Patents

Literature

234 results about "Glass recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass recycling is the processing of waste glass into usable products. Glass that is crushed and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective products detected and rejected by a quality control process during the industrial process of glass manufacturing, transition phases of product changes (such as thickness and colour changes) and production offcuts. External cullet is waste glass that has been collected and/or reprocessed with the purpose of recycling. External cullet (which can be pre- or post-consumer) is classified as waste. The word "cullet", when used in the context of end-of-waste, will always refer to external cullet.

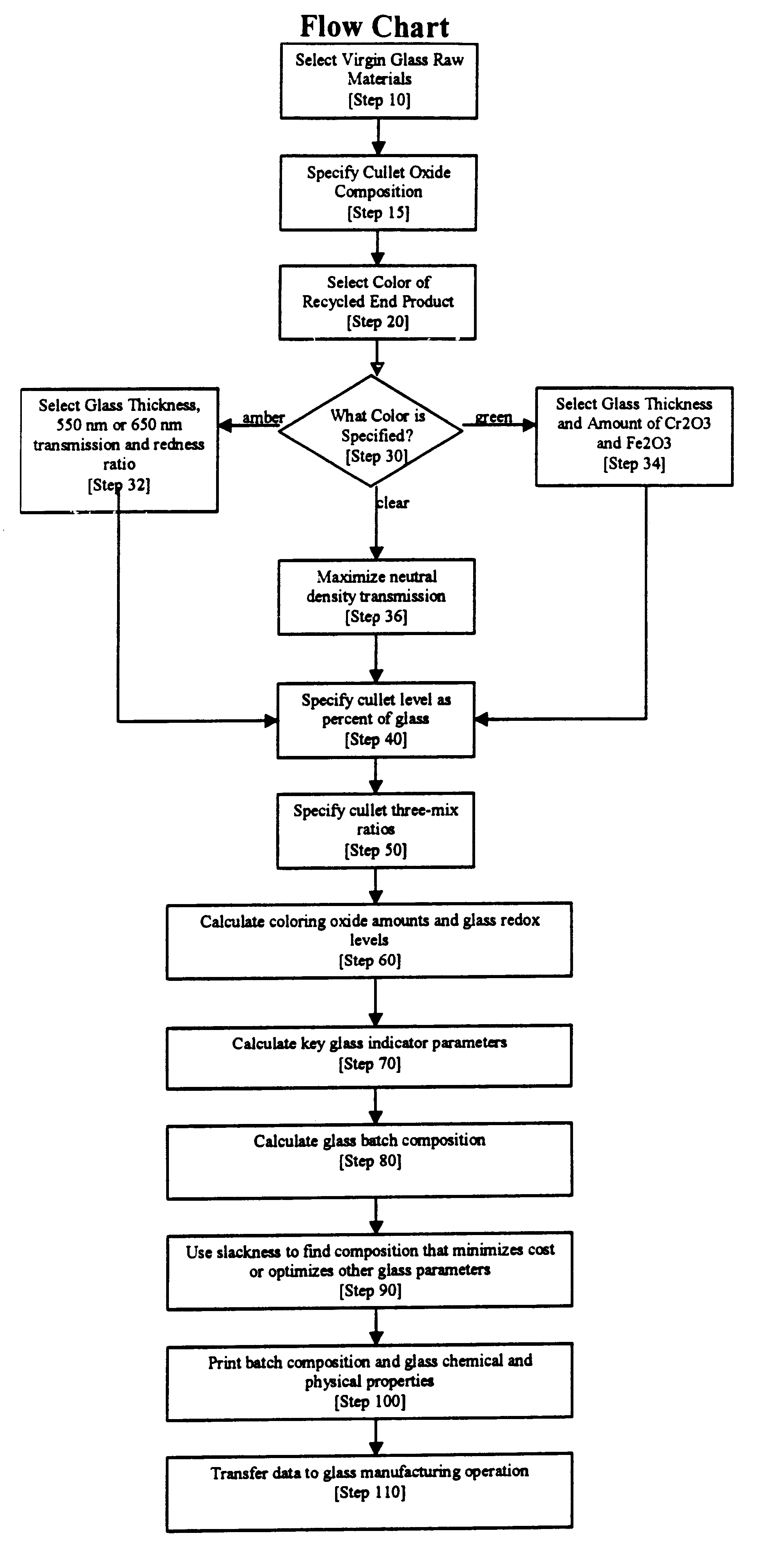

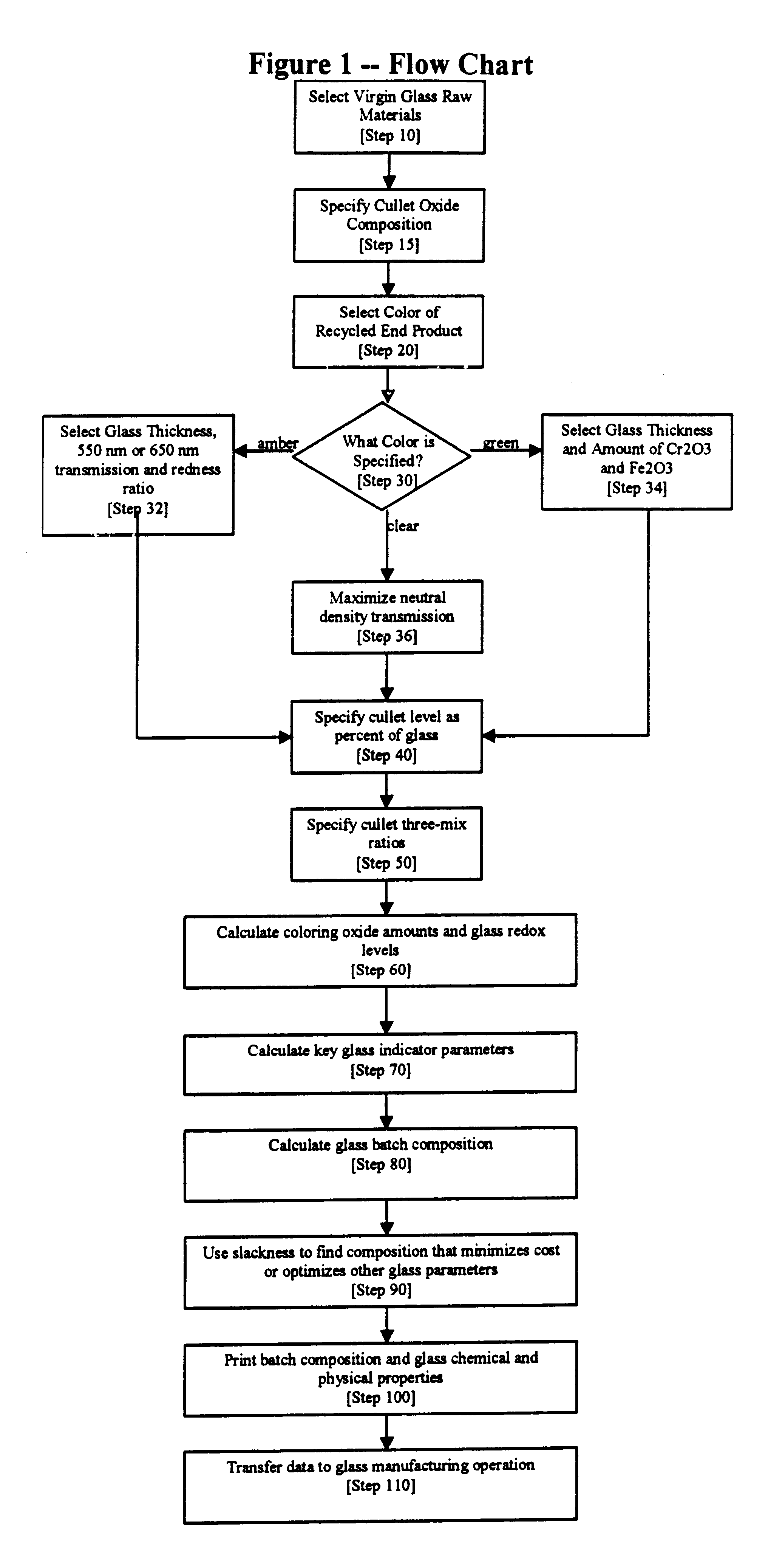

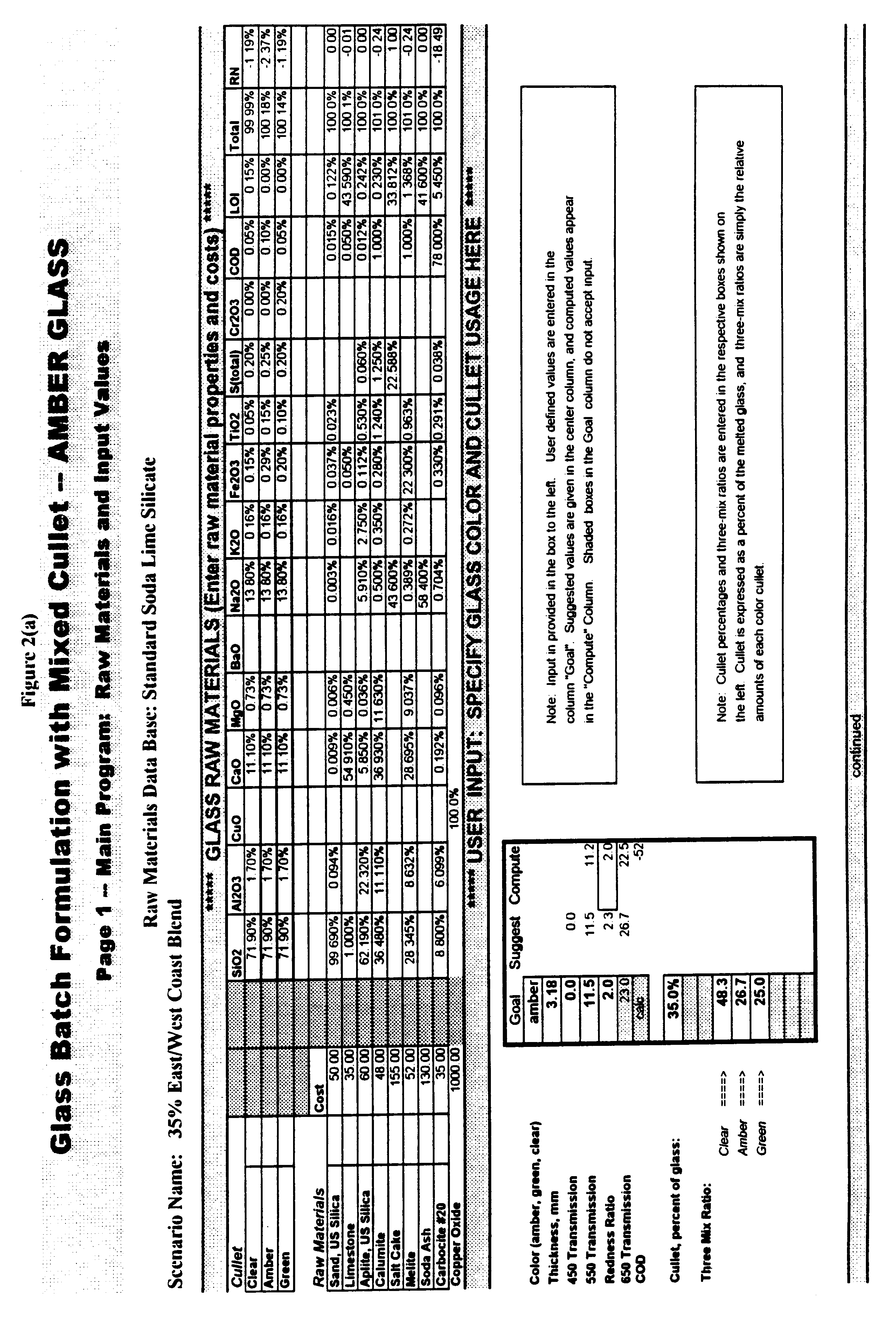

Method of recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6230521B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsOxidation-Reduction AgentBottle

An automated method for recycling mixed colored cutlet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

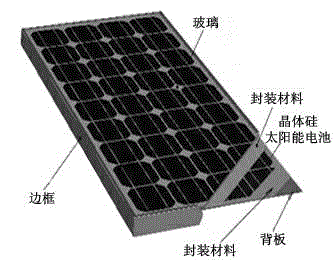

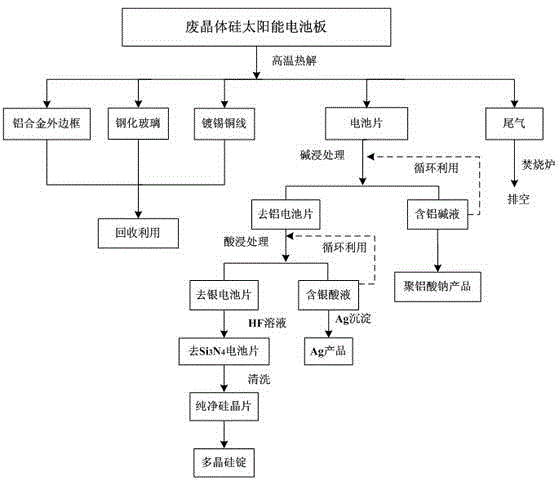

Waste crystalline silicon solar cell panel disassembling and recovering method

ActiveCN103978021AIncrease added valueRealize sorting and recyclingWaste processingSolid waste disposalWaferingPhysical chemistry

The invention discloses a waste crystalline silicon solar cell panel disassembling and recovering method. The method can realize the classification recovery of aluminum frames, toughened glass, silicon wafers, aluminum, silver and copper of waste crystalline silicon solar cell panels. The method adopts a heat treatment technology and a chemical technology combination technique to realize the frame and glass recovery of the waste crystalline silicon solar cell panels, the silicon wafer separation, and the valuable metal and silicon wafer recovery. The method has the advantages of recovery treatment difficulty reduction, tail gas harmlessness realization, secondary pollution control and environment protection; and an alkali dipping treatment and acid dipping treatment solution can be recycled, so the reagent consumption is reduced, the waste acid and waste alkali generation amount is reduced, and the final waste treatment cost is reduced.

Owner:刘景洋

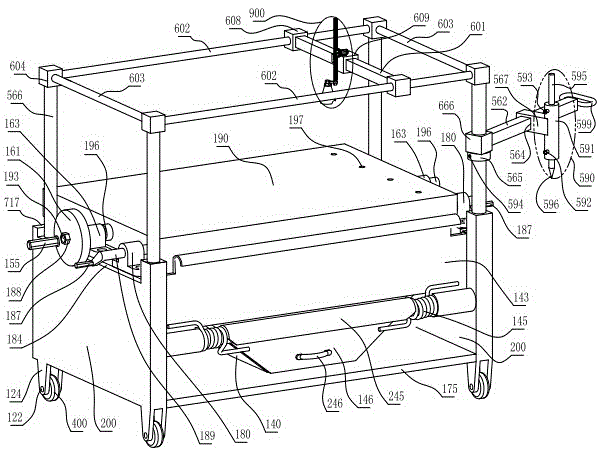

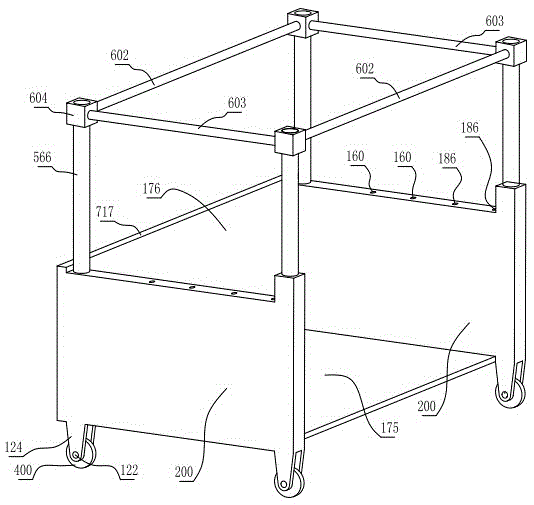

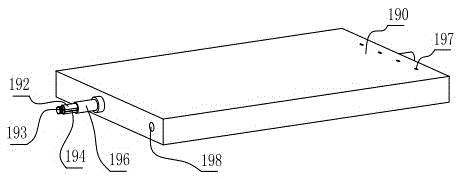

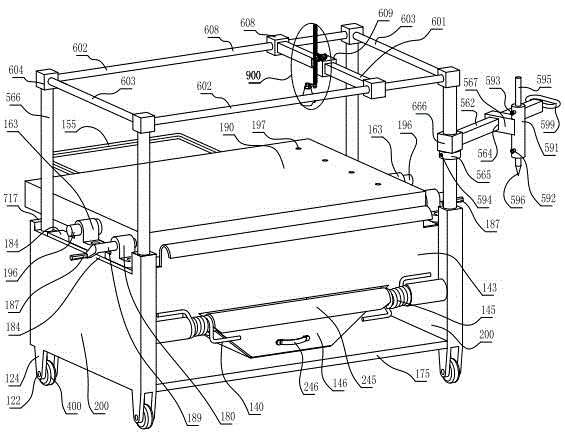

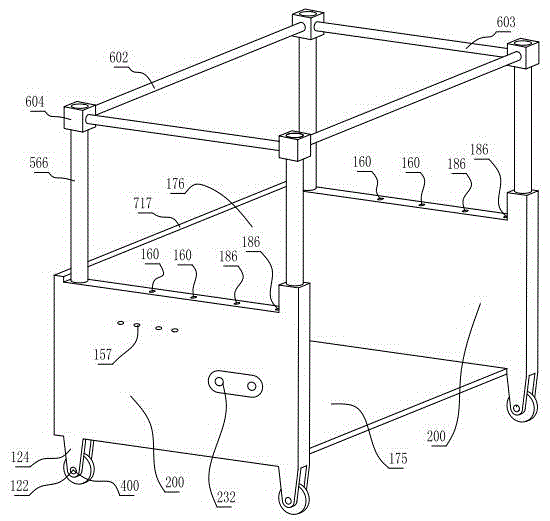

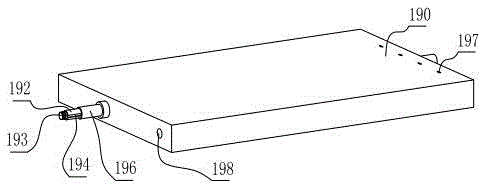

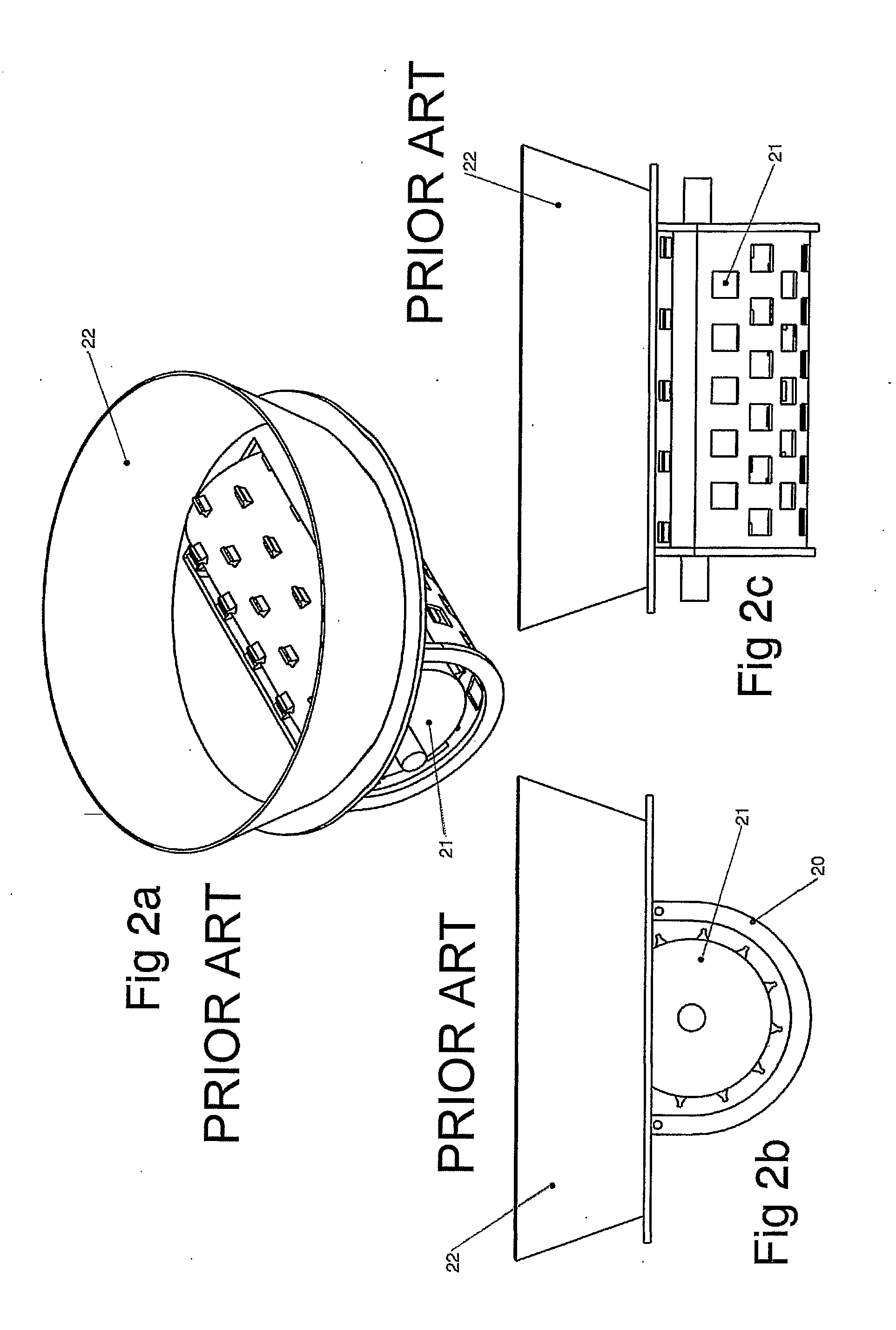

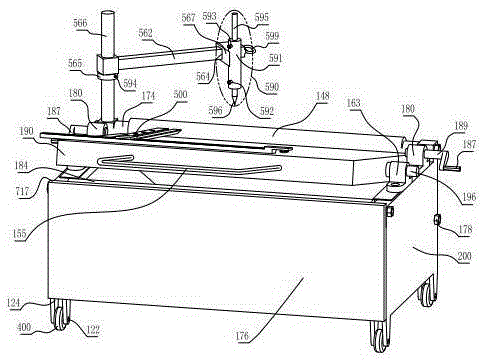

Disk wheel rotating bench rack shooting V-shaped clamping plate nickel alloy glass examination apparatus

InactiveCN105527156AEasy to moveEasy to removeMaterial strength using repeated/pulsating forcesMobile cameraNickel alloy

The invention relates to a toughened glass test examination apparatus, and concretely relates to a disk wheel rotating bench rack shooting V-shaped clamping plate nickel alloy glass examination apparatus. The apparatus is characterized in that a bench plate rotating shaft at one side is fixedly provided with a hand-operated disk wheel, a disk wheel flat key is arranged between the bench plate rotating shaft and the hand-operated disk wheel, and the outer side surface of the hand-operated disk wheel is provided with a disk wheel cranking handle; two transverse horizontal rods are in sliding fit with shooting transverse slide blocks, a shooting square bar is fixedly arranged between the two shooting transverse slide blocks, the shooting square bar is provided with a mobile camera assembly, an impact cross bar is fixedly provided with a cylinder impacter in a slidable manner, the upper plane of a test bench plate is fixedly provided with a coplanar V-shaped groove clamping plate assembly, and a broken glass recovery container is fixedly arranged between an entirety of bench plate bearers and lock pin bearers and the upper plane of a supporting side plate; and an integral frame is provided with a rack elevating industry camera, a disk wheel overturns test bench plates, a screw thread lock pin is arranged to fasten, and especially the coplanar V-shaped groove clamping plate assembly and the cylinder impacter are also arranged to form an automatic whole-course detection base apparatus.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

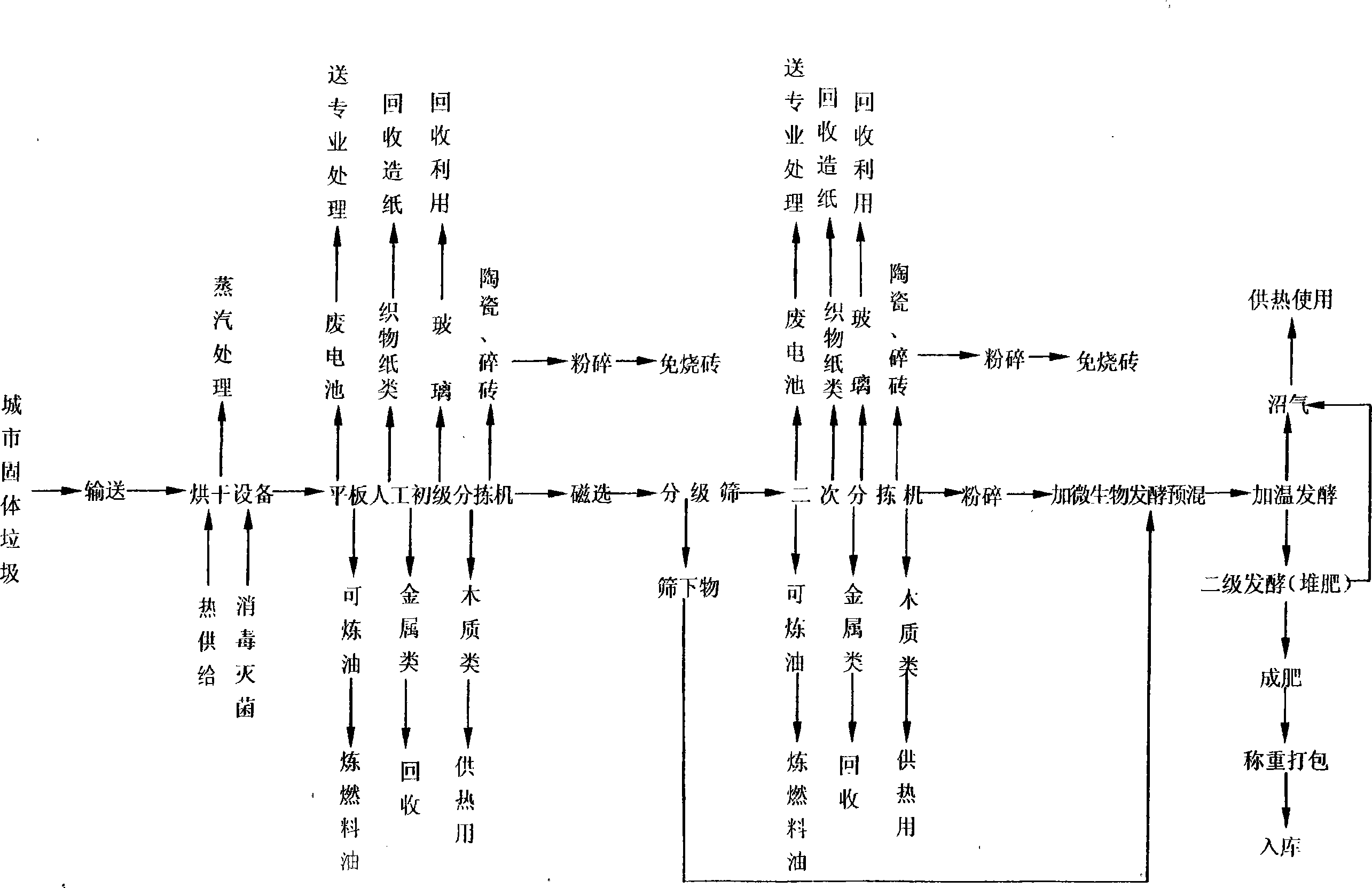

Integrated ulilization processing system for treating daily-life garbage without environmental pollution by reclaiming and regenerating

InactiveCN101081402ABe harmlessBe resourcefulBio-organic fraction processingSolid waste disposalBrickLitter

The present invention is one comprehensive innocuous city solid refuse treating system. In the system, the city solid refuse is first stoved, sterilized and sorted, then magnetically separated to separate out iron containing waste, and finally sieved into the undersize fed to one mixing tank and the oversize further sorted, with the rest matter being crushed and fed also to the mixing tank for fermentation to produce organic fertilizer. The sorted fabric, paper, iron, glass are reused; the sorted building refuses are crushed and further produced into no-burning brick; the waste battery is specially treated; the waste plastic and rubber are treated to produce oil; and the marsh gas generated in the fermentation process is used to provide heat for stoving refuse and refining oil. The present invention has excellent refuse treating effect.

