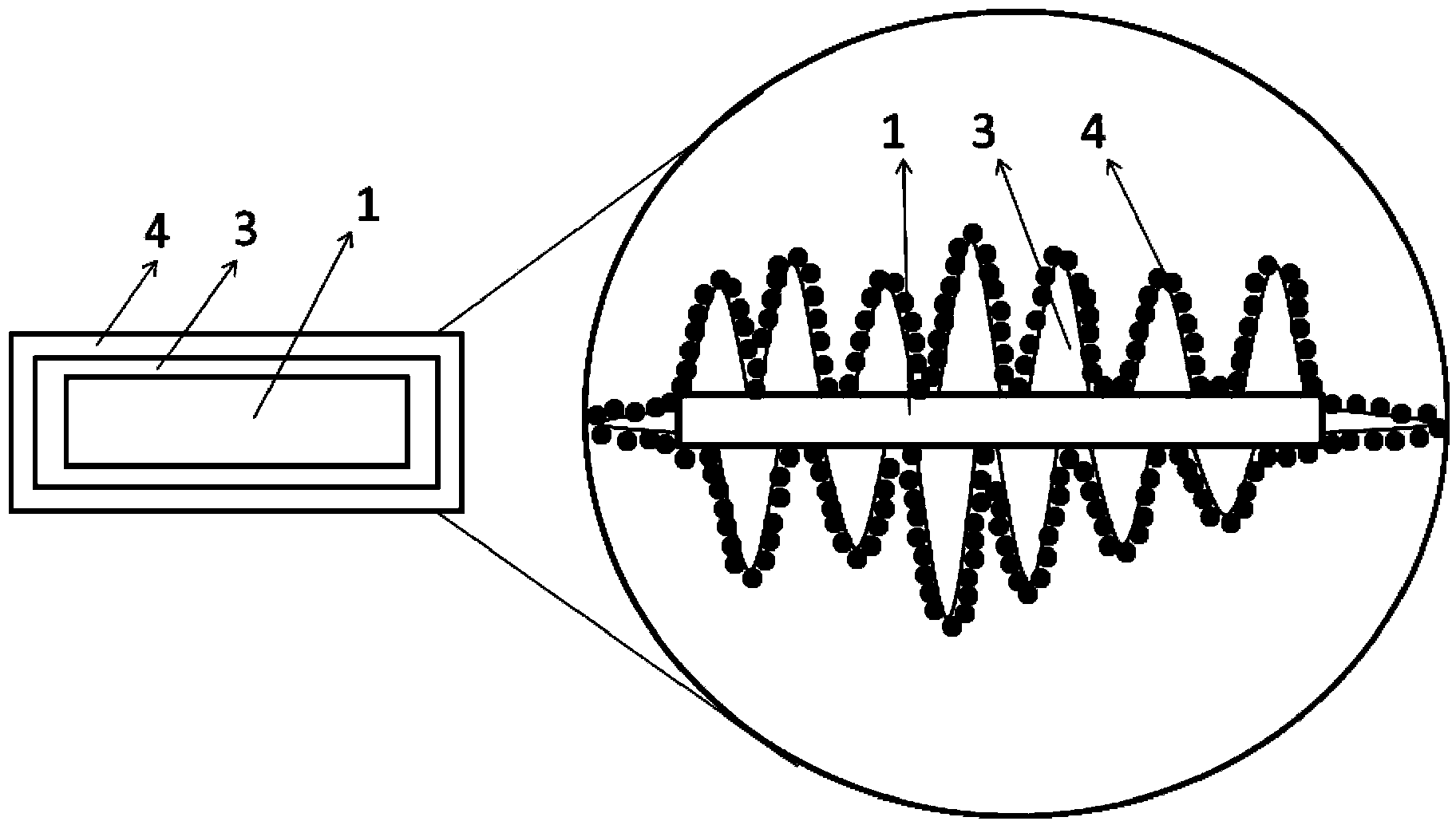

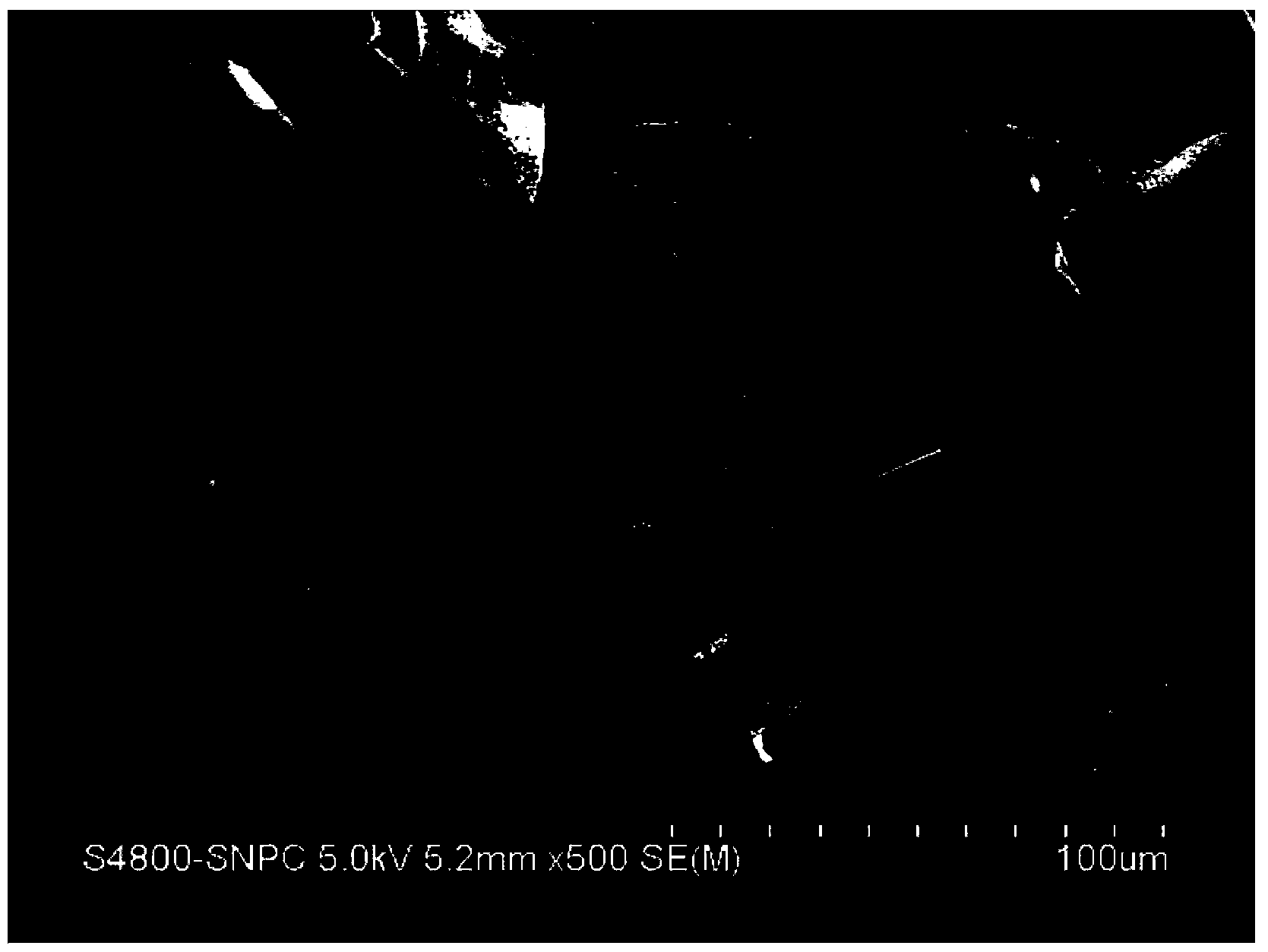

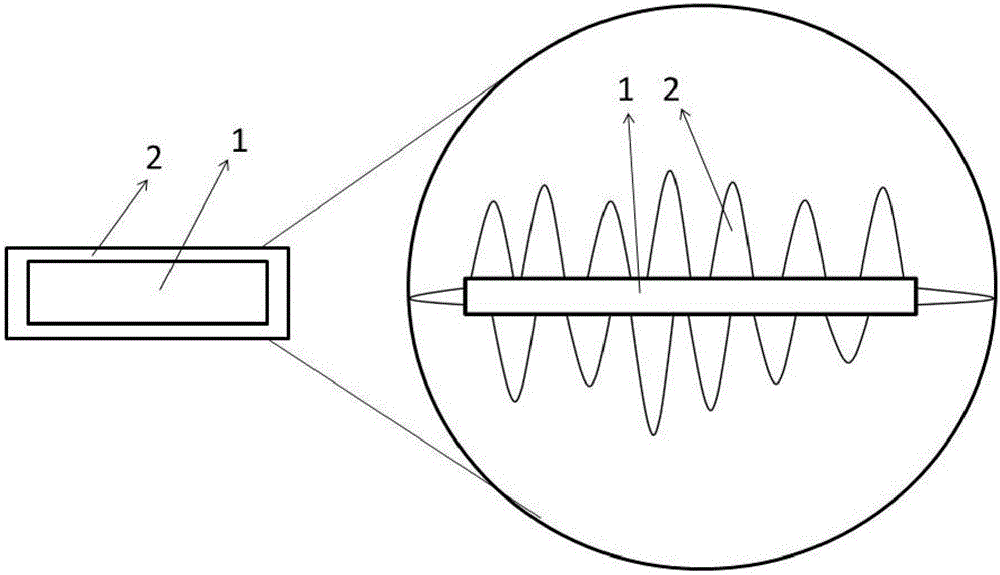

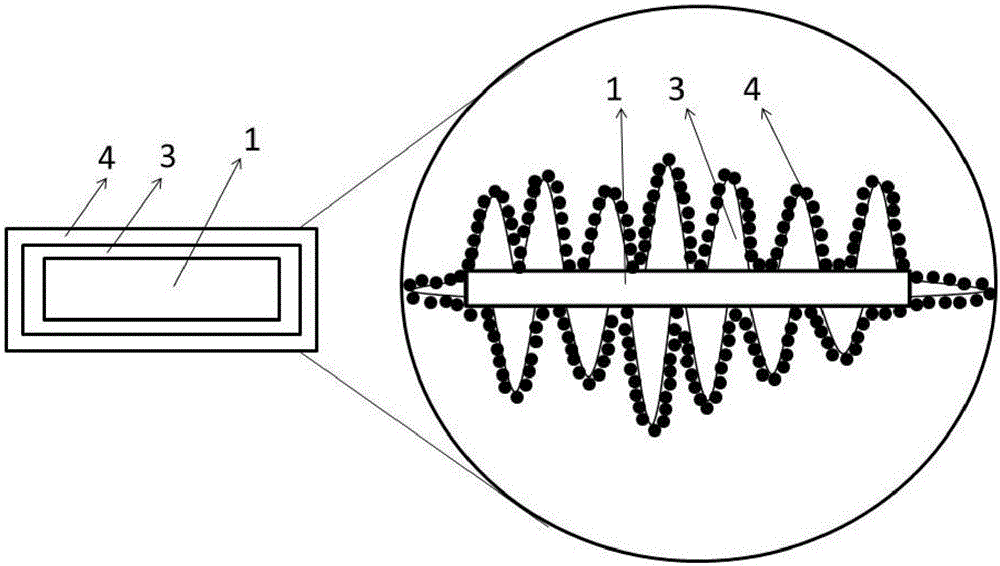

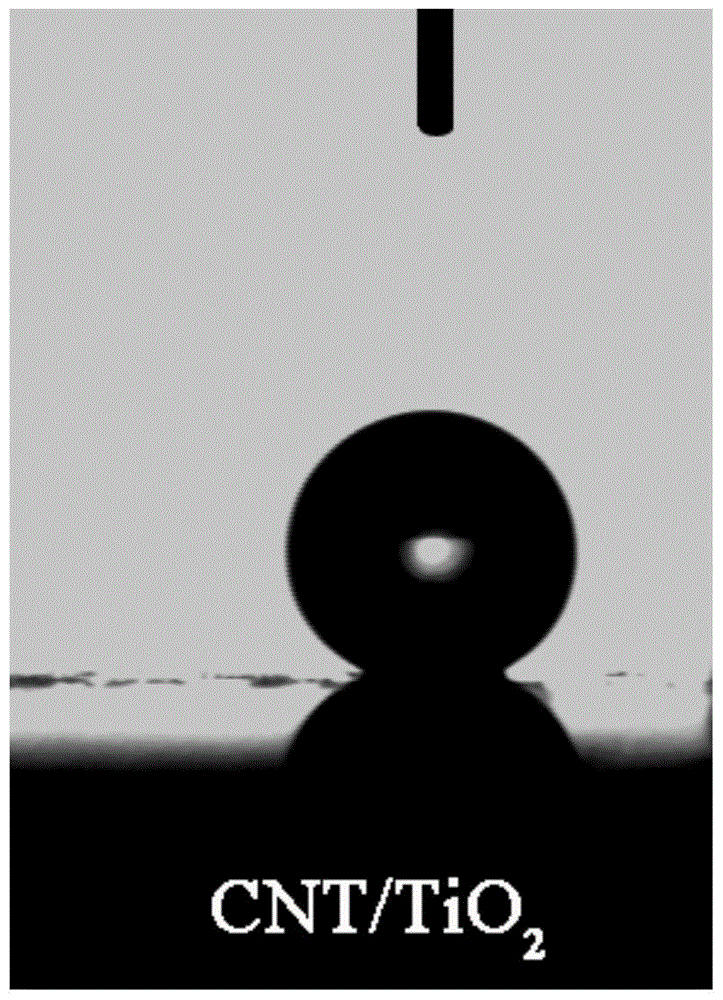

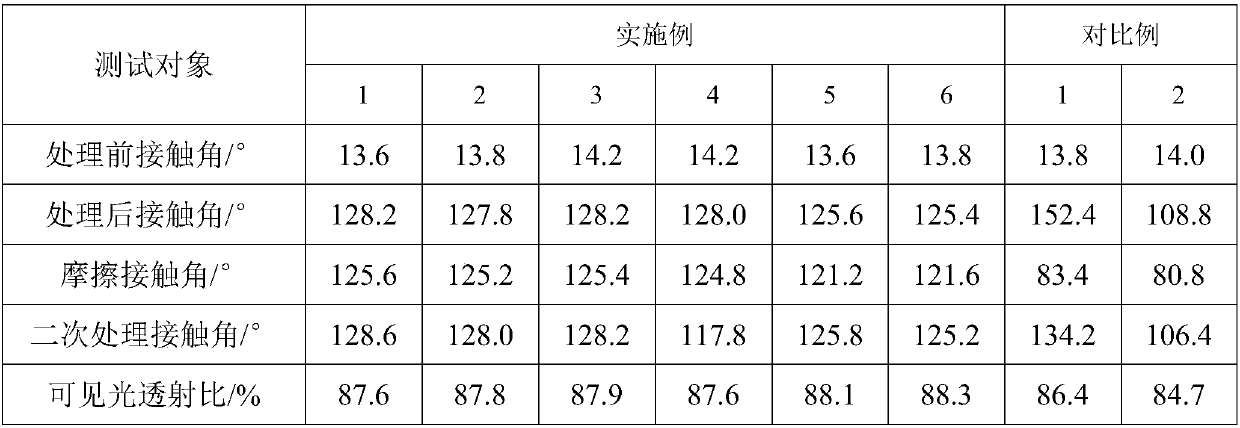

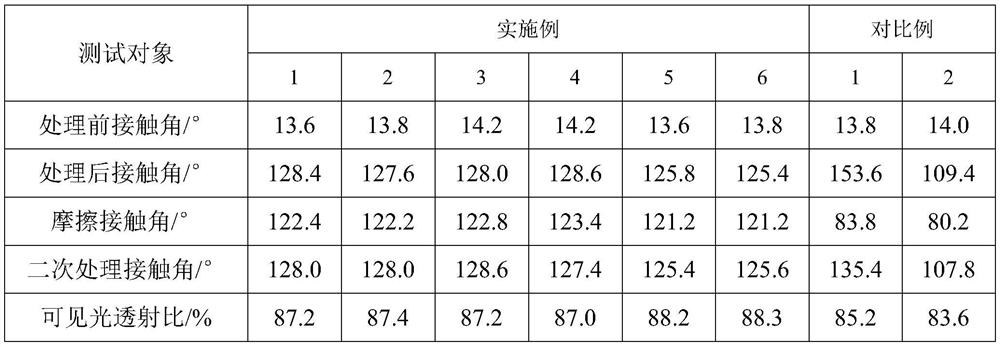

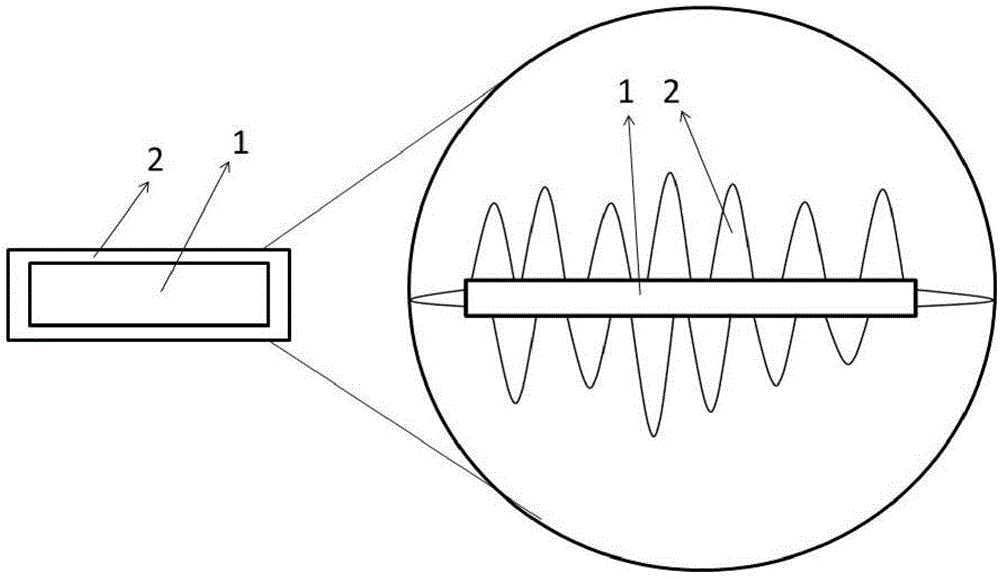

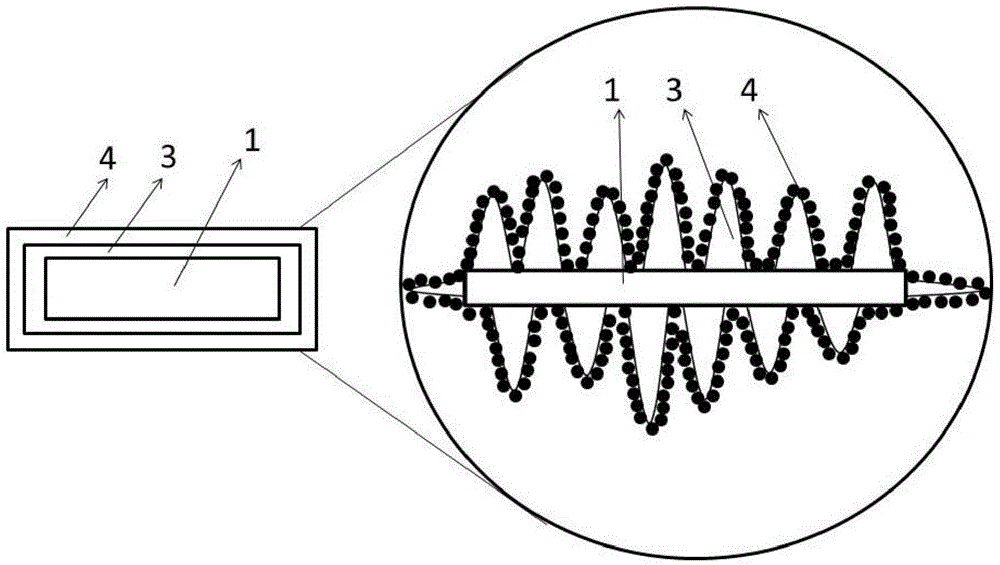

Method for preparing superhydrophobic CNTs/TiO2 hybrid film on base plate

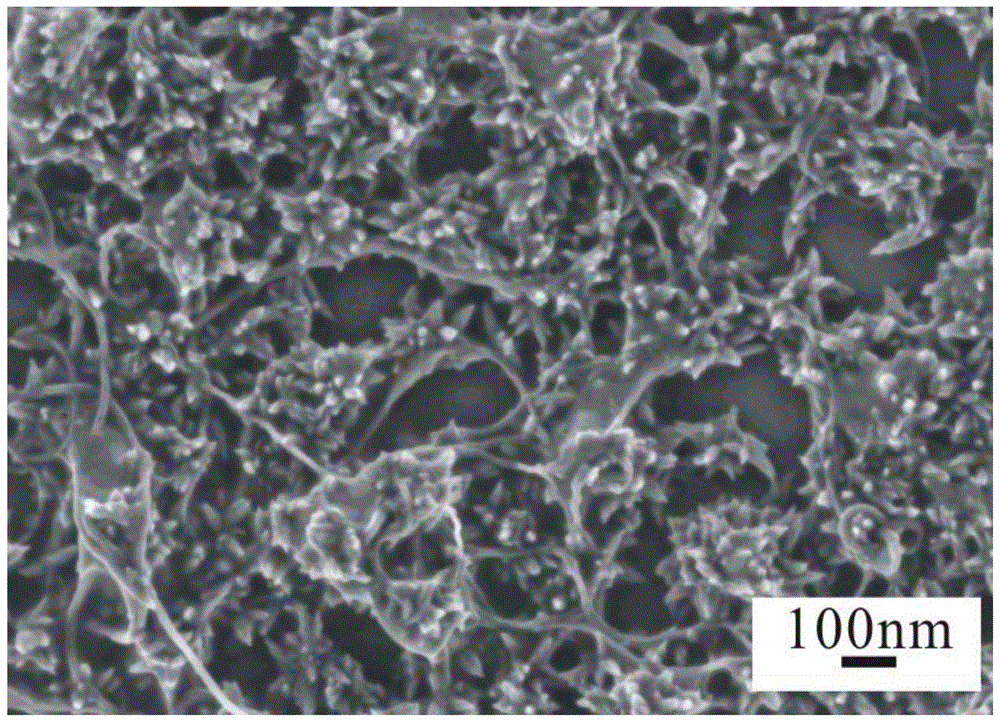

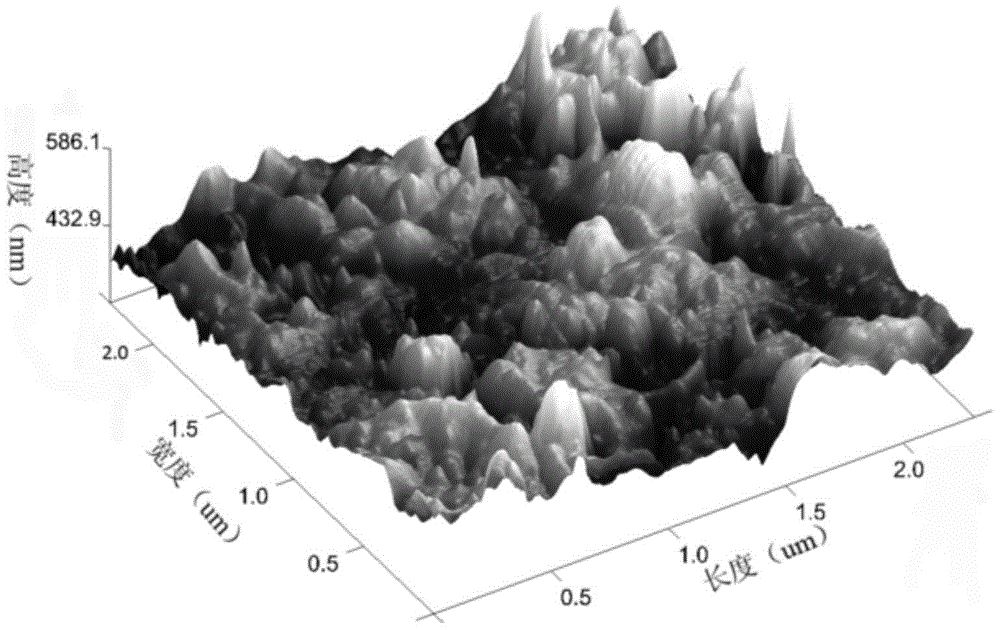

ActiveCN103757611ALow operating temperatureSimple equipmentLiquid/solution decomposition chemical coatingPhotocatalysisFilm material

The invention discloses a method for preparing a superhydrophobic CNTs / TiO2 hybrid film on a substrate, and relates to CNTs / TiO2 hybrid films. The method aims at preparing the superhydrophobic CNTs / TiO2 hybrid film of a high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube on the substrate through a low temperature liquid phase sedimentation method; a mixed solution of ammonium hexafluorotitanate and boric acid is used as a raw material, meanwhile, the carbon nanotube is added, and the CNTs / TiO2 hybrid film is prepared on the substrate through the low temperature liquid phase sedimentation method. The method comprises the steps as follows: 1) surface polishing of the substrate; 2) surface sedimentation of the substrate; 3) surface ornament and solidification of the substrate. The CNTs / TiO2 hybrid film of the high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube can be obtained without complex treatment. Before and after coated with fluorosilane on the surface, the CNTs / TiO2 hybrid film always has the photocatalysis effect. Therefore, the superhydrophobic CNTs / TiO2 hybrid film is a film material with better performance and self-cleaning function.

