Coal-to-oil synthetic wastewater treatment system and process

A wastewater treatment system and coal-to-oil technology, applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of environmental pollution, high oil content, waste of water resources, etc. Benefit, prolong the adsorption time, reduce the effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

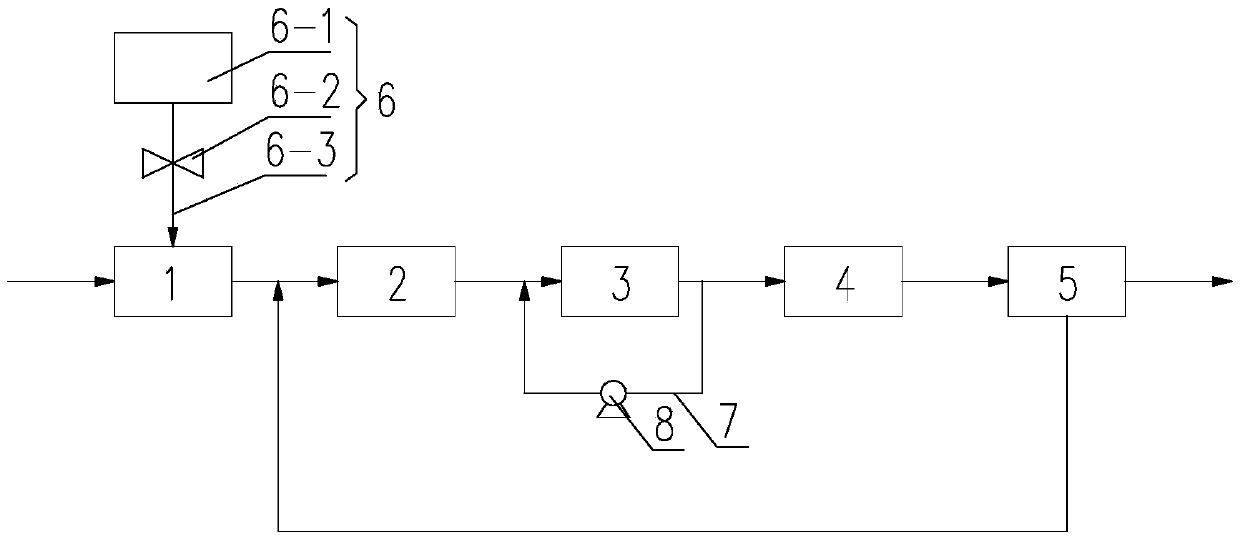

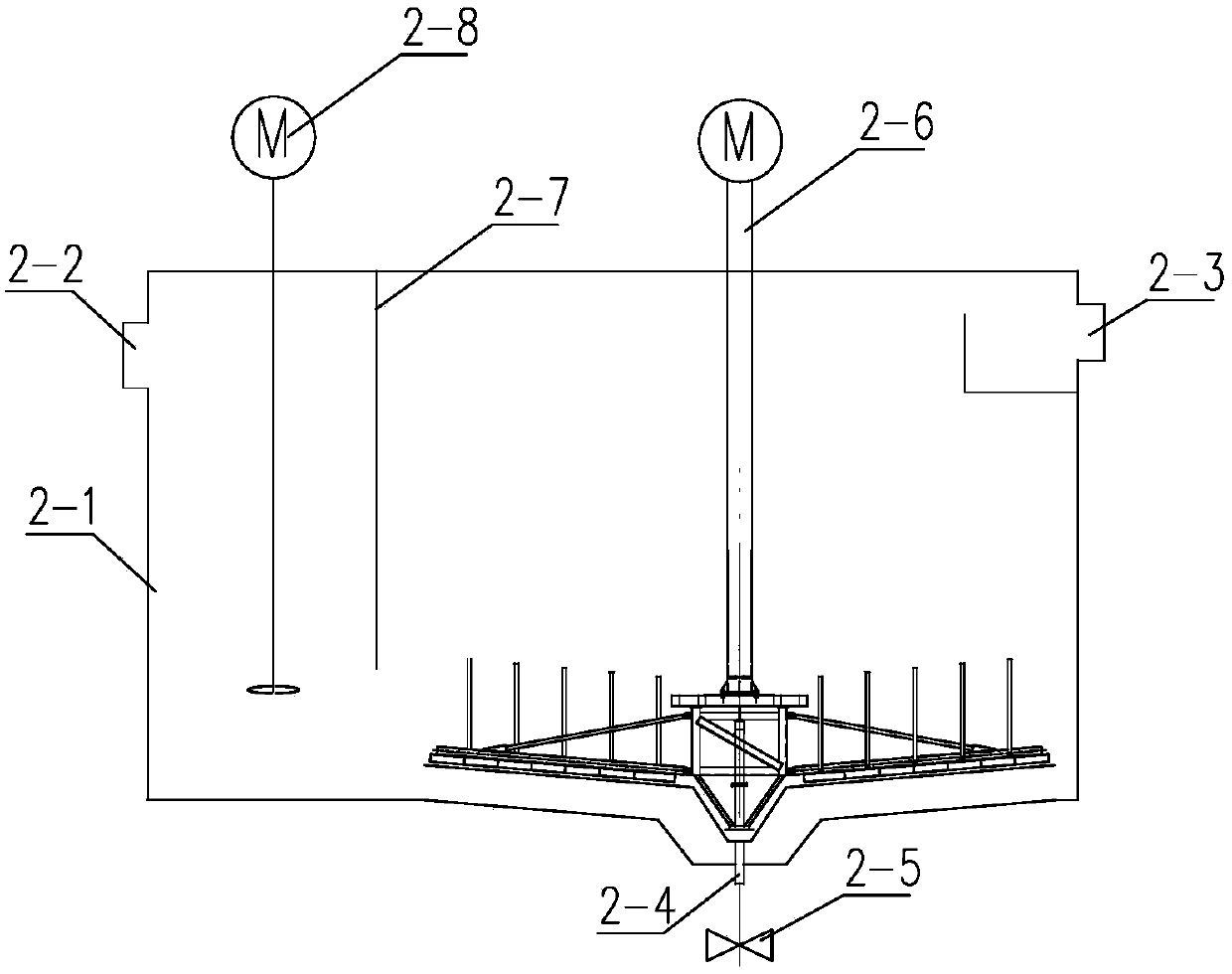

[0031] Such as figure 1 , figure 2 The shown coal-to-oil synthetic wastewater treatment system includes a regulating tank 1, an oil removal device 2, a UASB reactor 3, an A / O pool 4, a secondary sedimentation tank 5, and an alkali addition unit 6;

[0032] The liquid outlet of the regulating tank 1 is connected with the inlet 2-2 of the degreasing tank 2-1 of the degreasing device 2, the water outlet 2-3 of the degreasing tank 2-1 is connected with the water inlet of the UASB reactor 3, and the UASB reacts The liquid outlet of device 3 is communicated with the water inlet of A / O pool 4, and the liquid outlet of A / O pool 4 is communicated with the water inlet of secondary sedimentation tank 5, and the mud outlet of secondary sedimentation tank 5 is connected with degreasing tank 2- The entrance of 1 is connected to 2-2;

[0033] Alkali adding unit 6 comprises lye tank 6-1, the liquid outlet of lye tank 6-1 communicates with one end of dosing pipe 6-2, and the other end of do...

Embodiment 2

[0043] Utilize the coal-to-oil synthetic wastewater treatment system described in Example 1 to treat the coal-to-oil synthetic wastewater, including the following steps: step one acid-base adjustment; step two oil removal; step three anaerobic treatment; step four anaerobic aerobic treatment; Process five settlement treatment; where:

