Vacuum suction type wood strip inputting assembly for wood processing machine

A processing machine, inhalation technology, applied in conveyors, transportation and packaging, etc., can solve the problems of high labor intensity, inconvenient operation, workpiece offset, etc., and achieve the effect of stable transmission position, reliable transmission performance and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and embodiments.

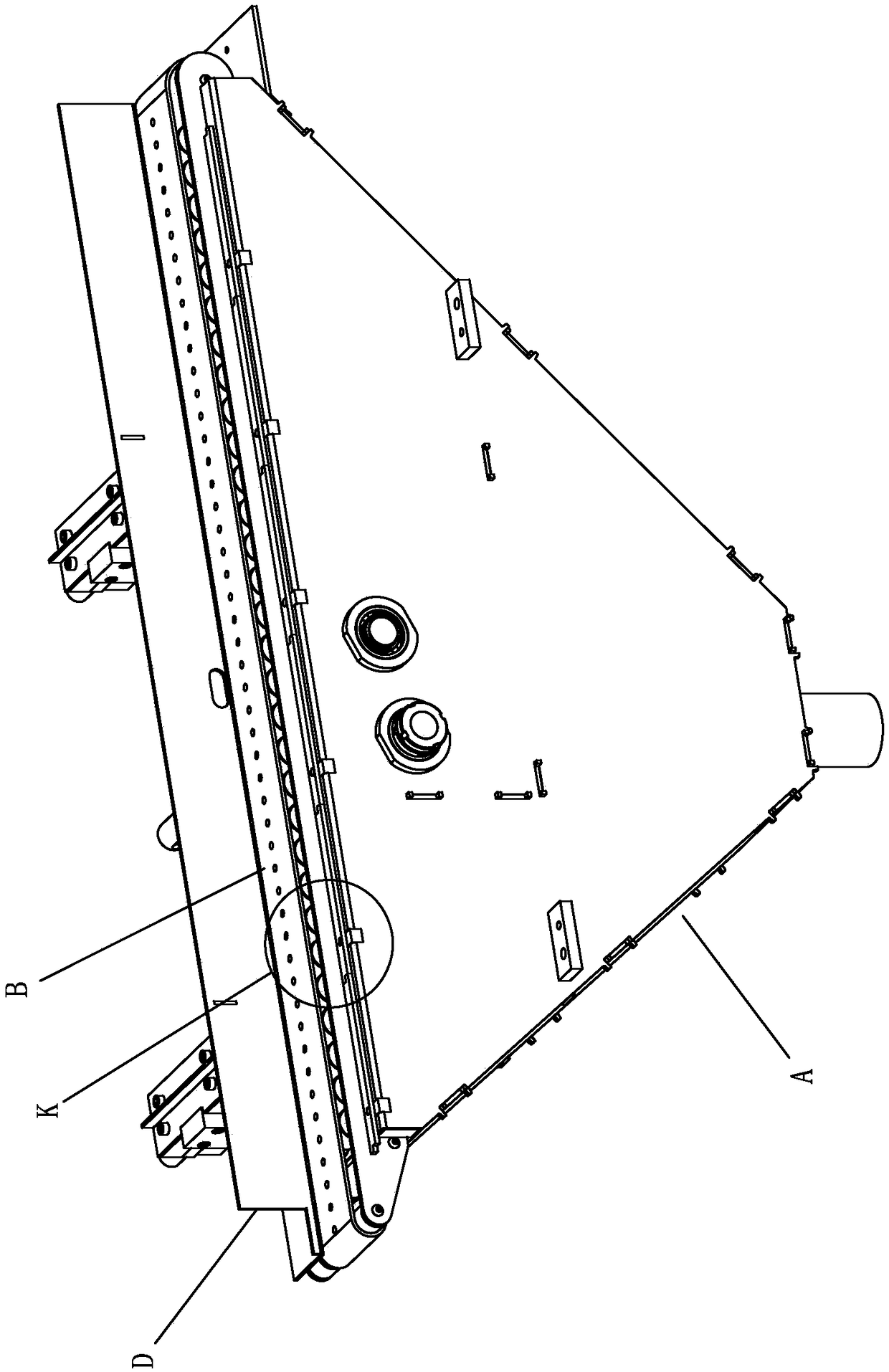