Owner:XIAMEN UNIV

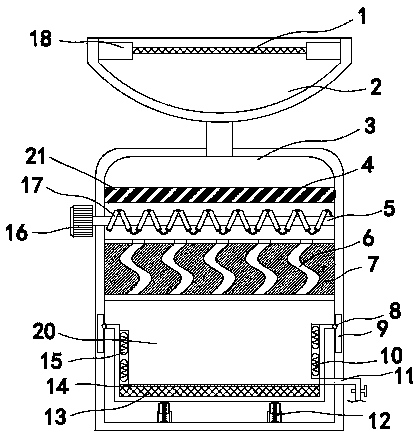

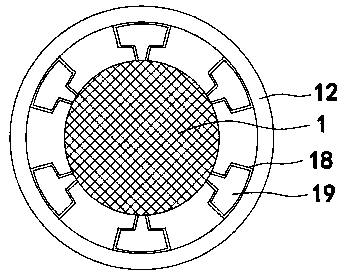

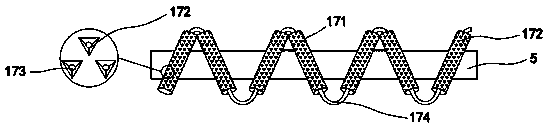

Ship rainwater purification device

InactiveCN109534588AImprove purification effectEasy to recycleWater/sewage treatment by irradiationWater contaminantsWater sourceEnvironmental engineering

Belonging to the technical field of water purification equipment, the invention provides a ship rainwater purification device. The device consists of: a rainwater collection hopper for collecting rainwater; a filter tank for purifying rainwater; a magnetic adsorption mechanism for adsorbing heavy metals in rainwater; adsorption pipelines for weakening the acidity of rainwater; and a reservoir fordisinfecting rainwater. The upper part at the middle of the filter tank is connected to the rainwater collection hopper through a pipeline, clamp slots are annularly distributed at the opening of therainwater collection hopper, detachable clamp seats are clamped inside the clamp slots, the clamp seats are connected to a coarse filter screen, and the filter tank is internally equipped with the magnetic adsorption mechanism, the adsorption pipelines and the reservoir from top to bottom in order. The device provided by the invention can quickly collect rainwater, and the rainwater purification degree is high, and after the steps of removal of heavy metals, weakening of the rainwater acidity, heating, sterilization and other steps, a drinkable water source can be produced.

Owner:ZHEJIANG OCEAN UNIV

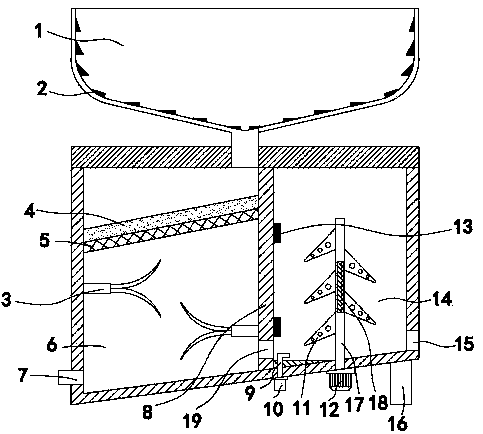

Sewage multi-stage purification device

InactiveCN110156239AWith photocatalytic effectIncrease water pressureFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationOil and greaseFiltration

A sewage multi-stage purification device provided by that invention belongs to the technical field of sewage treatment and comprise a water collecting bucket, an oil-water separation elastic piece, asedimentation chamber and a fine filtration chamber, wherein the sedimentation chamber is connected with the lower part of the water collecting bucket through a connecting pipe, the fine filtration chamber is arranged on the right side of the sedimentation chamber, the sedimentation chamber and the fine filtration chamber are separated by a partition plate, and the fine filtration chamber is supported by a support foot. The device can filter the sewage step by step, quickly separate the grease in the sewage, effectively absorb the dissolved pollutants such as heavy metals and organic substances in the sewage, reduce the PH value of the sewage, and improve the safety of the sewage utilization.

Owner:金华市景和科技有限公司

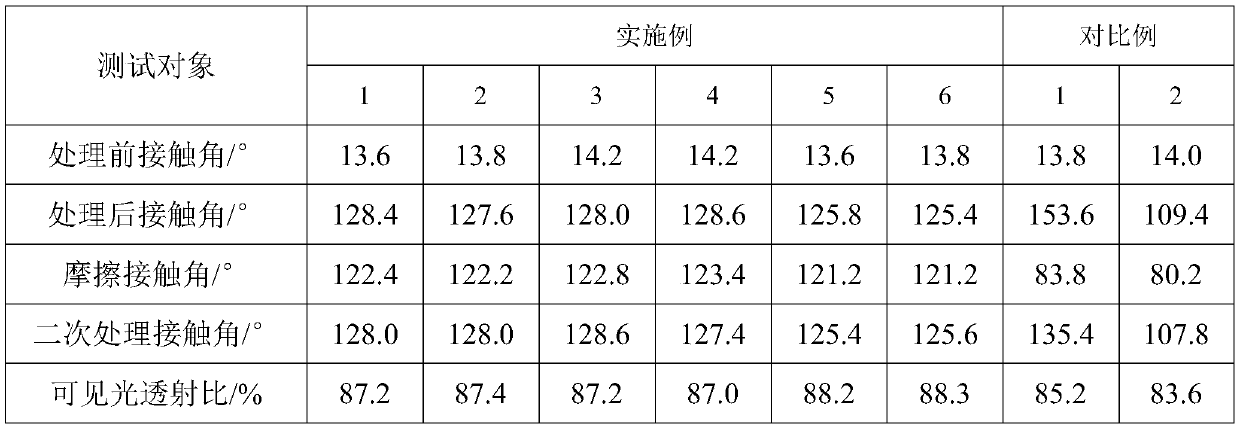

Self-cleaning glass water repellent agent

The invention belongs to the technical field of surface treatment of glass and particularly relates to a self-cleaning glass water repellent agent. The self-cleaning glass water repellent agent comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 100 parts of dimethylcyclosiloxane, 20-50 parts of phenyl siloxane, 5-10 parts of a silane coupling agent, 0.1-10 parts of a basic catalyst, 5-40 parts of a surfactant and 10-90 parts of a solvent; the component B is prepared from the following raw materials in parts by weight: 80 parts of organic fluorine, 4-15 parts of a silane coupling agent, 10-30 parts of dimethylcyclosiloxane, 10-20 parts of phenyl siloxane, 0.1-10 parts of a basic catalyst, 5-40 parts of a surfactant, 10-90 parts of a solvent and 1-20 parts of nano-titanium oxide. After the water repellent agent is used on glass of an automobile, water drops can form water beads on the surface of the glass, the contact angle of each of the water beads can be as high as 125 degrees, and the water beads can automatically fall off without leaving a trace, so that the problem of unclear sight is solved.

Owner:湖北隆胜四海新材料有限公司

Method for preparing metal coated pearlescent pigment

ActiveCN103788720AImprove photocatalytic activity and antibacterialAnti-foulingCosmetic preparationsBiocideChemistryTitanium dioxide

The invention discloses a method for preparing a metal coated pearlescent pigment. The pearlescent pigment is characterized by comprising a flaky substrate and a plurality of titanium dioxide nanorods which are arranged at intervals and are formed on the flaky substrate, so that a nano-structured surface with roughness can be formed by the titanium dioxide nanorods of the pearlescent pigment, and then, a plurality of metal particles are deposited on each titanium dioxide nanorod and the flaky substrate respectively.