Owner:周建华 +1

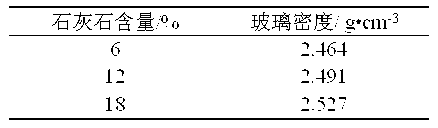

Waste glass slag reutilization method and obtained glass

The invention discloses a waste glass slag reutilization method and obtained glass. The reutilization method comprises the following steps of: first, breaking waste glass slags, grinding, soaking with water to remove most soluble substances in the waste glass slags, filtering and drying the soaked waste glass slags, and directly firing into glass or using the waste glass slags as a raw materials for making glass. A method and a process for the pretreatment and the reutilization of waste borosilicate glass slags collected from a flue of a flame kiln for producing borosilicate glass are first pointedly provided by the invention, a direction is pointed out for the reutilization of the waste glass slags produced by volatile condensation, a novel feasible approach is provided, and a solution for solving the problem which puzzles borosilicate glass producing enterprises is found. With the method, filtrate and filter residues are respectively utilized after the waste glass slags are pretreated, the wastes are fully reutilized, and environment pollution is reduced.

Owner:UNIV OF JINAN

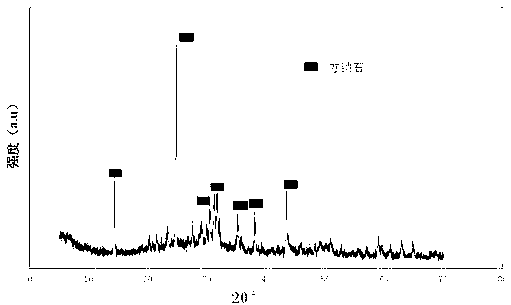

Method for preparing micro crystal glass plate for building using waste glass

InactiveCN1648090AIn line with the problem of weak crystallization ability and inability to crystallize during sinteringWeak ability to overcome crystallizationOptoelectronicsSurface grinding

The preparation process of micro crystal glass plate for building with waste glass as material includes the following technological steps: sorting waste glass, cleaning, crushing, ball milling, sieving, adding devitrifying promoter, mixing, sintering reaction to devitrify, mechanical surface grinding and polishing. The present invention features that the crystal is not separated out from glass but formed through the reaction between the glass powder and the devitrifying promoter during sintering. The separated crystal is controlled with the type of added devitrifying promoter and not dependent on the glass components. Without the step of smelting glass with special components, the present invention has simple process, low power consumption and low cost, and opens one way for the utilization of waste glass.

Owner:DALIAN JIAOTONG UNIVERSITY

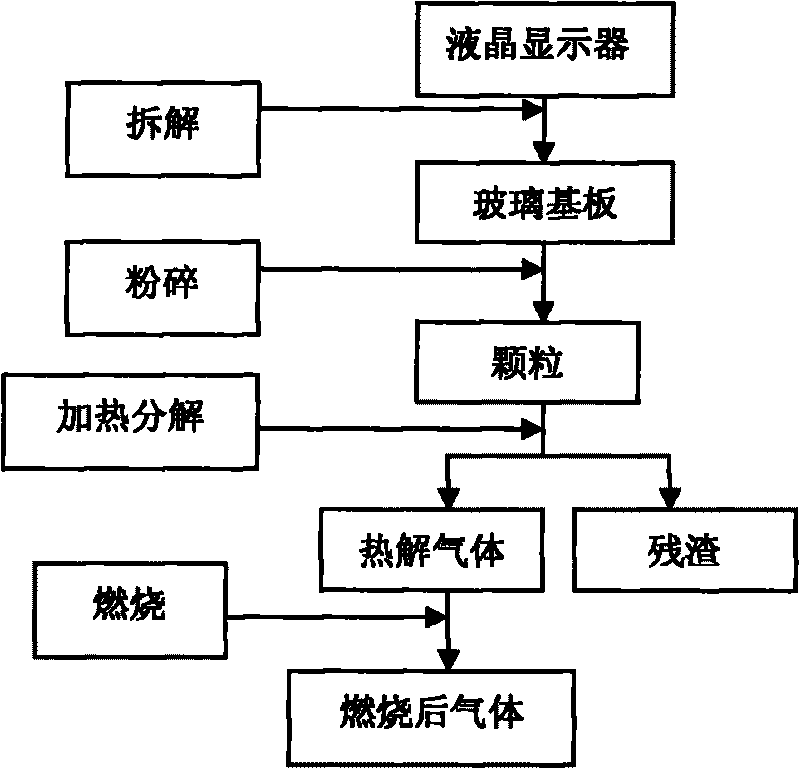

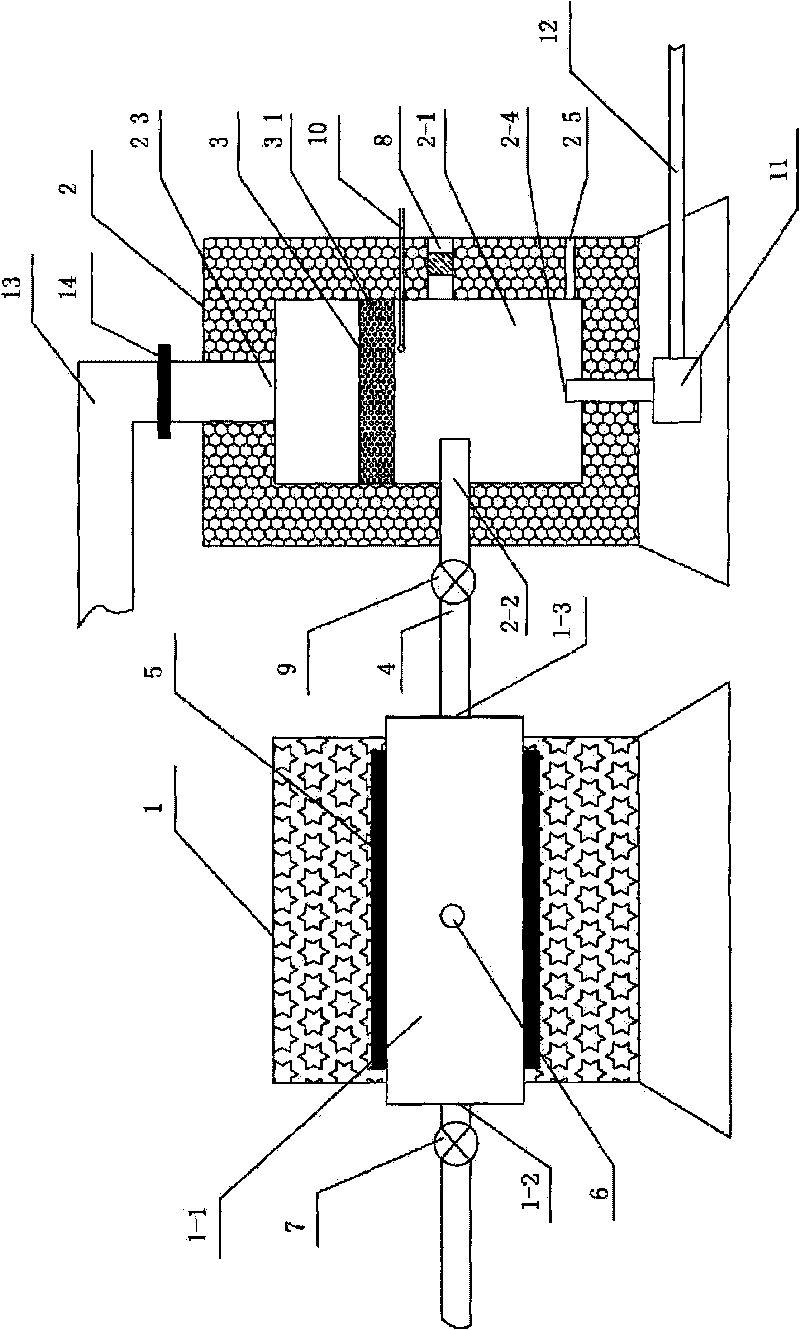

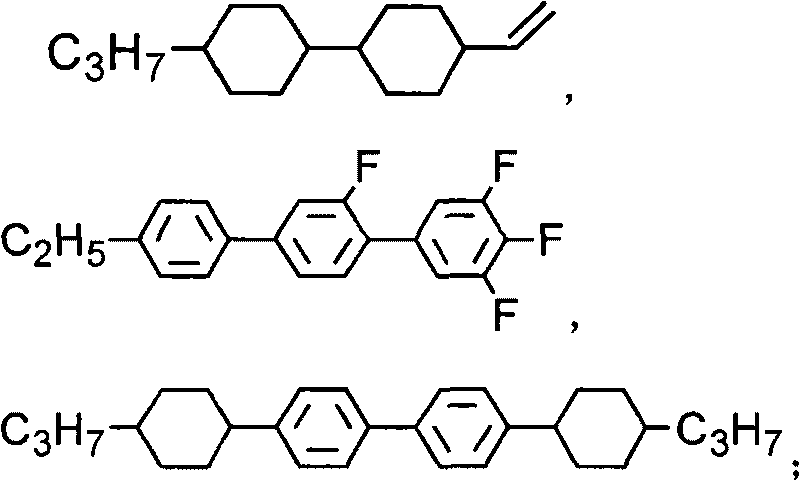

Method for harmless heat treatment of waste liquid crystal display

InactiveCN101722169AImprove protectionReduce the temperatureSolid waste disposalIndiumLiquid-crystal display

The invention provides a method for the harmless heat treatment of a waste liquid crystal display, comprising the following steps of: crushing glass substrates containing liquid crystals in the waste liquid crystal display for pyrolysis treatment under a nitrogen condition; sufficiently combusting an organic gas generated by pyrolysis under a high-temperature condition, and then harmlessly discharging; and recovering residues generated by the pyrolysis. In the invention, the poisonous and harmful pyrolytic organic gas generated by the pyrolysis treatment of the waste liquid crystal display isharmfulness and generates CO2 and water after being further sufficiently combusted, can be directly exhausted to atmosphere and is beneficial to environmental protection; the residues generated by the pyrolysis can be recovered, further processed and used for glass recycling and indium recovery; and in addition, the pyrolysis treatment of the waste liquid crystal display has low temperature and is beneficial to saving energy.

