Preparation method of cement-based composite carbon electrode

A composite carbon and cement-based technology, applied in the field of electrochemistry, can solve the problems of insufficient electrode cohesion and short life, and achieve the effects of insufficient cohesion, high service life and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a cement-based composite carbon electrode, comprising the following steps:

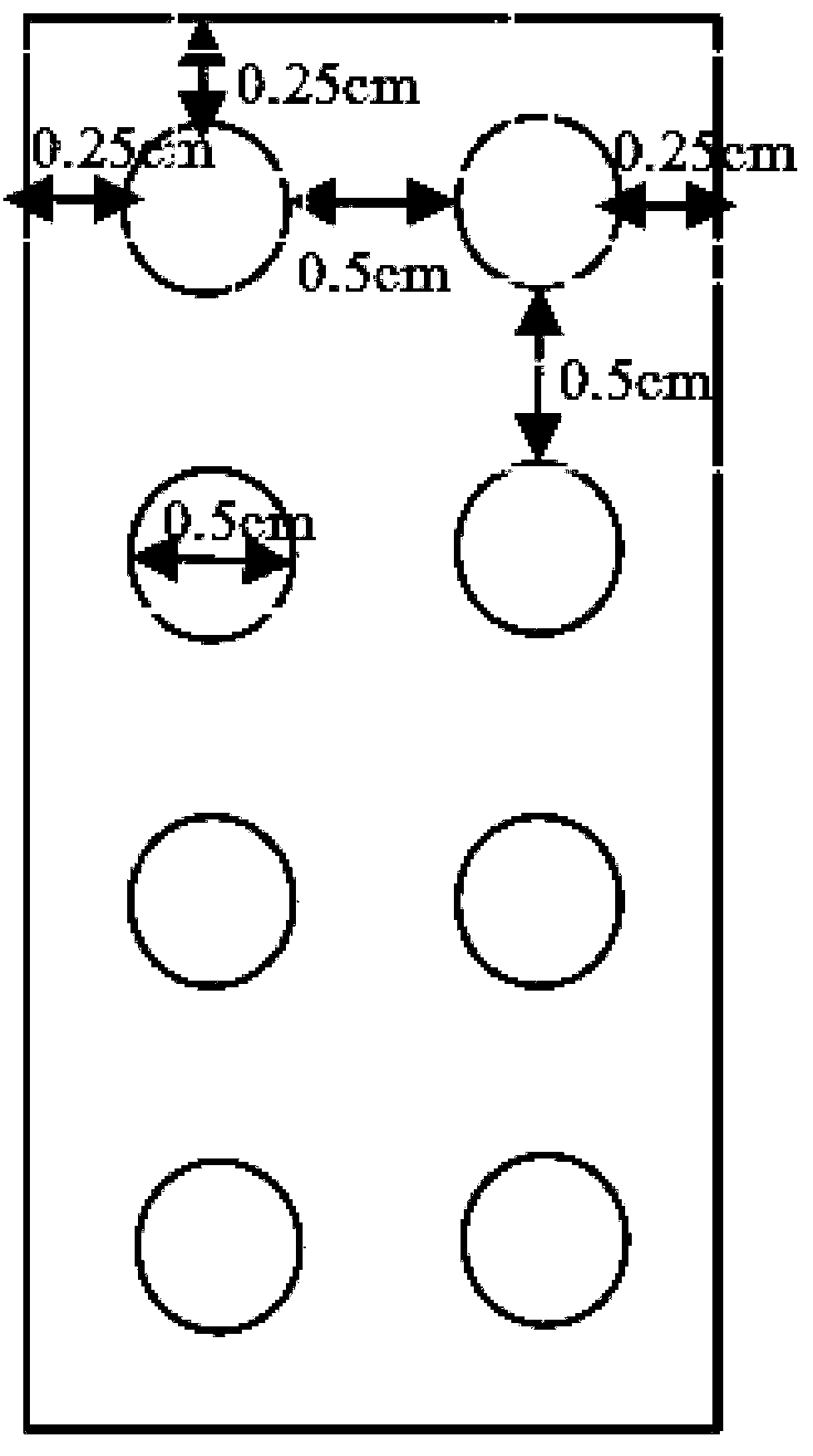

[0018] 1) A step of punching holes on graphite paper; the size of the graphite paper is 2cm*4cm, and 8 holes with a diameter of 5mm are evenly drilled on its surface, (such as figure 1 shown)

[0019] 2) a step of preparing graphite powder-activated carbon-cement-fly ash composite material;

[0020] Activated carbon is used as the active material, graphite powder is used as the conductive agent, cement and fly ash are used as the binder, and the mass ratio of cement, fly ash, activated carbon and graphite powder is 4.5:3:1.5:1. Mix, add deionized water, stir well until it is completely mixed, press the obtained muddy solid on both sides of graphite paper to make the surface coating smooth, and then place it in a cement incubator at 90% humidity and 25°C The graphite powder-activated carbon-cement-fly ash composite material was prepared after being...

Embodiment 2

[0024] An example of rapid degradation of methyl orange in wastewater by using the cement-based composite carbon electrode improved by the method of the present invention.

[0025] Electrochemical degradation of methyl orange by a three-electrode system, with the cement-based composite carbon electrode prepared by the present invention as a working electrode, with titanium mesh as an auxiliary electrode, with Ag / AgCl (saturated) as a reference electrode, stirring at a speed of 150r / min Next, take 150mL of methyl orange with a concentration of 20mg / L as the degradation object, apply a square wave potential [the upper potential (Eu) and the lower potential (El) are 1.5V and -1.5V respectively, and the alternating period (T) is 1min, The concentration of methyl orange was measured every 30 min with a spectrophotometer.

[0026] Compared with the cement-based composite carbon electrode before improvement, the degradation rate of this new electrode was 73.33% (76.62% before improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com