Owner:浙江瑞成新材料股份有限公司

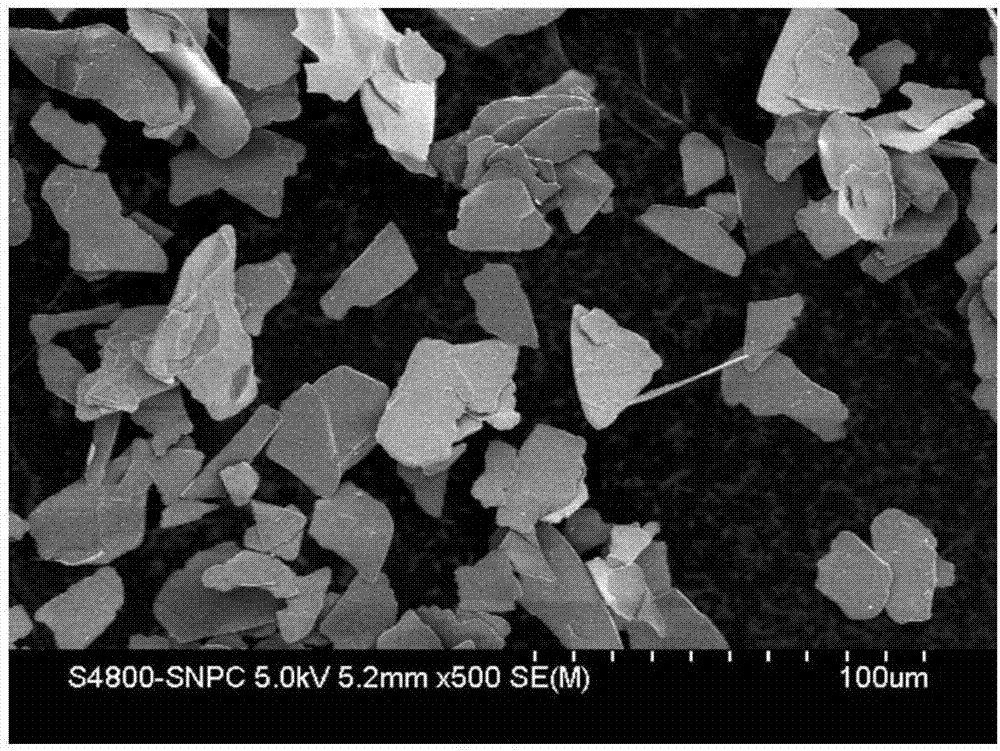

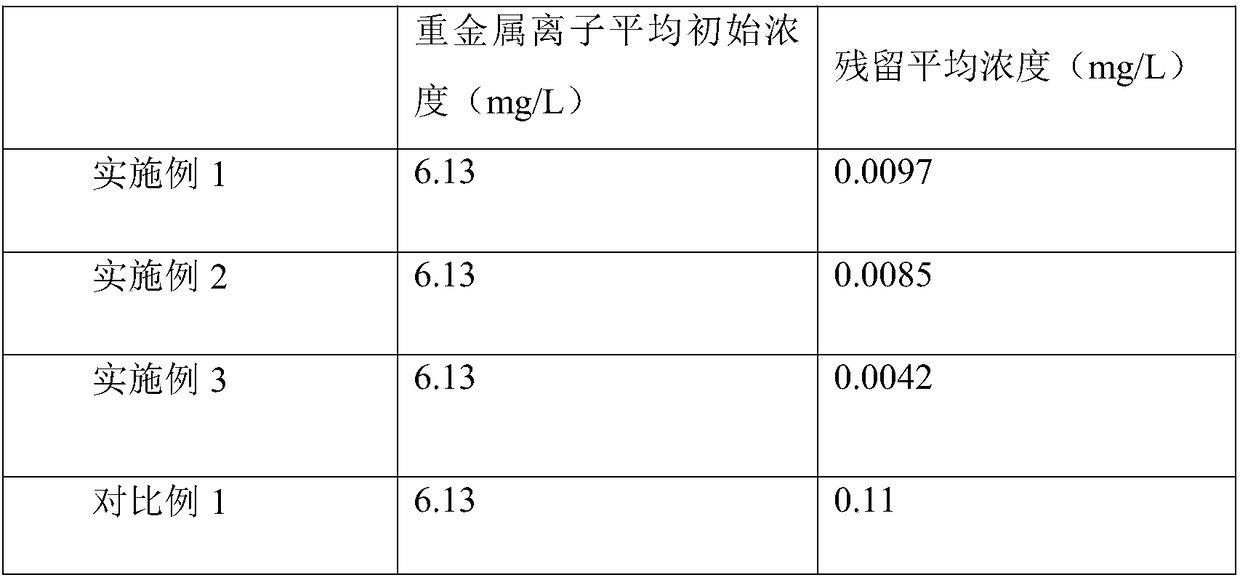

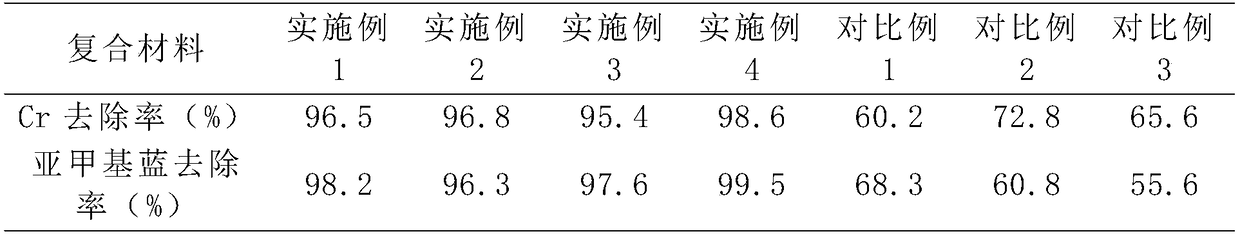

Nano-composite material used for water purification and preparation method thereof

InactiveCN108928876AWith photocatalytic effectDeveloped specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationCross-linkActivated carbon

The invention discloses a nano-composite material used for water purification, which includes, by weight, 48-54 parts of chitosan, 12-16 parts of nano-TiO2, 24-28 parts of active carbon supported nano-bentonite and 3-6 parts of nano-hydrotalcite, wherein the mass ratio of the chitosan, the nano-TiO2, the active carbon supported nano-bentonite to the nano-hydrotalcite is (65-75):(8-12):(14-18):4. With chitosan being a carrier, the product has stable properties. The cross-linked structure in the active carbon form fine pores, so that the product has well-developed pore structure; by supporting the nano-bentonite on the active carbon, the nano-bentonite is increased in specific surface area, so that the product is enhanced in heavy metal adsorption effect.

Owner:合肥岑遥新材料科技有限公司

Pearlescent pigment with bactericidal power

ActiveCN103788722AAnti-foulingWith dustproofBiocideCosmetic preparationsNano structuringMetal particle

The invention discloses a pearlescent pigment with bactericidal power. The pearlescent pigment is characterized by comprising a flaky substrate, film forming resin and a plurality of titanium dioxide nanorods which are arranged at intervals and are formed on the flaky substrate, so that a nano-structured surface with roughness can be formed by the titanium dioxide nanorods of the pearlescent pigment, and then, a plurality of silver metal particles are deposited on each titanium dioxide nanorod and the flaky substrate respectively.

Owner:浙江瑞成新材料股份有限公司

Antibacterial and mould-proof polyethylene compound plastic masterbatch

InactiveCN106633310AGood antibacterial propertiesKeep yourself cleanFilament/thread formingNano-carbonMasterbatchFiber

The invention discloses an antibacterial and mould-proof polyethylene compound plastic masterbatch. The plastic masterbatch is prepared from a titanium dioxide compound antibacterial agent; the titanium dioxide compound antibacterial agent is prepared by carbonizing electrospun enteromorpha nano-particles / titanium dioxide fibers, carrying out acid-washing, soaking in antibacterial liquid, drying and grinding into micro / nano-particles, wherein the antibacterial liquid is extracting liquid of a traditional Chinese medicine antibacterial component. The material has very good antibacterial property, and can effectively inhibit the propagation of microorganisms such as bacteria and mould on the surface of the material, so as to achieve the effects of resisting bacteria and preventing mould and maintain self cleanness.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

A kind of preparation method and application of self-cleaning glass hydrophobic agent

The invention belongs to the technical field of glass surface treatment, and particularly relates to a preparation method and application of a self-cleaning glass hydrophobic agent, comprising the following steps, S1, preparing component A, mixing methylcyclosiloxane, methylphenylsiloxane Alkane and silane coupling agent are polymerized under certain conditions to obtain ternary copolymerized polysiloxane, which is filtered to obtain component A after reacting with surfactant and solvent; S2, to prepare component B, and dimethyl cyclosiloxane Alkane, methyl phenyl siloxane and silane coupling agent are polymerized under certain conditions to obtain ternary copolymerized polysiloxane, which is reacted with surfactant and solvent and then filtered to obtain component B. The preparation method is simple, and the quantitative production requirements are low. After the prepared product acts on the glass surface, water droplets can form water droplets on the glass surface, and the contact angle can be as high as 125°, which can automatically roll off without leaving traces.