Owner:郭玉文

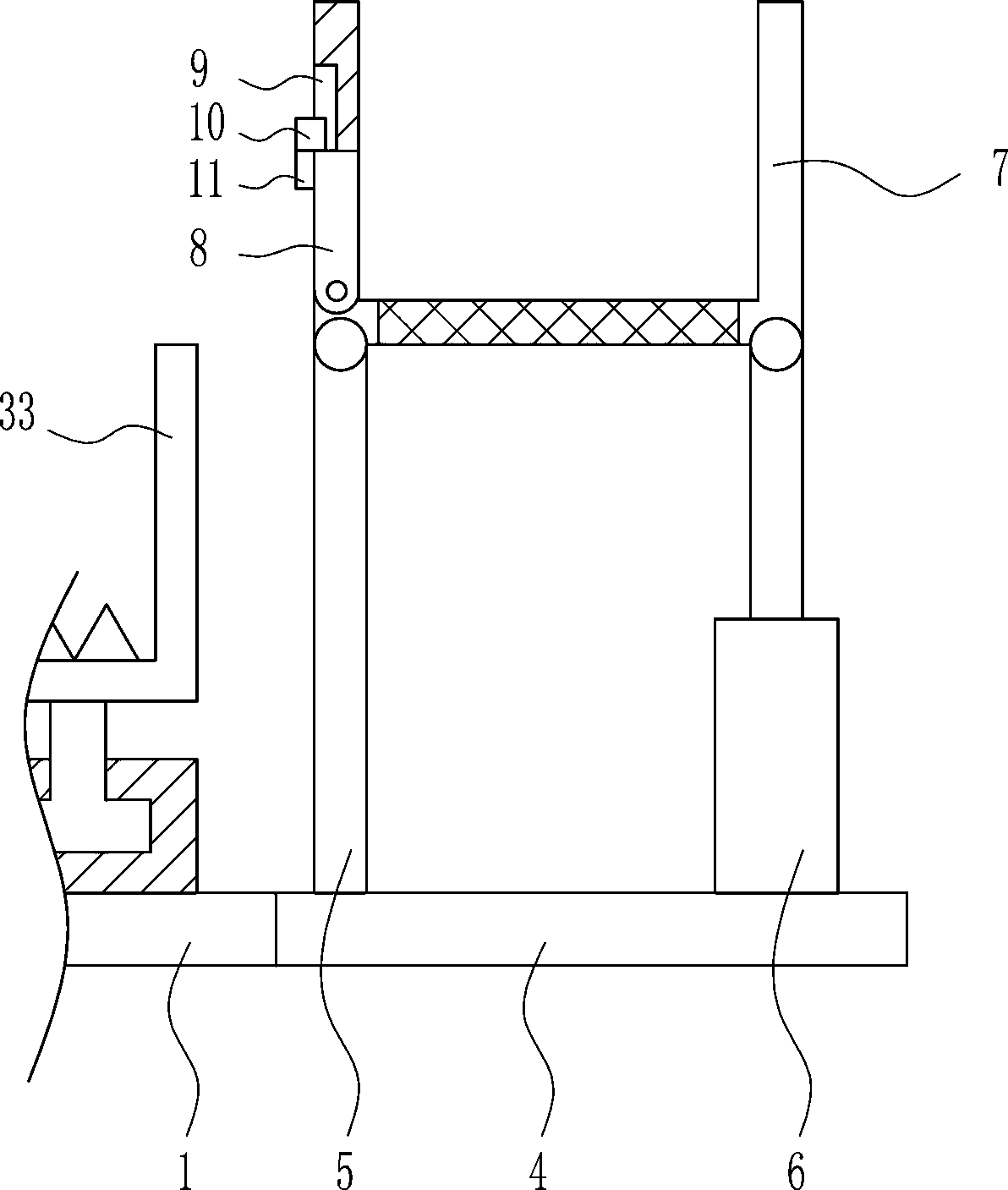

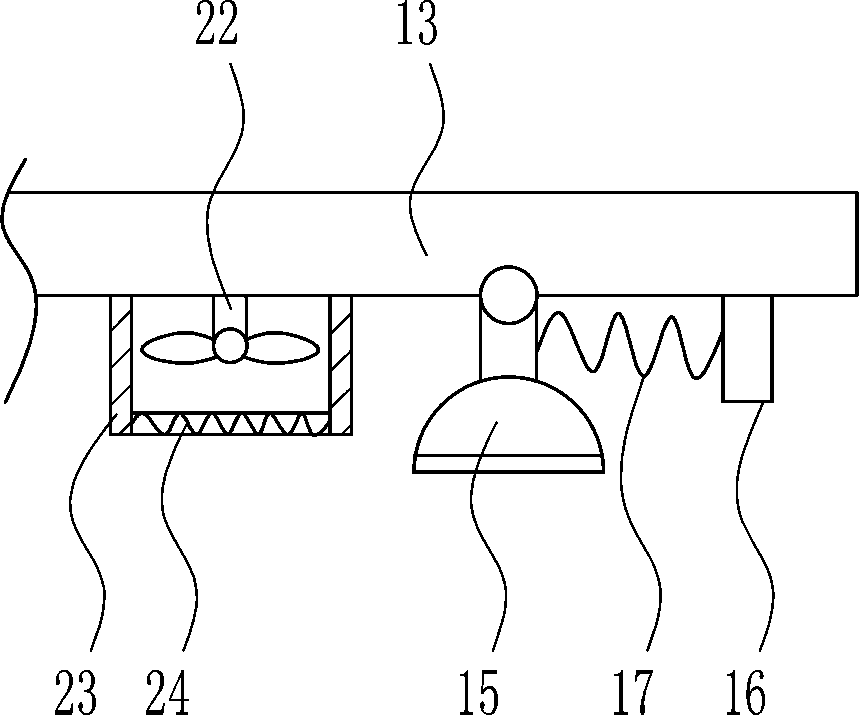

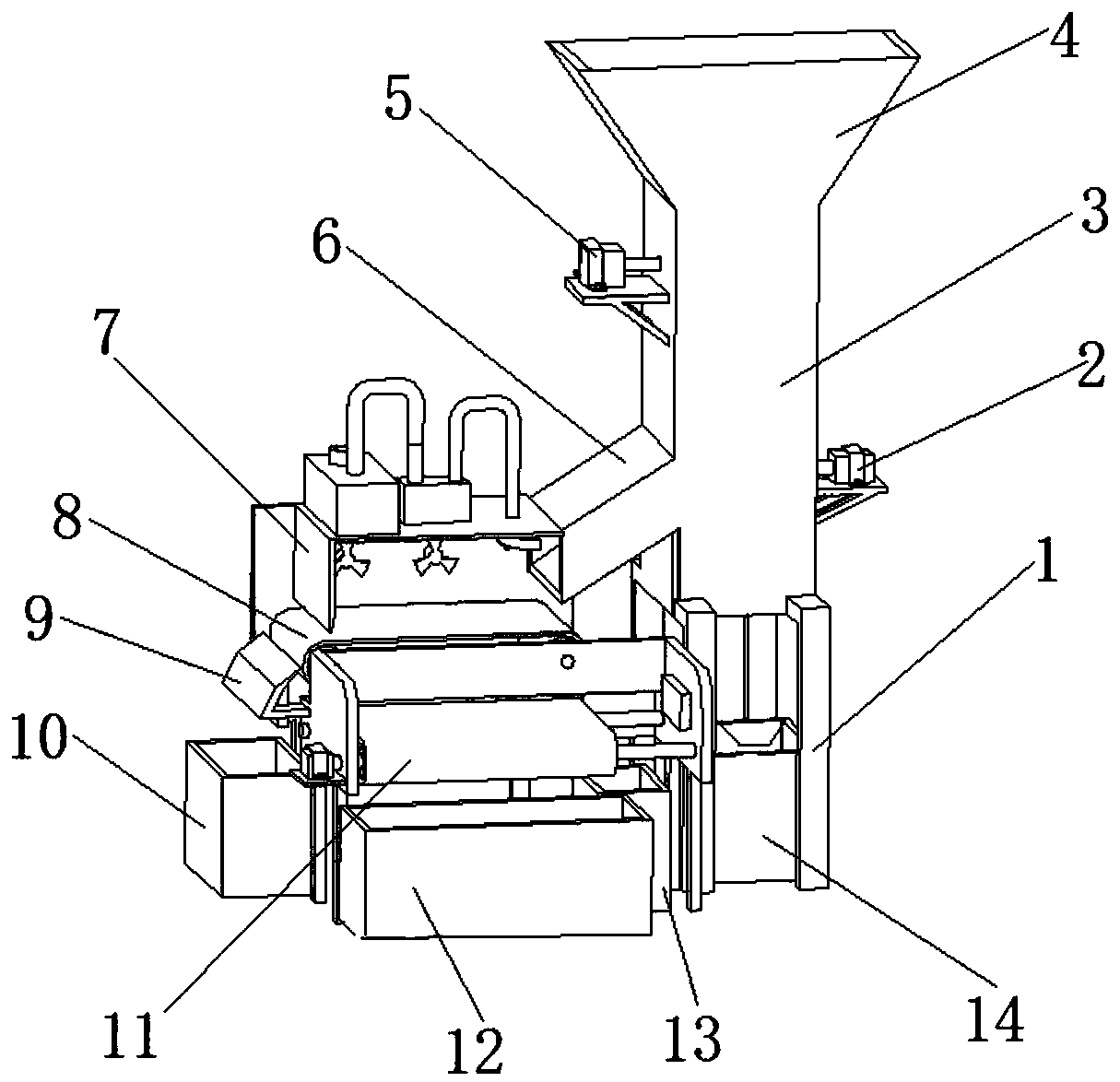

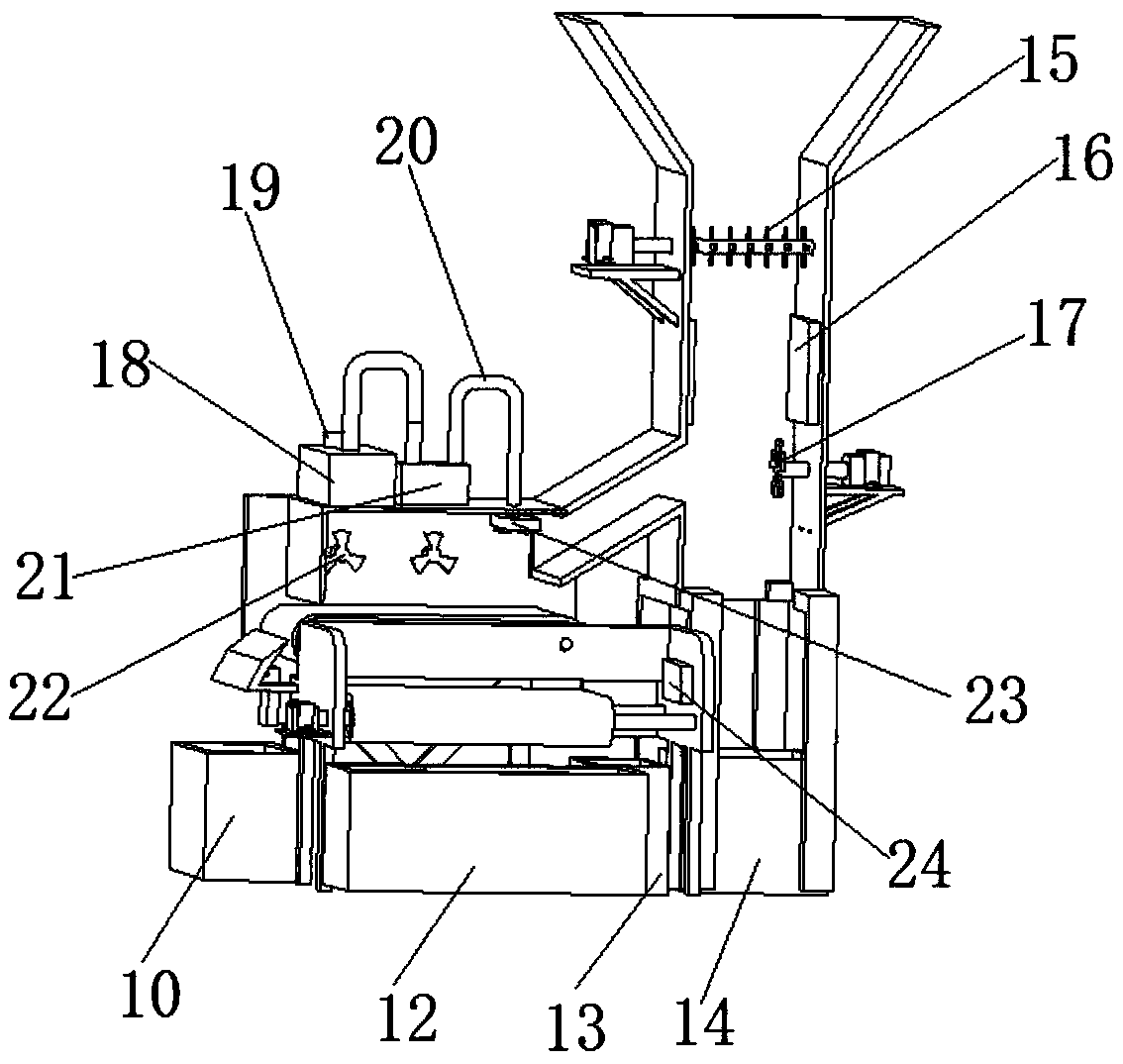

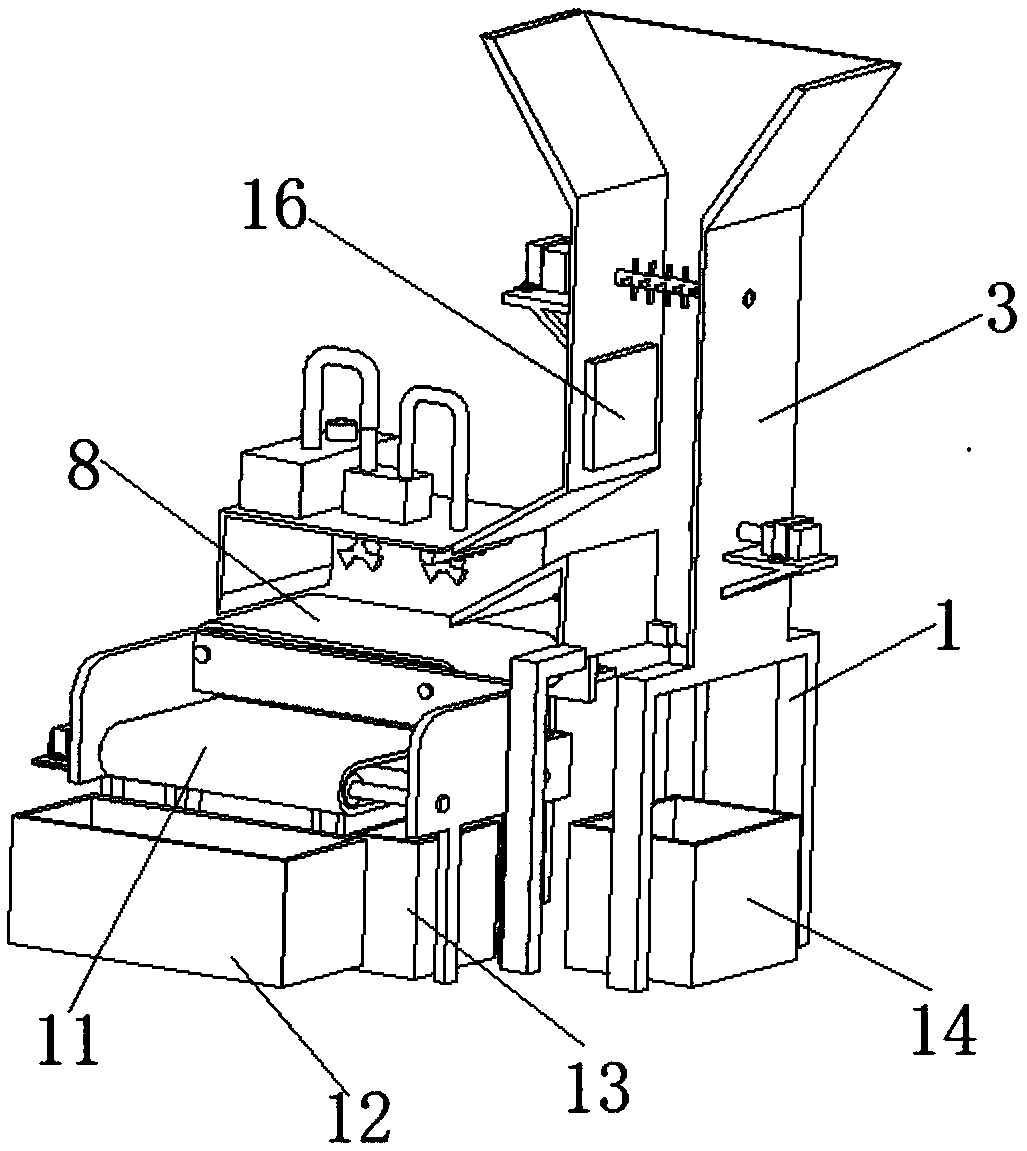

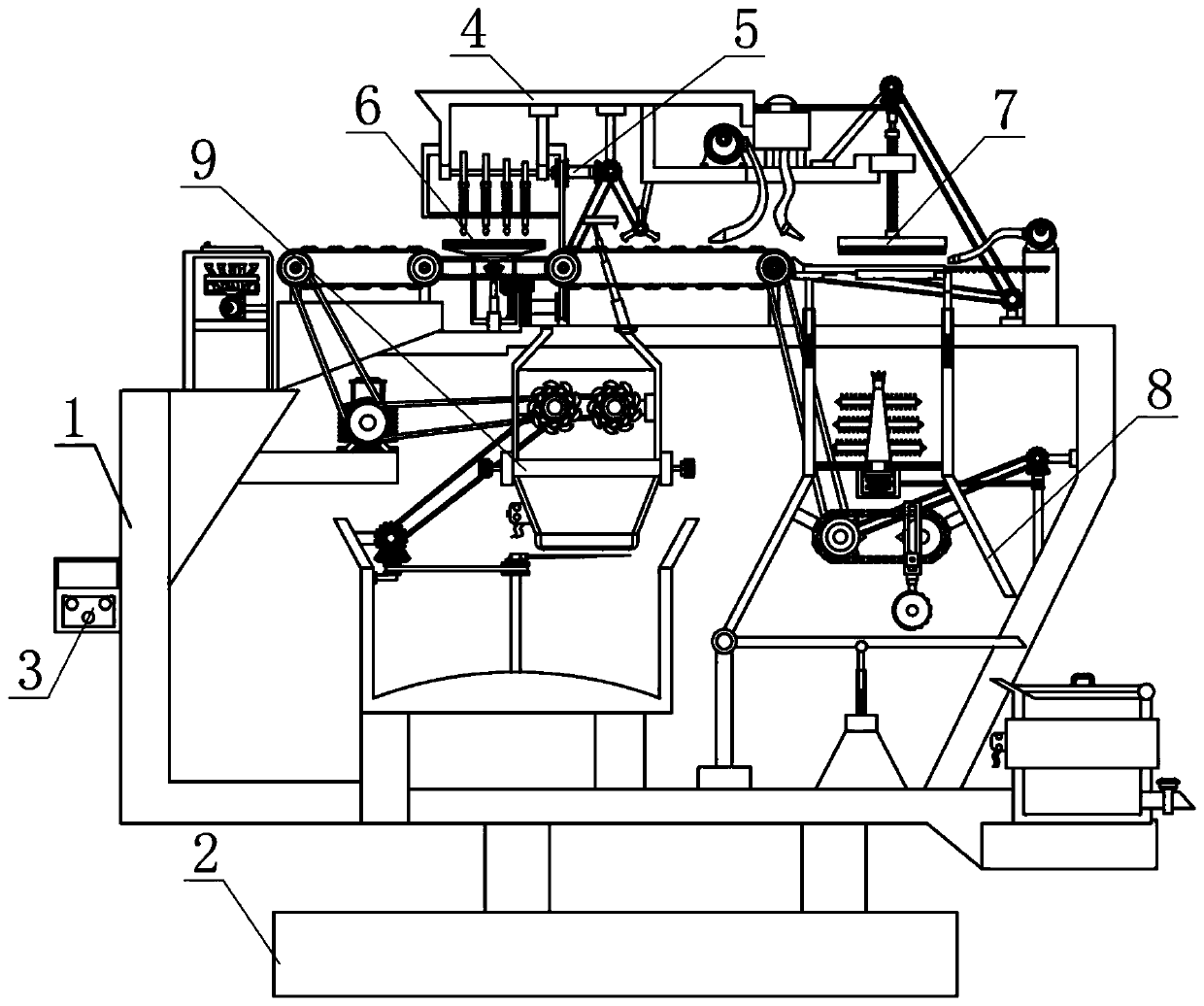

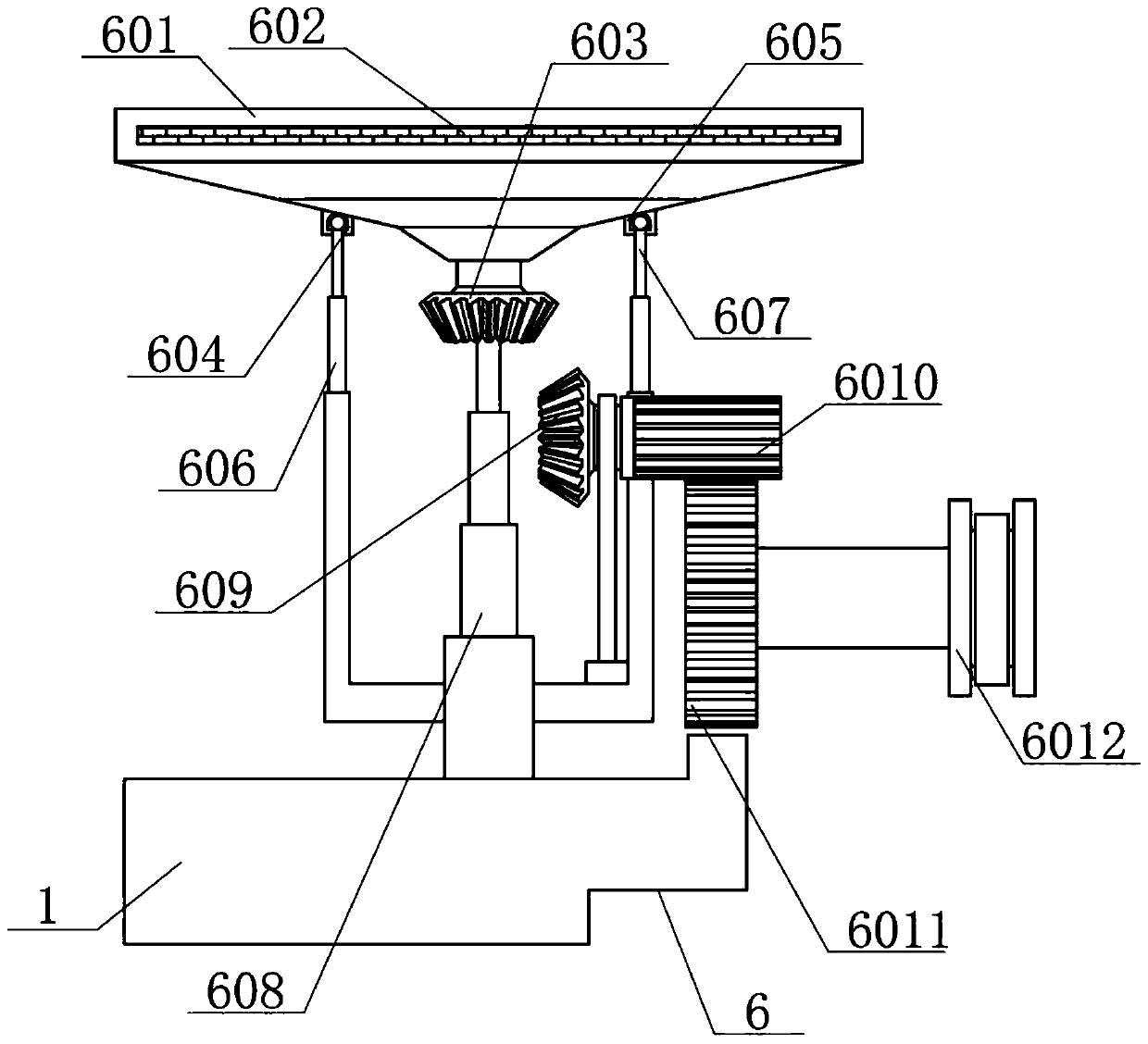

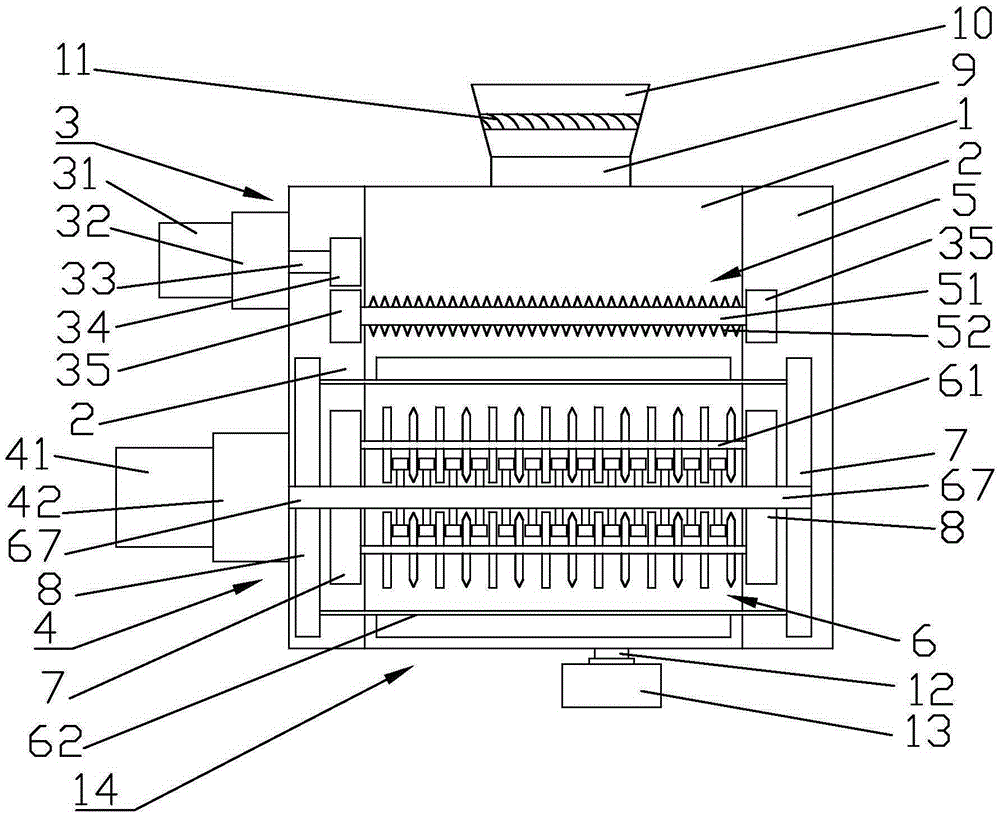

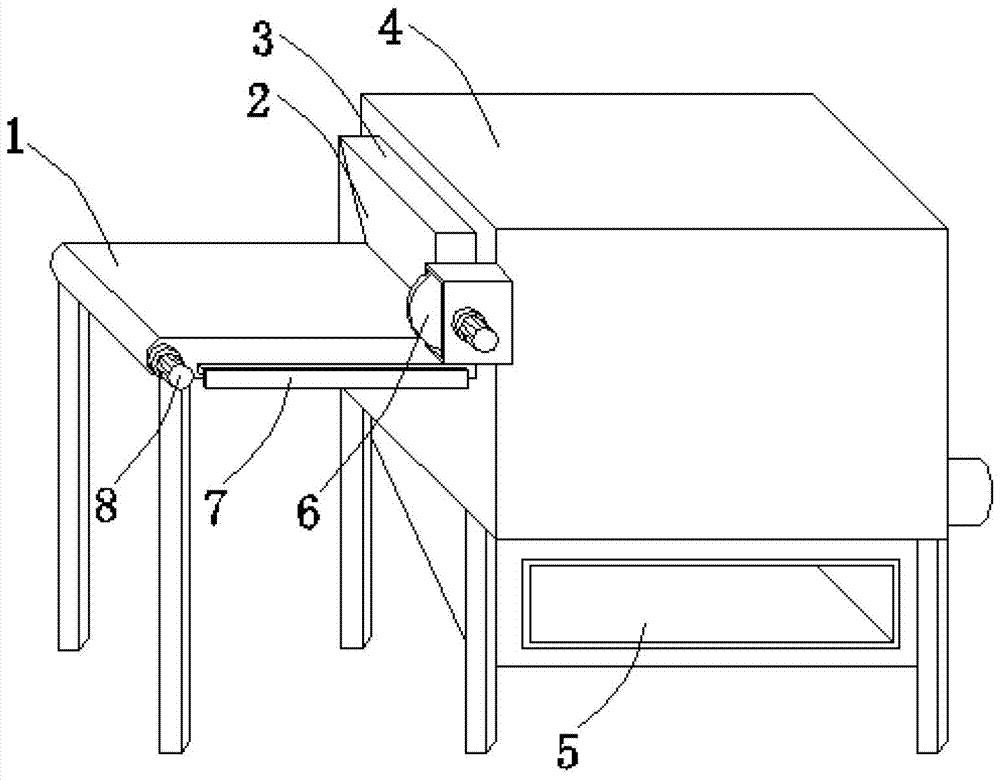

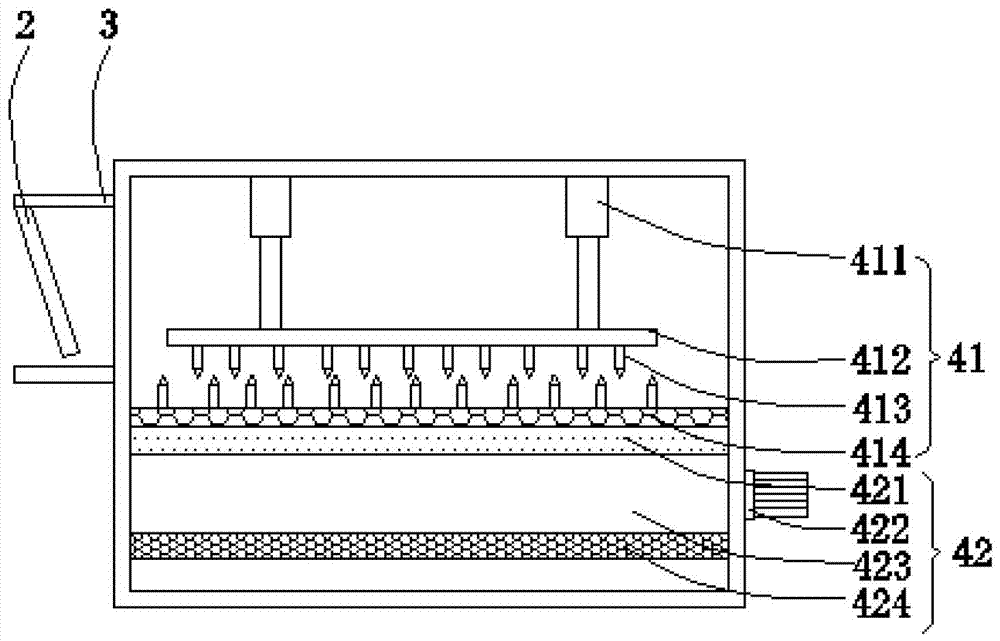

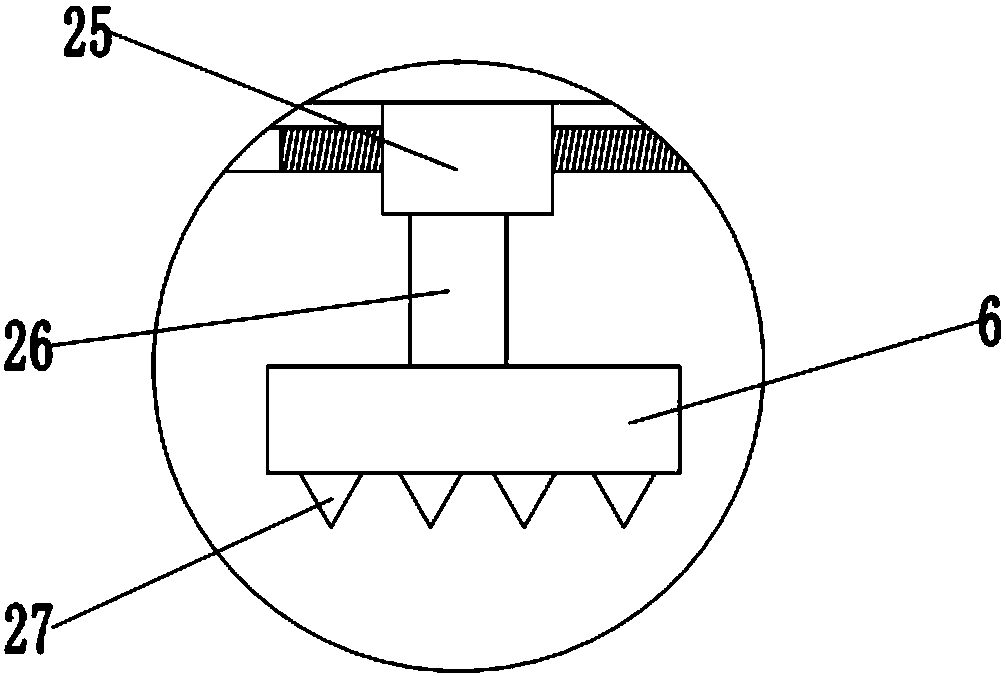

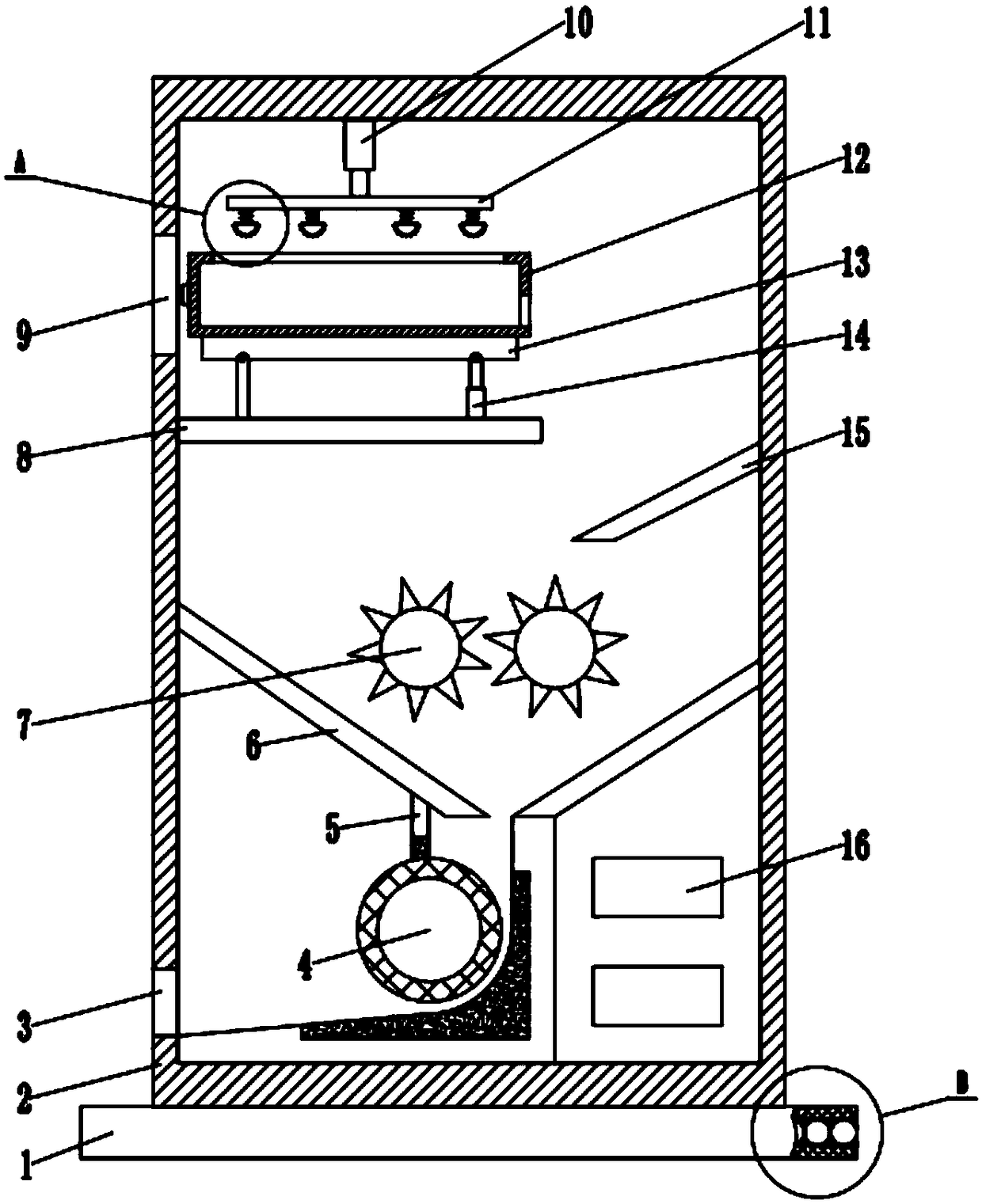

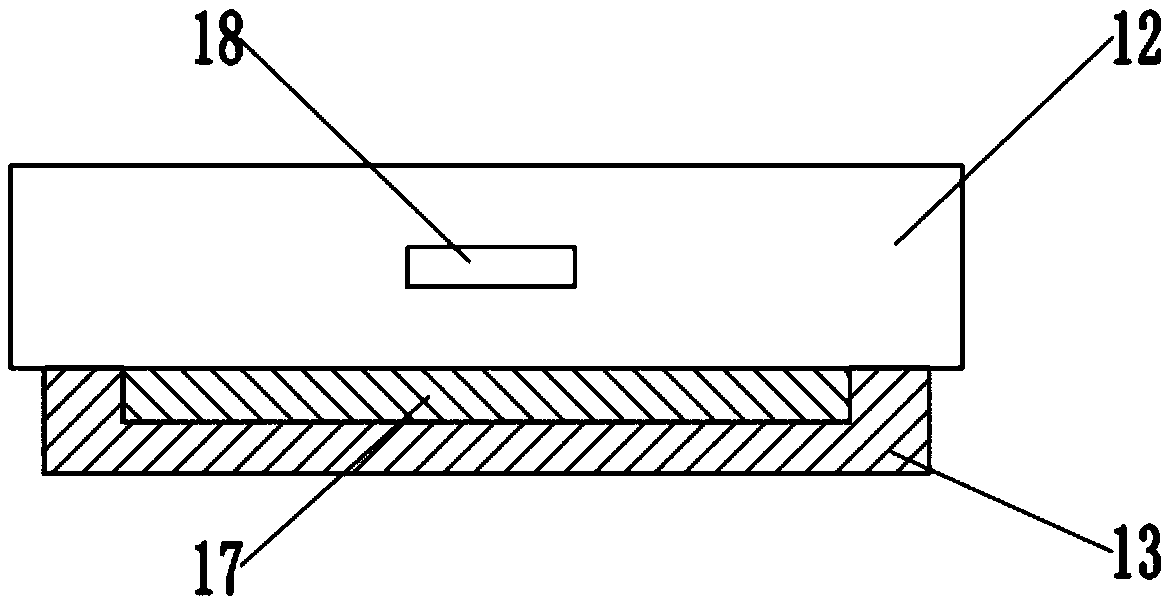

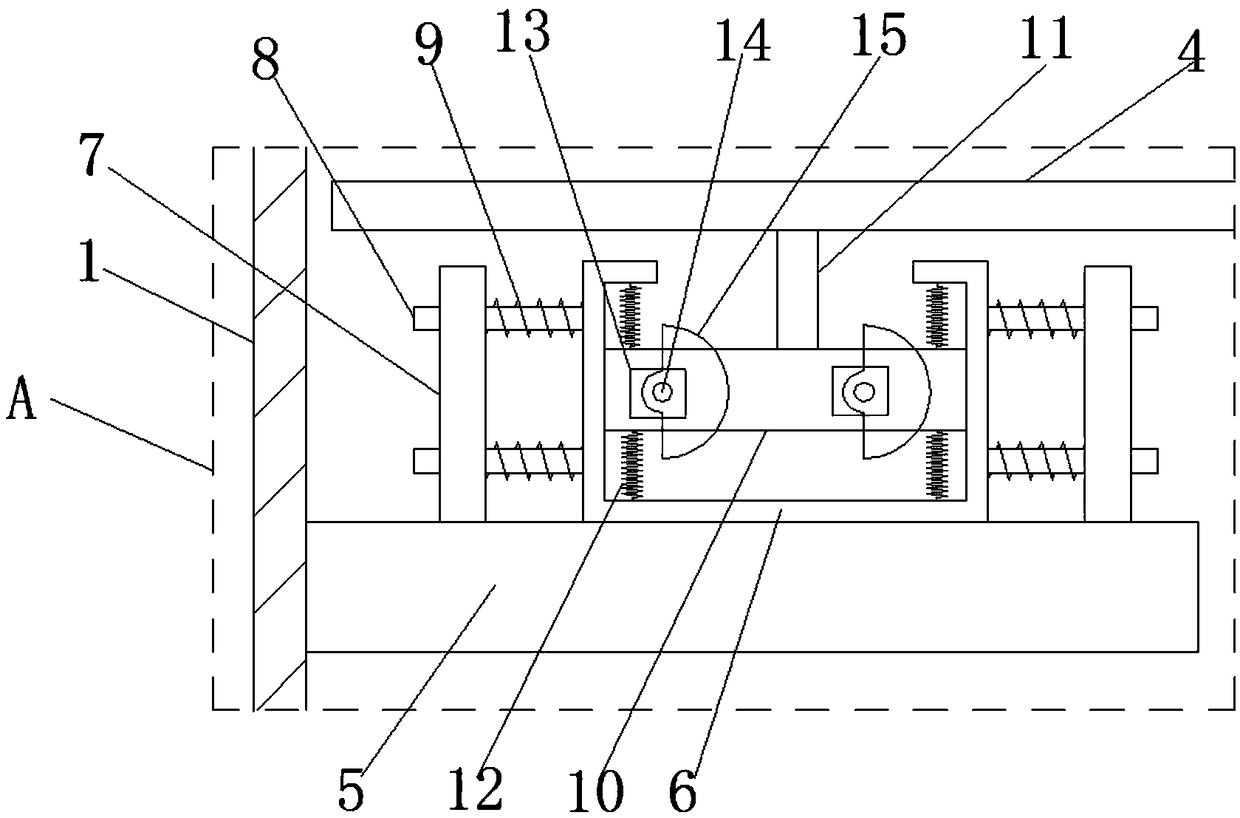

Automobile waste glass recovery processing equipment

InactiveCN107899647AWon't splashNo accidental injuryDrying gas arrangementsFlexible article cleaningGlass recycling

The invention relates to glass recovery processing equipment, in particular to automobile waste glass recovery processing equipment. The automobile waste glass recovery processing equipment achieves the aims of being complete and thorough in smashing and high in safety factor, and during the smashing process, glass does not splash at will. The automobile waste glass recovery processing equipment comprises a mounting rack and the like, wherein an extruding mechanism is arranged at the upper part of the mounting rack; and a rotating mechanism is arranged at the bottom of the interior of the mounting rack. According to the automobile waste glass recovery processing equipment, a first motor is controlled to rotate clockwise and anticlockwise so as to drive tooth blocks to move up and down; anda second motor is controlled to rotate so as to drive a breaking frame and waste glass in the breaking frame to rotate, so that breaking teeth and the tooth blocks have more remarkable smashing action to waste glass, and the effects of being high in smashing speed and more thorough in smashing and improving the follow-up product quality are realized.