[0044] Process 1 acid-base adjustment: Send the synthetic wastewater with a pH value of 3.5, a COD of 15000 mg / L, and an oil content of 50 mg / L to the adjustment pool 1 of the coal-to-oil synthetic wastewater treatment system, and add The lye is used to adjust the acid and alkali of the synthetic wastewater to obtain the adjusted wastewater with a pH value of 5;

[0045] Process 2 Degreasing: Send the adjusted wastewater obtained in the process 1 acid-base adjustment to the degreasing pool 2-1 of the coal-to-oil synthetic wastewater treatment system for degreasing treatment, and add sludge to the degreasing pool 2-1 , through the adsorption of ...

Embodiment 3

[0051] Utilize the coal-to-oil synthetic wastewater treatment system described in Example 1 to treat the coal-to-oil synthetic wastewater, including the following steps: step one acid-base adjustment; step two oil removal; step three anaerobic treatment; step four anaerobic aerobic treatment; Process five settlement treatment; where:

[0052] Process 1 Acid-base adjustment: Send the synthetic wastewater with a pH value of 3, a COD of 17000 mg / L, and an oil content of 60 mg / L to the adjustment tank 1 of the coal-to-oil synthetic wastewater treatment system, and add alkali to the adjustment tank 1 The synthetic wastewater is acid-base adjusted, acid-base adjusted, and the adjusted wastewater with a pH value of 4.7 is obtained;

[0053] Process 2 degreasing: send the regulated wastewater obtained in the process 1 acid-base adjustment to the degreasing pool 2-1 of the coal-to-oil synthetic wastewater treatment system, add sludge to the degreasing pool 2-1, and pass the sludge Ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com