Owner:深圳市吉鹏硅氟材料有限公司

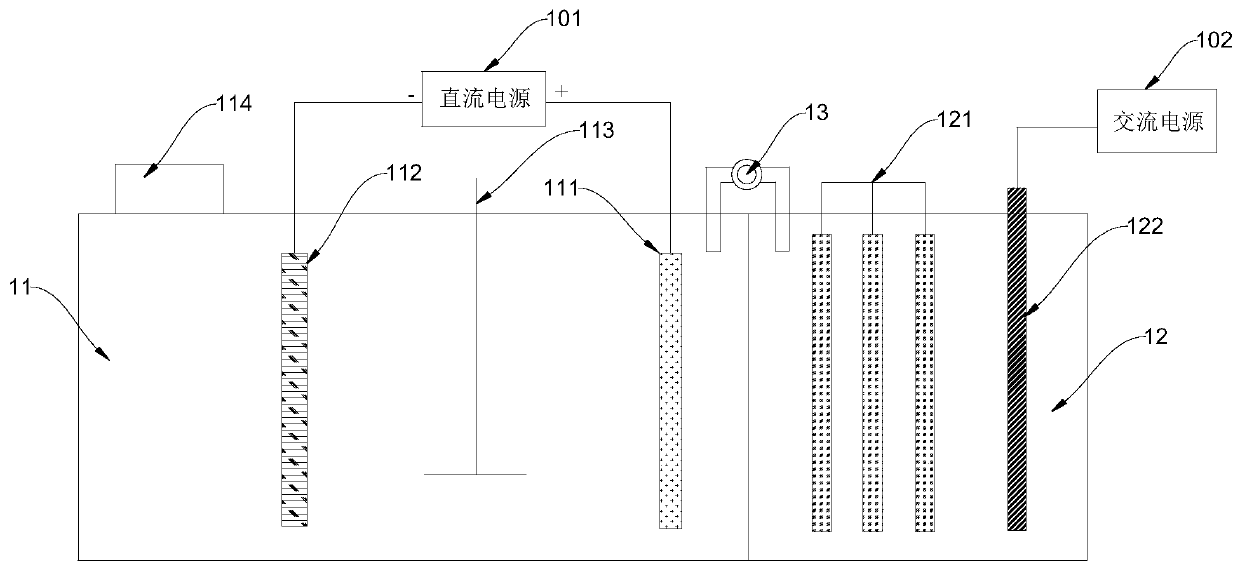

Coupling process for advanced treatment of landfill leachate

InactiveCN110482749AEffective aggregationImprove stabilityWater/sewage treatment by irradiationSpecific water treatment objectivesElectrolysisEngineering

The invention is applicable to the technical field of garbage treatment, and provides an electric flocculation coupling system for advanced treatment of landfill leachate. The system comprises an electric flocculation coupling filter device provided with an electrolytic flocculation tank at the front end and a photocatalytic ceramic membrane filter tank at the rear end; the electrolytic flocculation tank is provided with an anode electrolytic plate, a cathode electrolytic plate, a stirrer and a PH adjusting device; a photocatalytic ceramic module assembly and a photocatalytic light source arearranged in the photocatalytic ceramic membrane filter tank; the electrolytic flocculation tank is used for pumping the landfill leachate subjected to electrolytic flocculation into the photocatalyticceramic membrane filter tank through a lifting pump; the density of current introduced into the electrolytic flocculation tank is 10-1000 mA / cm<2>, the distance between the anode electrolytic plate and the cathode electrolytic plate is 1-20 cm, the PH value is 6-9, and the electrolytic flocculation time is 20-90 min; and the photocatalytic ceramic membrane assembly is formed by combining at leasttwo non-metal doped titanium dioxide ceramic membranes, and the pore diameter is 100-1000 nm.

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

Pearlescent pigment with environment cleaning capacity

InactiveCN103804976AAnti-foulingWith dustproofCosmetic preparationsMake-upNano structuringMetal particle

The invention discloses a pearlescent coating with environment cleaning capacity. The pearlescent coating is characterized by comprising a sheet substrate and film forming resin, and multiple spaced titanium dioxide nanorods are formed on the sheet substrate, therefore, a nano-structure surface with roughness can be formed by use of the titanium dioxide nanorods on the pearlescent coating, and then multiple metal particles are deposited on each titanium dioxide nanorod and the sheet substrate.

