Patents

Literature

72results about How to "Complete process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-concentration difficultly degraded chemical waste water treatment method

ActiveCN106045235AHigh shock load resistanceEasy to handleTreatment using aerobic processesWater/sewage treatment by irradiationHigh concentrationWater treatment

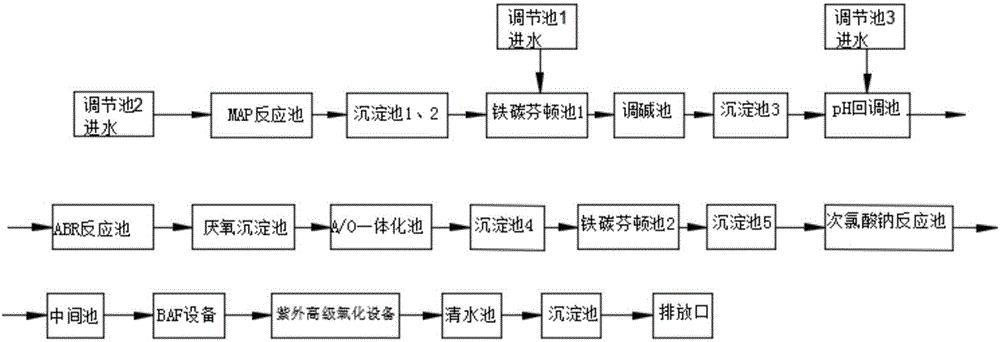

The invention discloses a high-concentration difficultly degraded chemical waste water treatment method. The method comprises 1, waste water collection, 2, pH adjustment and preliminary removal of high-concentration ammonia nitrogen in waste water, 3, deposition separation, feeding of the supernatant into a first iron-carbon Fenton reaction pool and mixing of the supernatant and waste water in a first adjustment tank, 4, hydrochloric acid-based pH adjustment, addition of hydrogen peroxide and ferrous sulphate into the first iron-carbon Fenton reaction pool, mixing of product water and domestic sewage and feeding of the mixture into an anaerobic pond, 5, treatment in the anaerobic pond and lifting of the product water to an A / O integrated tank, 6, treatment on the product water in a second iron-carbon Fenton reaction pool, deposition, supernatant pH adjustment, treatment in a sodium hypochlorite reaction tank and feeding of the product water into a BAF biological aeration filter tank, and 7, treatment on the product water from the BAF biological aeration filter tank through UV high-grade equipment, treatment in a sedimentation basin and discharge of the supernatant into a total discharge opening. The method has high impact resistance, a high treatment capability, a complete process and good treatment efficiency.

Owner:江西沃邦兴环保科技有限公司

Automatic sand clearing device

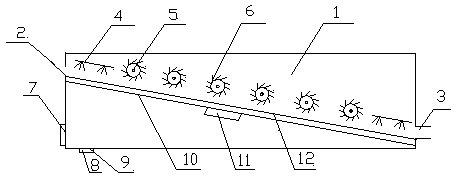

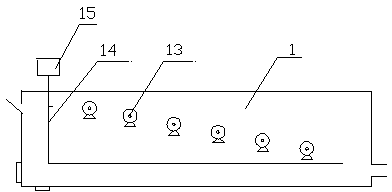

The invention discloses an automatic sand clearing device which comprises a clearing box provided with a feeding port and a discharging port, the feeding port is formed in the upper portion, and the discharging port is formed in the lower portion. A filter net is fixed between the feeding port and the discharging port, a supporting strip is arranged below the filter net, and a vibrating motor is arranged below the supporting strip. Motors are arranged on the front face of the clearing box and drive rotating shafts to rotate, and brushing bristles are fixed to the rotating shafts. High-pressure air jets are formed on the two sides of the rotating shafts and communicated with an external air source through an air pipe, and the ligature of the heights of the rotating shafts and the centers of the high-pressure air jets form a straight line. A sand outlet is formed in the lower portion of the clearing box, and a sand-discharging operation opening is formed below the feeding port. The automatic sand clearing device is simple in structure, convenient to use and practical, a casting enters the clearing box and then is vibrated continuously, so that molding sand is vibrated to be loose, the workpiece rolls downwards continuously because the filter net has a gradient, firstly, compressed air is used for clearing away the floating sand of the workpiece through blowing, then the surface is cleared through the brushing bristles, finally, compressed air is used for clearing the workpiece through blowing, and therefore the whole process is continuous and complete.

Owner:江阴金属材料创新研究院有限公司

Paper wrapping and pasting device of full-automatic hamburger packaging machine

ActiveCN105857702ARealize automatic paper wrappingThe process is complete and smoothWrapper folding/bending apparatusWrapper supporting apparatusMeat burgerPulp and paper industry

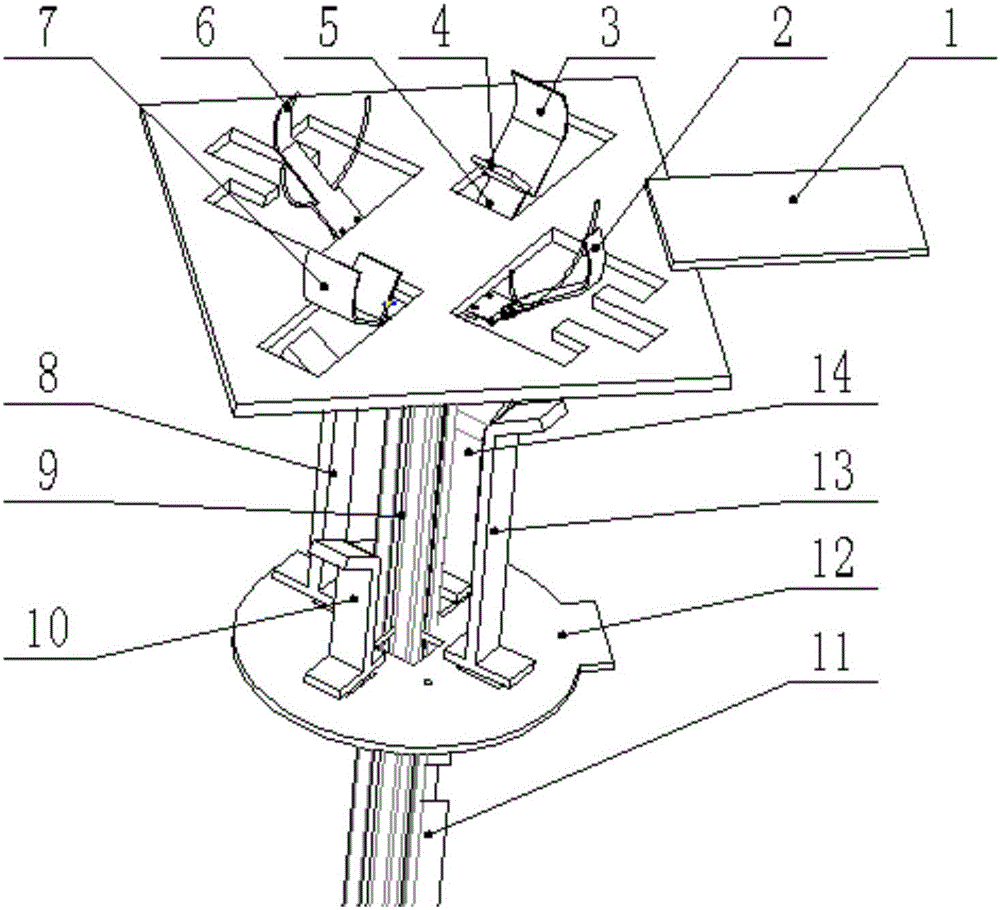

The invention discloses a paper wrapping and pasting device of a full-automatic hamburger packaging machine. The paper wrapping and pasting device comprises a rack, wherein a working platform is arranged on the rack; four mechanical claw arms are respectively arranged on the working platform; the four mechanical claw arms comprise two groups of front claw arms and rear claw arms arranged oppositely; sponge strips are arranged in the middle of the rear claw arms; the sponge strips face to a paper wrapping station; compression springs are arranged at the connecting parts of the four mechanical claw arms and the working platform; push rods are mounted on a push platform; the push platform is connected with a lifting driving component; through holes through which the mechanical claw arms are turned downwards and the push rods penetrate are formed in outer sides of the four mechanical claw arms on the working platform; a paper pressing cylinder and a pressing block are arranged above the paper wrapping station; a paper pasting mechanism is arranged on a side above the paper wrapping station; the moving end of the paper pressing cylinder is connected with a paper belt plate; an upper paper coiling wheel is mounted on the rack; a paper pasting piece is mounted on a roller of the upper paper coiling wheel in a sleeving manner; and the paper pasting piece penetrates through the end part of the paper belt plate and penetrates through a lower paper coiling wheel. The paper wrapping and pasting device is automatic in operation, saved in time and labor and relatively high in working efficiency, and automatic paper wrapping of hamburgers can be achieved.

Owner:ZHEJIANG UNIV OF TECH

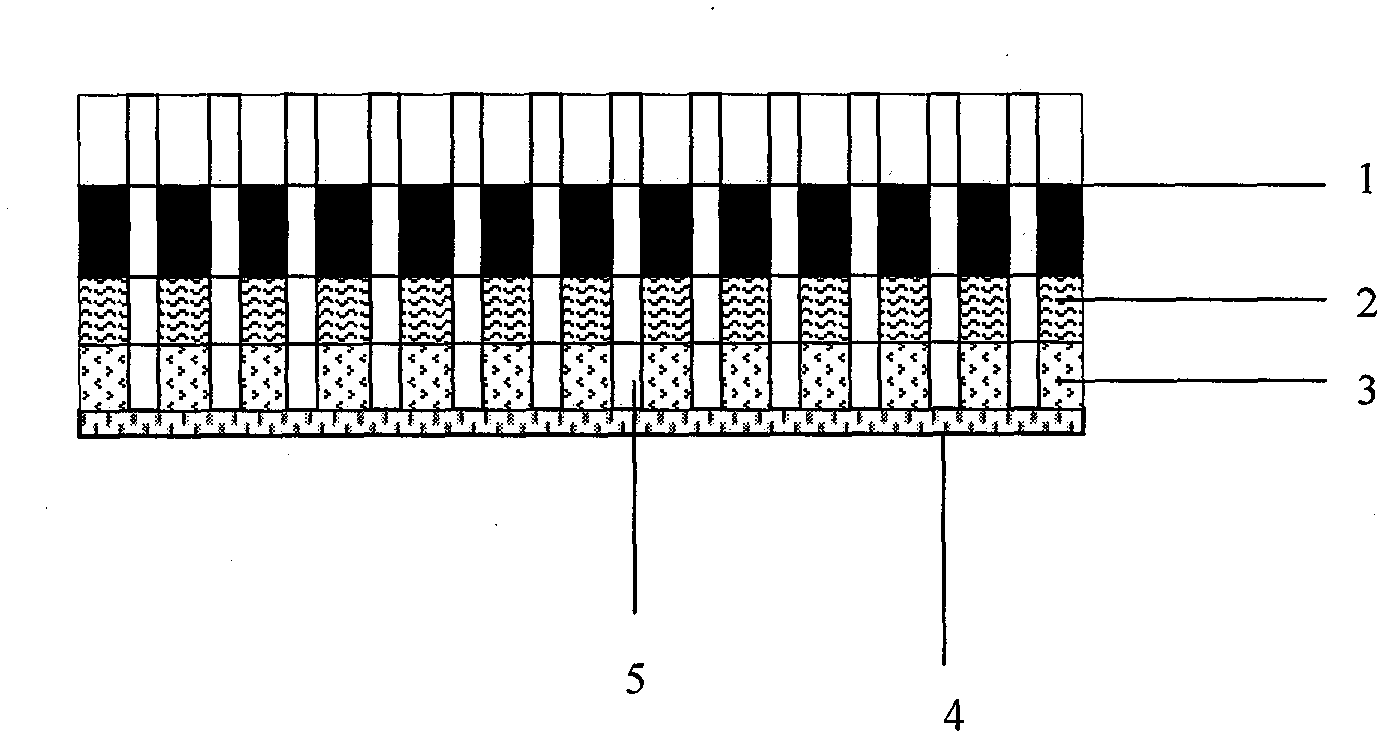

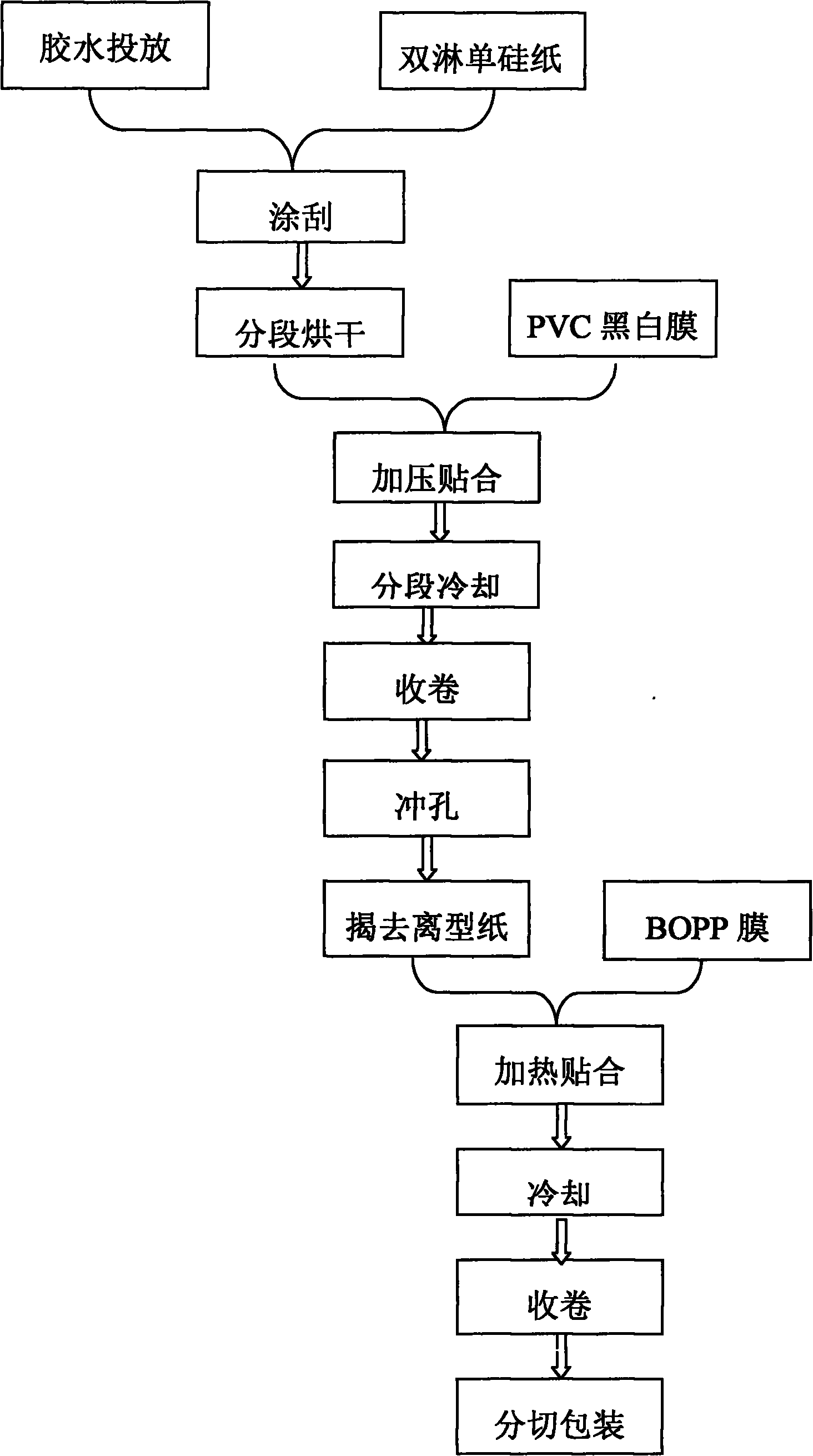

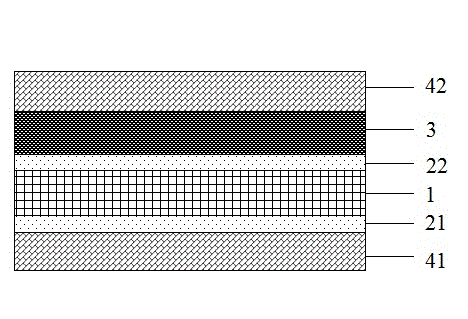

One-way perspective digital printed material with bottom coated with BOPP membrane and process method

ActiveCN102862409AAvoid deformationPrevent leakageLamination ancillary operationsDuplicating/marking methodsPunchingAdhesive glue

The invention belongs to an one-way perspective digital printed material with bottom coated with a BOPP membrane and a process method, the one-way perspective digital printed material is in a layer-shaped structure composed of a PVC black-white film, a glue layer, an adhesion-resistant release paper layer and a BOPP membrane bottom layer in order, and the process method comprises the steps of PVC black-white film back-gluing, punching and film coating. The process flow is complete, the operation is simple, and bottom paper is not replaced after punching and film coating is conducted directly, the one-way perspective digital printed material with bottom coated with the BOPP membrane resolves the problem of deformation of a small hole during the stripping process, enables the aperture to maintain circularity, simultaneously the production cost is reduced, the absorbency is excellent, the leakage of printing ink of a single permeable membrane during the painting process can be solved; the good stretching performance of the BOPP membrane can protect the destroy of the pulling force of a machine on a glue-faced microstructure during the painting process, so that the viscosity and stability of the glue face can be protected.