Owner:谢剑和

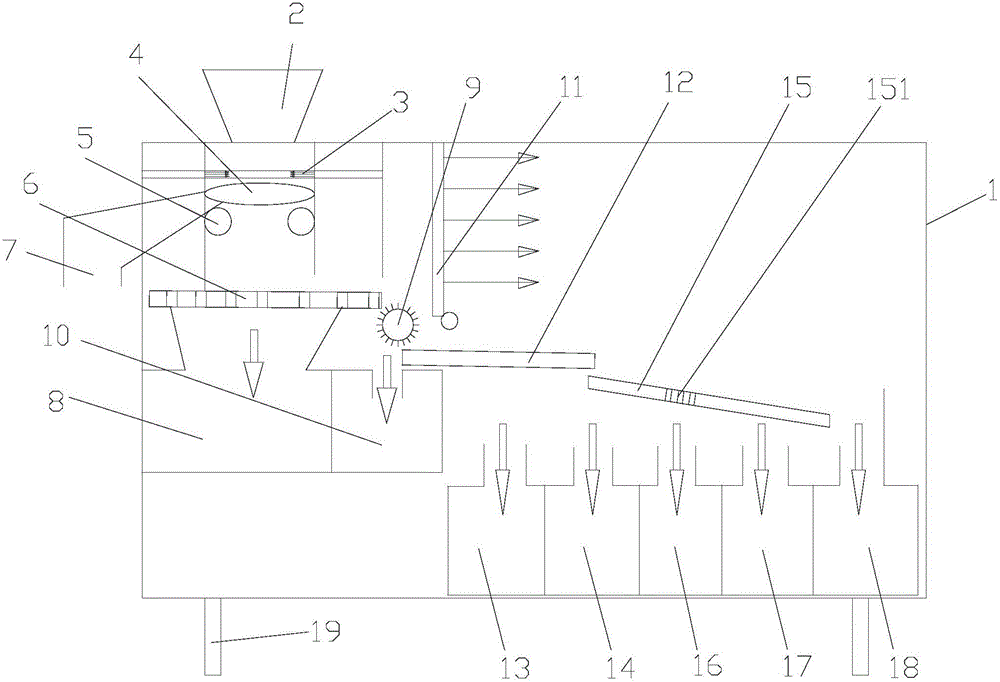

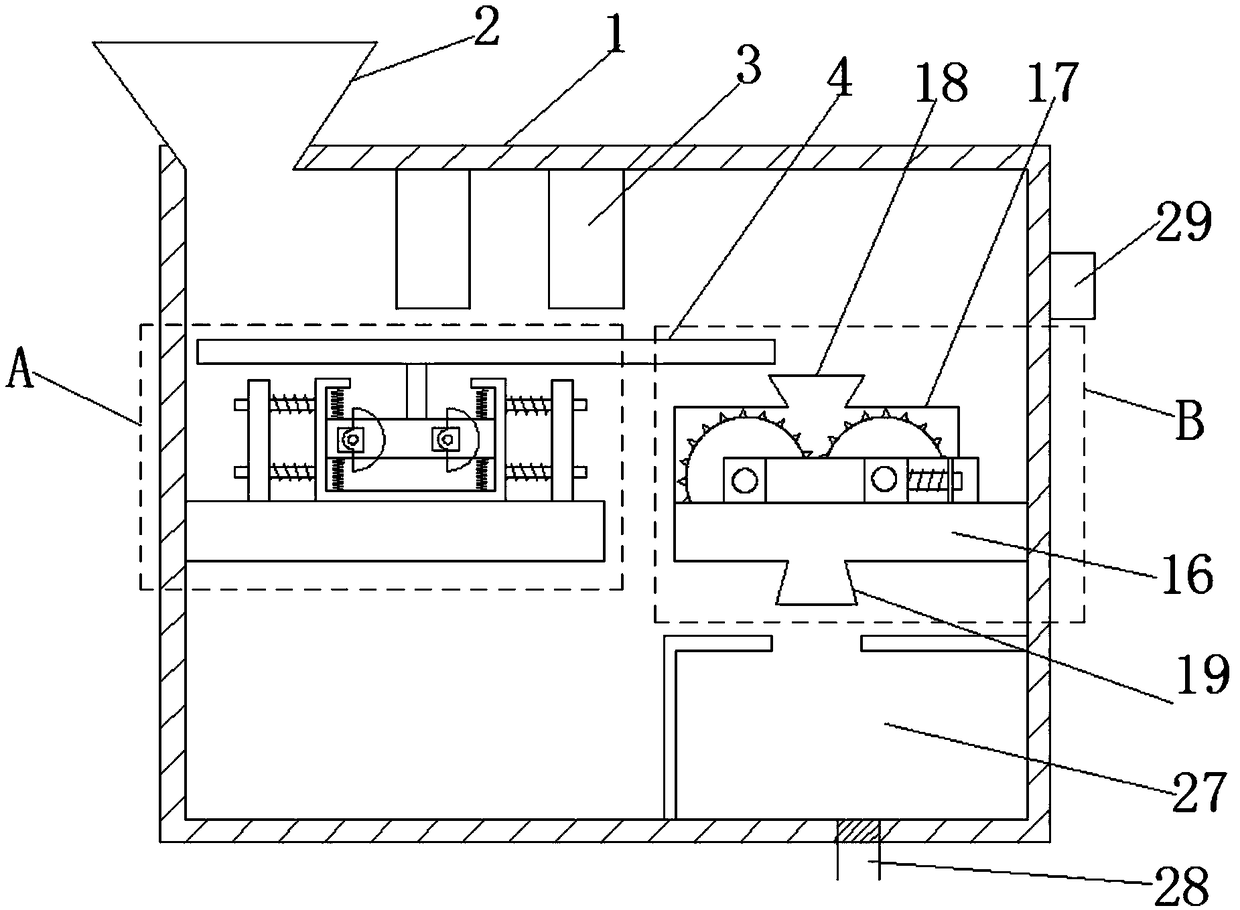

Solid domestic waste crushing and sorting device

InactiveCN108906263AImprove classification efficiencyImprove protectionGas current separationPlastic recyclingElectrometerEngineering

The invention discloses a solid domestic waste crushing and sorting device. The device comprises an underframe, the underframe is vertically fixedly provided with a feeding pipeline, the bottom of thefeeding pipeline is provided with a discharging opening, a glass recovery box is arranged below the discharging opening, a discharging tube is arranged at one side of the feeding pipeline below a crusher, the inner wall of the feeding pipeline is provided with a sheet magnet, a powder collecting box is arranged at the injection opening of the discharging tube, one side of the powder collecting box is opened, fans are arranged at one side opposite to the opening, a first conveyor belt is arranged at the bottom of the powder collecting box, a waste paper recovery box is arranged below the outlet of the first conveyor belt, a second conveyor belt is arranged just below the open side of the powder collecting box, the side surface of the second conveyor belt is provided with an electrometer, aplastic recovery box is arranged below the electrometer, and a nonmagnetic metal recovery box is arranged below the outlet of the second conveyor belt. A problem of difficult sorting and recovery ofsolid domestic wastes in the prior art is solved.