Owner:浙江瑞成新材料股份有限公司 +1

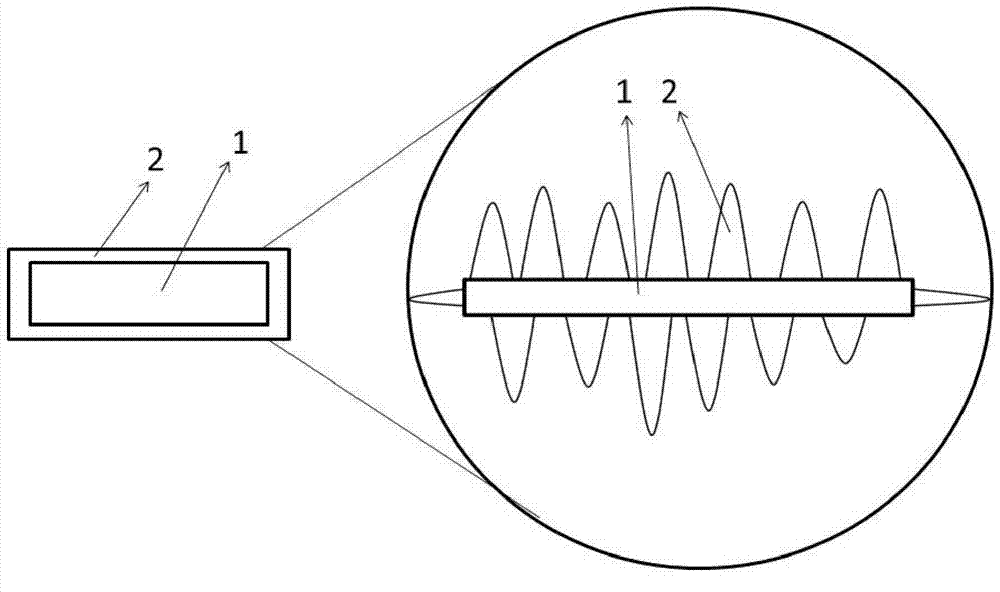

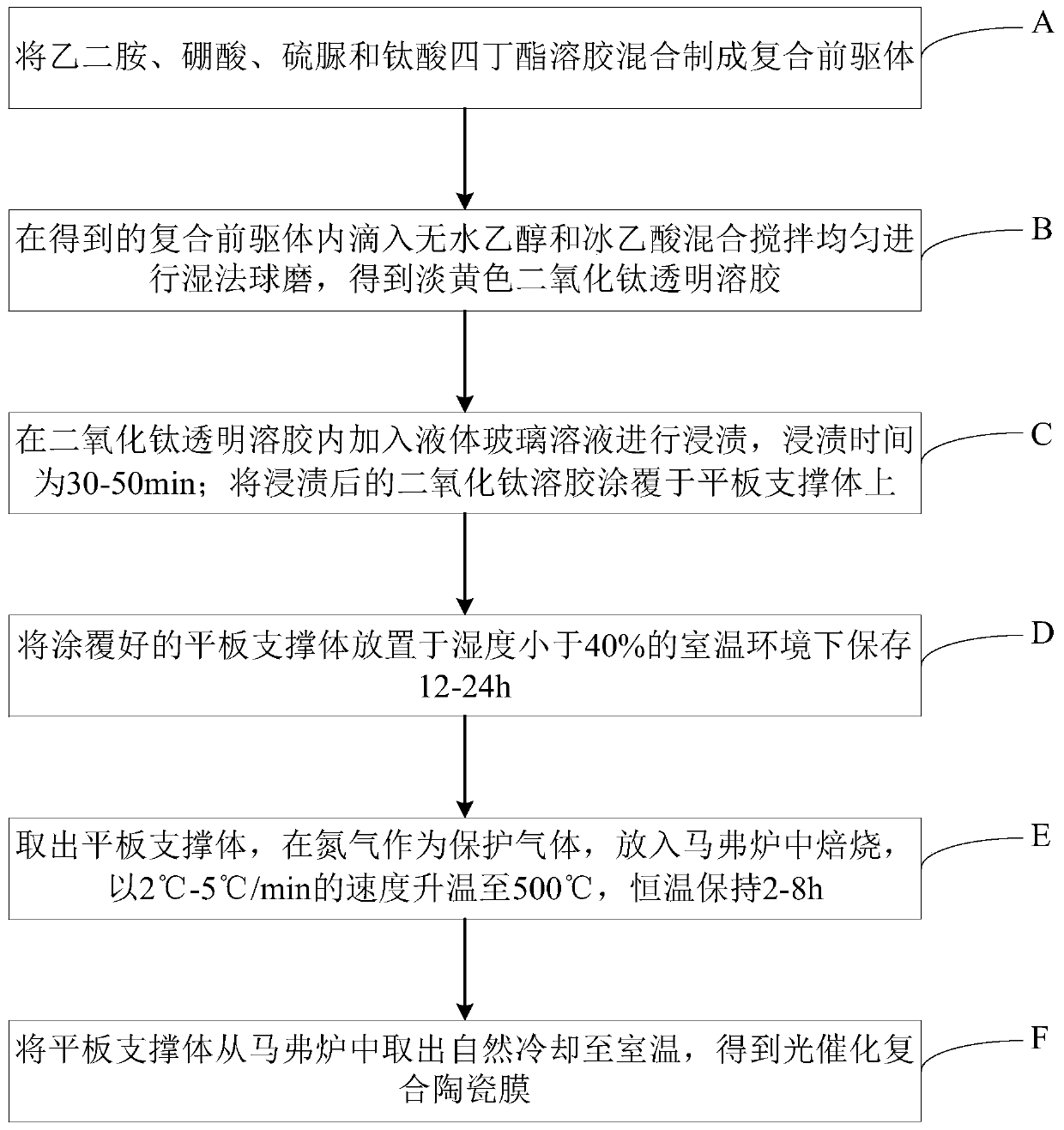

Preparation method of photocatalytic composite ceramic membrane

InactiveCN110479111AReduce pollutionImprove separation efficiencySemi-permeable membranesWater/sewage treatment by irradiationEthylenediamineComposite ceramic

The invention is applicable to the technical field of ceramic membrane preparation, and provides a preparation method of a photocatalytic composite ceramic membrane. The method comprises the followingsteps: mixing ethylenediamine, boric acid, thiourea and tetrabutyl titanate sol to prepare a composite precursor; dropwise adding absolute ethyl alcohol and glacial acetic acid into the obtained composite precursor, uniformly mixing and stirring, and carrying out wet ball milling to obtain faint yellow titanium dioxide transparent sol; adding a liquid glass solution into the titanium dioxide transparent sol for dipping, wherein the dipping time is 30-50 minutes; coating a flat plate support body with the the impregnated titanium dioxide sol; placing the coated flat plate supporting body in aroom temperature environment with the humidity smaller than 40% to be stored for 12-24 h; taking out the flat plate support body, roasting in a muffle furnace by taking nitrogen as a protective gas, heating to 500 DEG C at a speed of 2-5 DEG C / min, and keeping the constant temperature for 2-8 hours; and taking out the flat plate support body from the muffle furnace, and naturally cooling to room temperature to obtain the photocatalytic composite ceramic membrane.

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

Methods for preparing and applying titanium dioxide-carbon composite photocatalyst

InactiveCN102527365BStrong physical adsorption capacityRealize resourcesPhysical/chemical process catalystsWater/sewage treatment by irradiationCarbon compositesDispersity

The invention relates to methods for preparing and applying a titanium dioxide-carbon composite photocatalyst. The technical scheme is that the method for preparing the titanium dioxide-carbon composite photocatalyst comprises the following steps of: preparing an ordered macroporous-mesoporous carbon material and TiO2 sol respectively, soaking the aged TiO2 sol on the prepared macroporous-mesoporous carbon material by an impregnation method, drying, raising the temperature and calcicining to obtain a TiO2 / C composite photocatalyst material. The method for applying the titanium dioxide-carbon composite photocatalyst is that photocatalytic reaction conditions are that: the adding amount of the titanium dioxide-carbon composite photocatalyst is 1 to 6g / L; a light source is an ultraviolet or visible light source and directly irradiates a solution, the depth of the solution is 0.4 to 0.6cm, and the exposure dose per unit area on the surface of the solution is 12.5 to 12.8mW / cm<2>; and the temperature of a solution system is kept at 20 to 40 DEG C, and air is continuously introduced to maintain the concentration of dissolved oxygen. Macroporous-mesoporous carbon material supported titanium dioxide is used as a photocatalyst, so that TiO2 has high dispersity and photocatalytic activity, and is easier to recycle.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A metal coated pearlescent pigment

The invention discloses a metal coated pearlescent pigment. The pearlescent pigment is characterized by comprising a flaky substrate and a plurality of titanium dioxide nanorods which are arranged at intervals and are formed on the flaky substrate, so that a nano-structured surface with roughness can be formed by the titanium dioxide nanorods of the pearlescent pigment, and then, a plurality of metal particles are deposited on each titanium dioxide nanorod and the flaky substrate respectively.

Owner:浙江瑞成新材料股份有限公司

Wide waveband photocatalyst air cleaner

ActiveCN101862467BWith photocatalytic effectImprove photocatalytic efficiencyDispersed particle separationDeodrantsProduction rateDolomite

The invention discloses a wide waveband photocatalyst air cleaner, which comprises a container, wherein compound photocatalyst particles are arranged in the container. The container is prepared by sintering anion power, dolomite and pore-forming agent. The compound photocatalyst particles are prepared by sintering the anion power, tourmaline, maifanitum, nanometer titanium dioxide, cerous oxide and viscous pottery clay. The invention has the following great advantages: 1, the production rate of anions is high; and 2, no additional power supply is needed, and natural light can penetrate through a container wall and an air hole on the container wall to exchange with the surfaces of the compound photocatalyst particles so as to realize the purpose of purifying air, thereby bringing greatly convenience for use. The air cleaner in the invention can be arranged on desks, bedside tables and windows as well as in automobile and the like. The container can be made into various ornaments, such as egg-shaped, vase-shaped, animal-shaped, cartoon-shaped ornaments and the like, and has beautiful appearance and practical use.

Owner:SHANGHAI ZHENAO BIOTECH +1

A preparation of superhydrophobic cnts/tio on a substrate 2 hybrid thin film method

ActiveCN103757611BLarge roughness valueShow photocatalytic effectLiquid/solution decomposition chemical coatingNanoparticleThin membrane

The invention discloses a method for preparing a superhydrophobic CNTs / TiO2 hybrid film on a substrate, and relates to CNTs / TiO2 hybrid films. The method aims at preparing the superhydrophobic CNTs / TiO2 hybrid film of a high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube on the substrate through a low temperature liquid phase sedimentation method; a mixed solution of ammonium hexafluorotitanate and boric acid is used as a raw material, meanwhile, the carbon nanotube is added, and the CNTs / TiO2 hybrid film is prepared on the substrate through the low temperature liquid phase sedimentation method. The method comprises the steps as follows: 1) surface polishing of the substrate; 2) surface sedimentation of the substrate; 3) surface ornament and solidification of the substrate. The CNTs / TiO2 hybrid film of the high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube can be obtained without complex treatment. Before and after coated with fluorosilane on the surface, the CNTs / TiO2 hybrid film always has the photocatalysis effect. Therefore, the superhydrophobic CNTs / TiO2 hybrid film is a film material with better performance and self-cleaning function.

Owner:XIAMEN UNIV

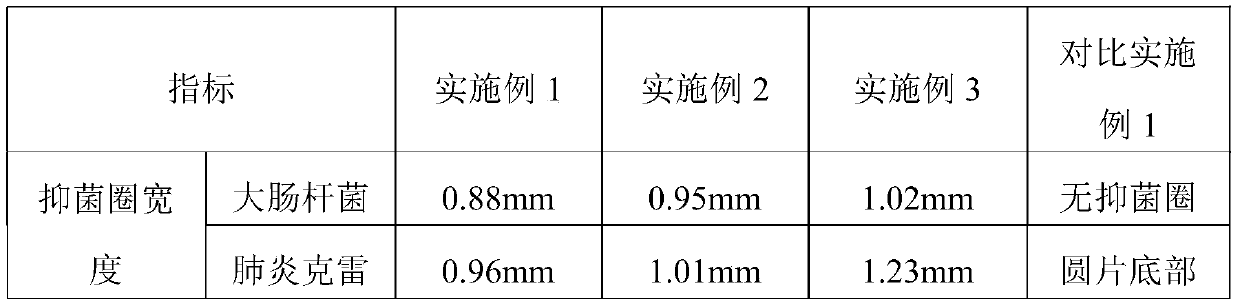

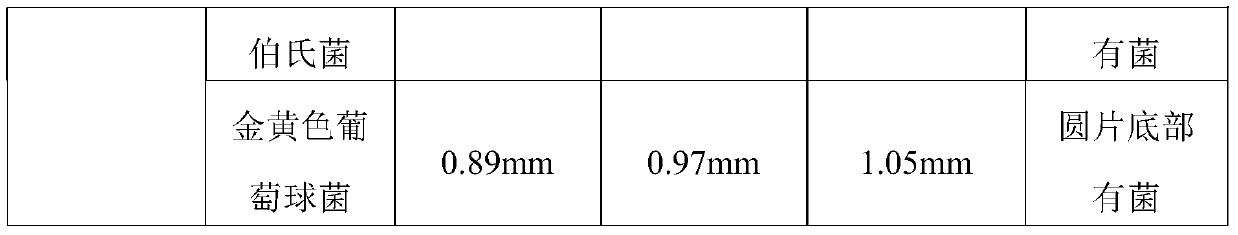

Antibacterial kraft paper and preparation method thereof

ActiveCN111455730BSuperhydrophobicAvoid breedingFlexible coversWrappersSuperhydrophobePhoto catalytic

