Glass leftover recycling production line and glass leftover recycling process

A technology of leftover material and production line, which is applied in the field of renewable resource recovery equipment, can solve the problems of low mechanization and automation in processing and utilization, and lack of automation in waste glass recycling equipment, and achieve the effect of high mechanization and automation and convenient proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

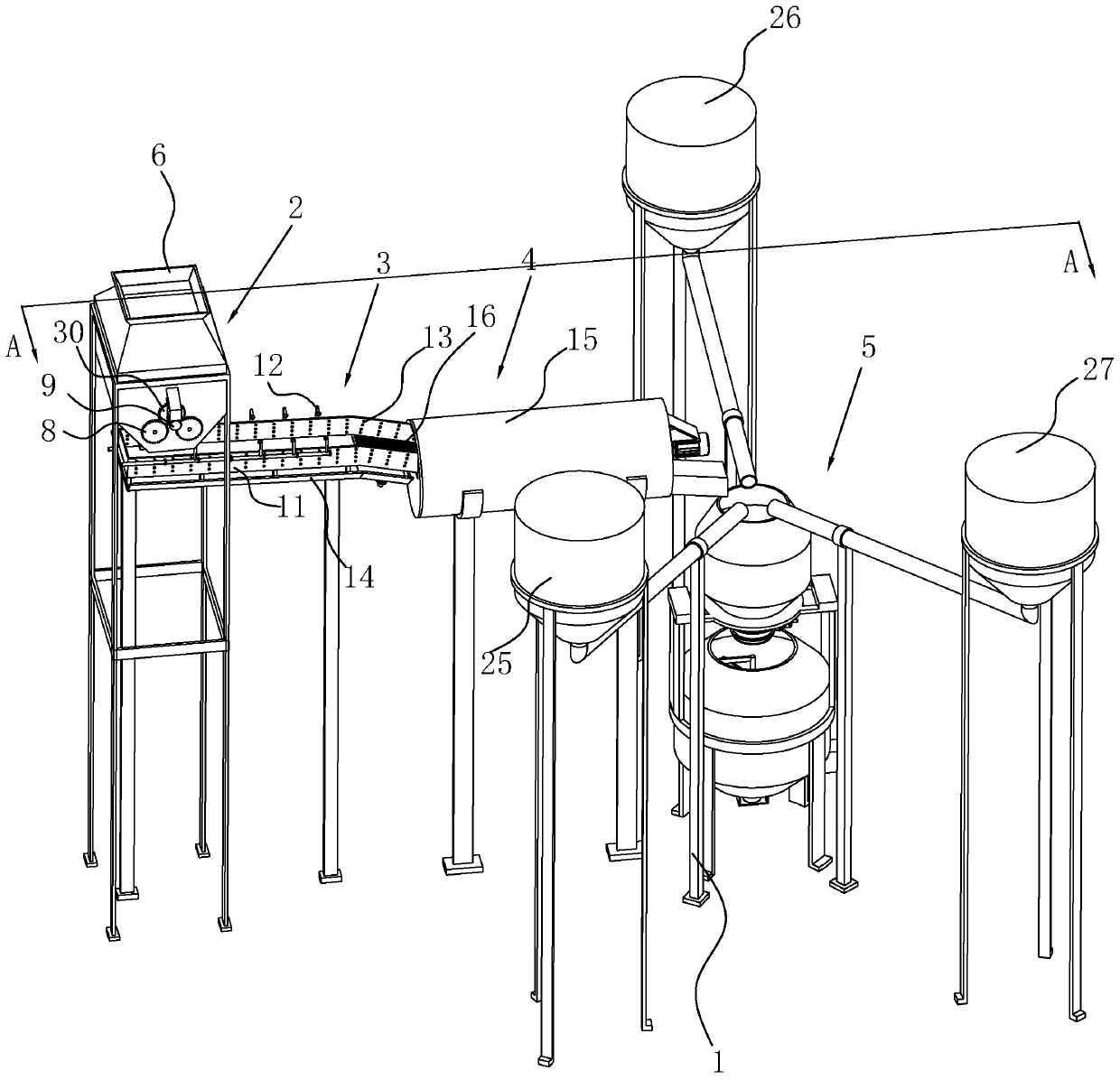

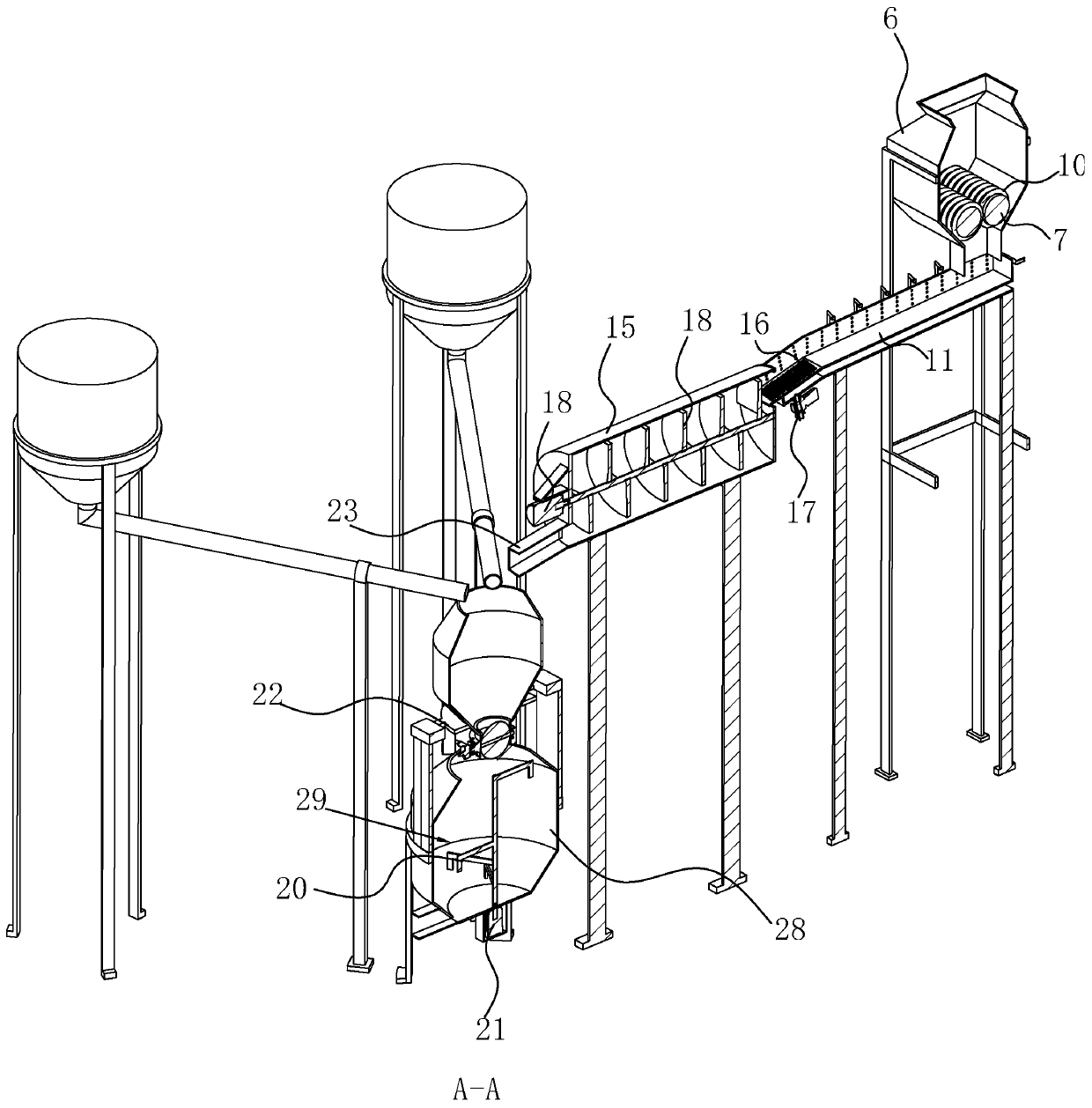

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] refer to figure 1 and figure 2, is a glass scrap recycling production line disclosed in the present invention, comprising a frame 1, on which a segmentation assembly 2, a washing filter assembly 3, a crushing assembly 4, and a mixing assembly 5 are sequentially arranged, and the segmentation assembly 2 includes a receiving hopper 6. The bottom end of the receiving hopper 6 is provided with two crushing rollers 7 arranged in parallel, and the rotating teeth 8 are arranged between the crushing rollers 7, and the side wall of the receiving hopper 6 is provided with a drive motor 9 for driving the rotation of the crushing roller 7, and the output shaft of the drive motor 9 is The active teeth 30 are provided, and the active teeth 30 are meshed with the rotating teeth 8. The outer peripheral wall of the crushing roller 7 is distributed with dividing knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com