Method for preparing metal coated pearlescent pigment

A pearlescent pigment and metal coating technology, applied in the field of pearlescent pigments, can solve the problems of affecting the stability of the coating, the presentation of efficacy cannot be manifested, and it is difficult to maintain the color quality of the pearlescent coating, and achieve the effect of improving photocatalytic activity and antibacterial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

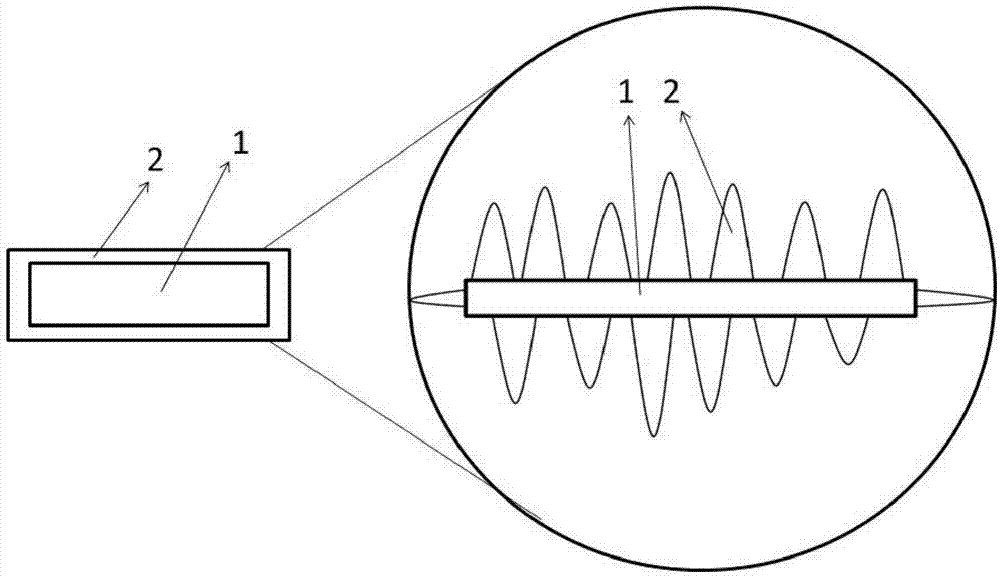

[0029] Embodiment 1: present embodiment provides a kind of pearlescent pigment, and its structure is:

[0030] (1) if figure 1 As shown, on the surface of the sheet substrate 1, a plurality of columnar Ti 2 o 3 The nanorod 2, the sheet substrate 1 can be natural mica sheet, synthetic mica sheet, glass sheet, sheet aluminum powder, sheet expanded perlite, aluminum oxide, silicon dioxide, etc., the sheet substrate 1 The particle size can be 2-800 microns, and the thickness can be 0.1-10 microns. In the present invention, an aqueous solution of titanium trichloride hydrochloric acid is slowly added dropwise to the solution containing sheet substrate 1 to hydrolyze titanium trichloride into trioxide Dititanium is adsorbed on the sheet substrate 1 to form a Ti 2 o 3 Nanorod 2, where Ti 2 o 3 Nanorods 2 can control Ti according to reaction rate, reaction time and pH value 2 o 3 The height of nanorod 2, to form the pearlescent pigment of different colors, just utilize Ti 2 o...

Embodiment 2

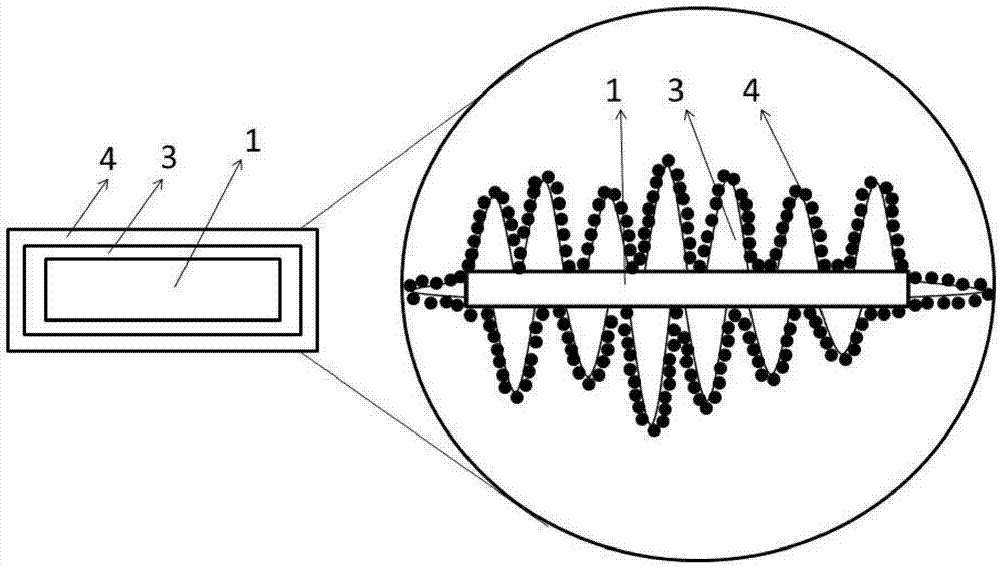

[0031] Embodiment 2: the present embodiment provides a kind of pearlescent pigment coated with metal, and its structure is:

[0032] (1) if figure 2 Shown, continue the follow-up step of embodiment 1, further provide another kind of pearlescent pigment. (2) Utilize Ti on the pearlescent pigment of embodiment 1 2 o 3 Reducibility, after redox reaction with metal salt, Ti 2 o 3 oxidized to TiO 2 , metal particles 4 are reduced and deposited on TiO 2 1 on the nanorod 3 and the sheet substrate; wherein the metal salt can be metal salts such as chloroauric acid, chloroplatinic acid, ruthenium chloride, palladium chloride, rhodium chloride, ferric chloride, copper nitrate and palladium acetate any one or a combination of two or more. Next, according to the use of different metal particles 4 deposited on the TiO 2 On the nanorod 3 and the sheet substrate 1, pearlescent pigments coated with different metals can be obtained. For example, after redox reaction with an aqueous so...

Embodiment 3

[0033] Embodiment 3: present embodiment provides a kind of pearlescent pigment, and its structure is:

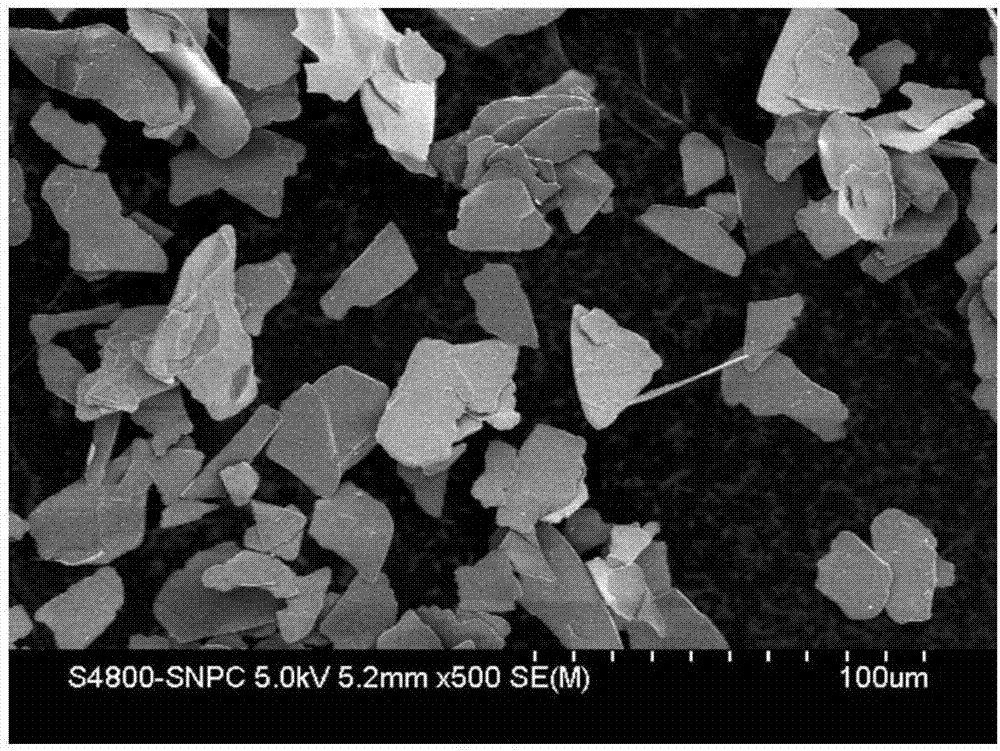

[0034] (1) Use commercially available pearlescent pigments (YB103, YB205, YB219, YB300, YB504, etc.) 2 o 3 The nanorods grow by reaction, and the Ti is controlled according to the time of adding the titanium trichloride solution 2 o 3 The growth height of the nanorods, after reacting for 8 to 12 hours, the pH value is controlled at 1.5-2.5, Ti 2 o 3 The growth height of the nanorod is 60-80 nanometers, and it has a length of 30-60 nanometers and a width of 30-60 nanometers, and a plurality of Ti rods arranged at intervals. 2 o 3 Nanorods will form a rough surface on their surface, and have a total roughness Rz(DIN) between 60-80, and Ti 2 o 3 Coated pearlescent pigments, and the pearlescent pigments form multiple Ti on the surface 2 o 3 The nanostructure of nanorods has a lotus effect, which produces anti-fouling and dust-proof effects.

[0035] Then, (2) using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com