Owner:SHANGHAI NAR INDAL

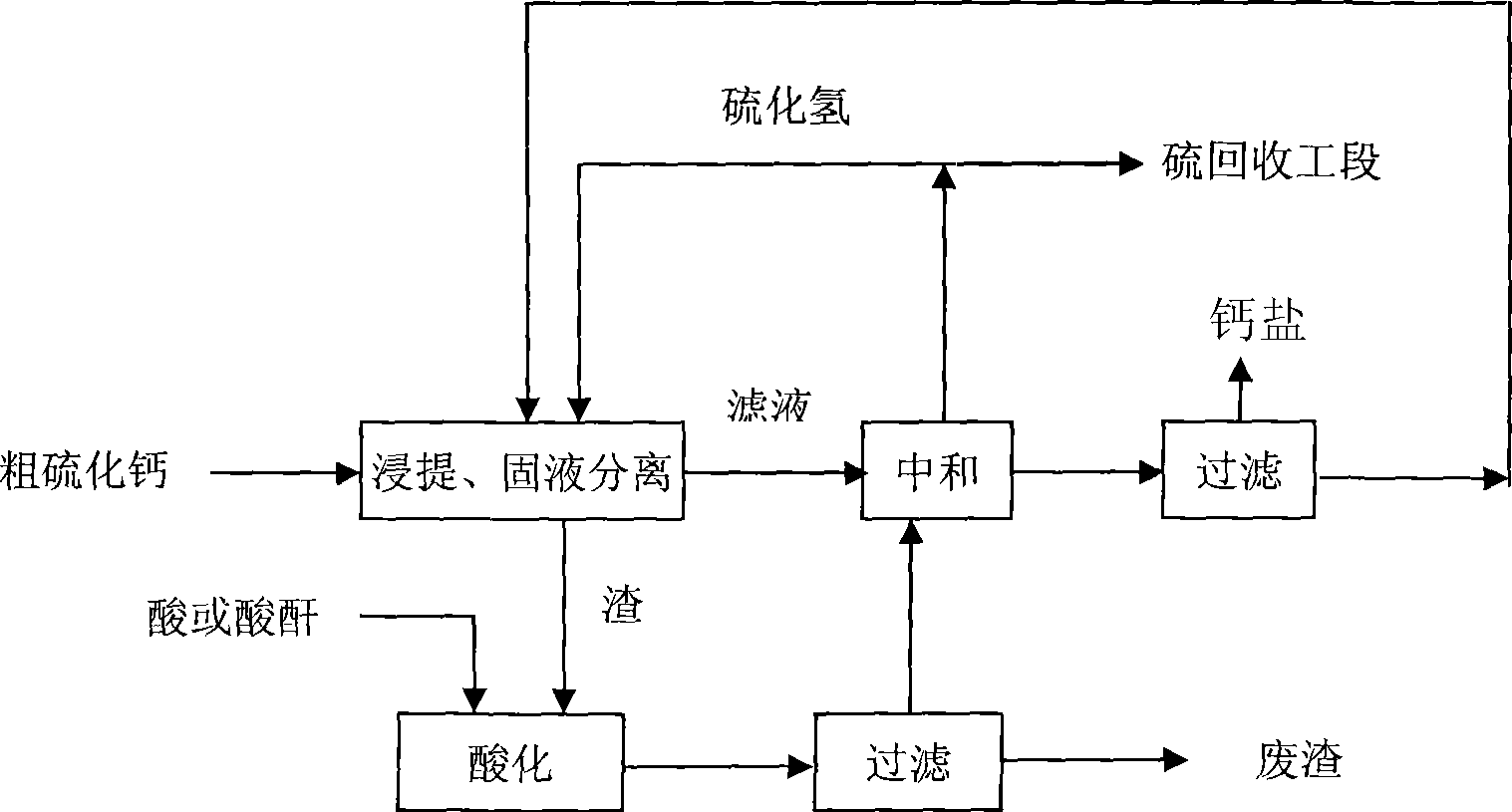

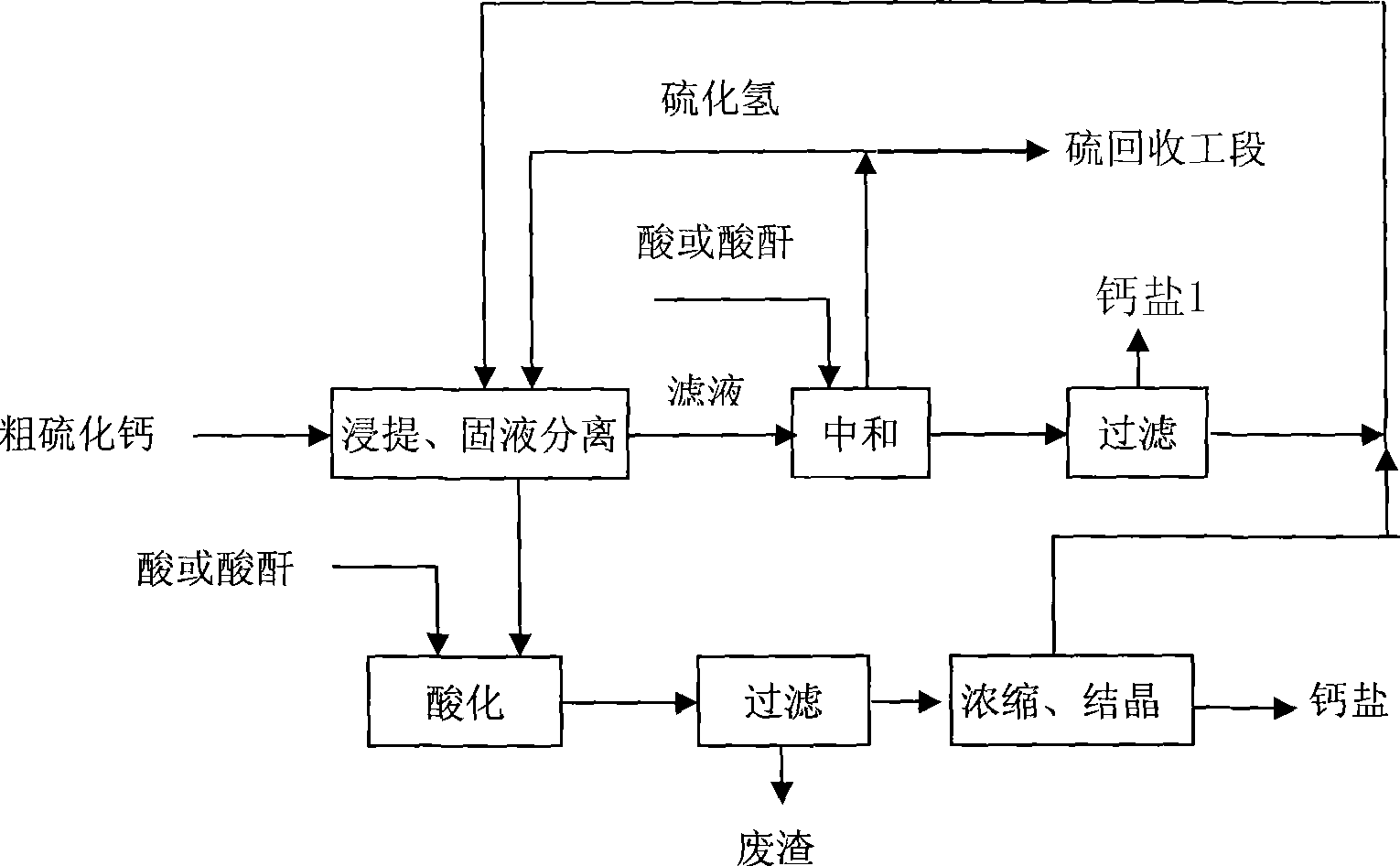

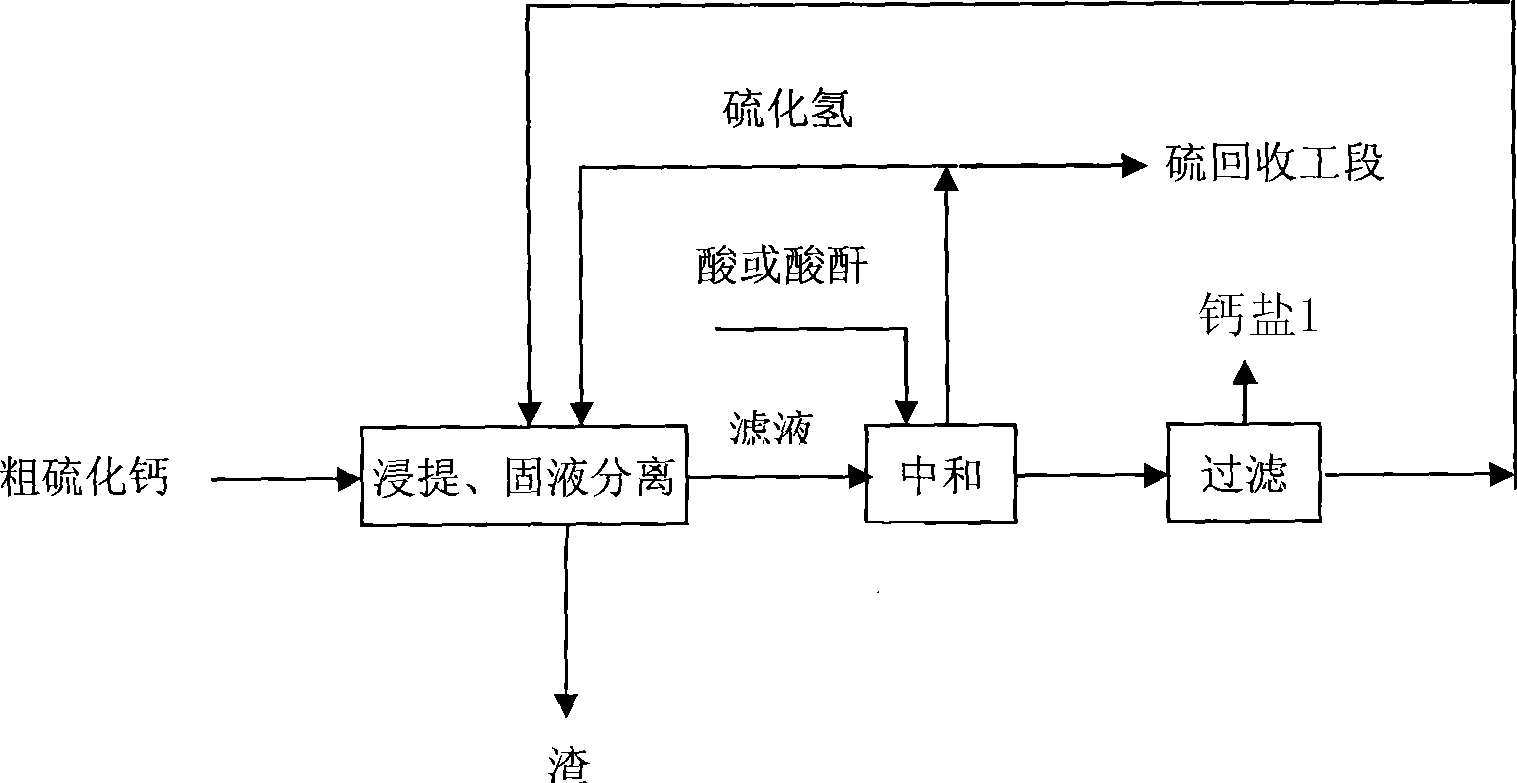

Method for producing sulfurated hydrogen and calcium salt with calcium sulphide

InactiveCN101372319ATake advantage ofHigh reaction conversion rateCalcium/strontium/barium compoundsHydrogen sulfidesCalcium hydroxideHydrogen

The invention relates to a method by adopting calcium sulfide to produce hydrogen sulphide and calcium salt and belongs to the technical field of environment protective treatment and chemical production, in particular to a method using calcium sulfide to react with acid or estolide to produce hydrogen sulphide and corresponding calcium salt; in the method, calcium sulfide reacts with acid or estolide to produce hydrogen sulphide and calcium salt; the method includes the following steps: a. coarse calcium sulfide is added into water to prepare calcium sulfide suspension; b. hydrogen sulphide gas is filled in the calcium sulfide suspension for reaction until the specific gravity of clear solution reaches 1.02-1.19, so as to obtain sulfur calcium hydroxide water solution; c. solid residue is removed by separation; d. after solid-liquid separation, the sulfur calcium hydroxide water solution or / and the residue is / are mixed with the acid or / and the estolide to prepare hydrogen sulphide and calcium salt; the method has the advantages of complete technological process, full utilization of calcium and sulfur resources, high reaction conversion rate and easy control of the production process.

Owner:YUNNAN CHEM RES INST

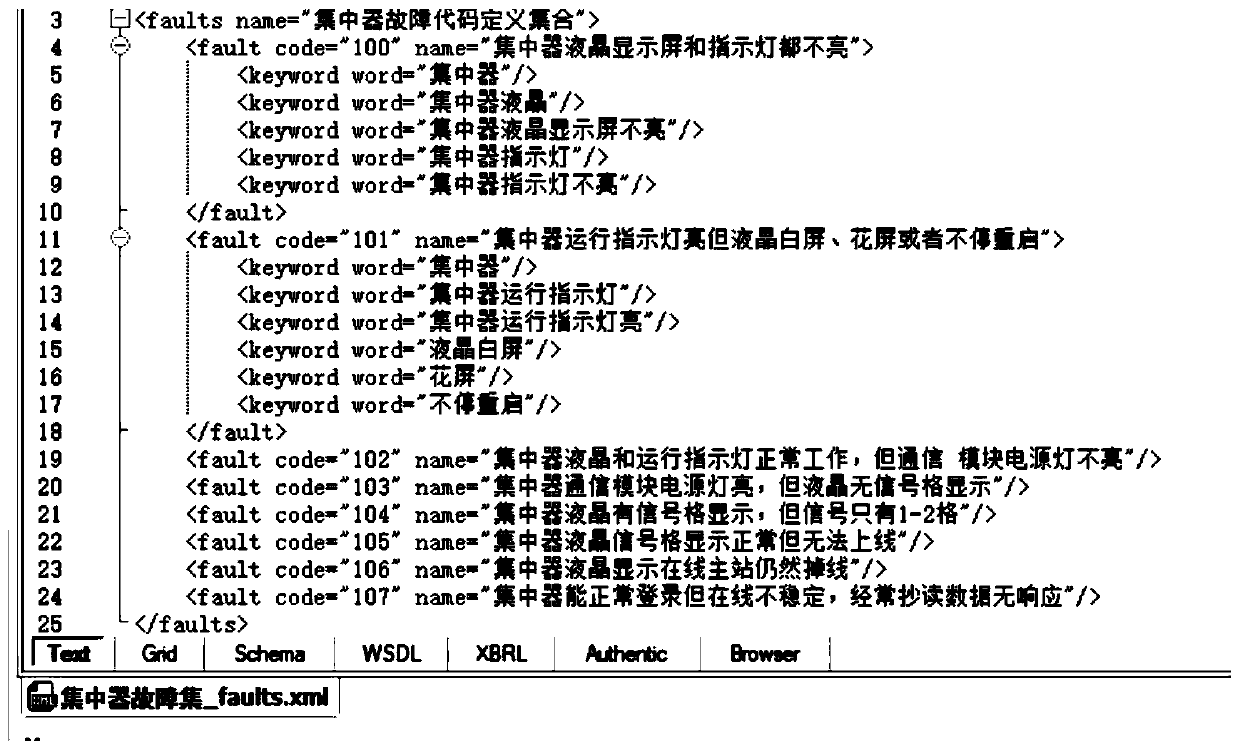

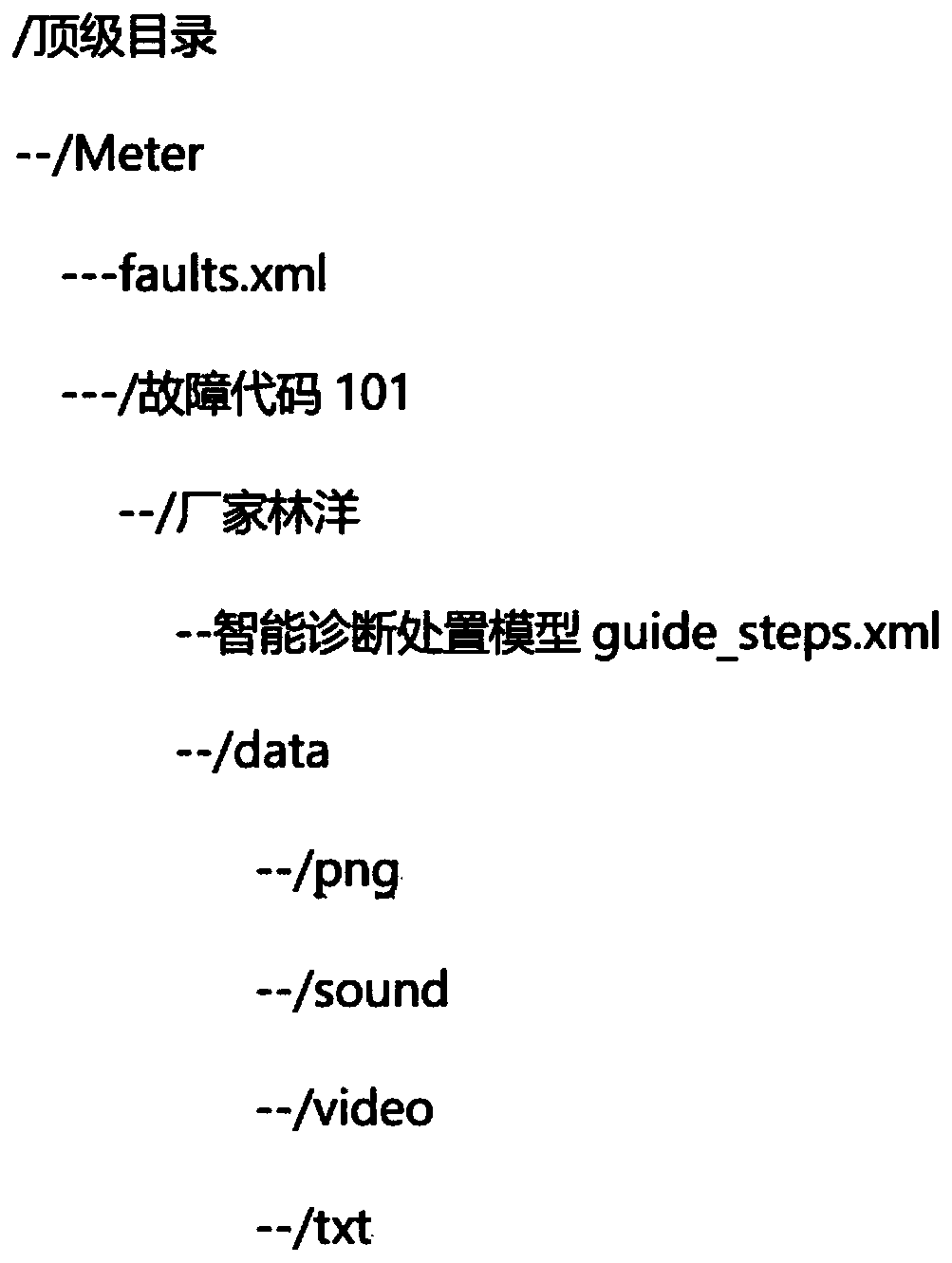

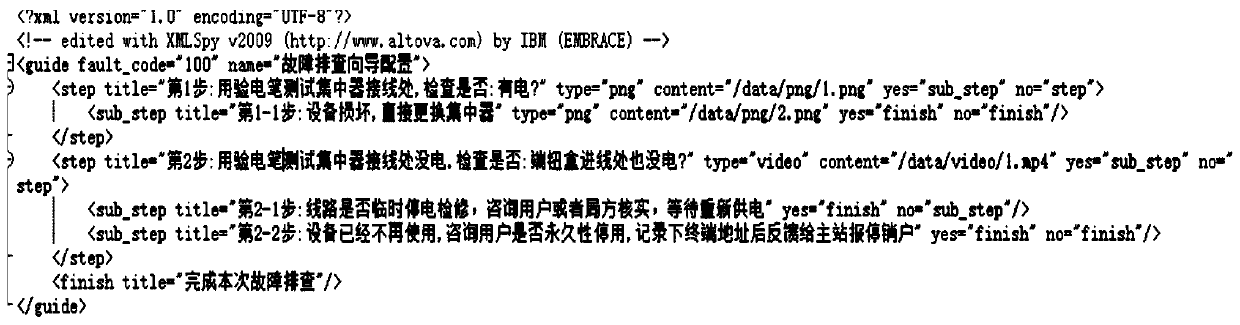

Knowledge database construction and management method for operation and maintenance of electric power metering equipment

ActiveCN110597791AEasy to set upImprove securityDatabase updatingData processing applicationsHuman powerTime cost

The invention discloses a knowledge database construction and management method for operation and maintenance of electric power metering equipment. The method comprises the following steps: defining afault operation and maintenance knowledge code set model in an xml format; setting a fault code definition set model file faults.xml of each metering equipment to adopt the xml format; a knowledge base operation and maintenance administrator adding, deleting, modifying and auditing operation and maintenance knowledge corresponding to each fault code of each device through a background web page; and constructing an xml format and a configured intelligent diagnosis and treatment model. The constructed database can achieve network access training at any time, update knowledge of operation and maintenance can be updated at any time and known in time, effective propaganda can be obtained in time, on-site operation and maintenance can be effectively supported, and labor and time cost is reduced.

