A kind of silver-modified tio2/graphene/bentonite composite material and preparation method thereof

A composite material and graphene technology, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problems of complex preparation process and expensive raw materials, and achieve simple preparation method, low material cost, and uniform distribution of Ag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

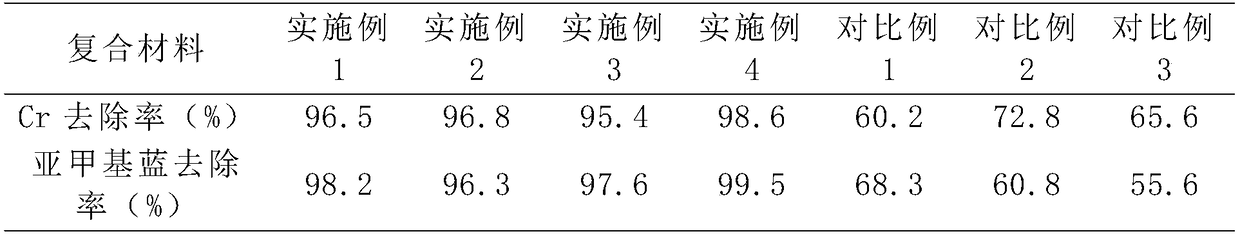

Examples

Embodiment 1

[0020] A silver-modified TiO 2 / The preparation method of graphene / bentonite composite material, the steps are as follows: (1) adding hydrazine hydrate to the graphene oxide suspension (graphene oxide is uniformly dispersed in aqueous solution, the same below), to control the quality of hydrazine hydrate and graphene oxide The ratio is 1:1.2, and the pH of the reaction system is adjusted to 7, and the temperature of the reaction system is guaranteed to be 60°C, and then the silver nitrate solution is added dropwise at 30 drops / min, and ultrasonic vibration is performed at the same time;

[0021] (2) Add bentonite suspension to the reaction system after the addition of the silver nitrate solution is completed, and ultrasonically vibrate at the same time, and the ultrasonic oscillation time is 5 minutes;

[0022] (3) Dry the intermediate product obtained in step (2) and then calcine it in an inert atmosphere at 700°C to finally obtain silver-modified TiO 2 / graphene / bentonite c...

Embodiment 2

[0024] A silver-modified TiO 2 / The preparation method of graphene / bentonite composite material, the steps are as follows: (1) Add hydrazine hydrate to the graphene oxide suspension, control the mass ratio of hydrazine hydrate and graphene oxide to be 1:1, and adjust the pH of the reaction system to be 10 , to ensure that the temperature of the reaction system is 90 ° C, and then dropwise add silver nitrate solution to it at 20 drops / min, while ultrasonically oscillating;

[0025] (2) After the addition of the silver nitrate solution is completed, add the bentonite suspension to the reaction system while ultrasonically vibrating for 10 minutes;

[0026] (3) Dry the intermediate product obtained in step (2) and then calcine it under inert gas at 600°C to finally obtain silver-modified TiO 2 / graphene / bentonite composite material, through the addition of graphene oxide, bentonite and silver nitrate, the mass ratio of bentonite to graphene is 50:5, the mass ratio of silver to gr...

Embodiment 3

[0028] A silver-modified TiO 2 / The preparation method of graphene / bentonite composite material, the steps are as follows: (1) Add hydrazine hydrate to the graphene oxide suspension, control the mass ratio of hydrazine hydrate and graphene oxide to be 1:1.5, and adjust the pH of the reaction system to be 10 , to ensure that the temperature of the reaction system is 100 ° C, and then dropwise add silver nitrate solution to it at 25 drops / min, while ultrasonically oscillating;

[0029] (2) Add bentonite suspension to the reaction system after the addition of the silver nitrate solution is completed, and ultrasonically vibrate at the same time, and the ultrasonic oscillation time is 4min;

[0030] (3) Dry the intermediate product obtained in step (2) and then calcine it under inert gas at 800°C to finally obtain silver-modified TiO 2 / graphene / bentonite composite material, the mass ratio of bentonite to graphene is 50:3, the mass ratio of silver to graphene is 18:1 through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com