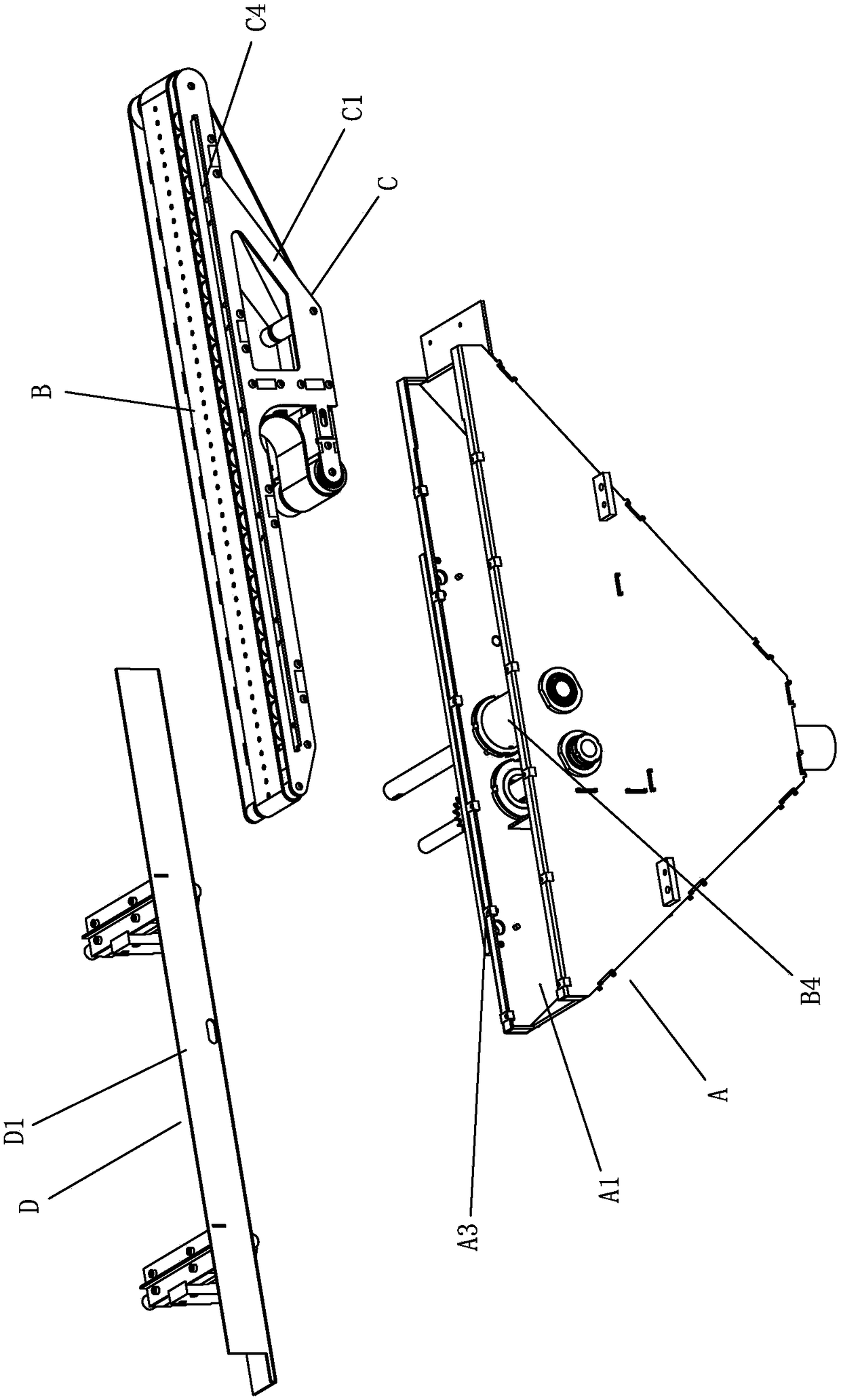

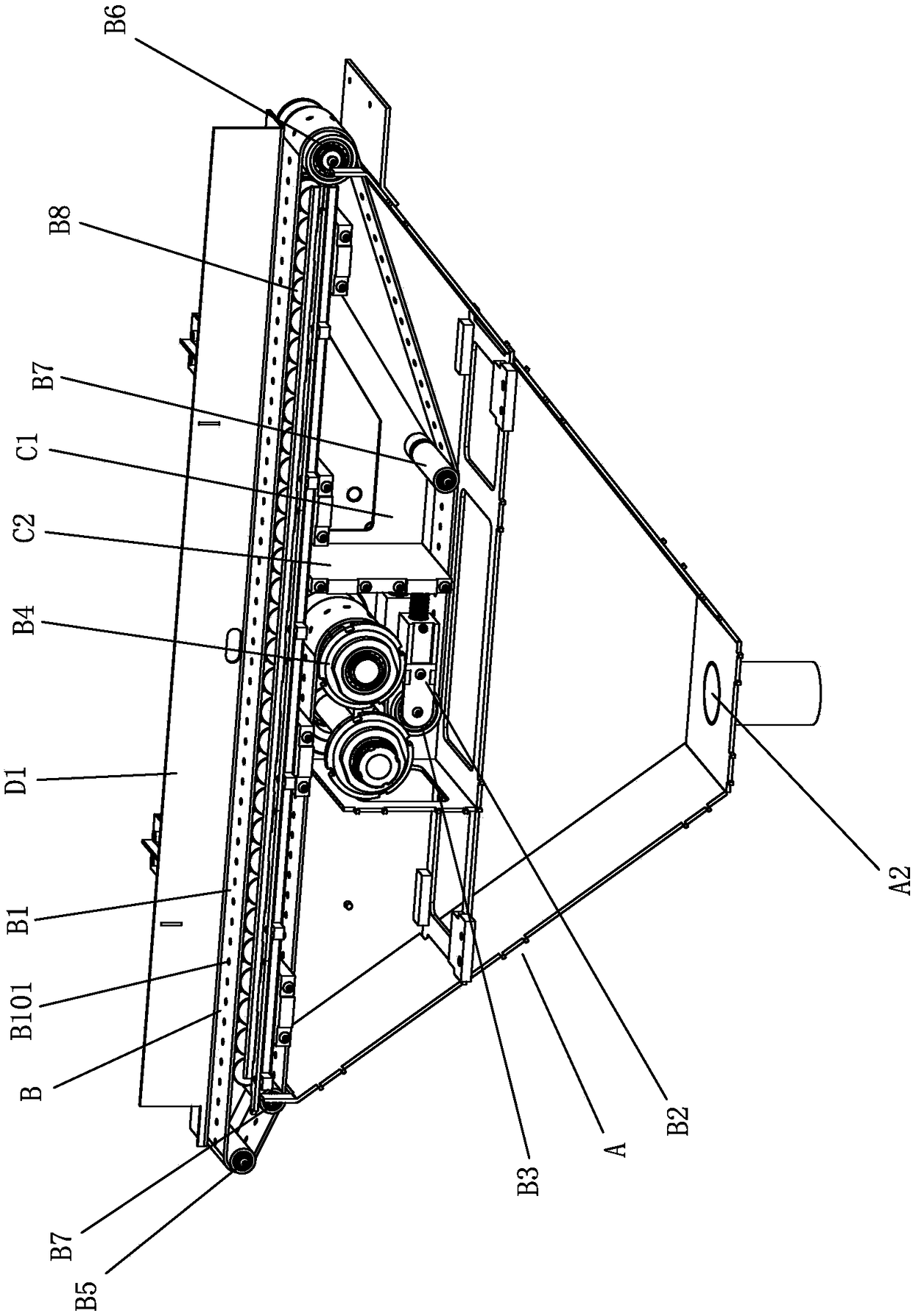

[0023] See Figure 1-Figure 6 , The vacuum suction type wooden strip input assembly for the wood processing machine is characterized in that it includes an evacuation box A and a wooden strip transmission assembly B, wherein the wooden strip transmission assembly B includes a drive motor (not marked in the figure) and a transmission belt B1, The output shaft of the driving motor is connected to the driving wheel B4. The driving wheel B4 is positioned and rotated in the cavity of the evacuated box A. The transmission belt B1 is at least partially set horizontally and forms a horizontal transmission area. When the driving motor is working, the driving wheel B4 drives the transmission belt through the transmission assembly B1 runs to achieve the horizontal transmission effect; in order to facilitate the replacement or maintenance of the transmission belt or transmission com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com