Owner:GUIZHOU POWER GRID CO LTD

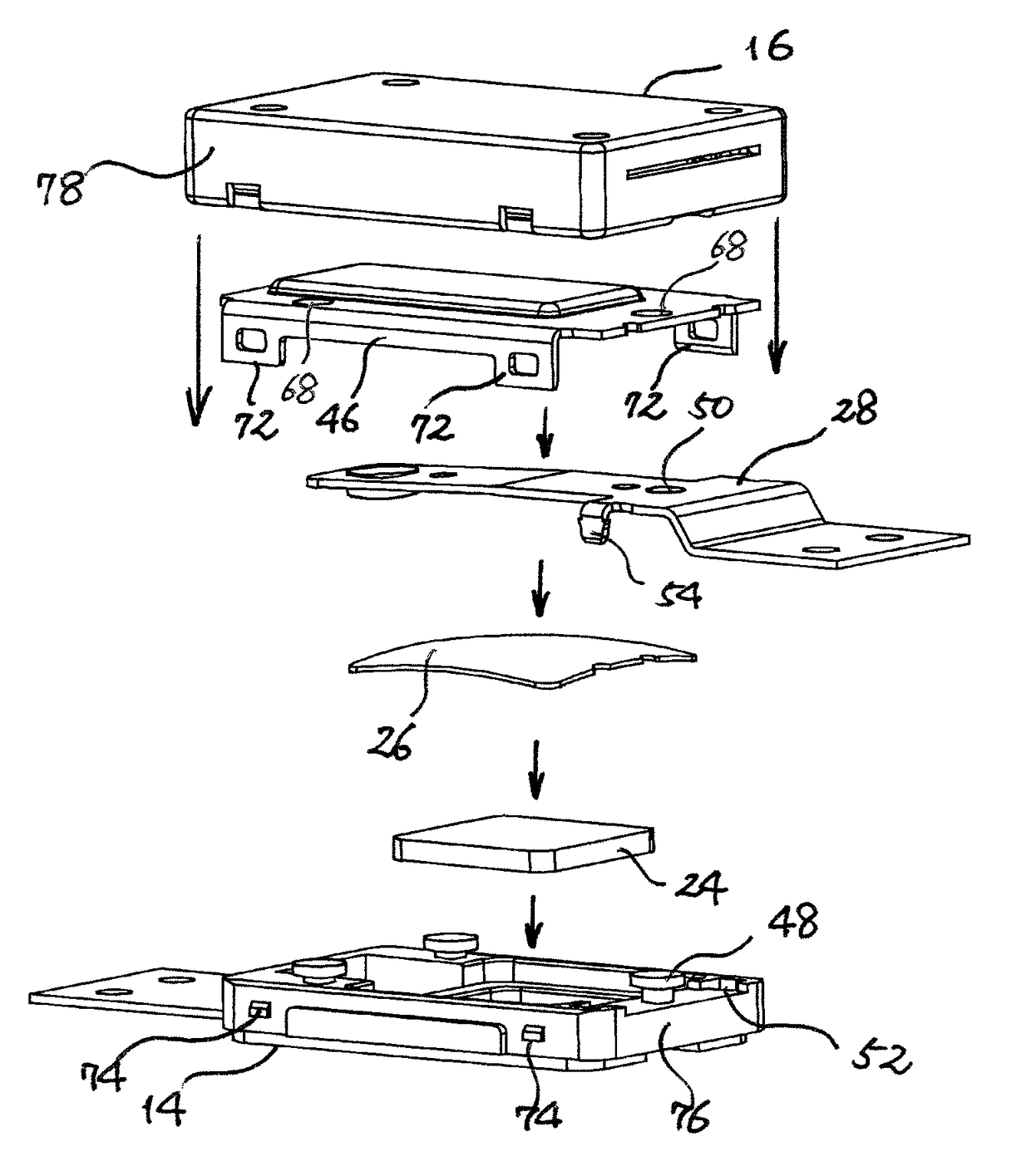

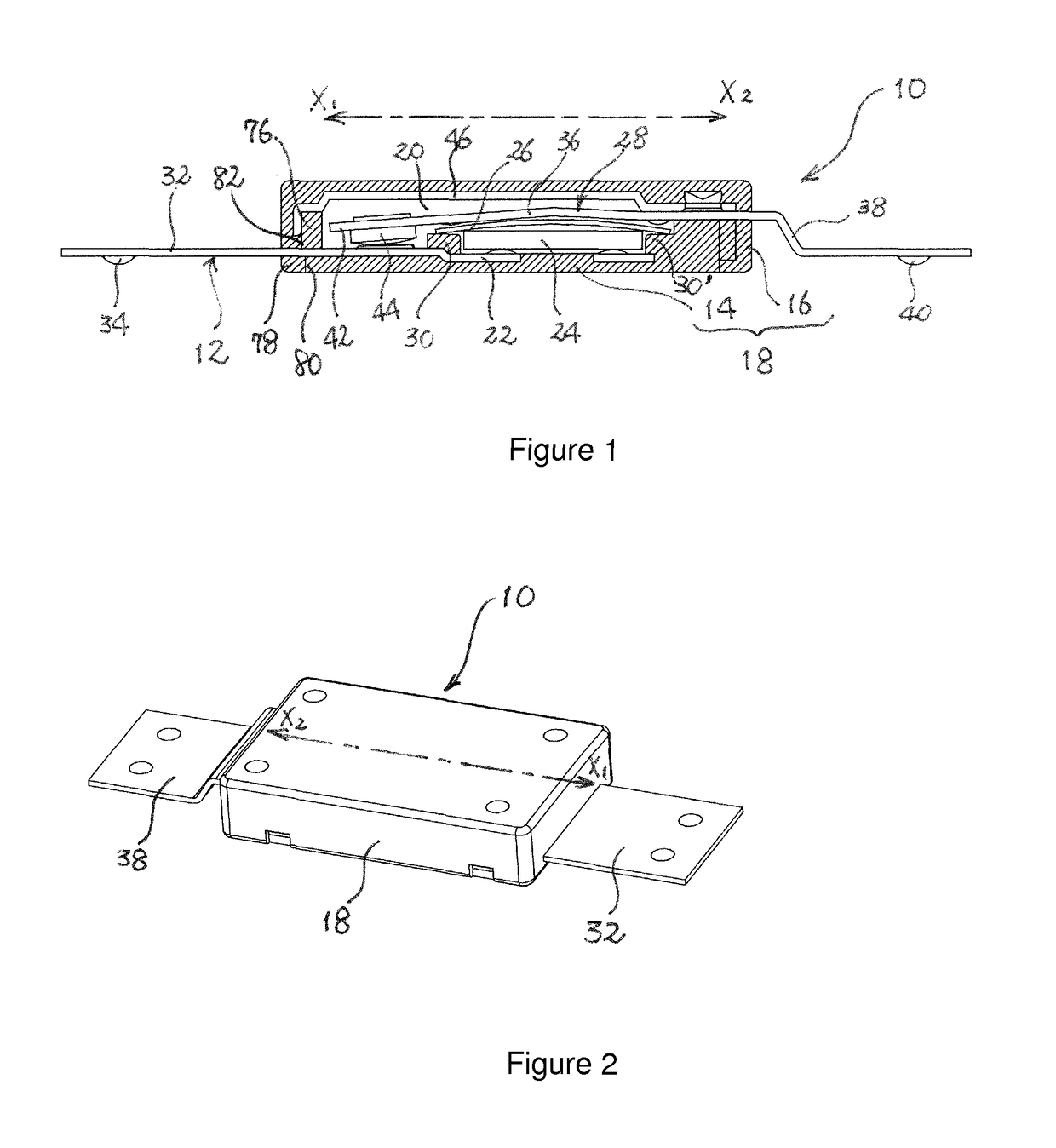

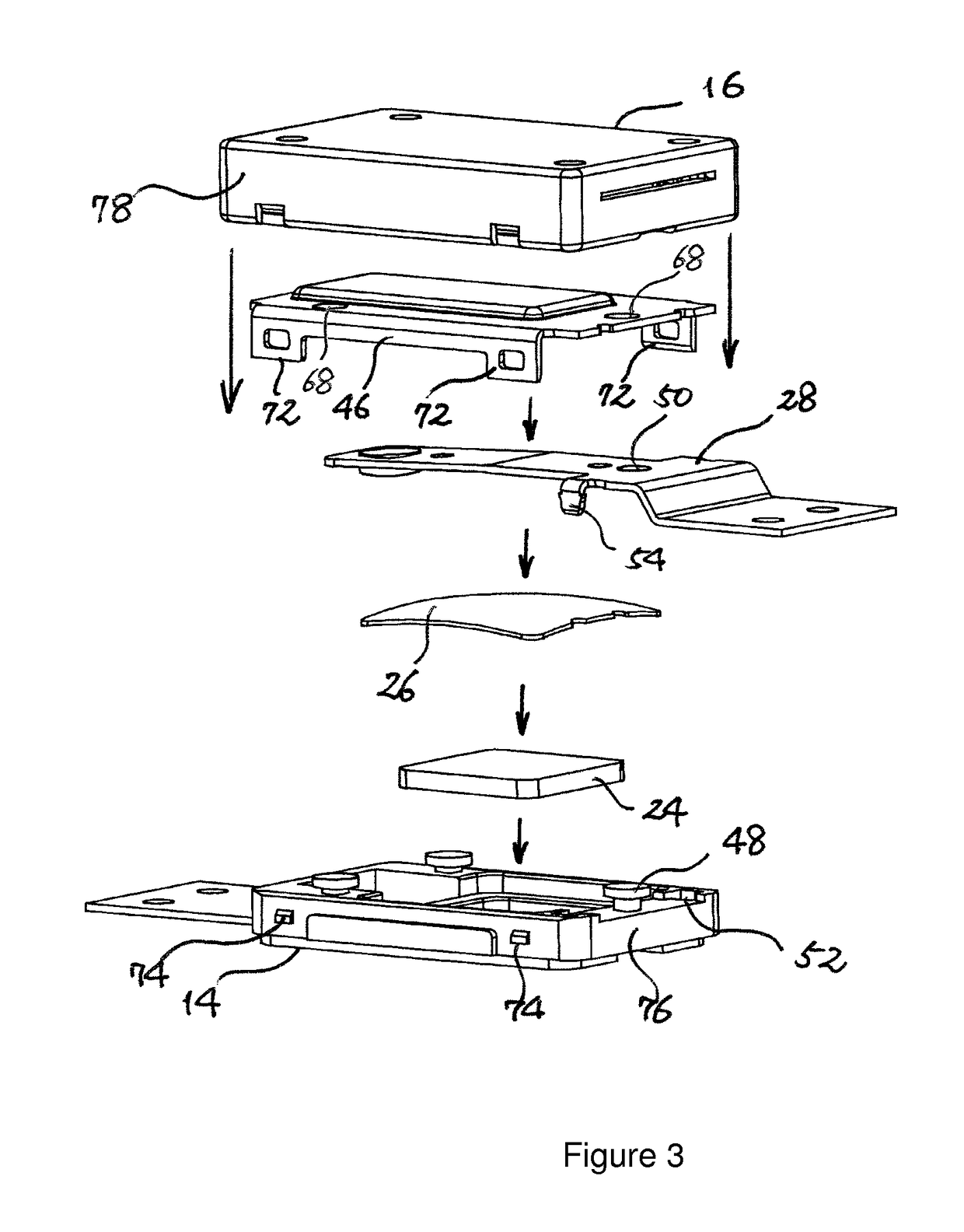

Protection device

ActiveUS9831056B2Longer perform its functionNot easy to penetrateProtective switch detailsFuse device manufactureEngineering

A protection device comprises a resin base, PTC component, bimetal component, arm and upper plate which are housed in a resin housing wherein the base includes a terminal integrated with the base by insert molding. A resin cover is formed by insert molding to cover the PTC component, bimetal component, arm and upper plate which are superposed in this order over the terminal within a space in the base. The space in the resin base is substantially closed by the upper plate, the base and the cover are integrally bonded to define the resin housing, the terminal and the arm are electrically connected in series in a normal state, and in an abnormal state where the bimetal component is activated, the terminal and the arm are electrically cut off, while the terminal, PTC component, bimetal component, and arm are electrically connected in series in this order.

Owner:LITTELFUSE JAPAN GK

Spray-painting advertisement cloth and production process thereof

InactiveCN104057684ASimple production processComplete processLaminationLamination apparatusEngineeringPolymer coating

The invention relates to an advertisement-displaying and decorative material carrier, and especially relates to spray-painting advertisement cloth and a production process thereof. The spray-painting advertisement cloth comprises base cloth, coatings at the two sides, and PVC films at two sides of the coatings; the production process comprises the following steps: 1) unreeling a PVC light-color film, coating the PVC light-color film with a polymer coating by an anilox roller; 2) attaching the PVC light-color film to base cloth; 3) treating a PVC dark-color film according to the step 1), coating the polymer coating, attaching the PVC dark color film to the other side of the base cloth; 4) preheating another PVC light-color film, and attaching to the PVC dark-color film; 5) reeling and packaging. The production process is concise, and the process flow is complete; the coating is thin and light in mass, which greatly improves the production efficiency and raw material utilization rate, and saves cost; the coating is flat and uniform; the product has good spray-painting performance, excellent ink absorption performance, high color rendition degree, and wide applications.

Owner:SHANGHAI NAR INDAL

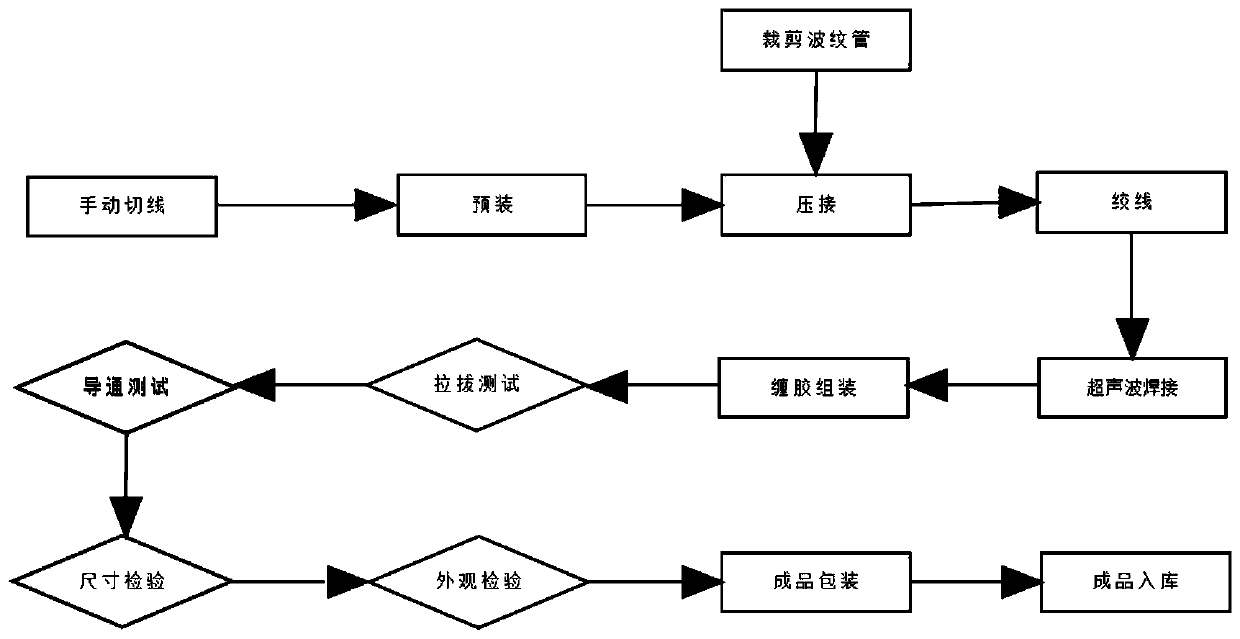

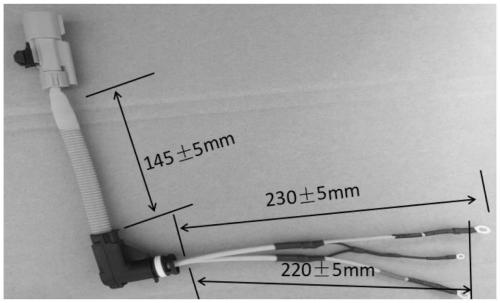

Production process of special wire harness for new energy automobile

PendingCN111489866AImprove featuresReduced characteristicsManufacturing wire harnessesUltrasonic weldingNew energy

The invention discloses a production process of a special wire harness for a new energy automobile. The production process comprises the following steps: S1, preparing materials; S2, cutting lines; S3, allowing main wires to penetrate holes of a sheath sealing rear cover in advance, loading a sealing plug, dividing each main wire into an A end and a B end, crimping two main wire A end shielding rings, assembling a high-voltage sheath, crimping two main wire B end shielding rings, fixing two single auxiliary wires with the two main wires, then performing wire stranding, preassembling a black double-wall heat shrinkable tube, carrying out ultrasonic welding, and heating the black double-wall heat shrinkable tube, wherein one end close to the sealing plug is the main wire A end, the other endis the main wire B end; S4, winding glue and assembling; and S5, carrying out drawing test, conduction test, size inspection, appearance inspection and finished product packaging, and warehousing qualified finished products to finish the production process of the special wire harness for the new energy automobile. The production process provided by the invention is high in percent of pass, and the produced wire harness is excellent in performance and long in service life.

Owner:WUHU BOKANG ELECTRICAL

Heat-resisting steel connecting pipe shell investment casting process

InactiveCN111604496AComplete processDetailsCasting plantsPreparing sample for investigationParaffin waxInvestment casting

The invention discloses a heat-resisting steel connecting pipe shell investment casting process. The process comprises the following steps that S1, paraffin is subjected to injection forming, a paraffin pattern is obtained, and an electric soldering iron is subjected to welding sticking to assemble a paraffin mold; S2, silica sol serves as a bonding agent, zirconium powder filler, a cracking-prevention agent, a wetting agent, and a defoaming agent are doped, slurry is made, the paraffin mold is immersed in the slurry to subjected to slurry loading, zircon refractory is removed, a mold shell isformed, after hardening, repeated operation is carried out for four times, and a mold shell is obtained; S3, the mold shell is placed in a paraffin removal furnace, steam is led in until the paraffincompletely flows out, the mold shell is placed in a modeling machine to be subjected to sand filling, roasting is carried out, and a high-strength mold shell is obtained; S4, a heat-resisting steel connecting pipe raw material is put into a smelting furnace to be subjected to heat preservation, and molten metal is obtained; S5, component detection is carried out; S6, pouring is carried out; S7, heat treatment is carried out; and S8, casting inspection is carried out, and the heat-resisting steel connecting pipe shell investment casting process is finished. According to the investment castingprocess, the high-quality casting can be produced, the casting yield is high, and phenomena of inclusion and cold shut are not prone to happening.

Owner:XIAN TECHNOLOGICAL UNIV

Production method of ginsenoside gel filter stick

InactiveCN110946324ADistinct taste characteristicsQuality improvementTobacco smoke filtersThroat irritationMedicine

The invention relates to a production method of a ginsenoside gel filter stick. The production method comprises the following steps: preparing ginsenoside gel, adding the ginsenoside gel, cooling, drying, packaging and the like. The filter stick produced by the method disclosed by the invention is stable in quality, uniform in ginsenoside gel addition amount, obvious in ginsenoside taste characteristic, low in oral cavity and throat irritation, free of obvious offensive odor and clean and comfortable in aftertaste.

Owner:王传涛

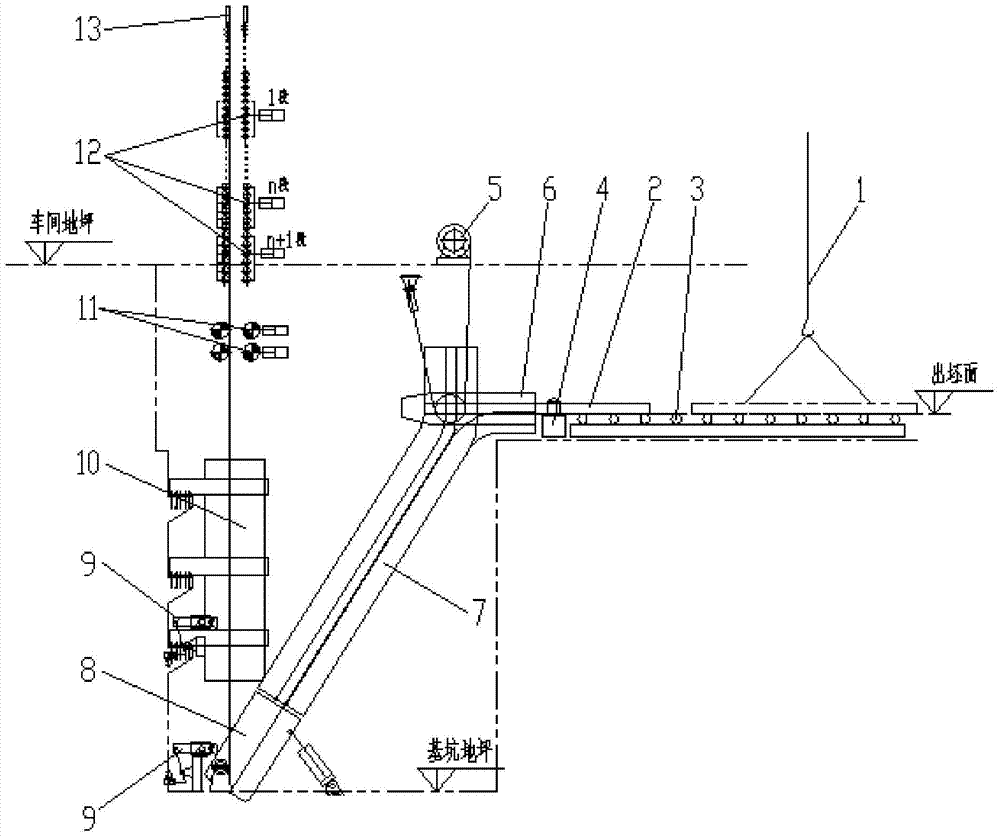

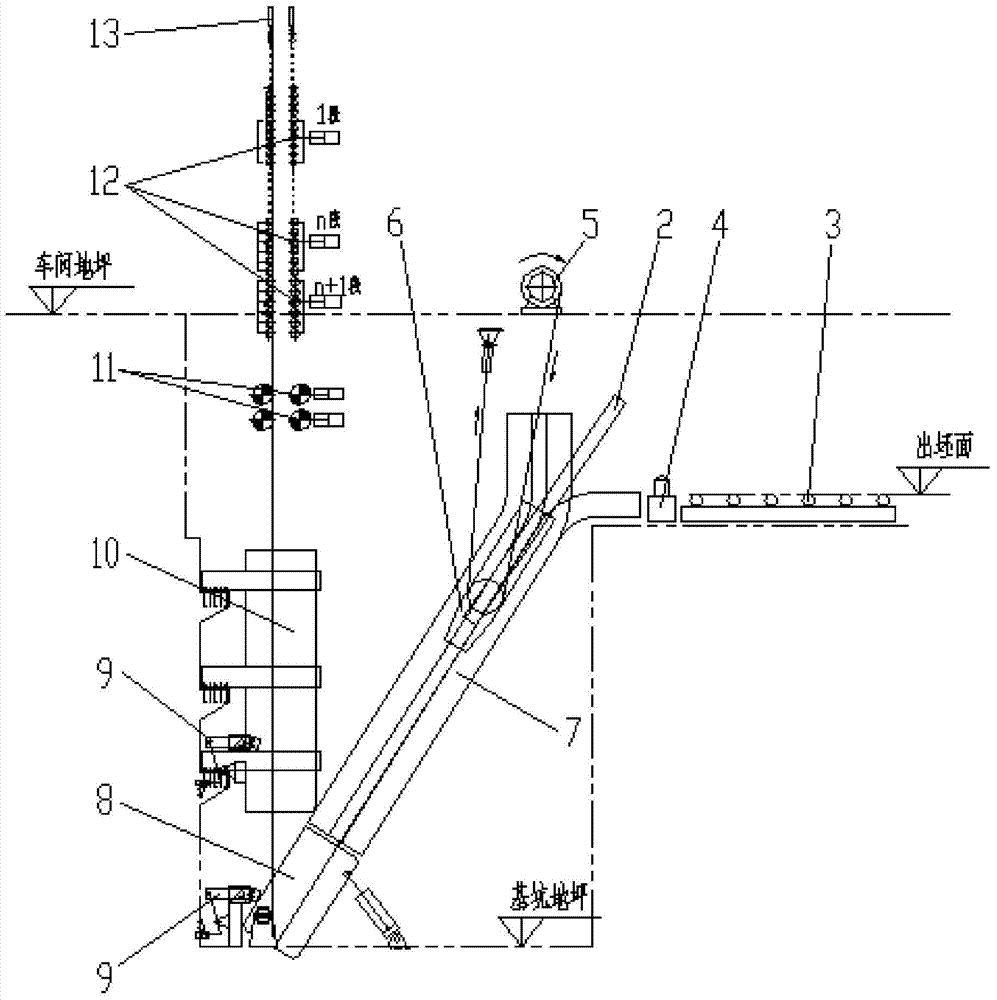

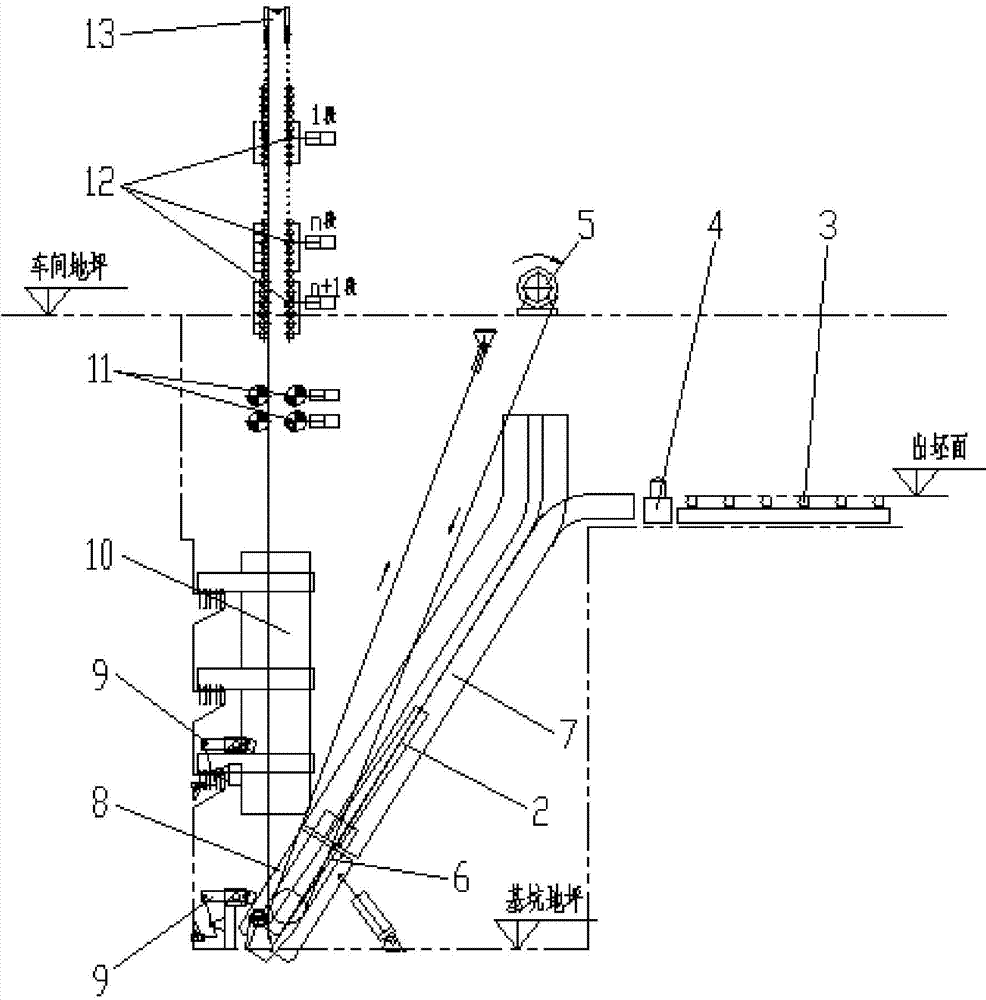

Method for sending vertical continuous casting rigid dummy bars upwards

The invention discloses a method for sending vertical continuous casting rigid dummy bars upwards. Under a casting preparing mode, the rigid dummy bars are placed on a blank outlet roller table through a workshop crane and are sent into a horizontal waiting blank receiving trolley; a coiling block of a winding plant runs clockwise, and the blank receiving trolley is pulled by a steel rope to obliquely enter a fixed oblique rail; the winding plant runs clockwise to enable the blank receiving trolley to enter a swinging track; the winding plant stops running and carries the blank receiving trolley and the rigid dummy bars to swing anticlockwise to a vertical position; a hydraulic electromagnetic positioning mechanism acts simultaneously to push and pull the rigid dummy bars to a stand state; the coiling block of the winding device runs anticlockwise, the rigid dummy bars are sent upwards to a crystallizer under the successive relay running of a plurality of sector-shaped driving rollers with the hydraulic cylinder clamping function and are clamped by the three sector-shaped driving rollers at the topmost part to keep static, and then the dummy bars are sent upwards. The method solves the problem of loading of the continuous casting rigid dummy bars, is safer and has higher maneuverability.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