Owner:SHAANXI UNIV OF SCI & TECH

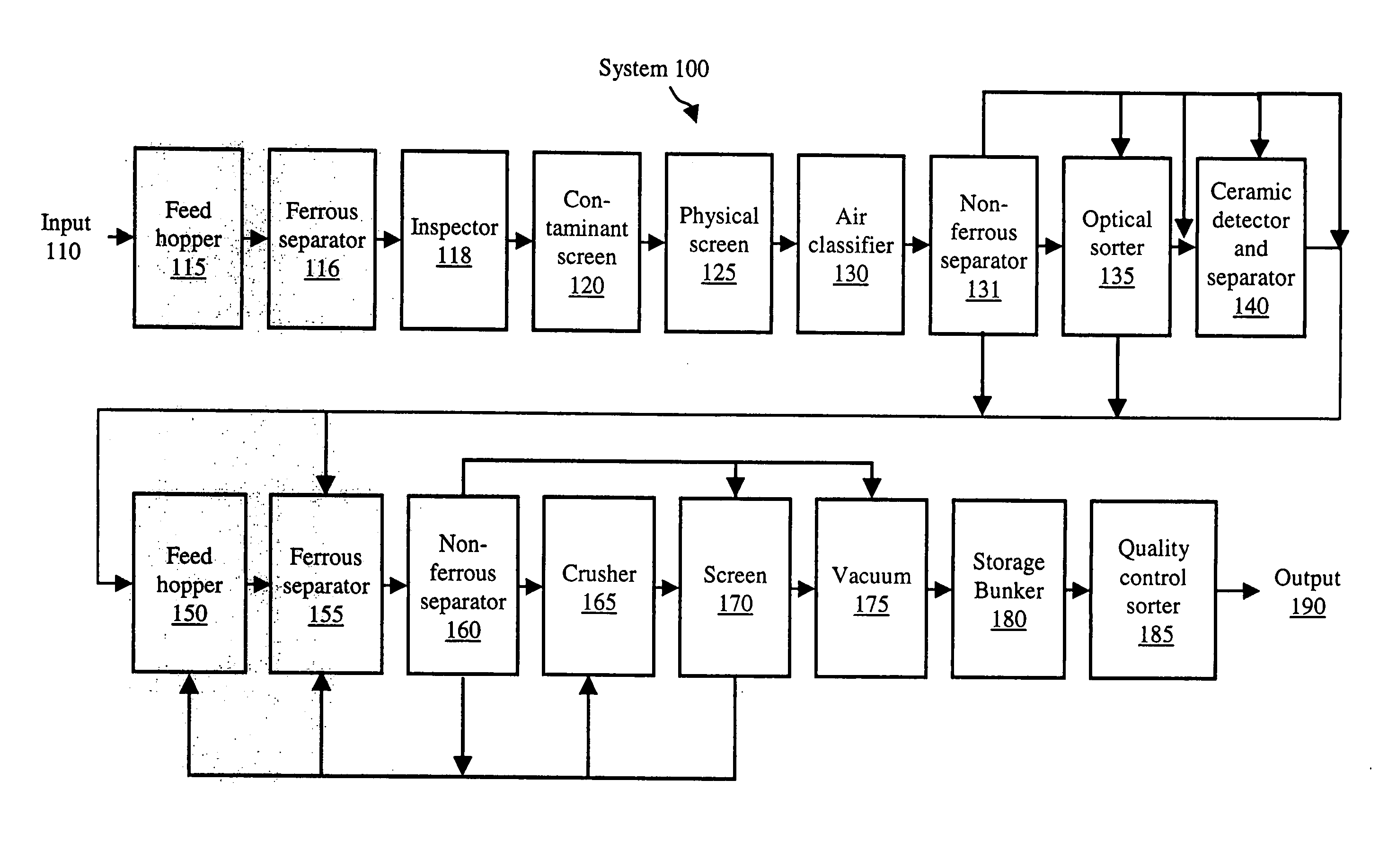

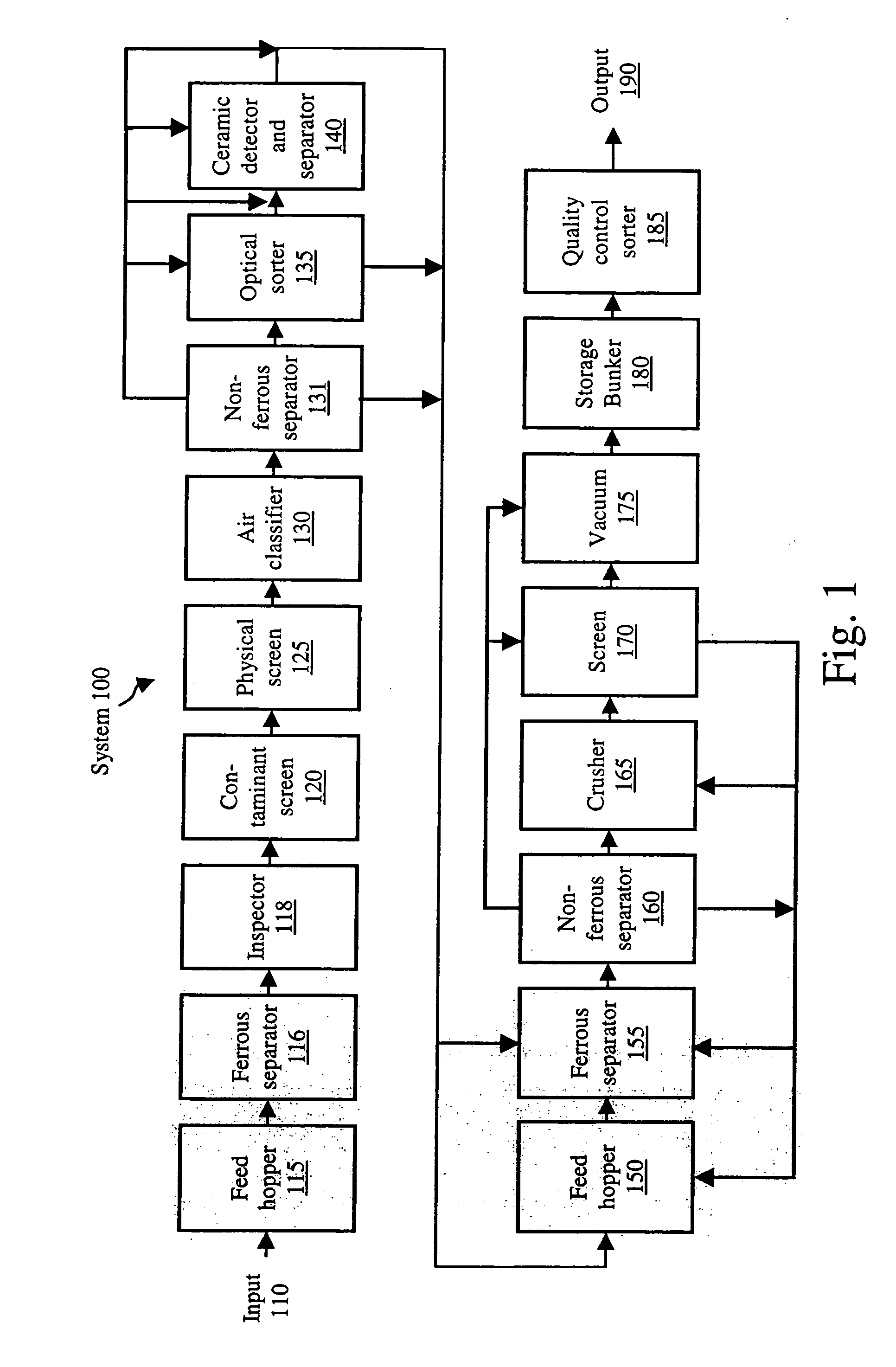

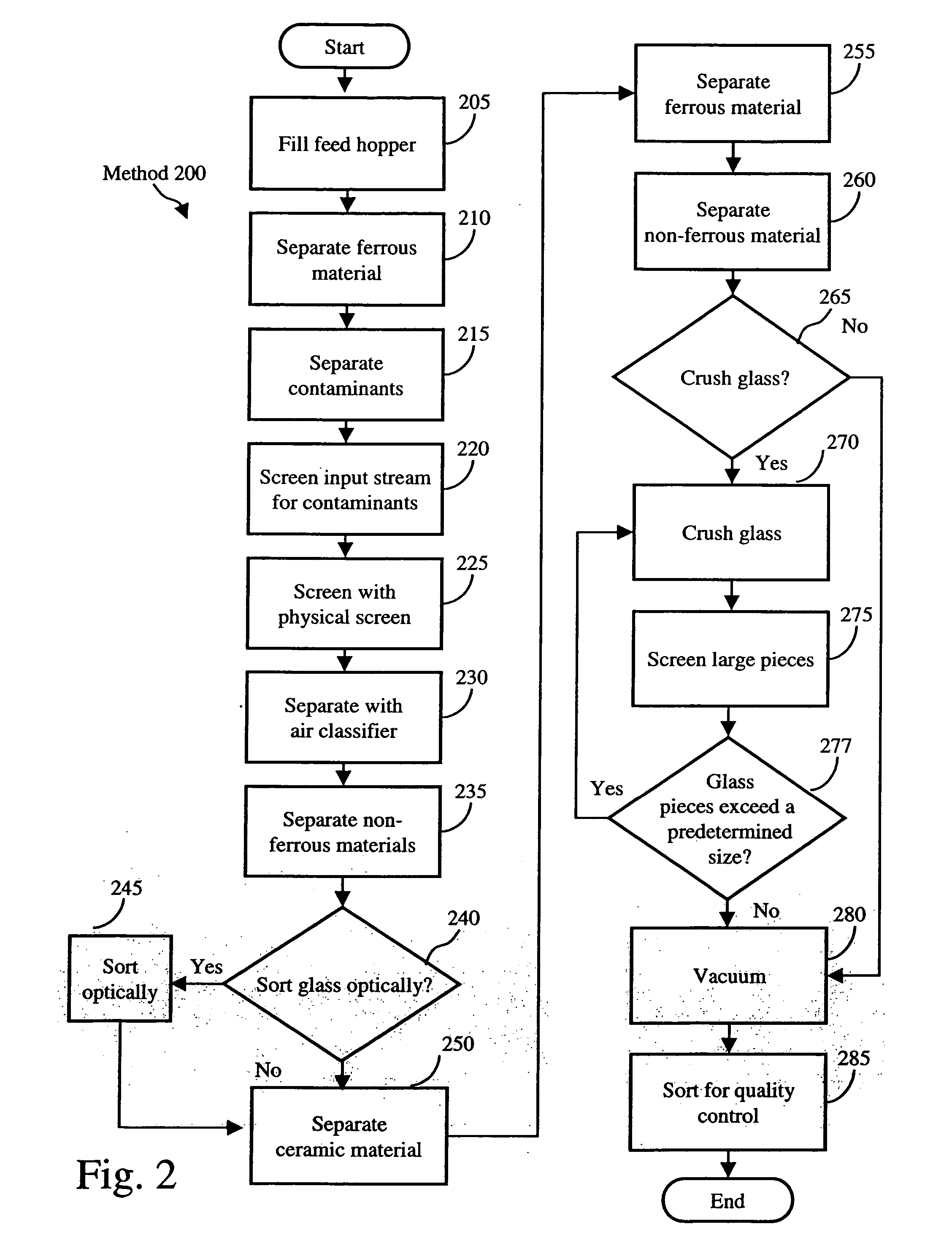

System and methods for glass recycling at a beneficiator

Owner:RE COMMUNITY HLDG II INC

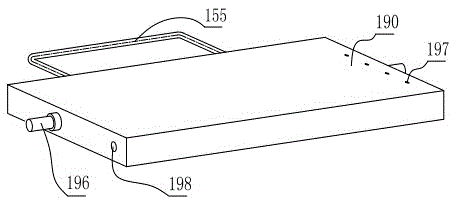

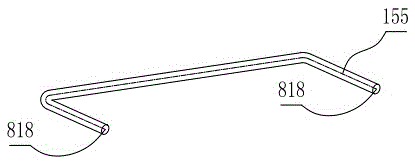

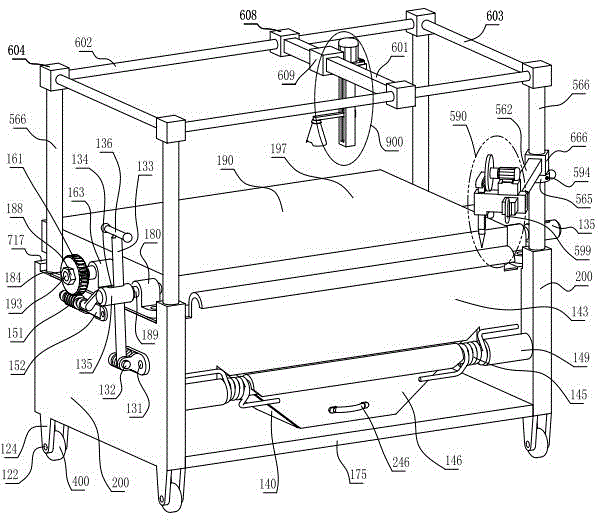

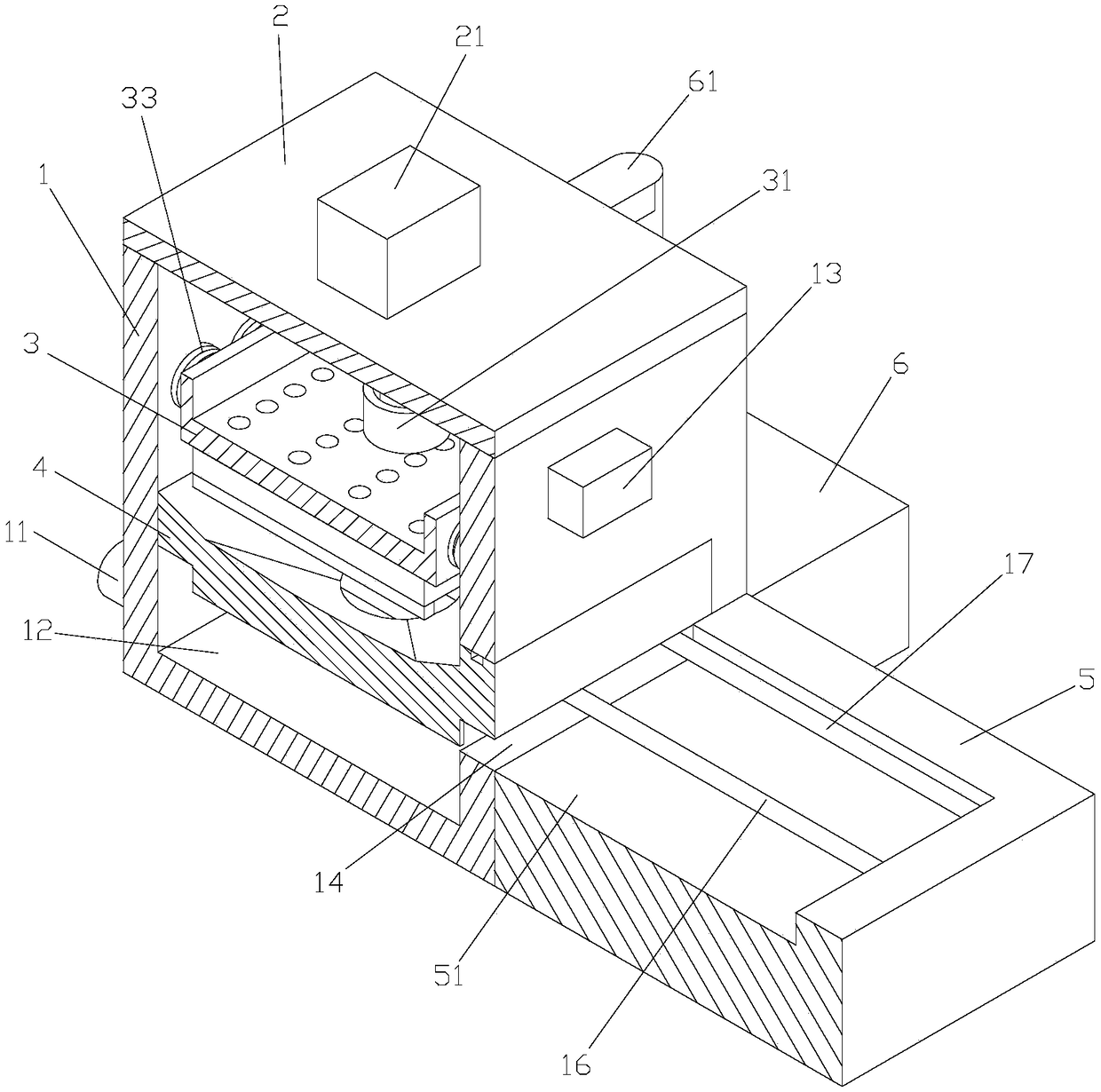

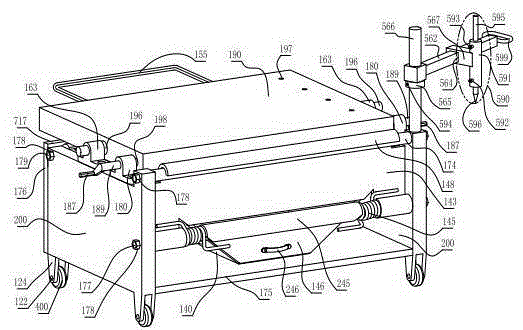

Copper alloy glass detection equipment provided with handle rotary table, rack, camera and wheel and pressure plate assembly

The invention relates to tempered glass test and inspection equipment, in particular to copper alloy glass detection equipment provided with a handle rotary table, a rack, a camera and a wheel and pressure plate assembly. The equipment is characterized in that the coplanar wheel and pressure plate assembly is fixed in an upper plane of a test table plate, a table plate handle is arranged on the rear end vertical surface of the test table plate, and two bent arc ends of the table plate handle are handle ends and are both fixed on the rear end vertical surface of the test table plate; table plate rotary shafts are arranged on two sides of the test table plate and are rotationally fixed in table plate support seats respectively, and the table plate support seats and lock pin support seats fix a broken glass recovery container together with the upper planes of support side plates; a mobile camera assembly is arranged on a camera square rod, and a cylinder impactor is glidingly fixed on an impact cross rod. The current situation that fragment detection basically depends on manual work is changed, a camera photographs, fragment pictures are transmitted to a computer processing center, the probability of breaking open of an adhesive tape due to breaking power of the tempered glass is avoided, and the personal safety of an operator is better guaranteed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

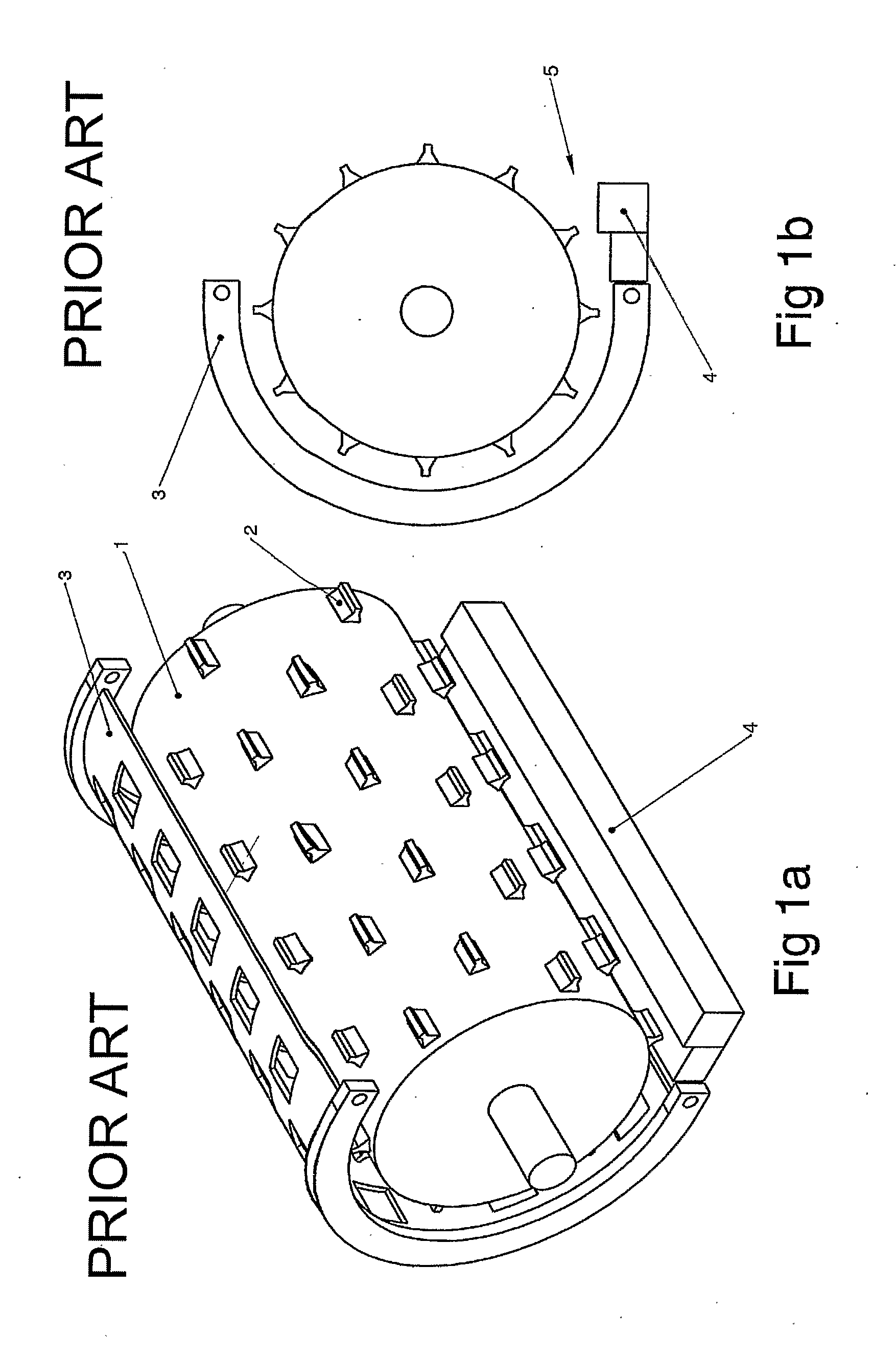

Method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates

InactiveCN105651629AChange labor intensityAvoid accidental splash damageStrength propertiesEngineeringGlass fragment

The invention relates to a tempered glass testing method, in particular to a method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates. Modifications include: one, an assembly process includes a clamp plate assembly process and a machine assembly process; two, a tempered glass fragmentation test includes the following steps: (one), a worm cranking handle at one end of a worm shaft is cranked by hand so that a test top plate is horizontal; (two), first, second, third and fourth clamp plates equal in structural size are placed on the test top plate; (three), a trapezoidal glass plate to be tested is placed on the test top plate within a surrounded space; (four), an impact motor is started to break the trapezoidal glass plate; (five), a photography motor is started to take photos and send fragment photos to a computer processing center; (six), the second and third clamp plates are moved so that tempered glass fragments can be conveniently cleared and dropped into a glass fragment recycling container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Automatic sorting machine of solid wastes

ActiveCN105983474AReduce disposal volumeEasy to installArticle unpackingMagnetic separationPlastic wasteSmall footprint

The invention provides an automatic sorting machine of solid wastes. The sorting machine comprises a box body and a box body bracket, wherein a feed hopper is arranged on the upper end of the box body, a bag breaking machine, a magnetic separation machine, a breaking machine, a first vibration screen, an adhering machine, a vibration plate, a fan and a second vibration screen are sequentially arranged in the box body, an ash residue waste recovery box, a corrosive waste recovery box, a combustible waste recovery box, an ultra thin plastic waste recovery box, a building waste recovery box and a waste glass recovery box which are used for housing the separated wastes are arranged in the box body. The eight kinds of materials can be effectively and automatically sorted, the sorted materials can be used as the raw materials for comprehensive utilization of wastes, and the waste disposal amount is reduced to the maximum limit. The automatic sorting machine can be conveniently mounted and occupies small area, the energy consumption is low, and the automatic sorting machine is suitable for waste sorting treatment of small-size waste transfer stations and waste disposal plants.

Owner:张小平

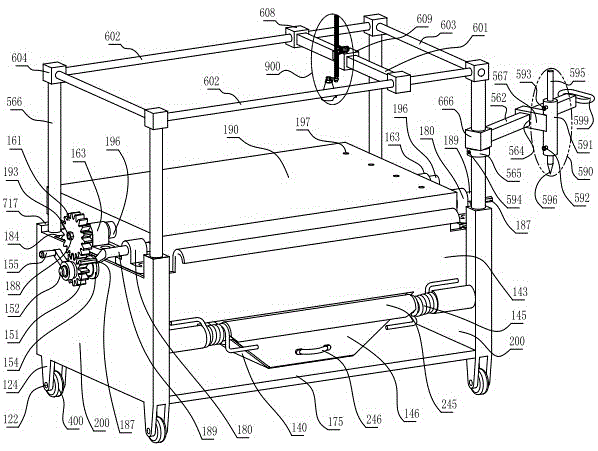

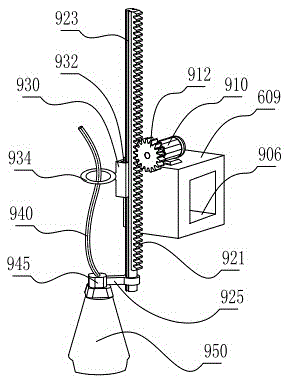

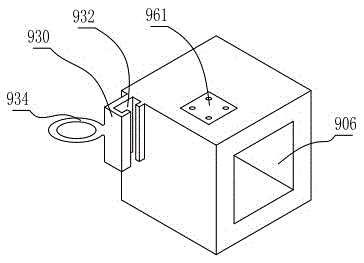

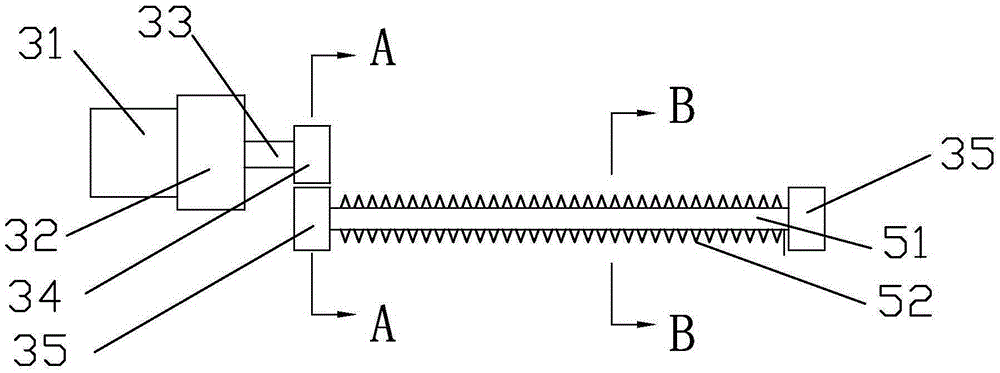

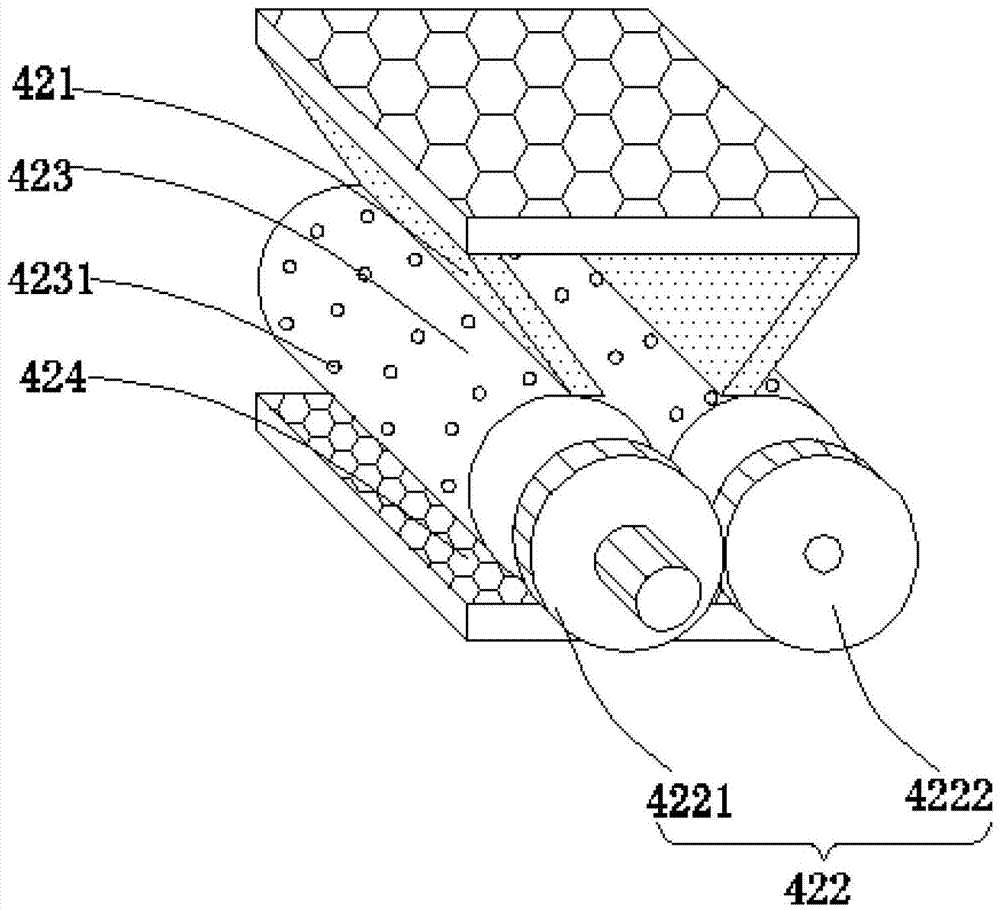

Hot air barbed film tearing type glass recovery device

InactiveCN110721981ALamination ancillary operationsTransportation and packagingPolymer scienceColloid

The invention relates to a glass protective film, in particular to a hot air barbed film tearing type glass recovery device. The hot air barbed film tearing type glass recovery device comprises a support frame, a foot, a control display screen, a top connecting frame, a breaking and barbed film tearing mechanism, a breaking and fixed connecting mechanism, a residual colloid processing mechanism, abreaking and powder processing mechanism and a glass film breaking and granulating mechanism, wherein the breaking and barbed film tearing mechanism is arranged in the middle of the top end of the support frame. With the glass recovery device, the glass film and glass are subjected to post-processing recovery processing, colloidal substances on the surface of the glass can be cleaned up after thefilm is torn, a film tearing opening is formed mechanically and automatically, and the continuous production line large-scale film tearing effect on the glass is achieved.

Owner:杨永清

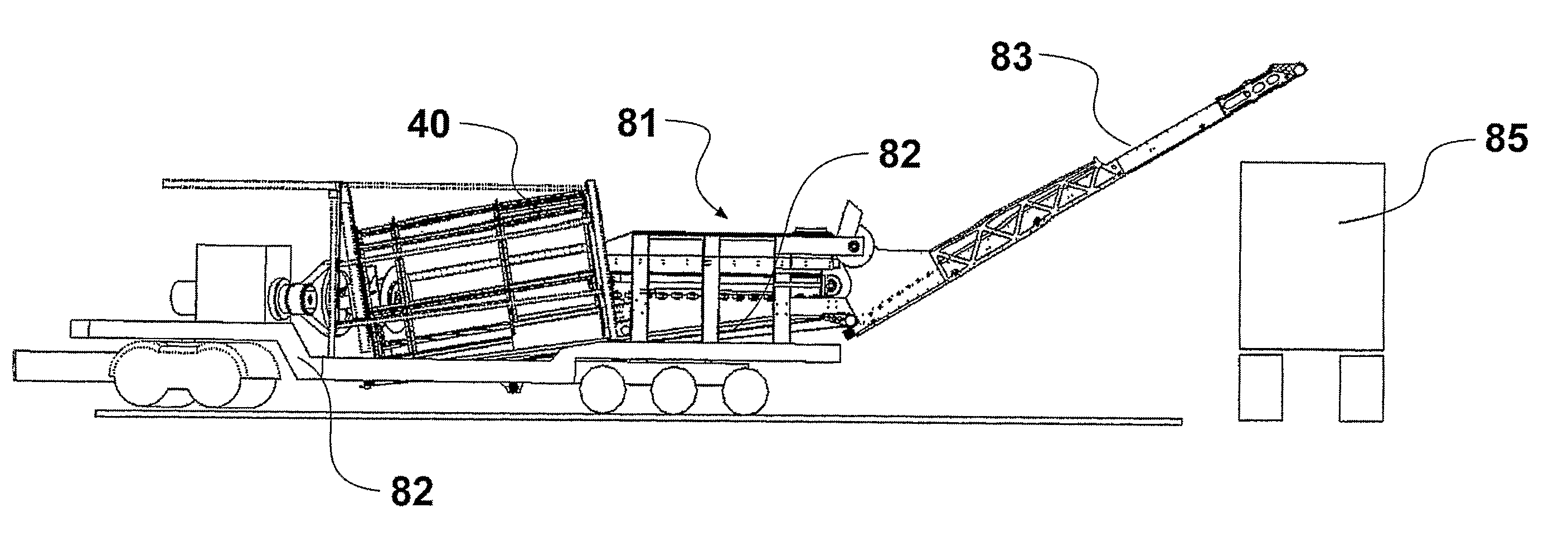

Wood Hogging Apparatus

InactiveUS20080099592A1Increase the sectionSmall sizeWood working apparatusCocoaForeign matterAsphalt

A hogging, sometimes known as reducing, apparatus for reducing wood waste into hog fuel, though some embodiments may also be used for reducing other materials including demolition timber, demolition masonry, mild steel scrap (thin sections), soft metal scrap, recycled cans, recycled glass, recycled plastic, soft rocks, occasionally hard rocks, recycled roading and asphalt, old tyres, and certain green garden waste. The apparatus includes a drum (40) inclined to the horizontal and into which raw material can be fed at its upper end. Rotation of the drum (40) assists driving raw material towards reducing elements (45) positioned at an angle near its (40) lower end. Screening apertures (41) allow sufficiently comminuted material to pass therethrough for removal. Optional features include internal agitators (60) for improving processing and screening, assisted drying of raw material by motor exhaust (71), and initial pre-screening of foreign material.