Owner:中山泰星纸袋制品有限公司

Antibacterial superhydrophobic coating for wrapping paper and preparation method thereof

ActiveCN111501415BSuperhydrophobicAvoid breedingFlexible coversWrappersMicron scaleSuperhydrophobic coating

The invention relates to an antibacterial superhydrophobic coating for wrapping paper and a preparation method thereof. Including (1) preparing clean, dry and flat wrapping paper for later use; (2) preparing a coating solution, dissolving titanate, rosin-modified alkyd resin, and hydroxypropyl starch in absolute ethanol, and stirring evenly; ( 3) Coat the coating solution evenly on the surface of the wrapping paper, let it stand for a period of time, evaporate part of the solvent ethanol, and then spray deionized water on the surface of the wrapping paper coated with the coating solution to carry out in-situ hydrolysis of the surface, hydrolysis After the reaction is complete, it can be dried. Through the in-situ hydrolysis of titanate, a nano-papillae structure is obtained on the surface of the coating, and the micron-scale surface roughness of the coating itself makes the coating surface superhydrophobic. In addition, the nano-titanium dioxide particles obtained by in-situ hydrolysis of titanate have antibacterial and photocatalytic effects, and with the superhydrophobic surface, the antibacterial effect of wrapping paper can be enhanced.

Owner:中山泰星纸袋制品有限公司

A formaldehyde-removing liquid added with biological enzyme auxiliary agent and preparation method thereof

ActiveCN110743357BGood dispersionImprove purification efficiencyGas treatmentDispersed particle separationActive agentAir decontamination

The invention relates to a formaldehyde-removing liquid added with a biological enzyme auxiliary agent and a preparation method thereof, and relates to the technical field of air purification, which includes a photocatalyst, and the photocatalyst includes the following raw materials in parts by weight: 30-34 parts of photocatalyst, 6-10 parts of nanofiber filler, 2-6 parts of water-based acrylic polyurethane, 1-3 parts of anionic surfactant, 1-3 parts of titanate coupling agent, 6-10 parts of dispersant, 80-84 parts of deionized water ; The photocatalyst comprises the following raw materials in weight percentage: nano-titanium dioxide 10-20%, nano-zinc oxide 10-20%, aluminum sulfate 10-14%, anhydrous sodium acetate 1-5%, synergist 6-10% , and the remainder deionized water. By modifying nano-titanium dioxide and nano-zinc oxide, the dispersibility of nano-titanium dioxide and nano-zinc oxide is improved, thereby improving the purification efficiency and effect of photocatalyst on formaldehyde.

Owner:浙江蓝民环保科技有限公司

A kind of silver-modified tio2/graphene/bentonite composite material and preparation method thereof

ActiveCN105921140BWith adsorption effectEfficient degradationPhysical/chemical process catalystsOther chemical processesMaterials scienceGraphite oxide

The invention belongs to the field of sewage treatment. It is a silver-modified TiO2 / graphene / bentonite composite material, in which the mass ratio of bentonite to graphene is 50:1-5, and the mass ratio of silver to graphene is 15-20:1. The preparation method of the above-mentioned silver-modified TiO2 / graphene / bentonite composite material, the steps are as follows: (1) Add hydrazine hydrate and titanium dioxide solution to the graphene oxide suspension, and then dropwise add silver nitrate solution thereto, and perform ultrasonic vibration at the same time ; (2) After the dropwise addition of the silver nitrate solution is completed, add the bentonite suspension to the reaction system while ultrasonic vibrating; (3) Dry the above-obtained intermediate product and then calcine it under an inert atmosphere to finally obtain the composite material. The preparation method in this application is simple, the materials are cheap and easy to obtain, and it not only has the adsorption effect of heavy metals, but also has a photocatalytic effect, and can effectively degrade organic pollutants.

Owner:JIANGSU CHENGGONG CONSTR TECH

Preparation method and application of self-cleaning glass hydrophobic agent

The invention belongs to the technical field of glass surface treatment, and particularly relates to a preparation method and application of a self-cleaning glass hydrophobic agent. The preparation method of the self-cleaning glass hydrophobic agent comprise the following steps of S1, preparation of a component A: carrying out polymerization reaction on methylcyclosiloxane, methylphenylsiloxane and a silane coupling agent under certain conditions to obtain a terpolymer polysiloxane, reacting the terpolymer polysiloxane with a surfactant and a solvent, and then filtering to obtain the componentA; and S2, preparation of a component B: carrying out polymerization reaction on dimethylcyclosiloxane, methylphenylsiloxane and a silane coupling agent under certain conditions to obtain terpolymerpolysiloxane, reacting the terpolymer polysiloxane with a surfactant and a solvent, and then filtering to obtain the component B. The preparation method is simple, the quantitative production requirement is low, after a prepared product acts on the surface of the glass, water drops can be formed when water is sprayed to the surface of the glass, the contact angle of the water drops can reach 125 degrees, and the water drops can roll off automatically without leaving marks.

Owner:深圳市吉鹏硅氟材料有限公司

A self-cleaning glass hydrophobic agent

The invention belongs to the technical field of glass surface treatment, in particular to a self-cleaning glass hydrophobic agent. The self-cleaning glass hydrophobic agent includes A component and B component. In parts by weight, the A component is prepared from the following raw materials: 100 parts of dimethylcyclosiloxane, containing 20 parts of phenylsiloxane ~50 parts, 5~10 parts of silane coupling agent, 0.1~10 parts of basic catalyst, 5~40 parts of surfactant, 10~90 parts of solvent; the B component is prepared from the following raw materials: organic fluoride 80 parts, 4-15 parts of silane coupling agent, 10-30 parts of dimethyl cyclosiloxane, 10-20 parts of phenylsiloxane, 0.1-10 parts of basic catalyst, 5-40 parts of surfactant parts, 10-90 parts of solvent, and 1-20 parts of nano-titanium oxide. After being used on automobile glass, water droplets can form water droplets on the glass surface, and its contact angle can be as high as 125°, which can automatically roll off without leaving traces, thus solving the problem of unclear vision.

Owner:湖北隆胜四海新材料有限公司

a tio 2 nanotube/sio 2 Airgel composite photocatalytic material and preparation method thereof

InactiveCN104874385BImprove photocatalytic efficiencyLarge specific surface areaPhysical/chemical process catalystsColloidal chemistry detailsNano catalystPhoto catalytic

A kind of TiO 2 Nanotube / SiO 2 Airgel composite photocatalytic material and preparation method thereof, the present invention first hydrothermally synthesizes TiO 2 nanotubes, followed by TiO 2 Nanotubes as discrete phase, SiO 2 The airgel is a continuous phase matrix, and the gel is prepared by the sol-gel method, and then the gel is aged, aged and modified to synthesize the photocatalytic material. Due to the combination of the hydrothermal method and the sol-gel method, the photocatalytic powder material prepared by the invention better maintains the appearance of the titanium nanotube, and the equipment adopted is simple and the operation is safe. The present invention prepares TiO 2 Nanotube / SiO 2 The airgel composite photocatalytic powder material has a porous structure, which can improve its catalytic activity to a certain extent by utilizing the excellent surface physical and chemical properties of the pore structure; at the same time, the SiO 2 Airgel is used as a carrier, which solves the loading problem of nano-catalysts, is easy to recover, and can be recycled, which is an environmentally friendly high-performance material.

Owner:CHANGAN UNIV

Method for preparing metal coated pearlescent pigment

ActiveCN103788720BWith dustproofWith photocatalytic effectBiocideCosmetic preparationsMetal particleNanostructure

The invention discloses a method for preparing a metal coated pearlescent pigment. The pearlescent pigment is characterized by comprising a flaky substrate and a plurality of titanium dioxide nanorods which are arranged at intervals and are formed on the flaky substrate, so that a nano-structured surface with roughness can be formed by the titanium dioxide nanorods of the pearlescent pigment, and then, a plurality of metal particles are deposited on each titanium dioxide nanorod and the flaky substrate respectively.

Owner:浙江瑞成新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com