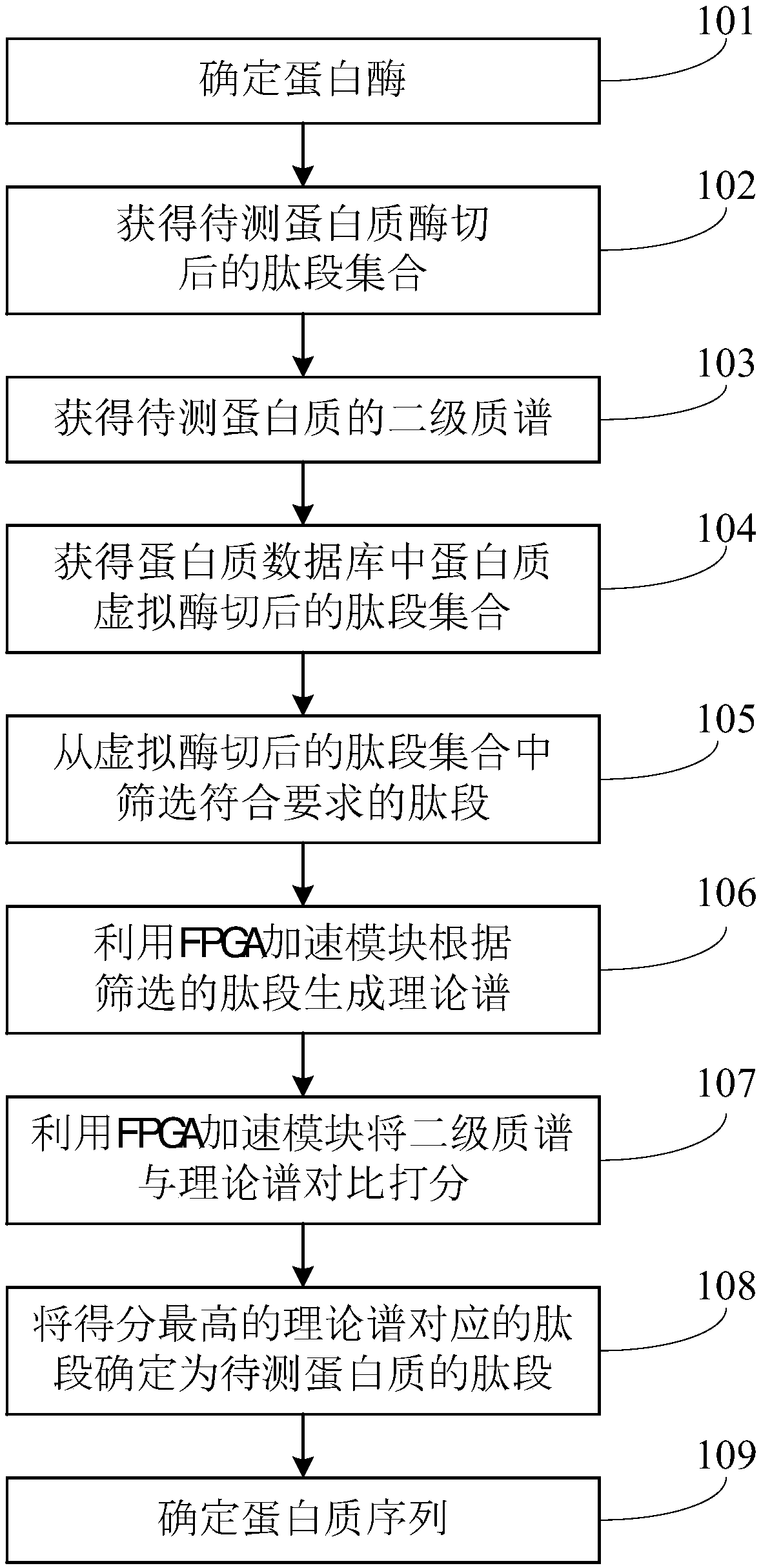

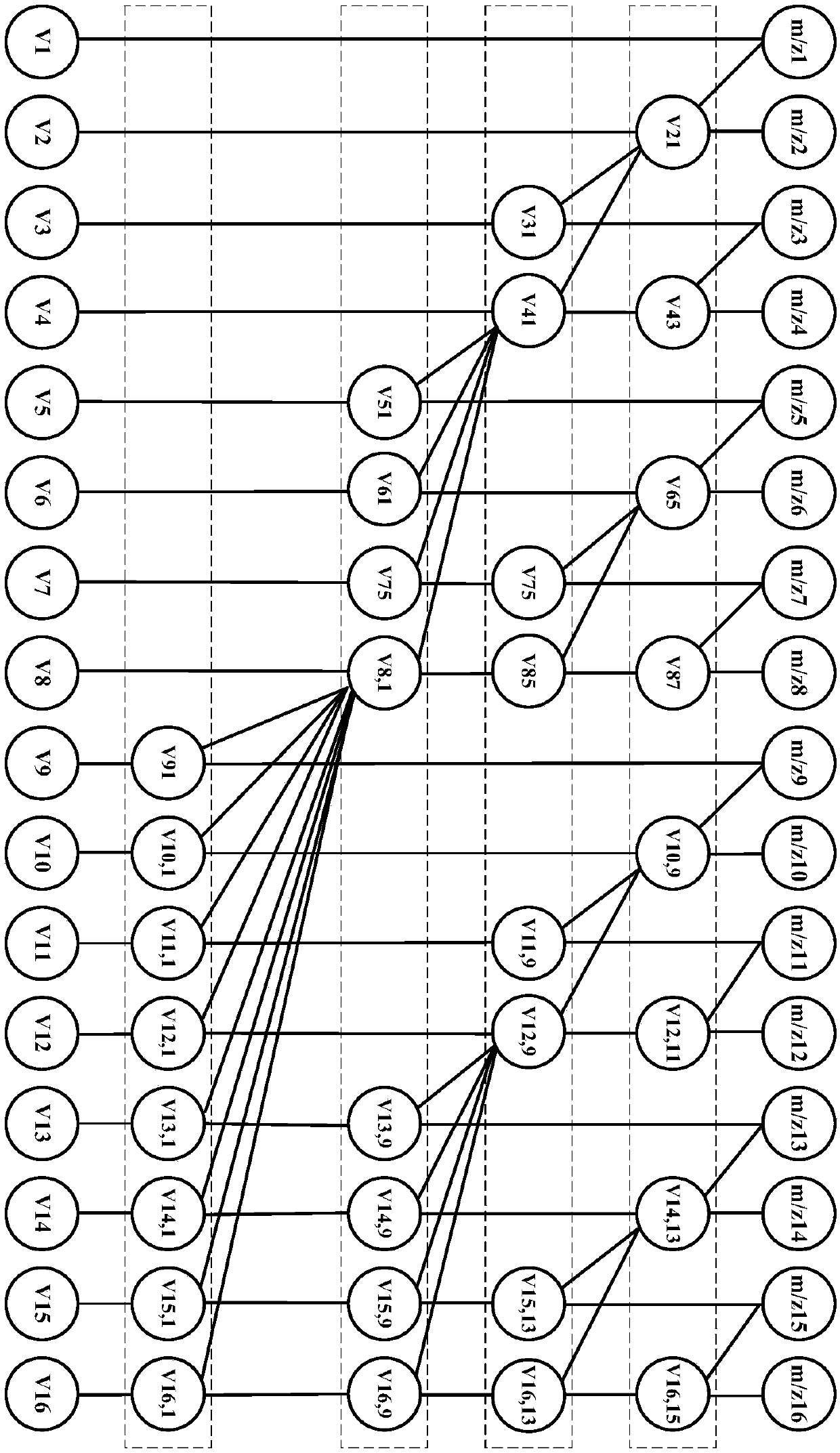

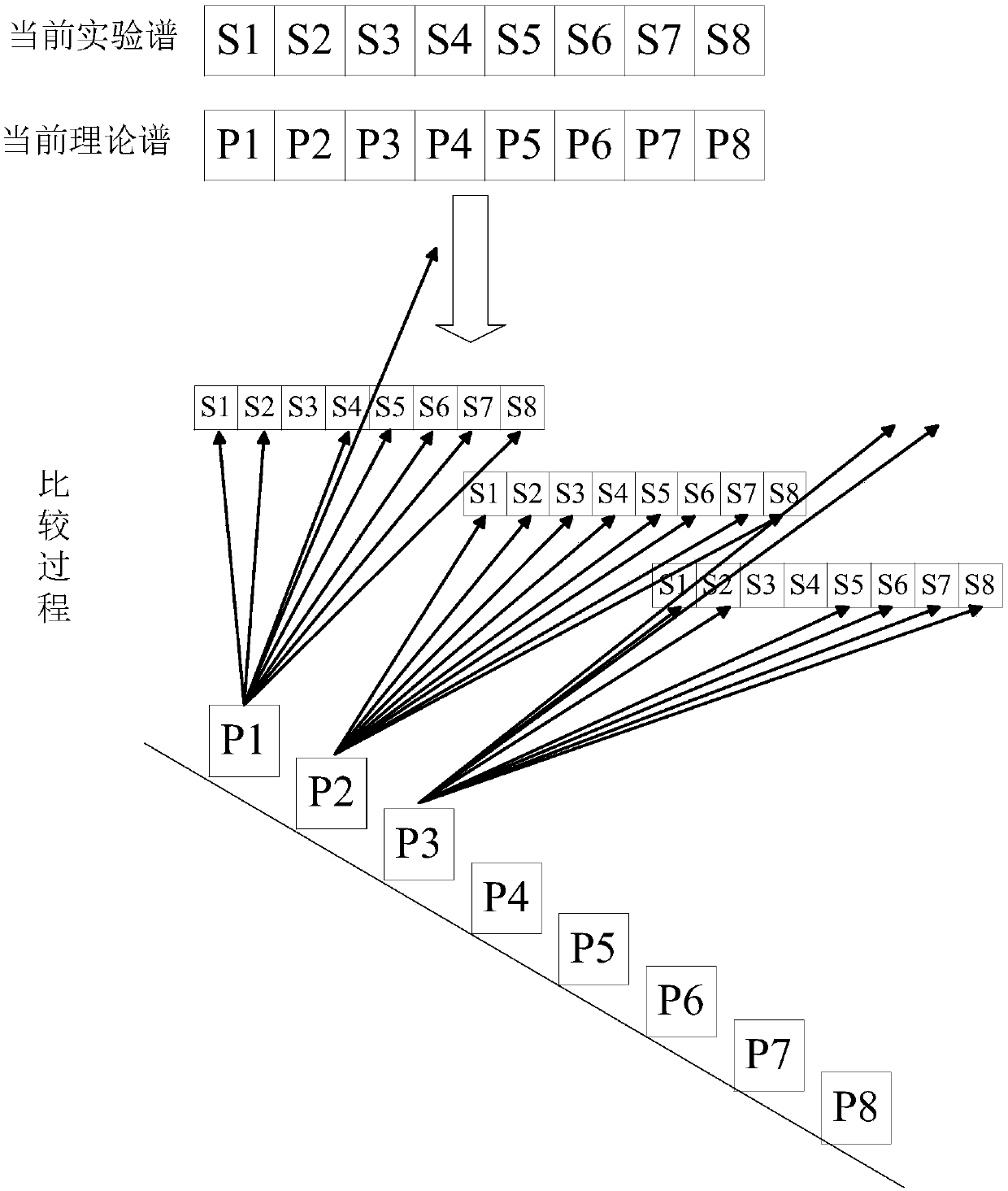

Protein identification method and system

ActiveCN107727727AThe acceleration effect is obviousComplete processMaterial analysis by electric/magnetic meansPeptide fragmentMass spectrometric

The invention belongs to the technical field of biological analysis and in particular discloses a protein identification method and a protein identification system. The protein identification method comprises the following steps: performing digestion operation on protein to be tested according to protease, and acquiring a secondary mass spectrum of the protein to be tested by using a protein tandem mass spectrum technique; performing virtual digestion operation on a protein sequence in a protein database, and extracting a first type of peptide fragments meeting requirements; generating a theoretic spectrum by using an FPGA (Field Programmable Gate Array) according to the first type of the peptide fragments; comparing the secondary mass spectrum of the protein to be tested with the theoretic spectrum by using an FPGA acceleration module, and performing similarity scoring; confirming a peptide fragment corresponding to a theoretic spectrum with a highest score as a peptide fragment of the protein; and sequentially confirming all peptide fragment sequences of the protein, thereby obtaining protein sequences. By adopting the protein identification method and the protein identificationsystem disclosed by the invention, acceleration on the FPGA is achieved, the whole scoring process is accelerated for about 25 times, a good acceleration effect is achieved, and the operation efficiency of the system is improved.

Owner:FUDAN UNIV

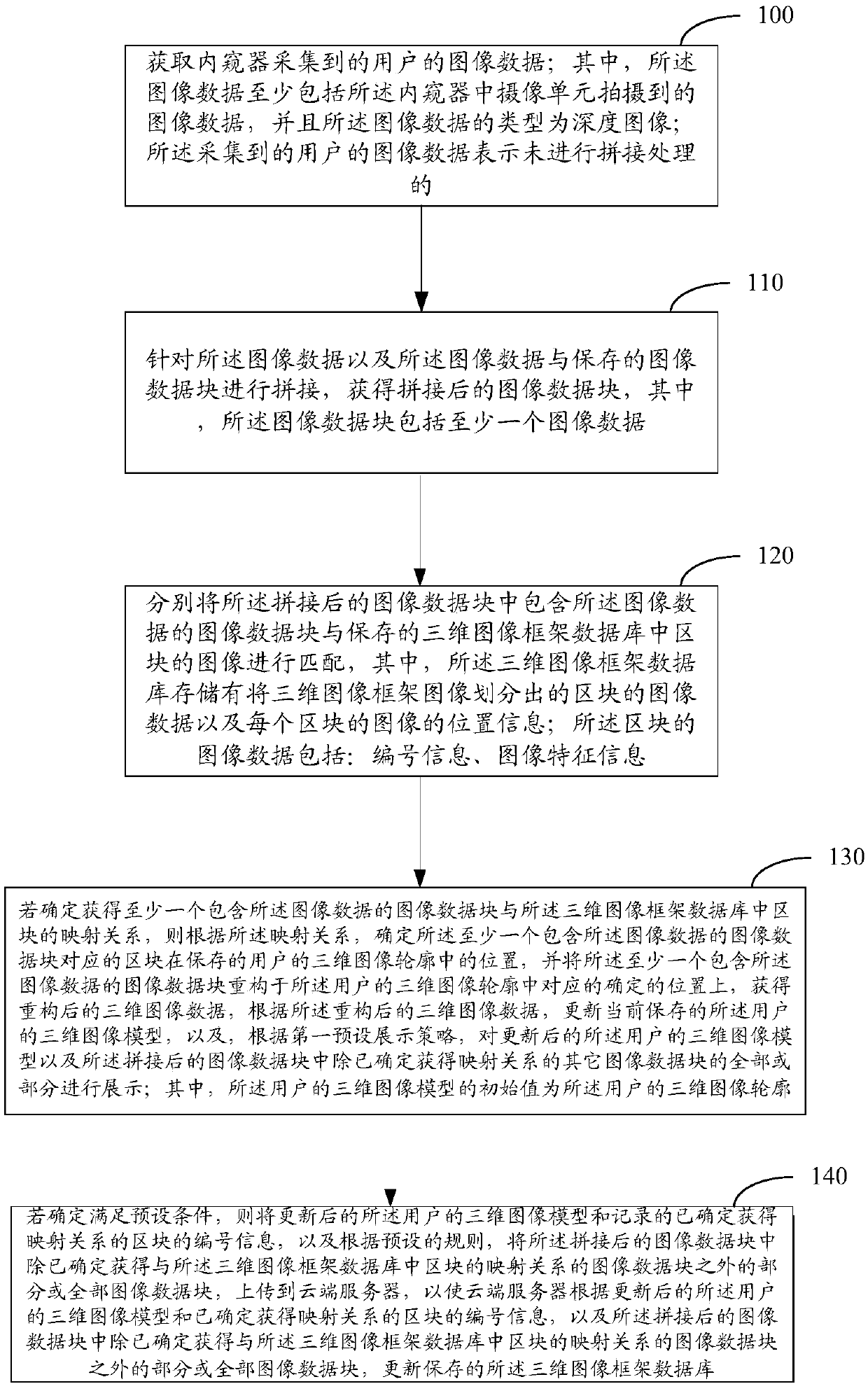

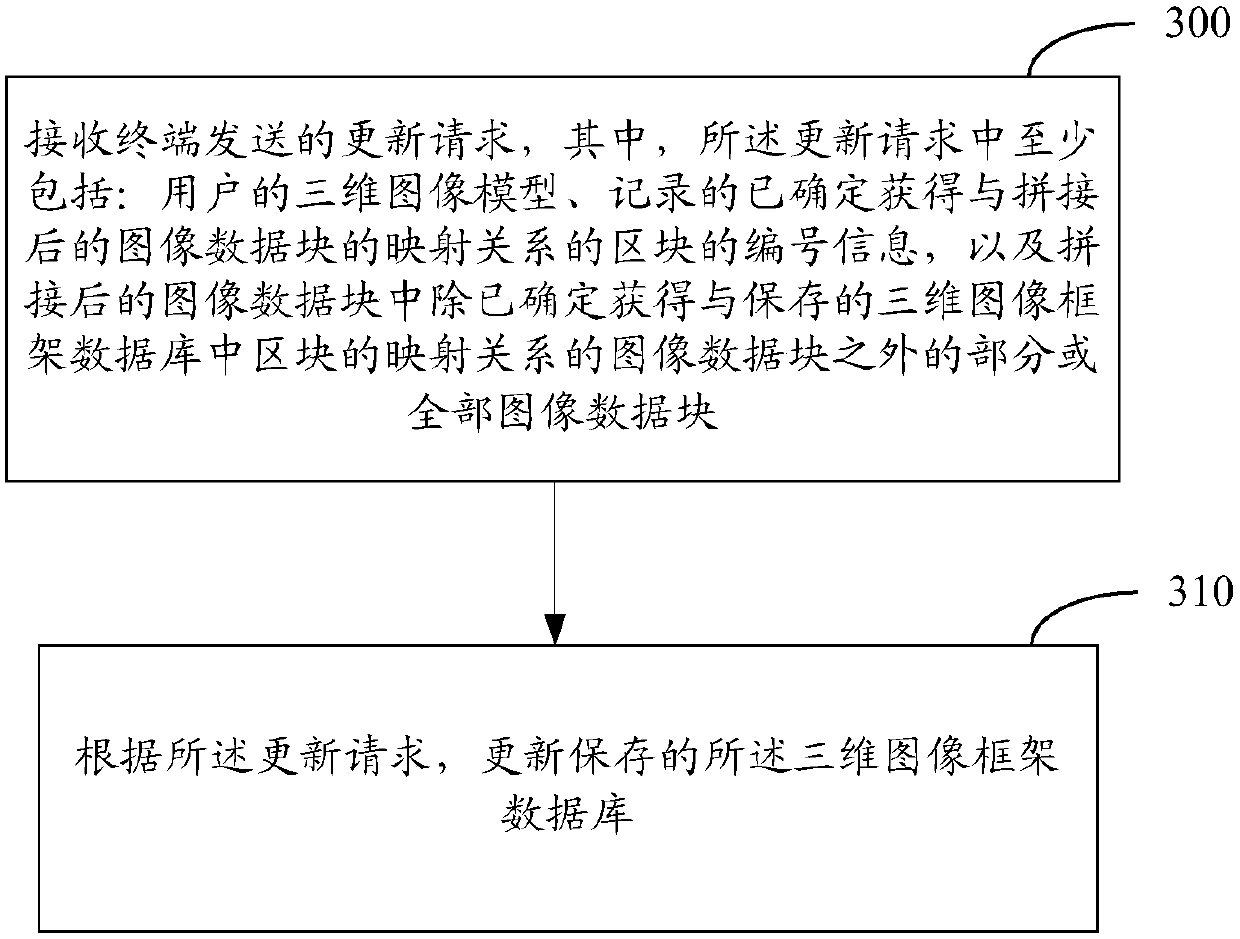

Image processing method and device

ActiveCN107909609ASolve matching problemsFix display issuesImage enhancementImpression capsImaging processingBlock match

The invention relates to the field of image processing, and in particular relates to an image processing method and device. The method comprises the steps that image data are acquired and spliced to acquire spliced image data blocks; an image data block containing the image data in the spliced image data blocks matches the image of a block in a three-dimensional image frame database; if at least one mapping relationship is acquired, the three-dimensional image model of a user is updated and displayed according to a first preset display policy; if the spliced image data blocks do not acquire the mapping relationship, displaying is carried out according to a second preset display policy; if a preset condition is satisfied, the three-dimensional image model of the user, the recorded number information of the determined block which acquires the mapping relationship and / or the image data blocks which do not acquire the mapping relationship are uploaded to a cloud server; the cloud server updates the three-dimensional image frame database; a three-dimensional image is acquired without continuously and sequentially scanning an oral cavity; and the three-dimensional image frame database iscontinuously improved to improve the matching success rate.

Owner:BEIJING KEEYOO TECH CO LTD

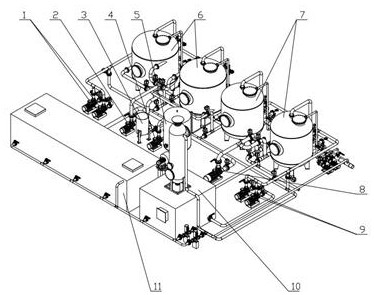

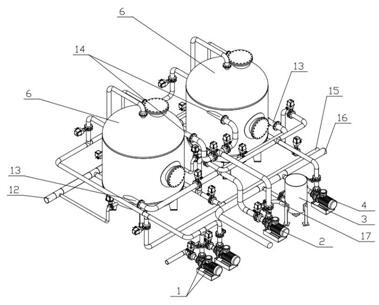

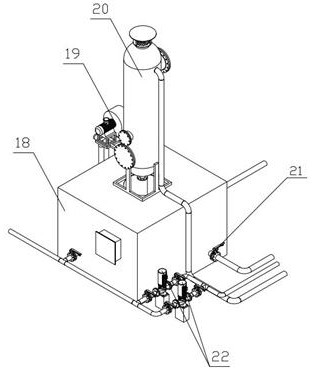

Skid-mounted combined oil removal-impurity removal-iron removal device for oilfield confecting polymer water

InactiveCN112174396AComplete processSimple processWaste water treatment from quariesWater contaminantsIron removalOil field

The invention discloses a skid-mounted combined oil removal-impurity removal-iron removal device for oilfield confecting polymer water. According to the invention, a primary lifting pump is connectedwith a liquid inlet of a filter through a pipeline; an outlet of the filter is connected with an inlet of an aeration device through a pipeline; an outlet of the aeration device is connected with a liquid inlet pipe orifice of a secondary lifting pump through a pipeline; a liquid outlet pipe orifice of the secondary lifting pump is connected with a liquid inlet pipe of an iron removing device; anda liquid outlet pipe of the iron removing device is connected with a liquid inlet pipe orifice of a filtered water tank. According to the invention, a treatment technological process is complete, thewhole treatment process of confecting polymer water can be independently completed, the process is relatively simple, chemicals are not added, operation cost is low, and secondary pollution is avoided; a main treatment device is skid-mounted, convenient to move and use, high in intelligent degree and capable of conducting continuous operation, and does not need to be shut down for backwashing; inthe operation process of the device, only gas and electricity are added and chemicals are not added, so the device is environment-friendly, safe and pollution-free to use, good in treatment effect, low in engineering investment and operation cost and convenient to manage; and the device can be widely applied to oil removal, impurity removal and iron removal treatment of confecting polymer water.

Owner:张后继

Protecting method for coating surfaces of steel components

InactiveCN107777136AProtection is in progressComplete processClosuresContainers to prevent mechanical damageRebarEngineering

The invention relates to a protecting method for coating surfaces of steel components. The protecting method comprises the following steps of 1, after construction of painting of the components is completed, the parts, needing paint protection, of the whole bodies of the components are subjected to first-layer wrapping by using hollow material and then fixed before hoisting; 2, then second-layerwrapping is carried out at the outer sides of a first layers on the parts, needing paint protection, of the components by using thick cotton cloth or rubber leather; 3, before the components are transported, an iron frame or a jig frame is made, the one or more components are assembled and fixed by using a steel bar bolt, and then the components are bound and fixed by using a binding tape or a steel wrapping tape; and 4, before the packed components are transported, the components are fastened by using a fixing rope and fixed on a transport vehicle or a shipping container, so that the components are stable on the transport vehicle or the shipping container. According to the protecting method, the protection of paint after the construction of painting of the steel structure components can be well met, so that completeness of the surface of the paint can be protected even when collision occurs in the hoisting and transporting process.