Owner:SHARP RODNEY WARWICK

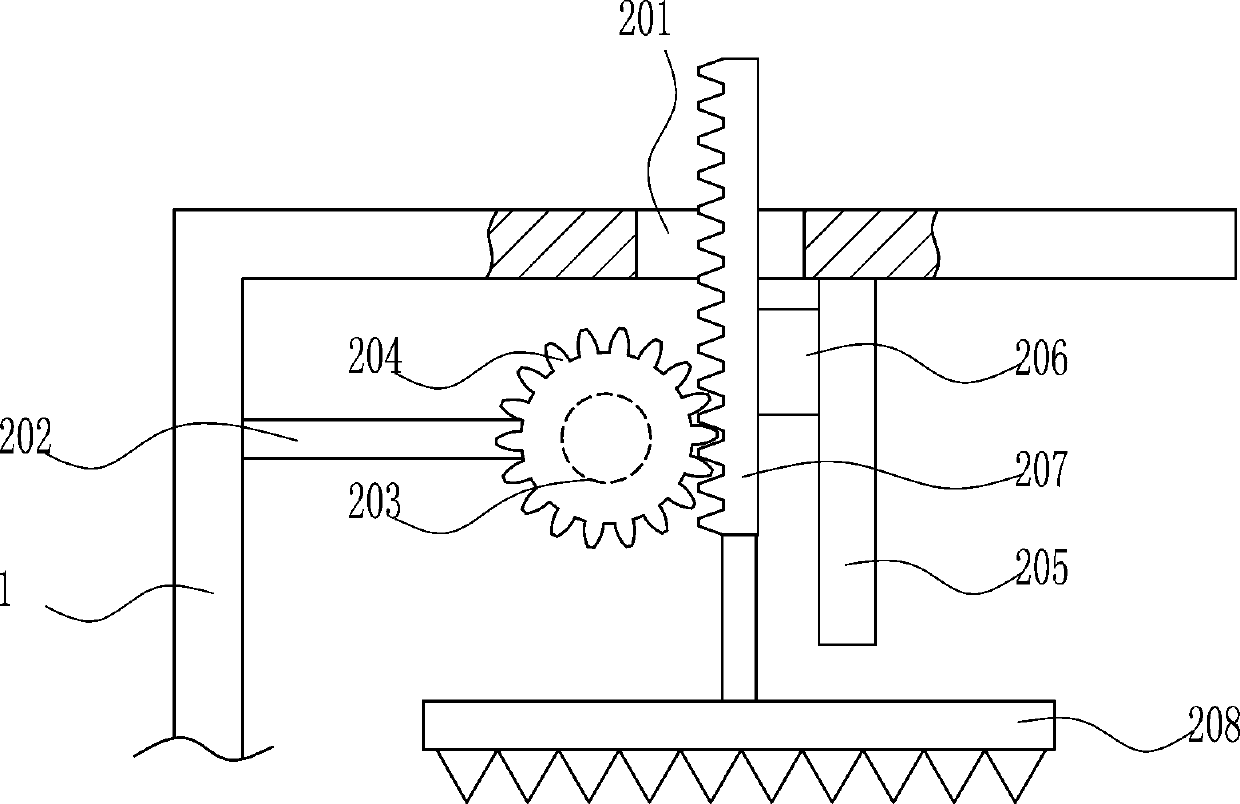

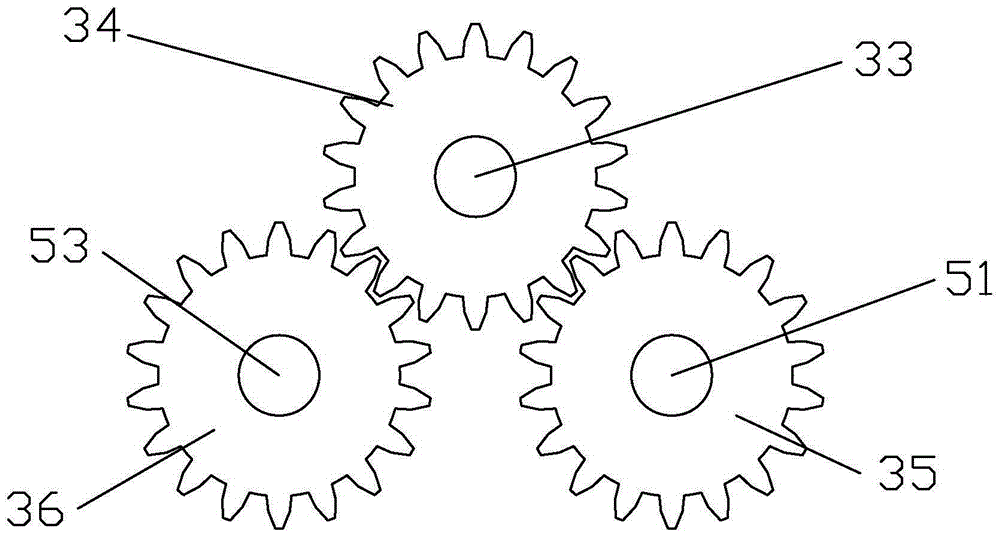

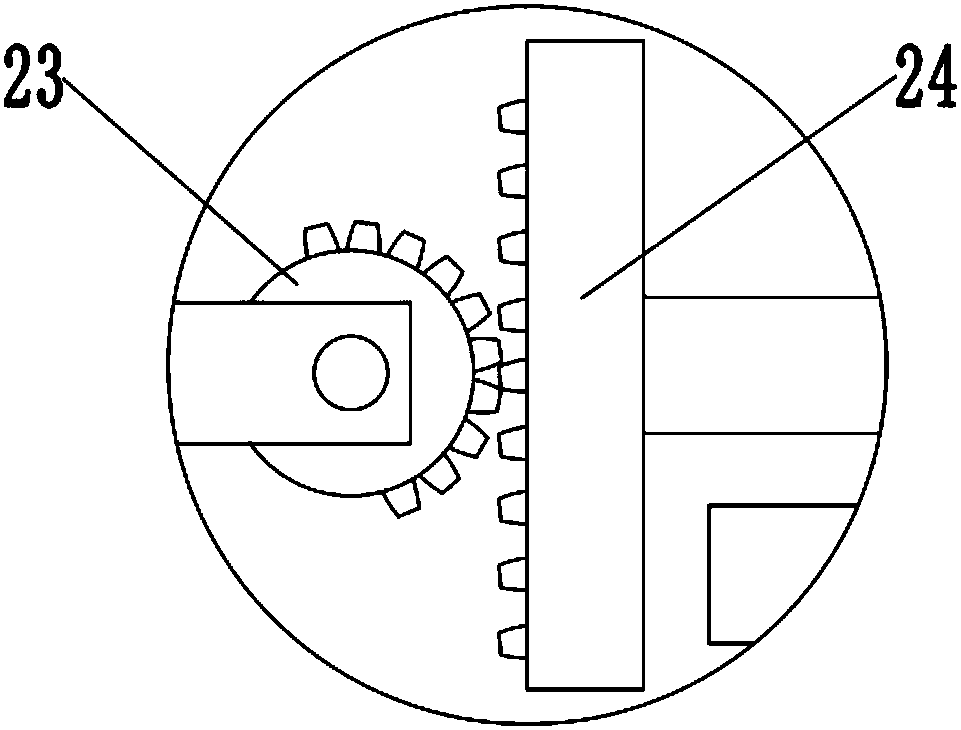

Method for detecting glass through gear turntable rack shooting V-shaped clamping plate

InactiveCN105606470AEasy to removeOvercome the defect that the fit does not have self-lockingStrength propertiesEngineeringGlass fragment

The invention relates to a method for testing and inspecting tempered glass, in particular to a method for detecting glass through a gear turntable rack shooting V-shaped clamping plate. As an improvement: the steps for performing fragmentation testing on tempered glass are as follows: firstly, turning a hand wheel crank handle with a hand to enable a cylindrical bulb at one end of bolt lock pin to enter lock pin positioning holes in the two sides of a testing platform plate so as to be locked and positioned, and to enable the testing platform plate to be fastened horizontally; secondly, forming a surrounding space among a clamping plate fixed side, a clamping plate left side, a clamping plate opposite side and a clamping plate right side with the same structural sizes; thirdly, putting a tempered glass plate to be tested on the testing platform plate in the surrounding space; fourthly, ensuring that a cylinder impactor rotates around the excircle of an upper pillar type column with an impacting cross rod, so as to be deviated from the upper part of the tempered glass plate; sixthly, cleaning tempered glass fragments, and enabling the tempered glass fragments to fall into a broken glass recovery container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

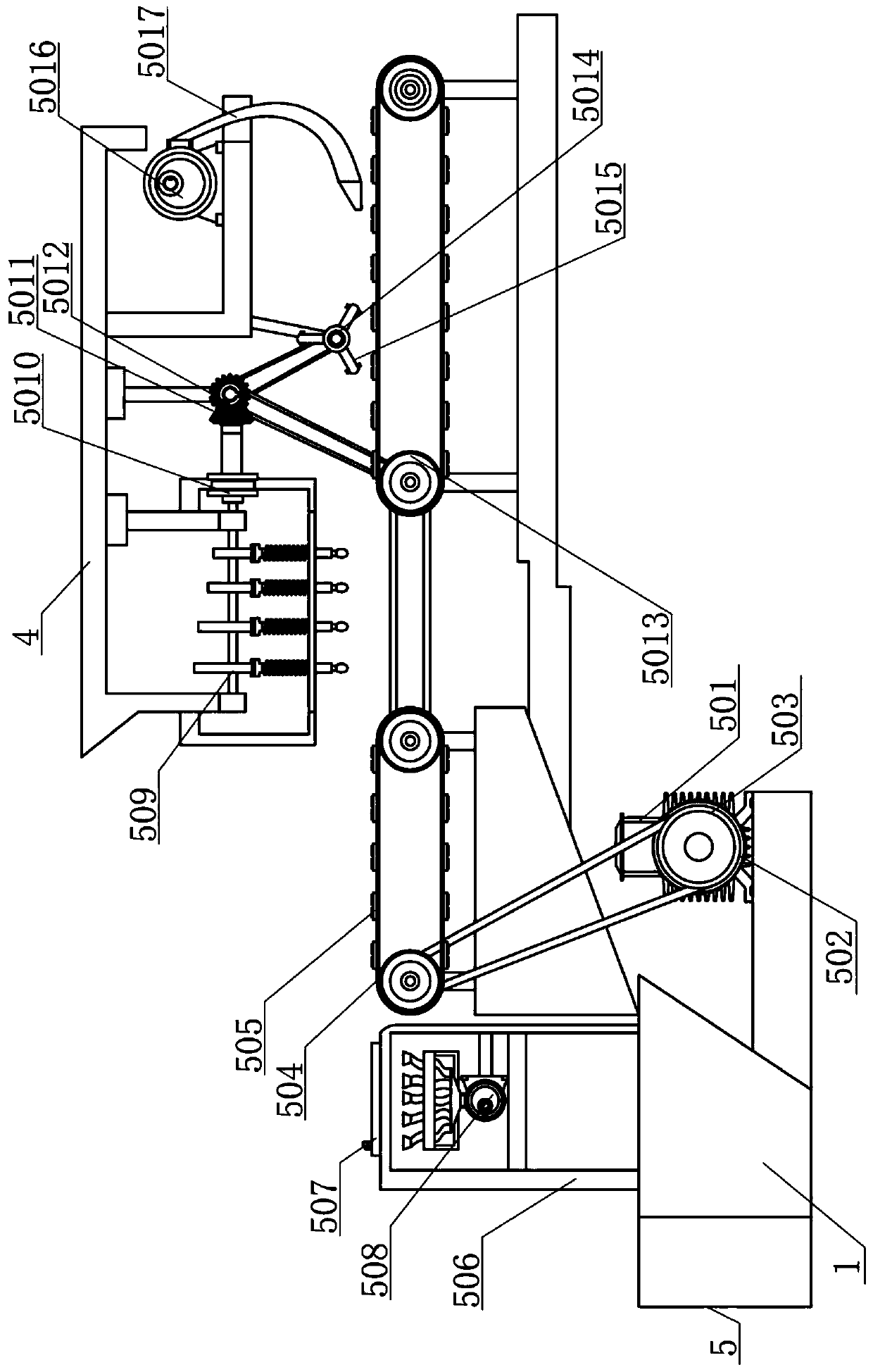

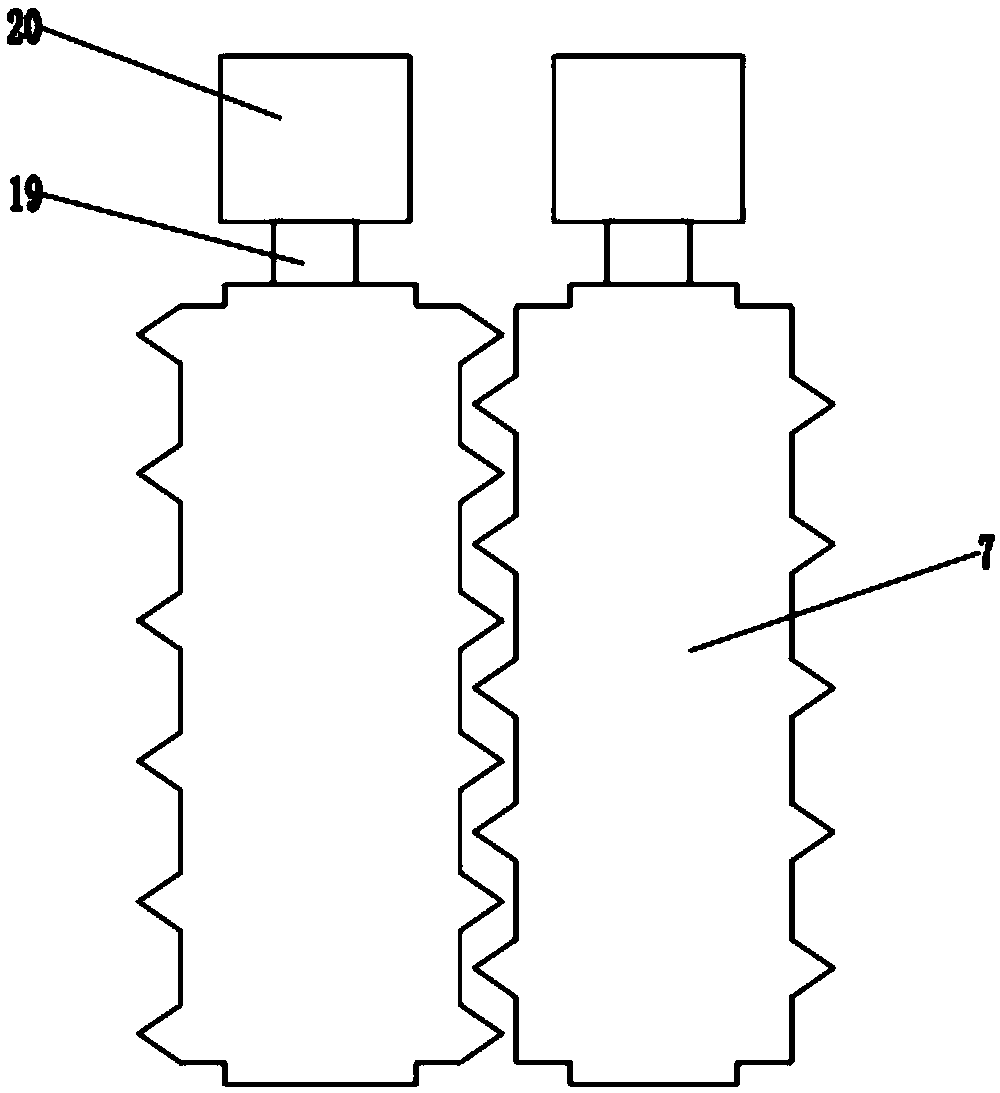

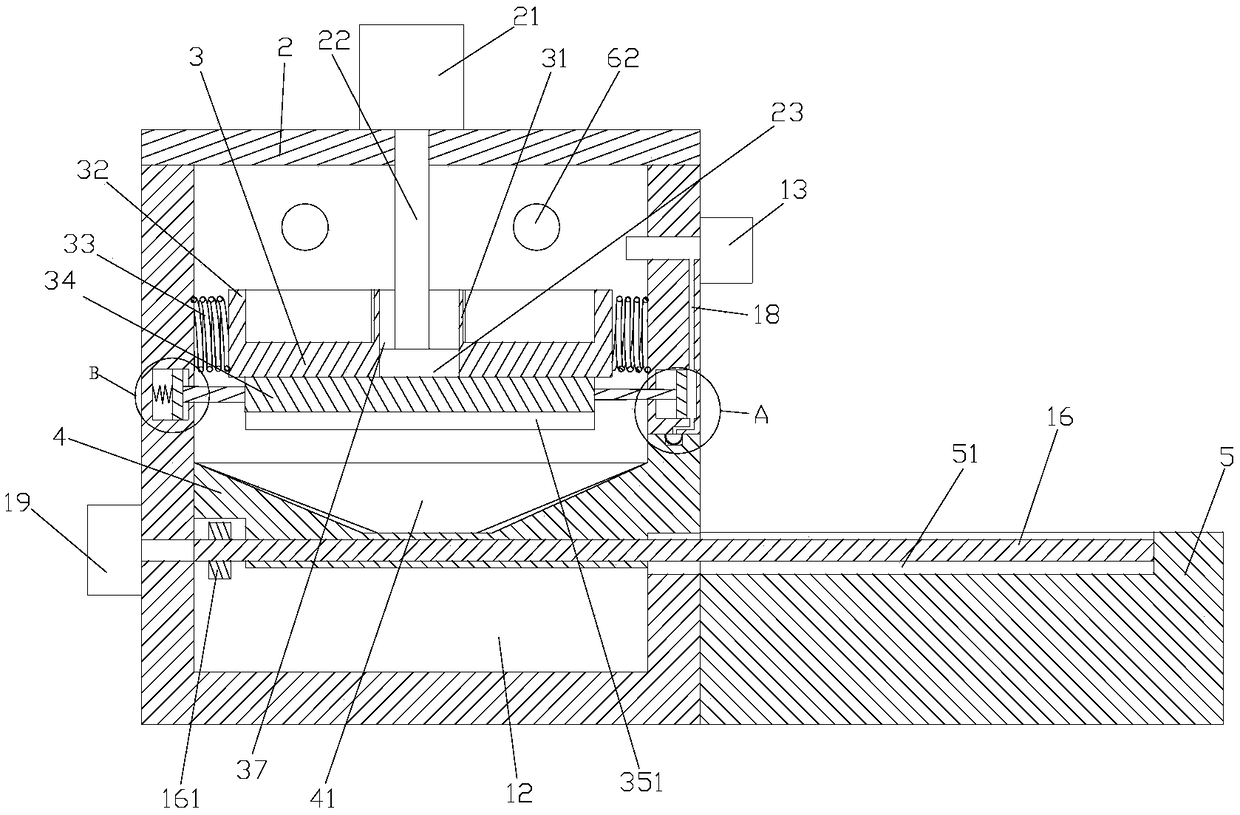

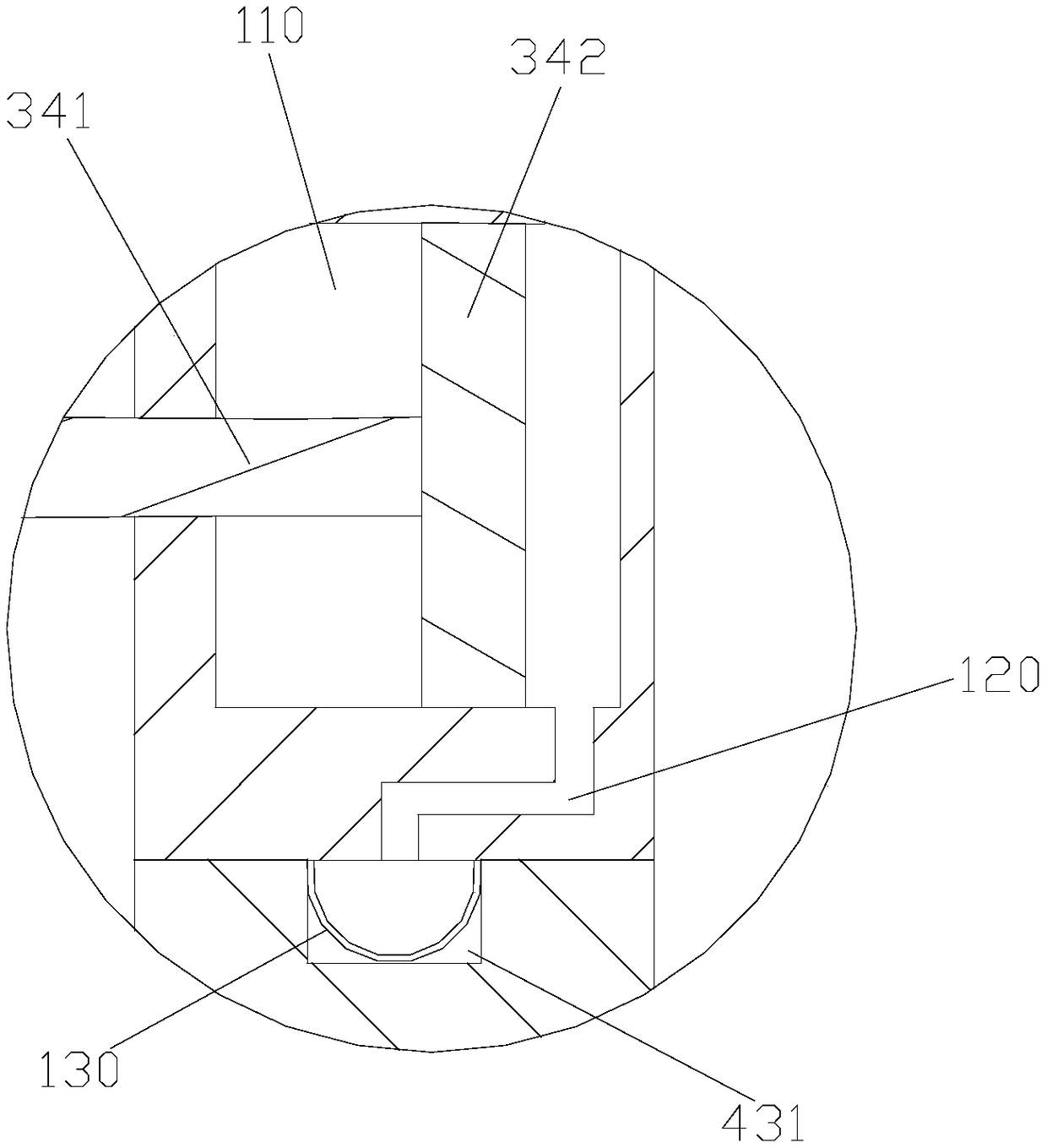

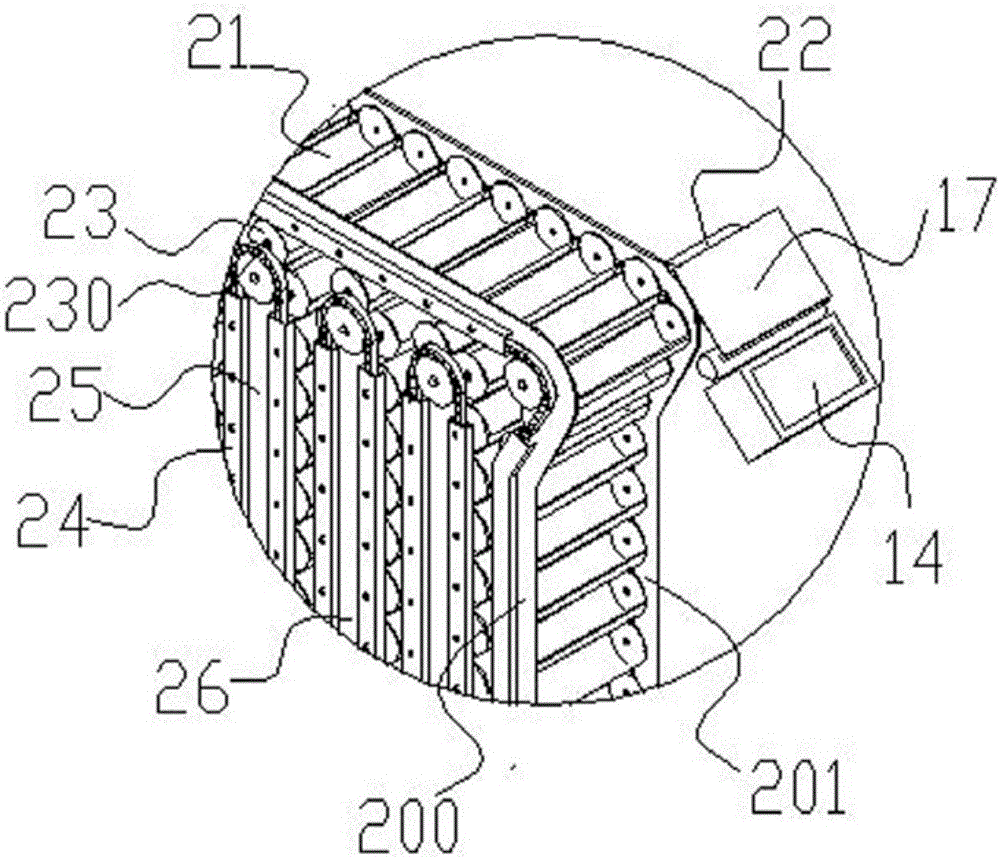

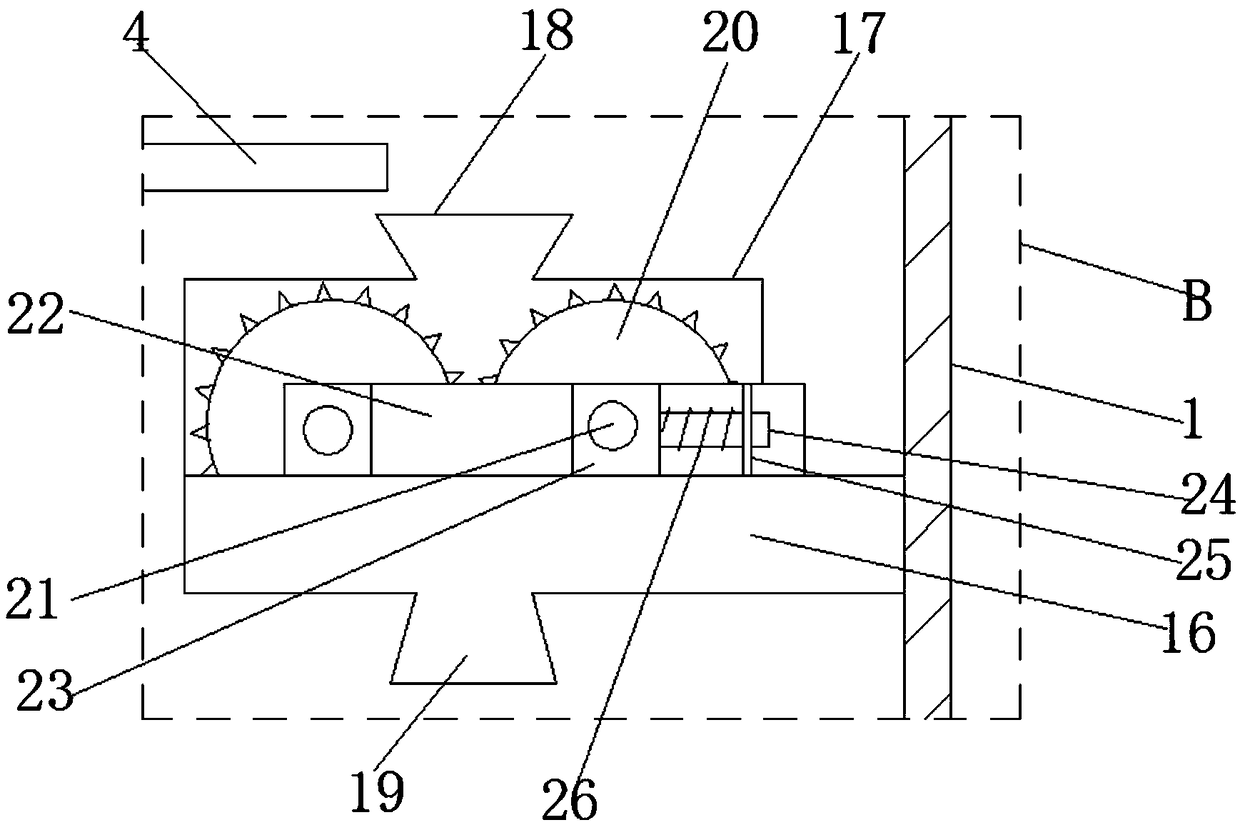

Pulverizer applied to recycling of waste glass

InactiveCN105413798ASolve the crushing problemSimple structureGrain treatmentsGlass fragmentGlass recycling