Owner:SHANGHAI BAOYE GRP CORP

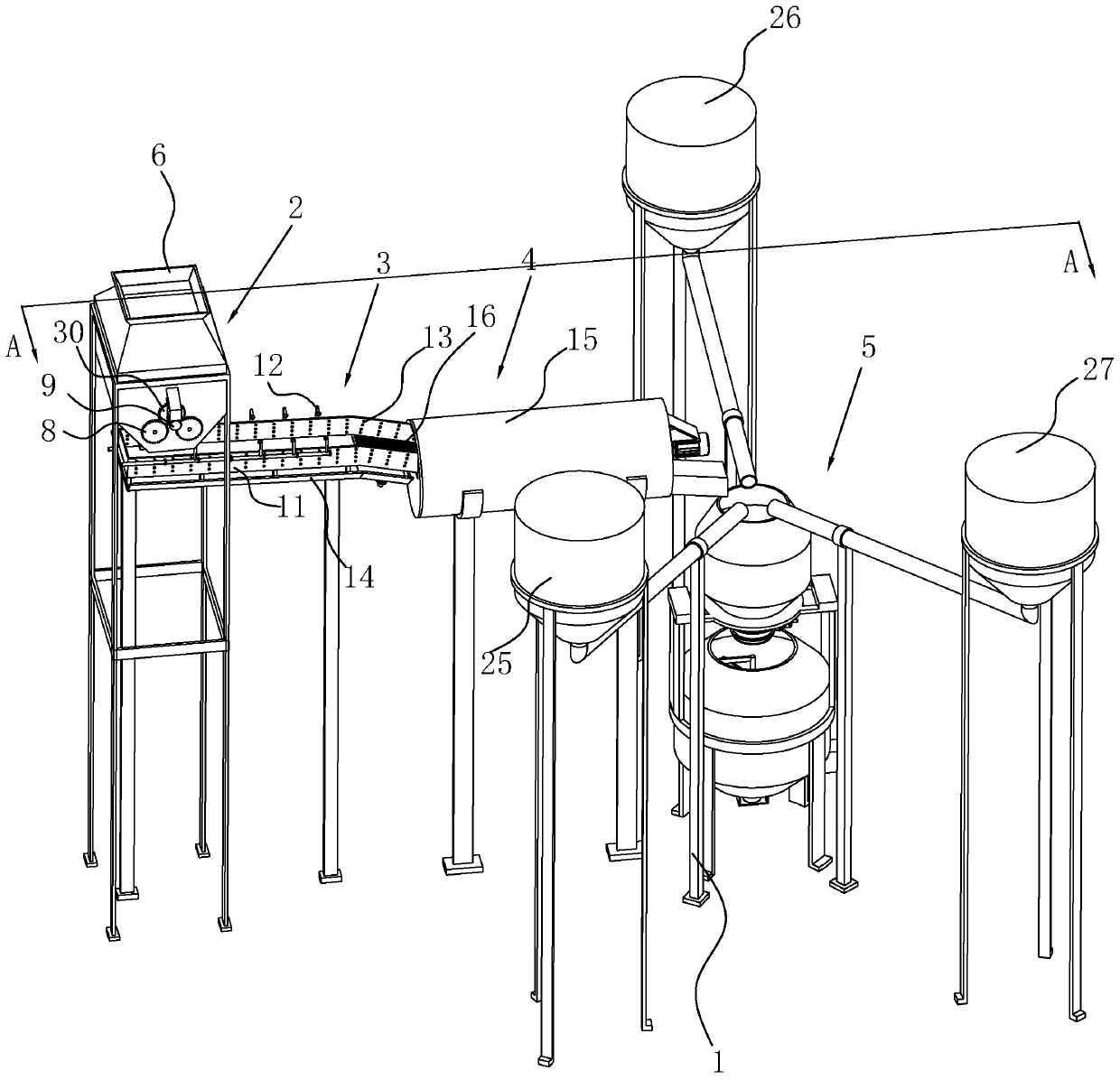

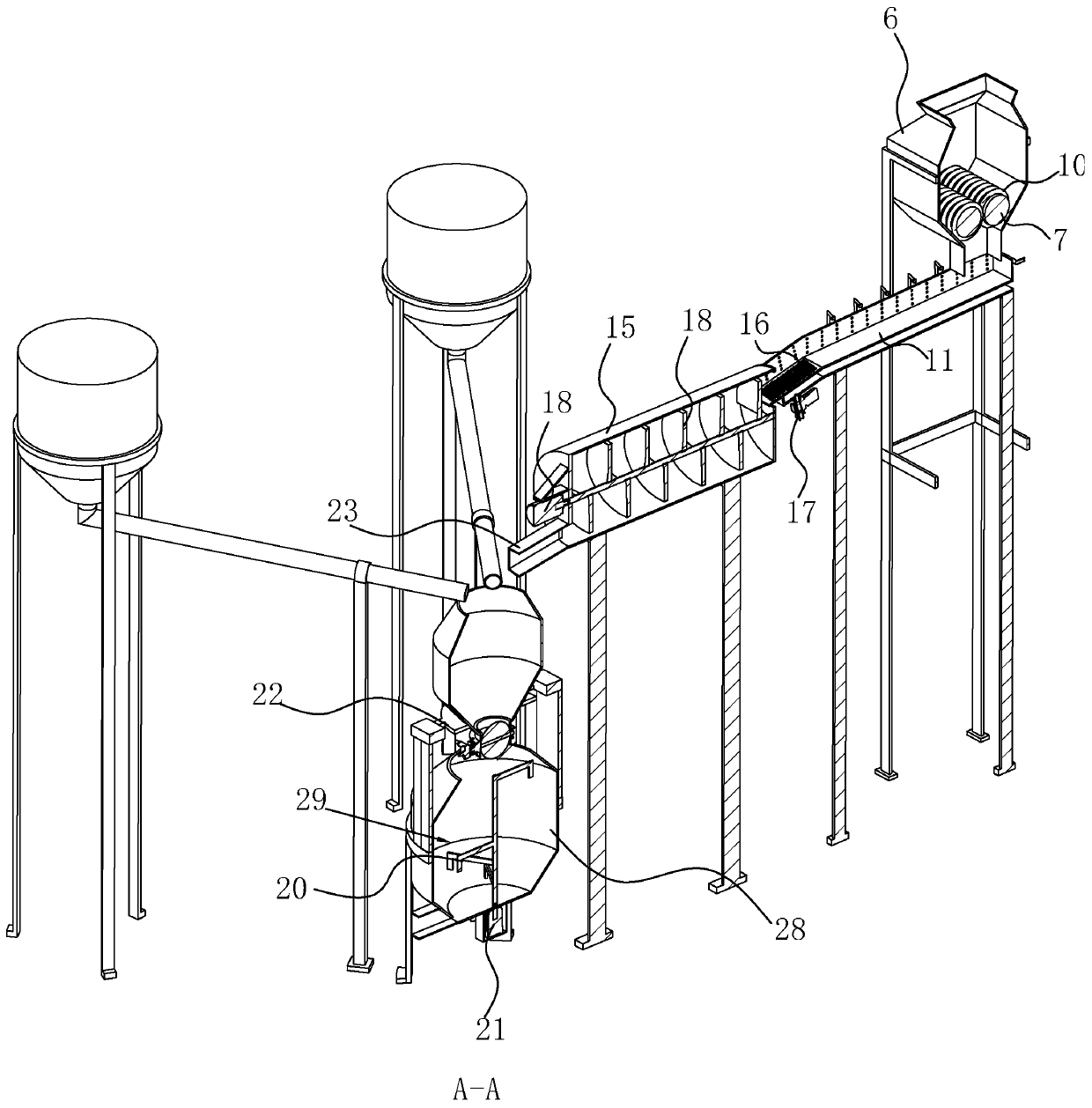

Glass leftover recycling production line and glass leftover recycling process

InactiveCN110508595AEasy to makeRaise the ratioWaste processingSolid waste disposalProduction lineResource recovery

The invention relates to a glass leftover recycling production line and a glass leftover recycling process, and relates to the field of renewable resource recycling equipment. The glass leftover recycling production line comprises a rack, wherein the rack is sequentially provided with a cutting component, a washing and filtering assembly, a crushing assembly and a stirring assembly, wherein the stirring assembly comprises a material receiving pipe and a transfer bin; an electronic scale is arranged in the transfer bin; a coal ash bin, a gravel bin and a cement bin are arranged on the rack; a stirring bin is arranged below the transfer bin, and the stirring assembly is arranged in the stirring bin; glass leftovers are broken into small pieces through the cutting assembly, and the small pieces are washed and filtered through the washing and filtering assembly, are crushed through the crushing assembly, and then are conveyed to the transfer bin; pulverized coal ash, gravel and cement areconveyed from the coal ash bin, the gravel bin and the cement bin to be mixed; the mixture is fed into the stirring bin below; and the stirring assembly is started to uniformly mix the mixture so as to prepare the finished product. The whole device can make the leftovers into building materials and can utilize other wastes, matching is convenient, and the device is high in mechanization and automation degree.

Owner:陕西美泰节能科技有限公司

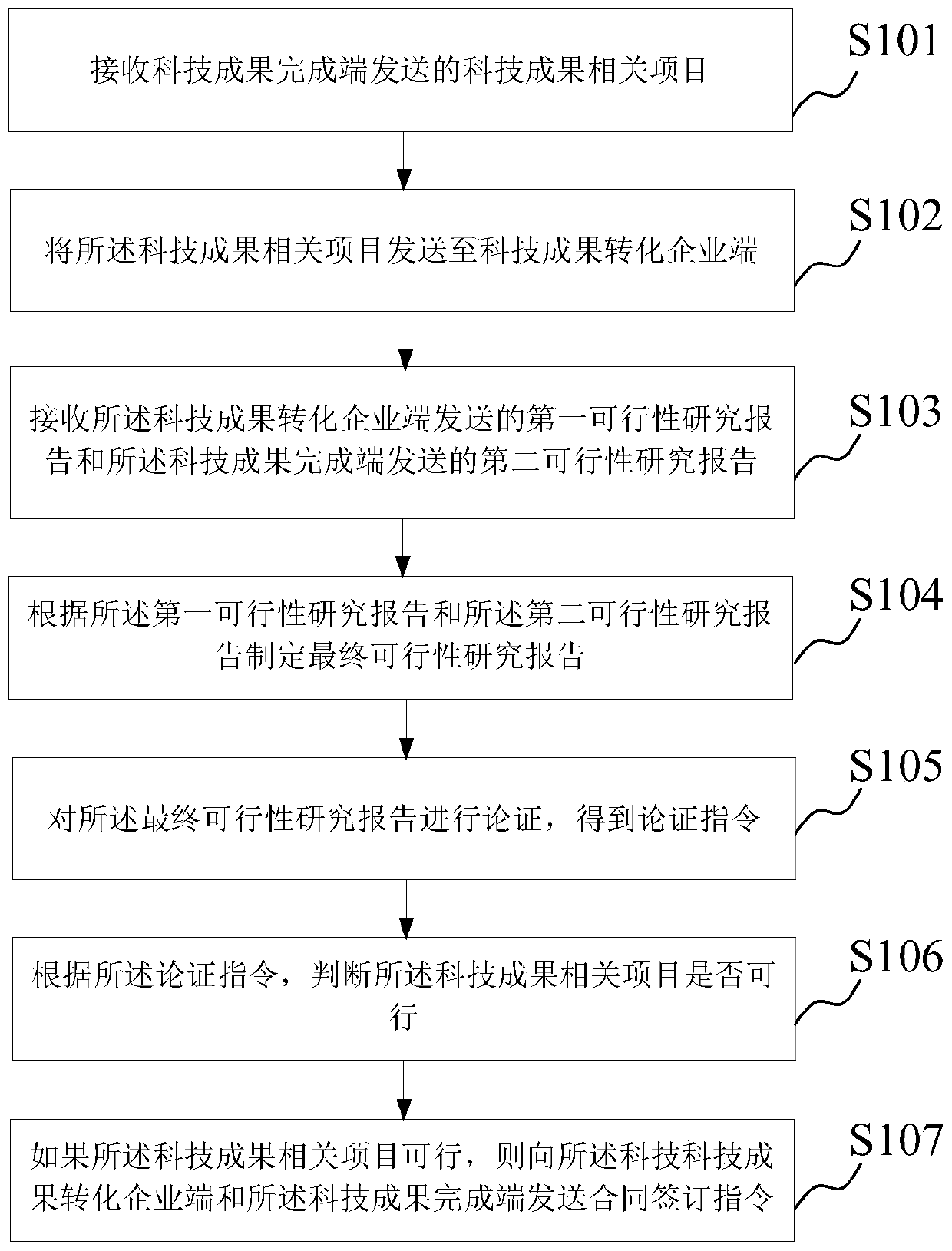

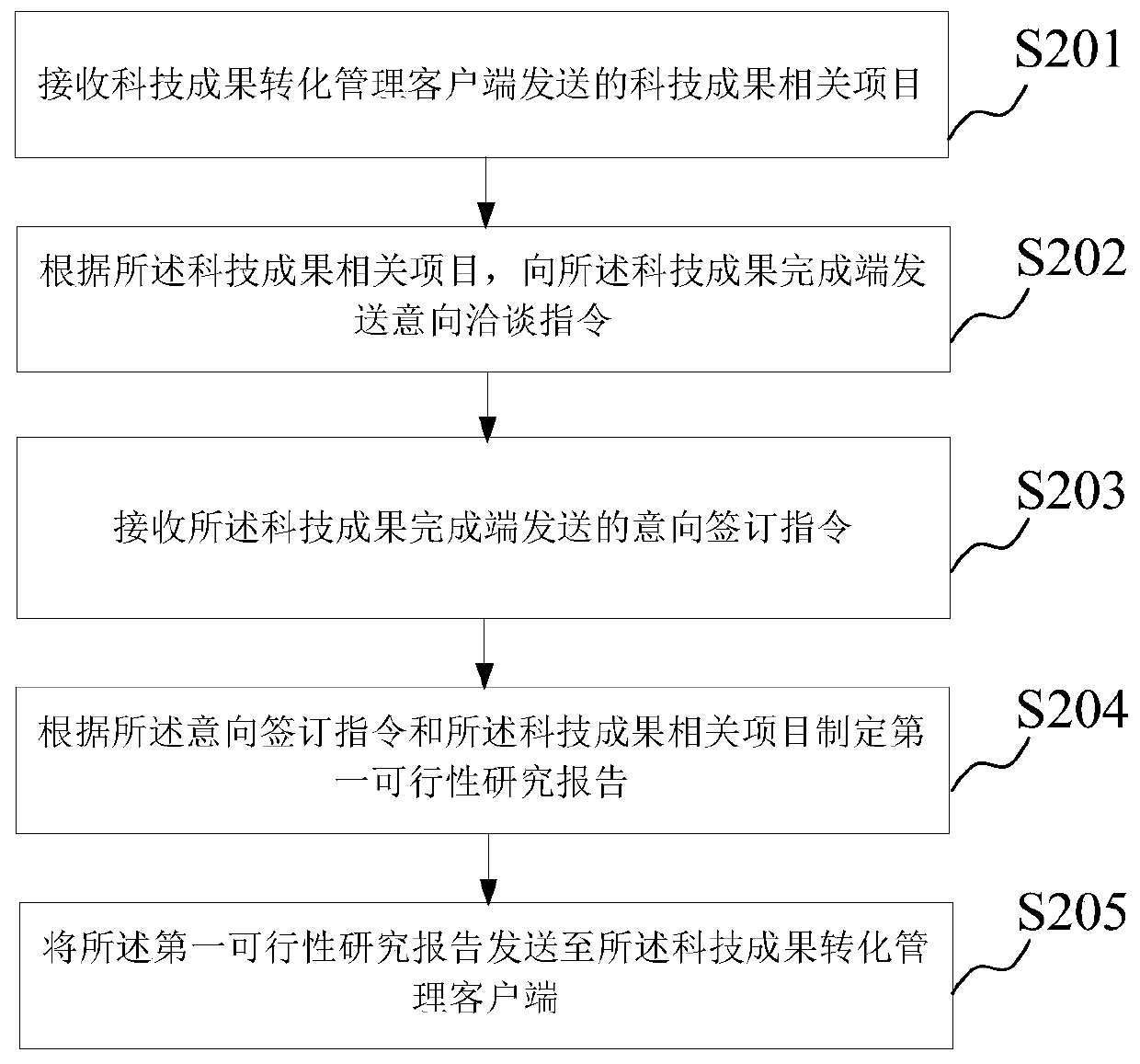

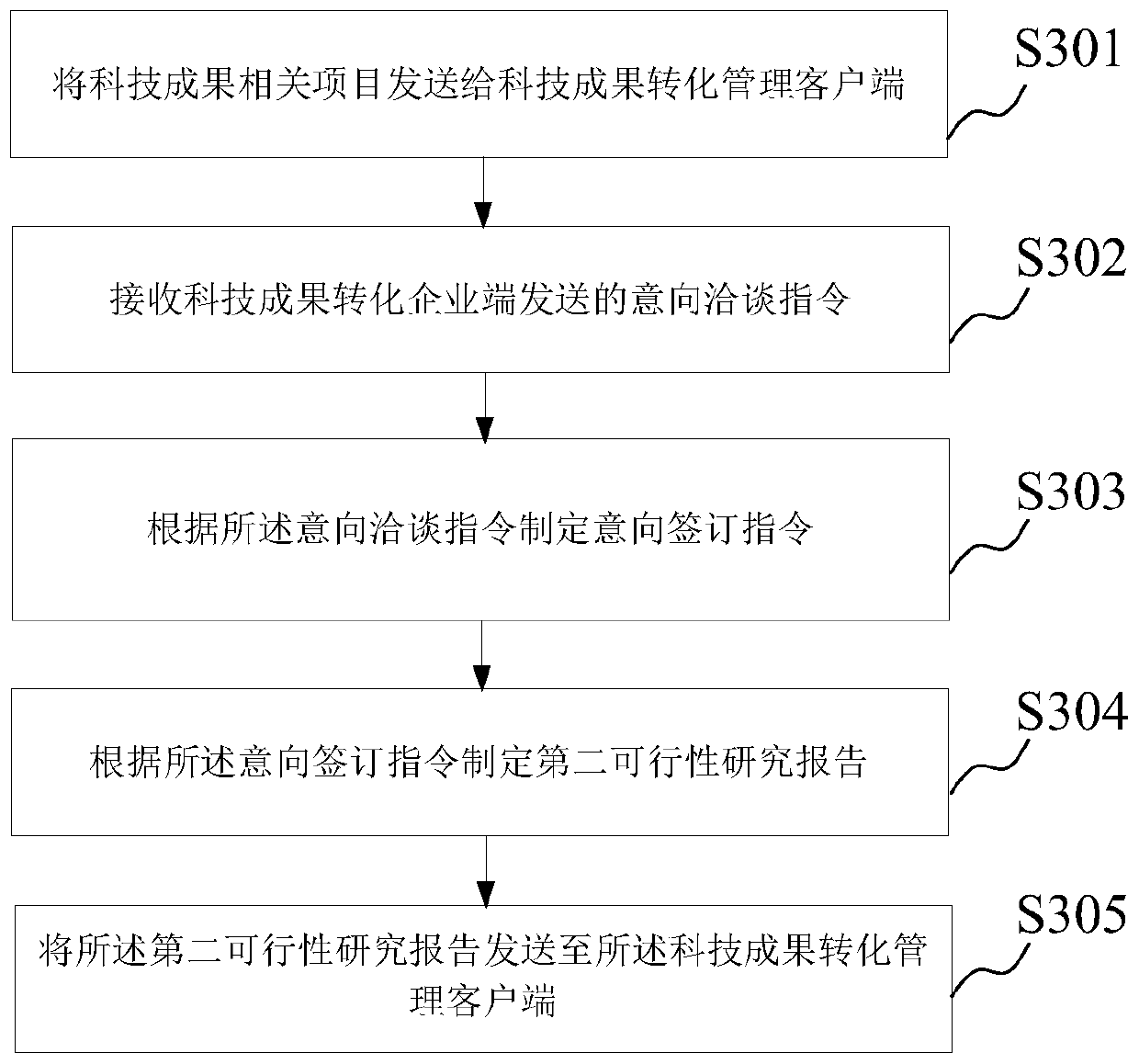

Scientific and technological achievement conversion information service method and system

PendingCN109801042ARealize managementComplete processOffice automationFeasibility studyBusiness enterprise

The invention discloses a scientific and technological achievement conversion information service method and system. Firstly, a scientific and technological achievement completion person uploads scientific and technological achievement related projects to a scientific and technological achievement conversion management client; sending to a scientific and technological achievement conversion enterprise end; after the intention negotiation and intention signing are completed; Simultaneous formulation of feasibility study reports, the scientific and technological achievement conversion managementclient assigns a final feasibility research report according to the formulated feasibility research report; and if the scientific and technological achievement related project is feasible, a contractsigning instruction is sent to the scientific and technological achievement conversion enterprise end and the scientific and technological achievement completion end, and the scientific and technological achievement conversion enterprise end and the scientific and technological achievement completion end complete contract signing. According to the invention, management of the whole life cycle ofscientific and technological achievement transformation work is realized, a complete and feasible process is provided for scientific and technological achievement transformation, the transformation work efficiency and quality can be effectively improved, the scientific and technological achievement transformation period is shortened, and scientific and technological asset value-added guarantee isrealized.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

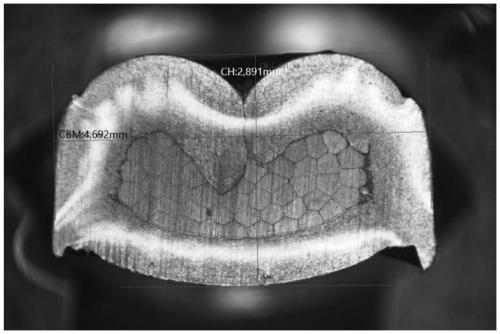

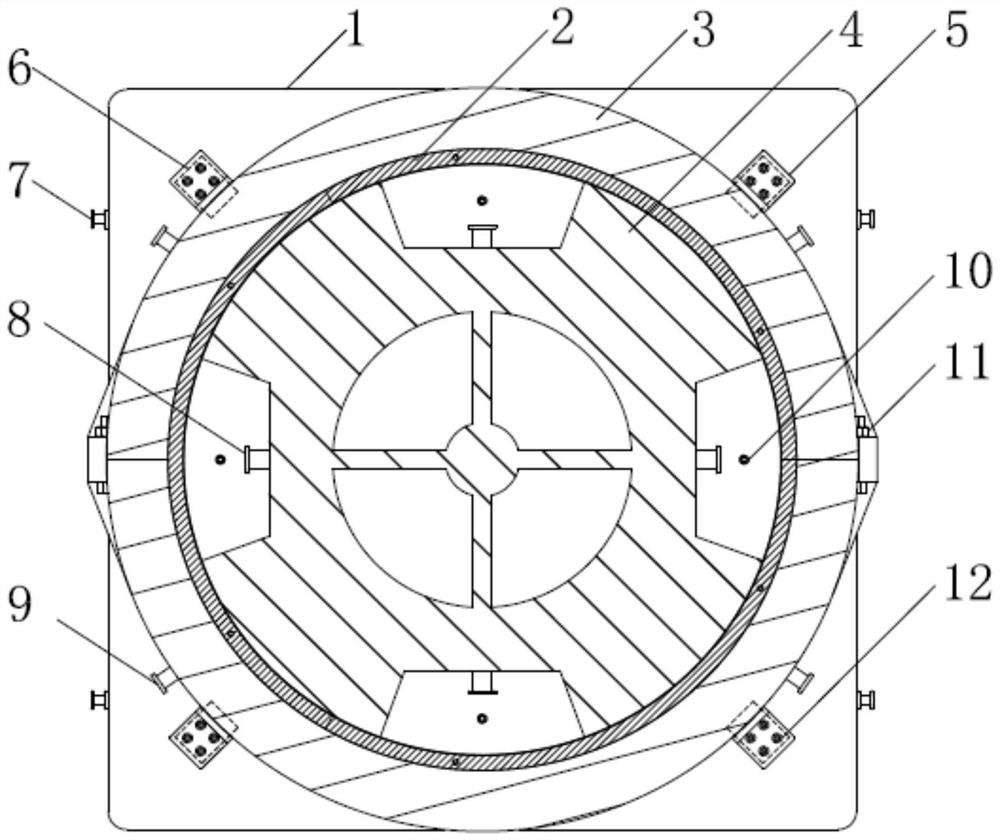

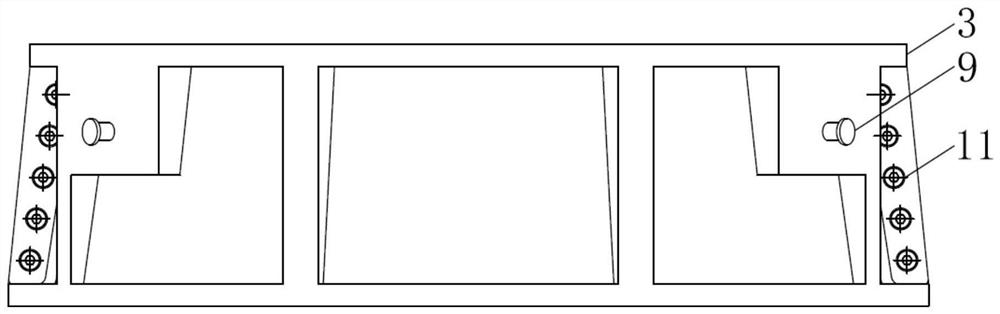

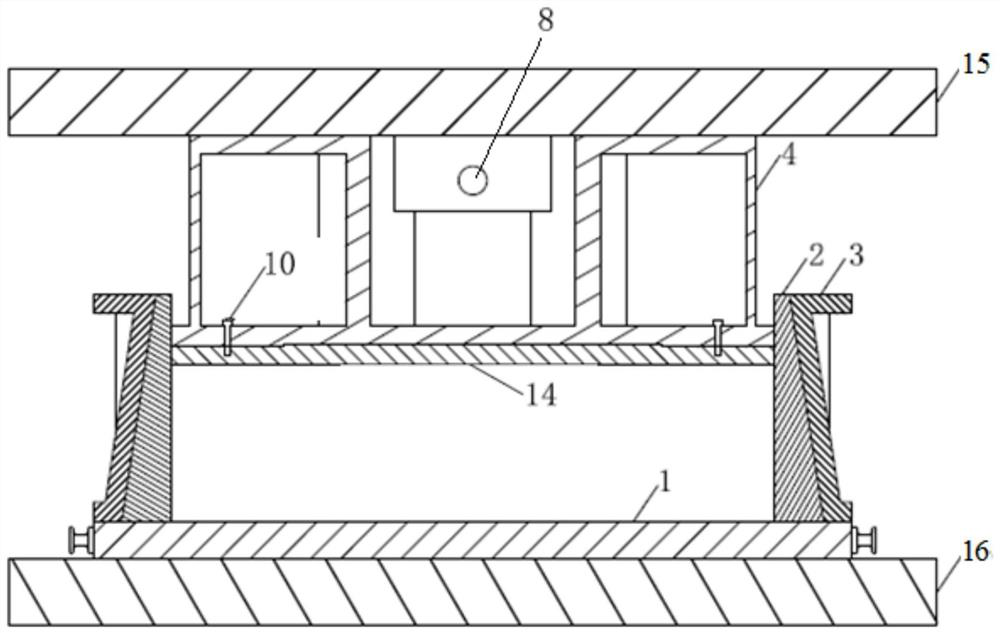

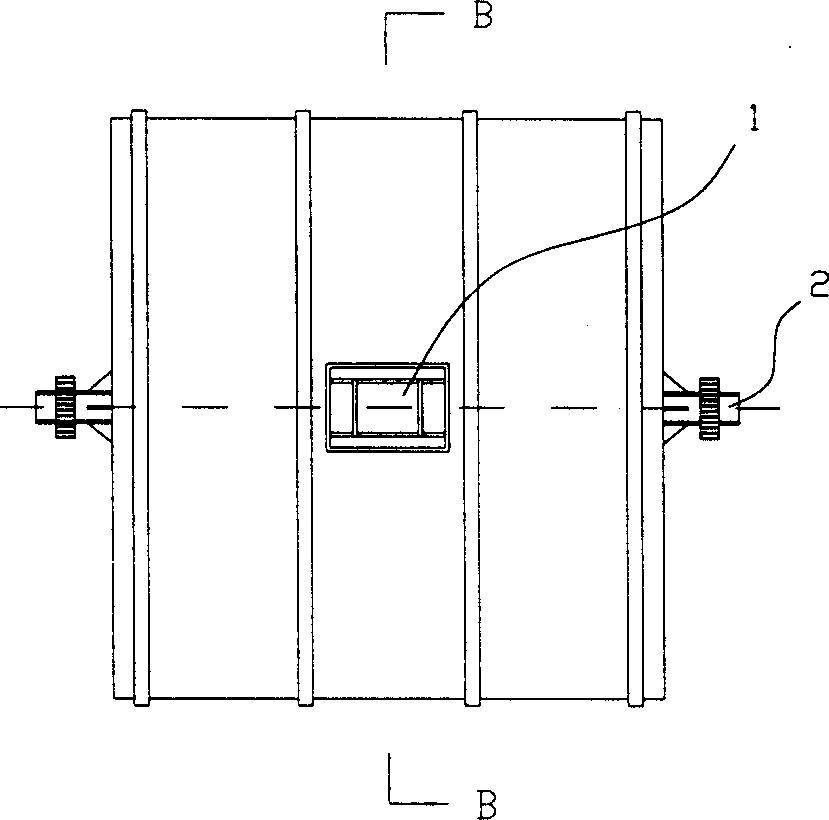

Pressing die for meter-scale buffer material circular building block and building block preparation method

ActiveCN112757453AExtended service lifeIrregular replacementDischarging arrangementFeeding arrangmentsArchitectural engineeringStructural engineering

The invention belongs to the field of preparation of buffer material large building blocks for high-level radioactive waste geological disposal, and particularly relates to a pressing die for a meter-scale buffer material circular building block and a building block preparation method. According to the pressing die, female die seats are semicircular, and the two female die seats form a circular female die; female die linings form a circular lining which is arranged on the inner walls of the female die seats; the female die linings and the female die seats are arranged on a bottom plate; a male die lining plate is arranged at the bottom of a male die seat, and the male die seat and the male die lining plate form an integral male die; a positioning baffle is arranged in a groove of the bottom plate; a bolt hole is processed in the groove, and a pressing plate is placed on the positioning baffle and is fastened through a bolt; and the female die is placed on the bottom plate and is limited through the positioning baffle. According to the pressing die and the preparation method, a buffer material large building block sample with diameter of 1.2-1.6 m, height of 0.2-0.5 m and dry density of 1.4-1.8 g / cm<3> in engineering scale can be pressed, and a raw material basis and a technical support are provided for carrying out an in-situ test of the buffer material in an underground laboratory.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

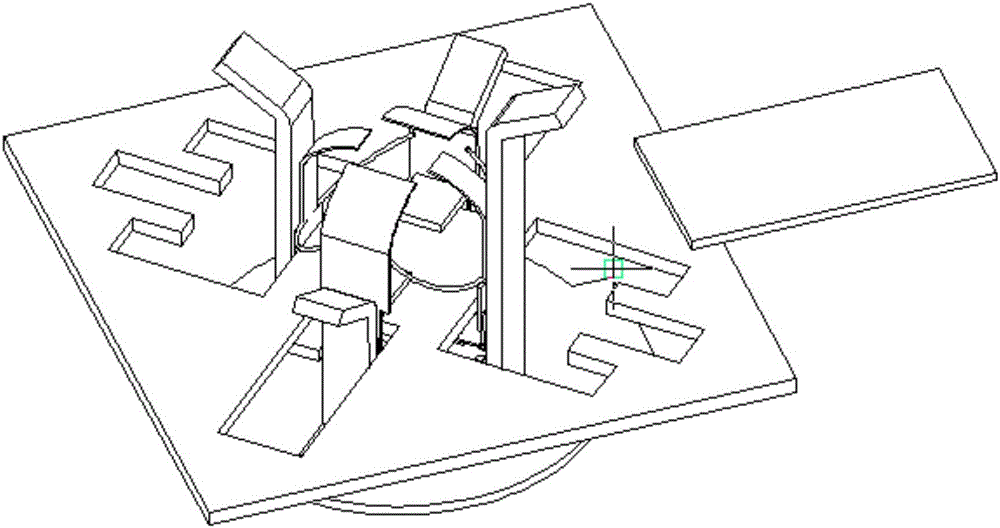

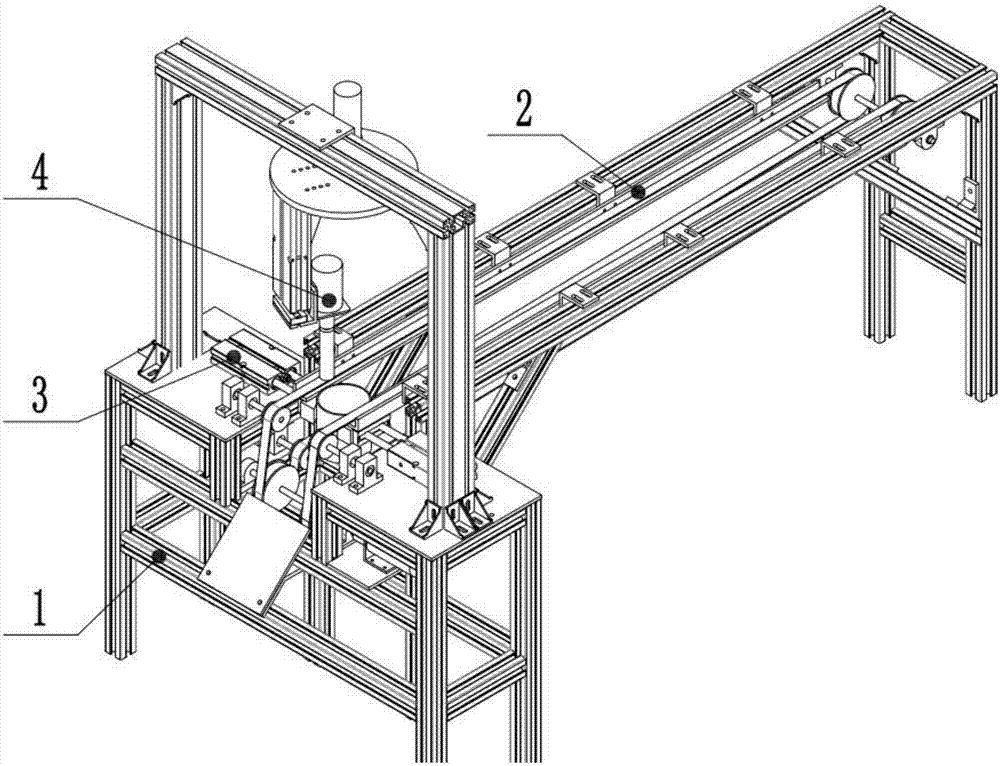

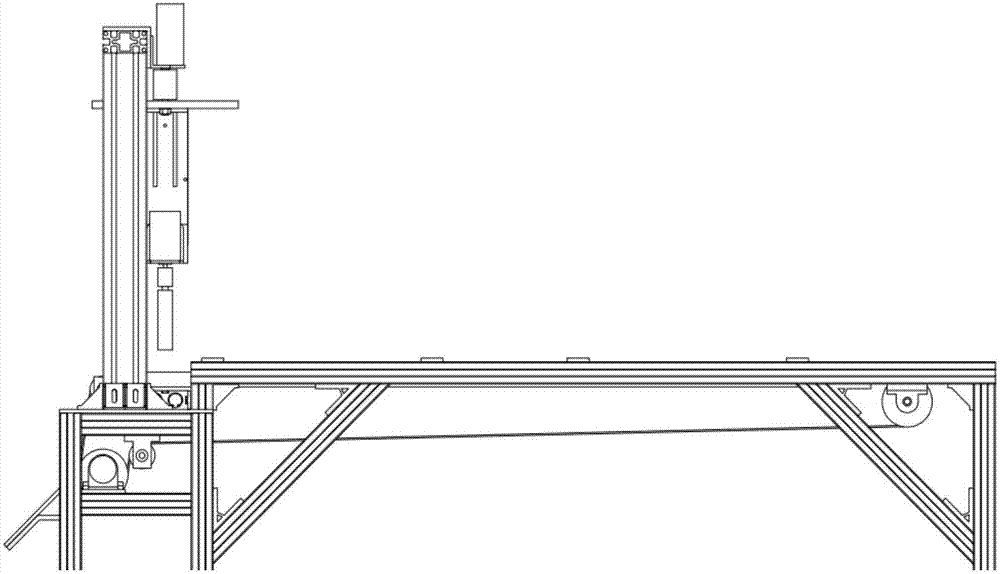

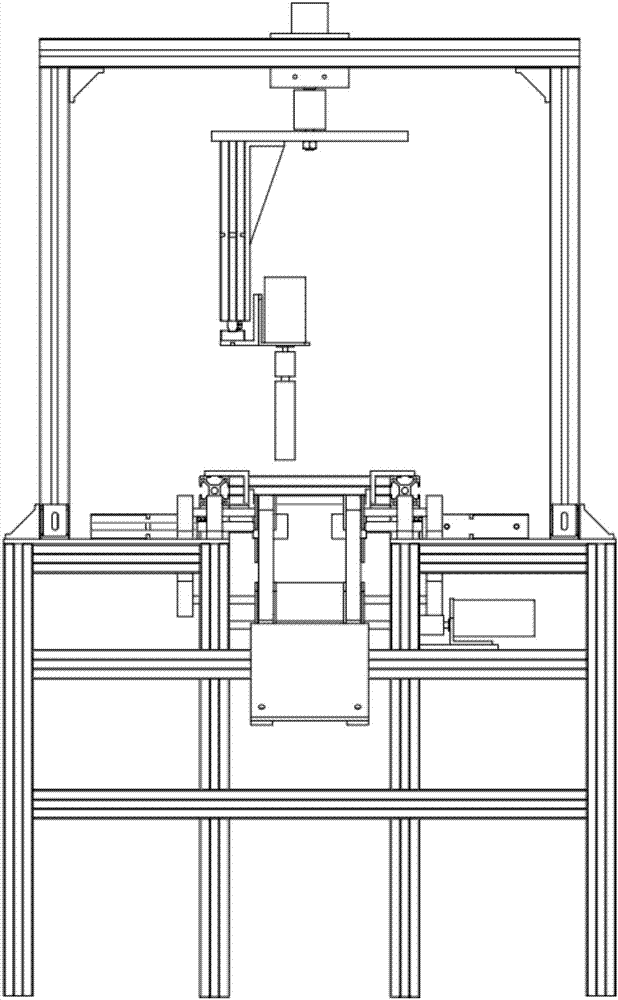

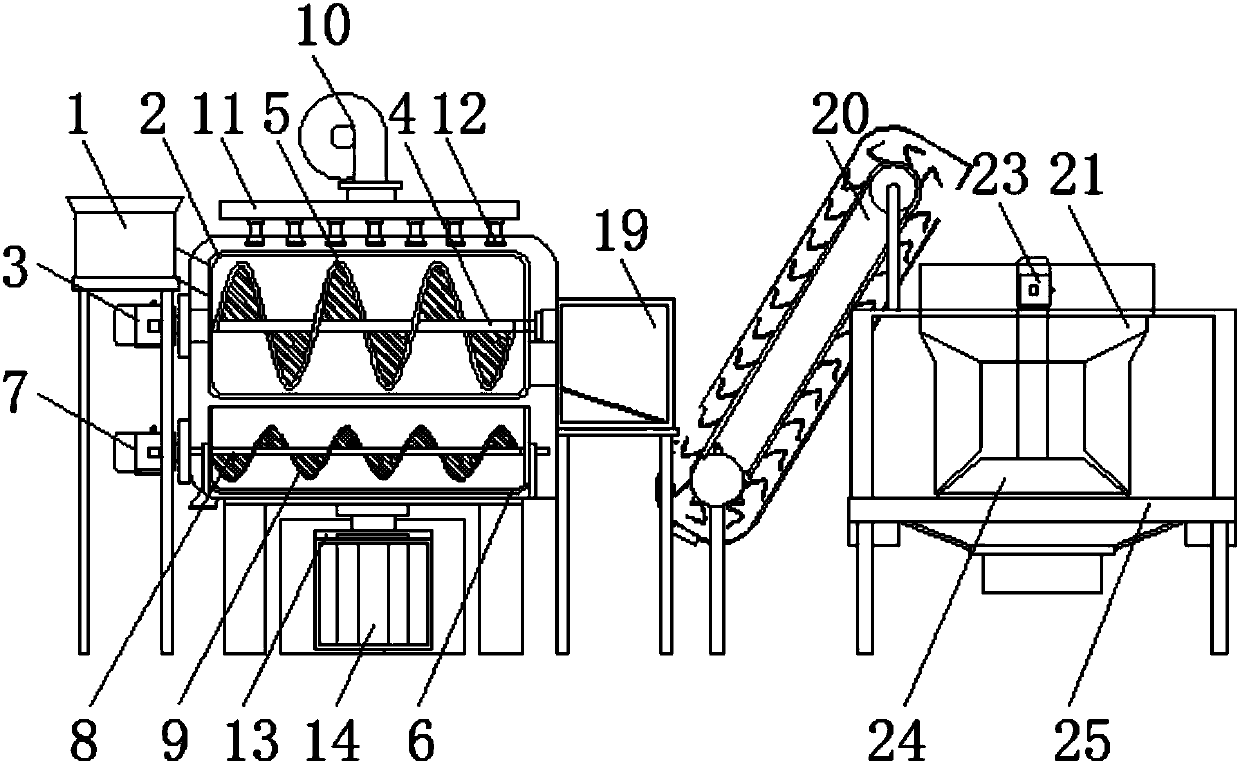

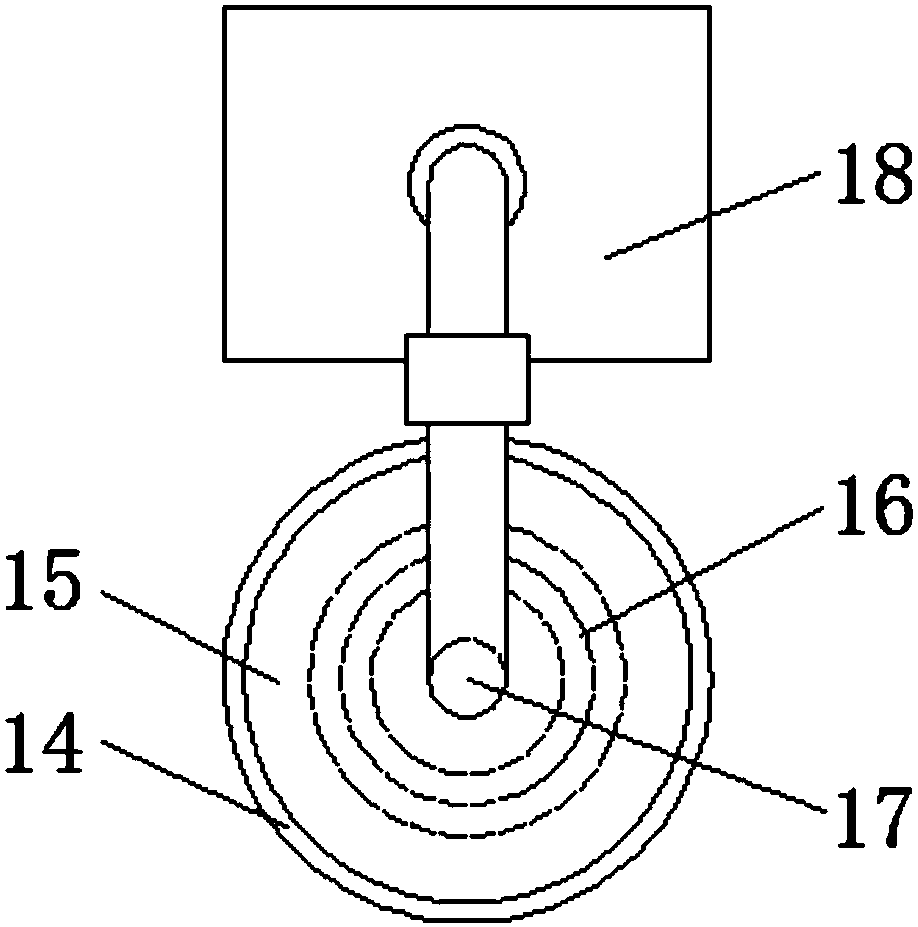

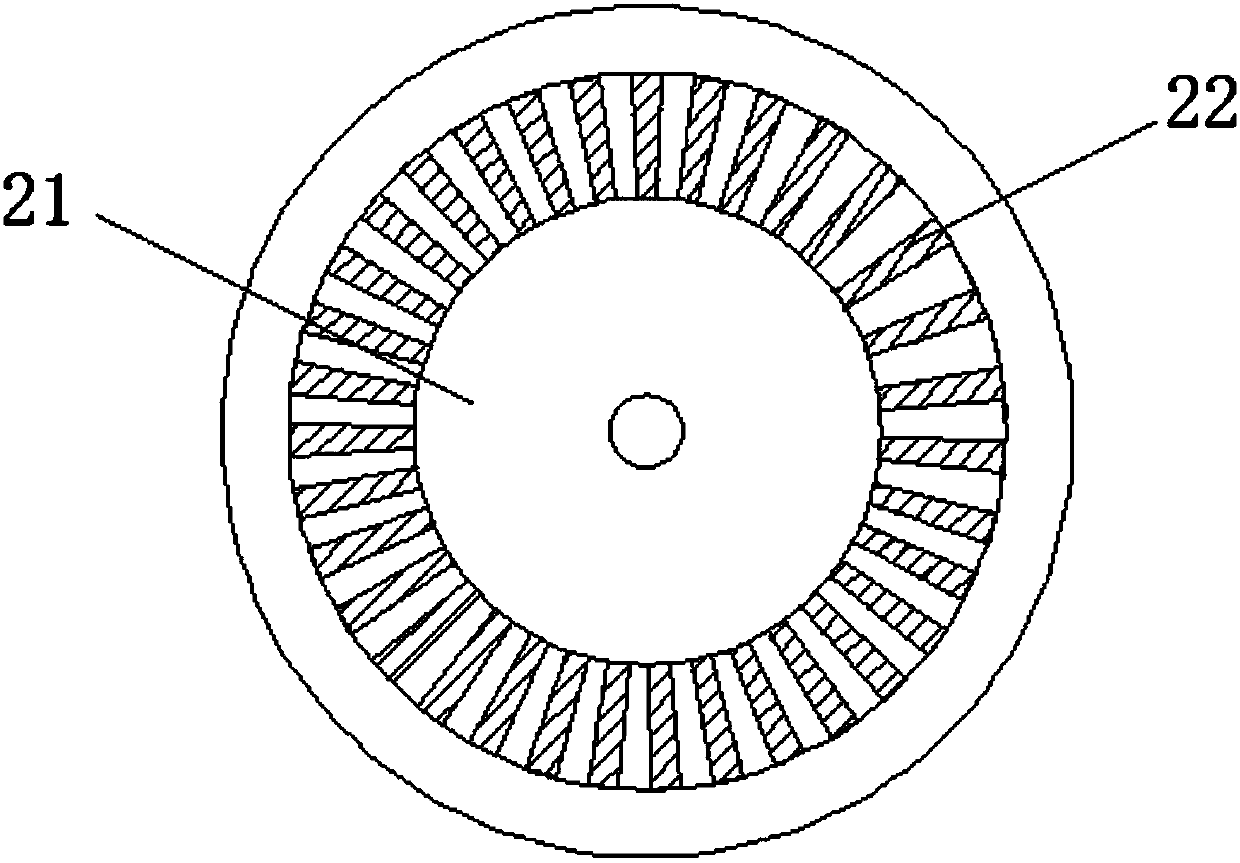

Oil cup inner wall grinding and brushing assembly line device

ActiveCN107414614AComplete processContinuously workingRevolution surface grinding machinesGrinding feedersDrive motorEngineering

An oil cup inner wall grinding and brushing assembly line device comprises an outer frame. The assembly line device further comprises a feeding mechanism, a clamping and centering mechanism and a grinding and brushing mechanism. An outlet of the feeding mechanism is connected with a clamping station of the clamping and centering mechanism. The grinding and brushing mechanism is located above the clamping station and comprises a dull polish bar, a drilling and grinding motor, an air cylinder, a rotary disc and a drive motor. The dull polish bar is vertically arranged and connected with an output shaft of the drilling and grinding motor. The drilling and grinding motor is arranged on the piston end portion of the air cylinder. The air cylinder is a driver capable of driving a piston to move up and down. The upper end of the air cylinder is fixed to the rotary disc. A rotation shaft of the rotary disc is connected with an output shaft of the drive motor used for driving the rotary disc to rotate. The drive motor is arranged on the outer frame. The oil cup inner wall grinding and brushing assembly line device capable of achieving machining and eliminating potential safety hazards, high in machining efficiency and good in rapidity is provided.