The invention discloses a pulverizer applied to recycling of waste glass. The pulverizer comprises a pulverizing cavity. The pulverizing cavity comprises a transmission room and a pulverizing room. A transmission device is arranged in the transmission room. A pulverizing device is arranged in the pulverizing room. The transmission device comprises a first transmission device body and a second transmission device body. The pulverizing device comprises a first pulverizing device body and a second pulverizing device body. The first pulverizing device body comprises a pulverizing roller which is connected with the first transmission device body. The pulverizing roller comprises a first pulverizing roller body and a second pulverizing roller body. The second pulverizing device body comprises a center pulverizing main shaft which is connected with the second transmission device body. According to the pulverizer, the two levels of pulverizing device bodies are adopted, the first pulverizing device body, the first pulverizing roller and the second pulverizing roller are used for conducting primary pulverizing on waste glass, and then the second pulverizing device body is used. Small glass fragments can be pulverized further, and in addition, the glass fragments is evenly pulverized further to become aggregate capable of being used for concrete.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

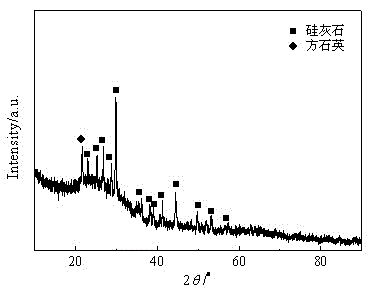

Method for preparing porous glass ceramics by waste glass through low-temperature melting and high temperature foaming

InactiveCN104445956ARealize environmental protection and energy savingHigh value-added utilizationGlass shaping apparatusRefractoryHigh intensity

The invention relates to a method for preparing porous glass ceramics by waste glass through low-temperature melting and high-temperature foaming, and belongs to the field of energy-saving building materials. The method comprises technological steps as follows: (1), an appropriate quantity of a cosolvent, a crystallizing nucleating agent and a foaming nucleating agent are added to the waste glass subjected to crushing and fine grinding, the mixture is subjected to ball milling and uniform mixing, and mixed powder is obtained; (2), the mixed powder is uniformly spread in a refractory material mold and is directly put in a fast heating furnace, the temperature of the heating furnace is increased to 700-800 DEG C, and the mixed powder is molten at the constant temperature; (3), the molten mixed powder is subjected to constant-temperature foaming when the temperature is increased to 850-1,000 DEG C. According to two processes of low-temperature melting and high-temperature foaming by the waste glass, light-weight and high-strength porous glass ceramics mainly comprising closed pores are prepared quickly, and environment-friendly, energy-saving and large-scale waste glass recycling with high added value is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

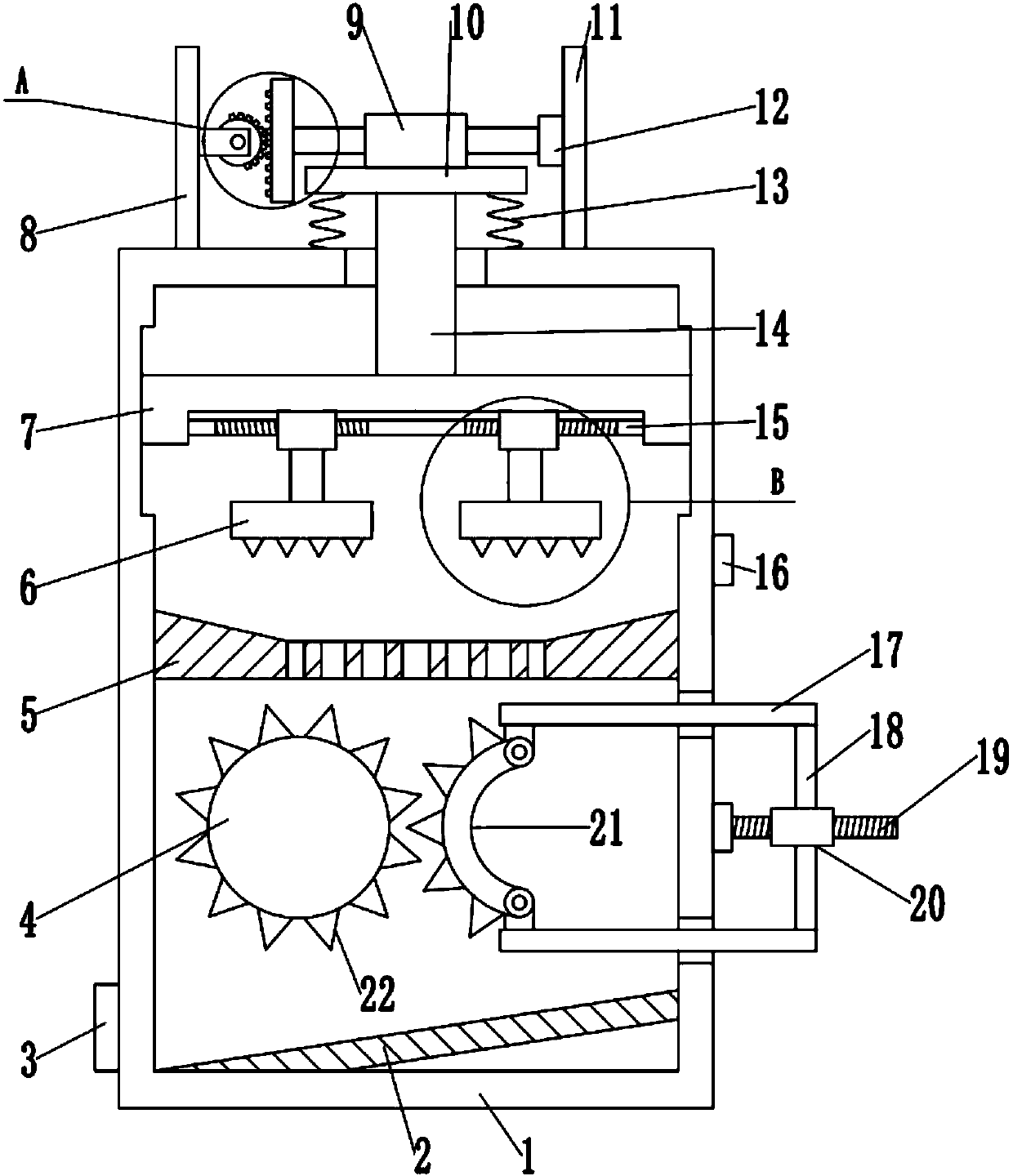

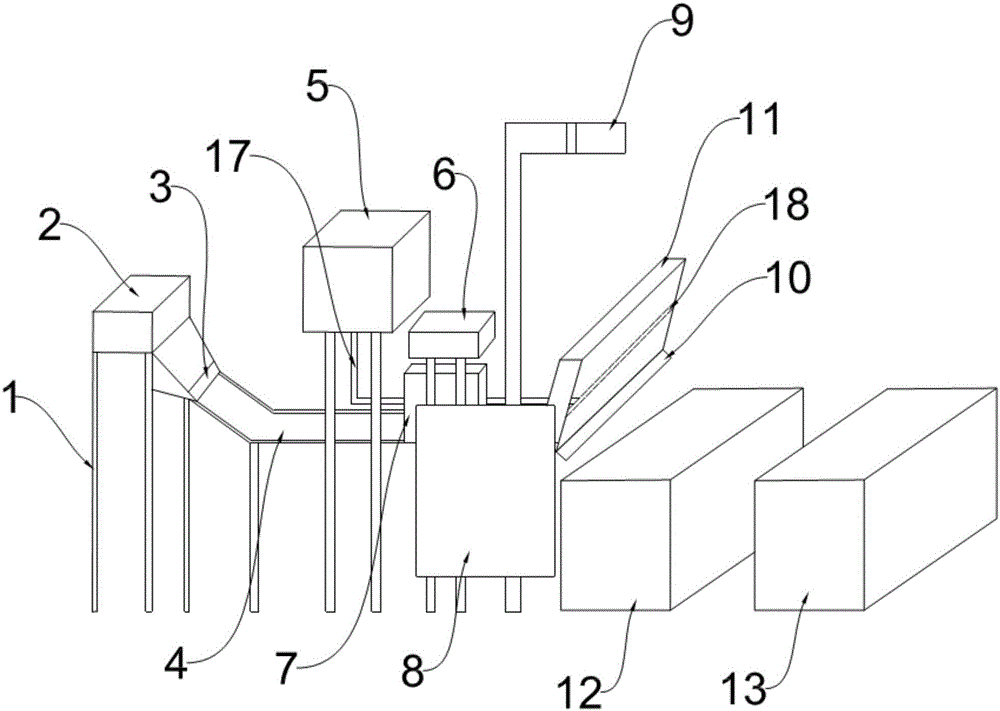

Glass breaking device for glass recycling

The invention provides a glass breaking device for glass recycling. The glass breaking device for glass recycling comprises a conveyor belt, a driving motor, a feeding channel, a breaking box body, acrushing mechanism, a grinding mechanism, and a discharging channel; the breaking box body communicates with the feeding channel; the crushing mechanism is disposed inside the breaking box body, and the crushing mechanism includes electric pushing rods, a lower platen, pressure heads, and a first filter screen; the grinding mechanism is arranged in the breaking box body, and the grinding mechanismcomprises a sloping baffle, a drive mechanism, a grinding roller and a second filter screen; the sloping baffle is fixed at the bottom of the first filter screen, and the grinding roller is disposedat the sidepiece of the sloping baffle; the drive mechanism is disposed at one end of the grinding roller, and the second filter screen is arranged at the bottom of the grinding roller; and the discharging channel communicates with the breaking box body. The glass breaking device for glass recycling has the advantages of complete and thorough crush and high efficiency.

Owner:长沙翼希网络科技有限公司

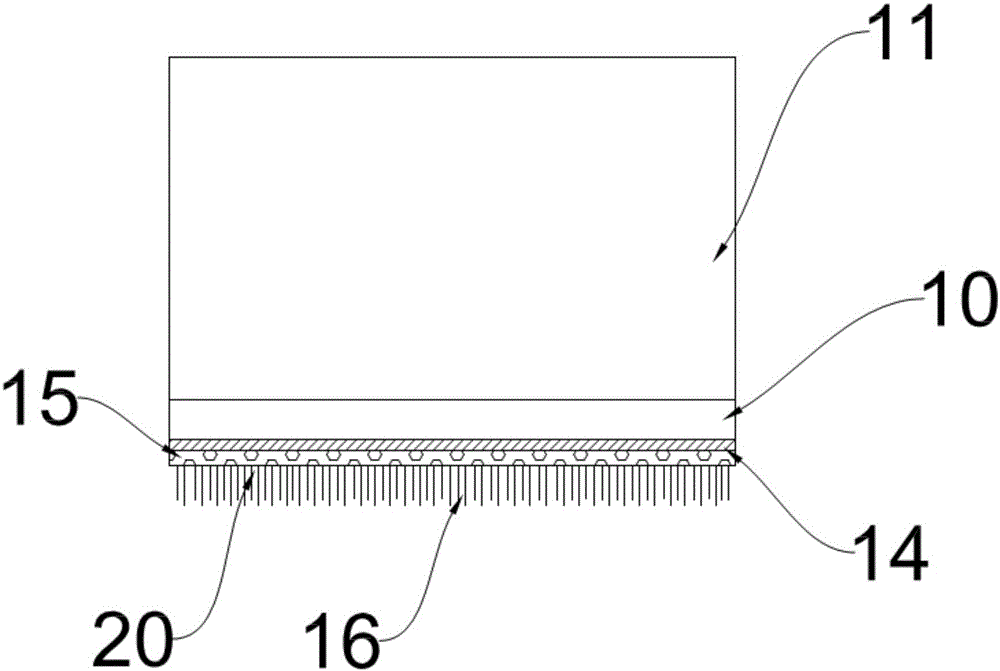

Building curtain wall glass recovering and pulverizing device

The invention discloses a building curtain wall glass recovering and pulverizing device. The building curtain wall glass recovering and pulverizing device comprises a main body, a lifting base and a lifting plate; a sieve plate is fixedly arranged in the main body; the sieve plate divides the internal part of the main body into a crushing chamber and a fine crushing chamber sequentially from top to bottom; two sliding sleeves are arranged at the bottom of the lifting base in a sliding way; supporting rods are fixedly arranged at the bottoms of the sliding sleeves; crushing plates are fixedly arranged at the lower ends of the supporting rods; pulverizing rollers are rotatably arranged in the crushing chamber; and an arc-shaped plate is arranged in the crushing chamber and positioned on theright side of the pulverizing roller. Through cooperation of the lifting base capable of moving up and down, the crushing plate capable of moving left and right and the sunken sieve plate, glass addedin the main body is crushed uniformly and subsequent pulverization is benefited; and the arc-shaped plate capable of moving left and right is provided, so that the distance between the pulverizing roller and the arc-shaped plate is adjusted and the size of the glass fragments after pulverization can be adjusted rapidly.

Owner:励根士

Multi-stage smashing device for recycling glass of building curtain wall

InactiveCN108970680AImprove the efficiency of recycling and reprocessingFully brokenGrain treatmentsGlass recyclingArchitectural engineering

The invention discloses a multi-stage smashing device for recycling glass of a building curtain wall. The multi-stage smashing device comprises a base and a smashing tank, wherein a crushing tank is arranged at the inner part of the smashing tank; a first electric pushing rod is fixedly arranged on a top plate arranged at the inner part of the smashing tank; a pressing plate is fixedly arranged onthe telescopic end of the first electric pushing rod; a plurality of electromagnets are uniformly and fixedly arranged at the bottom part of the pressing plate; the electromagnets are sleeved with springs; crushing hammers are fixedly arranged on the lower ends of the springs; the crushing hammers are made of iron; a second material guiding plate is obliquely arranged on the inner wall of the right side of the smashing tank; two crushing rollers are arranged under the second material guiding plate located at the inner part of the crushing tank. According to the multi-stage smashing device disclosed by the invention, the glass put in the smashing tank can be crushed, smashed and ground by utilizing the crushing hammers, the crushing rollers and a grinding roller, the glass can be fully crushed into small granules, and the efficiency of recycling and reprocessing the glass is improved.

Owner:赣州市兴顺辉科技有限公司

Automobile glass screening equipment

InactiveCN109482478AImprove recycling effectImprove recycling efficiencySievingScreeningGlass particleDrive motor

The invention discloses automobile glass screening equipment. The automobile glass screening equipment comprises a separating box, a top cover arranged on the top of the separating box, a screening plate arranged in the separating box and a material receiving plate arranged under the screening plate; the screening plate is provided with first filtering holes; a water storing tank is arranged on one side of the separating box and communicates with the interior of the separating box through a first water delivery pipe; a supporting platform is arranged on the other side of the separating box andprovided with a first groove matched with the material receiving plate; a moving plate is arranged at the bottom of the screening plate and provided with second filtering holes corresponding to the first filtering holes; the side wall of the separating box is provided with an air pump used for driving the moving plate to move; and the side wall of the separating box is further provided with a driving motor used for driving the material receiving plate to move. Through the effect of the driving motor, screened glass particles are delivered out from the separating box, the recycling effect on screened glass can be conveniently achieved, and the glass recycling efficiency is improved.

Owner:HANGZHOU LESHOU TECH CO LTD

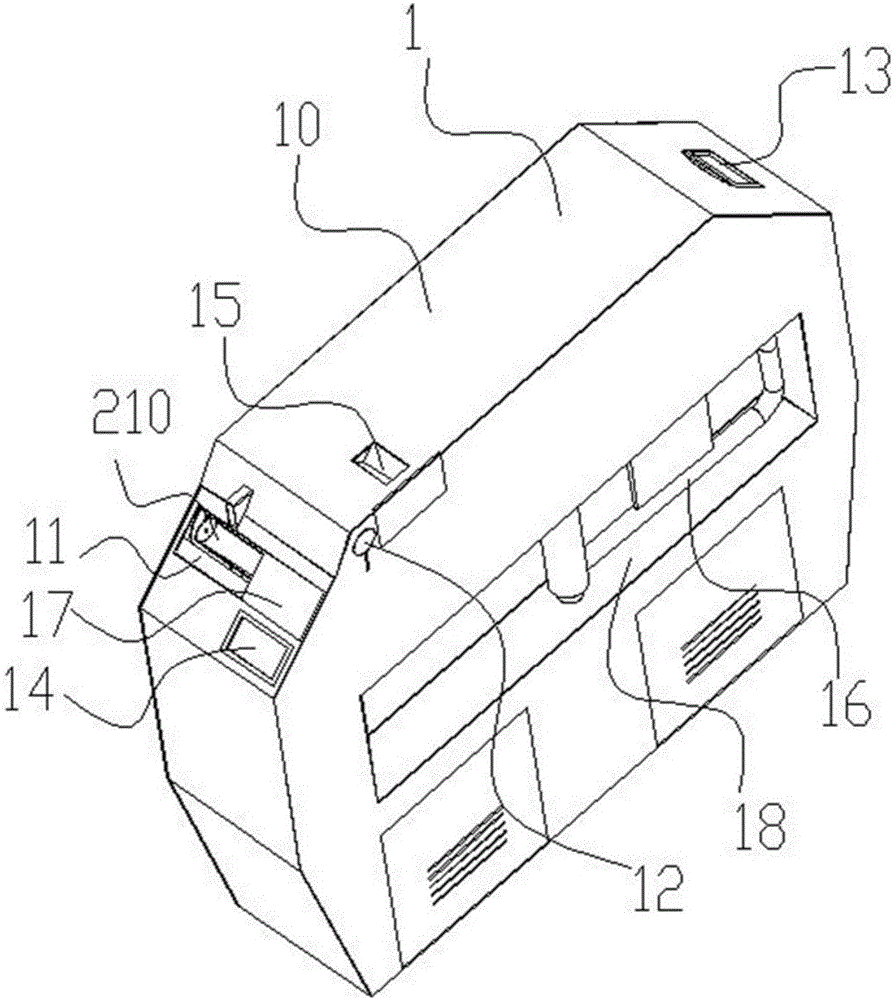

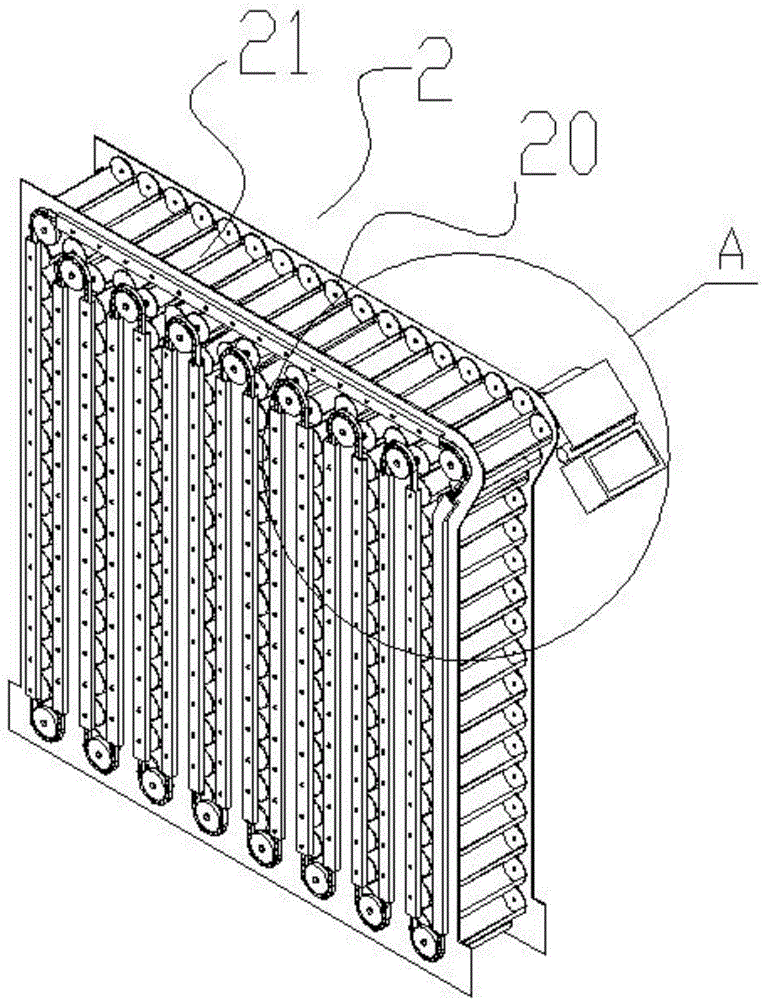

Gate machine in cinema general affair automation system

PendingCN106485792AFully understand the purposeUnderstand the purposeTicket-issuing apparatusApparatus for meter-controlled dispensingEyewearInductor

The invention discloses a gate machine in a cinema general affair automation system, and the gate machine comprises a case, a swinging gate core, and a gate rod. The gate machine is characterized in that the interior of the case is provided with a glasses storage and conveying mechanism and a ticket business controller; the case is provided with a glasses taking port, a glasses recycling port, a glasses taking inductor, a glasses recycling inductor, an entrance ticket checker, and an exit ticket checker; the gate machine carries out the conveying of 3D glasses through the glasses storage and conveying mechanism; the 3D glasses can be taken and recycled at the glasses taking port and the glasses recycling port; the entrance ticket checker and the exit ticket checker are connected with the ticket business controller, and transmit the ticket information to the ticket business controller, so as to transmit different information through the ticket business controller to control the opening / closing of the gate rod or control a thermal sensitive printer to print child tickets for access; the above operations does not need to be carry out manually; the gate machine is high in automation degree, achieves the high-efficiency operation, and saves the time.

Owner:广州市轻工高级技工学校

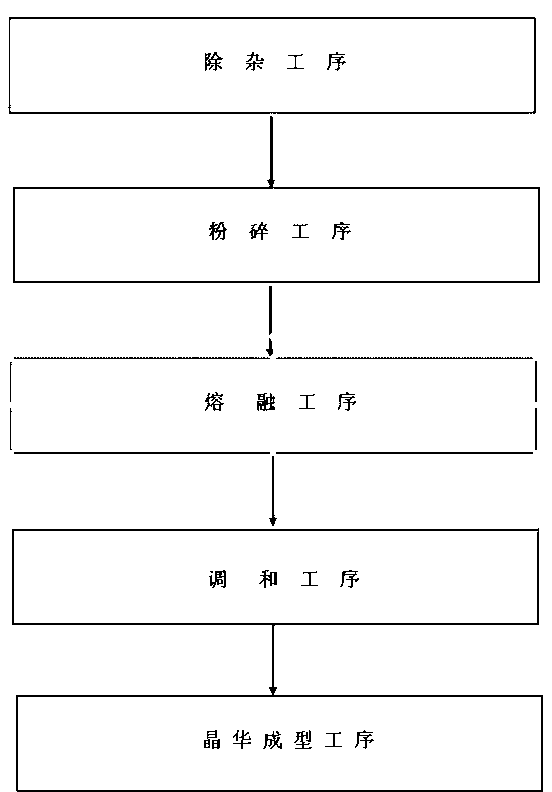

Novel method for recycling waste glass

The invention discloses a novel method for recycling waste glass. The method comprises an impurity removal process, a pulverizing process, a melting process, a mixing process and a crystallization molding process, wherein in the impurity removal process, some garbage and other wastes in the waste glass are removed; in the pulverizing process, the waste glass is pulverized; in the melting process, the pulverized glass is molten; in the mixing process, an additive is added; in the crystallization molding process, processed glass liquids are made into glass. The new method for recycling the waste glass provided by the invention is simple in operation process, low in cost, energy-saving and environment-friendly, and can bring strong economic and social benefits.