Owner:杭州亦侬农业科技有限公司

Marine product dewatering and grinding integration device with filtering function

The invention discloses a marine product dewatering and grinding integration device with a filtering function. The device comprises a first feed box, a second filter box, a hot air generating device,a water guide pipe, a water storage box, a second feed box, a grinding barrel, guide strips and a screening tray, wherein a first filter box is connected with the right side of the first feed box andis internally provided with a first rotating shaft and a first mixing blade; the first rotating shaft is connected with a first motor; the second filter box is arranged at the lower side of the firstfilter box and is internally provided with a second rotating shaft and a second mixing blade; the second rotating shaft is connected with a second motor; an air distributing plate is connected with the lower side of the hot air generating device, and air spray nozzles are arranged at the lower side of the air distributing plate; the filter boxes are connected with the lower side of the water guidepipe. The marine product dewatering and grinding integration device with the filtering function is provided with the first filter box and the second filter box, thus being capable of screening and separating out marine products with different quality and sizes, and further enabling the marine products to be dried in a separated way.

Owner:张巧芳

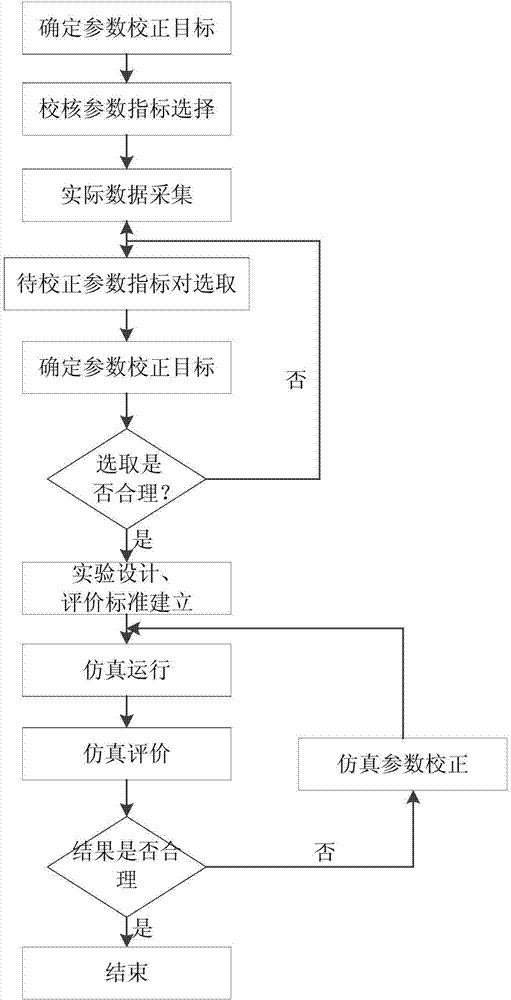

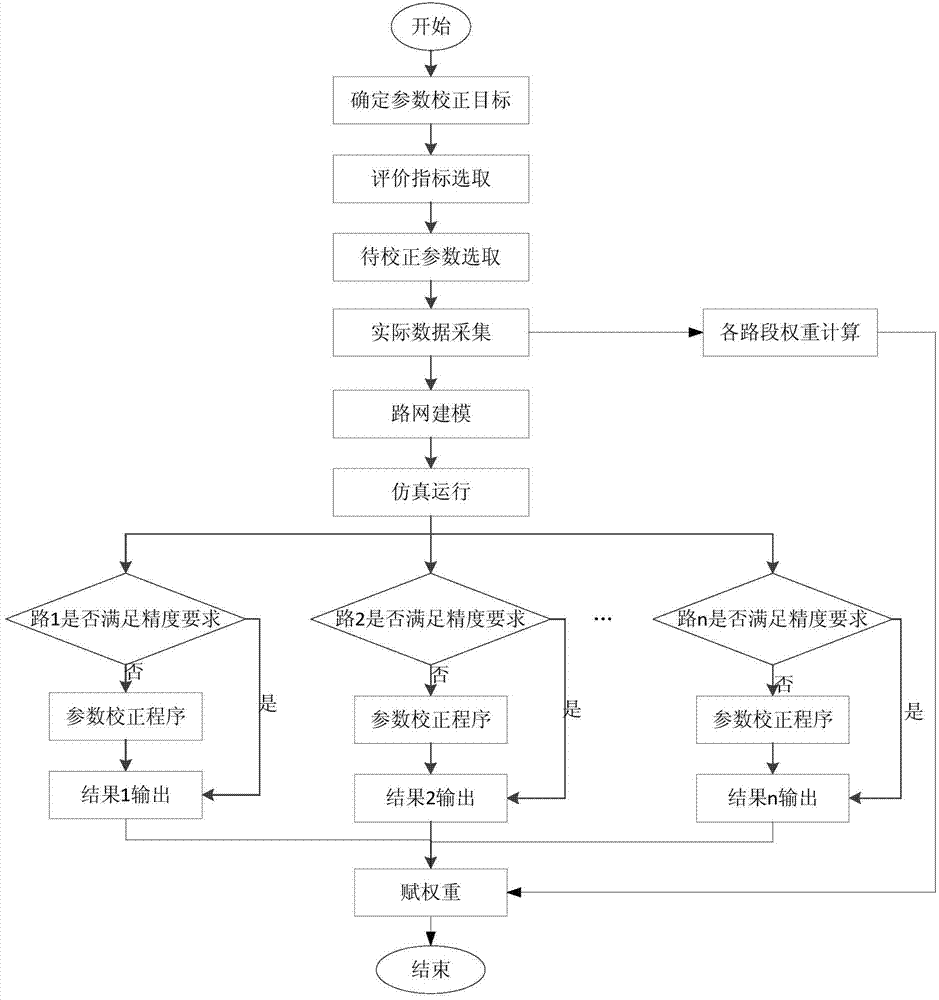

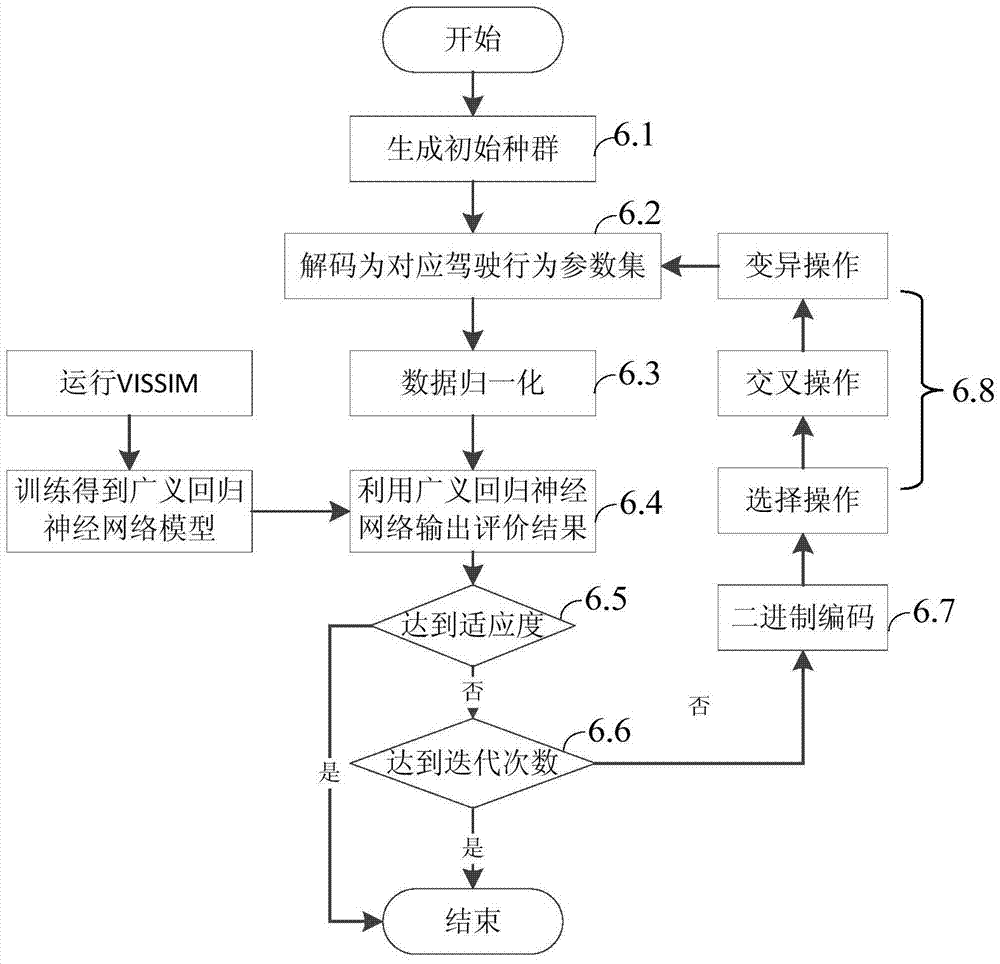

Road network parameter correction method specific to VISSIM

InactiveCN104850684AComplete processReduced simulation timeSpecial data processing applicationsAlgorithmStructure of Management Information

The invention provides a road network parameter correction method specific to VISSIM. The method comprises the following steps: (1) determining a parameter correction target; (2) selecting an evaluation index; (3) selecting a parameter to be corrected; (4) acquiring practical road data and evaluation index data; (5) performing route network modeling and simulation run; (6) correcting the parameter to be corrected; (7) calculating the weight and sensitive factor of each road segment; (8) multiplying respective obtained convergence correction parameter value of each road segment with respective sensitive factor respectively, and performing summation to obtain the correction parameter of a global road network. The correction method is irrelevant to the structure of simulation software, so that the correction method is suitable for the mentioned VISSIM software and can be applied in other simulation environments. Parameter automatic correction is performed with a generalized regression neural network method in the method, so that the simulation time can be shortened effectively; the iteration times are reduced; and the correction efficiency is increased effectively.

Owner:JIANGSU CAS JUNSHINE TECH

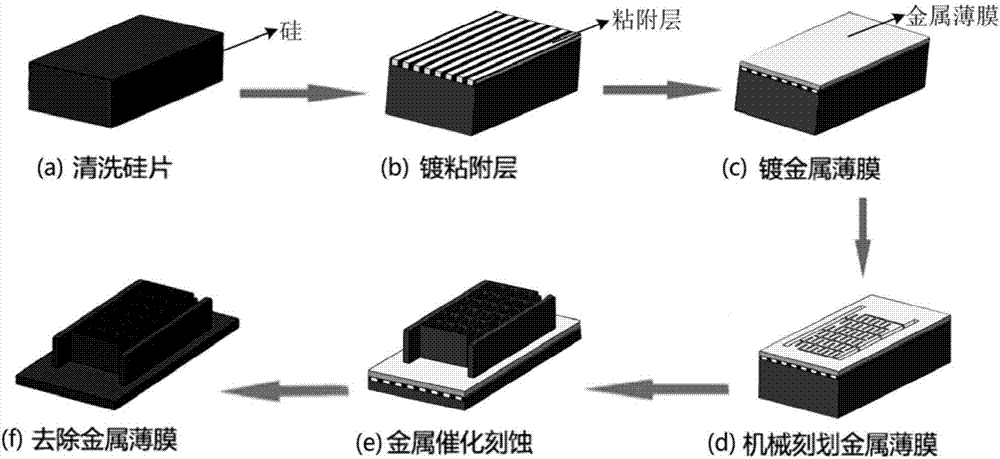

Preparation method for silicon micro/nano structure based on mechanical carving and metal catalysis etching

InactiveCN107265398AHigh aspect ratioNot easy to wearMaterial nanotechnologyDecorative surface effectsHydrofluoric acidNano structuring

The invention discloses a preparation method for a silicon micro / nano structure based on mechanical carving and metal catalysis etching. The method comprises the following steps of S1, preprocessing a silicon wafer, cleaning the surface of the silicon wafer and then carrying out drying to obtain a sample A; S2, integrating noble metal nano-film, depositing an adhesion layer on the surface of the sample A and integrating the noble metal nano-film on the surface of the adhesion layer to obtain a sample B; S3, mechanically carving the noble metal nano-film, carving the surface of the sample B through mechanical carving and removing the carved part of the noble metal nano-film, thereby obtaining a sample C which is located at any required position and has a set shape pattern; and S4, preparing the silicon micro / nano structure, placing the sample C into mixed solution of hydrofluoric acid and hydrogen peroxide and etching the sample C, thereby obtaining the silicon micro / nano structure with a high aspect ratio. In general, the preparation method has the advantages that the cost is low, the operation is simple and the processing can be positioned. Mass production is hopeful.

Owner:SOUTHWEST JIAOTONG UNIV

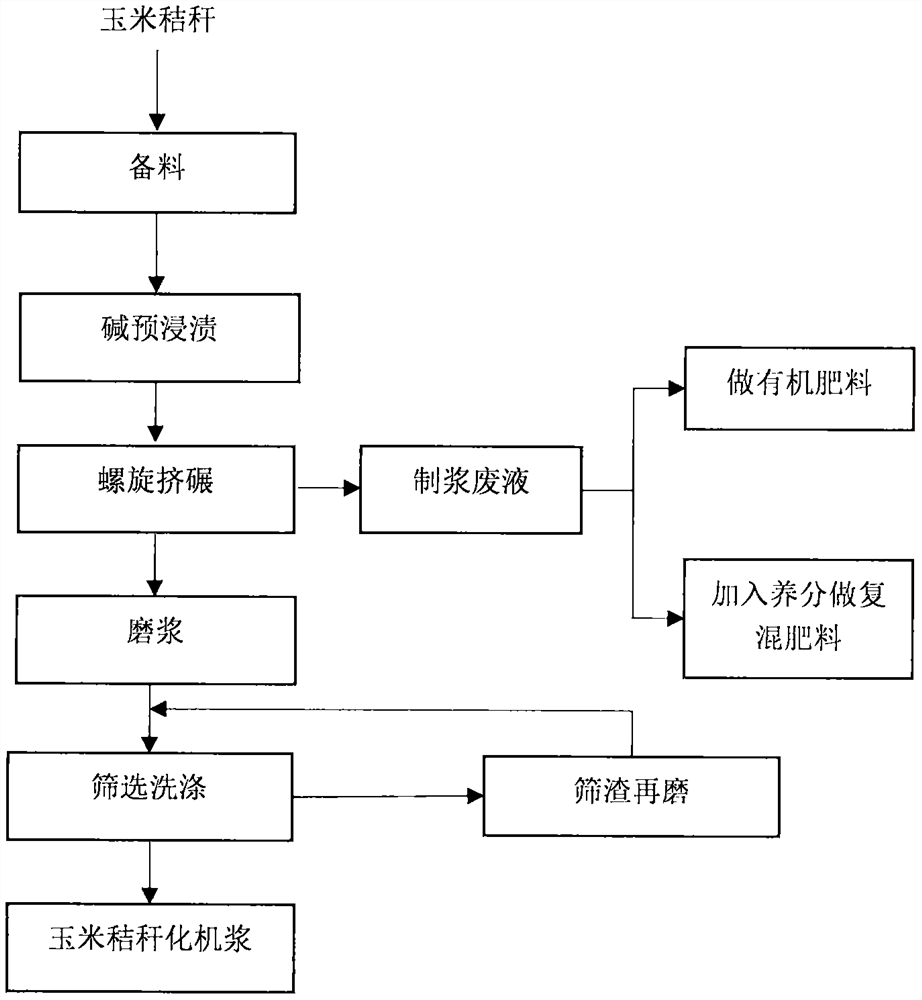

Method for preparing chemithermomechanical pulp from corn straw by potash process and extracting pulping waste liquid to prepare fertilizer

ActiveCN111689807AReduce processing costsLow running costAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFiberPotassium hydroxide

The invention discloses a method for preparing chemithermomechanical pulp from corn straw by a potash process and extracting pulping waste liquid to prepare a fertilizer, and relates to the technicalfield of pulping and papermaking utilizing agricultural solid wastes and resource utilization of the waste liquid in the pulping process. Corn straw is pre-impregnated with a potassium hydroxide solution and then ground into pulp to obtain corn straw chemithermomechanical pulp, and the pulp can be used for preparing qualified corrugating medium paper without being matched with other paper pulp; anorganic fertilizer can be prepared from the waste liquid generated in the pulping process only by concentration or granulation without the need of adding nutrients, and an organic-inorganic compoundfertilizer can be prepared by adding related nutrients for concentration and granulation. A complete process for preparing chemithermomechanical pulp by pre-impregnating and grinding corn straw and preparing a fertilizer from pulping waste liquid is provided by the invention, the process is complete, the implementation process is simple, the potential of straw fiber raw material pulping and papermaking is explored, and the fertilizer prepared from the waste liquid is used for agricultural production, and therefore resource cyclic sharing of the pulping and papermaking industry and agriculturalproduction is embodied, and sustainable development of the two industries is promoted.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

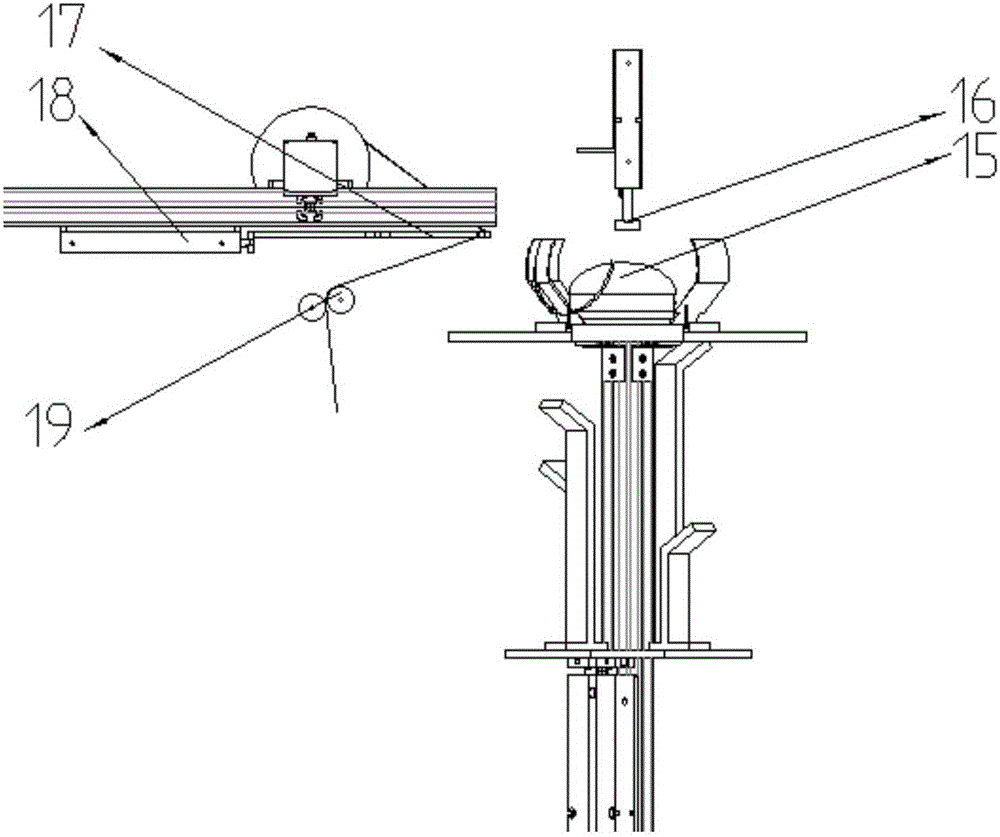

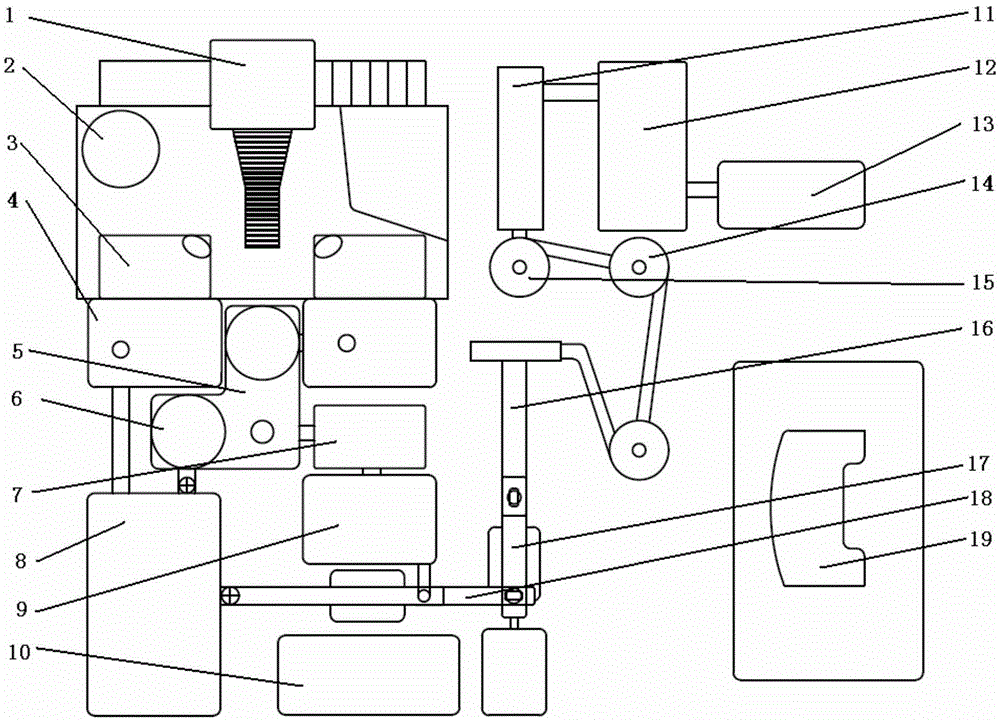

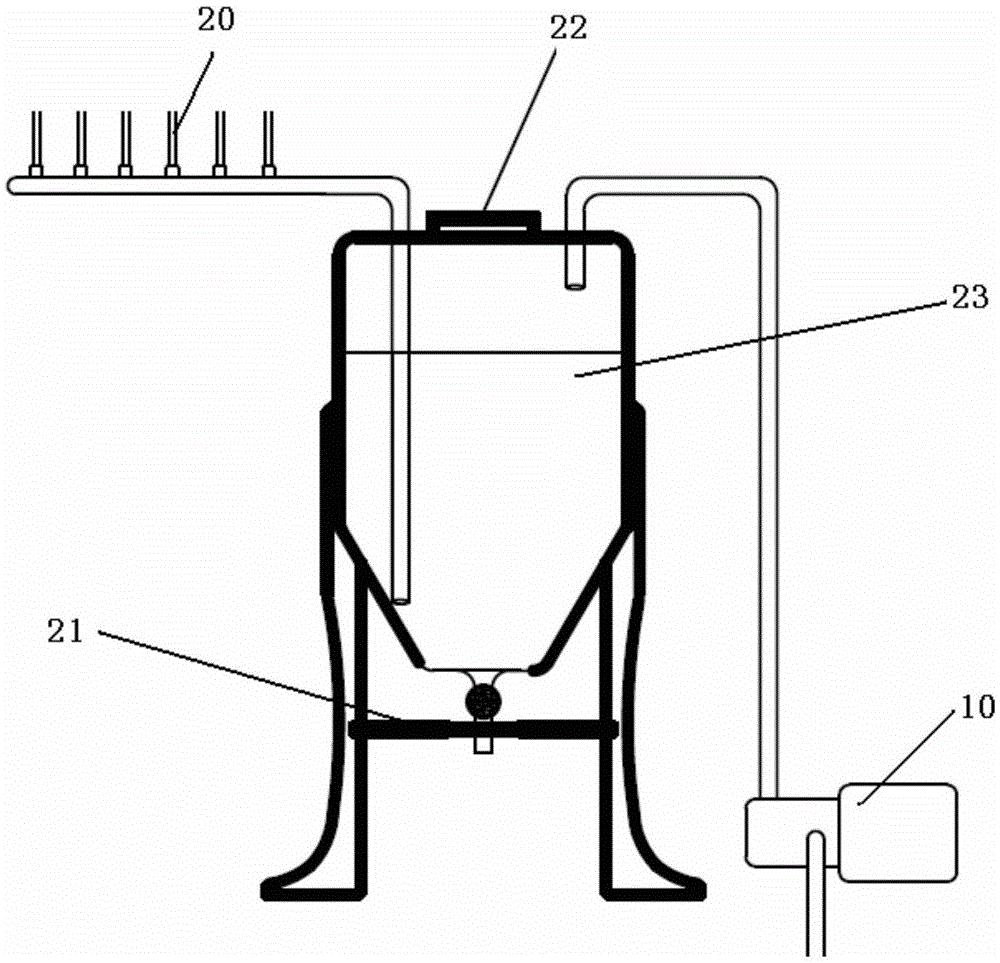

Rubber powder aftertreatment equipment

The invention relates to rubber powder aftertreatment equipment. The rubber powder aftertreatment equipment consists of multiple working modules, and comprises a loading platform (1), an oil tank (2), a stirring machine I (3), a hopper I (4), a hopper II (5), a dynamic automatic metering machine (6), a stirring machine II (7), a desulfurizing machine (8), a hopper III (9), a vacuum pump (10), a vibrating screen (11), a finished product tank (12), an automatic metering packer (13), an air cylinder I (14), an air cylinder II (15), a granulator (16), a mixing machine (17), a mixing mill (18) and a central control room (19). In addition, the rubber powder aftertreatment equipment further comprises a set of negative-pressure water filter device. The equipment has such advantages as high automatic control degree, good environmental protection performance and low energy consumption, and can prepare desulfurized rubber powder to particles or can renewedly match the desulfurized rubber powder to prepare direct products-rubber particles.

Owner:SUZHOU HONGLEI RUBBER & PLASTIC TECH CO LTD

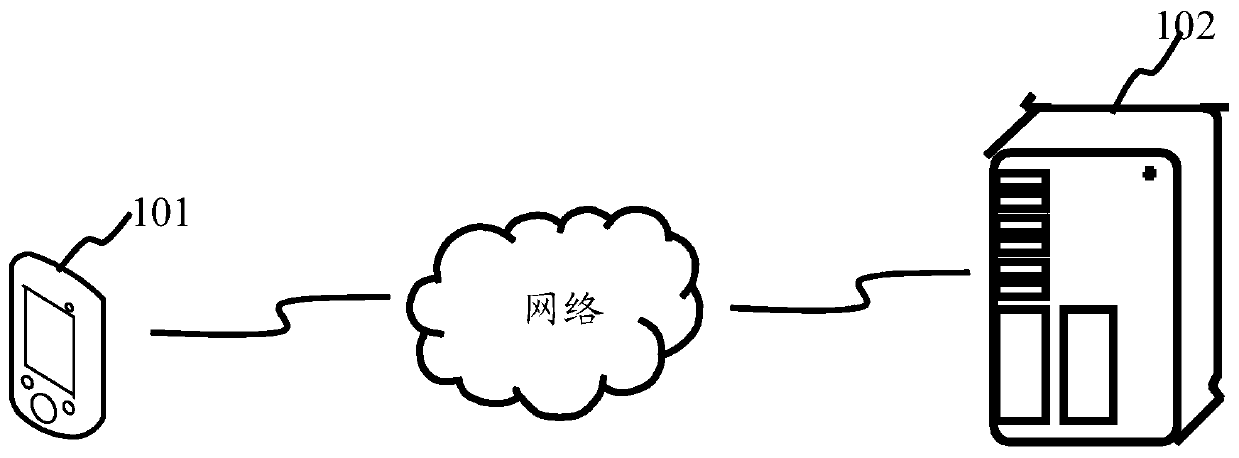

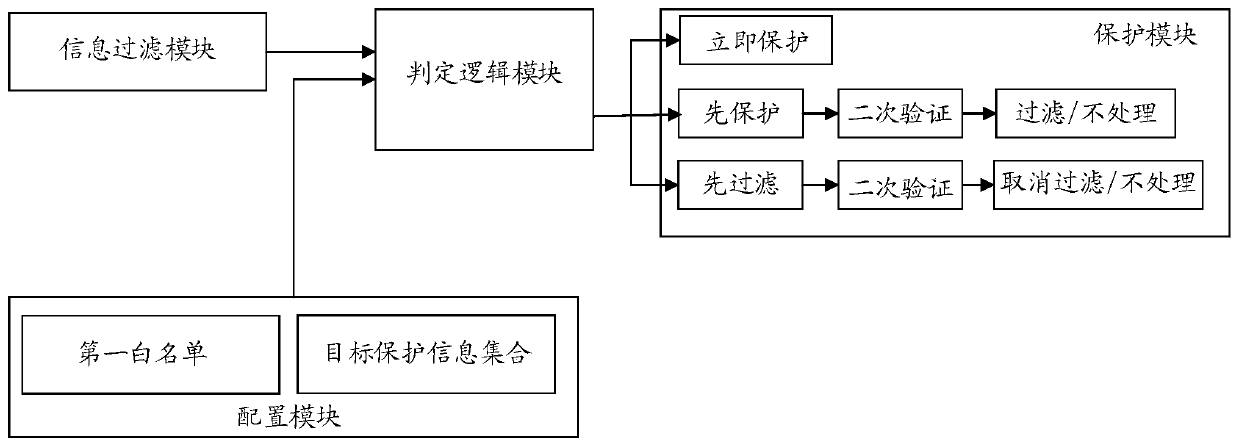

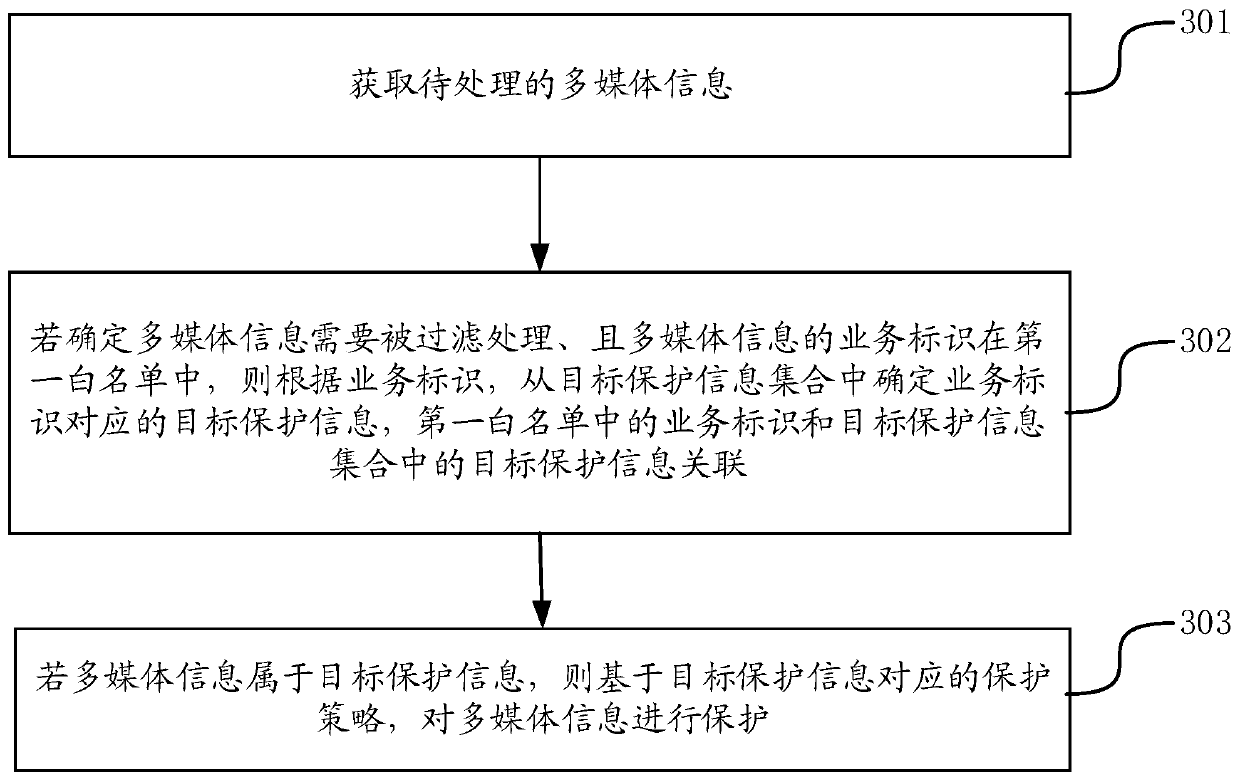

Multimedia information processing method and device and server

ActiveCN110688628AImprove efficiencyComplete processDigital data protectionProgram/content distribution protectionInformation processingWhitelist

The invention provides a multimedia information processing method and device and a server, and belongs to the technical field of information. The method comprises the following steps: acquiring multimedia information to be processed; if it is determined that the multimedia information needs to be filtered and the service identifier of the multimedia information is in the first white list, determining target protection information corresponding to the service identifier from a target protection information set according to the service identifier, and the service identifier in the first white list being associated with the target protection information in the target protection information set; and if the multimedia information belongs to the target protection information, protecting the multimedia information based on a protection strategy corresponding to the target protection information. Due to the fact that the target protection information set is added and the target protection information corresponding to the service identifier is stored in the target protection information set, if the multimedia information needing to be protected is adjusted, the incidence relation between the service identifier in the first white list and the target protection information is directly modified, and the adjustment efficiency is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Production method of pet articles and its equipment

InactiveCN1268200CSolve the disadvantage of being expensiveLow costAnimal feeding stuffLeather/skins/hides/pelt chemical treatment apparatusIt equipmentAdhesive

The present invention relates to a method for making pet article and its equipment. Its raw material adopts second layer of hide and its below various layer, and said method includes: pretreatment procedure, including removing fat from hide, layering, adding softening agent and softening and washing with water; forming procedure, wet forming procedure is a wet hide leather processing method including the steps of draining, extruding, cutting and weaving, etc. or wet hide colloidal particle material processing method including the steps of draining, extruding, mincing, adding adhesive and stirring, pressing or extruding, etc. and the dry forming procedure is a dry hide leather processing method including the steps of drying, cutting, soaking in water and weaving or pressing or dry hide colloidal particle material processing method including the steps of drying.

Owner:刘尚武 +3

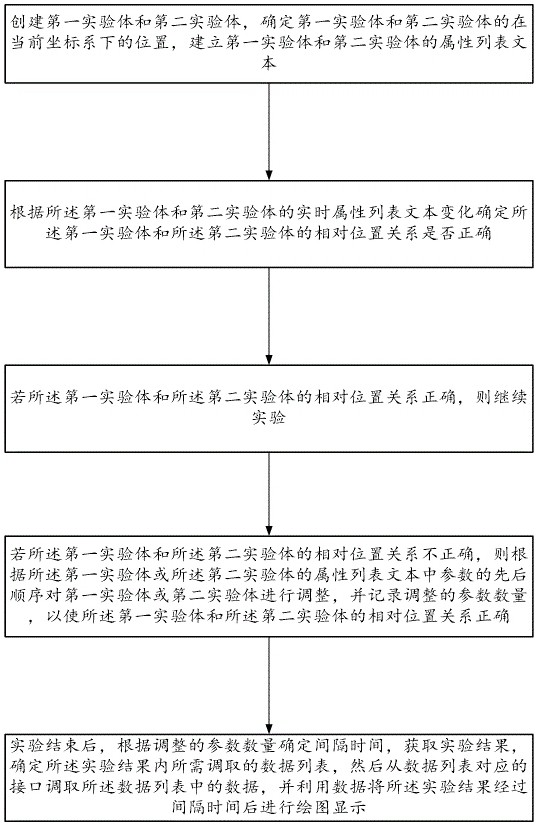

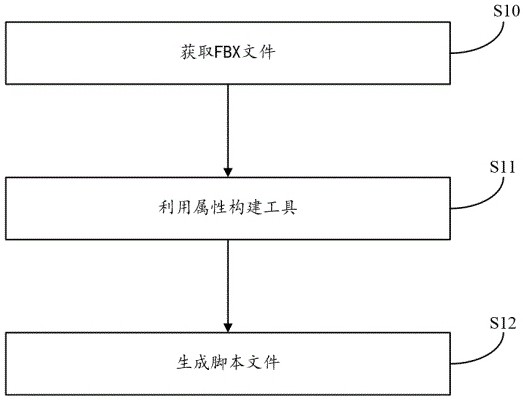

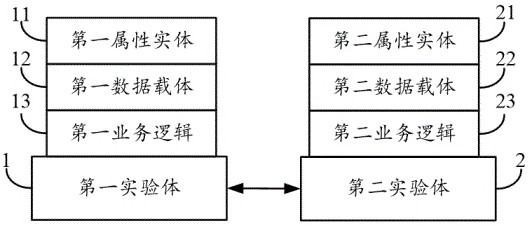

Three-dimensional simulation experiment method based on data driving

ActiveCN112558782AStable positionGuaranteed correctnessInput/output for user-computer interactionCosmonautic condition simulationsDimensional simulationAlgorithm

The invention relates to a three-dimensional simulation experiment method based on data driving, and the method comprises the steps: determining the positions of a first experiment body and a second experiment body, and building the attribute list texts of the first experiment body and the second experiment body; when an experiment is carried out, determining whether the relative position relationbetween the first experiment body and the second experiment body is correct or not according to the real-time attribute list text change of the first experiment body and the second experiment body; if the relative position relationship between the first experiment body and the second experiment body is correct, continuing the experiment; if the relative position relationship between the first experimental body and the second experimental body is incorrect, adjusting the attribute list text of the first experimental body or the second experimental body, so that the relative position relationship between the first experimental body and the second experimental body is correct. The second experiment body is dynamically adjusted according to the attribute list sequence of the second experimentbody, so that the relative positions of the first experiment body and the second experiment body are accurate in the experiment process, the experiment error is reduced, and the accuracy of the experiment result is ensured.

Owner:北京润尼尔网络科技有限公司

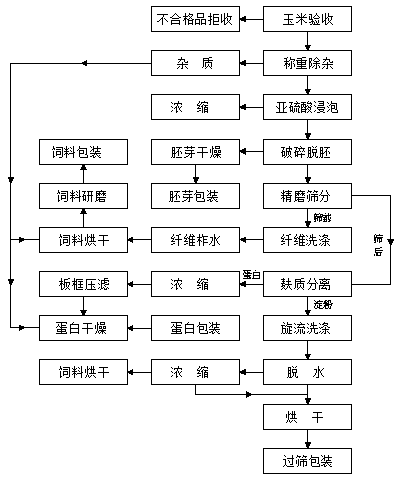

Preparation method of corn starch

InactiveCN111303304ACorn fiber retentionEasy to keepPeptide preparation methodsProcess engineeringGluten

The invention discloses a preparation method for preparing starch from corn, and relates to the technical field of corn deep processing. The specific operation method comprises seven steps of impurityremoval and soaking, crushing and degerming, fine grinding and screening, gluten separation, nine-stage cyclone washing, dehydration and drying, and screening and packaging. According to the invention, the technological process is complete, and in the preparation process of corn starch, corn fibers and corn protein are well reserved and prepared into a feed to be reused, so that the yield of terminal products is greatly increased, the economic value of total products is increased, and resource waste is also avoided; and the technological process is compact, and through long-time actual operation, the screened technological conditions are low in energy consumption and high in yield, so that the method is suitable for actual production.

Owner:HEILONGJIANG HAOTIAN CORN DEV

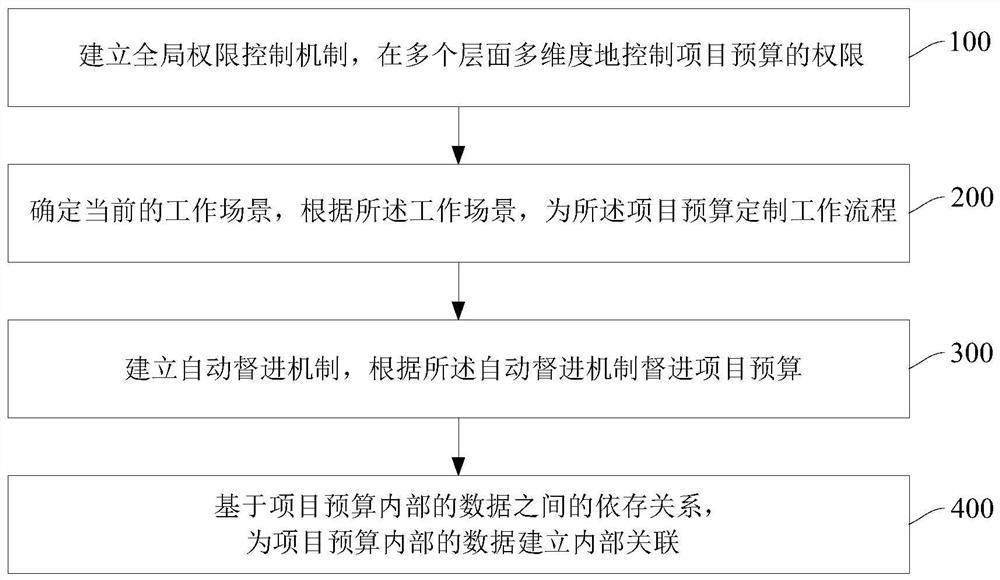

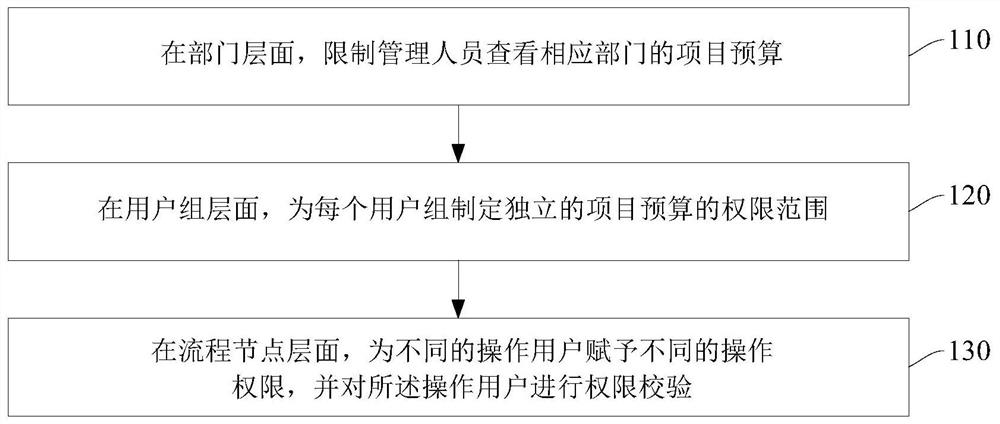

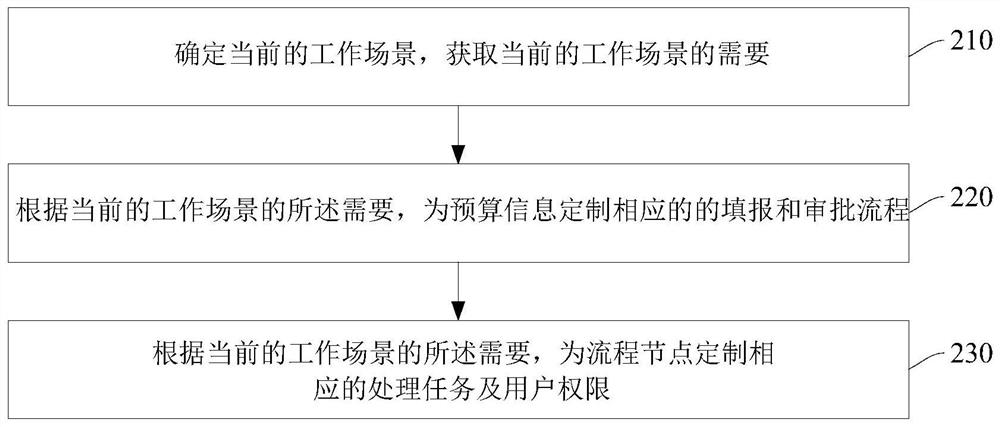

Project budget full life cycle management device and method

InactiveCN113256243AReduce managementEasy to operateFinanceDigital data authenticationFull life cycleProject management

The invention provides a project budget full life cycle management method and device, and relates to the technical field of project management, and the management device comprises: an authority control module which is used for building a global authority control mechanism, and controlling the authority of project budget in multiple levels and multiple dimensions; a process control module which is used for determining a current working scene and customizing a working process for the project budget according to the working scene; a process governor mechanism module which is used for establishing an automatic governor mechanism and carrying out project budgeting according to the automatic governor mechanism; and an information association module which is used for establishing internal association for the data in the project budget based on the dependency relationship among the data in the project budget. Related processes are simplified, authority and process control is enhanced, operation risks possibly brought by manual Excel maintenance are reduced, meanwhile, the user operation experience is improved, and information filling, consulting and archiving are more convenient and normative.

Owner:厦门国际银行股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com