Owner:宁夏祺腾数据产业发展有限公司

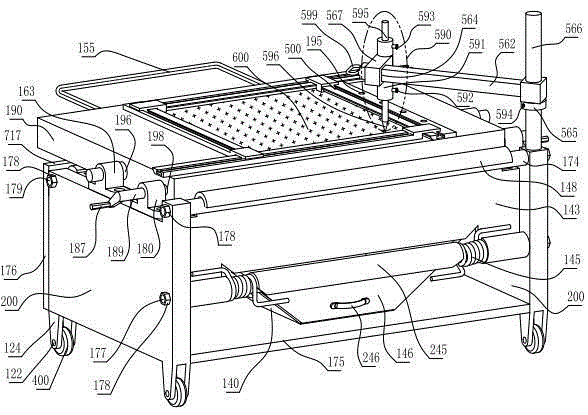

Handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment

PendingCN105319125AEasy to removeOvercome the defect of no self-lockingStrength propertiesTest specificationStructural engineering

The invention relates to tempering glass testing and detecting equipment and provides handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment. As improvement, a vertical face of the rear end of a testing bedplate is provided with a bedplate handle, the two curved ends of the bedplate handle are handle end heads, and the handle end heads of the two curved ends are fixed to the vertical face of the rear end of the testing bedplate; an upper plane of a supporting side plate on one side is provided with an impact stand column, an impact cross rod is rotatably fixed to the impact stand column, a height positioning ring is liftably fixed to the impact stand column, the height positioning ring is provided with a tightening screw, and the height positioning ring supports the impact cross rod; an air cylinder impactor is fixed to the impact cross rod in a slidable mode, the knocking strength is consistent each time through the air cylinder impactor, and it is guaranteed that crushing test specifications are unified; a coplanar wheel pressing plate assembly is fixed to the upper plane of the testing bedplate, and tempering glass plates of different specifications and sizes are adjusted continuously at will; a middle pull rod in front of a rack, an upper pull rod in front of the rack and an upper pull rod behind the rack jointly fix a broken glass recycling container.

Owner:孙冬兰

Method for preparing conducting paint from waste glass in silver plating industry

ActiveCN101654581AReduce primary pollutionEliminate serious secondary pollutionElectrically-conductive paintsFilling materialsSolvent

The invention relates to the fields of chemistry, environmental protection and material science, in particular to a method for preparing a conducting paint by cleaning and recycling waste glass in silver plating industry. The method comprises the following two steps: the recycling and the surface treatment of waste glass in silver plating industry, and the preparation of the conducting paint. Therecycling and the treatment of the waste glass in silver plating industry are realized in such a way that: using the glass discarded by factories in silver plating industry as the main raw material; after recycling, washing and pulverizing according to classifications, wetting with a surfactant, and meanwhile, coupling with a coupling agent. The preparation of the conducting paint is realized in such a way that: adding the main film forming material into a high-speed dispersion machine; adding a solvent, a dispersion assistant and the like; adding silver-plating glass powder; adding metal andnonmetal filling materials, a defoamer, a thixotropic agent, a thickening agent and other assistants, evenly dispersing and mixing, and filtering to obtain the conducting paint. The method reduces theprimary environmental pollution caused by waste glass in silver plating industry, prevents the more serious secondary environmental pollution caused by acid liquor in the process of recycling silverby a chemical method, and has the advantages of no corrosion on equipment and low energy consumption.

Owner:东莞市惠德丽实业有限公司

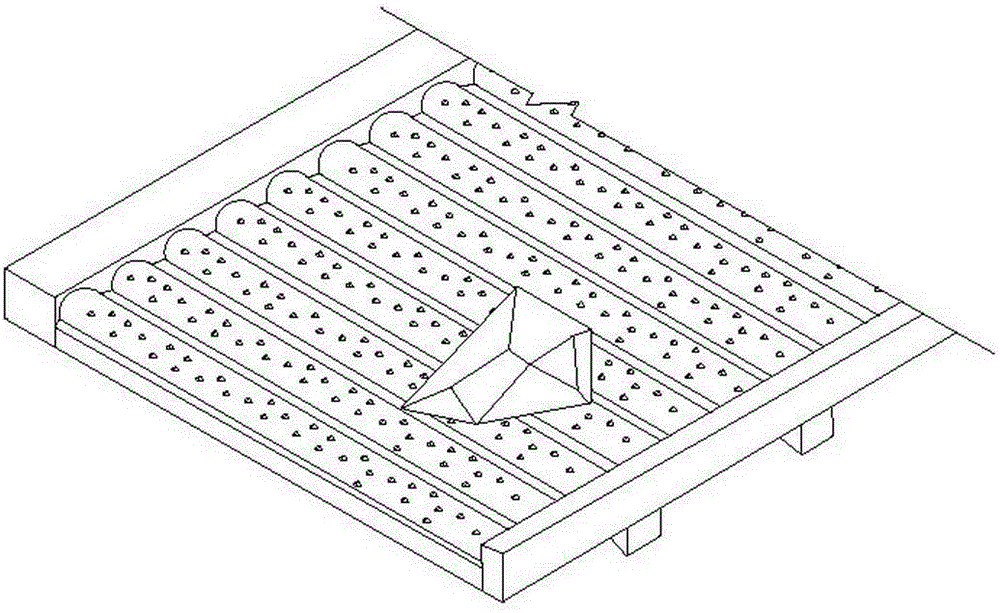

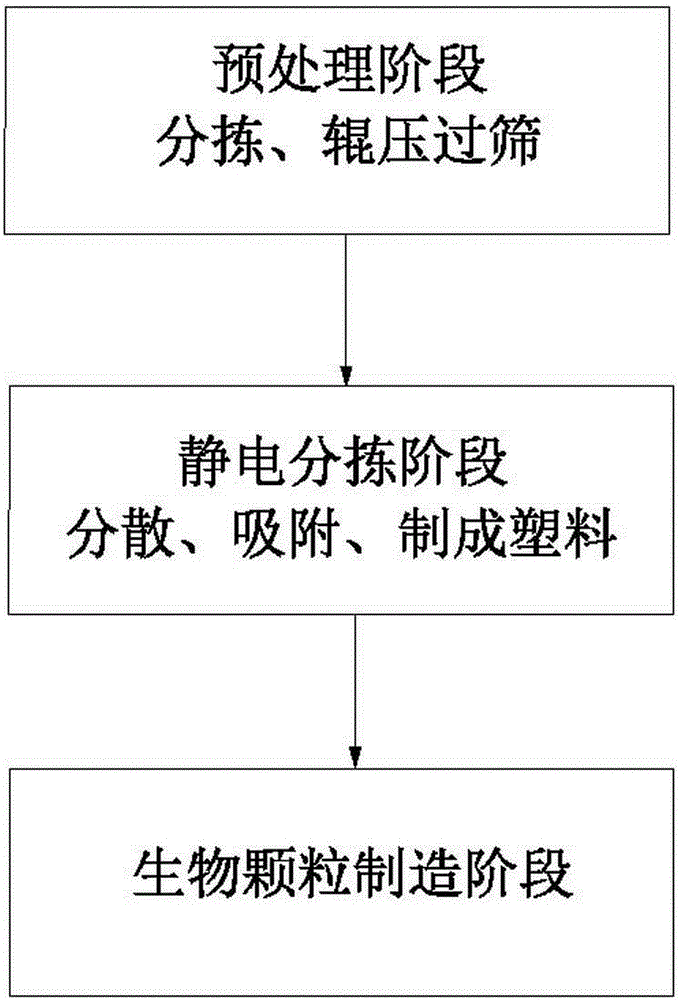

Environment-friendly household garbage treatment method

The invention relates to the field of solid waste treatment, in particular to an environment-friendly household garbage treatment method. The method includes the following steps of a pretreatment stage, a static sorting stage and a bio-particle manufacturing stage, particularly, metal and glass are sorted, recovered and treated first, garbage left after sorting is rolled to be smashed, plastic bags in the garbage is collected through static electricity and recycled, remaining garbage is prepared into small bio-particles, and the small bio-particles are compressed into blocks to be used as fuel. The problem that as sorting is difficult, the garbage cannot be recycled fully and therefore pollute the environment is solved. The method is easy to operate and implement and low in cost, fully uses household garbage and reduces pollution to environment by the garbage.

Owner:乔光辉

Glass recovery smashing device

InactiveCN109368989AFully brokenUniform particlesGlass furnace apparatusElectric furnaceEngineeringGlass recycling

The invention discloses a glass recovery smashing device, comprising a shell. A feed hopper is arranged at the upper end of the shell. A plurality of crushing devices are arranged at the upper end ofthe interior of the shell. A first movable plate is arranged below the crushing devices. A first fixed plate is arranged below the first movable plate and located on one side wall of the shell. A fixed frame is arranged at the upper end of the first fixed plate. Limiting plates are arranged on the two sides of the fixed frame and located at the upper end of the first fixed plate. A plurality of fixed rods are arranged on the side walls of the two ends of the fixed frame and penetrate through the limiting plates. The fixed rods are sleeved with first springs which are located between the fixedframe and the limiting plates. A first limiting block is arranged inside the fixed frame. A connection rod is arranged in the middle of the upper end of the first limiting block, and the end, away from the first limiting block, of the connection rod is connected with the first movable plate. The glass recovery smashing device has the beneficial effect of achieving the purposes of effectively crushing waste glass and quickly heating, smelting, purifying and recycling the glass, thereby being highly efficient, energy-saving and environmentally friendly.

Owner:马珍妮

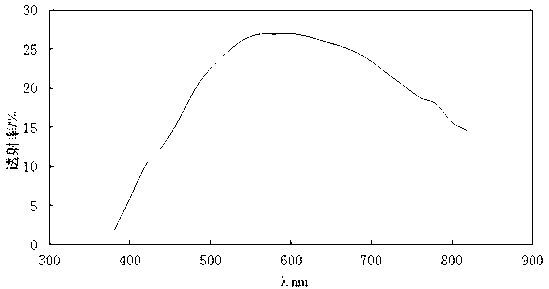

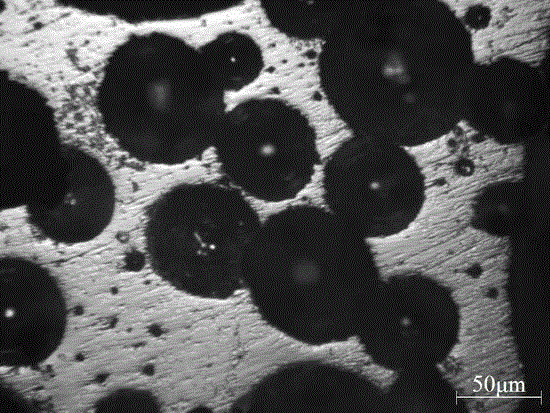

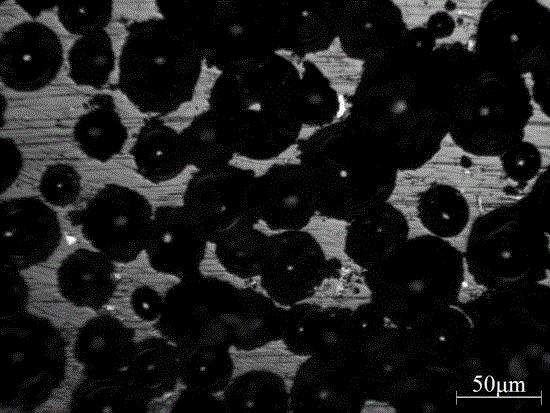

Recovering and classifying system for cullet

InactiveCN106694400AHigh light transmittanceImprove recognition rateCleaning using liquidsSortingWater storage tankEngineering

The invention especially relates to a recovering and classifying system for cullet, belonging to the field of environmental protection equipment. According to the invention, a material washing pipe is arranged above a material discharging end of a slide rail and connected with the bottom of a water storage tank via a pipeline; a water outlet is formed in the bottom of the material washing pipe; cullet to be recovered is dirty and needs cleaning so as to increase the transmittance of light penetrating the cullet; a lamp source is arranged above the material discharging end of the slide rail; the material discharging end of the slide rail is further provided with a sensor and an air jet hole; and the air jet hole is connected with a high-speed air valve through a flexible pipe. When the cullet is passing through the material discharging end of the slide rail, the lamp source directly irradiates the cullet; the sensor identifies the transmittance of light penetrating the cullet so as to realize classification of transparent glass and colored glass; and in virtue of the high-speed air valve, the colored glass with low transmittance is allowed to fall into a second recovery tank through blowing, and the transparent glass with high transmittance is allowed to directly fall into a first recovery tank. The recovering and classifying system provided by the invention is simple in structure, high in identification rate, good in classification effect, environment friendly, energy-saving and safe to use.

Owner:史立

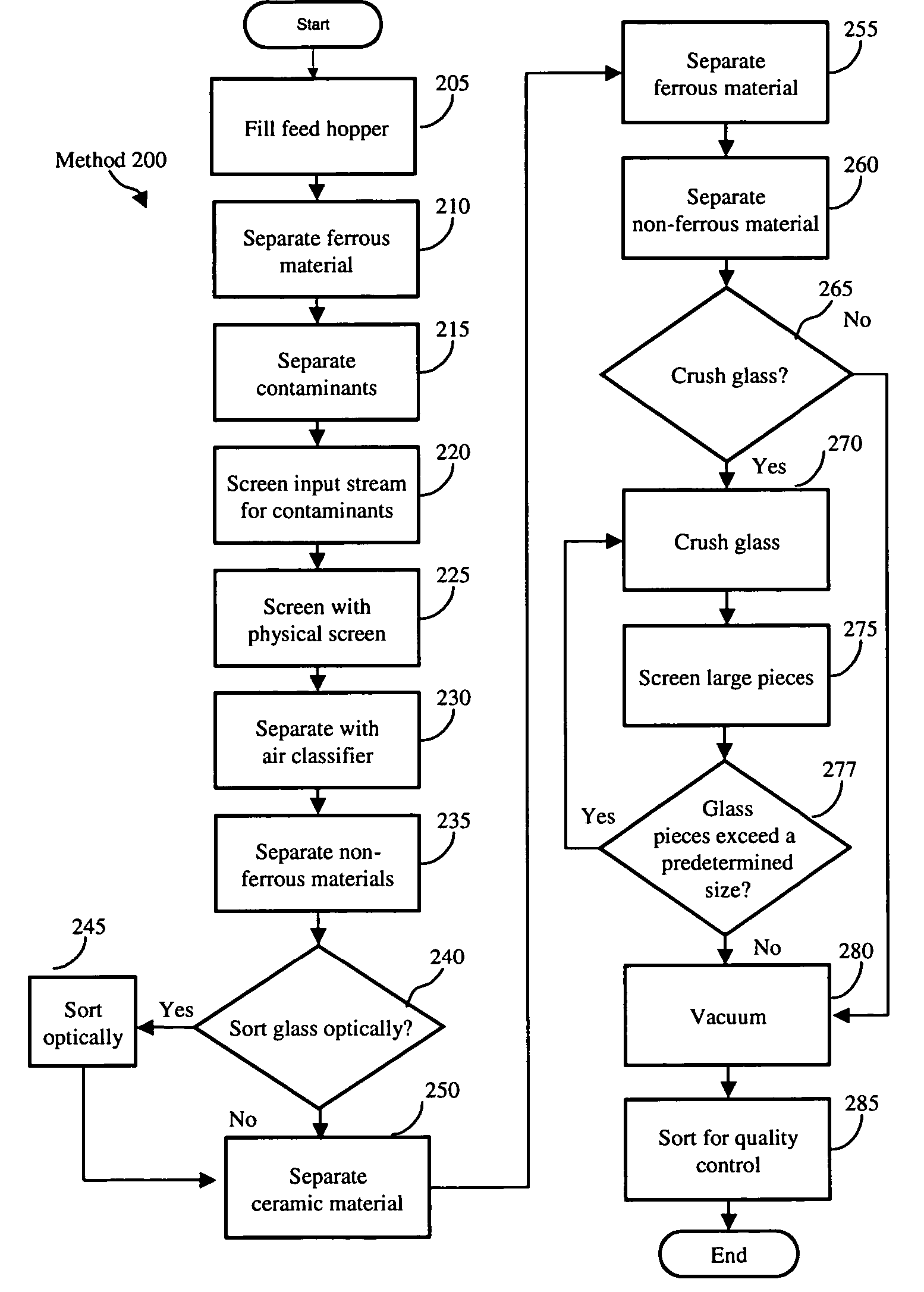

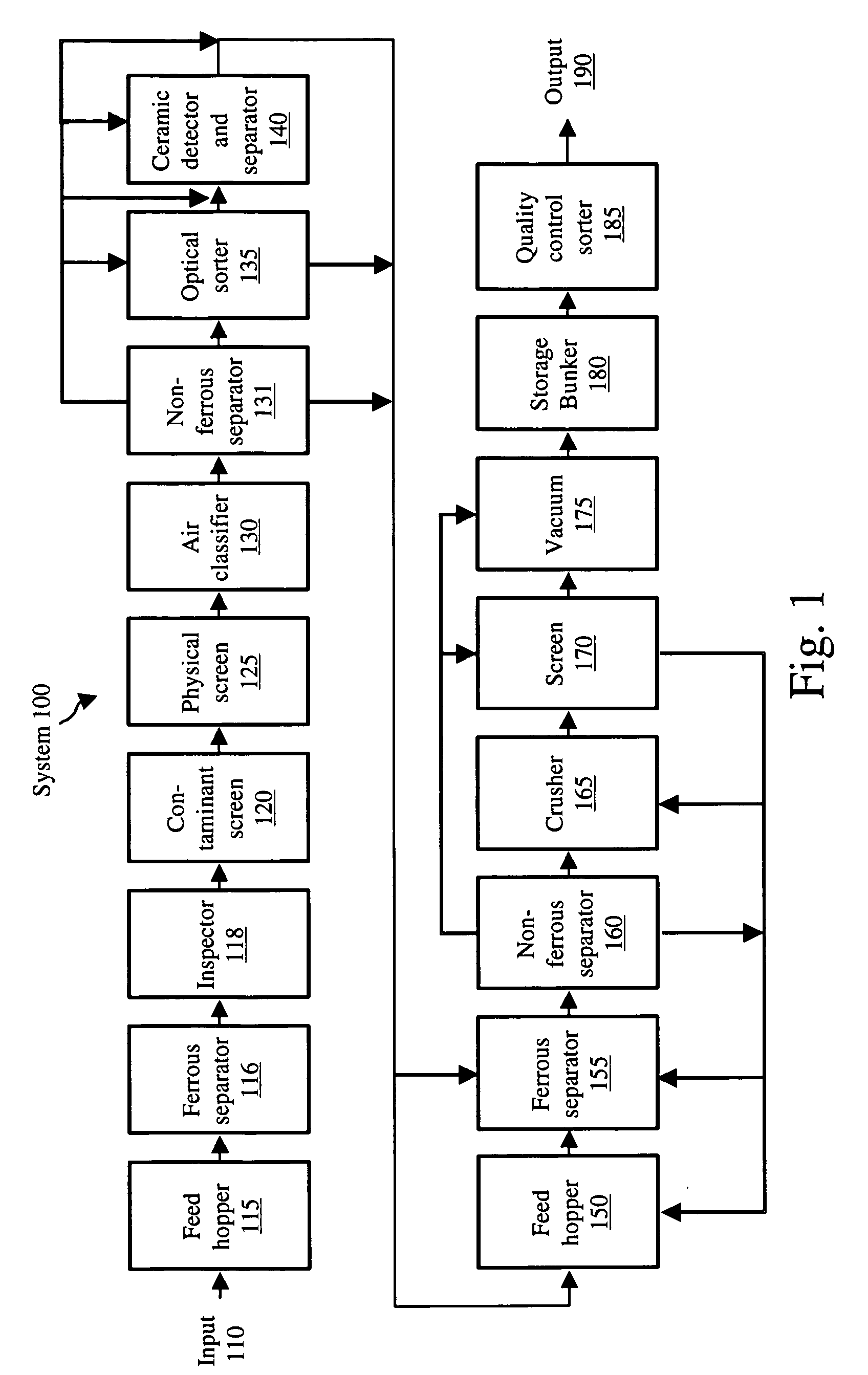

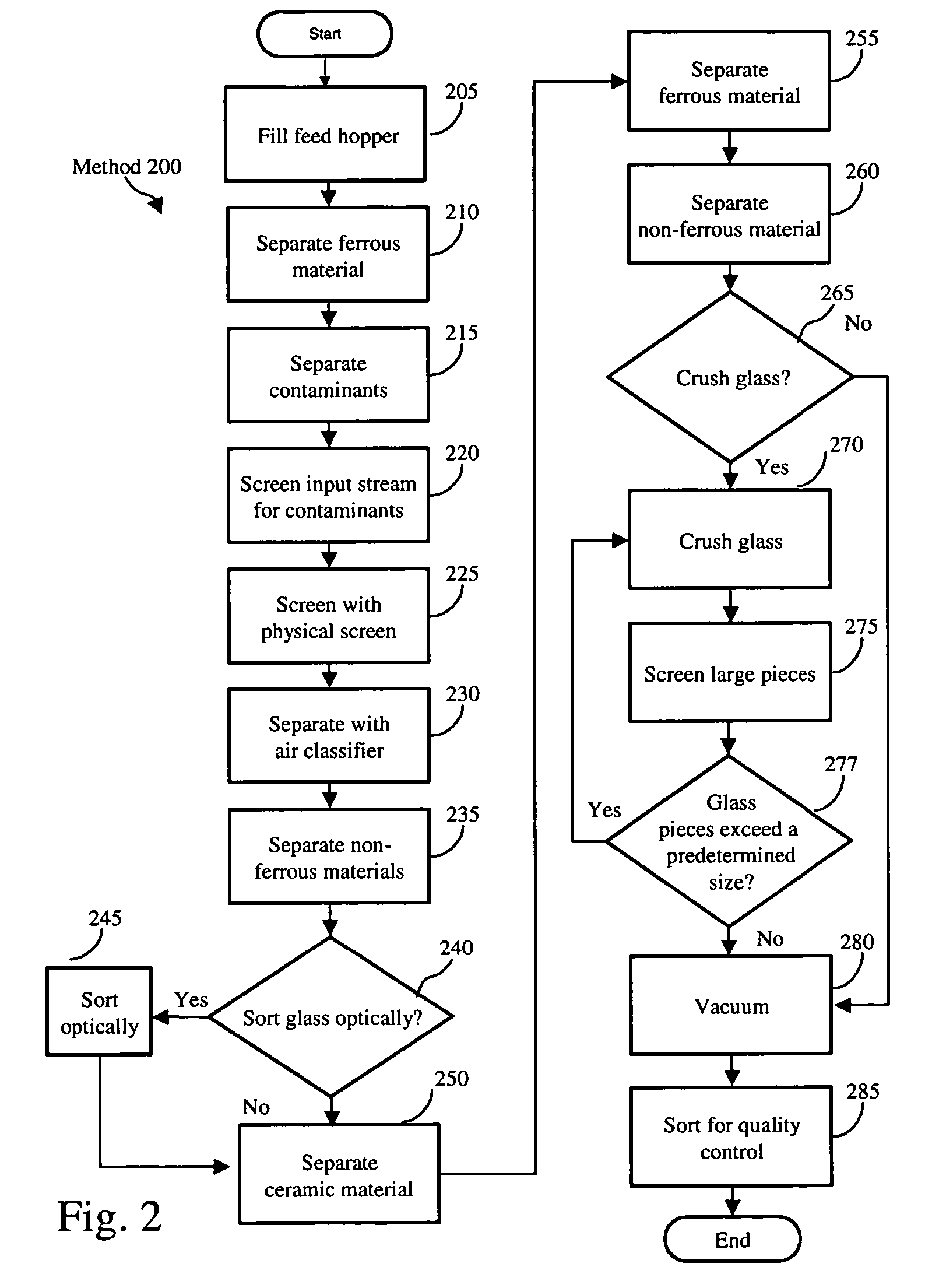

Systems and methods for glass recycling at a beneficiator and/or a material recovery facility

Embodiments of the present invention provide systems and methods for obtaining recycled mixed cullet at a beneficiator and / or a material recovery facility (MRF). The composition of the cullet, or portions thereof, can be certified for use by a party other than the beneficiator and / or the MRF. The recycled mixed cullet can be used, for example, by glass plants to make new glass articles, such as beverage bottles.

Owner:RE COMMUNITY HLDG II INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com